Ctc 3d printer review

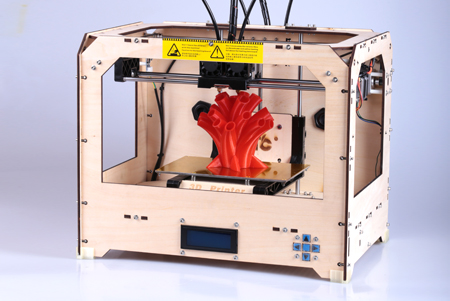

CTC LTD CTC-3D Bizer 3D Printer

| Brand | CTC LTD |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

| Materials | PVA, PLA, ABS, FLEX (Elastic TPE), Rubber-like (TPU), Flexible Resin, (taulman) PCTPE, PC-ASA, PVDF (PolyvinylideneFluoride), FR-ABS (Flame Retardant) |

| Website | http://www.ctcprinter.com |

| Average Price | $799.00 |

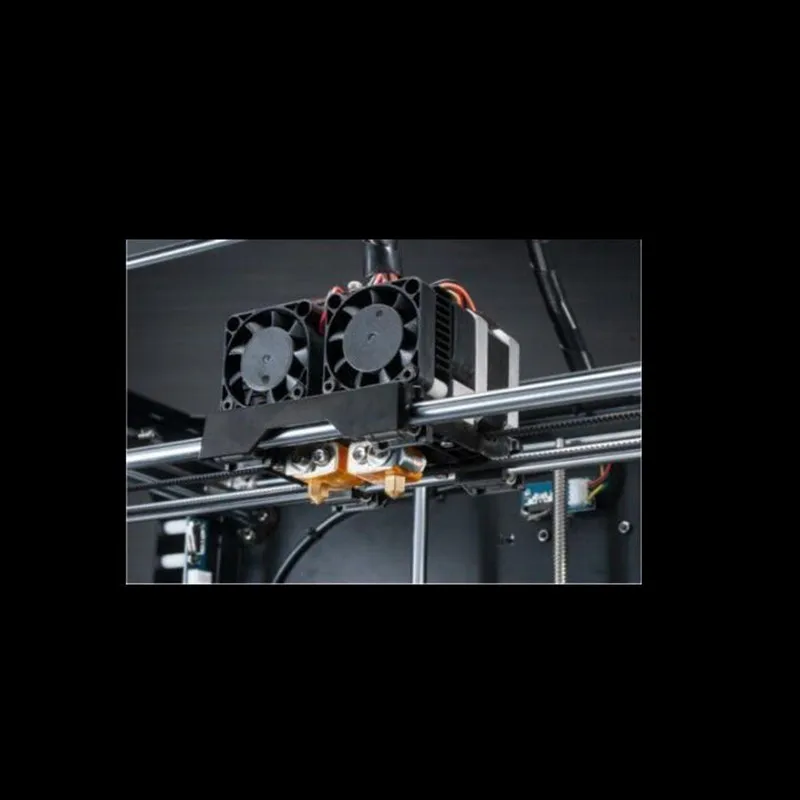

| CTC 3D PRINTER "BIZER" WITH DOUBLE NOZZLE | |

| Model | Bizer |

| Case Material | Wood |

| Input Voltage | AC110V-230V |

| Output Port | USB2. |

| Touch Screen | No |

| Printer Dimesion | 320*467*381mm |

| Buidling Size | 225 * 145 * 155mm |

| Packing size | 565 * 430 * 535mm |

| Layer Accuracy | 0.1mm-0.5mm |

| Positioning Accuracy | XY axis 0.011mm |

| Input File Types | stl, gcode |

| Extrusion Nozzle Flow | About 24cc / hour |

| Nozzle diameter | 0.4mm |

| Recommended Nozzle Moving Speed | 35-40 mm / s |

| Print Material | ABS or PLA with 1.75mm diameter filament |

| Drawing Software | Rhino3D, Proe, 3dMAX, CAD, UG, Soliwork |

| Software | ReplicatorG or west to CTC Chinese Version |

| Print Color | Cyan, Magenta, Yellow, black, Write, Green , Clear , etc. |

Reviews 4.

0 2 reviews

0 2 reviews Print Quality

Reliability

Ease Of Use

Failure Rate

Running Expenses

Software

Build Quality

Customer Service

Community

Show reviews Hide reviews

Nov 7, 2018

fsdfsdfsdfsd

Nov 7, 2018

descr es fsd fs r s

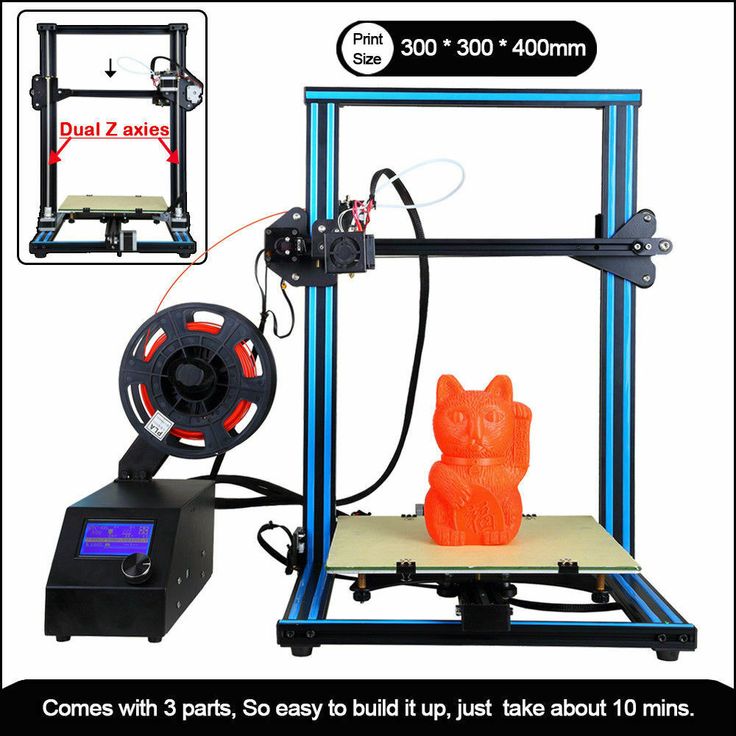

CTC 3D Printer 2020 Upgraded Full Quality High Precision Reprap Prusa i3 DIY 3D Printer MK8 Resume Power Failure Printing Sale, Price & Reviews

Share to:

- Description

- Reviews(2)

Descriptions

Main Features

Power Failure Resume Printing: When suddenly power failure, the printer will store the print data and then shut down. When it is restarted, it will prompt to continue printing and canceling. If you choose to continue printing, you can automatically print to the position when the power is off.

When it is restarted, it will prompt to continue printing and canceling. If you choose to continue printing, you can automatically print to the position when the power is off.

Product Description:

Input Voltage: 110V-220V

Output Port: USB2.0, TF Card

Max Tem of Bed: 130(usually65℃)

Buidling Size: 200mm*200mm*180mm

Max Tem of Nozzle: 260(usually210℃)

Print head: Single

Layer Accuracy: 0.1mm-0.5mm

Positioning Accuracy: XY axis 0.011mm

Input File Types: stl, gcode

Extrusion Nozzle Flow: 30mm/s_100mm/s

Nozzle diameter: 0.4mm

Recommended Nozzle Moving Speed: 35-40 mm / s

Print Material: ABS, PLA 1.75mm

Operation System: Windows7/8(32-bit/64-bit)

Drawing Software:Rhino3D, Proe, 3dMAX, CAD, UG, Soliwork

Software:Cura

3D printer Package:

1.All assembly units

2.All assembly tools

3.Software(English version)MAC OS need download the software on Cura official website.

4.30M(ABS/PLA)

5. A CD(English product manual+software+test file)

Note: the product will be updated at any time. A small number of accessories may not match the picture on the description. Please give priority to the ten actual items received. If you mind, please do not purchase

A small number of accessories may not match the picture on the description. Please give priority to the ten actual items received. If you mind, please do not purchase

Specification

Package Size(L x W x H)

50cm*42*21

Package Weights

View More

- All (2)

- Photos (1)

- Videos (0)

- Sort By: All

All Hottest Most helpful Most recent

-

Translate into EngLish

-

kong

Yes (0)

OK

- It's really a very good 3D printer, and the supporting software is also very easy to use. My son likes it very much. The printing effect is very fine, the precision is high, and the size is large. It should be the most cost-effective printer. It is easier to use than I thought. It is recommended to buy

Jul 10,2020

-

NXG_LeShuuk

Yes (0)

Lieferung

- Lieferung ging sehr lange obwohl der Artikel in Deutschland vorrätig war!

Der Support war sehr gut !

Dec 01,2020

- Lieferung ging sehr lange obwohl der Artikel in Deutschland vorrätig war!

Your Recently Viewed Items

Pre-sale Service

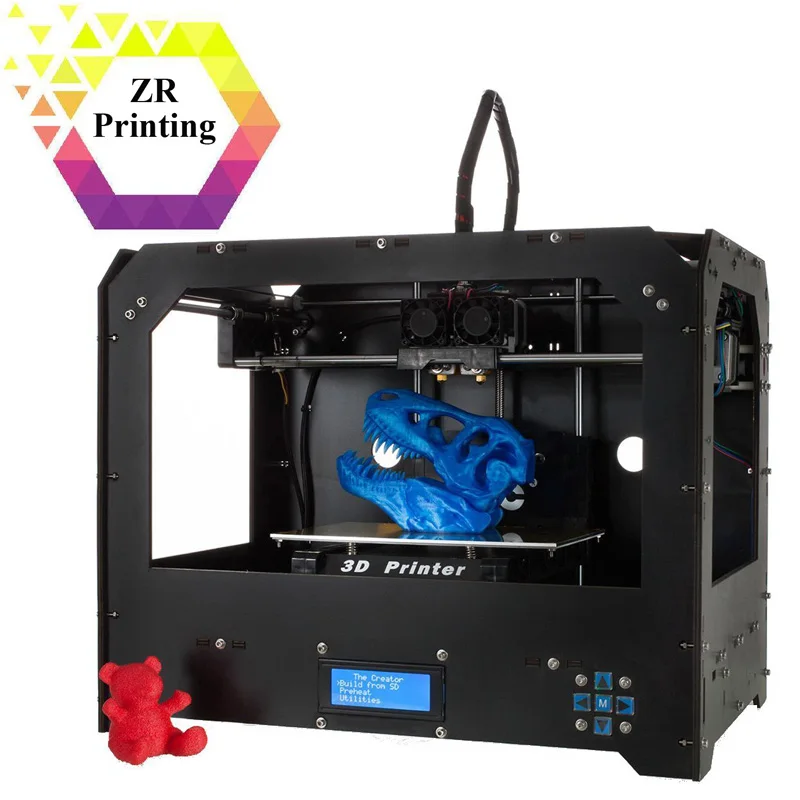

CTC 3D Printer Prusa i3 Reprap MK8 MK2A LCD Screen Exclusively Impressed 3d Drums Power Check to Resume Printing

Share to:

- Description

- Reviews (3)

Descriptions

Main features

Search resume printing: when there is a sudden power failure, the printer will store the print data and then shut down. When he recovers the art, he will continue printing and suppressing. If you choose to print, you can automatically print to the position when the power is off.

When he recovers the art, he will continue printing and suppressing. If you choose to print, you can automatically print to the position when the power is off.

Product description:

Input voltage: 110V-220V

Output port: USB2.0, TF card

Max bed estrus: 130 (usually 65℃)

Gel size: 200mm*200mm*180mm

Max indicator nozzles: 260 (normal 210℃)

Print head: single

Layer accuracy: 0.1mm-0.5mm

Positioning accuracy: XY axis 0.011mm

Input types: bristle code

Nozzle extraction: 30mm/s_100mm/s

Diameter nozzle: 0.4 mm

Recommended rotation speed: 35-40 mm / s

Print material: ABS, PLA 1.75mm

Operating system: Windows7/8 (32-bit / 64-bit)

Drawing software: Rhino3D, Pro, 3dMAX, CAD, UG, Resh

Software: Cura

Package 3D printer:

1. All assembly

2. All assembly tools

3. Software (English version) MAC OS software needs to be downloaded from Cura official website.

4.30M (ABS/PLA)

5. CD(English product manual + software + test)

CD(English product manual + software + test)

Note: The product will be updated at any time. Small accessory numbers may not match the picture in the image description. Please prioritize ten items received. If you think, please do not purchase All (3)

All Popularity Most Helpful Most Recent

Translate to English (0)

Excellent printers

- A very good DIY printer, the best gift for children, too many surprises

My son used it to make rabbits, squirrels, cats and dogs. In his toy cabinet, there are models of his own design everywhere. He likes it very much 9Yes (0)good

- I am very satisfied with the printer. First of all, I am most satisfied with the price, the product quality is good, and the printing accuracy is higher than I expected0002 Yes (0)

good

- I am very satisfied with the printer. First of all, I am most satisfied with the price, the product quality is good, and the printing accuracy is higher than I expected

Jul 10,2020

- I am very satisfied with the printer. First of all, I am most satisfied with the price, the product quality is good, and the printing accuracy is higher than I expected0002 Yes (0)

Your Recently Viewed Items

Pre-Sales Support

What kind of gadget? 3D printer”

07/06/2016

Once the great Michelangelo, when asked how he creates his sculptures, replied: “I take a stone and cut off everything superfluous.” This principle is followed by many modern industries, converting materials into tons of shavings, sawdust and other waste. But there is another approach, akin to pottery - when, in fact, there is no waste, which makes production cheaper, more environmentally friendly and more accessible. 3D printers are just the technical embodiment of this approach. What is a 3D printer and how does it work?

But there is another approach, akin to pottery - when, in fact, there is no waste, which makes production cheaper, more environmentally friendly and more accessible. 3D printers are just the technical embodiment of this approach. What is a 3D printer and how does it work?

A 3D printer is a device that allows you to create objects with the same ease with which conventional printers print text. Of course, the speed of printing objects is significantly different from the speed of printing text - a modern printer will print one sheet in a fraction of a minute, and it will take several hours for an object. But hand-crafting the same item will also take more than a couple of minutes, and even an appropriate level of skill. And the 3D printer will do everything on its own, so that the freed up time can be usefully spent on other things. In fact, such a printer can be called a universal factory on your desk.

There are several basic technologies for printing objects. One involves the use of lasers, which crystallize the desired structure layer by layer from a special polymer. After the formation of the layer, a special clamp slightly lifts the object from the polymer bath and the next layer crystallizes. The process, in terms of entertainment, resembles the transformation of a liquid metal robot from Terminator 2. Although this technology is still at the development stage, it is already the fastest way to 3D print. However, it is also the most expensive one. Lasers, special polymers - all this is very expensive. Although now there are models that use LCD displays instead of a laser, and the price for them is more reasonable.

One involves the use of lasers, which crystallize the desired structure layer by layer from a special polymer. After the formation of the layer, a special clamp slightly lifts the object from the polymer bath and the next layer crystallizes. The process, in terms of entertainment, resembles the transformation of a liquid metal robot from Terminator 2. Although this technology is still at the development stage, it is already the fastest way to 3D print. However, it is also the most expensive one. Lasers, special polymers - all this is very expensive. Although now there are models that use LCD displays instead of a laser, and the price for them is more reasonable.

The second way is a little cheaper. Lasers are also used here (some artisanal implementations work with solar energy to print glass vases). In this option, a container with a powder filler is used. The laser sinters one layer of material, after which the next layer of powder is added and leveled, and the laser passes over it again. As a result, as the capacity is filled, the required object is formed. Upon completion of printing, it is pulled out and cleaned, and the remaining powdered material is reused. Such models are more often used in industrial solutions, as they are rather bulky (due to deep capacitance).

As a result, as the capacity is filled, the required object is formed. Upon completion of printing, it is pulled out and cleaned, and the remaining powdered material is reused. Such models are more often used in industrial solutions, as they are rather bulky (due to deep capacitance).

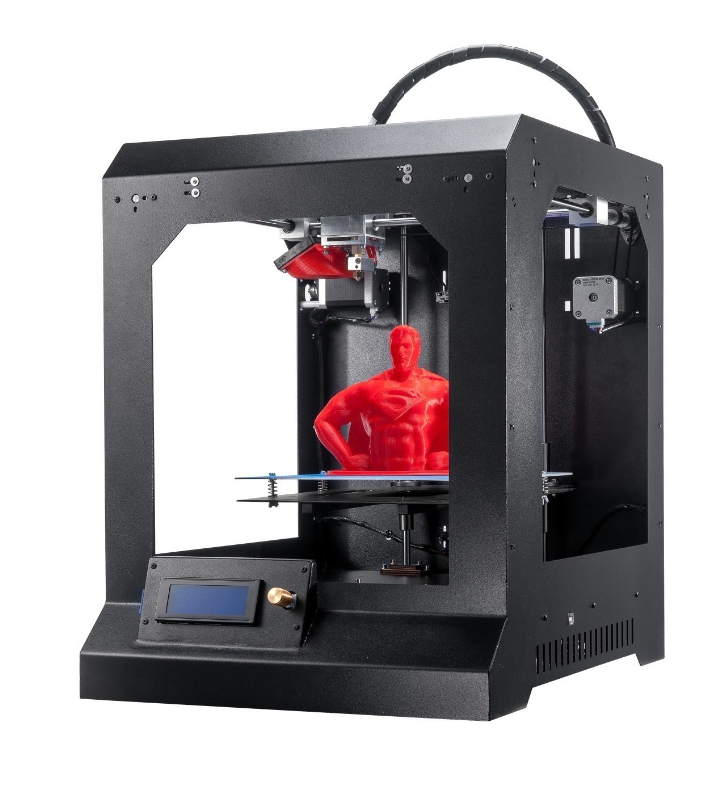

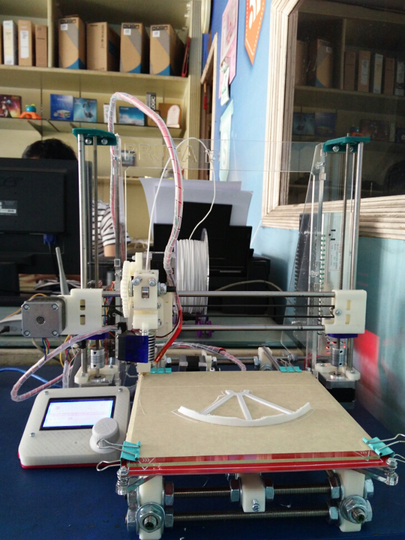

The third and most common type of 3D printer creates objects layer by layer by depositing molten material onto a print bed. Consumables in them usually come in the form of bays or bars. They are wound at one end into the print head, where the heating element is located. The molten material is fed through the extruder at the same speed, which guarantees the uniformity of each applied layer. The thinner the layers, the more precise and smoother the surface of the printed object will be. Most often, there are models with a single extruder, which allow you to print only one material at a time. But there are also devices with a large number of extruders, which make it possible to obtain not only objects of complex shapes, but also combining various materials. These are the slowest of the 3D printers, but also the most common, as they take up minimal space and do not require any special conditions. This technology is so simple that even a 3D pen printer was developed on its basis, allowing you to quickly and easily create small crafts and models. And at the same time, it is the most versatile – both solutions for printing buildings and bioprinters for printing internal organs have been created on its basis.

These are the slowest of the 3D printers, but also the most common, as they take up minimal space and do not require any special conditions. This technology is so simple that even a 3D pen printer was developed on its basis, allowing you to quickly and easily create small crafts and models. And at the same time, it is the most versatile – both solutions for printing buildings and bioprinters for printing internal organs have been created on its basis.

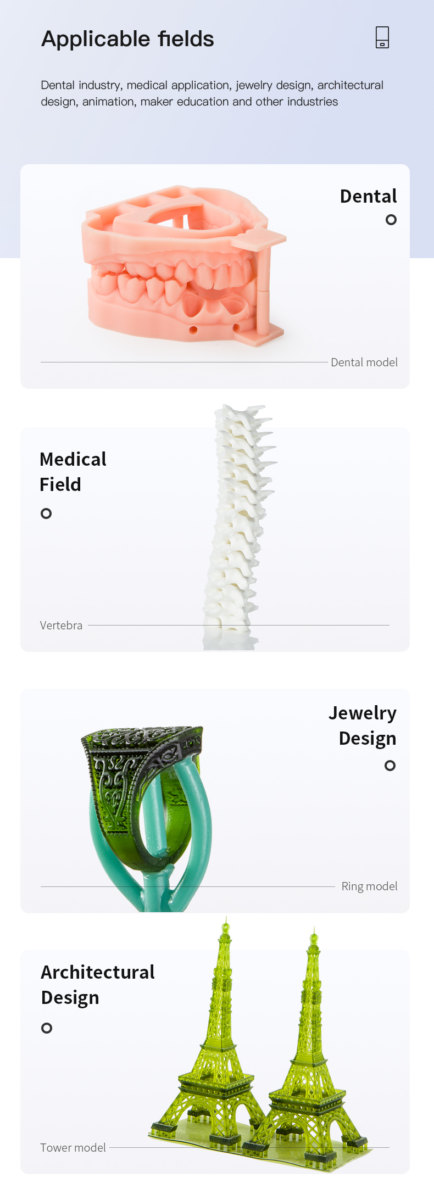

What is a 3D printer for?

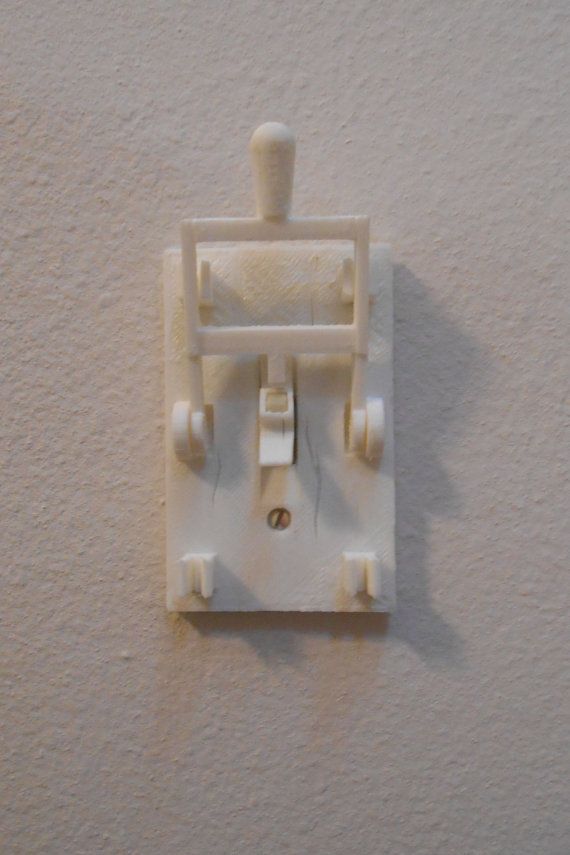

The applications for 3D printers are varied. These devices, in addition to plastics, have mastered printing with metal, wood and mixed materials. Therefore, they are used not only for prototyping and various household trifles, but also for creating jewelry, dishes, art objects, mechanisms and many other things, up to parts of rocket engines. But this is the general case. At home, a 3D printer is useful for replacing broken parts of various devices - handles, gears, housings. It will allow you to forget about looking for a suitable smartphone stand or flower vase. The child will be able to supplement his homework with a visual embodiment of various geometric objects or chemical elements. And for fun, he will be able to print himself a designer, funny decorations for a doll, and even figures of cartoon characters or classmates. You can have fun yourself, testing your ideas in practice and creating designs that have never been seen before.

It will allow you to forget about looking for a suitable smartphone stand or flower vase. The child will be able to supplement his homework with a visual embodiment of various geometric objects or chemical elements. And for fun, he will be able to print himself a designer, funny decorations for a doll, and even figures of cartoon characters or classmates. You can have fun yourself, testing your ideas in practice and creating designs that have never been seen before.

You can create everything yourself, or you can use the developments of other users. A lot of communities have formed around 3D printers, in which there is an exchange of recommendations, ideas and ready-made 3D models for printing. So if you got a printer and don’t know what to create, you can peep a couple of interesting ideas in them.

Which 3D printer models are on the market?

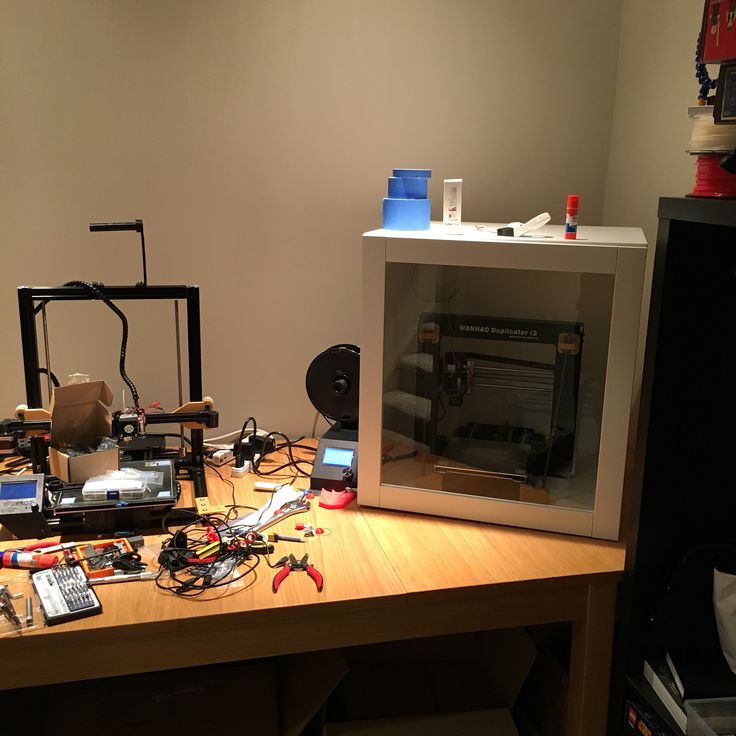

In the field of 3D printers, there is a division into open and closed systems. Openness implies the availability on the network of all circuitry, drawings, files for printing and instructions for creating and assembling your own printer. In fact, you can assemble it yourself from improvised materials, and then print another one for your friend. At the same time, the software of such systems is available in open source. The most popular and proven open system is RepRap printers. There are many models in this system. Some are assembled almost entirely from snap-on printed parts, some are geared towards miniature crafts, and some are geared towards large objects. But all of them are united by an open design, as well as the ability to improve and upgrade the device in the future. So, choosing an open system, you get not only a device for printing, but also a hobby for constantly improving your 3D assistant.

Openness implies the availability on the network of all circuitry, drawings, files for printing and instructions for creating and assembling your own printer. In fact, you can assemble it yourself from improvised materials, and then print another one for your friend. At the same time, the software of such systems is available in open source. The most popular and proven open system is RepRap printers. There are many models in this system. Some are assembled almost entirely from snap-on printed parts, some are geared towards miniature crafts, and some are geared towards large objects. But all of them are united by an open design, as well as the ability to improve and upgrade the device in the future. So, choosing an open system, you get not only a device for printing, but also a hobby for constantly improving your 3D assistant.

There are no less closed systems. They are more focused not on enthusiasts, but on end users. The issues of modernization and updating in them lie entirely with the manufacturer, and if he does not want to develop your model, but releases a completely new model, then you will have to come to terms with the fact that the device is outdated.