3D printing wilmington nc

3D Printing | Digital Makerspace

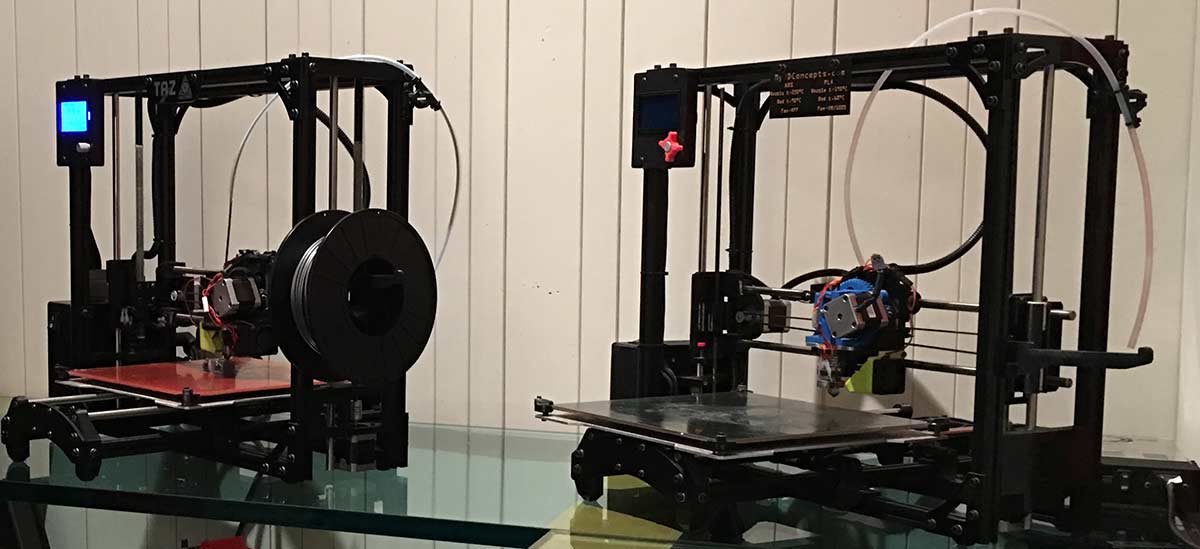

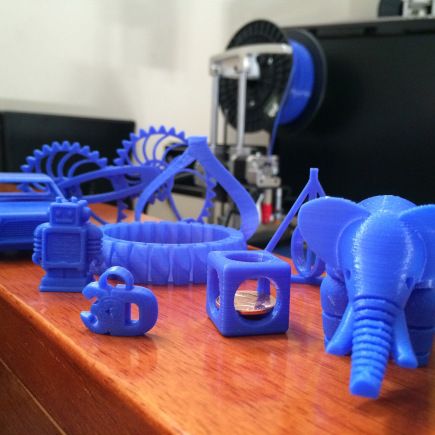

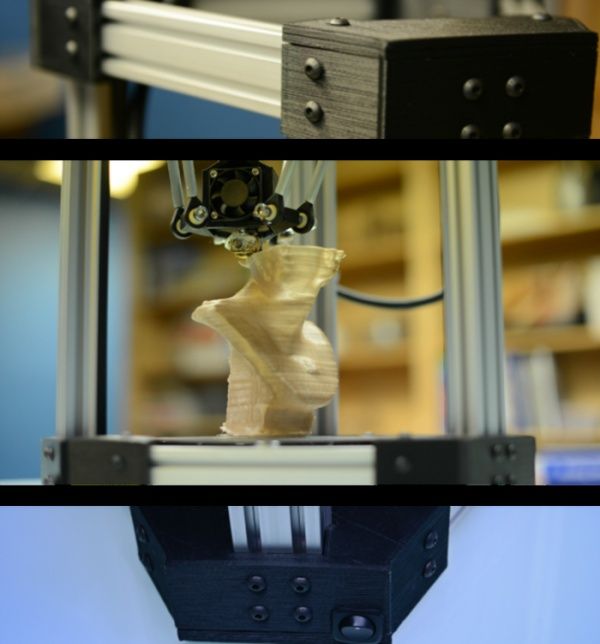

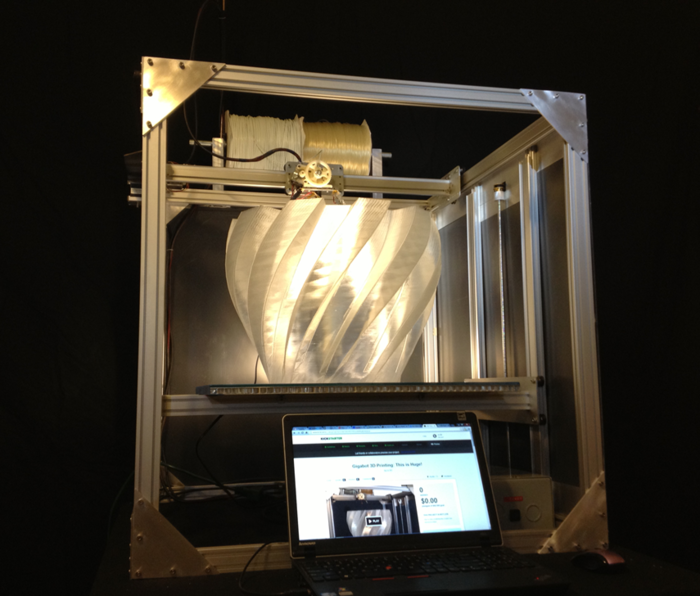

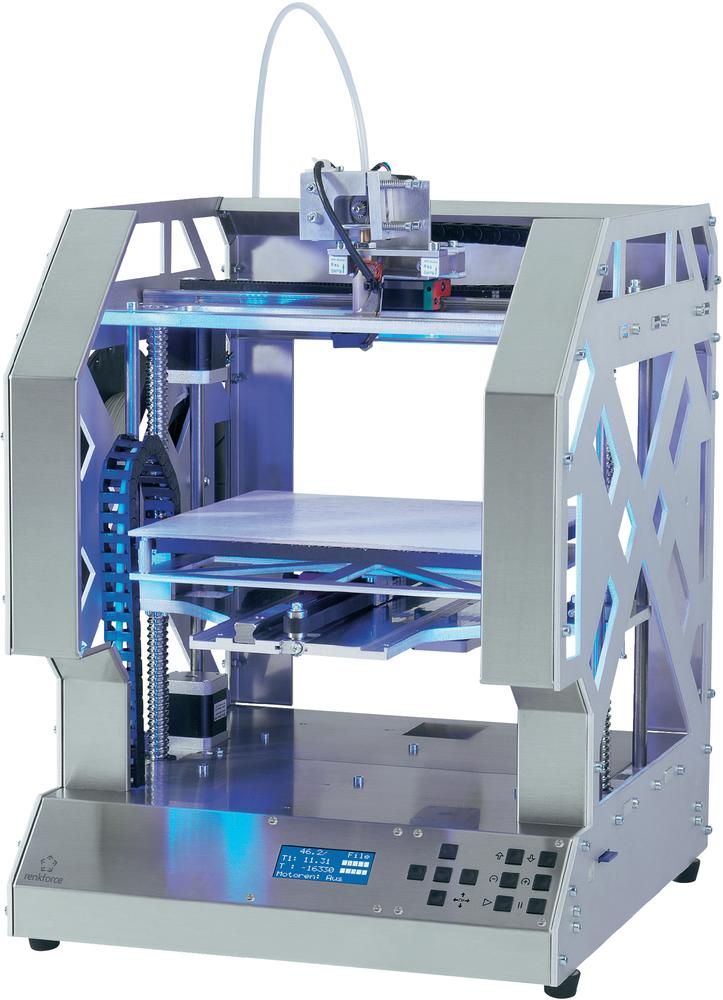

The Digital Makerspace has eleven 3D Printers to support classroom assignments and personal creativity. We currently offer a mediated printing service, as well as a 3D Printer that can be reserved for use after a training session with our staff.

Why was my print job cancelled?

Your print job could be cancelled for a number of reasons, including the following:

- Not using your UNCW email when submitting your request.

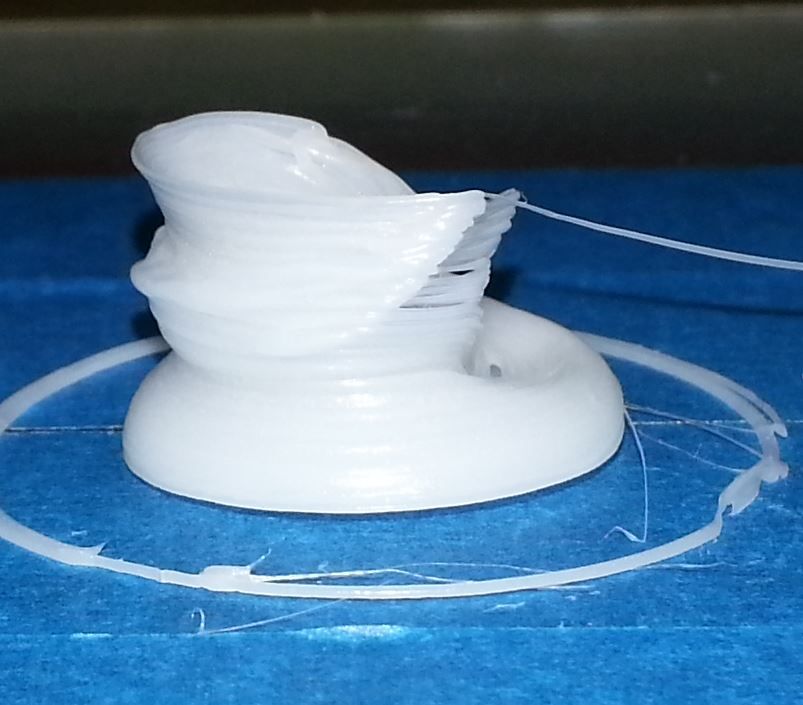

- Unoptimized file for 3D Printing. You may have to review your file and optimize it for 3D printing. This is a common occurrence with requests people have modelled/designed themselves.

- Sizing error. Your print may be too large or too small to print.

- Your print will take too long. The DMS cannot run machines outside of operating hours. Prints that exceed our open hours or staffing capacity may be declined.

- Request specifications. Sometimes we get requests that ask for 100% infill or disproportionate scaling of models.

We may contact you about questions regarding these items. We will very rarely print anything with 100% infill without confirmation from the person requesting the job. Infill is the density of the print, and can sometimes mean a very large amount of filament used. If you're not sure what infill is, don't worry—we can handle it for you.

Unless infill is absolutely vital to your model, there is no need to input infill specifications on your model, allow the DMS to handle that for more efficient printing.

Why isn't my print job showing up in the queue?

As we work on print jobs, we will change their status to pending, approved, and printing. These changes keep it in our queue on the backend, but make them temporarily disappear from the queue displayed above. Don't worry—we're working on it! You will get email updates as your print status changes.

3D Printing Services

Our 3D Printing Service is for UNCW faculty, staff and students. Before making a print request, please estimate the cost of your print job and read over all 3D Printing guidelines.

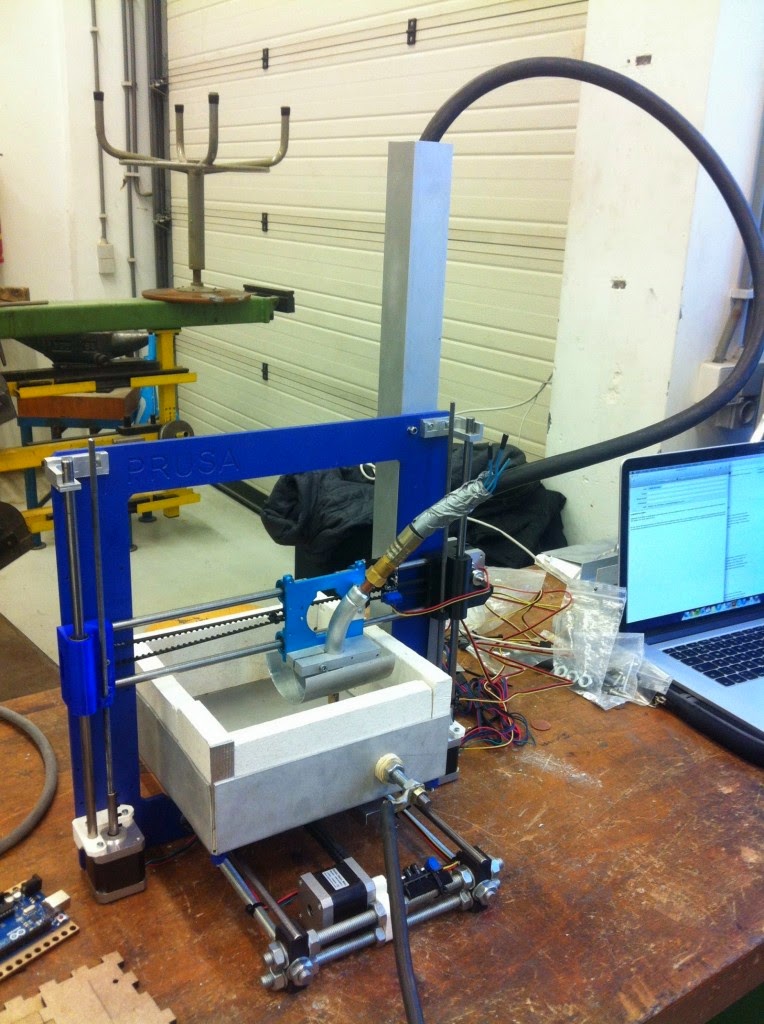

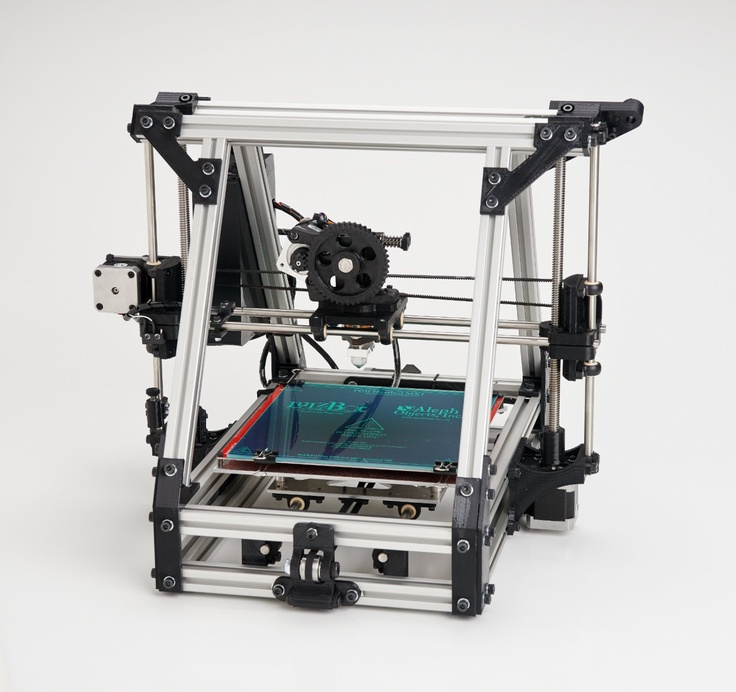

For a more in-depth and independent 3D Printing experience, the Digital Makerspace offers a training session for anyone in the UNCW community who is interested in learning how to 3D Print themselves. Users will be able to reserve a Prusa i3 MK3S in the public area of the DMS after going through an hour long one-on-one training session with DMS Staff. Cost for using this printer is the same as if using our 3D Printing Service. Book your training appointment today!

Need help with 3D Modelling? The Digital Makerspace can help walk you through learning different 3D Modelling programs to make your perfect design. For beginners, we recommend using TinkerCAD, a free browser-based modelling software. Other free modelling software includes Blender, Meshmixer, and ZBrush Core Mini.

Need help finding 3D Models online? Popular websites for finding 3D Models online include Thingiverse, Morphosource, NIH 3D Print Exchange, NASA 3D Resources, and Smithsonian 3D.

The Digital Makerspace Staff can offer additional assistance with finding, creating, and optimizing your 3D Model for printing.

Filament Recycling

The Digital Makerspace primarily uses PLA (Polylactic Acid) plastic filament. With heat treating, this plastic can be biodegradable. Instead, we choose to completely recycle our 3D Print failures, scraps, and supports to create new spools of filament that are perfect for drafts and prototypes. Our unused print scraps are broken down to pieces and fed into our Filastruder and Filawinder system, which not only extrudes new filament, but winds it onto a reused spool for us as well.

3D Printing Guidelines

- All 3D print requests must be submitted as a .STL file. Other file types will be returned for correction.

- Please allow up to 7 days for job completion.

- All print requests are processed in the order they are received. We cannot guarantee specific delivery times.

- If the item is not picked up in 14 business days it will become property of Randall Library and will be recycled.

- The cost to print is .12¢ per gram with a $1.00 minimum purchase. Total is then rounded up for service fees to the next dollar. Payment is due upon print completion.

- Prints can be picked up at the Digital Makerspace.

- UNCW does not guarantee a successful print. The cost of a completed print, regardless of quality, will be still be charged.

- All UNCW computer, network and Copyright policies apply to the use of the 3D printers.

- You may not use the printer to create material that is:

- Prohibited by local, state, or federal law.

- Unsafe, harmful, dangerous, or poses and immediate threat to the well-being of others.

- Obscene or otherwise inappropriate for the University environment.

- In violation of another’s intellectual property rights, including to reproduce material that is subject to copyright, patent, or trademark protection. It is the responsibility of the user to verify the eligibility of the item to be printed.

- Mass production of items beyond prototyping.

- We reserve the right to refuse any 3D print request for any reason.

- UNCW takes no responsibility for the end-use of an object once that object is printed.

3D Printing Service Wilmington, NC | Instant Quotes Online

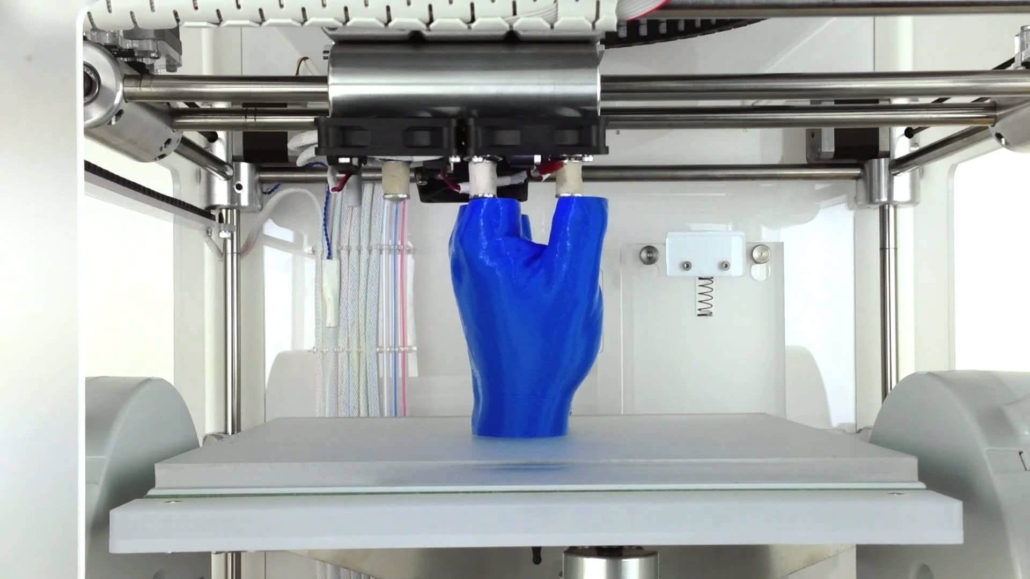

Our 3D printing capabilities

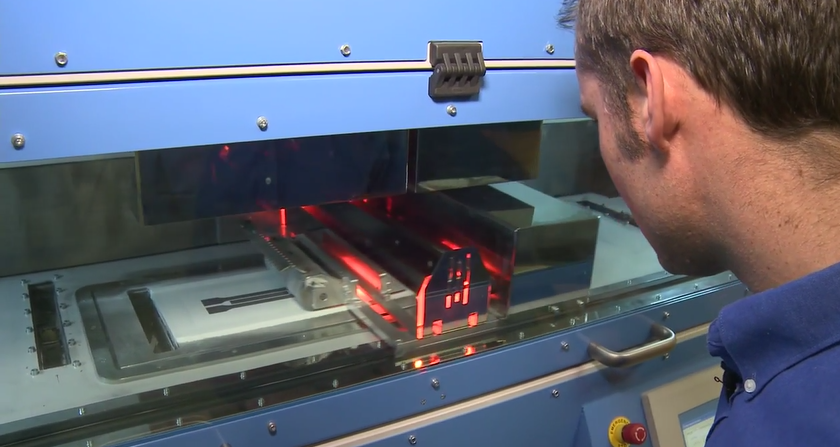

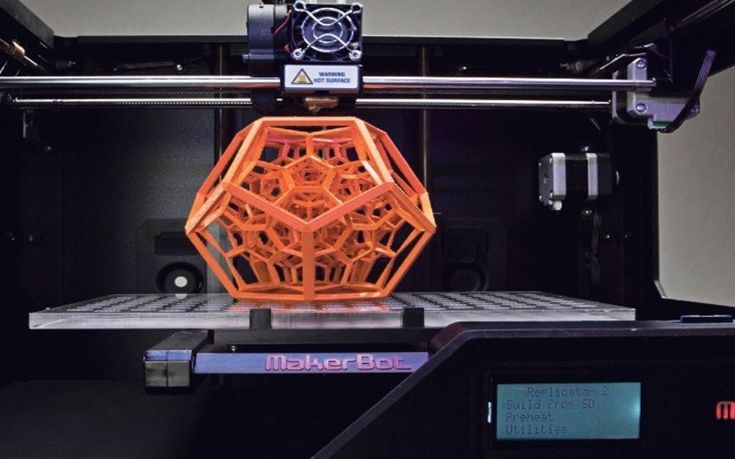

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

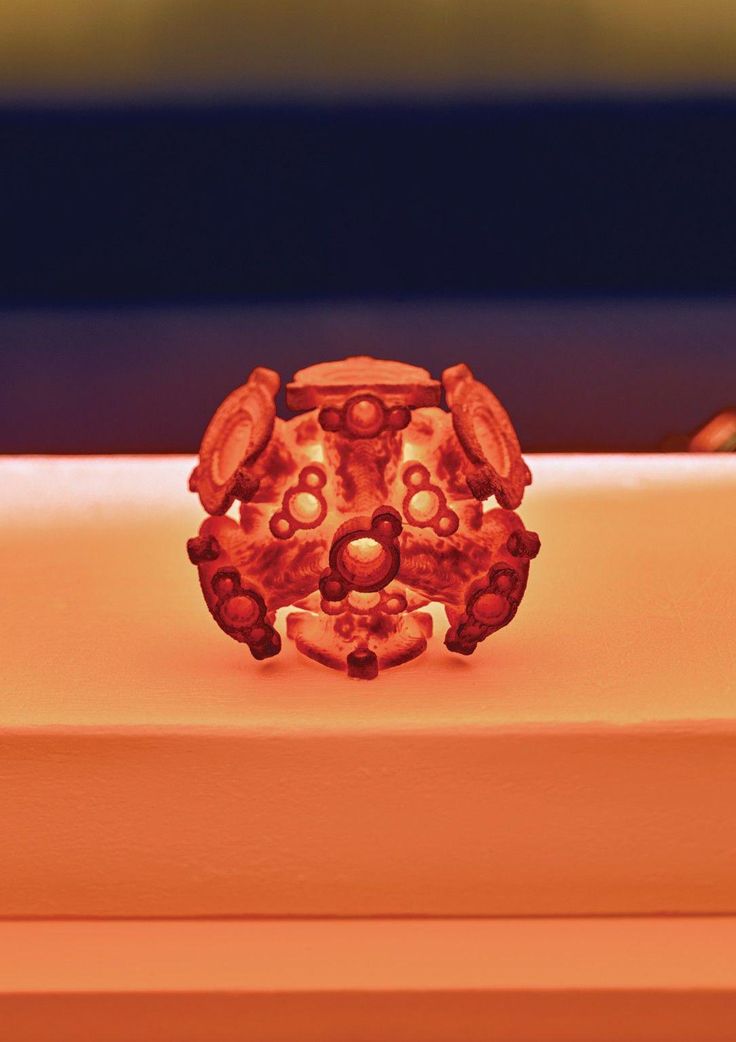

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

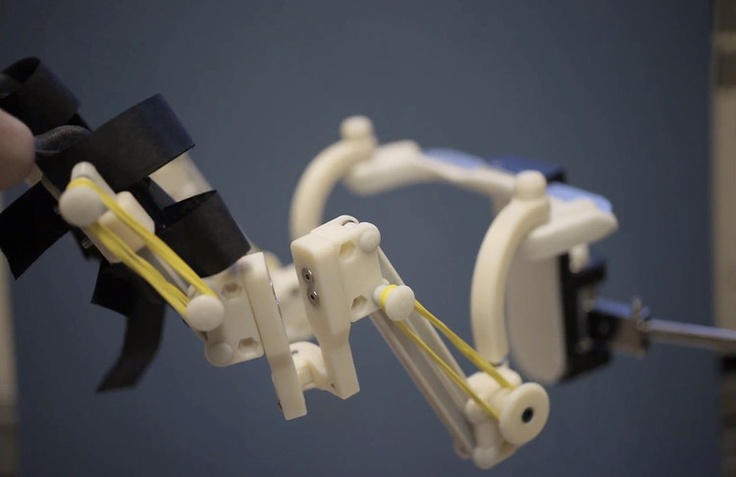

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.

9/5

9/5 Over 249 customers are satisfied with our 3D printing service.

“Excellent service, fast communication, and very helpful through every part of the process. Strives for 100% customer satisfaction”

“Very courteous and printed two of the provided objects. ”

“Great print quality and customer service.”

“These parts are perfect! Highly Recommended”

“Product was great, expect specifications and worked perfectly for what they were needed for.”

“Very happy with print quality and speed. We are interested in knowing max build size for future models. Thank you”

“Order was completed early and as expected!”

“Great hub, quick service and helpful information.”

“Great service again. Parts received as expected.”

“Very happy with the print quality and service. ”

”

“Absolutely amazing and high quality 3D prints! I recommend to all! ”

“Good quality prints, would be willing to use again”

“The prints look great. Much appreciated.”

“Exactly the what I ordered and delivered quicker than expected. Knowledgeable. professional, and efficient!”

“Quick turn-around for a prototype! Very affordable! Will use again!”

“Thank you so much for your help and for taking the order! I know it wasn't worth much. It has definitely helped me already!”

“Great service and way faster than expected!”

“Everything went well. Great service for my first try on your site. I will be taking a look a the 3D Printing Handbook next. Very quick turn around time. thank you again, Jeff”

“Easy transaction, fast print, fast ship. Part looks exactly as I expected. ”

“I greatly appreciate your promptness and quality of your print. This design is being used as a cell phone holder installed into the console of my Nissan 370Z, whereas otherwise, this car has no other practical place to hold a cell phone. The new install looks like an OEM feature of the console and adequately provides for the intended purpose. Thank you sincerely for your professional service.”

The new install looks like an OEM feature of the console and adequately provides for the intended purpose. Thank you sincerely for your professional service.”

“Very helpful, super quick with responses and printing and questions. Glad to be able to work with him. ”

“The parts look great - thanks for completing this for me!”

“Fast turnaround, and parts turned out great.”

“Part was made quickly and quality was excellent ”

“The print came out great, the team did a great job with communication and explanation of different materials. Will use them again!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

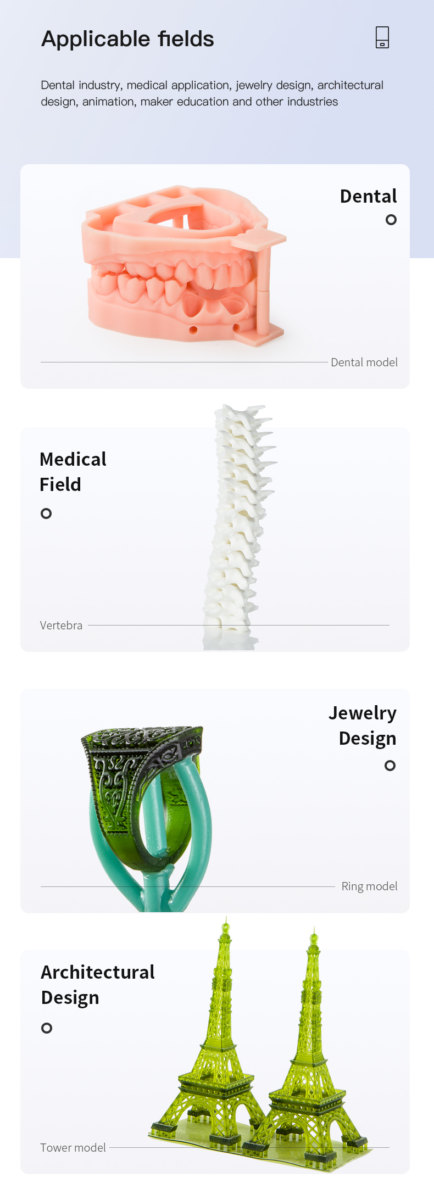

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Wilmington, NC

Wilmington, NC Myrtle Beach, SC Jacksonville, NC

Goldsboro, NC New Bern, NC Fayetteville, NC

Greenville, NC Florence, SC Apex, NC

Raleigh, NC

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

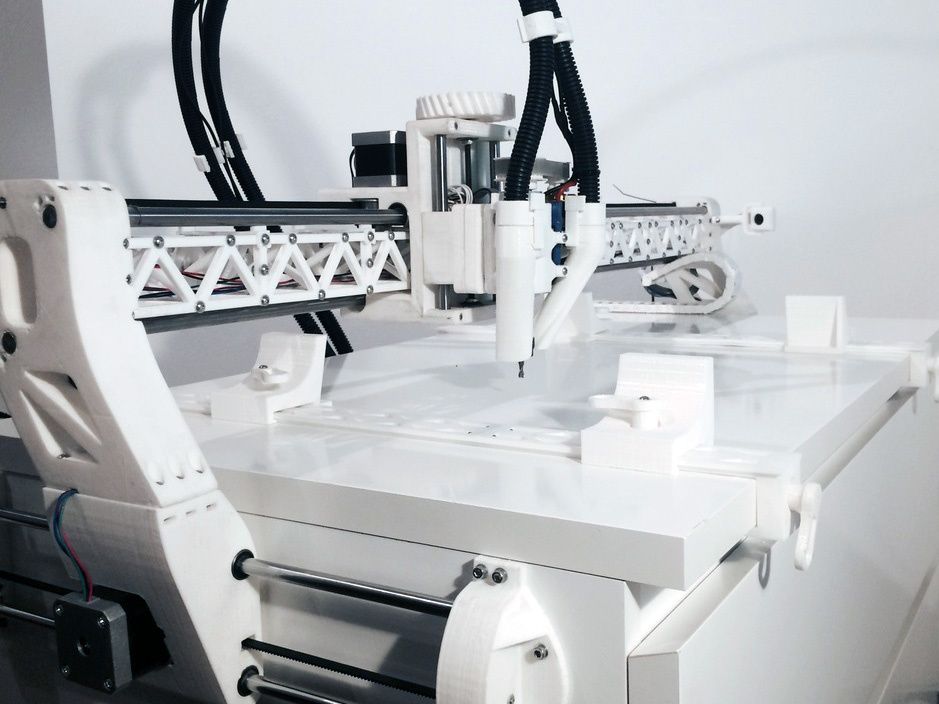

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Page not found - Wall Printer

10/25/2020.

UV Wall Printer Upgrades.

UV Wall Printer Upgrades. All the UV wall printers can be upgraded to the latest version software, which will significantly improve your printing quality.

11/01/2020. PhotoPrint RIP Software Available

All wall printers can be installed by PhotoPrint RIP Software as optional. If you need it, contact your engineer.

03/12/2021 Ink Level Alarm Tank is Available

UV wall printer has equipped with the ink level alarm tank. 5 ink tanks, 260ml each. White ink will be with the stirrer.

04/12/2021 The World's First Floor Printer is Ready

The Floor Printer can print directly on the ground. Check more: 3D parking spot printer machine

Jan.

14th, 2022 The latest LED UV Wall Printer "T series" has been released

14th, 2022 The latest LED UV Wall Printer "T series" has been released T series is the most portable UV wall printer HKHR tech has been made. It can be split into 6 parts and each one is no more than 15kg. What’s more, it also combined the rails driving system and wheel driving system in one model. Introducing the "T series" UV wall printer

For technical support, please contact our engineer Adam: [email protected]

For sales inquiry, please contact our sales director Alex: [email protected] 9

Everything You should Know About Wall Printer

The Ultimate Guide For How to Choose the Best Wall Printing Machine

Please take 5 minutes to check this article, and you will get well know about wall printer:

Everything you should know about the wall printer.

Support

SAi FlexiPrint RIP Software We can pre-installed the US PhotoPrint RIP software for all UV printers and water-based ink printers.

After printing tests and calibration curves, the output ink quality of all series of HKHR wall printers has been significantly improved.

Language: English, Portuguese, French, Italian, German, Spanish, Chinese, Japanese, Korean, Dutch, Danish, Finnish, Russian uses 5 basic colors of CMYK+White , which can print on dark background walls (such as gray, blue, black, etc.).

At the same time, it can also print white colors independently, which is more suitable for some special scenes.

How to Unpack & Assemble & Operate The Wall Printer

We have packed 6 UV wall printing machines in the factory. Three of them were sent to the United States. The unboxing video was shot and edited in the United States.

This video also shows how to operate our wall printer .

High Resolution Printing

All series of our wall printers support up to 16pass, 2880dpi printing resolution.

The original scene of the picture is vividly restored, which is full of praise.

Portable UV Wall Printer—The Best Selling Wall Printer

You can choose a wheeled wall printer. It can move on its own automatically and can be applied to flat indoor floors.

Equipped with height-adjustable guide rails, allowing you to print easily outdoors. Disassembly, transportation, and installation are very convenient, 10 minutes is enough! (TWP is our distributor for North America)

Watch the video tutorial for taking down and setting up the Wheeled UV wall printer

You will Never Be worried About Power Cut and Sudden Accidents for stopping Printing

We have developed the power -off supplement function .

It allows you to set up the software to continue to finish your work next time when power is lost, raining, and various emergency situations have to be suspended.

There is no need to return the guide rail to its original position, it can be completed by software and laser calibration.

Check the supplement tutorial --->>

Amazing Stitching Ability Allows You to Print Murals Up to 10 Meters High

Excellent expansion performance.

We can customize the vertical rail of the wall printing machine for you to adapt to the indoor height of different countries.

At the same time, we can add an extension rod for you to obtain a one-time printing height of up to 3 meters.

And through powerful operating software, you can use stitching technology to obtain larger-format pictures.

Four Printheads and The Fastest Wall Printing Speed You Have Never Seen

The water-based model of wall printer machine is equipped with up to 4 Epson print heads, each of which works independently and can print 80m2 per hour in the 2 Pass mode.

Such an amazing high-speed printing technology is already ranked first in the world in the field of vertical inkjet printers.

UV Curing System with Air-Cooled UV Lamp

that of the water-cooled UV lamp.

At the same time, the UV curing effect is more efficient, suitable for printing on various materials. Such as walls of any material, metal, glass, wood, canvas, plastic, ceramic tiles, etc.

The Seventh Generation

EPSON Micro-Piezo Printhead We use high-quality EPSON micro-piezo print heads for all series of printers. We refuse to use cheap, inferior, and second-hand EPSON print heads.

We refuse to use cheap, inferior, and second-hand EPSON print heads.

Because we know that the quality of the nozzle directly affects the printing effect and the life of the wall printer.

High-Quality and Stable Components

We use 3 independent power supplies to avoid interference; The frame uses high-quality steel to increase its rigidity and precision; At the same time, we use large wheels to increase precision and anti-skid. . .

We only purchase top-quality accessories to provide customers with safe, assured, durable products, and user experience. Save Your Time, Save Your Money

Only the colored areas are printed. And the white area, the print head no longer scans to save time.

Watch carefully at the end printing for the tail, the printhead just prints the area for the tail, not scan other white areas.

Eco-friendly ink

Our printer uses environmentally friendly and durable highly colored pigment ink, which can be used in any scene.

At the same time, you can purchase high-quality printer inks suitable for our machines worldwide.

Tracking System to keep the right distance to the wall

The entire series of our wall printers are equipped with two American Banner ultrasonic sensors so that the print head can print on curved and uneven surfaces.

Which means it can automatically follow the wall without worrying about the flatness of the wall.

Manual Laser Calibration Function

The manual laser calibration function allows you to better grasp the status of the machine.

Come Follow The Lens And Visit Our Factory

We are a vertical printing technology company with R&D capabilities. We are not a trading company or an assembly company for the wall printer .

We are not a trading company or an assembly company for the wall printer .

You deserve to have a professional after-sales guarantee.

Pantents and Certifications

We have the most comprehensive certifications and patents, two invention patents for the wall printer, and 8 other patents.

In addition, we have a CE certificate, ink certificate, and so on. We prove ourselves through strength and service, not sales words.

R&D Ability

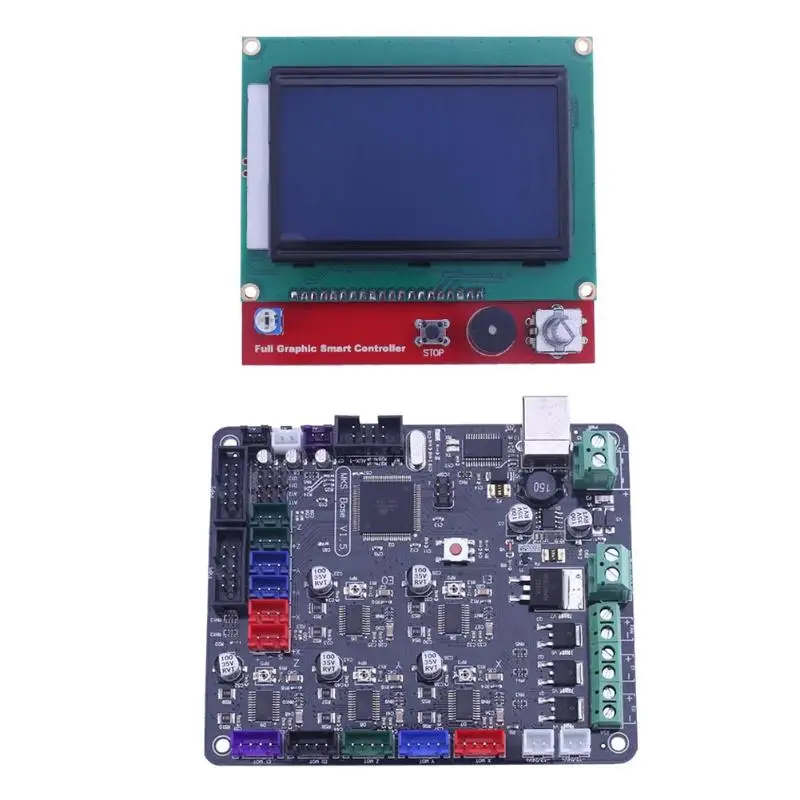

All the PCB motherboards for wall printer and programming systems for wall printers are developed by us, so our machine update iteration is very fast.

After-sales support is more convenient, and there is no need to contact the motherboard supplier to resolve customer questions.

The motherboard and program are very stable. As we have been supplying the inkjet printer market for more than 10 years.

Market Share

We have more than 2,000 customers in China, this is just a part of these cases.

Dealership and Agents

We have very good partners in the United States, Russia, and the Czech Republic. . .

—> Dealership network over the world

We provide high-quality products and reliable services to win more and more partners.

Do you want to join us too?

Aging Test

We will do 24 hours aging test for all the wall printers before shipping, making sure they are all in good condition.

After-sales Guarantee And Technical Support

We provide a one-year after-sales guarantee . Our after-sales team has rich experience , has served the Chinese market for a long time, and can speak Good English. They Can solve technical problems for you through video calls.

We send accessories through FedEx and DHL, and we will bear the first year’s cost. WhatsApp: 86 15952051055

How to print 10m * 12m photo wallpaper on the wall with a wall printer?

BlogBy Alex Wang

Our smart Chinese customers have printed a HUGE 10m x 12m mural on the wall using the stitching function of the software wall printer. The standard print height of the wall printer is 2 meters, but we have developed the STAPLE FUNCTION in the software. If you want to print a large mural on the wall, you just need to lift the printer by the platform and print...

The standard print height of the wall printer is 2 meters, but we have developed the STAPLE FUNCTION in the software. If you want to print a large mural on the wall, you just need to lift the printer by the platform and print...

Read more

CMYK + White Wall Mounted UV Printer with Wheel and Guide Show Show

BlogBy Alex Wang

This is a great video made by our partner in Ukraine. If you want to know more about them and our dealers and agents around the world, please click here: Worldwide Wall Printer Agents and Dealers By watching this video, you can see how amazing the S Series UV Wall Printer can do. Using white ink, he…

Read more

Everything you need to know about the wall printer

BlogBy Alex Wang

This article is contributed by our engineer Adam. Now he works for Beijing Huake Hengrun Intelligent Technology Company, which is the most professional wall printer manufacturer in China. We sell wall printer abroad. I have been designing and manufacturing wall printers since 2011. I have witnessed how the scale of this industry has grown from small to large, and ...

Now he works for Beijing Huake Hengrun Intelligent Technology Company, which is the most professional wall printer manufacturer in China. We sell wall printer abroad. I have been designing and manufacturing wall printers since 2011. I have witnessed how the scale of this industry has grown from small to large, and ...

Read more

Russia UV Wall Printer, Steel Wall Printing

BlogBy Alex Wang

This video has been verified by our Russian agent. They use UV S series wall printer to print on the steel wall.

Read more

King of Oman print on wall with wall printer

BlogBy Alex Wang

We use HK-K2 wall printer, a water based pigment ink wall printer with 2 print heads. Seal of the King of Oman on the wall.

Read more

Wall print depicting the Hindu god - Lord Ganesha

BlogBy Alex Wang

The HK-K2 #wallprintingmachine has two Epson nozzles to print high quality posters quickly and efficiently.

Read more

Universal UV Wall Printer[2021 Updatd]

BlogBy Alex Wang

How to choose the right wall printer for you? What to choose: a printer with water-based ink or UV curing ink? I suggest you choose an all-in-one UV printer if your printing business has a lot of different print materials. What materials can UV wall printers print on? In theory, UV wall printers can print on any material. Such as walls, acrylic, glass,…

Read more

American and Turkish engineers assembled a metal-to-metal desktop 3D printer

News

creation of a budget 3D printer capable of printing all-metal products.

Let's talk about what they did.

Let's talk about what they did.

Direct 3D printing with metals (without intermediate steps such as growing polymer-metal blanks, and then etching and sintering) can be divided into two areas, referred to in Russian GOST as “synthesis on a substrate” (in the English terminology Powder Bed Fusion or PBF) and "direct energy and material supply" (Directed Energy Deposition or DED). Synthesis on a substrate involves sintering or fusing metal-powder compositions in containers using laser emitters or electron beam guns. In the direct supply of energy and material, various energy sources can also be used, for example, the same lasers or electron beams, and the materials can be either powders deposited into the sintering or fusion zone or metal wire.

A project by scientists from California State University and Osman Ghazi University of Eskisehir is a variant of the second track called Wire Arc Additive Manufacturing or WAAM. Here, the material is wire, and the products are grown by arc welding, specifically in this case, with a non-consumable electrode in a protective inert atmosphere. WAAM is already being used in industry, for example in the repair and even additive manufacturing of ship parts: in 2017, the Dutch production center RAMLAB produced the first type-certified 3D printed ship propeller ( in the illustrations above and below ).

WAAM is already being used in industry, for example in the repair and even additive manufacturing of ship parts: in 2017, the Dutch production center RAMLAB produced the first type-certified 3D printed ship propeller ( in the illustrations above and below ).

The resolution of WAAM 3D printers, to put it mildly, is small and requires a lot of post-processing, but they are easily scaled up and do not require fuss with relatively expensive, and often dangerous powders, and at the same time outperform traditional methods in terms of producing geometrically complex products with minimum waste. But you can scale both up and down, and the heroes of our story decided to create such a device not on the basis of an expensive industrial-grade multi-axis robotic arm, but by redesigning a budget desktop FDM 3D printer with the intention of keeping within one thousand dollars.

As a basis, the guys took an open source "drygost" called Bukobot by the Californian company Deezmaker. The team assembled the device themselves by printing plastic parts on a Stratasys uPrint SE Plus 3D printer, and the power source for the head is an Everlast-branded welding machine. The movable electrode is mounted on one carriage with a mechanism that feeds a metal wire into the melt zone.

The team assembled the device themselves by printing plastic parts on a Stratasys uPrint SE Plus 3D printer, and the power source for the head is an Everlast-branded welding machine. The movable electrode is mounted on one carriage with a mechanism that feeds a metal wire into the melt zone.

Inconel 718 Single Layer Metallography

Experiments were carried out with two types of consumables - AISI 1030 high-carbon steel wire and Inconel 718 heat-resistant nickel-chromium alloy with a diameter of 0.8 mm using tungsten electrodes with a diameter of 2.37 mm and blowing with an inert gas - argon. A series of experiments included experiments on 3D printing at different speeds with the appropriate adjustment of the material feed rate and current strength. For steel, these parameters varied within 2.5-3.5 mm/s with a feed rate of 14-18 mm/s at 45-55A, and with Inconel they tried to print at speeds of 4.88-5.03 mm/s with a feed rate wire 7.69-10.49 mm/s at 40-50A.

Exterior and cut of 30 ply Inconel 718 specimen

Predictably, the team faced a host of challenges, including mechanical failures, errors in machine code, overheating and even burnout of electrical connections, and electronic and stepper motor failures caused by welder noise.

When working out the parameters, the results varied greatly: when working with the same steel, even at a current of 50A, 3D printing at high speeds produced a series of drops instead of solid lines, so the combination of a paving speed of 3 mm / s with material feed at a speed of 18 mm / s at a current of 55A ( option number 8 in the illustration above ). With these settings, we managed to get a wall of twenty-five layers in the illustration below.

In general, the experiment was recognized as successful, as the very possibility of WAAM 3D printing with metals on budget, self-assembled equipment with a total cost of around one thousand dollars was proved without significant defects, such as interlayer oxidation or cracking. The team's full report can be found at this link.

The team's full report can be found at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

budgetary metal printing WAAM

Follow author

Follow

Don't want

13

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

On October 21, the solemn opening of the production site for the production of so-called...

Read more

6

Subscribe to the author

Subscribe

Don't want

A team of scientists from the Perm National Research Polytechnic University has developed.