3D printer outline

Why Do 3D Printers Make an Outline/Skirt? – 3D Printerly

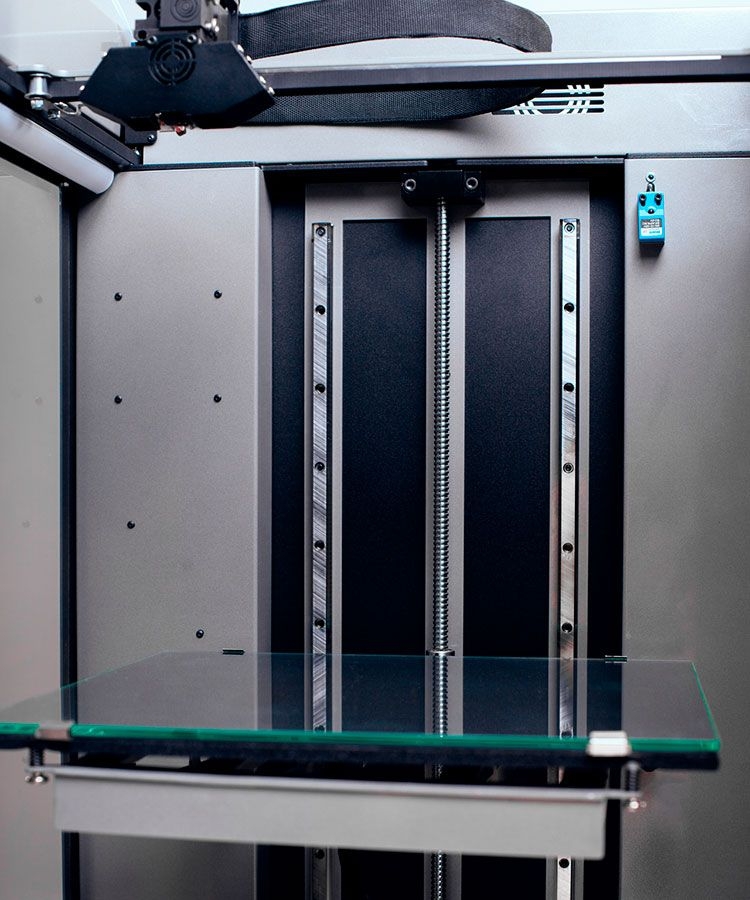

You might have noticed, when a 3D print is about to start it makes an outline wider than the actual object itself. It seems pretty odd at first, especially to beginners, so I set out to answer why 3D printers actually make an outline.

Why do 3D printers make an outline? 3D printers make an outline, called a skirt mainly to ensure that the nozzle is primed and ready to smoothly print your 3D object. Sometimes your nozzle can be slightly blocked, so making this outline can remove this blockage so your first layer comes out clean and forms a good foundation.

This is the basic answer which explains the question, but there are some more details you will want to know in terms of these outlines and how to make sure it’s done properly in your settings.

Why is a Skirt/Outline Important When 3D Printing?

In your 3D printing journey you may have heard of skirts, brims, and rafts; three terms which help your prints finish more successfully. In this case we are talking about a skirt, which is named quite well because it looks like the skirt of your main print.

I’m going to describe its importance and why they are used.

To Build a Great First Layer

It’s always good practice to print at least one single-layer skirt before your main print is started. A skirt is a great way to get your material flowing and evenly extruding before going in and building the actual layers.

Similar to when you test your pen on the corner of your page before you start writing.

The first layer of a print is arguably the most important. Once it’s completed, the success rate of your print completing without issues goes up substantially.

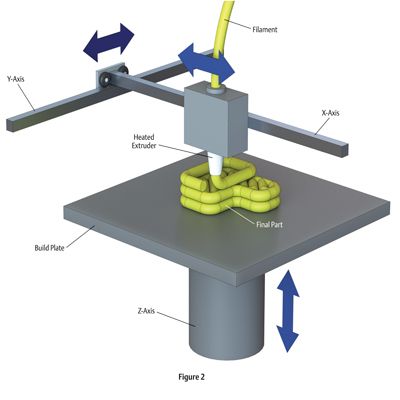

Since your printer works by extruding plastic filament through your heated nozzle, it can take some time to build up enough pressure to extrude as smoothly as it needs to build up a solid foundation with full layers.

A lot of times after laying the skirt down, you’ll see a little blob of plastic come out which is just the leftover material from your last print.

You wouldn’t want this coming out during your vital first layer, so it’s better extruded beforehand, around your main print.

A skirt is also a good way to see just how well your bed is levelled and whether the nozzle and material is creating enough contact with the bed’s surface to create a sturdy first layer.

When the nozzle is too high off the bed, it doesn’t create enough downward pressure to stick to the bed firmly. When it’s too close to the bed it doesn’t flow through evenly and can even scrape the bed surface.

Making sure you add a skirt to your 3D print will save you a lot of time, filament and frustration in the long-run so definitely add this to your 3D printing routine.

To Gauge How Well Your Printing Parts Are Working

This ties in with the first layer, so it gives you the insight into how well your printer, and its parts are working when printing.

After printing out one or two layers of the skirt, you’ll easily be able to tell whether you need to stop your print and do some troubleshooting, or if things are ready to continue to create a high quality model.

If things aren’t flowing so great you know you might need to adjust your printing temperature, increase your bed temperature, clean out the nozzle, re-level the bed and so on.

It’s a great way to save time from going halfway through a print and realizing that there are many imperfections on your print.

Sometimes after changing materials or colors you may still have some left in the nozzle. A skirt will print this out first so your changes are properly implemented before it’s printed to be a part of your final object.

Use the Skirt as a Barrier

Most people don’t think about this use, but you can use the skirt as a thermal or draft barrier which protects your prints. A print bed which has a nice skirt around it can provide slight insulation and protection from drafts which can easily alter temperatures around the room the printer is in.

It can help with surface warping with these protection layers.

If you don’t have an enclosure and sometimes experience these adverse environments, a skirt can be just enough protection to have your print finish without issues.

How Do I Add a Skirt to my Prints?

This will depend on your slicing software, but it’s pretty straightforward for all the main ones out there. You simply want to go into your slicer and look into your settings. It will usually be under ‘print settings’ then under some type of adhesion title.

To add a skirt on the Cura slicer:

- Go to print settings near the top right corner

- Scroll down to the ‘Build Plate Adhesion’ row and expand by pressing the down arrow

- Beside the ‘Build Plate Adhesion Type’ put in ‘Skirt’

- Beside the ‘Skirt Line Count’ put in the number of skirts you want your prints to have.

If the skirt line count is on 0, this means it will disable the skirt. You want to have at least one skirt in your prints.

A lot of times, when you download the STL files from a website like Thingiverse, they will have already added the skirt in the settings, so you won’t have to manually add the skirt, but not every file that you download will have it.

What Will Happen If I Don’t Add An Outline/Skirt to my Prints?

You might be thinking, what’s all this hassle about skirts and not want to go through worrying about adding a skirt.

The end result here is that you’ll save a few centimeters of filament in the very short term, but if your first layers don’t come out up to standard because you avoided using a skirt, you’ll just be giving that saved filament right back and even more than you saved in the first place.

I don’t see there being much advantage over removing a skirt from your printer settings, so I wouldn’t recommend it. The main reason you wouldn’t use a skirt is because you don’t know just how beneficial they are to your 3D printing process.

Since you’ve read this article I’m sure you now know the benefits and will continue using a skirt in your 3D printing journey!

Why Do 3D Printers Make an Outline Before Printing? – Printing It 3D

If you’re new to 3D printing, there may still be many things you don’t understand about how it works. You may have noticed that the printer makes an outline, called a skirt, of the object you’re printing, and this outline is wider or larger in comparison. So why is there a need to outline?

You may have noticed that the printer makes an outline, called a skirt, of the object you’re printing, and this outline is wider or larger in comparison. So why is there a need to outline?

Before printing, a 3D printer makes an outline to ensure that the heated nozzle is primed and ready to print smoothly and evenly. The nozzle sometimes doesn’t extrude filament immediately, so the outline gives it time to work through this slight blockage before it starts printing the first layer.

Read on to find out more about why a skirt is essential when printing 3D objects.

Why Is a Skirt Important in 3D Printing?

The skirt or outline of your main print is an important element in 3D printing because it helps give you a smooth finish for your 3D model. But its initial goal is to help you build a good first layer, which is the foundation for the piece you are printing.

A skirt also helps ensure there are no issues with your 3D model during the rest of the printing process.

It’s good practice to print a single-layer skirt before it starts printing the main object or model. This single-layer outline or skirt is an effective method to get the filament extruding and flowing evenly from the 3D printer’s nozzle before it starts forming your object.

Building an overall good first layer is critical to the success of your 3D print output. Moreover, a skirt can also help prevent adhesion-related issues. And it does so without actually using much filament.

How Does a Skirt Work in 3D Printing?

In 3D printing, a skirt or outline for 3D printing is like testing a pen on the corner of your sheet of paper before you start drawing or writing. A 3D printer works by extruding or expelling melted plastic filament through its heated nozzle.

It usually takes a while until the printer builds up enough pressure to extrude the filament needed to form full layers for a solid foundation. The skirt, therefore, provides the necessary allowance while this pressure accumulates.

It’s common to see a small blob or clump of plastic filament coming out of the nozzle after laying down your outline. This blob is usually the leftover material from your last 3D print and isn’t a part of your current piece. As such, you wouldn’t want this clump of excess plastic coming out while printing the very important first layer of your 3D object.

The outline helps ensure that this leftover material being squeezed out doesn’t make it to the crucial first layer of your current 3D project as you start printing. It allows this blob of leftover plastic to be extracted before the first layer is even printed.

Other Benefits of a Skirt

A skirt is a reliable way of seeing how well the bed of your 3D object is leveled. You can also see whether the printer’s nozzle and the filament are creating enough contact with the surface of the bed. With this, you can create a first layer that is sturdy.

When your printer’s nozzle is too high off the bed’s surface, it won’t create sufficient downward pressure. Therefore, the first layer of your 3D model can’t stick firmly to the bed.

Therefore, the first layer of your 3D model can’t stick firmly to the bed.

Similarly, the filament won’t flow through evenly when the nozzle is too close to the bed. A heated nozzle that’s too close can even scrape the surface of the bed.

Additionally, using a skirt allows you to assess how well the printing is doing.

After printing out a couple of layers of the skirt, you can easily gauge if your print is doing well. You can also see if you need to troubleshoot and stop the process before you waste too much filament.

If your print isn’t flowing as smoothly and evenly as it needs to, you may need to adjust certain settings. Consider adjusting the bed temperature and the printing temperature to clean the printer’s nozzle or adjust the bed’s level.

Skirts can also function as a draft or thermal barrier that protects your 3D prints. A skirt around a bed, for instance, can provide a certain degree of insulation from drafts that can easily change temperatures in the room. Changes in temperatures can contribute to surface warping.

Changes in temperatures can contribute to surface warping.

What Happens When You Don’t Use a Skirt?

If you don’t use an outline or skirt in 3D printing, it won’t change the fact that your printer’s nozzle will still need to get primed. Priming will still take place, and your printer will do so on the first layer of the 3D piece you’re printing.

This, in turn, could lead to issues related to adhesion and poor first layer quality.

So, in knowing how important a skirt or outline is, the question is more of why shouldn’t you opt to use an outline. It can also be why you shouldn’t opt for another adhesion solution.

How To Add a Skirt to Your Print

While adding a skirt is straightforward, it may also depend on the kind of slicing software you’re using.

Go to your slicing software, then go to settings. Under print settings, you can select the adhesion options.

For instance, in Cura slicer, you can scroll down to the Build Plate Adhesion row then press the down arrow to expand. Put “Skirt” beside the Build Plate Adhesion Type. And beside the Skirt Line Count key in the number of skirts you want to use for your prints.

Put “Skirt” beside the Build Plate Adhesion Type. And beside the Skirt Line Count key in the number of skirts you want to use for your prints.

Conclusion

Using an outline for 3D printing ensures that you get a clean, smooth, and even 3D object afterward. The skirt protects the first layer of your piece, which is the very foundation of any 3D object. It also gives your nozzle the time to prime itself and get ready to print.

There’s no need to worry about filament waste when using a skirt, though, because it uses up very little. The assurance of getting a good-quality 3D object after printing also saves you the amount of filament you’ll otherwise be wasting if you print an entire bad piece.

problems and forecasts - SKB Kontur

March 3, 2017

Over the past 15 years, 3D printing has gone from a curiosity of small souvenirs to a complex technology that is poised to transform mega-industries. What awaits her in the future?

What awaits her in the future?

Alexander Ermakov

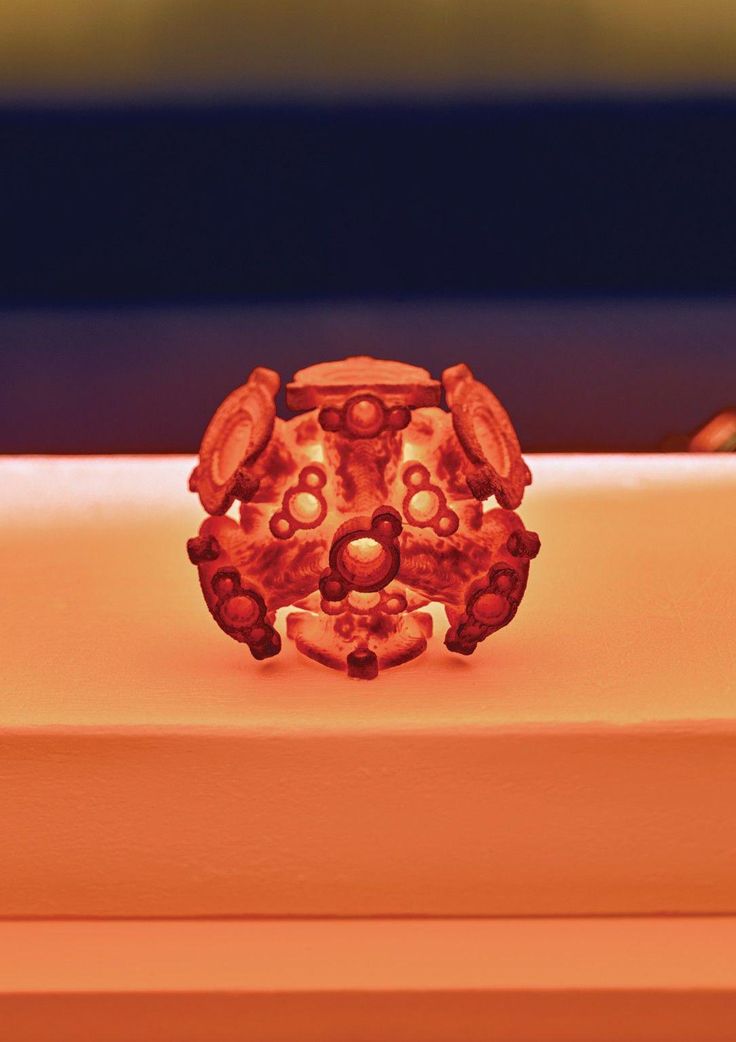

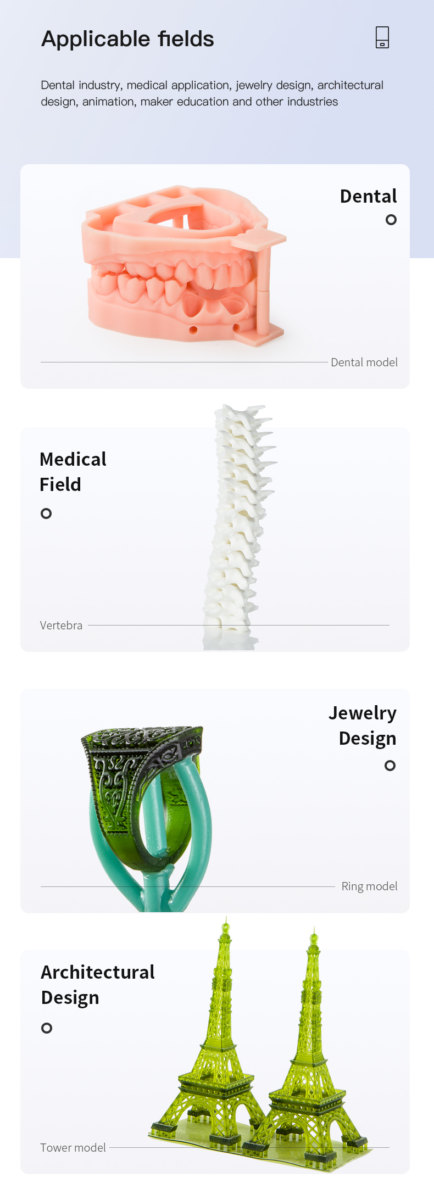

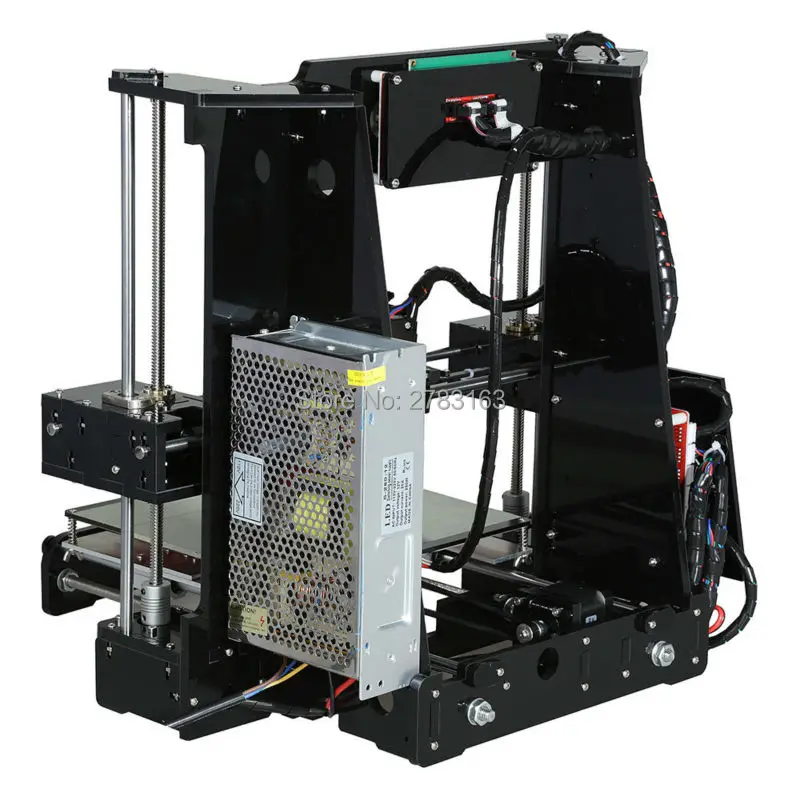

Modern 3D printing uses metal and polymers: hard or flexible, hard or soft, combustible or fireproof, which are used everywhere - from manufacturing and construction, medicine and electronics to the fashion industry and even the fine arts.

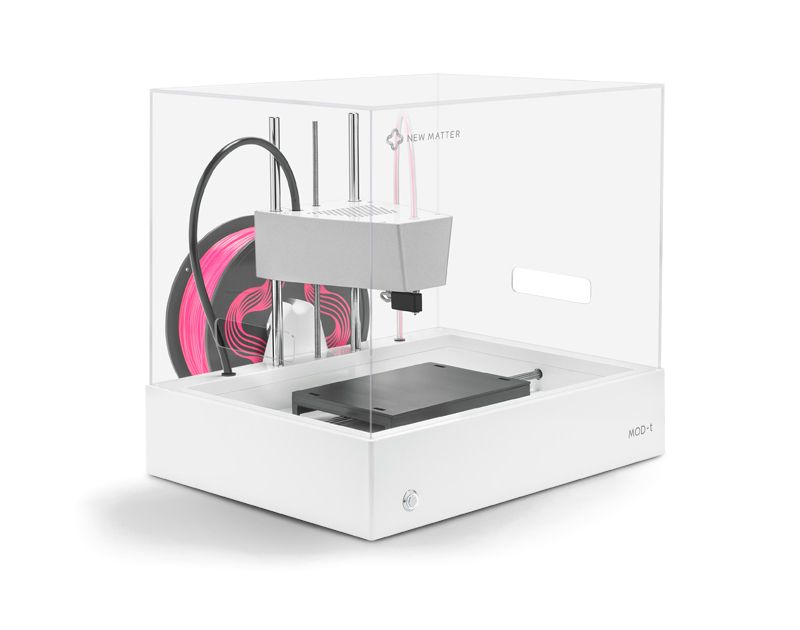

The technical issue has not been finally resolved, the search for further optimization is ongoing, but in general terms the possibilities of 3D printing have begun to be outlined: modern printers can print a high-rise building, a bridge, a rocket nozzle, a titanium skeleton, an author's dress, furniture, art decor or jewelry decorations. With accumulated experience and new technologies, the cost of finished products is continuously reduced. The price of printers over the past five years has fallen by an order of magnitude: from tens of thousands and millions to several hundred and even tens of thousands of dollars.

The question of practical and marketing strategy is becoming more and more urgent: what exactly will the transition from mass to individual production bring to the world? And in what industries can you look for profit?

Production

3D printing of metal parts is progressing very fast. The advantages over outdated methods are colossal: mathematical modeling of given characteristics, instant prototyping, creation of forms that were previously inaccessible to machine execution, etc. Even if you do not listen to the "apostles" and 3D printing enthusiasts, the facts speak for themselves. The world's largest manufacturers - BMW, Mercedes, Volkswagen, Ford - have invested billions in the development of new technologies over the past two years. For example, GE bought the Concept Laser, Siemens announced plans for cooperation with HP and Trumpf, most major automakers announced their intention to use new technological equipment for their own production in the near future.

The advantages over outdated methods are colossal: mathematical modeling of given characteristics, instant prototyping, creation of forms that were previously inaccessible to machine execution, etc. Even if you do not listen to the "apostles" and 3D printing enthusiasts, the facts speak for themselves. The world's largest manufacturers - BMW, Mercedes, Volkswagen, Ford - have invested billions in the development of new technologies over the past two years. For example, GE bought the Concept Laser, Siemens announced plans for cooperation with HP and Trumpf, most major automakers announced their intention to use new technological equipment for their own production in the near future.

Recently, specialists have been talking more and more about the arrival of 3D printing in the aerospace industry: NASA, Boeing, Airbus, SpaceX - all are already working with printed parts for their aircraft and spacecraft. The European Aviation Safety Agency (EASA) has even certified parts created on a 3D printer. 3D technologies are especially in demand in the aerospace industry, because here the number of single parts is measured in tens and hundreds. Toyota Camry consumes millions of parts, and in such volumes it is still more profitable to stamp them on outdated machines, rockets and airplanes are another matter.

3D technologies are especially in demand in the aerospace industry, because here the number of single parts is measured in tens and hundreds. Toyota Camry consumes millions of parts, and in such volumes it is still more profitable to stamp them on outdated machines, rockets and airplanes are another matter.

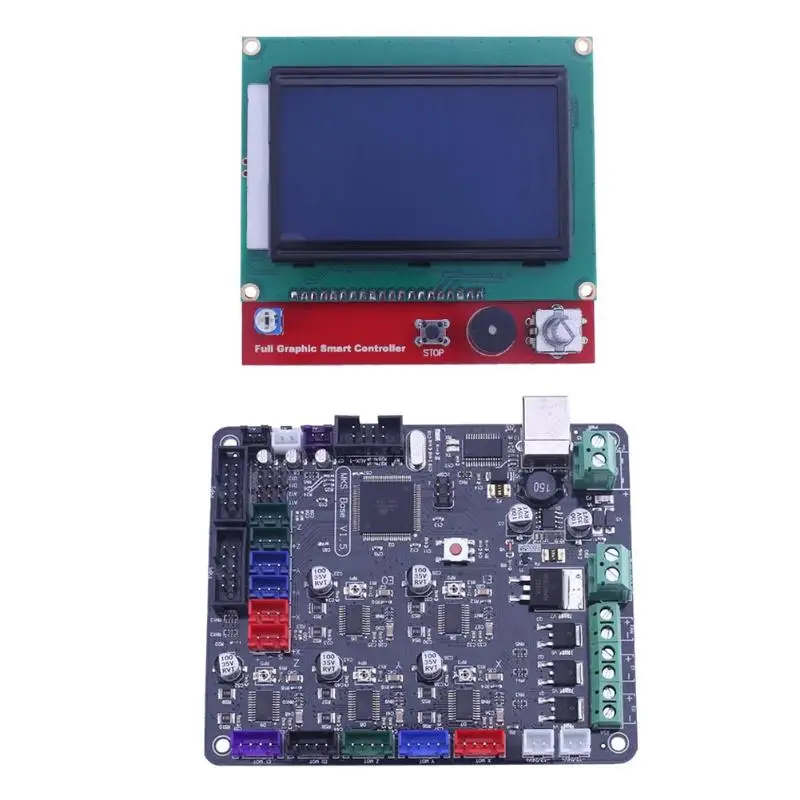

Electronics

Italy has developed a technology to produce carbon nanotubes (CNTs) that can be printed using a standard commercial 3D printer. You might think that this is just an interesting task for highly specialized scientists. Fortunately, this is not the case. CNTs are the basis of conductive composite materials with improved electrical properties. When 0.1% CNT is added to the polymer mixture, the electrical conductivity of the material increases by three orders of magnitude. For ordinary users, I will explain: with the further development of technology, forget about wires - a 3D printer will print parts that initially include conductive channels. Dozens of companies around the world are working on similar projects: for example, the American Voxel8 has already developed a specialized 3D printer that can be used to print not just conductors, but embedded electronics in general.

Medicine

Progress in manufacturing and electronics can seem abstract: the last three generations of people live in an era of technological breakthroughs that have become a familiar backdrop to modern life. But 3D printing can surprise even against the backdrop of the Internet and Apollo 11 — say, in the field of medicine. For example, we can take Wake Forest, which has developed an integrated program for printing cells, bones and even organs (ITOP).

ITOP uses native human cells to create organs based on their genetic code that can be surgically implanted into the human body without the risk of rejection. They have already printed bones, muscles and cartilage using ITOP and successfully implanted them into rats. Yes, so far these are laboratory tests, but successful: after several months of observation, the researchers confirmed that the implanted tissues developed their own system of blood vessels and nerves. The next stage is the transition to human trials, where the founders of the project will try to repeat the same results.

In general, the trend is obvious: science is striving for the replacement of every organ, every part of the human body. And this will make it possible to treat the vast majority of chronic diseases or serious injuries, where the need for treatment or relief will be replaced by simple and affordable replication.

A revolution in materials

MIT has 3D printed a graphene sheet one molecule thick. It was an experimental experience within the framework of creating a new composite with currently outrageous characteristics: lighter than air, but ten times stronger than steel.

Another advanced technology is the use of so-called "ceramic foam" in 3D printing, whose characteristics (density, elasticity, weight) can be changed. Simply put, it is possible to print both an inflatable figure swaying in the wind and a granite monument weighing 4 tons from the same raw material. This is work not only on the form, but also on the material of printed objects: microstructural control (through foam processing) and architectural control (through modeling and printing). The theoretical stage has been passed, there are still several years of practical tests and improvements ahead.

The theoretical stage has been passed, there are still several years of practical tests and improvements ahead.

Another revolutionary breakthrough has been made in the field of laser metal sintering. A new method, in which metal powder is mixed with a polymer in a 3D printer, increases the strength of the final metal parts by an order of magnitude.

Modeling

Much of the potential of 3D printing comes from software. Using software like AutoCAD allows you not only to build the most complex models yourself, but also automate the process, leaving calculations and prototyping to the machine mind. Even an average computer models objects that, in terms of mass, strength, ergonomics, exceed obsolete designs developed by living engineers by 50-70%. And not even so much due to new materials, but due to greater production flexibility compared to casting, machining or stamping. Printable designs replace complex composite structures and improve them dramatically.

Today, the software component is developing even faster than the technological one. New software appears on the market that is responsible for 3D scanning, creating models in a three-dimensional version, prototyping from scratch or optimizing finished samples. One of the priorities for new software developers is maximum usability, focusing not only on specialists, but also on ordinary users. In 3D printing, it is important that high-quality software is not only for 3D printers, but also for editing programs, providing design freedom and mass customization.

New software appears on the market that is responsible for 3D scanning, creating models in a three-dimensional version, prototyping from scratch or optimizing finished samples. One of the priorities for new software developers is maximum usability, focusing not only on specialists, but also on ordinary users. In 3D printing, it is important that high-quality software is not only for 3D printers, but also for editing programs, providing design freedom and mass customization.

Problems

Of course, with all the promise of 3D technologies, there are a number of serious problems in this area. From an economic point of view, the main limiting factor is the cost of consumables for 3D printing. The properties of existing polymers are still extremely variable and do not yet meet the requirements of the industry, while metal solutions, although they have overcome the technological threshold of the required strength, are still limited and too expensive for widespread use. Now the world produces only 40,000 tons of powdered steel per year, although its volumes are doubling every year.

Another factor is the prevalence of 3D printers themselves. Contrary to a popular joke, complex and advanced models cannot yet print themselves. In addition, they themselves must become faster and larger. The third important problem is the lack of well-trained designers, lack of experience, knowledge and understanding of specific industry needs. Manufacturers and users are only groping for effective communication channels. Fortunately, the number of educational programs in this area has grown significantly in recent years.

Finally, the lack of a mass consumer market. The 3D printing business will have to replace entire segments of the economy. And the market and the consumer are not yet ready to move into a new formation, where any necessary household item can simply be ordered through the network and picked up from a small studio on the first floor of his house.

Forecasts

- 3D printing will enter the mass segment within the next five years.

Print studios will appear wherever there are at least a thousand potential buyers.

Print studios will appear wherever there are at least a thousand potential buyers. - The cost of consumables will steadily decline in both polymers and metal parts.

- 3D printing will very soon replace small-scale production of anything, while there will be a noticeable price reduction due to reduced capital investment costs, logistics costs, storage capacity, etc.

- A massive 3D modeling market will emerge. Studios will appear that calculate the shape of parts and mathematical formulas for their physical characteristics. A significant part of the drawings will be in open free access, individual orders will be paid, but reasonable and affordable for the widest range of customers.

- 3D printing will create a new market for medical services, where the increasingly frequent recommendation is not to treat or relieve symptoms, but to replace diseased organs with new ones grown from the patient's own cells.

- The construction industry will experience significant metamorphoses associated with mass, individual, low-cost construction.

Most likely, future projects will be implemented in the concept of "new urbanism".

Most likely, future projects will be implemented in the concept of "new urbanism". - Russia will enter this market without any noticeable lagging behind the world, moreover, it will occupy a solid niche in the field of 3D modeling and printing software development.

Alexander Ermakov

Up-to-date materials once a week

Subscribe

By subscribing, you agree to the processing of personal data and receiving informational messages from the SKB Kontur group of companies.

Free STL file CONTOUR I BM005・3D printer model for download・Cults

XXL Combination Spanner Set 26pcs metric 6-32 mm Wall Holder 016 I for screws or peg board

Free

Holder for Socket Wrench Set 28pcs 1/4" with Extension Bar and Sockets for Wall Mount 007

Free

Tool Holder for 18pcs Screwdriver Set 059 I for screws or peg board

Free

Holder for Screwdriver Set 6pcs 030 I for screws or peg board

Free

Combination Spanner Set 12pcs metric 6-22mm Wall Holder 056 I for screws or peg board

Free

CENTERLINE I BM004

Free

Tool Holder for Single Screwdriver 061 I for screws or peg board

Free

Tool Holder for Power Bits 40pcs with Connectors 003 I for screws or peg board

Free

The best files for 3D printers in the Tools category

Mini UNTZtrumment Midi Controller

Free

Reel holder attachment

2. 68 €

Pegboard hangers for Park Tool DAG derailleur alignment gauges

free

Filament dry box with quick filament change up to 6 spools

€15.90

Motorized Marble Machine

Free

Face mask ear loop tensioner and comfort piece

Free

Tablet holder for car

Free

Smart Parking

7.50 €

Bestsellers in the Tools category

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.97 €

Phone holder

1.97 €

PRECISION CALIPER 3D PRINT DIY

3,08 €

Quick print stackable parts containers / storage boxes

2.88 €

Grinder | Grinder

€1. 50

well designed: Hemera fan duct

2.50 €

Paint stand with scissors

5.47 €

Business card embossing system

3 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.65 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.88 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

2,97 €

NEW GENERATION CAR PHONE HOLDER

2,50 €

Printer boxes for Ikea Lack Table

1,99 €

phone ring holder

0,90 €

Tool holder for 3D printer V3.0

1.09 €

FAST PRINT STACKING STORAGE BOXES STACKING CONTAINERS

1,50 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple.