3D printing the future of manufacturing

6 Predictions for the Future of 3D Printing

3D printing is quickly becoming a mature manufacturing technology. It’s useful for prototypes and offers significant benefits for small and medium-sized production runs. But just how much will 3D printing change manufacturing and supply chain — and how will the technology get there? Here are six predictions about the near future of additive manufacturing.

1. 3D printing will be bigger, faster and cheaper. 3D printing technologies are developing quickly. Rising demand for specialized materials to fulfil the required properties of end parts will continue to drive developments in the range and types of options available. The key for the new generation of printers, especially industrial-grade solutions, will be the ability to handle a greater range of advanced materials. This opens the door for businesses to benefit from additive manufacturing in areas where they previously could not.

Although machine costs remain high, increased print speed is pushing the price of parts down. As more and more businesses adopt 3D printing, these advancements will accelerate. With the addition of processes such as dual extrusion, the versatility of 3D printing is growing. As a result, 3D printing is being adopted in a wider range of industries. Another trend likely to significantly drive development is printing without the use of support structures, which again broadens the range of applications additive manufacturing can offer. In our eyes the potential for cost and time savings is high.

2. Additive manufacturing will become part of an integrated supply chain approach. To maximize benefits, manufacturers need a large range of printers and materials and, importantly, connections with other industry professionals. Furthermore, interoperability among different systems is becoming important to maximize the potential of 3D printing. Automation in production and post-processing as well as in integrated usability will be important trends this year and beyond. Additive manufacturing can provide a whole new supply chain approach as part of a holistic and secure platform in which the individual steps are combined into one process, from concept to materials, digital inventory, production and delivery. As manufacturers strive toward Industry 5.0, services offering a fully automated, yet secure, platform will be essential.

3. Working together is imperative. Partnerships can create mutual benefits and synergies that lead to a greater product for customers. In 3D printing, this has proven to be a main enabler to scale industrial production. However, to progress further, there is a need for more holistic collaboration. Standards have to be developed, and printer and post-processing systems should be able to work together. In addition, shared production data can lead to improved printers and materials for all. Likewise, close collaborations are essential to achieving the best solution. An ecosystem where service providers, material producers and print farms worldwide are connected is the next step to building a better service.

4. There must be ways to provide quality and cybersecurity assurance. 3D printing continues to transform today’s industries, with companies adopting the technology for more and more of their needs, thereby giving rise to a more integrated production environment. However, for industrial production, businesses must be assured that their 3D printed parts will meet necessary quality requirements. Moreover, data ownership will play a crucial role. Intellectual property needs to stay in the right hands. As manufacturing progresses into the digital era, data management will be critical. In terms of quality assurance, it’s important to carefully select production partners, check their capabilities and ensure repeatable fit-for-purpose parts. Further steps are required to ensure design data is kept in the right hands. In addition, organizations must enforce manufacturing parameters by encrypting the data so the parts can only be produced in the requested amount and material. By collecting manufacturing data and analyzing it, mistakes can be detected quickly, improving the process and ensuring all quality requirements are met.

5. 3D printing will boost supply chain resilience. 3D printing has been used in the past as a solution to a variety of supply chain disruptions. As the technology develops, additive manufacturing’s role in solving these problems will only increase. Because 3D printing production can be situated closer to the consumer location, manufacturing organizations leveraging this technology can build shorter, stronger and more resilient supply chains. Physical inventory is the weak point in any supply chain. But with printing on-demand capability, inventory becomes digital. Engineers and manufacturers can send the design file to the 3D printer nearest the next step in the supply chain, whether it is the manufacturer receiving the component or the consumer receiving the final product. Then, there is less need to store and incrementally move inventory. Instead, parts can be printed and shipped the shortest practical distance, thus reducing carbon dioxide emissions and boosting supply chain resilience.

6. Additive manufacturing will drive sustainability forward. Demands of end-customers, official regulations and even moral duty are making sustainable production and supply chains increasingly necessary. This trend also is present in 3D printing, which can reduce waste during production. By specifically designing a part for 3D printing, engineers can drastically decrease the weight of the end part, therefore reducing the material needed for production. Moreover, when 3D printing is used as part of an on-demand and decentralized digital warehouse, it can reduce the number of parts in inventory and the associated waste. Plus, by locating production closer to the next step in the supply chain, carbon dioxide emissions during transport are reduced. Moreover, there will be growth in sustainable 3D printing materials such as recycled, reusable and biodegradable plastics.

Is 3D printing the future of manufacturing? – Northbridge Insurance

The world of manufacturing is constantly evolving and changing. And 3D printers may be the next big step.

3D printing, or additive manufacturing, is a process that allows for a three-dimensional solid object to be created from a digital file. For years, when the technology was first introduced, it appeared to be more of a novelty than a practical tool, creating one-off trinkets and souvenirs. But now, with lower costs and technological advances, 3D printing is within more people’s reach and has already been used in a number of interesting ways, ranging from medical applications to shoe production.

But like any other relatively new technological advancements, there are both pros and potential drawbacks. Here we examine those consequences, and look at where 3D printing is now and where it might be headed.

The current state of things

The 3D printing market has been steadily growing over the years. The primary market, including 3D printing systems, materials, supplies, and services, has grown at least 30 per cent each year from 2012 to 2014, according to a report published by the Consumer Technology Association (CTA) and the United Parcel Service (UPS).

The report, titled “3D Printing: The Next Revolution in Industrial Manufacturing,” found that two thirds of manufacturers already use 3D printing in some way, and 25 per cent had plans to adopt the technology in the future. Corporations cited prototyping, product development, and innovation as their top reasons for using 3D printing.

The consumer electronics and automotive industries each contribute 20 per cent of the total 3D printing revenue, using the technology primarily during the prototyping phase of production, according to the report published by the CTA and UPS. But some are expanding outside of just prototyping. For instance, smartphone manufacturers have begun using 3D printing for some component parts.

The medical industry is the third largest 3D printing market, contributing 15 per cent of the total 3D printing revenue. The industry uses the technology for mass customized finished goods, such as hearing aids. 98 per cent of hearing aids worldwide are now manufactured using 3D printing.

Despite all of this, 3D printing has not taken over much of the manufacturing landscape, with less than one per cent of all manufacturing output being 3D printed today.

Currently, less than one per cent of all manufacturing output is being 3D printed.

The arguments for and against

Currently, 3D printing is most commonly used for producing prototypes because changes are typically easier and cheaper to make compared with having to reset tools in a factory. The technology is ideal for low-volume production, such as craft items like jewellery or customized products like prosthetics. Dental crowns and hearing aid buds are already being made by the million with 3D printers.

It’s also great for producing lightweight and complex shapes for high-value products ranging from aircrafts to racing cars. This is because the printer deposits material only where it’s needed. GE has already spent $1.5 billion on the technology in order to make jet engine parts, among other things.

But some believe that 3D printing may never be fully embraced by the manufacturing industry because it’s so time consuming; some complex items can take up to two days to create. Currently, the cost of equipment and materials for 3D printing is also quite high, and the choice of materials available is a fraction of the variety used in conventional methods.

During a keynote presentation at the Canadian Manufacturing Technology Show, Kirk Rogers, technology lead at the GE Center for Additive Technology in Pittsburgh, warned that additive manufacturing may not supplant traditional manufacturing entirely. Of the parts GE makes at additive manufacturing centers, he said, 85 per cent have required traditional manufacturing technologies, like machining.

What the future could hold

While 3D printing may not be taking over the entire manufacturing industry just yet, analysts predict there will be a great deal of growth and the market will be worth 32.78 billion USD by 2023.

Analysts have predicted the 3D printing industry will be worth 32.7 billion USD by 2023.

Many manufacturers have already started to explore the market to see what potential may be there. Adidas, for instance, has started to use a form of 3D printing called “digital light synthesis” in order to produce the soles of trainers, pulling them fully formed from a vat of liquid polymer. This method will be used in some new Adidas factories in Germany and America in order to produce one million pairs of shoes annually to market more quickly than conventional processes would allow.

The economics of metal printing could be changed by 3D printing too, with a new technique called bound-metal deposition. The technique can build objects at a rate of 500 cubic inches an hour compared to one to two cubic inches an hour when using a typical laser-based metal printer.

The full consequences of 3D printing in the manufacturing industry are hard to predict. But based on what’s happened already in the industry and what analysts expect to see in the coming years, it seems safe to say that we haven’t seen 3D printing used to its full potential just yet.

Want to learn more about current trends in manufacturing? Check out our blog on the topic! Or visit our Manufacturers’ Insurance page and find out how our experts can help your business today!

This blog is provided for information only and is not a substitute for professional advice. We make no representations or warranties regarding the accuracy or completeness of the information and will not be responsible for any loss arising out of reliance on the information.

Share on email

Share on linkedin

Share on twitter

what lies ahead for 3D printing

The prospects for 3D printing

Even now, the prospects for 3D printing are extremely promising. Scientists are actively developing existing 3D printing techniques, developing new technologies and types of materials, and finding new areas of application. Many call 3D printing the technology of the future, and for good reason. The technique is able to completely turn the usual way of life, changing the way most things are produced. In fact, a 3D printer is a real multifunctional factory, small and compact. Due to this, the future of 3D printing can definitely be called successful.

3D printers can significantly reduce production costs, thereby reducing the cost of products. Judging by the growing trend towards the popularization of 3D technologies, raw materials for 3D printing will become the main commodity unit in the future. In general, the prospects for 3D printing are defined for many areas. And now we will try to reveal them as much as possible.

The Future of 3D Printing

If you try to imagine the future of 3D printing, your imagination paints a rather interesting picture. Given the great interest of scientists in the 3D bioprinting technique, which is one of the most promising 3D printing technologies, the production of artificial organs on a 3D printer is not far off. It is also safe to say that the future of 3D printing will bring us dramatic changes in areas such as:

- Construction. 3D printing of houses, or contour construction, attracts many with its futurism and simplicity. The first steps in this direction have already been taken. The pioneers in 3D printing of houses were the Chinese, followed by the government of Dubai who discovered contour building. The first 3D printed office building has already been built in this city of the future, and an entire block is planned to be printed in the near future. And just recently, the first printed house in Europe was created on a 3D printer;

- Electronics. When listing the prospects for 3D printing, this point should be given special attention. Scientists believe 3D printing of electronics is the future of digital device manufacturing, and with good reason.

Graphene properties and its application in additive manufacturing are currently being actively researched. A huge breakthrough in this area is the creation of a graphene battery with an unlimited service life on a 3D printer;

- Automotive and aerospace industry. The future of 3D printing is largely based on its ability to reproduce almost any element of varying complexity. In this regard, 3D printing is already widely used in the development of aircraft, machines and satellites. The ISS even has its own 3D printer, not to mention a number of successful 3D printing of cars.

- Pharmaceutical industry. Yes, yes, you can imagine. The future of 3D printing is in the manufacture of tablets and other medicines. This is confirmed by epilepsy pills legalized in the USA, made according to a special technique. The essence of this perspective of 3D printing is the gradual release of active substances, so that instead of many tablets, you can drink just one.

- Food industry.

3D food printers are gradually gaining space in cafes and restaurants. While this is probably one of the most raw 3D printing technologies out there, it has potential. Food 3D printers are especially interesting for the possibility of making food for astronauts, as well as the freedom to display culinary talent. This is confirmed by the amazing 3D-printed desserts of our compatriot.

Other questions and answers about 3D printers and 3D printing:

- Finance Which 3D printer manufacturers are best?

- Finance Which 3D printer is better to buy?

The future of 3D printers

Now let's try to imagine the future of 3D printers. There are several important points to be noted here. Below we list the most likely scenarios for the future of 3D printers.

- Improving the reliability and quality of instruments. Surely, many users are looking forward to this, because most of the existing models of 3D printers cannot boast of uninterrupted operation and the absence of printing errors;

- Large-scale distribution.

It is certain that the future of 3D printers will please us with their popularization. Even now, one can observe a growing trend towards the use of 3D printing in almost all areas of industry. In parallel with the fact that more users are learning about the possibilities of technology, the demand for desktop 3D printers is also growing;

- Availability. In continuation of the previous paragraph, it is worth noting that the growing demand for 3D printers will lead to lower prices for these devices. The use of 3D printing for domestic purposes is gaining momentum, which brings new equipment manufacturers to the market. Naturally, such a step will entail a reduction in the cost of devices;

- Enlargement of the construction area. 3D printing of large-sized objects has long occupied the minds of developers. Of course, this applies to industrial 3D printers, because the functionality of 3D printing at this scale will allow you to create full-fledged components, for example, cars and aircraft;

- Expanding the range of available materials.

The future of 3D printers depends a lot on 3D printing materials, because more means more possibilities. The development of special equipment and related materials is being carried out by many companies, and news about the release of new polymers is constantly appearing.

3D technologies of the future

Summing up, it remains to consider only 3D technologies of the future. These include various futuristic scenarios that, to one degree or another, are already beginning to develop today. These include the technique of virtual reality, 3D scanning to create the perfect clothes and shoes, 3D printed makeup, and more. In a way, 3D technologies of the future also include bioprinting. By the way, scientists are talking about building the first 3D printed settlement on the Moon and Mars, so the prospects for 3D printing are also relevant outside the Earth.

This was a list of the main scenarios for the future of 3D printing. Let's see how they are destined to come true. If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team.

Our store offers a wide range of 3D printers, 3D scanners, 3D plastics and resins, as well as other accessories at the best prices on the Ukrainian market with delivery to all cities (Kharkiv, Nikolaev, Dnepropetrovsk, Lviv, Zaporozhye, Kherson, Donetsk, Odessa ). We also provide 3D printing, 3D scanning and 3D modeling services. For all questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

Back to home

3D printing and the future of small-scale production

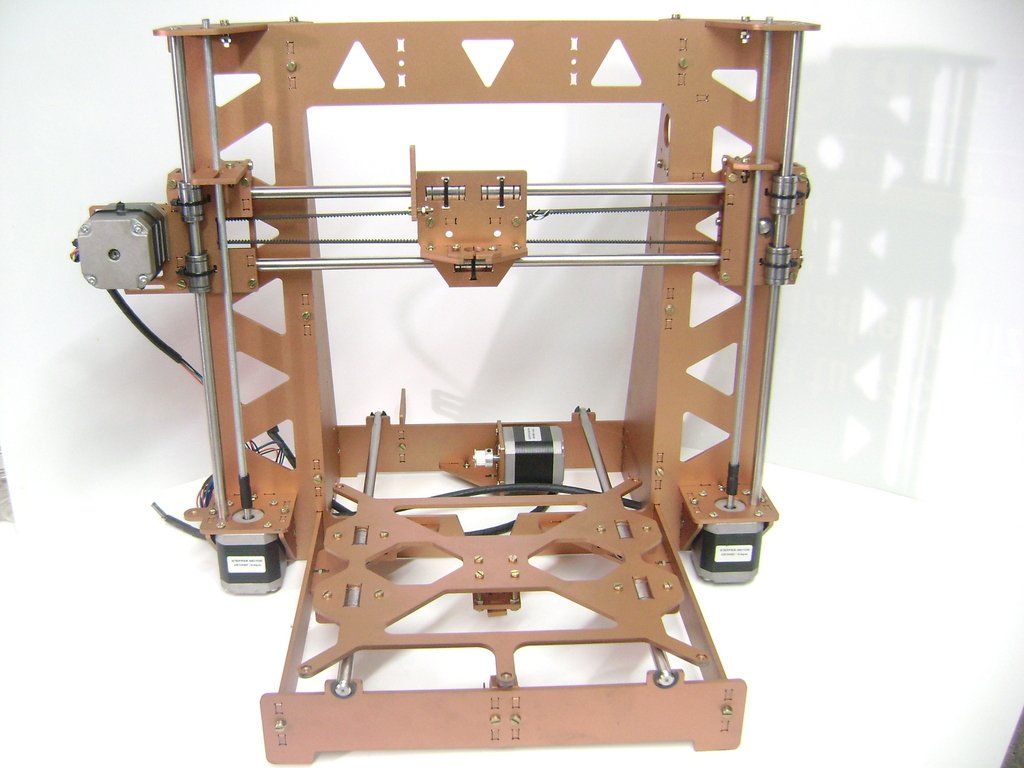

Modern desktop 3 D-printing began a little over 10 years ago when a community of enthusiasts arose pRap.9006 The aim of the project was to "self-copy", replicate the components of the 3D printers themselves. The task was to small-scale production of 3 D-printers on the same 3 D-printers. The idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the biggest farm 3 D-printers for printing plastic parts produced by his factory 3 D-printers. The total number of printers in his factory reaches 1000 pieces; the achievement was even registered in the Guinness Book of Records.

In this case, I would note the marketing talent of Josef Prusz , because his company produces about 100,000 printers a year: production can hardly be called small-scale. However, he continues to print plastic components for his printers on them. Thus, their reliability is emphasized, because printing is part of the testing process, on the one hand, and on the other hand, it demonstrates to customers the quality of models made on a 3D printer. The effectiveness of such an approach from the point of view of the production itself is negligible. A single injection molding machine would easily handle this task, saving a lot of space and electricity, and there would be no need for a large number of jobs.

Opportunities 3 D-printing for small-scale production

What are the possibilities of desktop 3D printing for small-scale production? I note right away that this article is about desktop 3D printers. I will not consider industrial systems in it, since they are in a different price category, both for the equipment itself and for printing materials.

First, let's talk about what can be produced on 3D printers. Usually we are talking about small plastic elements, plugs, clamps, housings, holders and other similar elements. The choice is to order a mold or 3D print the elements. It is easy to make a choice by calculating the cost of a mold, the cost of products obtained on an injection molding machine and the cost of printing the same product on a 3D printer of the required circulation.

You need to understand: how many units of production per unit of time do you need to produce and, accordingly, how many and what kind of 3D printers will be needed for this task? Having made such an initial analysis and having previously understood that 3D printing is what suits you, you should carefully start choosing equipment.

If you already know what you are going to print, the choice becomes easier. If you plan to produce models with different tasks in the future, you should carefully analyze the possible options before buying. The main factor influencing the choice of equipment is the presence or absence of certain functionality in future models. The printer should print with materials that will ensure the functionality of your products. For example, a future part must withstand a certain heating or cooling temperature, be strong, rigid, wear and impact resistant, or, conversely, soft, rubber-like, elastic, flexible. The more versatile a 3D printer is, the more expensive it is. Indeed, for printing various types of plastic, printers are equipped with closed chambers, interchangeable extruders, perforated platforms, feed mechanisms with adjustable filament pressure, etc.

Solutions based on FDM/ FFF technologies

This is the FDM/FFF printing technology most commonly used today for small-scale production. Let's look at a few technological solutions that manufacturers offer. The most affordable and suitable for printing simple models from plastics such as PLA or PETG is a solution based on budget printers such as CrealityEnder-3. These are very simple models that are installed on racks.

3D printing farm in Creality3D

Among the advantages of this solution: the ability to quickly deploy it in almost any suitable place, quickly increase the number of printers to increase the productivity of the farm. Of the minuses: the impossibility of printing with engineering plastics, the need to manually remove models, as well as the impossibility of remote monitoring and control over printing.

The next level of small-scale production organization is a printer farm capable of handling the most diverse tasks. For example, a farm built on the basis of Raise3DPro2 3D printers. Each such printer is equipped with two extruders, a closed camera and a built-in webcam for remote monitoring. On such printers, you can easily change the "manufactured" models. Today it can be simple plugs made of PLA plastic, and tomorrow it will be complex models made of carbon fiber or nylon gears. The disadvantages include only the high cost of equipment and the remaining need to shoot finished models manually.

3D printing farm at 2050.AT

Another solution is a printer-based farm with two independent IDEX type extruders. In the photo below you can see a similar farm based on Raise3DE2 printers. The solution has the added benefit of increasing productivity: each printer can print two identical models at the same time instead of one. The disadvantages remain the same: the need to shoot models manually and the rather high cost of the printers themselves. The benefits are the same - plus increased productivity.

3D printing farm at 3D.RU

If small-scale production is one of the possible applications for the previous solutions, then the printer that will be discussed next is created specifically for this task. The TierTimeX5 model is a mini conveyor with 12 interchangeable pads for long continuous printing. After the printing of the model or models is completed, the platform moves off the platform, a new one takes its place, after which printing can continue. In this case, both the same and different models can be printed. The printer also supports a print queue: different employees can send jobs to it, they will be executed as they arrive. Models from the sites will still have to be removed manually, so it’s too early to talk about full automation.

Of the minuses, it is worth noting the high cost of equipment and its low productivity. For comparable money, you can buy up to 10 printers of the same level, but their performance will be 10 times greater. True, they will take up much more space; keeping track of 10 printers is also much more difficult than keeping track of one. At the same time, it should be taken into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks down, you are left without equipment for an indefinite period of time - depending on the repair time.

Another printer option designed specifically for low volume production is the Creality3DCR-30 PrintMill ribbon type. The printer is created on the principle of a conveyor belt: models can be printed endlessly and fall into the box themselves, you just have to remember to change the plastic. Human participation is minimal, but due to the complex design, where printing is carried out at an angle of 45 °, there are many restrictions on the geometry of models, the location of supports and other nuances. But this is the most automated process of all possible today, especially given the modest budget for the purchase.

In an effort to fully automate small-scale production, manufacturers and builders of 3D printing factories or small-scale production add various equipment. In particular, to automate the removal of models, “cobots” (collaborative robots) are used, which are programmed to remove the platform along with the printed model and install a new printing platform, after which printing resumes. This is an insanely expensive solution that does not really improve productivity and can only be justified in countries with incredibly high wages.

| 3D Printing Farm VooDooManufacturing | 3D Printing Farm VooDooManufacturing |

Another possible solution for the complete automation of the small-scale production process using 3D printing was presented by the Latvian company MassPortal. She created a portal system for this task. The printers are installed in a rack, where the manipulator arm removes the platforms with finished models and transfers them to a special storage rack. The solution almost completely automates the entire process, but the cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks.

Photopolymer Solutions

All of the solutions discussed earlier in this article were based on FDM/FFF technology, which involves printing with molten plastic filament.

Recently, photopolymer 3D printers are gaining popularity, which print on the principle of forming a model from a liquid photopolymer. From the point of view of small-scale production, this technology has a number of advantages. First of all, performance. The technology allows you to illuminate the entire layer at once - in this way, the printer spends the same time printing one or any other number of models that fit into the construction area. Whereas earlier desktop photopolymer printers had modest pad sizes and, accordingly, their production potential was not very high, already this year a number of models with a large print area and high detail were introduced, for example, the PhrozenSonicMega 8K printer model.

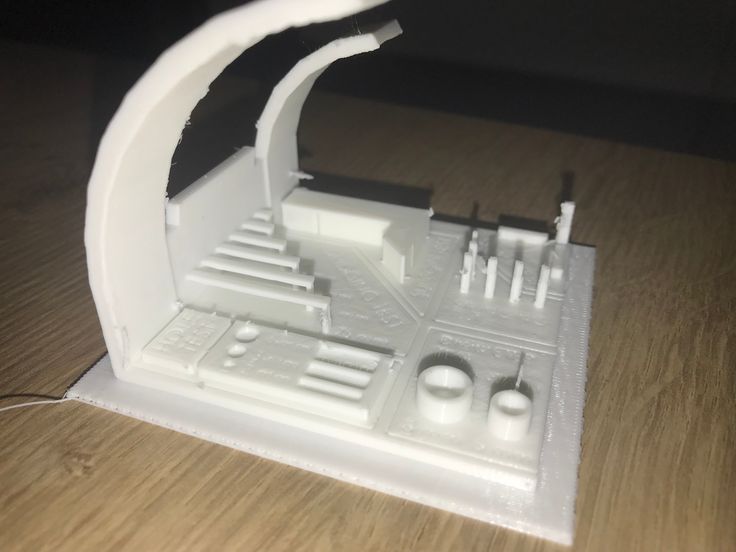

Printing models in the photo lasted 3.5 hours. It is quite easy to calculate the performance of the printer. In this case, even one printer is a mini-factory and is capable of solving serious production problems. Also important is

but note that, unlike FDM / FFF printers, all photopolymer 3D printers are initially universal - you can print on them with any resins available on the market or even those that will appear in the future.

It should come as no surprise that the creators of 3D printing farms were inspired by the huge opportunities that were opening up and many small-scale productions were created based on such equipment. For example, the British company Photocentric has opened the largest such center in Europe based on its LCMmagna model. It came in handy during the pandemic, when it was necessary to urgently establish the production of elements necessary for the treatment of patients, for example, replacement valves for ventilators.

Unfortunately, it can't do without significant disadvantages, but let's talk about everything in order. First of all, this is the process of post-processing of printed models, which consists of washing the models in alcohol and subsequent illumination in a UV camera. Without these procedures, the model will not acquire the final quality. Processes cannot be automated, they require a lot of labor — this must be taken into account when choosing equipment. In addition, it should be taken into account that the cost of photopolymer resin is on average 3 times more than plastic for 3D printing, respectively, the cost of the resulting products will be higher. Another factor that must be taken into account is the need for special preparation of the installation site for printers, the availability of high-quality ventilation and the possibility of waste disposal.

Summary

In summary, even a single 3D printer is a suitable solution for small-scale production. 3D printing is ideal for small-scale production. The main thing is to choose the right equipment, calculate the payback period and the cost of the final product. Based on this, it will be possible to draw a simple conclusion whether you solve your problems or create new problems.