3D printing vinyl record

3d Printed Vinyl - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Vinyl records are far from dead, now you can 3D-print your own

Pocket-lint is supported by its readers. When you buy through links on our site, we may earn an affiliate commission. Learn more

- Home

- Gadgets

- Gadget news

Elyse Betters, US News Editor

· ·

News Based on facts, either observed and verified firsthand by the reporter, or reported and verified from knowledgeable sources.

Why you can trust Pocket-lint

(Pocket-lint) - You can use 3D printers and custom software to make everything from houses to pizzas, but did you know you could also 3D-print vinyl records?

Developer Amanda Ghassaei from Instructables is known for her alogorithm that converts audio data into 3D geometry data. She has subsequently used that alogorithm to manufacture 3D vinyl records for singles from artists like Nirvana, Pixies, Daft Punk, and Radiohead. More recently, the track Down Boy, performed by Bobbie Gordon and produced by Kele Okereke, was put onto a 3D-printed vinyl record using her alogorithm.

She has subsequently used that alogorithm to manufacture 3D vinyl records for singles from artists like Nirvana, Pixies, Daft Punk, and Radiohead. More recently, the track Down Boy, performed by Bobbie Gordon and produced by Kele Okereke, was put onto a 3D-printed vinyl record using her alogorithm.

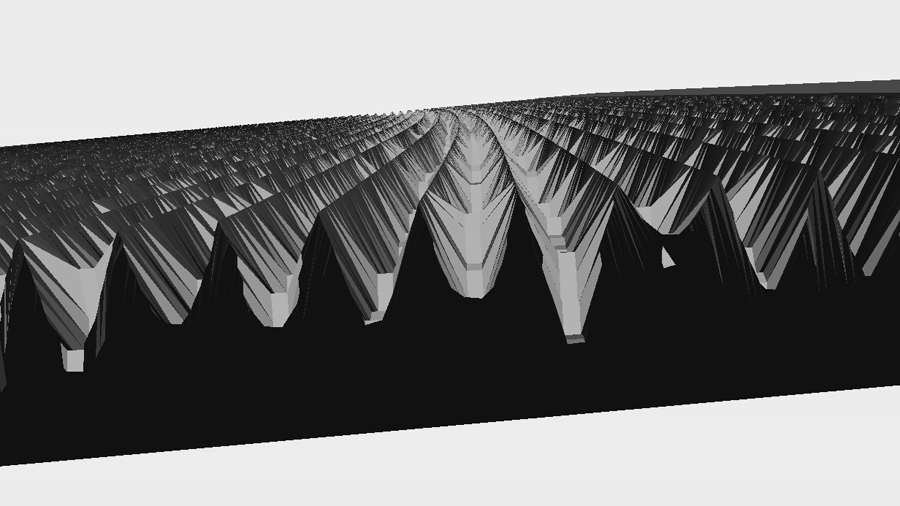

An Objet500 Connex 3D printer generated the disc for Down Boy, at fine settings like 600 dpi, with 16 micron steps. Gordon recently performed the tune at a launch party for the world's first 3D-printing record store, where the limited-edition, 3D-printed version of her track went up for sale. Down Boy was a sponsored and documented project by Bacardi Beginnings, and it marked the first time that an original song had been released and sold as a 3D-printed album.

Ghassaei's algorithim uses an 11 Khz sampling rate however, so the resolution of Down Boy is quite low. In fact, the final output is around 25 per cent of what you could get from an MP3. With such a poor rate, the Objet500 Connex actually cuts off high-range tones in most songs. It's been said that 3D-printed records have a sound that is audible and distinguishable but still distant and hollow. Watch the video below for an example.

It's been said that 3D-printed records have a sound that is audible and distinguishable but still distant and hollow. Watch the video below for an example.

READ: Ten houses 3D printed in 24 hours

Ghassaei also said the resin residue of 3D-printed albums will eventually wear down a turntable’s needle, but she insisted it is still "really cool to kind of push the technology." Furthermore, it takes more than a gigabyte of data to 3D print an entire song, meaning a standard 12-inch LP can only hold one single. Her DIY website on Instructables explains in detail how to convert audio files into 33 RPM resin records. It also demonstrates how 3D printers create albums, layer by layer.

Although 3D-printed albums are thicker and stiffer and sound horrible when compared to vinyl records, you must think of all this as a stepping stone of sorts. The technology to produce 3D objects is still new and will likely be honed over time. Maybe one day it'll be responsible for the full comeback of vinyl records. After all, music has been experiencing a vinyl revival over the last decade as audiophiles seek a warm and authentic music sound.

Maybe one day it'll be responsible for the full comeback of vinyl records. After all, music has been experiencing a vinyl revival over the last decade as audiophiles seek a warm and authentic music sound.

You can view Bacardi Beginnings' video documentary for both Down Boy and the first 3D-printing record store (called The Vinyl Factory in central London), below.

Writing by Elyse Betters.

Sections Headphones Speakers

Vinyl record filament.

Consumables

Subscribe to the author

Subscribe

Don't want

28

Hi Friends!

Remember, vinyl is not to be trifled with! If possible, you should not experiment with melting this material at all.

Today I will try to print from vinyl records. I can imagine how dissatisfied fans of vinyl records will be. I have a lot of this stuff. I will donate 5 pieces for the sake of the experiment.

I will donate 5 pieces for the sake of the experiment.

I didn't expect plastics to be so flexible. The label can not be torn off the plate, pasted on the Soviet glue. It remains only to cut out this pasted circle. It was possible to shove the entire record into the grinder.

The shredder looks like it was designed to shred vinyl records. For further grinding, I will use the Chinese saucepan that you saw in past videos. I grind the material with a respirator, being afraid that small particles of the material can fly in the air.

Vinyl cured to dust, just a little check on a Chinese extruder. To begin with, I will set the temperature on the extruder to 180 degrees so that the previous test polymer comes out, after which I will lower the temperature.

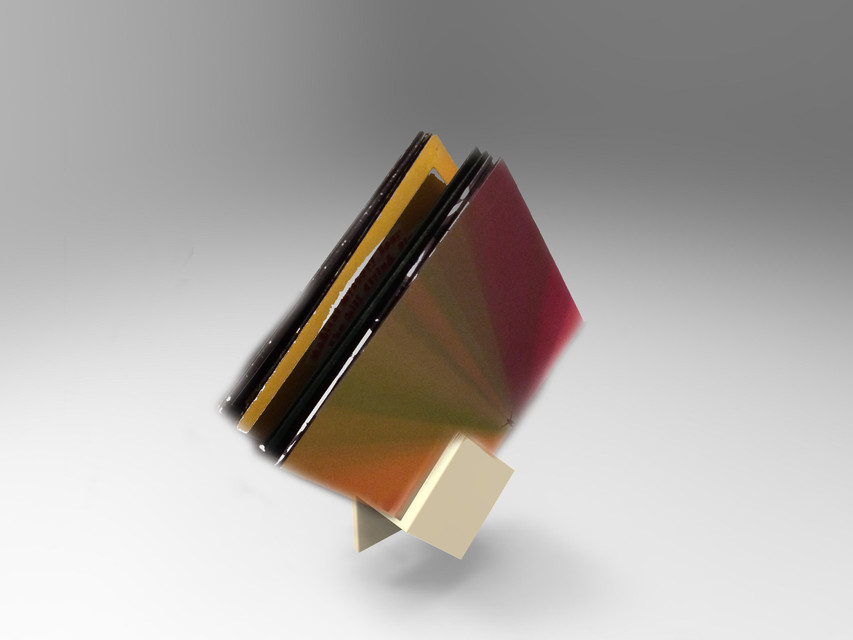

It's hot! I didn't expect vinyl to be so malleable. The filament is even. I believe that the finer the material is crushed, the more stable the filament is. There are slight deviations, but it's not terrible. I have seen factory filament with much larger deviations. I thought that the filament would turn out to be brittle, but it was not there. It turned out a very elastic and durable thread.

I have seen factory filament with much larger deviations. I thought that the filament would turn out to be brittle, but it was not there. It turned out a very elastic and durable thread.

Now is the time to print the test disc. Instead of glue, I print the first layer of PLA plastic and then change the filament to the test one. It's a miracle that I started printing the first time. Nozzle temperature 245°, table 60° nozzle diameter 0.8mm., Z step 0.20mm. Of course with a nozzle diameter of 0.4mm. the tested part would have turned out much more attractive. I'm printing these discs to see if it's possible to print with the tested plastics.

Next I want to test the spiral print. It has already become a tradition. Previous samples I printed from car headlights, PVC windows, audio tape. At first, of course, I was a little upset that such a low-quality print was obtained.

I looked closely and noticed that the previous layers do not have time to cool. Most likely for printing with this polymer you need a good airflow. Unfortunately, there was no airflow on the printer on which I am testing. Will have to make from improvised materials. Blowing solved the problem.

Most likely for printing with this polymer you need a good airflow. Unfortunately, there was no airflow on the printer on which I am testing. Will have to make from improvised materials. Blowing solved the problem.

You will not find such a filament in the store. When heated, gas vapors are poisonous. Heating above 80° is already dangerous. I read that vinyl has a sweetish taste when heated, which of course I felt myself in the workshop. I use protective equipment and I turn on the ventilation at full capacity.

Finally, as always, you need something for yourself. Without hesitation, the idea arose to print a mount for goggles. These glasses are constantly lying around the room, more than once I broke stepping on them. We need to make sure they are in the same place.

If you want, I will upload this model for download, but I think you can easily develop such a simple detail yourself.

You can create things out of vinyl, I don't think it's necessary. Vinyl records are already valuable. And take care of your health.

Vinyl records are already valuable. And take care of your health.

God bless you! See you!

vinyl

Subscribe author

Subscribe

Don't want

28

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

Hi all!

The other day I received a new series of PLA plastic in rainbow colors from the compa...

Read more

3

Subscribe to the author

Subscribe

Don't want

In this article we will tell you about new photopolymer resins from our catalog!

Se. ..

..

Read more

daymon

Loading

08/03/2017

44412

229

Follow the author

Subscribe

Don't want

There are enough articles on materials for publication. But many of them are overloaded with theoretical data...

Read more

Printing vinyl on a 3D printer and the eternal dispute

?

|

It turns out that it is possible, although it is still very bad, to print records on a printer. Not for the records, but for the idea. But I wanted a little about something else.

It turns out that it is possible, although it is still very bad, to print records on a printer. Not for the records, but for the idea. But I wanted a little about something else.  For example, any room distorts the sound due to reflections from walls and objects, but we hardly notice this. There are many more nuances associated with the production process, but here each format has its pros and cons. Usually, the bad or good sound quality of a particular recording is not due to the format, but to a bad or good production process. There are great and bad sounding vinyl, there are great and bad sounding CDs. But one of the unique properties of vinyl is the ability to record sound almost directly from a microphone to a master disc. Physically, this is the shortest path of a sound wave from the performer to the ear of the listener, separated by years and decades.

For example, any room distorts the sound due to reflections from walls and objects, but we hardly notice this. There are many more nuances associated with the production process, but here each format has its pros and cons. Usually, the bad or good sound quality of a particular recording is not due to the format, but to a bad or good production process. There are great and bad sounding vinyl, there are great and bad sounding CDs. But one of the unique properties of vinyl is the ability to record sound almost directly from a microphone to a master disc. Physically, this is the shortest path of a sound wave from the performer to the ear of the listener, separated by years and decades.