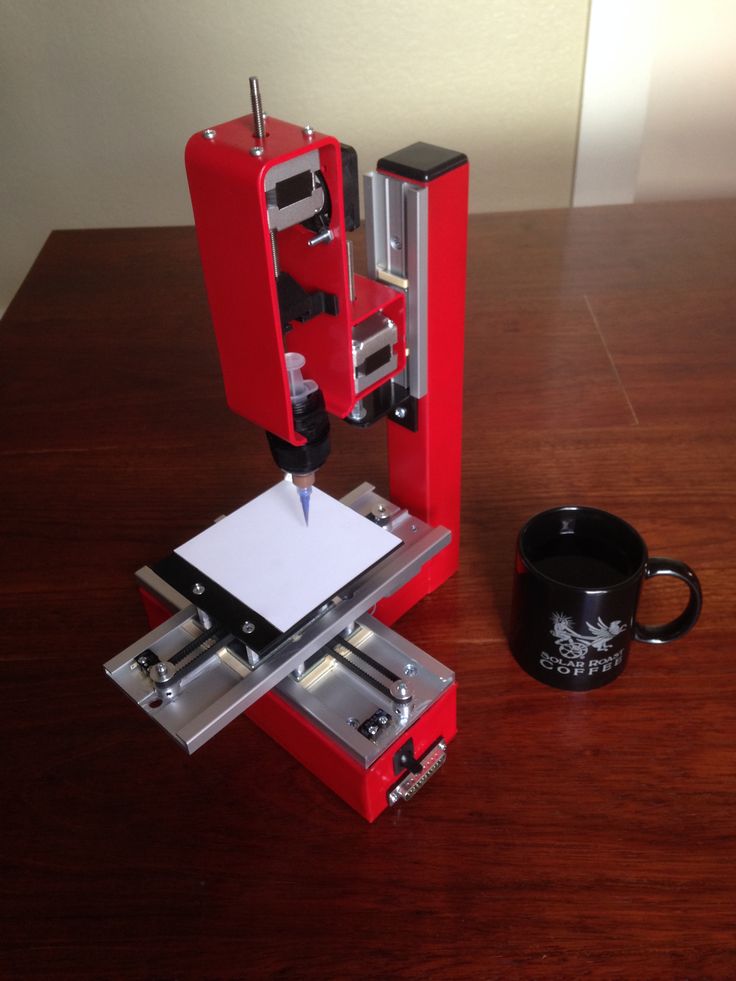

3D printed golf divot tool

▷ golf divot repair tool 3d models 【 STLFinder 】

Painless360 Golf Divot Repair Tool

thingiverse

This is a printable divot repair tool for all of you golfers out there. No need to lose tools costing cash, just print another if it gets broken or lost on the course. I'd print it in ABS and use a 100% infill so it's as strong as possible. There...

Star Trek Golf divot repair tool

thingiverse

Saturday I've lost my divot tool, so today I created this one with the Star Trek's delta.

Golf Divot Tool

thingiverse

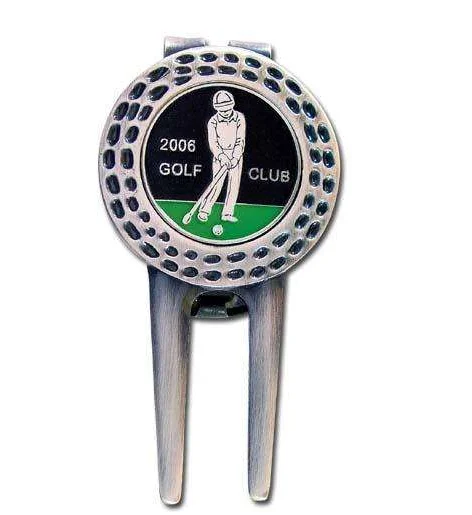

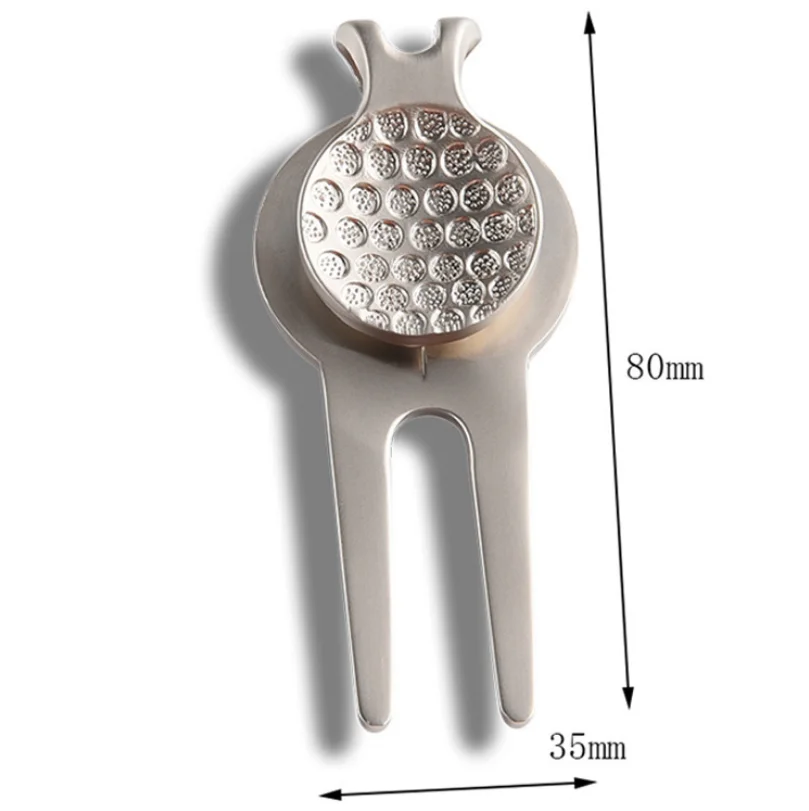

Golf Divot Repair Tool Fix ball marks on the green with ease, customize ball marker.

J. ...Rodrigue 5/2/2019

Golf Divot Tool

thingiverse

This is a golf tool to repair divots and hold your ball marker. I bought magnets from Michaels to superglue in the wedge face. Most magnetic golf coins will fit inside the wedge face to hold your ball marker. ... share pics if you make one!

Golf Ball Divot Tool

thingiverse

A very basic Divot Tool!

Golf Divot Tool Yankees

thingiverse

Golf divot tool with Yankees logo No raft needed Print Settings Printer Brand: MakerBot Printer: MakerBot Replicator Rafts: No Supports: No Resolution: . 2 mm Infill: 30%

2 mm Infill: 30%

Golf Divot Tool

thingiverse

Just another divot tool. ...No logos, etc...

Golf Divot tool

thingiverse

Fix your divots.

Golf Divot Tool

thingiverse

I couldn't find a Divot Tool design that I liked, so I created my own. I have a Replicator 2X and set the plate temp to 117 degrees so that the prongs stay stuck to the build plate. ... Note: This design has been extensively field tested on my home...

Golf Grass Divot Tool

thingiverse

Designed for a coworker as I do not play golf. I printed horizontal with support under handle and peg touching build plate.

Works great at .2mm Layer Height. ...

I don't foresee a problem with scaling.

I printed horizontal with support under handle and peg touching build plate.

Works great at .2mm Layer Height. ...

I don't foresee a problem with scaling.

Golf Divot Tool

thingiverse

This is a simple tool that is a quick print. It is recommended to print it at 100% infill to avoid a break on the two prongs. Also it should be printed in the orientation of the file, if printed with the prongs sticking upward, it will easily break...

Bearcat Logo divot repair tool

thingiverse

Divot repair tool with De Leon school logo

Divot repair tool w/C

thingiverse

Made for Comanche Indians Golf team Print Settings Printer Brand: MakerBot Printer: MakerBot Replicator Rafts: Yes Supports: No Infill: 10% Notes: Makerbot Tough PLA is prefered

Golf Divot Tool, Anchor Logo

thingiverse

Remix of a golf divot tool to add an anchor logo Update (05/28/2019): v1-0-2, increased the thickness slightly. ... The depressed image didn't print as nicely as the raised one, so only uploading a new version of the raised one.

... The depressed image didn't print as nicely as the raised one, so only uploading a new version of the raised one.

McGuffey Ball Marker and Divot Repair Tool

thingiverse

McG ball marker and divot repair tool.

Golf Divot

thingiverse

wedge golf divot tool

Golf Divot Tool and Ball Marker

thingiverse

Add some 3D printing to your golf game with this divot tool and ball marker. This simple tool has two prongs to fix that divot from your absolute monster of a drive (or personally, I use it when I hit it a mile... straight up). The ball marker...

This simple tool has two prongs to fix that divot from your absolute monster of a drive (or personally, I use it when I hit it a mile... straight up). The ball marker...

Golf Divot Tool and Ball Marker

thingiverse

Our golf coach asked me if I could make a golf tool for the team. I accepted the challenge and after getting inspiration from my buddy Corben and a healthy learning curve in Inventor, I came up with this! It includes a ball marker and has the team...

Golf Divot Tool

prusaprinters

DADs Golf Divot tool

thingiverse

Customized version of http://www. thingiverse.com/thing:334355 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=334355

thingiverse.com/thing:334355 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=334355

Divot Tool

thingiverse

Repair your ball marks

Divot tool MB

thingiverse

golf divot tool MB

Golf Ball Mark Repair Tool Sheath

thingiverse

I keep my ball mark repair tool in my pocket, along with a Tee and a Ball. When getting it out for use, the sharp points were poking me. With use, the points became very sharp, so I decided to make a sheath for it. The tool I use is a Scorpion, but...

The tool I use is a Scorpion, but...

Divot tool 2

thingiverse

Divot tool 2 with customizable text

Switchblade Divot Tool (OTF)

thingiverse

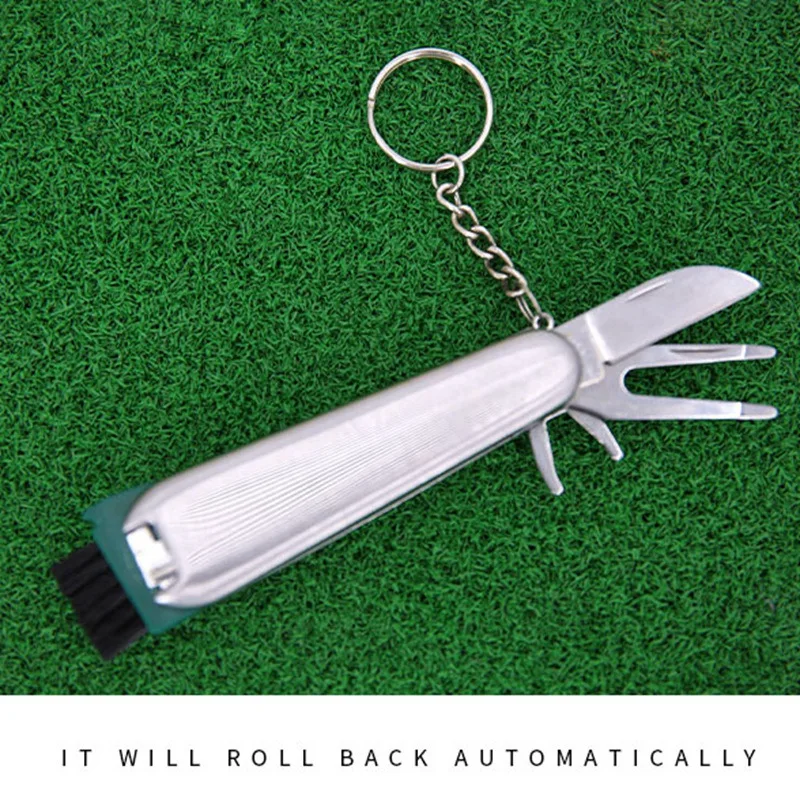

-This is a 'golf divot tool' bit to replace the key from my 'switchblade key' All other required files can be found in the 'remix sources' widget **!The design has been updated with a new rounded case!** --It may require some wiggling to get...

Divot Tool and Dime Marker

thingiverse

Needed a divot tool and a marker so made one using a dime as the marker. ...Print on the flat back.

...Print on the flat back.

Divot tool 3D print model

cgtrader

Divot tool is an 3D printable model which can be easily customized. It is made in 3ds max. Model is created in units of measurement that are suitable for 3D printers.You can download the STL file from the download button. ...

Divot Tool 3D print model

cgtrader

Divot tool is an 3D printable model which can be easily customized. It is made in 3ds max. Model is created in units of measurement that are suitable for 3D printers.You can download the STL file from the download button. ...

Repair tool

3docean

3D model of Repair tool like Asteroids: Outpost

Divot tools relève pitch golf

thingiverse

A imprimer côté badge

Une pièce de 5 CTS est collée dans le logement

Le badge est fabriqué à part et aimanté sur cette pièce

https://www. youtube.com/watch?v=mjyKGAQcxws

youtube.com/watch?v=mjyKGAQcxws

Gopher Golf Ball Divot Repair Tool 3D Printed Made in Canada

-

Item in the photo is in Primary color: American Walnut

Option selected!

This option is sold out.

-

Loading

-

Item in the photo is in Primary color: Light Blue

Option selected!

This option is sold out.

-

Item in the photo is in Primary color: Pink

Option selected!

This option is sold out.

-

Item in the photo is in Primary color: Silver

Option selected!

This option is sold out.

Click to zoom

23 sales |

5 out of 5 stars€7.32

Loading

VAT included (where applicable), plus shipping

Primary color

Select a color Gold Green Pink Red White Carbon Fibre Black Copper Silver Marble Wood American Walnut Black Cherry Stain Weathered Grey Stain Light Blue Dark Blue Transparent Blue Transparent Pink Clear

Please select a color

Quantity

12345678910111213141516171819202122232425

Ships to Germany

Explore related categories & searches

Listed on Sep 13, 2022

One favorite

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

STL file Golf club swing weight and length measurement tool・Model for download and 3D printing・Cults

StarCraft Boat Logo Recreation

2.05 €

Real nuts for Nutz trucks

102.32 €

Real Nutz - double nuts for trucks - big nuts for manly trucks - won't rust!

€102.32

The best files for 3D printers in the Tools category

Paint mixer for citadel paint

Free

Pirates Hook

Free

2.5" HDD CASE

1 €

ANTI-VIRUS MASK

Free

Multi-Color Christmas Candle

Free

Printed Design Ideas Volume 1

3. 05 €

05 €

Master Spool FilaworKs

Free

Bestsellers in the Tools category

Tool holder for 3D printer V3.0

1.13 €

Version 2 Alligator 2 || Repeating crossbow || 3d printed shop || Inspired by Joerg Sprave

1.50 €

Printer boxes for Ikea Lack Table

1.99 €

Paint stand with scissors

5.65 €

Grinder | Grinder

€1.50

SUPERBOX

1,50 €

Cooling system Minimus Hotend

€2.54 -twenty% 2.03 €

NEW GENERATION CAR PHONE HOLDER

2,50 €

AIR DUCT 5015 OR 4020 ENDER 3 S1/PRO V3

€2. -twenty% 2.18 €  73

73

PET-Machine, make your own plastic bottle filament at home!

50 € -80% 10 €

Quick print stackable parts containers / storage boxes

2.87 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.67 €

Housing FLSUN SR

€8.50

FAST PRINT STACKING STORAGE BOXES STACKING CONTAINERS

1,50 €

telephone ring holder

0,90 €

Filament shielding

2.97 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are is a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Additive technologies at the service of the automotive industry: 3D printing applications

You can't buy a fully 3D printed car in a car dealership yet, but additive technologies have been used in car design for many years. Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of the 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023. For example, luxury car companies including Bentley, Porsche, BMW and Ferrari are using 3D printing to create custom car interior parts. GM, Volvo, Ford are using 3D printing to produce tooling to save money, improve design and reduce delivery times. 3D printing constantly has new opportunities, it becomes more and more accessible. If the first 3D printers cost about $20,000, now you can find 3D equipment for $100. Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

For example, luxury car companies including Bentley, Porsche, BMW and Ferrari are using 3D printing to create custom car interior parts. GM, Volvo, Ford are using 3D printing to produce tooling to save money, improve design and reduce delivery times. 3D printing constantly has new opportunities, it becomes more and more accessible. If the first 3D printers cost about $20,000, now you can find 3D equipment for $100. Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

Source 3dprinting.com

New materials on 3D printers can print high-precision, functional final parts. Additive technologies facilitate the production of custom products and increase productivity. But this is only the beginning of the journey. Here are five key ways 3D printing is driving innovation in the automotive industry, from car design to production. Plus one bonus.

1.

Changing the Prototyping Process

Changing the Prototyping Process

Prototyping was the beginning of 3D printers in the automotive industry. 3D printed prototypes took much less time than traditional methods required.

Using Raise3D 3D printers and ideaMaker software, Crazy Grandpa Garage was able to automate the process of creating custom car parts. Production costs have been reduced by 50%, design reliability has improved significantly, and lead time has been reduced by 83%. The parts now come out very well fitted to the car.

Source: facebook.com

Using 3D printing, car designers can quickly prototype individual parts or assemblies, from interior detail to dashboard, or even full-size car models. Thanks to 3D prototyping, the initial idea quickly turns into a physical embodiment of the concept - a conceptual model. The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

For example, the assembly plant of American car manufacturer General Motors claims that the purchase of a 3D printer in 2016 saved more than $300,000.

Ringbrothers designers and engineers are not dependent on third parties to implement laser stereolithography (SLA) in their facility. The cost is reduced, the development time is reduced. Source: formlabs.com

Hose for BMW M4 by Eventuri, Source: ultimaker.com

Traditional prototyping was time consuming and costly, in part because the product went through more iterations. With 3D printing, you can create high-quality prototypes in one day and at a much lower cost. More examples.

The Ford Fiesta ST with 3D printed parts, ext. SEMA 2016, ultimaker.com

For example, General Motors has partnered with Autodesk to produce low-cost, lightweight automotive parts using 3D printers. Tools, fixtures and fittings can now be produced at a fraction of the cost, according to Autodesk. For example, a 3D printed tool used to align engine and transmission ID numbers costs less than $3 at General Motors. A traditionally produced instrument will cost $3,000. In addition, downtime due to faulty tools can be significantly reduced as new tools are produced in-house.

Tools, fixtures and fittings can now be produced at a fraction of the cost, according to Autodesk. For example, a 3D printed tool used to align engine and transmission ID numbers costs less than $3 at General Motors. A traditionally produced instrument will cost $3,000. In addition, downtime due to faulty tools can be significantly reduced as new tools are produced in-house.

2. Creating custom and complex parts

Daihatsu, the oldest car manufacturer in Japan, launched a project in 2016 to customize its Copen model.

Source: 3dprint.com

In partnership with Stratasys, Daihatsu customers can design and order custom 3D printed panels for their front and rear bumpers, with a choice of over 15 basic patterns in 10 different colors.

Source: 3dprint.com

In Europe, the BMW MINI brand also uses 3D printing to create personalized car parts. Since the beginning of 2018, MINI customers have been able to personalize various trim elements such as the instrument panel, LED treadplates and illuminated bumpers, as well as choose from different colors and textures. These parts are then 3D printed using a range of technologies from DLS Carbon to SLS.

These parts are then 3D printed using a range of technologies from DLS Carbon to SLS.

Source: formlabs.com

Volkswagen Motorsport’s I.D. R Pikes Peak is designed with over 2000 3D printed test parts.

Source amfg.ai

The use of 3D printers makes it possible to experiment in the development of non-standard designs, reduces the cost of their production. Long production processes for custom-made products are becoming much shorter.

Ringbrothers uses 3D printing to create customized end pieces such as ventilation grilles. Source: formlabs.com

Large companies combine 3D printing technologies and traditional production methods. Volkswagen has recreated its iconic 1962 Microbus by replacing the petrol engine with a 120 hp electric one. The Type 20 concept electric minivan has received many improvements using 3D printed parts. These improvements include cast aluminum wheels. Even the wheel hubcaps, while looking like stamped steel, are actually printed on a Formlabs SLA 3D printer, then electroplated and polished.

Source: formlabs.com

SLA specifications of the Formlabs Form 2 3D printer

Source top3dshop.ru

The Bentley Speed 6 is another example. Bentley has used cutting-edge metal 3D printer technology to produce a grille, side vents, door handles and exhaust pipes much more complex than those used on current production models.

Bentley used metal 3D printing to create intricate micron precision parts. Source: formlabs.com

3D printing has also made it possible to create parts that could not be made in any other way.

Bugatti's monobloc brake caliper is a prime example. For some components, Bugatti would have preferred titanium due to its high performance, but processing this metal with traditional methods is expensive and difficult. 3D printing has allowed Bugatti to produce a titanium alloy brake caliper. Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2.9kg compared to currently used aluminum, which weighs 4.9 kg.

Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2.9kg compared to currently used aluminum, which weighs 4.9 kg.

The Bugatti Brake Monobloc is the industry's largest functional 3D printed titanium vehicle component. Source: formlabs.com

3. Tool making

Various tools help to facilitate and speed up the production and assembly processes, and increase the safety of workers. Automotive factories and component suppliers use a large number of non-standard tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs.

Automotive factories and component suppliers use a large number of non-standard tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs.

This 3D protective wheel disc was purchased for 800 euros but can now be printed for just 21 euros. Tool development time has been reduced from 56 to 10 days.

Source: ultimaker.com

Outsourcing custom tooling and fixtures to service providers who machine parts from solid metal or plastic stock can delay production by weeks.

Thus, the development and prototype of a commutator motor using traditional manufacturing methods can take up to four months and cost about half a million dollars. Thanks to 3D printing, Ford was able to develop several variants in just 4 days and 99.4% cheaper - only $3,000.

Additive technologies allow you to complete the task in a few hours and significantly reduce costs compared to ordering from a third-party enterprise. Since increasing the complexity of a 3D printed model does not incur additional costs, products can be better optimized for their application. New elastic materials for 3D printing in many cases allow you to print plastic parts instead of metal or create prototypes on a 3D printer to test the tool before using it in production

Since increasing the complexity of a 3D printed model does not incur additional costs, products can be better optimized for their application. New elastic materials for 3D printing in many cases allow you to print plastic parts instead of metal or create prototypes on a 3D printer to test the tool before using it in production

Gradually, the production of 3D printed accessories and tools is becoming one of the largest applications of additive technologies.

Pankl Racing Systems uses 3D printed fixtures to fasten workpieces to a conveyor belt. Source: formlabs.com

For example, Pankl Racing Systems uses multiple Formlabs SLA 3D printers to make critical manufacturing tools. The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

With the help of 3D printing, Pankl's engineers have reduced the production time of the aids by 90%, from 2-3 weeks to around 20 hours. Costs were also reduced by 80-90%, saving $150,000.

Costs were also reduced by 80-90%, saving $150,000.

The shift to 3D printing has enabled Volkswagen Autoeuropa to cut tooling development costs by 91% and cut tooling times by 95%.

4. Solving problems with spare parts

Spare parts have always been a problem for the automotive industry. The demand for them is either there or not, so the production of spare parts is not economically viable, and the storage of pre-fabricated replacement components is also costly. But if there are no repair parts available, difficulties arise and the main product becomes less valuable.

3D printing could solve the problem of parts in the automotive industry in many ways. The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

Using computer-aided design, drawings of all parts can be stored digitally, so there is no need to store the parts themselves. The parts needed by the client can be printed on a 3D printer right in the workshop.

The parts needed by the client can be printed on a 3D printer right in the workshop.

Even obsolete parts whose drawings have not survived can in principle be recreated by making a 3D scan of existing parts of this type and applying reverse engineering (reverse engineering). You can read more about this in our blog. Old projects can take on new life. There are many lovers of vintage cars, with the help of 3D printing it would be possible to create parts for them.

Ringbrother 3D printed the Cadillac emblem for a custom built old car. Source: formlabs.com

5. Production of standard parts

As 3D printers and materials for 3D printing become more affordable, a gradual transition to the production of mass-produced automotive parts using additive technologies is possible.

3D printing makes it possible to combine components into a single whole. Let's say there is a mechanism assembled from six or seven car parts that can be combined into one printed part. It will save time and assembly costs. With 3D printing, it is also possible to reduce the weight of the combined assembly, as a result, the car will use fuel more efficiently.

It will save time and assembly costs. With 3D printing, it is also possible to reduce the weight of the combined assembly, as a result, the car will use fuel more efficiently.

3D Systems has designed an advanced exhaust pipe for a sport bike. In the image below, you will see 20 sheet metal and hydroformed parts needed to assemble the original exhaust pipe. On the right is a monolithic exhaust pipe that does not require assembly, made using metal 3D printing.

Source designnews.com

The 3D printed tube was produced using Grade23 titanium in just 23 hours, compared to three weeks for traditional production. Design development time reduced from 6 weeks to 6 days. Additive manufacturing also eliminates the need for tooling, fixtures, multiple welding and multiple inspections.

Geometry optimization has reduced the amount of material required for maximum productivity. All elements of the original exhaust pipe are incorporated into the new design and, when printed with a typical wall thickness of 0. 5mm, the 3D printed exhaust pipe is about 25% lighter than the original one.

5mm, the 3D printed exhaust pipe is about 25% lighter than the original one.

A wide range of 3D printing materials is beginning to meet the requirements of various vehicle components. Since additive methods reduce costs compared to traditional methods (such as molding and injection molding), it makes a lot of sense from a production and financial point of view to further introduce 3D printing into the production of basic parts.

Volkswagen, one of the world's largest and most innovative car manufacturers, is using an HP Metal Jet 3D printer to produce high-performance functional parts with special design requirements, such as shift knobs and mirror mounts. Volkswagen's long-term plans to work with HP include accelerating the production of mass-customized parts such as key rings and exterior nameplates.

+1. 3D Printed Cars

Although complete 3D printed cars have not hit the market yet, some interesting designs and concepts can be seen as a possible direction for the automotive industry.

Light Cocoon. German engineering firm EDAG was clearly inspired by nature to create the 3D printed supporting structure of the Light Cocoon concept car. The frame resembles the veins of a tree leaf or its branch. Despite the fact that the design of the EDAG took less material than a conventional frame, all the strength requirements for structurally significant components are met. Outside, the case is covered with a lightweight and durable waterproof fabric.

The coating protects the EDAG Light Cocoon from the weather and gives the car a unique personality. Source: formlabs.com

Blade. Blade ("Blade") announced as "the world's first 3D-printed supercar." It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

The world's first 3D printed Blade supercar. Source: formlabs.com

Strati. The American company Local Motors 3D printed and assembled the Strati electric car right at the exhibition stand, in just 44 hours. Most of the components were printed - the body, seats, interior parts. A car is made up of less than 50 assemblies, far fewer than the thousands of parts that go into a traditional car. The company intends to reduce the print time to 10 hours.

The American company Local Motors 3D printed and assembled the Strati electric car right at the exhibition stand, in just 44 hours. Most of the components were printed - the body, seats, interior parts. A car is made up of less than 50 assemblies, far fewer than the thousands of parts that go into a traditional car. The company intends to reduce the print time to 10 hours.

Local Motors Strati has less than 50 individual parts*. Source: formlabs.com

LSEV. Developed by the Italian company XEV, the LSEV could be the first in the 3D printed electric vehicle market when it goes on sale. The 3D printed chassis, seats, windshield and all visible parts of the LSEV. Thanks to the active use of 3D printing, the number of components was reduced from 2000 to just 57, resulting in a very lightweight design. The electric car weighs only 450 kg.

The LSEV is the first 3D printed electric vehicle to hit the market in 2020. Source: formlabs.com

While most of these and many other 3D printed car projects remain at the concept stage, the extent to which 3D printing has penetrated various areas of the automotive industry is striking.