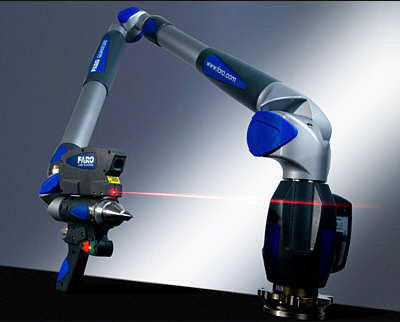

3D scanner arm

News - Kreon Technologies

May 17, 2022

Despite a smaller number of exhibitors than in previous years, visitors were able to discover Kreon’s new product: the Onyx measuring arm, developed and designed with innovative technologies.

May 9, 2022

9 years after the launch of the first Ace measuring arm, Kreon is innovating and unveiling the new Onyx measuring arm. With its completely new product architecture, the Onyx measuring arm is packed full of innovations.

Jan 4, 2022

Nov 15, 2021

Johan Thiriet, founder of ASTTUS, understood the benefits of a 3D scanning solution for part design early on, particularly for projects involving reverse engineering.

Nov 15, 2021

The aeronautics sector, well known for its demands in terms of quality, requires parts where the tolerances are respected absolutely. The Ace arm is very capable of validating machine tolerances.

Oct 20, 2021

Kreon recently launched an Ace measuring arm with an exceptionally large working volume of 5 m to round off its existing range of large size measuring arms. The advantages offered by these arms are numerous and respond effectively to your needs when measuring large parts.

Sep 27, 2021

Zephyr III range of 3D scanners optimise the use and thus the profitability of a single scanner by using it on both a CMM and a measuring arm.

Mar 29, 2021

All the 6-axis Kreon measuring arms are evolving to provide greater accuracy and improved ergonomics. Launched at the beginning of 2020 with a 7-axis version, the ACE+ arm offers the maximum performance of all Kreon measuring arms, and is now available in a 6-axis version for unparalleled performance.

Feb 8, 2021

In 2020, we were consulted by GAGGENAU Company, a part of Bosch Siemens Hausgeräte German group, specialized in design and production of luxury household appliances. They wanted to develop their static geometric measurements towards dynamic geometric...

They wanted to develop their static geometric measurements towards dynamic geometric...

Oct 8, 2020

Over a period of time, the accuracy and measuring results of your 3D scanner can be affected by long use. Recalibration means checking and adjusting your scanner so you can be sure it continues to meet the specifications that Kreon guarantees.

Jul 7, 2020

The Zephyr III 50 is a 3D scanner designed for high-quality digitisation, at outstanding resolution and precision, for small geometries. With its accuracy of 5 µm, it captures parts in minute detail – and much faster than traditional probes. For all its precision, it offers uncompromised speed.

Feb 26, 2020

From February 2020, Kreon ACE measuring arms will be certified in accordance with the 10360-12 standard. This international certification requires common tests to be performed by all players in the sector to ensure greater transparency of product specifications for buyers.

Feb 26, 2020

It is essential to have complete confidence in a measuring instrument when handling quality processes in an industrial environment. A scanner with good specifications and clearly defined limits can be put to better use and will provide consistent results for the application concerned.

Feb 7, 2020

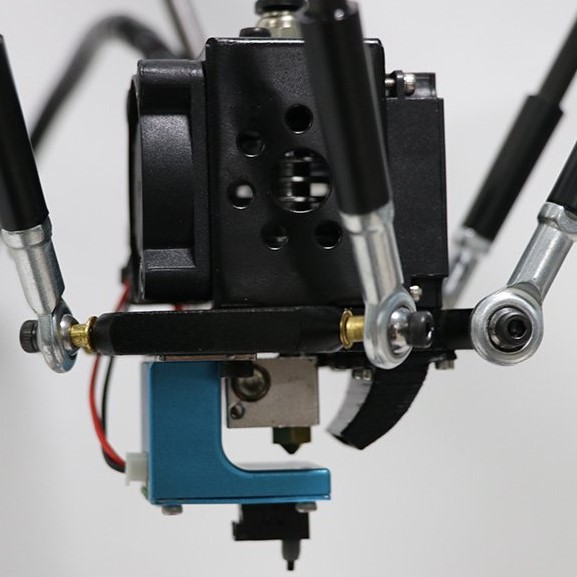

The ACE+ arm is our new 3D measuring solution for the most challenging parts. With unprecedented levels of precision, it satisfies all digital needs, for both scanning and probing.

Jan 8, 2020

Ateliers Paul Bracq brought in Digimeca’s expertise to digitize the entire bare body of a Mercedes Pagoda as part of an atypical project.

Dec 18, 2019

Kreon Technologies wishes you a Merry Christmas and a Happy New Year.

Sep 11, 2019

A manufacturer of deep-draw dies and die-cutting tools for the automotive sector, Aggressive Tool & Die, Inc. uses its Kreon Ace measuring arm in tool development and quality control.

uses its Kreon Ace measuring arm in tool development and quality control.

Sep 11, 2019

Eurotech’s wind tunnel testing of aerodynamics pertaining to new aircraft concepts, surfaces and assemblies have to be extremely rigorous. Only the highest levels of quality ensure the results of the wind tunnel tests are reliable.

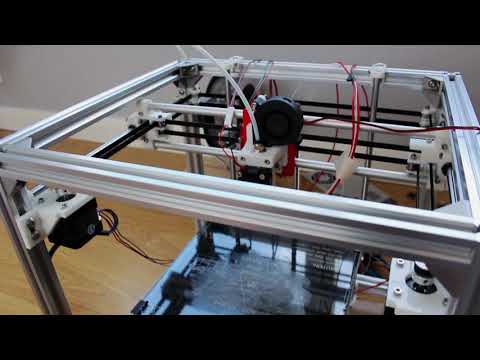

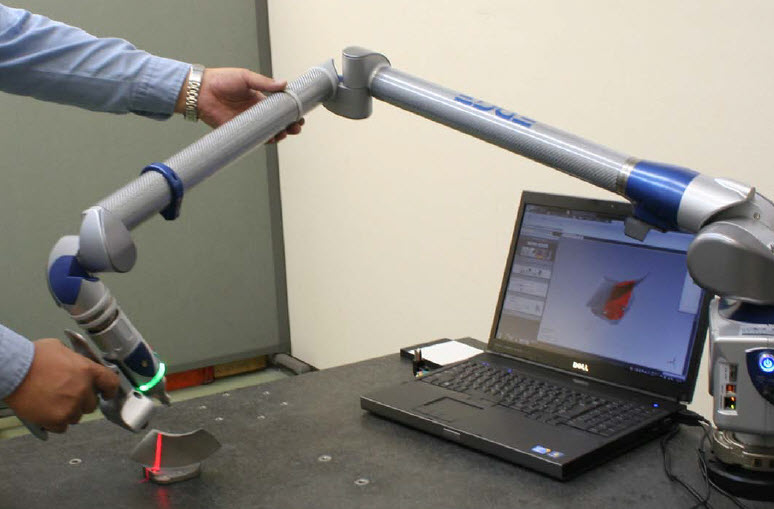

Kreon Ace 3D Scanning Arms - 7 axis

Thermo-regulated for better accuracy regardless of ambient temperature

Carbon fibre constructed arm

Internal counterbalance system takes the weight away from the user’s wrist

Ergonomic grip for comfortable use

Renishaw joint creates an interface for the use of laser scanners or probe.

Wifi connectivity to the PC

Integrated battery for portability, Upto 4hrs scanning or 8 hours probing

The Kreon Ace and Ace+ 7 Axis 3D Scanning Arms use the highest grade materials to produce an extremely accurate portable measuring arm suitable for shop floor or metrology lab applications.

The carbon fibre structure is thermally compensated to ensure the highest level of accuracy is achieved in all environments. Built in WIFI and internal battery mean the arm is truly portable, for use in probing applications. The Ace is compatible with the full range of Kreon 3D scanners.

Contact Us Download Kreon 7 Axis Brochure

3D Inspection Against CAD Model

Compare dimensions and overlay 3D Scan data in comparison to native CAD Models with Kreon probing and scanning arms.

Reverse Engineering

Create Parametric CAD models and drawings from scan data for parts that have no legacy dimensional information.

3D Digital Archiving

Europac3D has an extensive range of 3D Scanning equipment to record and create digital models of any object.

3D Animation and Rendering

3D Scanning for the creation of digital assets used for visualisation, CGI, animation and rendering.

Rapid Prototyping

Use 3D scanners to create triangulated mesh models of objects and use this file directly in 3D Printing Applications.

First Article Inspection

First Article Inspection of components to ensure all Geometric Dimensions and Tolerances have been achieved.

Key Specifications

2.5 Metre Ace+ 7 Axis Arm

0.012mm

Sphere Measurement Error

0.033mm

Length Measurement Error

0.034mm

Scanning Accuracy Zephyr II Blue

Arm Sizes

Starting at 2m and going up to a 4.5m spherical volume Kreon have listened to the needs of their customers and created a range of 3D scanning arms to suit most industries and applications.

THIS ARM WORKS WITH THESE SCANNERS

Kreon Skyline

https://europac3d. com/wp-content/uploads/2017/04/Kreon-Ace-Skyline-3D-Scanner-Featured.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-10 14:27:292018-11-20 10:34:21Kreon Skyline

com/wp-content/uploads/2017/04/Kreon-Ace-Skyline-3D-Scanner-Featured.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-10 14:27:292018-11-20 10:34:21Kreon SkylineKreon Zephyr 2 Blue

https://europac3d.com/wp-content/uploads/2017/04/Kreon-Zephyr-2-blue-3D-Scanner-Europac-3D-500x375.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-09 17:16:072018-11-20 11:01:15Kreon Zephyr 2 BlueKreon Zephyr 2

https://europac3d.com/wp-content/uploads/2017/04/Kreon-Zephyr-2-3D-Scanner-Europac-3D-500x375.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-08 15:01:572018-11-20 10:58:41Kreon Zephyr 2Kreon Solano Blue

https://europac3d. com/wp-content/uploads/2017/04/Kreon-Solano-Blue-3D-Scanner-Featured.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-07 14:59:102018-11-20 11:06:29Kreon Solano Blue

com/wp-content/uploads/2017/04/Kreon-Solano-Blue-3D-Scanner-Featured.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-07 14:59:102018-11-20 11:06:29Kreon Solano BlueKreon Solano

https://europac3d.com/wp-content/uploads/2017/04/Kreon-Solano-Red-3D-Scanner-Featured.jpg 375 500 Europac https://europac3d.com/wp-content/uploads/2016/12/Europac-3d-logo.png Europac2017-04-06 16:44:432018-11-20 10:50:30Kreon SolanoCLICK TO PLAY VIDEO

Built using innovative technology and high quality materials

Sector Suitability

Aerospace

Automotive

Industrial

Technical Specifications

| Ace+ 7 Axis | Axes | Working Volume | P Size Size Error on a Sphere | P Form Form Error on Sphere | L Dia Articulated Location Error | SPAT Single Point Articulation Tets | E Uni Length Measurement Error |

|---|---|---|---|---|---|---|---|

| Ace+ 7-25 | 7 | 2. 5 m 5 m | 0.012mm | 0.022mm | 0.047mm | 0.025mm | 0.033mm |

| Ace+ 7-30 | 7 | 3.0 m | 0.017mm | 0.030mm | 0.074mm | 0.039mm | 0.057mm |

| Ace+ 7-35 | 7 | 3.5 m | 0.021mm | 0.037mm | 0.089mm | 0.045mm | 0.067mm |

| Ace+ 7-40 | 7 | 4.0 m | 0.026mm | 0.042mm | 0.105mm | 0.054mm | 0.084mm |

| Ace+ 7-45 | 7 | 4.5 m | 0.040mm | 0.051mm | 0.114mm | 0.067mm | 0.105mm |

| Ace 7 Axis | Axes | Working Volume | P Size Size Error on a Sphere | P Form Form Error on Sphere | L Dia Articulated Location Error | SPAT Single Point Articulation Tets | E Uni Length Measurement Error |

|---|---|---|---|---|---|---|---|

| Ace-7-20 | 7 | 2. 0 m 0 m | 0.012mm | 0.020mm | 0.044mm | 0.022mm | 0.037mm |

| Ace-7-25 | 7 | 2.5 m | 0.015 mm | 0.024 mm | 0.055 mm | 0.027mm | 0.041mm |

| Ace-7-30 | 7 | 3.0 m | 0.020 mm | 0.035 mm | 0.081 mm | 0.042mm | 0.069mm |

| Ace-7-35 | 7 | 3.5 m | 0.024 mm | 0.041 mm | 0.095 mm | 0.054mm | 0.079mm |

| Ace-7-40 | 7 | 4.0 m | 0.029 mm | 0.048 mm | 0.0115 mm | 0.066mm | 0.094mm |

| Ace-7-45 | 7 | 4.5 m | 0.045 mm | 0.060 mm | 0.125 mm | 0.078mm | 0.114mm |

For more information please get in touch

Contact us

Services

3D Scanning Service

3D Printing Service

Reverse Engineering Service

3D Inspection Service

Contact Us

Europac 3D

The Old Piggeries

Park View Business Centre

Combermere

Whitchurch

SY13 4AL

Tel: 0330 229 0175

sales@europac3d. com

com

© Copyright - Europac 3D

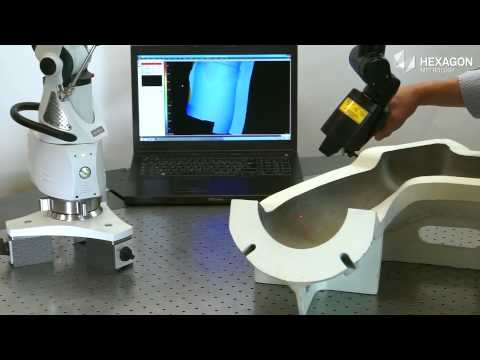

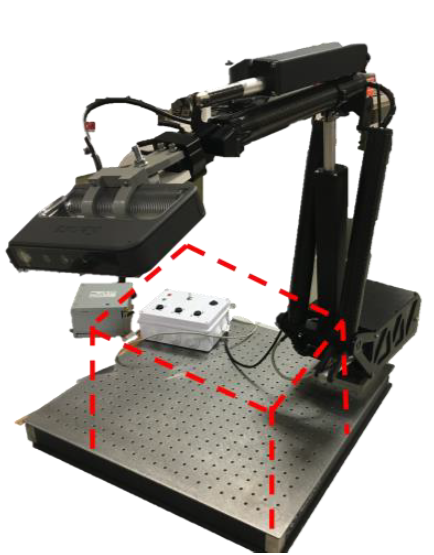

MetraSCAN BLACK|Elite Ultra Precision Optical Scanner

Toggle Nav

Back

July 22, 2021

Today we will tell you about the MetraSCAN BLACK|Elite universal handheld optical scanner, which can work not only as a 3D scanner, but can also easily replace the Hand CMM, thanks to the HandyProbe measuring probe.

Hand-held scanners are still inferior to stationary coordinate measuring machines (CMMs) in terms of measurement accuracy, but can easily replace Hand-type CMMs. This will be especially noticeable when measuring large-sized products of complex shape, where it is required to scan the entire product, and not specific points.

If you need to measure at a specific point, the HandyProbe comes to the rescue.

A range of tasks that can be assigned to MetraSCAN BLACK|Elite and HandyProbe:

- Product inspection.

You can perform manual measurement or automatically control the parameters of manufactured products.

You can perform manual measurement or automatically control the parameters of manufactured products. - Reverse engineering. Devices are suitable for scanning large objects inside and out, creating digital models of complex parts and structures.

- Control and development of prototypes. A 3D scanner and software for processing models will be useful when developing a new product or design - a digital model can be edited in special programs, modified, changed shape.

- 3D modeling. Scanned objects can be finalized in the program, make changes and print on a 3D printer.

- Training. The scanner helps to explain in practice how the measuring equipment works.

- Field measurements. Optical handheld scanner does not require laboratory conditions - can be used in the shop and on site, no fixing required, vibration proof

Benefits:

- Mobility.

Measurements can be taken anywhere: in the laboratory, directly on the machine, on the street, in a mine, in the back of a car, etc.

Measurements can be taken anywhere: in the laboratory, directly on the machine, on the street, in a mine, in the back of a car, etc. - There is no need to move the part and put it on the plate, the equipment can be placed next to the part and take measurements.

- Possibility of simultaneous measurement with MetraSCAN BLACK|Elite 3D scanner and HandyProbe measuring probe.

- Time saving for measurements.

- Lightweight scanner - 1.5 kg.

- It takes 1-2 minutes to get ready to work, it starts easily, automatically calibrates.

- Accuracy from 0.025 mm.

- Handy Probe is missing wires.

A new optical 3D scanner has recently appeared in our assortment - MetraSCAN BLACK and its improved version BLACK|Elite. This is the third generation of scanners that have long been known to metrologists. The new design has improved accuracy and speed, using blue lasers. And along with the technical update of the design, functions in the software were added - new features are available to owners of previous versions of the device.

Scanning does not require any additional hardware setup, drawing up verification algorithms, so you don’t need high qualifications to work - an operator with basic training can handle the job. This is an important advantage over laboratory CMMs, which are usually only used by experienced professionals.

Complete set:

- MetraScan BLACK|Elite 3D scanner

- Optical tracker C-Track or C-Track|Elite to track the position of the scanner in space

- 250 marks

- Calibration panel

- Four meter cable

- Controller for connection

- HandyProbe (option)

If you have any questions about the area of use, technical specifications, equipment, please call +7 (495) 988-20-00 ext. 1505 or email [email protected] and consult with our technical specialist.

© 2015–2021 Norgau Russland LLC

how to quickly create prostheses and other unique products

Reverse engineering

Implementation stories

Medicine

Author: Aleksey Chekhovich

Author: Aleksey Chekhovich

Video: Real-time 3D Face Scan | Order a free test scan | 3D scanner helps victims | 3D scanning of the human body in great detail

3D Prosthesis Creation: Era of New Possibilities

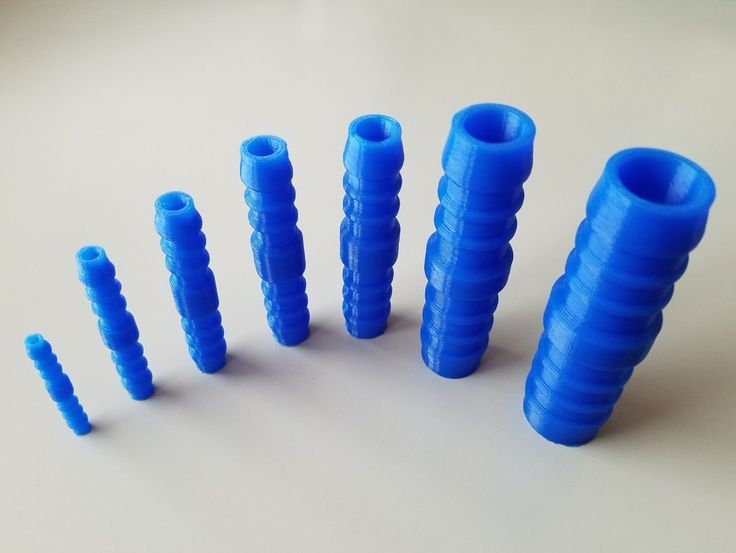

As technology improves and becomes more accessible, there are new opportunities to solve the most complex medical problems. A team of researchers from the company Chabloz Orthopedie (France) managed to create a unique and truly revolutionary prosthesis.

A team of researchers from the company Chabloz Orthopedie (France) managed to create a unique and truly revolutionary prosthesis.

Chabloz Orthopédie worked with Denis Gauthier, who had his forearm amputated. First, the experts performed a 3D scan of the patient's healthy hand using a peel 3d scanner to get its mirror image. This was done so that the designed product ideally repeated the proportions of a healthy limb. The rest of the amputated arm was also scanned to achieve a comfortable and ergonomic fit for the prosthesis.

Denis Gaultier with finished prosthesis

The team then proceeded to design a CAD model and develop a myoelectric prosthesis. Batteries, sensor cables and an artificial hand were integrated with the fabricated forearm. The prosthesis itself was designed in CAD and printed on a 3D printer. HP Jet Fusion technology was used to print various components of the forearm. After manufacturing, all parts were finished and painted.

The use of 3D scanning and 3D printing guarantees not only the correct fit of the fixture, but also gives complete freedom of movement. A new approach to prosthesis design allows professionals to develop solutions that are lightweight and highly customizable. Did you know that 3D printed parts are 20% lighter than their carbon or fiberglass counterparts? Such products also have the necessary rigidity, hardness and durability.

A new approach to prosthesis design allows professionals to develop solutions that are lightweight and highly customizable. Did you know that 3D printed parts are 20% lighter than their carbon or fiberglass counterparts? Such products also have the necessary rigidity, hardness and durability.

Later, this innovative prosthesis was combined with the BeBionic hand, one of the most advanced bionic limbs, and a state-of-the-art myoelectric forearm and hand was custom-made. Gauthier's case is a great example of the innovative use of 3D measurement and 3D printing technologies.

The video shows the complete process of digitizing the face and ears using the Creaform Go!SCAN 20 portable 3D scanner (its analogue in white peel 2 is now being produced). This solution provides a detailed digital model for use in areas such as plastic and reconstructive surgery, in particular, facial prosthetics.

This solution provides a detailed digital model for use in areas such as plastic and reconstructive surgery, in particular, facial prosthetics.

Order a test 3D scan for free!

3D scanner helps victims

Unfortunately, tragedies inevitably occur around the world, and those affected need help. But, fortunately, there are organizations such as Médecins Sans Frontières (Doctors Without Borders) that do their best to provide them with the necessary treatment and care. Since 2016, the organization has been working tirelessly to solve the problem of providing prostheses to those in need around the world. The goal is to help amputees regain independence. The solutions that are used in this case are 3D technologies.

Upon completion of the medical examination of the patient, doctors determine his needs and expectations. Using the peel 3d scanner, with minimal discomfort for the victim, a high-precision digital model of the injured limb is created. Compared to traditional impression making, 3D scanning is significantly faster and does not require contact. The result of the 3D scan is then transferred to the virtual sleeve and prosthesis design software. The developed component is made on a 3D printer and installed on the patient's limb. If necessary, during the installation process, the prosthesis and sleeve are finalized. After three months of use, the patient is invited to evaluate the comfort of the prosthesis.

Compared to traditional impression making, 3D scanning is significantly faster and does not require contact. The result of the 3D scan is then transferred to the virtual sleeve and prosthesis design software. The developed component is made on a 3D printer and installed on the patient's limb. If necessary, during the installation process, the prosthesis and sleeve are finalized. After three months of use, the patient is invited to evaluate the comfort of the prosthesis.

MSF has also developed a similar procedure to create compression masks for burn patients. Here, the use of non-contact technology also provides significant advantages over traditional plaster bandages, not only making the procedure less painful for the patient, but also speeding it up, allowing for a much larger number of people in needy countries to be treated.

Physiotherapist Pierre Moreau scans a patient with head burns. Then, based on the scan, a transparent pressure therapy mask is created / Photo: Elisa Oddone, Al Jazeera

Pierre Moreau, a physiotherapist from Médecins Sans Frontières, says: “The purpose of the 3D project is to help patients in need of special rehabilitation care. We launched this project in Amman in 2017, where we started providing upper limb amputees with 3D printed prostheses. But simply printing a prosthesis is not enough - we try to understand the needs of the victims, find individual solutions and keep them in their new position for as long as possible. We are assisted by an interdisciplinary team of rehabilitation workers and engineers. Then our specialists helped more than 30 patients in Jordan.

We launched this project in Amman in 2017, where we started providing upper limb amputees with 3D printed prostheses. But simply printing a prosthesis is not enough - we try to understand the needs of the victims, find individual solutions and keep them in their new position for as long as possible. We are assisted by an interdisciplinary team of rehabilitation workers and engineers. Then our specialists helped more than 30 patients in Jordan.

In 2018, we began to use the technology in another direction - for patients with burns, especially on the face and neck. Skin complications are a very serious problem for burn victims. Hypertrophic scars may form, and pressotherapy is needed. This requires transparent masks, but they are quite difficult to produce on site. Therefore, we started to explore 3D scanning, 3D printing and computer modeling in an attempt to help our team in the production of these devices for patients who so desperately need them. Now we provide more than 50 transparent facial orthoses.

When I think about this project, I always remember one story that demonstrates its development. In 2017 in Jordan, we had a small patient with burns and an amputation - she had no arm, and the condition of her remaining part was too complex to develop a prosthesis. Then we couldn't help her. But she came back the following year and we were finally able to make a prosthesis for her. For the first time, she was able to use her hand. This is one of our best memories of the project and a measure of its success.”

3D scanning of the human body in great detail

There are already more than 7.5 billion people on Earth, and although some are very similar to each other, there are no completely identical people. With such a variety of faces, it is not at all surprising that in the process of evolution the human brain became masterfully recognizing the smallest details that help to distinguish them. To get as close as possible to the original, the 3D scan of the statue must be extremely accurate and have a high geometric resolution.

3D copies: 2013 Kinect scan (left figure) and peel 3d (right figure)

To improve the quality of scanning, the Canadian company USIMM has begun using peel 3d. The company specializes in the machining of non-metallic materials and is constantly involved in artistic projects. The main goal was to show the evolution of CNC machining by comparing the results of a 3D version of one employee made a few years ago with current results.

According to USIMM's Leia Lepage, scanning a living person is not an easy task: “Scanners are usually quite sensitive to the smallest movements, even if it's just breathing. Scanning a person is very difficult.” In order to accomplish such an extraordinary task, the USIMM team needed a 3D scanner that was immune to certain movements - but at the same time had high resolution and accuracy. Peel 3d possesses such qualities: a resolution of up to 0.5 mm and a volumetric accuracy of 0.5 mm/m.

The team scanned the same employee in the same pose as they did a few years ago.