3D scanner for orthotics

3D Scanning for Custom Orthotics: How Does It Work?

Given how much we rely on our feet for many of our everyday activities, a problem in any of their structures can be agonizing or even incapacitating.

When your foot or ankle hurts, you might be inclined to look for a quick fix, such as over-the-counter insoles. However, the question is do they even work or are they really safe?

While some over-the-counter insoles live up to their claims, there’s just no guarantee as to whether the ones you got are the right solution for you. Wearing the wrong ones can put you at risk for even worse problems.

The best thing to do is to consult a podiatrist to get proper assessment. Based on your diagnosis, your podiatrist will create medical orthotics that are tailored to your specific foot or ankle injury, deformity, or biomechanical deficit.

Here at Cincinnati Foot & Ankle Care, our board-certified podiatrists combine their expertise with cutting-edge technology to produce the best possible treatment outcomes. We are highly trained in various techniques in designing custom orthotics, among which utilizes digital imaging. With the sophisticated 3D scanning technology we use, you can rest assured that your orthotics are free from design flaws and material defects, and that they perfectly serve their purpose—whether to correct a deformity, provide optimal comfort, stabilize your gait, and/or protect you from injury.

In this blog post, we are going to delve into 3D scanning for custom orthotics, particularly how it works and its remarkable benefits.

How We Produce Custom Orthotics Using 3D Scanning Technology

We employ Allied OSI Labs’ scanning technology to capture a full-color, 3D digital cast of your foot. We utilize a tablet (iPad) with a built-in structure sensor scanner to develop dense, real-time geometry, which creates quick but precise 3D models with high-resolution textures.

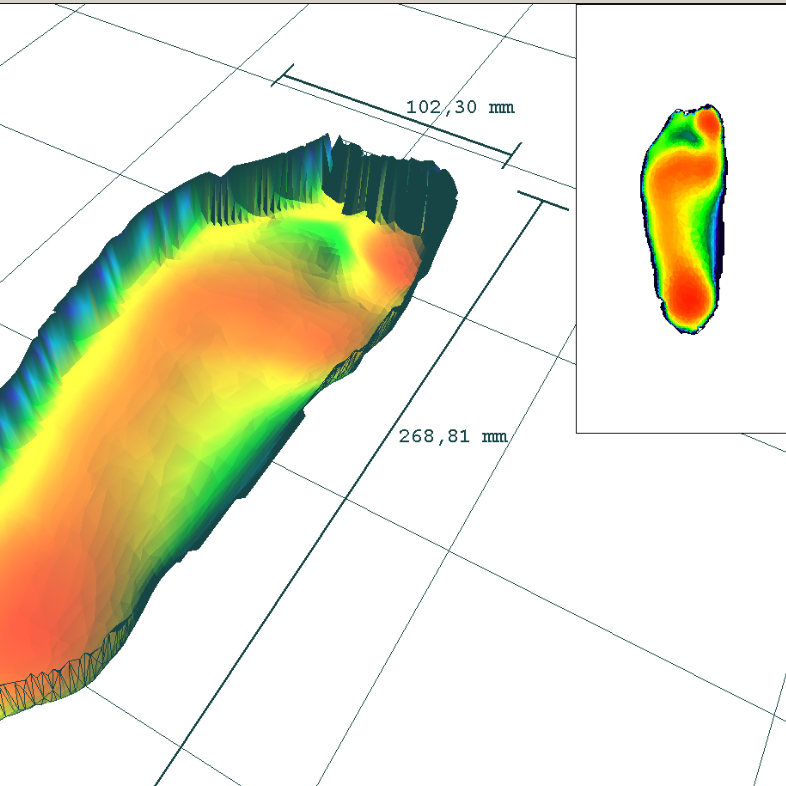

The laser on the sensor shows a “point cloud,” which is a set of data points in a three-dimensional coordinate system. Once our technician starts scanning your foot, the camera also starts taking multiple pictures as it is moved around your foot, thereby producing a 3D image.

Once our technician starts scanning your foot, the camera also starts taking multiple pictures as it is moved around your foot, thereby producing a 3D image.

The procedure usually takes up to two minutes. We will have you lie on a table as our technician scans your foot.

Benefits of 3D Scanning for Custom Orthotics

While our podiatrists are experts in a variety of techniques for creating foot impressions for custom orthotics, such as plaster casting, we recommend 3D scanning—for a number of good reasons, such as the following:

- Provides quick results- Allows for faster production of orthotics, so you can wear them right away

- Ensures optimal precision- Helps ensure better-quality, more comfortable orthotics

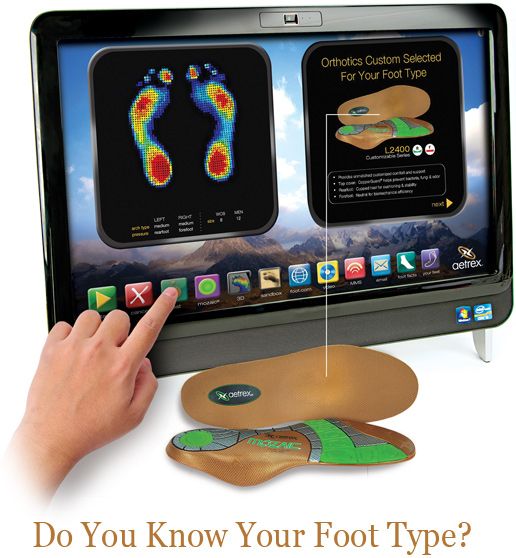

- Yields comprehensive information- Provides you with details about your gait, pressure points, sizing, arch type, pronation, etc.

- Environmentally friendly- Results in less material waste compared to traditional casting methods

Ready to reap the benefits of 3D scanning for your custom orthotics? Schedule a consultation with one of our other podiatrists today. Call us at our clinic nearest you or use our convenient appointment request form.

Call us at our clinic nearest you or use our convenient appointment request form.

3D Scanning for Custom Orthotics

Dr. Boggs and Dr. Boyce are pleased to offer three-dimensional scanning for the manufacturing of custom foot orthotics. At WWMG Podiatry we continue to provide the most advanced podiatric healthcare services, equipped with highly trained podiatric specialists and state-of-the-art technology.

Benefits Of 3D Imaging

Three-dimensional digital scanning is used across the medical field as a tried-and-true method for producing accurate depictions of parts of the human body, removing the need for plaster or foam impressions. By scanning the foot using digital imaging, the podiatrists at WWMG are given a highly accurate, scalable, quick and easy solution for collecting and interpreting a patient’s foot data.

With clear imagery and data, the scanner provides a highly accurate, reliable image. The digital scanner allows physicians to take measurements of a patient’s foot with precision and ease of use.

How Is The Foot Scanned?

The new digital scanner allows for 3-D scanning of a patient’s foot in a non-weight bearing condition. The foot is scanned in a sub talar joint-neutral position. This allows for the foot to be scanned in the exact position we desire in order to produce an orthotic that will exceed our exacting specifications. Digital scans are completely non-invasive and can be taken right in our office.

The digital imaging technology creates a simple, streamlined process for physicians. After a preliminary consultation with the patient and a digital scan of the patient’s foot, the physician will assess the digital scan and place an order for fabrication of one of many custom-made orthotics.

Who Is 3D Scanning For?

Our physicians serve patients with a variety of different podiatric needs. With our three-dimensional scanning technology, we are able to help patients that need orthotics. From patients who simply desire greater comfort on a daily basis, to patients who need orthotics to correct or stabilize their gait or prevent injury.

Custom orthotics are a long-term, customizable solution for patients suffering from problems with the foot and ankle. There are two main types of orthotics. They are as follows:

Accomodative Orthotics

Accommodative orthotics are orthotics that are intended to alleviate force throughout the foot, by providing a force-absorbent, soft layer of cushioning between the foot and the shoe. Accommodative orthotics help distribute force by softening impact; they do not correct the biomechanics. The goal of accommodative orthotics is to provide comfort.

Some examples of accommodative orthotics are:

Diabetic orthotics: To provide relief from diabetes-related pain. This type of orthotic is designed to prevent injury, relieve pain, and absorb everyday shock.

Dress orthotics: Orthotics that are intended for everyday use with arch supports that are specifically designed for dress shoes, casual, and fitted shoes.

As a rule-of-thumb, any orthotics that are designed to improve comfort are considered to be accommodative orthotics.

Functional Orthotics

The goal of functional orthotics is to correct biomechanical abnormalities by providing harder and softer surfaces that direct the foot toward a more structurally aligned gait, regulating motion. Functional Orthotics help stabilize the foot to provide support and help with movement of the foot. They’re also designed to treat injuries like shin splints and tendinitis.

With three-dimensional digital scanning, the physicians at WWMG are able to prescribe and design custom orthotics to serve those that need both accommodative and functional orthotics including highly specialized sport orthotics to prevent injury and help optimize performance.

WWMG Podiatry

We strive to improve the health and well-being of patients by focusing on the prevention, diagnosis, and treatment of conditions associated with the foot and ankle. Whether you are in the market for new orthotics or have other foot and ankle needs, we offer comprehensive care with advanced surgical and non-surgical capabilities. Our podiatrists are devoted to creating customized treatment plans to best suit your needs.

Our podiatrists are devoted to creating customized treatment plans to best suit your needs.

With three-dimensional imaging, we are able to continue to provide the highest quality of service, designed and streamlined to serve you.

3D scanners in medicine and dentistry

Supplier of 3D equipment since 2010

+7 495 646-15-338 800 333-12-82

3D-scanners 3D-printer-software service

On the Project-Prosalgoscid Stalgodservice-Service

Contacts

3D scanner is an important attribute of medical research centers and practicing medical institutions around the world. With the help of three-dimensional scanners, it is possible to obtain, for example, an accurate 3D model of the structure of the human body or its individual parts. Plastic surgeons can obtain an accurate color 3D model of the breast, face and any other part of the body in minutes and visually demonstrate the results of future work.

- 3D-innovations in medicine

- Opportunities

- Choosing 3D scanner

- 3D-innovations in medicine

- Choice 3D-scanner

- Scan any part of the body to create functional prostheses

- 3D archiving - no need to store multiple castings

- Modeling and planning in plastic surgery

- Orthopedics and cosmetology, dentistry

- Scanning of the head of a child to fit a soft helmet

- Subsequent head scan to track change

- Color and texture wound scanning for quick selection of treatment methods.

- Scan any part of the body to create functional prostheses

- 3D archiving - no need to store multiple castings

- Modeling and planning in plastic surgery

- Orthopedics and cosmetology, dentistry

- Scanning of the head of a child to fit a soft helmet

- Subsequent head scan to track change

- Color and texture wound scanning for quick selection of treatment methods.

3D-investment in medicine

Three-dimensional paranas and orthopedists to create high-precision scans of body parts. This means that specialists can produce prostheses that are ideally suited to their patients without spending as much money on design as before.

Previously, the process of producing prostheses and corsets was labor-intensive and uncomfortable. The patient was covered with plaster and waited. After hardening, the gypsum was cut off and sent to production. The manufacturer received the form and manually took measurements.

Now that medical institutions have the opportunity to use 3D scanners, there is no longer a need for expensive and time-consuming work to create plaster models, there is no need to contact the delivery service and wait for the cargo to arrive. Corsets created according to a 3D model are more accurate than plaster corsets, because they take into account all the nuances of the body structure.

Corsets created according to a 3D model are more accurate than plaster corsets, because they take into account all the nuances of the body structure.

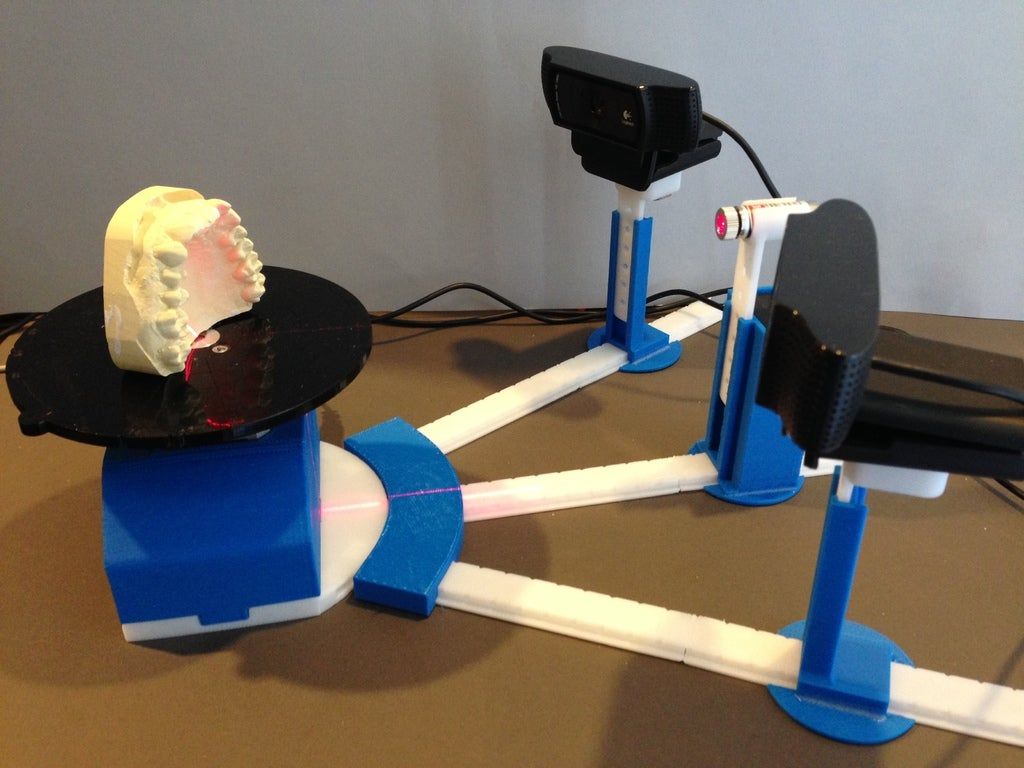

Most recently, the design of dentitions took several weeks. Now, thanks to the advent of ultra-precise 3D scanners, the process is simplified and accelerated to several days.

3D innovations in medicine

3D scanners are being successfully used by prosthodontists and orthopedists to create high-precision scans of body parts. This means that specialists can produce prostheses that are ideally suited to their patients without spending as much money on design as before.

Previously, the process of producing prostheses and corsets was labor-intensive and uncomfortable. The patient was covered with plaster and waited. After hardening, the gypsum was cut off and sent to production. The manufacturer received the form and manually took measurements.

Now that medical institutions have the opportunity to use 3D scanners, there is no longer a need for expensive and time-consuming work to create plaster models, there is no need to contact the delivery service and wait for the cargo to arrive. Corsets created according to a 3D model are more accurate than plaster corsets, because they take into account all the nuances of the body structure.

Corsets created according to a 3D model are more accurate than plaster corsets, because they take into account all the nuances of the body structure.

Most recently, the design of dentitions took several weeks. Now, thanks to the advent of ultra-precise 3D scanners, the process is simplified and accelerated to several days.

Features

Placement of prostheses

Diagnosis of the development of the skull of children

Wound care

Capabilities

Placement of prostheses

Diagnosis of the development of the skull of children

Wound care

Application of 3D scanning in medicine

Application of 3D scanning in medicine

Choosing a medical 3D scanner

3 Artec EVA

Artec LEO

ARTEC EVA

13

13 7 495 646-15-338 800 333-12-82

3d@globatek. ru

ru

2010–2022, Globatek JSC. All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

choose the best in 2022 in our direction

In order to expand the user audience, SHINING3D offers universal solutions - the same 3D scanner is able to satisfy the needs of ordinary consumers and be in demand in industrial production. Based on the feedback and reviews of device owners, the developers have improved the line of models, making 3D digitization and additive technologies even more accessible.

Contents:

- 3D Scanners of the EINSCAN

- series for beginners, designers or educational directions

- Scanners for objects of different sizes

- 3D scanning of people and their persons

- 3D scanner Einscan Pro 2x 2020

- 3D 3D-scanner TRANSCAN C

- 3D 3D 3D 3D 3D 3D 3D What other indicators do you need to understand in order to choose what you need

- Accuracy

- The use of professional 3D scanners in metrology

- The use of 3D scanners in mechanical engineering

- reverse engineering

- Quality control

- Laser Laser 3D scanner Freescan UE

- High-flow stationary 3D scanner Autoscan

- Metrological 3D scanner detramine det MIX

EinScan Series 3D Scanners

For Beginners, Designers or Educational Entities

Small figure scanning applications require precision and advanced settings in the capture software. The first thing users are guided by is the scanning area. Using two models - EinScan-SP and EinScan-SE - it will be possible to scan an object from 30 × 30 mm.

The first thing users are guided by is the scanning area. Using two models - EinScan-SP and EinScan-SE - it will be possible to scan an object from 30 × 30 mm.

EinScan-SP and EinScan-SE are useful for beginners, designers and educational users. Desktop scanners SE and SP are the easiest to learn.

Key benefits:

- Easy device setup with Plug and Play technology;

- Russian software interface;

- the ability to scan objects of different sizes - from small to large;

- texture tracking.

- 4-8 seconds per scan;

- Russified software;

- automatic and fixed operation;

- Align scanned data with marks.

- 8 seconds per scan;

- 2 minutes for 360 degree Auto Scan;

- Russified software;

- automatic alignment of multiple scans;

- API access service for 3D printers of any brand.

Scanners for objects of various sizes

aIn this category, models with the “H” index successfully demonstrated their capabilities: EinScan H , EinScan HX from the line of hybrid devices.

The portable EinScan H is the most affordable for the price.

0014

This high-tech solution makes it possible to use these two professional scanners. Manual mode allows you to scan objects of different sizes - medium and large.

Photo of 3d scanner EinScan HX- Structured emission of LED source and scanner laser;

- In Laser Scan mode, the scan accuracy is 0.04 mm;

- Minimum point distance 0.05 mm;

- High efficiency in fast scan mode - 1,200,000 points/s;

- Full color copy.

Copying accuracy is so great that when scanning works of art, it is possible to obtain a perfect replica. For medical institutions, this is also a worthy find. Separately, it should be noted the presence of a built-in color camera.

3D scanning of people and their faces

Living objects require special scanning technology. You can get a digital copy of a fragment of a human body, face and hair using EinScan H hybrid models - thanks to two light sources and a color camera, they produce an ideal 3D model with texture preservation.

- Two scanning technologies - LED and invisible infrared light, combined in one device;

- Scanning people (portrait, full-length) and other living objects;

- High accuracy of scanned data up to 0.05 mm and volumetric accuracy of 0.1 mm/m;

- Fast scanning and large scanning FOV 420*440 mm.

HX is a universal model, and Einscan Pro HD/Einscan pro 2x 2020 are multifunctional scanners, have the ability to perform tasks in various industries.

The EinScan Pro HD is an upgrade from the older model of the Einscan Pro 2x series due to its ergonomic and high quality design. Models in this range can be used with a special tripod.

This professional 3D scanner provides high scanning accuracy in both operating modes: up to 0.045+0.3 mm/m.p. in manual mode and up to 0.04 mm. in fixed scan mode.

Manual mode has two sub-modes: Rapid and HD, the latter providing a higher level of detail.

The maximum possible speed of this scanner is 3 million points per second. Even aside from the specs, you can see that the device is extremely fast in real-life scenarios. For example, a 220 x 71 cm low relief sculpture can be fully digitized in color in less than a minute.

Scanning of human bodies is also possible with this device, it provides decent quality. Last but not least, the device can scan color materials, including even textured images. This feature is available as a paid option called the Color Pack.

EinScan HX is more expensive than EinScan H, and professional scanners, which include EinScan Pro HD, are traditionally more expensive than other "classmates" and therefore available to large additive manufacturing.

EinScan Pro 2X 2020 3D Scanner

Portable and versatile handheld 3D scanner for high precision results

The EinScan Pro 2X 2020 3D Scanner is an excellent option for scanning small, medium and large objects.

3D scanner EinScan Pro 2X 2020The updated model has improved the main characteristics, added new 3D scanning algorithms. Thus, Einscan Pro 2x 2020 has become a more affordable version of Einscan Pro HD, retaining the advantages and features of the old model.

The main improvements of the new model:

- A new 3D scanning principle in HD handheld mode, which allows scanning without the use of markers (as Einscan Pro HD does). The old model could not scan without markers in this mode.

The quality and detail of scans have also been improved.

The quality and detail of scans have also been improved. - Higher scanning accuracy in manual HD mode, improved volumetric accuracy for scanning large objects

- Higher scanning speed in manual HD mode

- Increased 3D scanning area hybrid alignment. This expands scanning capabilities and efficiency in a wider range of tasks and areas.

Einscan Pro 2x 2020 is compact and lightweight, you can take it with you anywhere. It has a comfortable grip and is light weight, and if you need HD mode accuracy, put the scanner on a tripod. The scanner is connected via USB 3.0 to a computer or laptop.

The latest developments in data capture and optimized algorithms make the Einscan Pro 2x 2020 3D Scanner a true breakthrough with a scanning speed of up to 1,500,000 points per second (at 30 frames per second) in manual scanning mode.

If you need to expand the functionality of the scanner, Shining 3D offers several options:

- Color Pack 3D Scanning Module - an additional camera that allows you to scan with color and texture;

- Industrial Pack - turntable and tripod.

Suitable for high quality scanning of small objects in the studio.

Suitable for high quality scanning of small objects in the studio.

Transcan C 3D Scanner

The professional grade Transcan C 3D Scanner is capable of capturing “superiorly” accurate, high-resolution scans of small to medium objects thanks to two 12-megapixel color cameras with adjustable scan range and multi-level switching permits within a single project.

The 3D scanner has a sliding design that allows you to easily switch the scanning range between 150mm x 96mm and 300mm x 190mm to suit different sizes of objects. The multi-resolution fusion algorithm allows you to mix high, medium and low resolutions in the same project, making the scanner much more efficient, and its two cameras can capture a 24-bit color map for detailed 3D color data.

The Transcan C features a structured light scanning mode with an automatic turntable that, in combination with the scanning software's stitching algorithm, allows “efficient 3D model acquisition without manual intervention.

What other indicators do you need to understand in order to choose what you need

The technical characteristics of the devices determine their use in a particular area: in jewelry, high detail is required, in industry - accuracy, in art - the possibility of color digitization, in the field of education - ease of setup and others. Of course, the properties are considered in a complex: the most important parameter is considered as a basic one, the rest are considered as auxiliary, but at the same time mandatory.

3D Scan Accuracy

The degree to which the copy matches the original is perhaps the most important indicator. The technical characteristics of scanners indicate the maximum allowable deviation of the scan size from the real object. The smaller the number, the more accurate the 3D scan will be. But the deviation in reality can be greater, since it is quite difficult to create ideal conditions for the device to work, the result is affected by:

- characteristics of the object;

- user qualification;

- scanner settings.

The use of professional 3D scanners in metrology

3D scanners handle the process of measuring the dimensions and shapes of models in a matter of minutes, unlike traditional coordinate measuring machines. The non-contact mode of operation makes it possible to scan surfaces of complex shapes (internal corners and edges), recesses and other hard-to-reach places.

After receiving all the necessary data, they are transferred to the computer for processing. The program performs a comparison of indicators in order to identify deviations - a mismatch in shape and size, the presence of chips, cracks and other deformations caused by mechanical stress or corrosion processes.

Innovatively adapted blue laser 3D scanning technology

For metrology purposes for scanning a small object, we recommend the OptimScan-5M, 3M and AutoScan Inspec Scanner-Inspector. All these devices, to some extent, belong to the same price niche, are multitasking, make it possible to obtain high-quality digital 3D models for comparison with reference samples, demonstrating:

- the highest accuracy;

- the ability to upload scans to processing programs;

- compatible with CAD/CAM technologies;

- work with objects of various sizes and shapes, including those with complex geometry;

- texture tracking and color imaging.

Professional, they are also industrial, 3D scanners help to perform the following tasks:

- reverse engineering;

- ultra-precise 3D quality control;

- implementation of intermediate stages of the technological chain of additive manufacturing;

- faster prototyping and other operations.

3D scanning in mechanical engineering

The integration of 3D scanning technologies into production processes gives undoubted preferences. Properties of modern industrial devices:

- high speed;

- ultra-precise measurement and digital copy saving;

- processing of objects regardless of the size and complexity of the form;

- possibility of integration into automated production systems.

With the help of 3D scanners and specialized software, numerous processes can be performed:

- reverse engineering, or reverse engineering;

- metrological control;

- test measurements of geometrical parameters for the purpose of quality control and detection of defects;

- creation of archives of digital models.

Reverse engineering

Reverse engineering of complex shapes is one of the areas of industrial engineering. A physical sample is converted into a digital copy using a 3D scanner. The resulting polygonal model is converted into a CAD format. The digital copy is modified and modified to achieve the specified parameters. Unlike traditional design, work takes many times less working time. The finished object becomes the basis for mass production.

Quality control

Metrological 3D scanners make it possible to obtain a point cloud of the test sample, on the basis of which an ultra-precise 3D model of the part is formed. It is compared with a digital copy of a reference sample or with an existing CAD model.

Benefits of 3D quality control:

- Absolutely accurate data for reference comparison;

- measurement of millions of surface points;

- high speed operation;

- possibility of automatic operation.

The obtained data can be used for reverse engineering.

Scanners from the metrological category are recommended for quality control.

FreeScan UE Handheld 3D Laser Scanner

Shining 3D FreeScan UE is the latest addition to the FreeScan high performance 3D scanner line. The device uses the patented blue laser technology and features high accuracy and stable repeatability.

Sunny Wong, product manager of Shining 3D, states: “Innovative adaptation of blue laser 3D scanning technology, high precision and stable repeatability, and easy and convenient operation of hardware and software, enable FreeScan UE to efficiently and accurately upgrade digital workflows in engineering and inspection tasks”.

The metrology-grade FreeScan UE system delivers 0.02 mm accuracy and 0.02 mm + 0.04 mm/m volumetric accuracy. With a maximum scan area of 510 x 520mm, users get a field of view suitable for large-scale reverse engineering projects.

AutoScan Inspec High Accuracy Stationary 3D Scanner AutoScan Inspec

- user friendly interface;

- the accuracy of the 3D model reaches the metrological level with an error of 10 µm;

- the device can be used for non-contact measurement and quality control;

- the process is fully automated.

Works with native software developed by SHINING 3D programmers for industrial applications.

OptimScan-5M 3D metrological scanner

OptimScan-5MThe professional 3D metrological scanner OptimScan-5M shows the best consumer characteristics required just for 3D inspection:

- accuracy - 15 microns;

- two 5-megapixel cameras;

- high processing speed;

- blue light scanning technology.

Desktop AutoScan Inspec is a two-in-one scanner-inspector that works in automatic mode. The scanner performs 3D scanning with the highest precision and 3D inspection of objects. This is one of the best devices for working with complex-shaped parts and the smallest elements:

Solutions for Dentistry

In dental orthopedics, 3D scanners – intraoral and dental – have become indispensable assistants for orthopedists and dental laboratory specialists. The former are used to create digital impressions and then produce perfectly fitted dentures, crowns, veneers and other dental restorations using a 3D model using CAD/CAM technology.