3D printed fish tank accessories

3d Printed Aquarium - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 394 relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Is 3D Printed PLA, ABS & PETG Safe for Fish or Aquariums? – 3D Printerly

3D printed objects are used in all sorts of hobbies and locations, but one that people wonder about is with their aquariums around with fish.

You can print with all sorts of plastic, but just how safe are materials like PLA, ABS & PETG for fish or aquariums?

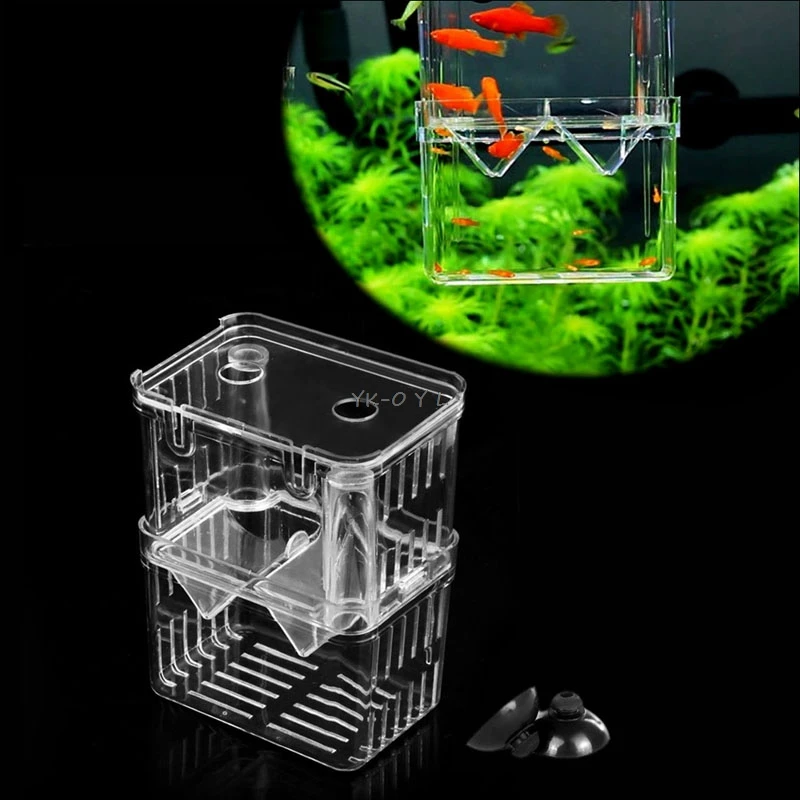

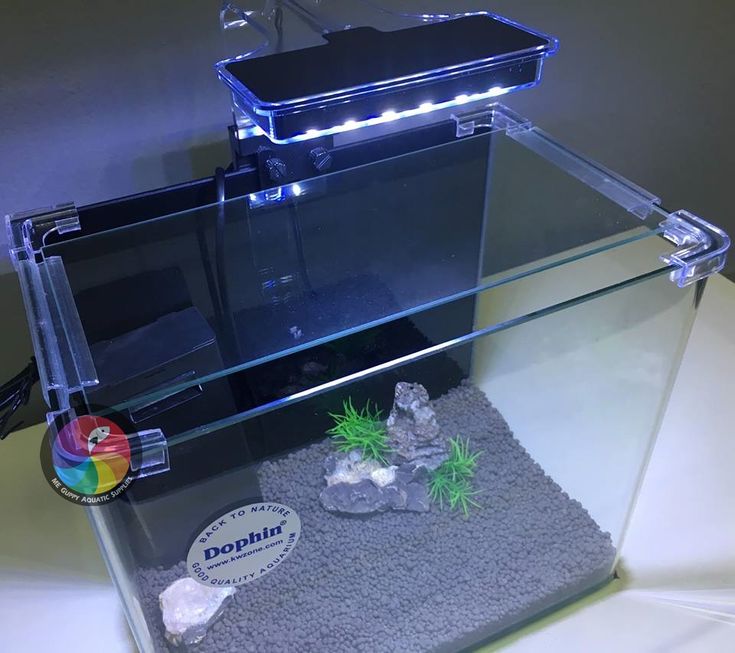

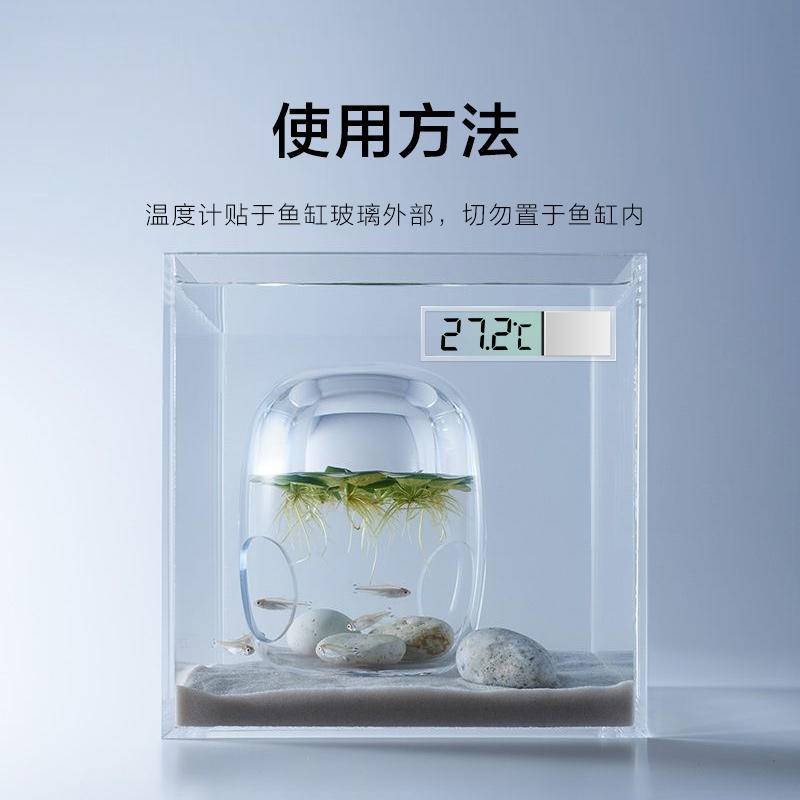

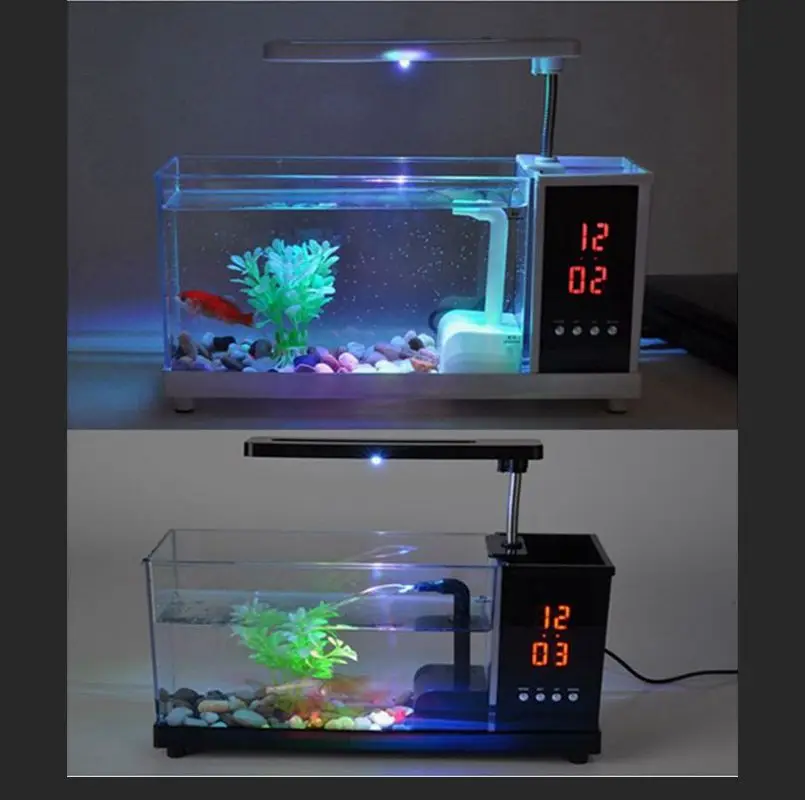

Whether you’re a pet owner, or you’re just using them for aesthetics, aquariums are very popular installations for living spaces. They offer a way to exhibit marine life in an artificial habitat.

Creating an aquarium requires just more than fishes. To make your tank awesome, you need to liven it up with various decorations like plants and other things.

3D printing offers an inexpensive way to design and build objects to spruce up the lacking areas of your tank. You can print anything from pump covers to decorative coral reefs with a 3D printer.

To answer this question, let’s take a look at some of the most popular materials used in 3D printing.

The video below is a cool illustration of creating floating aquarium platform 3D prints in Fusion 360.

Are 3D Printed PLA Objects Aquarium Safe?

PLA printed objects are aquarium safe. Their non-toxicity makes them an ideal choice for use in your aquarium. However, when using PLA filaments in your aquariums, there are some things you should know to avoid harming your marine life.

While PLA itself is not dangerous to marine life, during the manufacturing and printing process some dangerous additives can find their way into the mix. These additives can have a very adverse effect on the aquarium’s ecosystem.

To avoid PLA prints that leach dangerous chemicals into your aquarium. It is advisable to stick with pure PLA brands or food-safe brands when printing anything for your aquarium.

Avoid any composite filaments like flex PLA, glow-in-the dark, wood-fill and so on.

Decomposition is another issue to look out for when using PLA. PLA filaments are 100% biodegradable and when biodegradable objects absorb water, they begin to break down.

In a water-filled environment like an aquarium, especially in saltwater tanks, this is a problem.

To keep the 3D print from breaking down, you can apply special treatments like waterproofing. Post printing treatments like this help protect prints against decomposition and also gives them proper surface finishes.

We’ll talk more about these treatments later in the article.

Are 3D Printed ABS Objects Aquarium Safe?

3D printed ABS objects are somewhat of a mixed bag when it comes to aquariums. Most users have reported no harmful effects while using while some have recorded fatalities with it. Like most filaments, the safety of ABS objects depends on the type of filament used.

Let’s take you through some things to look out for.

ABS is a strong petroleum-based plastic material. It is a material that is very popular among plumbers. It ranks up there with PVC as a top material for making pipes and piping materials It is used in applications strength and flexibility are required.

It is a material that is very popular among plumbers. It ranks up there with PVC as a top material for making pipes and piping materials It is used in applications strength and flexibility are required.

It is often considered superior to PLA in this respect.

When selecting ABS filaments to print with for your aquarium, you need to exercise a lot of caution. There are a lot of brands out there that can leach dangerous chemicals into the water and harm your marine life.

Few filaments like natural “white” ABS have been deemed to be safe by aquarium enthusiasts. So, be sure to look out for those.

Also, another advantage ABS filaments have over PLA filaments is that they are not biodegradable. The most organic environment of the tank will not affect your 3D print one bit because it’s made up of petrochemicals.

But, objects printed with ABS filaments are not waterproof. So, post-processing treatments like vapor smoothing need to be applied to make them waterproof. We’ll go through more on that later in the article.

We’ll go through more on that later in the article.

Are 3D Printed PETG Objects Aquarium Safe?

PETG printed objects are very safe for your aquarium. PETG and PET have long been the gold standard for non-toxicity in plastics. They offer a cross-section of safety and durability not seen in other filaments.

This makes them very popular in the consumer industry.

PETG filaments are made from the same popular PET plastics used in the consumer industry for things like soft drinks and food coverings. Almost all PETG brands are certified safe by the FDA.

But just to be sure of what you are buying, you should stick to the food safe brands or the pure clear brands. By nature, the clear variants are reputably safe for use with aquariums.

Structurally speaking, PETG filaments are some of the strongest filaments around. As a plus, they are also made from the same petrochemicals that are found in filaments like the ABS.

This makes them very resistant to decomposition and other environmental conditions

PETG printed objects are also hydrophobic by nature. This property is sort of like a natural waterproofing ability that will enable them to better resist moisture attacks.

This property is sort of like a natural waterproofing ability that will enable them to better resist moisture attacks.

Although, when printing with PETG filaments you have to be careful. PETG filaments are hygroscopic-they absorb water from the environment.

They have to be kept in a moisture-free environment otherwise they can absorb moisture which can ruin the 3D print.

What is the Best Aquarium Safe Filament for Fish?

We have gone through some of the more popular filament materials, but the question remains which filament brands are safe for aquariums.

To minimize the damage to your aquatic life, we’ve gone out and put together a list of some of the tried and trusted aquarium filaments available on the market.

Aquarium owners and enthusiasts use these 3D filaments to create 3D prints for their tanks to great success. You can go through them and select anyone that suits you.

Here are some of them and their prices on Amazon:

Aquarium Safe PETG Filament

When it comes to aquarium safe PETG, there are a few options that you can go with.

The eSun PETG (Black, White) from Amazon is a popular option that is used by thousands of users, some of which have aquariums and successfully used it in the past. It comes with a clear spool that allows you to easily see how much filament is left.

eSun has been manufacturing and delivering filament for several years now, and they have a brilliant reputation that you can trust.

Another great filament that you can use with your aquarium is 3D Solutech (Black) from Amazon. You’re getting a filament which is designed to have no bubbles or residues, doesn’t need a heated bed, has no odor, and prints “ultra smooth”.

Some people have even gone so far to say that this is the best PETG they have ever printed with. Another user says this is his go-to PETG after being on their fourth spool of it, so I would definitely look into trying this one out.

Other tested aquarium safe PETG filament to try:

- Hatchbox PETG (White)

- MG Chemicals PETG (Black)

Aquarium Safe PLA Filament

Many PLA filaments have been tested by aquarium users that work really well.

Let’s start off this list with the HATCHBOX PLA Filament from Amazon. This is another very reputable company that take pride in delivery great quality filaments to its users.

Each spool of filament comes vacuum-sealed, packed with desiccant to absorb any moisture within the packaging, giving you a smooth printing experience right from day 1.

Performance includes minimal warping, no heated bed requirement, and little to no odor. This one is definitely work a try.

Another PLA filament that works well with aquariums is the 3D Solutech PLA Filament from Amazon, in the clear, green, and black colors. These are colors that have specifically been tried by users and work for their aquarium, so it doesn’t mean you have to avoid other colors.

At time of writing, there are over 2,000 ratings for this filament, a majority of which provide a positive experience (76% rate 4.0/5.0 or higher). People mention just how great the quality of this filament is.

Even at different speeds and temperatures, this filament seems to work really well for its users.

Other tested aquarium safe PLA filament to try:

- Prusa (Silver)

- MakerGear (Black)

- ZYLtech (Black, Translucent)

Aquarium Safe ABS Filament

ABS can be a little harder to work with compared to PETG and PLA, but it has been tried and successfully tested in the aquariums of some users. The first ABS that users recommended is the Gizmo Dorks ABS Filament (Hot Pink).

This brightly colored filament can work really well for the look of your aquarium, especially if you have been longing for some color and contrast. Users love just how much this color stands out, though it can be difficult to print at times.

Once you have your setup fine-tuned, printing with ABS can be pretty simple.

Check out my article about ABS Prints Not Sticking to Bed? Quick Fixes for Adhesion which can assist you with printing ABS.

Coming back to this brand of filament, we have to include the Hatchbox ABS Filament (Black, Orange, Blue, Clear, White, Green) from Amazon. This very popular, and competitively-priced filament is also a great choice for aquarium safe 3D prints.

This very popular, and competitively-priced filament is also a great choice for aquarium safe 3D prints.

colorFabb nGen (White) Aquarium Safe Filament

The colorFabb nGen (White) has been tested and confirmed to work well with aquariums, though you might run into stock issues when trying to get the white. Check the link to see if the white color is in stock or thte 1.75mm filament.

You can check the colorFabb website for the nGen white filament as the stock levels look a lot better on there. nGen is a great all-round copolyester filament that provides glossy, high quality looking prints.

Best 3D Printed Aquarium Decorations

3D printing is already becoming very popular within the aquarium community. Aquarium owners are increasingly using the technology to print different decorations. There are many designs available online that you can choose from to make your tank come to life.

Here are some favorites from Thingiverse:

Castles

Every little mermaid needs a castle. This 3D printed Hideout should be perfect for your little fishes. Inside its high towers, your fish royalty should feel right at home.

This 3D printed Hideout should be perfect for your little fishes. Inside its high towers, your fish royalty should feel right at home.

You can also spice up the property by adding Driftwood or some Coral Reefs to add a bit of color castle. Rock Formations also add a very nice touch to your mermaid castle providing a shore for unlucky sailors to wash up on.

Pirates

This one is for fans of Jack Sparrow and his merry gang of Pirates. Looking to replicate Davy Jones’ locker to boot with his henchmen guarding his Treasures against filthy landlubbers? Then this is perfect for you.

Add a little mystery lighting with some LED strips, and you’re ready to terrorize all who dare to enter the deep.

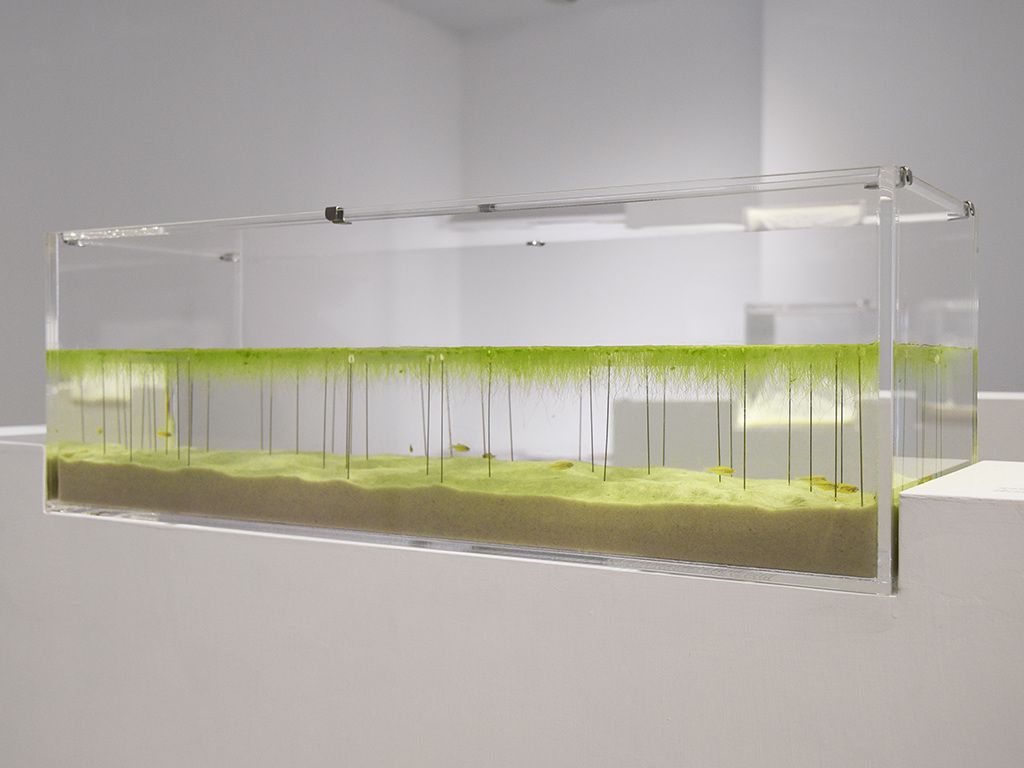

Zen Garden

Being undersea doesn’t mean that you can’t have a nice garden. Using this support for Bonsai Trees and this Moss Dome, you can create beautiful trees and fauna for your aquarium.

You can also add Zen Undersea Planters and a Buddha statue to act as centerpieces to tie everything together.

How Do I Waterproof 3D Printed Objects for Aquarium?

Waterproofing your 3D prints can be done with the help of some post-printing treatments. These treatments help seal up the porous spaces in the 3D print and also, they cover it with a protective barrier against chemical attacks.

Waterproofing 3D prints is easy and can be handled with some standard products that can be easily purchased online. Just note, you should be careful when using some of these chemicals as they can be toxic.

Let’s go through some of the methods we can use.

Spray-On Sealant

Spray on sealants are a great way to waterproof your 3D prints. These sealants provide a rubberized coating that seals up the porous spaces in the 3D print. This coating protects against moisture, air, and other chemical attacks.

Usually, when selecting a sealant for your print, commercial sealants used for wood are often enough.

Since you are planning to use the prints in your aquarium, you should consider going with non-toxic variants like Zinsser Shellac Spray and the Krylon Acrylic Spray for maximum safety.

The Zinsser Rust-Oleum 408 Bullseye Clear Spray from Amazon is a great product which is recommended by many toymakers because it is more natural compared to other similar sprays.

A light spray dries pretty quickly and gives your 3D prints a hard, smooth finish. It does take a little practice to not get the spray dripping from applying too much, and takes a short sprays while moving the can over the piece to do it properly.

Ensure that you spray outdoors, while wearing a mask so you don’t breathe in the fumes.

Many people love this product and use it for all sorts of applications, so I would try this out for your prints.

Another spray on sealant that is loved by many users is the Krylon Crystal Clear Acrylic Spray Paint from Amazon. This spray is a fast-drying, moisture-resistant, and smudge-proof.

You can use it for your 3D prints with ease, and it also extends to other objects like paper, wood, metal, ceramic, plastic, glass, and even fabric in some cases..jpg) It’s a really versatile product that works great.

It’s a really versatile product that works great.

One user mentioned just how well it works for their own 3D printed painted minis, providing a great coat to objects.

Epoxy Resin Coating

Using an epoxy resin to coat your 3D print is another great way of waterproofing it. Epoxy resins are very popular, especially among the DIY art community.

Coating your 3d print in epoxy seals all the cracks and grooves in the print. It also gives it a smooth glossy exterior that is waterproof and chemically resistant.

When selecting an epoxy, it’s always advisable to go for the food-safe brands. Most epoxies are notoriously toxic and the wrong brands can harm your fish, so it’s better to use food-safe brands like the MAX CLR Epoxy Resin from Amazon.

Also, always cure any resin-coated object for a sufficiently long period before putting it in your aquarium.

My 3D Printed Marble Machine / Habr

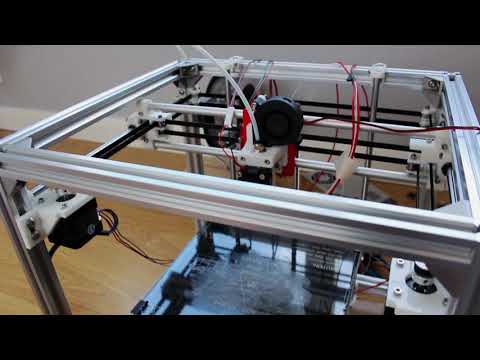

I'm trying to master 3D printing - I got a FLSUN-QQ printer, I installed 3D editors for myself: Fusion 360, Blender, I'm trying Compass 3D. Something works, something doesn't work. This Marble Machine on video is one of my first successful projects. The project, although visually not large, but its implementation required considerable effort from me. I also had to master 3D editors and invent mechanics and set up and debug this device.

Something works, something doesn't work. This Marble Machine on video is one of my first successful projects. The project, although visually not large, but its implementation required considerable effort from me. I also had to master 3D editors and invent mechanics and set up and debug this device.

Next, I will tell you what parts this machine consists of.

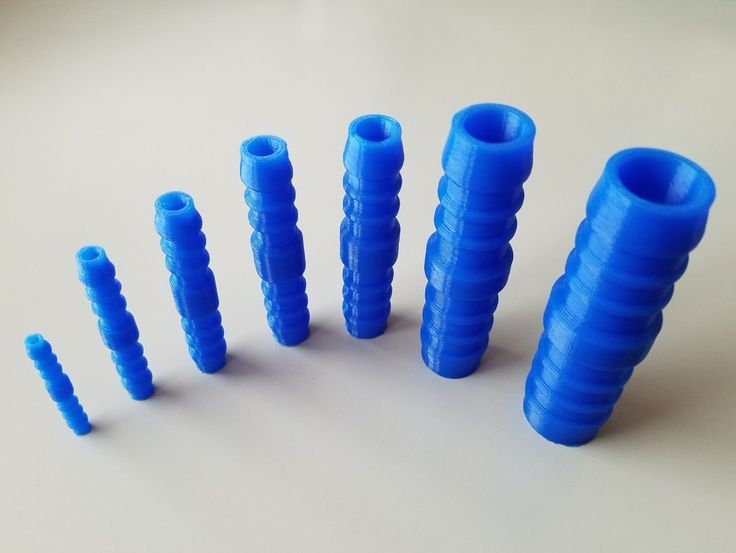

The most important part is, of course, the upward spiral. She had the most problems. I have designed many different types of coils and many versions have been rejected for either aesthetic or technical reasons. Yes, even due to the fact that the promised printing time was too long, I had to give up various ideas ... I wanted to get something airy, beautiful and so that I could print on my printer in a reasonable time.

The final model of the coil looks like this:

The coil installed on the machine:

There were several problems with the coil. First, it was necessary to decide what profile the spiral should have. Several options were considered. The simplest of them can be schematically represented in a section like this:

Several options were considered. The simplest of them can be schematically represented in a section like this:

Here is the thing - in the first version, if the border near the shelf protrudes strongly, then the printer software, and I use Ultimaker Cura, will make me supports that will need to be removed manually, and then if it is poorly cleaned, then they will also prevent the ball from rolling. If we take the second option with a thickening shelf, so that the ball seems to roll down to the plane of the spiral, then there will definitely not be any supports, but it is not known how well the ball will be held. I even printed a fragment of such a spiral to see how it would be in real life. But all the same, the third option won, an intermediate one, with a border / curb in the form of a corner. If it is not made very large, then the printer manages to print this without support.

Another problem with the spiral printing was purely manufacturing. I have never been able to print it in its entirety. I'm not sure what the reason is - it is possible that such a figure has too much cooling surface. While the extruder will pass along the entire trajectory, part of the model has probably already cooled down significantly. But these are just my guesses. Moreover, which is strange, at the very table, which is heated, the printing is normal, but the printing rises higher and plastic delaminations appear. At the same time, the printing of small test models occurred without problems. It’s not very pleasant when I started typing and everything seems to be going well for an hour. You leave to print for the whole day (another 13 hours of printing) until you leave for work. You come home, the printing is finished, but it turned out to be a marriage - the model has stratified on the upper layers. I even thought about printing a spiral in sectors, and then gluing it together. However, later I managed to pick up the print modes, temperature and speed, when the print went completely from start to finish with an acceptable result.

I'm not sure what the reason is - it is possible that such a figure has too much cooling surface. While the extruder will pass along the entire trajectory, part of the model has probably already cooled down significantly. But these are just my guesses. Moreover, which is strange, at the very table, which is heated, the printing is normal, but the printing rises higher and plastic delaminations appear. At the same time, the printing of small test models occurred without problems. It’s not very pleasant when I started typing and everything seems to be going well for an hour. You leave to print for the whole day (another 13 hours of printing) until you leave for work. You come home, the printing is finished, but it turned out to be a marriage - the model has stratified on the upper layers. I even thought about printing a spiral in sectors, and then gluing it together. However, later I managed to pick up the print modes, temperature and speed, when the print went completely from start to finish with an acceptable result. There were a few toffee hairs left, it would be necessary to clean them all, but then I was a little too lazy.

There were a few toffee hairs left, it would be necessary to clean them all, but then I was a little too lazy.

Another question was how to make the spiral spin. As you can see, a gear goes along the edge of the spiral. To be honest, I didn't really expect it. I thought the main thing was to make teeth on the edge of the spiral, and then somehow give rotation from a toy collector engine with another gear. This idea didn't work for me for several reasons. Firstly, the gears still need to be pre-calculated. Secondly, the idea was almost implemented like this:

But then it turned out that it was not easy to regulate the speed of the collector motor, then, the shaft of the toy motor backlashed quite a lot, and it made an unpleasant noise in operation. In general, this idea was abandoned. I took a 28BYj-48 stepper motor with a motor driver:

Step control made on Verilog in the FPGA board Mars rover:

If anyone is interested in how to program stepper motor control on Verilog, then this is the topic of a separate article. Now the speed can be easily programmed and runs almost silently. Only now it is a pity that when printing a spiral, a significant amount of printing time was spent on printing the gear. I think without it I would have saved 2 hours of printing.

Now the speed can be easily programmed and runs almost silently. Only now it is a pity that when printing a spiral, a significant amount of printing time was spent on printing the gear. I think without it I would have saved 2 hours of printing.

So, the 28BYj-48 stepper motor is installed in a special rack. The rack model I designed looks like this:

In the car, the stand with the engine looks like this:

but at least save a little printing time. Although, what a time saving there is, if you remember that the first version of the rack, which was supposed to be used in the version with a collector motor, was like this:

The problem with this rack is a large play of the spiral shaft. Well, again, as I already wrote, the option with a commutator motor and a gear did not work, so I had to make a new rack for a stepper motor.

It just so happens that I printed almost every detail at least twice. The first option, even if almost a worker had to be rejected often. Here, for example, is the “snake” part:

Here, for example, is the “snake” part:

It would seem that this might not be the case, but it turned out that when the ball descends in a straight line, it accelerates decently and flies out due to centrifugal force. I had the first turn to increase the height of the side. Well, at the same time, when re-printing, I reduced the height of the print layer. Let it print longer and better. Here is the "snake" installed in the car:

The project also required buns for attaching M4 studs:

These buns are attached to the board with double-sided tape - it turned out pretty strong. It's funny that I printed the quadruple buns twice. At first I printed it with black plastic and with a little infill. The model stuck so tightly to the 3D printer table that while tearing it off, it bent a little. And that's all - it does not stand exactly on the table. But it’s good that I reprinted it, it seems to me that combining white and black was a good idea.

Gutters:

Single turn:

Well, a number of minor details. In general, I had to print and reprint a lot. However, I'm glad I completed this project. Perhaps after some time I will be able to expand this Marble Machine, add new lifts and slopes, because there is still room on the board on the right for the next machine.

I was thinking of posting the sources of my models, but then I decided that there was no point in doing so, because each Marble Machine is, first of all, a fantasy of its creator. It is unlikely that anyone will want to repeat everything exactly as it is here. You can do better or just differently.

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale industries. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom Heads for LEGO Men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures inspired by the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

Thomas has modeled, printed and made publicly available several miniatures inspired by the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

3D model of a chaplain from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Weapon Seal

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Broken Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, if dropped. The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0139

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over the classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts model and make models and detailed instructions for assembling traction prosthetic hands and fingers publicly available so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

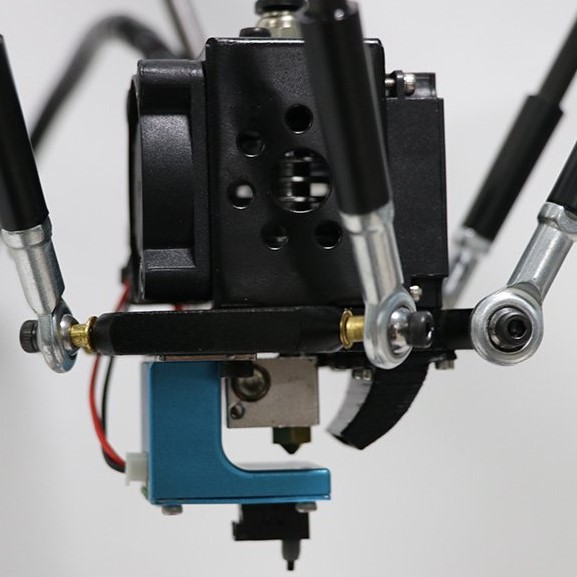

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Base Model Aerialtronics

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, not only has production been accelerated, but more time has been devoted to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to produce and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Prototyping

Prototyping of gas turbines.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production.