3D printing vietnam

3D Printing Service Ho Chi Minh City Vietnam

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

read more...

Choosing the right China injection molding company is vital to the success of your project. There are several aspects to consider when choosing a China injection molding company.

read more...

Designing with Multi Jet Fusion is a process of 3D printing that is done by using different types of lasers.

read more...

3D printing is a great way to prototype and produce parts that are not accessible by other means

read more. ..

Introduction: What is a 3D Printing and Why Have They Become So Popular In The Last Decade?

read more...

With the promise of low costs and fast turnaround times, Chinese CNC machining services are a popular choice for companies looking to outsource their machining needs. In fact, carrying out CNC machining in China is a vital step for many product developers, since few other countries can match China for cost and efficiency.

read more...

Cyient additive manufacturing is new supplier in partZpro network

read more...

The first benefit of using CNC machining for prototyping is the ability to make changes at any time before the part is finalized.

read more...

Stainless steel is a useful material and has many applications that can be found in many different industries.

read more. ..

..

Customized manufacturing has become more popular in the last decade, and it is not hard to understand

read more...

Anodizing is an electrochemical process that changes the surface of a metal or alloy and the thickness of its oxide layer.

read more...

A coordinate measuring machine or CMM is a device that is used to manually measure 3D coordinates of a surface

read more...

Precision CNC machining has many benefits. It can be used to produce highly accurate parts, parts that are difficult to produce by other methods,

read more...

Sheet metal is a thin metal sheets, cut, folded and then tapered to a specific edge and from a single pattern

read more...

Hardware startups have many risk factors that often make things harder for them than others startups.

read more. ..

..

Industry 4.0 has become a trend in the business world. With the emergence of the internet of things, robots and 3D printers,

read more...

CNC milling is a manufacturing process where raw materials are carved and sculpted into shapes to produce a finished product.

read more...

3D printing is one of the most intricate, innovative, and revolutionary technologies that has ever been developed.

read more...

Scientists around the world declared COVID-19 a global pandemic just one year ago.

read more...

CNC Turning is a process in which a CNC machine takes a block of material and shapes it for a specific use.

read more...

Finding a proper and reputable CNC machine shop in China is easier than you might think

read more...

Medical devices can take a number of shapes and sizes and plastic injection molding is often used in the manufacturing process

read more. ..

..

The newest system for 3D printing is the SLS 3D printing technology

read more...

Plastic injection molding is a manufacturing process that converts a lot of liquid plastic into a number

read more...

Manufacturers of medical devices have a new, cost-effective way to produce their products

read more...

There is a mindset among product manufacturers that by just moving the manufacturing to any Chinese manufacturer they would reduce their costs helping them in today's competitive market.Given the growing number of Asian custom manufacturers, it is difficult for designers to pick the right suppliers while

read more...

All top global economies have adopted many new inventions. People and companies are developing new products, and this has created a gap in research and development that is costly and takes considerable time.

read more...

Times are changing, and so are businesses. Companies are adapting to new operation methods and are evolving swiftly.Recently, numerous organizations have begun utilizing prototypes for doing business.

read more...

3D printing started as just another means for people and companies to print and get things done. Now, it’s the cornerstone of printing. Hardly anyone had access to 3D printers about a decade ago. Now, they’re as ubiquitous as you can imagine.

read more...

The corona virus is already the watershed moment for 2020. The virus that started like a minor issue in China quickly spread like wildfire, and soon enough, just about every continent has now had to deal with it in one way or the other over the course of the past few months.

read more...

Also known as DMLS, Direct Metal Laser Sintering is a manufacturing method where technicians create metal parts from 3D CAD data without the need for any cumbersome tooling.

read more...

Plastic injection molding has grown to be the most popular molding technique. The process used varies in a wide array of ways, including but not limited to applications. To wit, here is some top industries hat apply this molding technique in their operations.

read more...

Injection molding is an interesting concept that a lot of companies use these days. However, the trend is also getting an exciting twist thanks to various innovations. Here are some of the most popular of those:

read more...

The injection molding industry is changing rapidly. With the times moving once more, it’s worth looking into the trends that drive change the most.

read more...

Plastic injection molding is a multifaceted production method that can help to improve plastic production. So far, it has provided various benefits over the other forms of plastic molding. Some of these benefits include:

Some of these benefits include:

read more...

Rapid prototyping can speed up the development process. Every product is formed and manufactured depending on the materials used and the type of prototyping that will best suit the product. The following are the different types of rapid-prototyping:

read more...

With the rapid growth of cloud computing in the second decade of the 21st century, the manufacturing industry has changed dramatically.

read more...

Recently machining center is shifting toward five-axis control. The five-axis machining has high precision and effectiveness. For instance, the high-end numerical control system with a five-axis linkage can also perform high-precision machining on complex spatial surfaces. Also, it is more suitable for processing modern molds such as automobile parts and aircraft structural components.

read more. ..

..

What precisely is Computer numerical-controlled (CNC) machining? It's a way to make parts by expelling material using fast, exactness mechanical machines that utilization a variety of cutting tools to make the Final Design. CNC machines usually used to make the geometric shapes required by clients are vertical processing machines, horizontal milling machines, and many more.

read more...

partZpro uses it's China manufacturers as China's most significant manufacturing network for on-demand manufacturing

read more...

Advantages of CNC processing:Material cost is low, and the material selection range is wideThe machine and equipment are stable and easy to operate.Parts can be appropriately decomposedIt can be easily adapted to parts with large size and simple structure.

read more...

Stereolithography 3D printing is a processing technique that is utilized in developing prototypes, models, and parts production layer after layer through a photo-chemical process. Monomers are often cross-linked together to create superior polymers. SLA processing has gained popularity over the years for producing parts with high precision and an excellent surface finish. It is considered the most cost-effective hence economically viable for the manufacturing of components. SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

Monomers are often cross-linked together to create superior polymers. SLA processing has gained popularity over the years for producing parts with high precision and an excellent surface finish. It is considered the most cost-effective hence economically viable for the manufacturing of components. SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

read more...

Sign up at our sign up page. Our machine shops or we will use your email for DFM analysis, and also platform will send your final quote to your email provided on this page.

read more...

partZpro is an online machine shop service that its idea originated in Orange County. It connects customers who are looking for CNC machining service in Southern California to machine shops in a few simple-to-follow steps. By having over 100 CNC machines at the fingertips of our Southern California customers, you can rest assured that you will get your quality parts in a fast turnaround while you have full payment protection by our platform.

By having over 100 CNC machines at the fingertips of our Southern California customers, you can rest assured that you will get your quality parts in a fast turnaround while you have full payment protection by our platform.

read more...

Product finishing services can be in form of metal finishing, industrial finishing, quality finishing among others. It is important to know the type of finishing that is suitable for your product as this will ensure that you have the right and proper finishing.

read more...

Stereolithography is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat.

read more. ..

..

The Computer Numerical Control also known as the CNC is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

read more...

There are many benefits of CNC Machining today such that there has been an increase in the use of CNC machines across different parts of the world. Some of the benefits of CNC Machining includes but are not limited to the following:

read more...

A computer numerical control (CNC) router is a computer-controlled cutting machine related to the hand-held router used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, glass, and foams. CNC routers can fill the roles of many carpentry dealers such as saw panels, spindles and drills.

read more. ..

..

The increase in the use of CNC Machining has left a lot of people wondering what it is about and how it came to be. This article highlights some interesting facts about CNC Machining you might not be aware of. These facts include:

read more...

Thanks to technology, a handful of websites have addressed some of the issues in the method (A). An engineer can upload their 3D files on their platform and enjoy the user-friendly interface on some of these websites to get an instant quote. Also, they can pay for their orders on the same platform, and these companies will take care of CNC machining of the parts using their network of qualified manufacturers. With the help of machine shops locally or in China, they can get the parts CNC machined in the time frame and to the price they had quoted to the customers.

read more...

A Computer Numerical Control (CNC) system offers an advanced combination skill and technology that is mostly controlled by an alphanumeric system that has been coded. A CNC machine is made up of five basic parts. These parts have their different functions but are blended in such a way that they work in synchronization with one another. This synchronic working of the basic parts of the CNC is what makes it a very great and advanced tool.

A CNC machine is made up of five basic parts. These parts have their different functions but are blended in such a way that they work in synchronization with one another. This synchronic working of the basic parts of the CNC is what makes it a very great and advanced tool.

read more...

Ensure that when choosing the CNC Machining service company/outlet, you are honest with what you want and are willing to pay to get the best services. Also, make sure that you verify the CNC service before going on with them. If possible, ask for samples of what they have done.

read more...

A CNC Machine is defined as a Computer Numerical Control Machine. A CNC machine comprises of the mini computer or the microcomputer that acts as the controller unit of the machine in the machine shops. Also, it can be defined as the automated control of machining tools (drills, boring tools, lathes). A CNC machine processes a piece of stock material (metal, plastic, wood, ceramic, or composite) to manufacture a CNC machined part by following code instructions or programmed instruction that usually come out of a cam software.

read more...

Often times people do not know what to check out for when choosing a machine shop to help them out with their equipment. Choosing a machine shop is more than just searching for a machine shop near you, one might be tempted to just search for “machine shops near me” and just go with the ones listed. We are not saying it is bad to search for machine shops close to you however, we want to make sure that you do not just visit any machine shop and not be totally satisfied with the services that they offer.

read more...

Traditional machining has evolved over the years, giving way to an era of more complex machining systems that are cost-effective and highly efficient. Computer numerical control (CNC) machining is a subtractive process of manufacturing that utilizes an automated power that is computer-integrated to control tools such as lathes, boring, and drilling machines. It is used to produce parts of high quality with high dimensional accuracy in a cost-effective manner. There has been tremendous growth in the use of CNC machining, thereby revolutionizing the manufacturing industry. As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

There has been tremendous growth in the use of CNC machining, thereby revolutionizing the manufacturing industry. As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

read more...

The CNC is a very vital and important part of handling any manufacturing job as it pays detailed attention to texture, length, and direction. Making use of the CNC during any form of manufacturing guarantees you that the work to be done will be done in a neat and smart manner such that you do not bother about how the work to be done is carried out. CNC systems usually offer far more expansive computational capacity.

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

It is a three-dimensional object that is made from polyurethane.

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

read more...

Choosing the right China injection molding company is vital to the success of your project. There are several aspects to consider when choosing a China injection molding company.

read more...

Designing with Multi Jet Fusion is a process of 3D printing that is done by using different types of lasers.

read more...

3D printing is a great way to prototype and produce parts that are not accessible by other means

read more...

Introduction: What is a 3D Printing and Why Have They Become So Popular In The Last Decade?

read more. ..

..

With the promise of low costs and fast turnaround times, Chinese CNC machining services are a popular choice for companies looking to outsource their machining needs. In fact, carrying out CNC machining in China is a vital step for many product developers, since few other countries can match China for cost and efficiency.

read more...

Cyient additive manufacturing is new supplier in partZpro network

read more...

The first benefit of using CNC machining for prototyping is the ability to make changes at any time before the part is finalized.

read more...

Stainless steel is a useful material and has many applications that can be found in many different industries.

read more...

Customized manufacturing has become more popular in the last decade, and it is not hard to understand

read more. ..

..

Anodizing is an electrochemical process that changes the surface of a metal or alloy and the thickness of its oxide layer.

read more...

A coordinate measuring machine or CMM is a device that is used to manually measure 3D coordinates of a surface

read more...

Precision CNC machining has many benefits. It can be used to produce highly accurate parts, parts that are difficult to produce by other methods,

read more...

Sheet metal is a thin metal sheets, cut, folded and then tapered to a specific edge and from a single pattern

read more...

Hardware startups have many risk factors that often make things harder for them than others startups.

read more...

Industry 4.0 has become a trend in the business world. With the emergence of the internet of things, robots and 3D printers,

read more. ..

..

CNC milling is a manufacturing process where raw materials are carved and sculpted into shapes to produce a finished product.

read more...

3D printing is one of the most intricate, innovative, and revolutionary technologies that has ever been developed.

read more...

Scientists around the world declared COVID-19 a global pandemic just one year ago.

read more...

CNC Turning is a process in which a CNC machine takes a block of material and shapes it for a specific use.

read more...

Finding a proper and reputable CNC machine shop in China is easier than you might think

read more...

Medical devices can take a number of shapes and sizes and plastic injection molding is often used in the manufacturing process

read more...

The newest system for 3D printing is the SLS 3D printing technology

read more. ..

..

Plastic injection molding is a manufacturing process that converts a lot of liquid plastic into a number

read more...

Manufacturers of medical devices have a new, cost-effective way to produce their products

read more...

There is a mindset among product manufacturers that by just moving the manufacturing to any Chinese manufacturer they would reduce their costs helping them in today's competitive market.Given the growing number of Asian custom manufacturers, it is difficult for designers to pick the right suppliers while

read more...

All top global economies have adopted many new inventions. People and companies are developing new products, and this has created a gap in research and development that is costly and takes considerable time.

read more...

Times are changing, and so are businesses. Companies are adapting to new operation methods and are evolving swiftly. Recently, numerous organizations have begun utilizing prototypes for doing business.

Recently, numerous organizations have begun utilizing prototypes for doing business.

read more...

3D printing started as just another means for people and companies to print and get things done. Now, it’s the cornerstone of printing. Hardly anyone had access to 3D printers about a decade ago. Now, they’re as ubiquitous as you can imagine.

read more...

The corona virus is already the watershed moment for 2020. The virus that started like a minor issue in China quickly spread like wildfire, and soon enough, just about every continent has now had to deal with it in one way or the other over the course of the past few months.

read more...

Also known as DMLS, Direct Metal Laser Sintering is a manufacturing method where technicians create metal parts from 3D CAD data without the need for any cumbersome tooling.

read more...

Plastic injection molding has grown to be the most popular molding technique. The process used varies in a wide array of ways, including but not limited to applications. To wit, here is some top industries hat apply this molding technique in their operations.

The process used varies in a wide array of ways, including but not limited to applications. To wit, here is some top industries hat apply this molding technique in their operations.

read more...

Injection molding is an interesting concept that a lot of companies use these days. However, the trend is also getting an exciting twist thanks to various innovations. Here are some of the most popular of those:

read more...

The injection molding industry is changing rapidly. With the times moving once more, it’s worth looking into the trends that drive change the most.

read more...

Plastic injection molding is a multifaceted production method that can help to improve plastic production. So far, it has provided various benefits over the other forms of plastic molding. Some of these benefits include:

read more...

Rapid prototyping can speed up the development process. Every product is formed and manufactured depending on the materials used and the type of prototyping that will best suit the product. The following are the different types of rapid-prototyping:

Every product is formed and manufactured depending on the materials used and the type of prototyping that will best suit the product. The following are the different types of rapid-prototyping:

read more...

With the rapid growth of cloud computing in the second decade of the 21st century, the manufacturing industry has changed dramatically.

read more...

Recently machining center is shifting toward five-axis control. The five-axis machining has high precision and effectiveness. For instance, the high-end numerical control system with a five-axis linkage can also perform high-precision machining on complex spatial surfaces. Also, it is more suitable for processing modern molds such as automobile parts and aircraft structural components.

read more...

What precisely is Computer numerical-controlled (CNC) machining? It's a way to make parts by expelling material using fast, exactness mechanical machines that utilization a variety of cutting tools to make the Final Design. CNC machines usually used to make the geometric shapes required by clients are vertical processing machines, horizontal milling machines, and many more.

CNC machines usually used to make the geometric shapes required by clients are vertical processing machines, horizontal milling machines, and many more.

read more...

partZpro uses it's China manufacturers as China's most significant manufacturing network for on-demand manufacturing

read more...

Advantages of CNC processing:Material cost is low, and the material selection range is wideThe machine and equipment are stable and easy to operate.Parts can be appropriately decomposedIt can be easily adapted to parts with large size and simple structure.

read more...

Stereolithography 3D printing is a processing technique that is utilized in developing prototypes, models, and parts production layer after layer through a photo-chemical process. Monomers are often cross-linked together to create superior polymers. SLA processing has gained popularity over the years for producing parts with high precision and an excellent surface finish. It is considered the most cost-effective hence economically viable for the manufacturing of components. SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

It is considered the most cost-effective hence economically viable for the manufacturing of components. SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

read more...

Sign up at our sign up page. Our machine shops or we will use your email for DFM analysis, and also platform will send your final quote to your email provided on this page.

read more...

partZpro is an online machine shop service that its idea originated in Orange County. It connects customers who are looking for CNC machining service in Southern California to machine shops in a few simple-to-follow steps. By having over 100 CNC machines at the fingertips of our Southern California customers, you can rest assured that you will get your quality parts in a fast turnaround while you have full payment protection by our platform.

read more...

Product finishing services can be in form of metal finishing, industrial finishing, quality finishing among others. It is important to know the type of finishing that is suitable for your product as this will ensure that you have the right and proper finishing.

read more...

Stereolithography is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat.

read more...

The Computer Numerical Control also known as the CNC is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

read more...

There are many benefits of CNC Machining today such that there has been an increase in the use of CNC machines across different parts of the world. Some of the benefits of CNC Machining includes but are not limited to the following:

read more...

A computer numerical control (CNC) router is a computer-controlled cutting machine related to the hand-held router used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, glass, and foams. CNC routers can fill the roles of many carpentry dealers such as saw panels, spindles and drills.

read more...

The increase in the use of CNC Machining has left a lot of people wondering what it is about and how it came to be. This article highlights some interesting facts about CNC Machining you might not be aware of. These facts include:

read more. ..

..

Thanks to technology, a handful of websites have addressed some of the issues in the method (A). An engineer can upload their 3D files on their platform and enjoy the user-friendly interface on some of these websites to get an instant quote. Also, they can pay for their orders on the same platform, and these companies will take care of CNC machining of the parts using their network of qualified manufacturers. With the help of machine shops locally or in China, they can get the parts CNC machined in the time frame and to the price they had quoted to the customers.

read more...

A Computer Numerical Control (CNC) system offers an advanced combination skill and technology that is mostly controlled by an alphanumeric system that has been coded. A CNC machine is made up of five basic parts. These parts have their different functions but are blended in such a way that they work in synchronization with one another. This synchronic working of the basic parts of the CNC is what makes it a very great and advanced tool.

read more...

Ensure that when choosing the CNC Machining service company/outlet, you are honest with what you want and are willing to pay to get the best services. Also, make sure that you verify the CNC service before going on with them. If possible, ask for samples of what they have done.

read more...

A CNC Machine is defined as a Computer Numerical Control Machine. A CNC machine comprises of the mini computer or the microcomputer that acts as the controller unit of the machine in the machine shops. Also, it can be defined as the automated control of machining tools (drills, boring tools, lathes). A CNC machine processes a piece of stock material (metal, plastic, wood, ceramic, or composite) to manufacture a CNC machined part by following code instructions or programmed instruction that usually come out of a cam software.

read more...

Often times people do not know what to check out for when choosing a machine shop to help them out with their equipment. Choosing a machine shop is more than just searching for a machine shop near you, one might be tempted to just search for “machine shops near me” and just go with the ones listed. We are not saying it is bad to search for machine shops close to you however, we want to make sure that you do not just visit any machine shop and not be totally satisfied with the services that they offer.

Choosing a machine shop is more than just searching for a machine shop near you, one might be tempted to just search for “machine shops near me” and just go with the ones listed. We are not saying it is bad to search for machine shops close to you however, we want to make sure that you do not just visit any machine shop and not be totally satisfied with the services that they offer.

read more...

Traditional machining has evolved over the years, giving way to an era of more complex machining systems that are cost-effective and highly efficient. Computer numerical control (CNC) machining is a subtractive process of manufacturing that utilizes an automated power that is computer-integrated to control tools such as lathes, boring, and drilling machines. It is used to produce parts of high quality with high dimensional accuracy in a cost-effective manner. There has been tremendous growth in the use of CNC machining, thereby revolutionizing the manufacturing industry. As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

read more...

The CNC is a very vital and important part of handling any manufacturing job as it pays detailed attention to texture, length, and direction. Making use of the CNC during any form of manufacturing guarantees you that the work to be done will be done in a neat and smart manner such that you do not bother about how the work to be done is carried out. CNC systems usually offer far more expansive computational capacity.

read more...

3D PRINTING TECHNOLOGY AND APPLICATIONS IN VIETNAM – vinnotek

- 15/07/2021

- Huân Đậu Văn

- en;

|

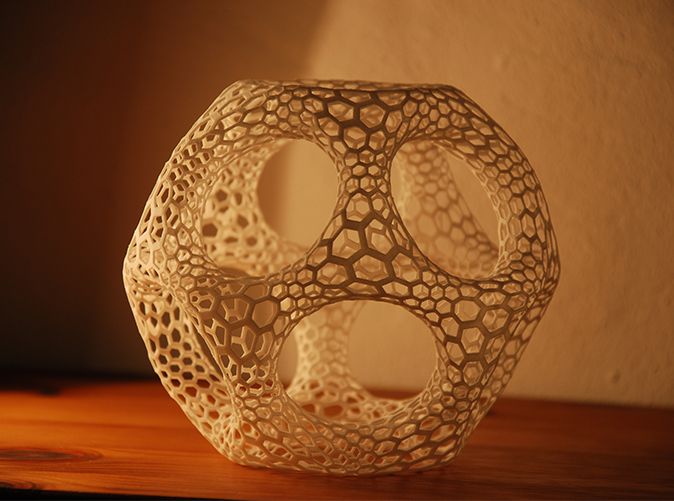

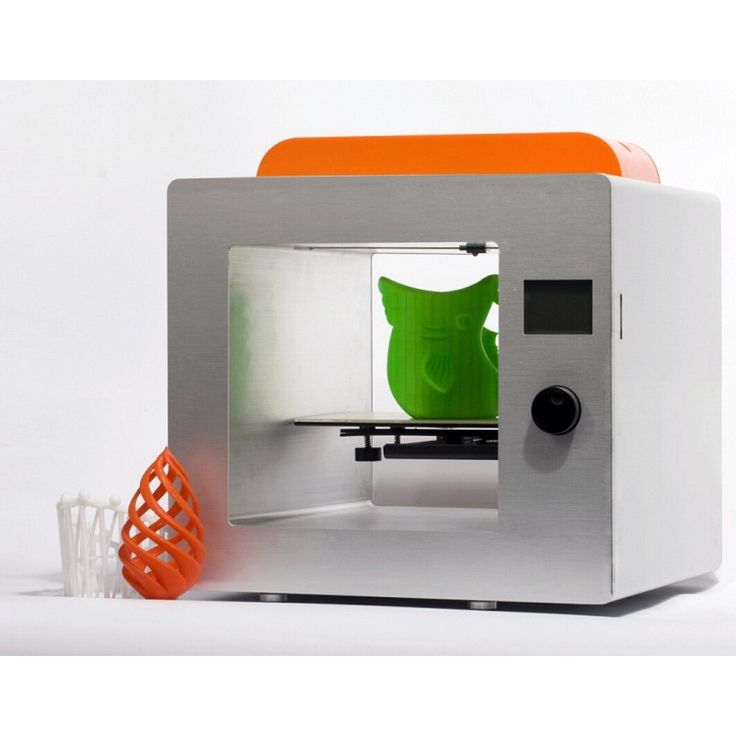

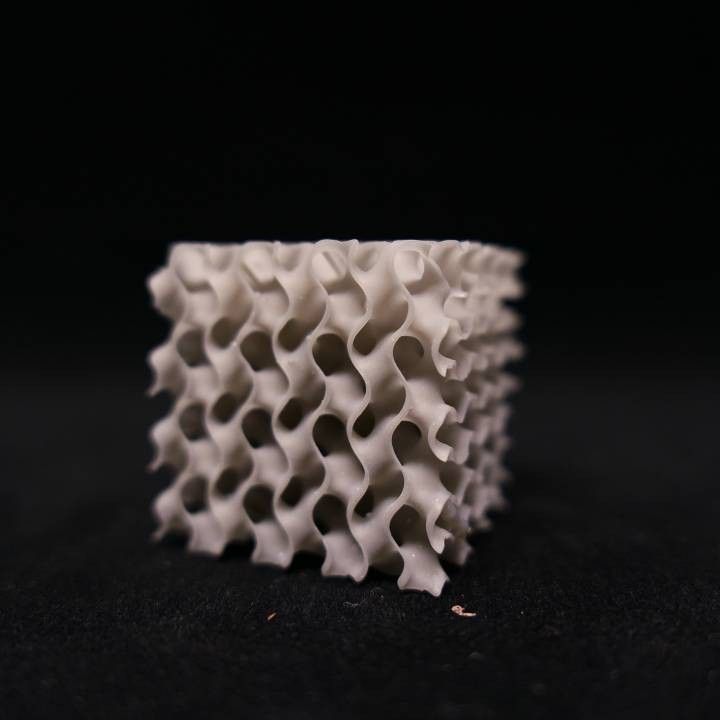

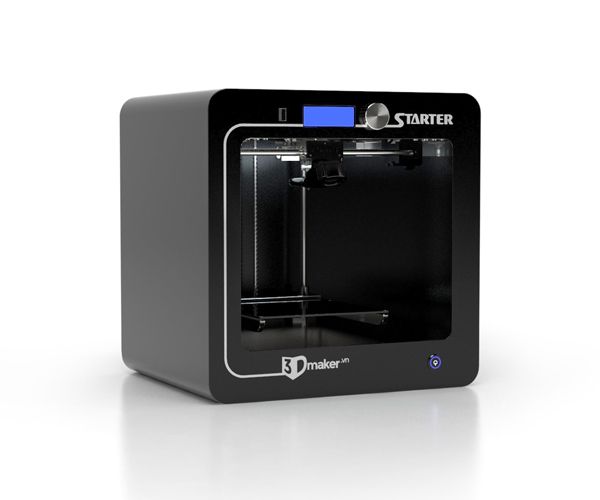

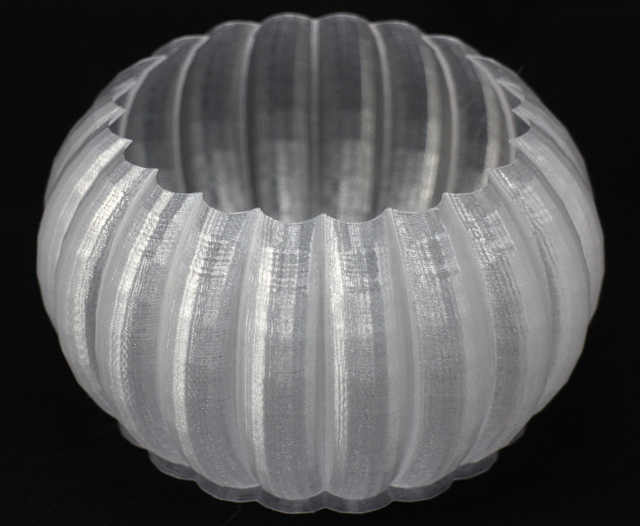

Nowadays, everyone must have heard of 3D printing technology. And this is a term as well as a technology that is not too strange in Vietnam. This technology is gradually replacing other traditional printing technologies. They can create very beautiful products, with extremely complex profiles. So what is 3D printing technology? How to print 3D products? Let's find out through the article below:

And this is a term as well as a technology that is not too strange in Vietnam. This technology is gradually replacing other traditional printing technologies. They can create very beautiful products, with extremely complex profiles. So what is 3D printing technology? How to print 3D products? Let's find out through the article below:

WHAT IS 3D PRINTING TECHNOLOGY?

3D printing is a process of creating three-dimensional solid objects from an electronic điệndigital file. The creation of a 3D printed object is done using additive processes. In an additive process, an object is created by placing successive layers of material until the object is created (also known as layer by layer). Each of these layers can be viewed as a sectionof the object. 3D printing is the opposite of cutting manufacturing which is cutting/hollowing a piece of metal or plastic, such as a milling machine. In 3D printing allows you to create complex shapes using less material than with traditional manufacturing methods.

Materials used: we can use plastic, metal, paper... stacked to complete an object. This technology was founded in 1980, researched and developed by Chuck Hull.

HOW TO PRINT 3D PRODUCTS?

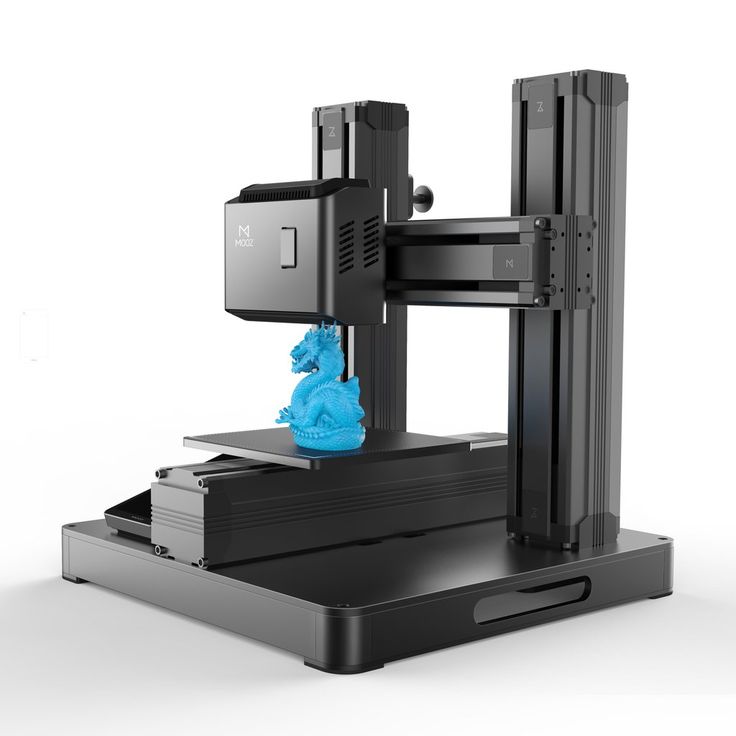

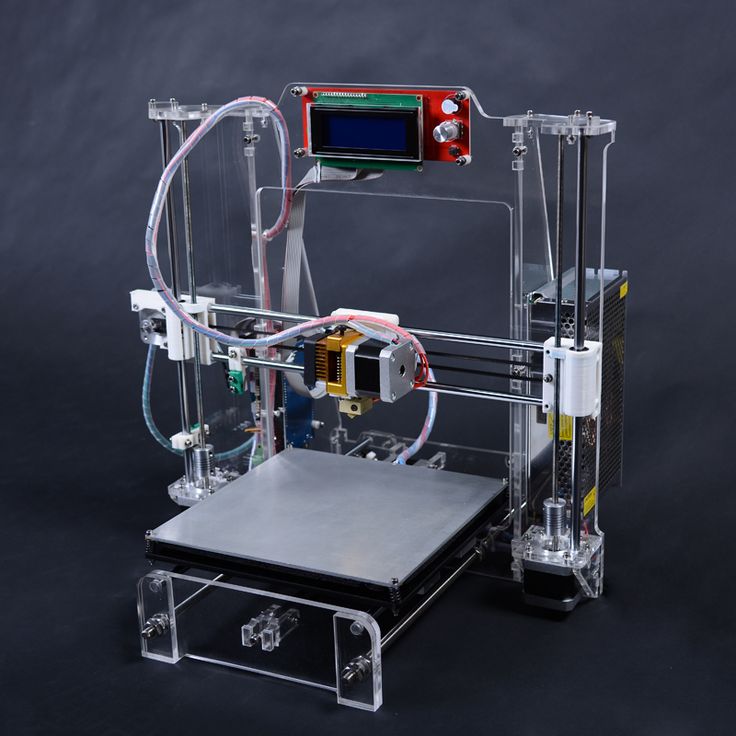

To 3D print, we need to prepare the following three tools: 3D design file, 3D printer, 3D printing ink. Specifically, we refer to the 3D printing process that includes the following steps:

Step 1: Prepare the 3D CAD model. This model you can design yourself or download from 3D libraries.

Step 2: Convert the file to STL (stereolithography) format. This is the standard format for representing solid objects in the prototyping industry.

Step 3: Put the file into the "splitting" software to adjust the size, position and orientation to the model. Then the software will proceed to cut, split, edit the data, set parameters so that the software can output the GCODE file so that the printer can read it.

Step 4: Data is transferred to the 3D printer by USB, SD card or by Wifi, using ink and built-in printing technology in the machine to create images. There are many types of ink for each specific 3D printing technology

There are many types of ink for each specific 3D printing technology

separate. About 3D printers today, there are many types with different prices, depending on the purpose such as mini 3D printers, office 3D printers, large format 3D printers, Resin 3D printers.

Step 5: The motor will pull and melt the plastic filament through the nozzle, then print multiple layers on top of each other like a pre-built design file, creating a complete object. The object will then be cleaned and surface treated by: sanding or coating to improve shape and durability.

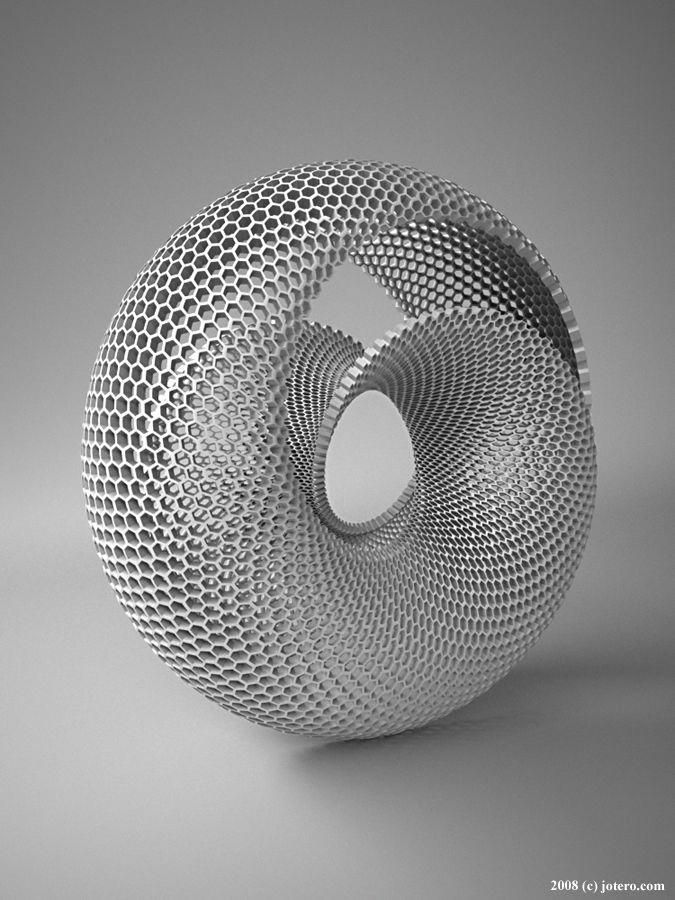

APPLICATION OF 3D PRINTING TECHNOLOGY

The application of 3D printing technology is becoming more and more widespread, it penetrates deeply into the fields of aviation, construction, food production, heavy industry, education, healthcare... from simple models. to real life products.

- Application in the electronics industry: Producing complex parts, components, equipment of machines, robots. ..

..

- Application to the manufacturing industry: 3D printing technology is applied the most when producing many products from small to large. From model complex shapes, cut scrap, quickly create test products on demand to save production time, increase efficiency and cut costs.

- Application in the fashion industry: Producing 100% clothes by 3D printing technology

- Application to the automobile industry: Manufacture of car parts.

- Application in the aviation industry: Producing parts for airplanes, spacecraft, rockets, especially parts with complex shapes.

- Application in the medical industry: Producing human anatomical models, biological tissues... for research and teaching

- Application to national security industry: Using 3D printing technology to produce guns and weapons

- Application in food production: Create food from 3D printer like the real thing

- Application in education: application in science - engineering - information technology to teach students

In addition, it also applies to many other fields.

Above are shares of vinnotek.com about 3D printing. Each type of 3D printing has different advantages, disadvantages, operating principles and printing capabilities. You should research carefully to choose the type of printing technology that is best for you!

New eSun factory opens in Vietnam

Miscellaneous

Ender 3 Ender 3 Pro Anycubic Photon S

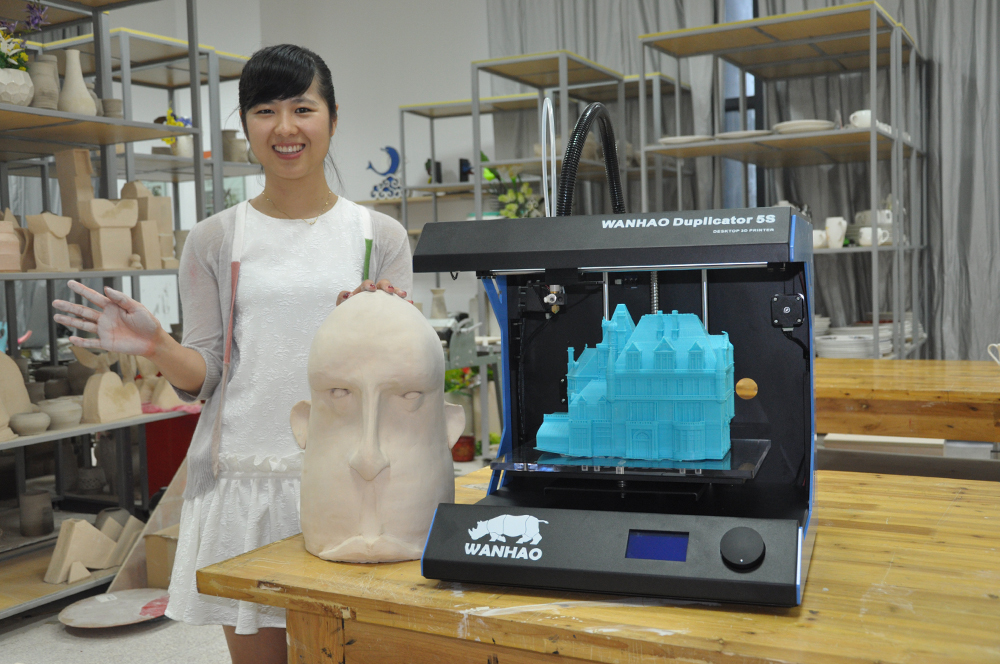

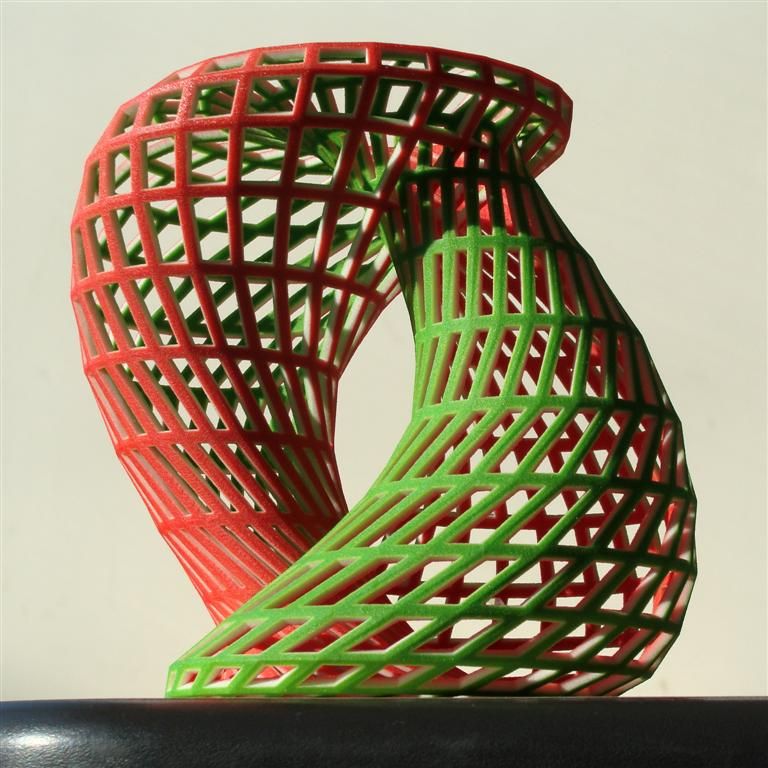

November 8, 2019 by Shenzhen Guanghua Weiye Co., Ltd. (abbreviated as "eSUN"), a new plant in Vietnam was officially put into operation.

The construction of new factories outside the PRC for the production of consumables for 3D printing is primarily due to the ever-increasing demand. To meet the increasing needs of customers, especially overseas, the company decided to launch a new project in Vietnam.

After a long market research and careful selection, the company decided to build a new production base in Vietnam, in the city of Ho Chi Minh. The expected capacity of the new factory will be about 1500 tons per year for FDM printing materials.

The expected capacity of the new factory will be about 1500 tons per year for FDM printing materials.

This is the next step in eSUN's global planning after building warehouses in the US, Rotterdam and the UK.

The Vietnamese factory will be an important overseas manufacturing base for eSun. All technological processes will be carried out on the territory of the plant, from equipment assembly, plastic extrusion, to packaging, warehousing and solving logistics problems.

Vietnamese factory eSUN reportedly plans to produce only FDM printing material in the first phase. On the day of the factory's commissioning, all eSUN PLA series consumables produced were thoroughly tested. The next step will be to expand production in the form of photopolymer resins as well as biomaterials.

In China, in the near future, Xiaogan Factory will start construction of a demonstration project with a planned investment of 200 million yuan to establish a demonstration center for biomaterials and smart manufacturing projects, which will use new materials and smart manufacturing to create new materials for 3D printing .

Since its founding in 2002, eSUN has been engaged in research, production and sales of biological materials. Entered the field of 3D printing in 2007, and now has become a world famous manufacturer of 3D printing consumables, its supply is among the best 3D printing materials in the world, and its products are exported to more than 90 countries around the world. And you can find all the most popular materials for 3D printing from eSun at low prices on our website https://rkgadget.ru.

eSUN production consumable

Follow author

Follow

Don't want

Article comments

More interesting articles

2

Follow author

Subscribe

Don't want

IMPRITA took part in TECHNOFORUM 2022, which was held in Moscow, Expocentre, from 24. ..

..

Read more

2

Subscribe to the author

Subscribe

Don't want to

Once 3D printing began to gain popularity, a few years ago, TV often showed...

Read more

daymon

Loading

01/27/2017

15982

81

Subscribe to the author

Subscribe

Don't want

Yep, again!

Here, for half a year, the topic of a joke on earnings on the printing of whistles was forcing. AT...

Read more

Vietnamese researcher wins the world's largest 3D printing technology award | Vietnews.ru

Dr. Tien and a group of senior experts won the Purmundus Innovation Award. Photo: VnExpress

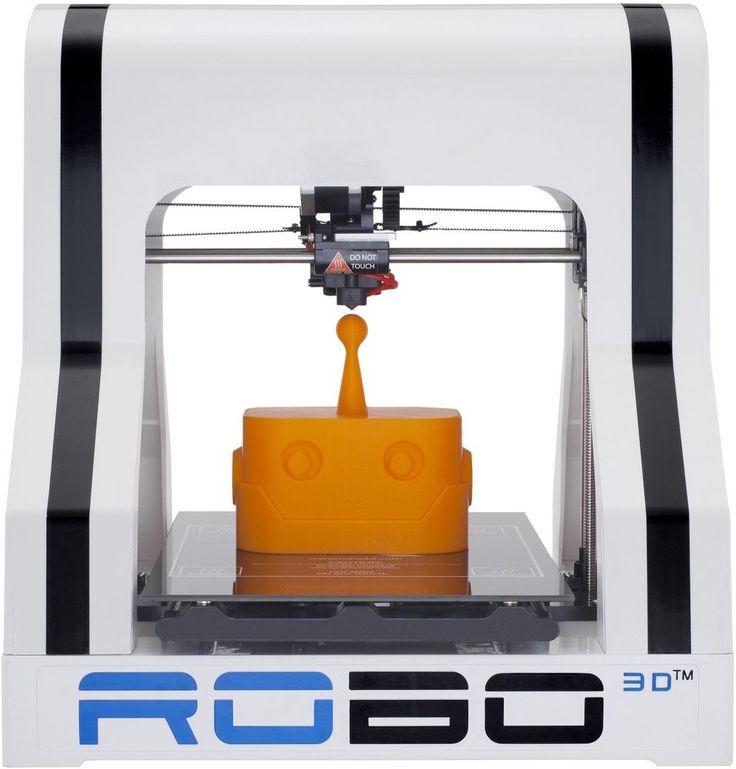

Photo: VnExpress Dr. Truong Van Tien and his soft robot research are internationally recognized for their breakthrough in manufacturing technology.

At the end of November 2021, the Innovation Award was awarded to Dr. Truong Van Tien and his team at the Bio-Inspired Robotics and Design Lab - Singapore University of Technology and Design in collaboration with the University of Washington, University of Colorado Denver) for the project "Custom 3D -printed soft robots.

Soft robots have a unique potential for advanced functionality through materials engineering, chemistry and advanced manufacturing. However, modeling and control of soft bodies of robots is a difficult task due to the non-linearity and dependence of the physical and chemical properties of materials on time.

With the rapid development of artificial intelligence (AI) technologies, deep neural networks (DNNs) have become an important tool for studying the relationships between the inputs and outputs of complex systems in complex environmental conditions.

"In this work, instead of physically modeling a soft robotic system, we consider the entire system, including its environment, as a complex but deterministic input-output system. As an example of application, our learning outcomes show that DNA can accurately model physical properties of an underwater soft robot inspired by biological principles. Validation experiments show that the measured propulsion forces are in good agreement with the target values predicted by DNA," Tien shared in the study abstract.

Photo: Purmundus Awards.The team's experiments show the potential of using DNNs to rapidly simulate bio-inspired engines and facilitate control, making breakthroughs in manufacturing technology.

This research is published in the August 2021 issue of the leading journal Advanced Materials, titled "Advanced Material Technologies".

Photo: Advanced Material Technologies, August 2021 issue The group's research has been reported by the world's leading technology sites such as Techxplore, Eureka, Azorobotics due to a breakthrough in manufacturing from affordable materials.

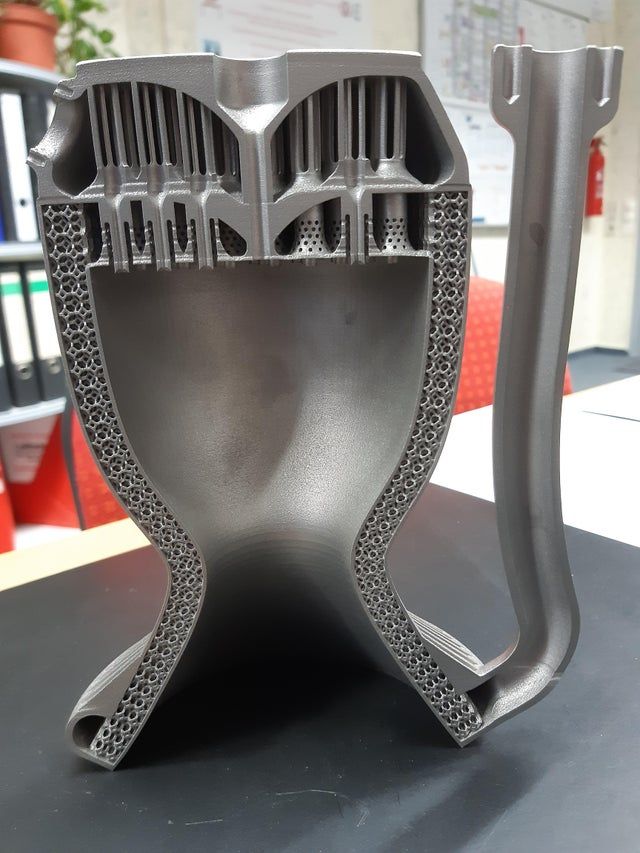

From this research result, the team 3D printed the robot in a project commissioned by the Singapore Ministry of Science and Technology with a grant of around SGD 2 million (US$1.4 million). It is a self-propelled underwater robot made of composite materials for observation and reconnaissance with a swimming speed of 1.5 times, superior to conventional robots. The robot is designed to optimize the 3D printing of various materials to improve productivity.

Dr. Truong Van Tien. Photo: VietnamnetAn aeronautical engineer became a 3D printing researcher

Dr. Truong Van Tien, a native of Lam Ha District, Lam Dong Province, studied aeronautical engineering at Ho Chi Minh University of Technology.

In 2008, he received a full doctoral fellowship to study in Korea, then participated in many research projects and worked in the US, Canada and Singapore.

Since 2018, Tien has been interested in learning about 3D printing technology and has been doing research in this field ever since.

The project that won him the Purmudus Awards is also his biggest work. While conventional 3D printing technology today uses only one material, Tien's team is developing a hardware/software system that can 3D print multiple materials on a single piece for maximum efficiency.

"The team studied the characteristics of each material in order to use an algorithm to calculate the distribution and ratio of many materials on the product to create the best efficiency of use," said Dr. Tien.

Purmundus

Purmundus is the world's largest award for 3D and 4D printing technology in the field of design, held annually since 2012 by the International 3D Printing Association. The 2021 award took place in November in Frankfurt, Germany and featured thousands of entries from universities, research institutes and businesses around the world, with a total prize of €30,000 ($34,330).

Purmundus finalists competed in 2021 under the motto "Innovation in Progress" and were awarded prizes during Formnext.

Award-winning designs range from ballet shoes to 3D printed musical instruments, bicycle helmets, heat exchangers and brake calipers.

Source: Vietnam Times

- Shrimp processing giant increased revenue by 9%

- High schools will use 3D technology to teach math

- Unique 3D coconut paper crafts

- Ten Vietnamese scientists ranked among the best in the world

- Vietnam's first 3D billboards (Video)

Tags: Vietnamese researcher wins the biggest international award in 3D printing technology

#Vietnamese scientists #3D technology

Tattoo artist takes Vietnamese ink to the world level

Tattoos created by artist Tran Thai Chung, aka Trung Tadashi, have become works of art. They impress with their originality, sophistication and artistic elements through the fusion of traditional Asian artistic culture and modern tattoo techniques.

They impress with their originality, sophistication and artistic elements through the fusion of traditional Asian artistic culture and modern tattoo techniques.

People,

1 month ago

People,

2 months ago

70-year-old Vietnamese paraglider conquered the skies of Vietnam

Nguyen Huu Nam, often referred to as "Old Nam", is a member of the Vietnam Paragliding Club of Hanoi. With over 15 years of experience in the sport, he is a household name in the country's paragliding scene.

People,

3 months ago

People,

5 months ago

The new Forbes Vietnam 30 Under 30 list includes six people

The latest Forbes Vietnam 30 Under 30 list includes six people who have shown a creative approach to entrepreneurship in the startup world, focusing on technology, e-commerce and investment.