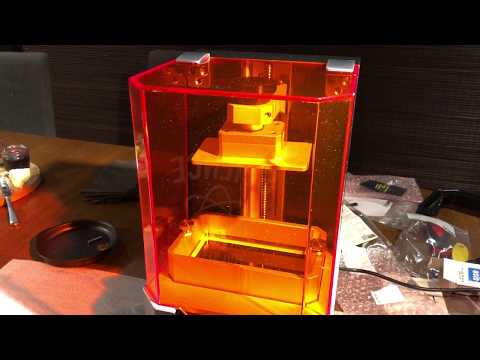

Prusa sl1 resin 3d printer

Original Prusa SL1S SPEED | Original Prusa 3D printers directly from Josef Prusa

See the Original Prusa SL1S Speed in action!

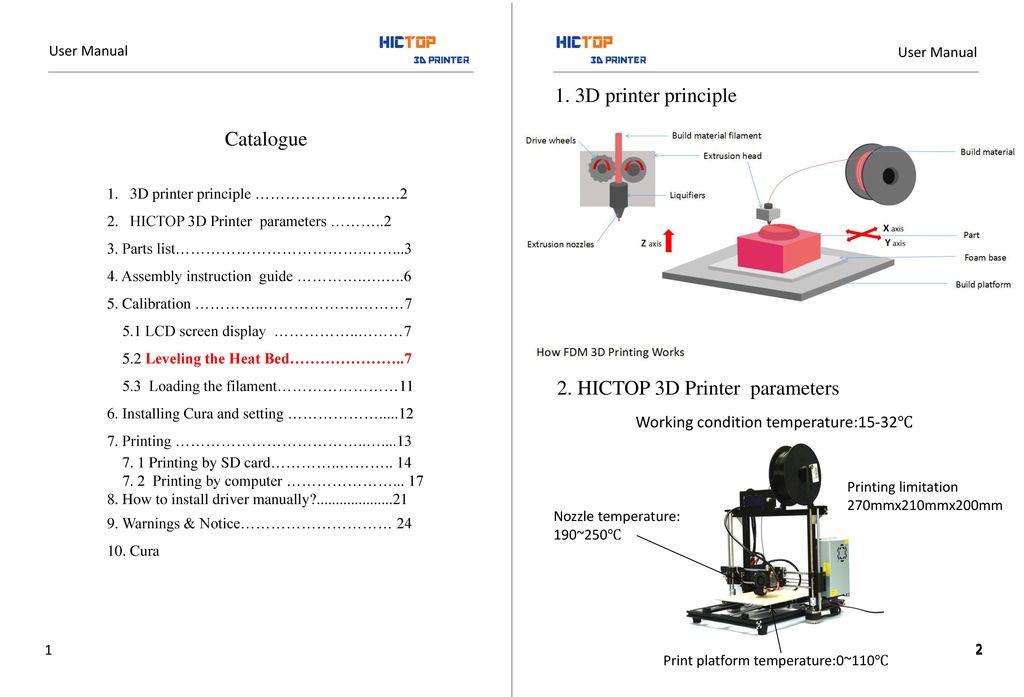

FFF vs SLA Basic Comparison

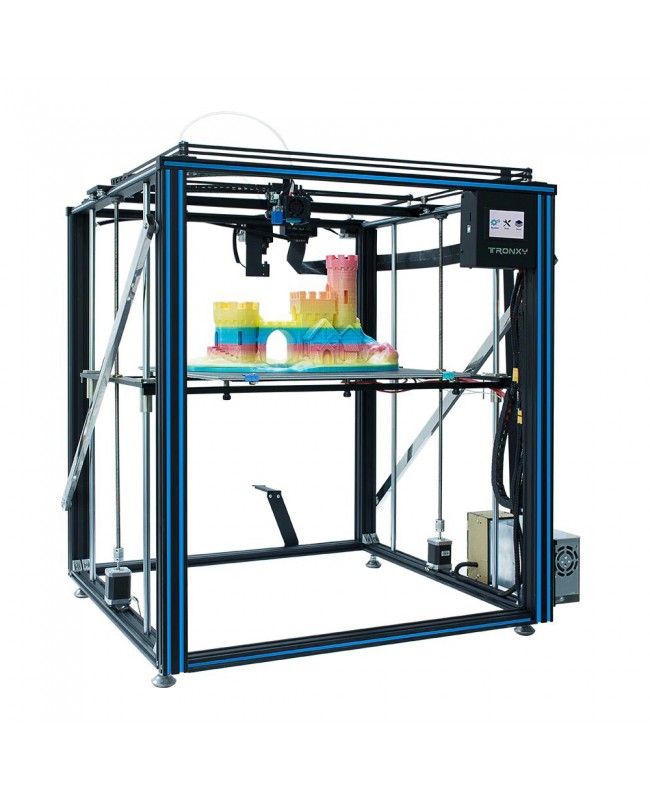

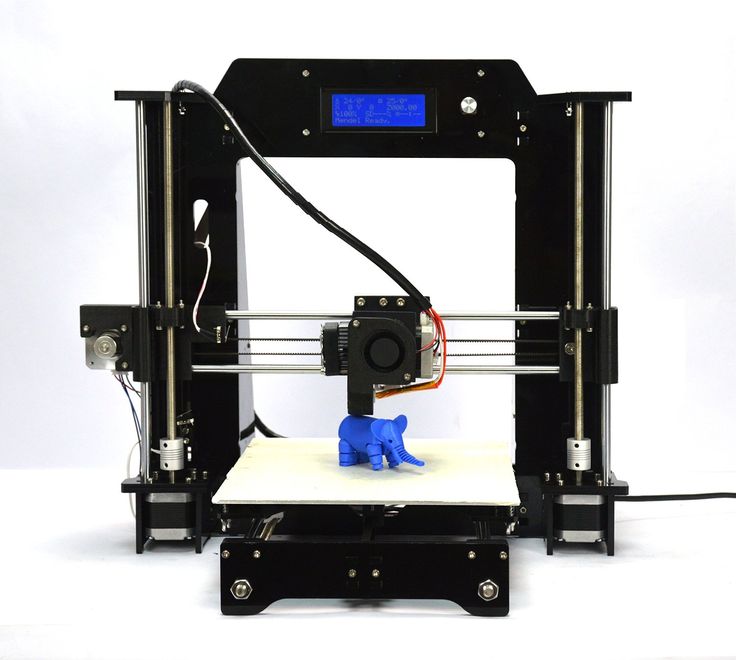

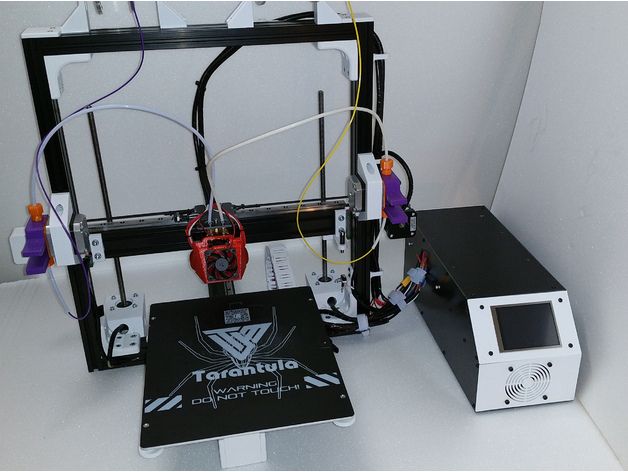

Original Prusa i3 MK3S+ (FFF printer)

Prints 3D objects by extruding melted plastic, compatible with materials such as PLA, PETG, ABS, flexible filaments and many more

Layer height 0.05 mm - 0.15 mm

Maximum print area size 25 x 21 x 21 cm (9.84 x 8.3 x 8.3 in)

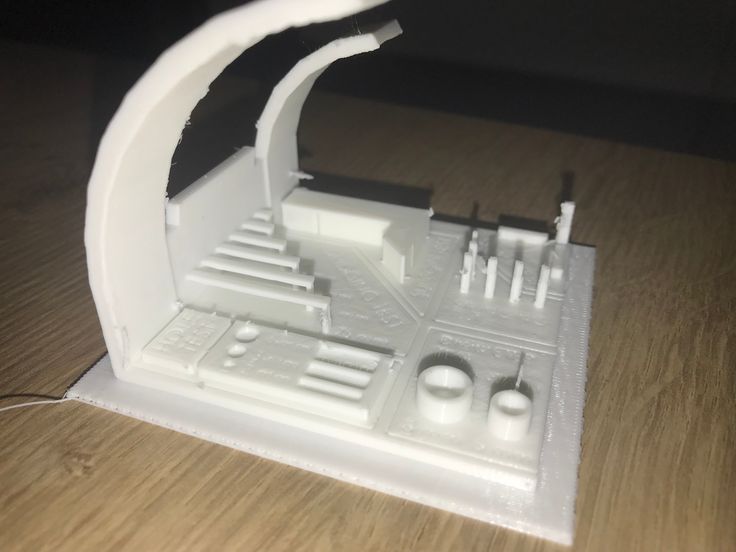

Great for: prototyping, printing toys, RC models or mechanical parts

Post-processing: possible, depends on the type of used materials. Possible sanding, gluing, painting

Original Prusa SL1S (SLA printer)

Uses UV light pattern to cure layers of resin. Photo polymers are cured layer by layer to create the final object

Min layer height: 0.01 mm, recommended layer height: 0.025 - 0.1 mm

Maximum print area size: 127 × 80 × 150 mm (5 × 3. 14 × 5.9 in)

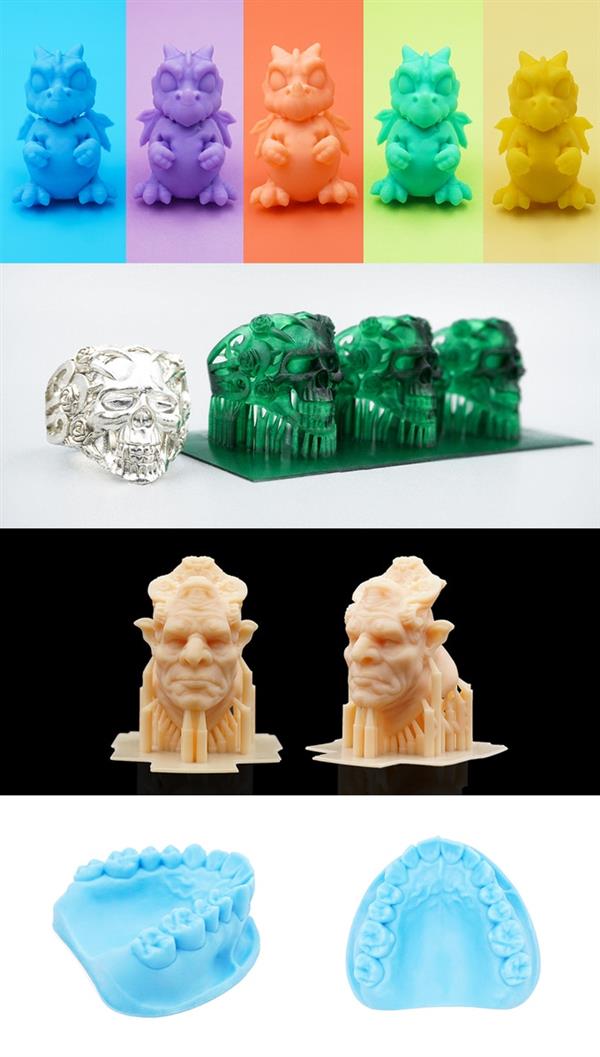

Great for: prototyping, jewelry, art models, medical use (e.g. dental molds for casting)

Post-processing: easy, models can be glued, sanded and painted

Main Features

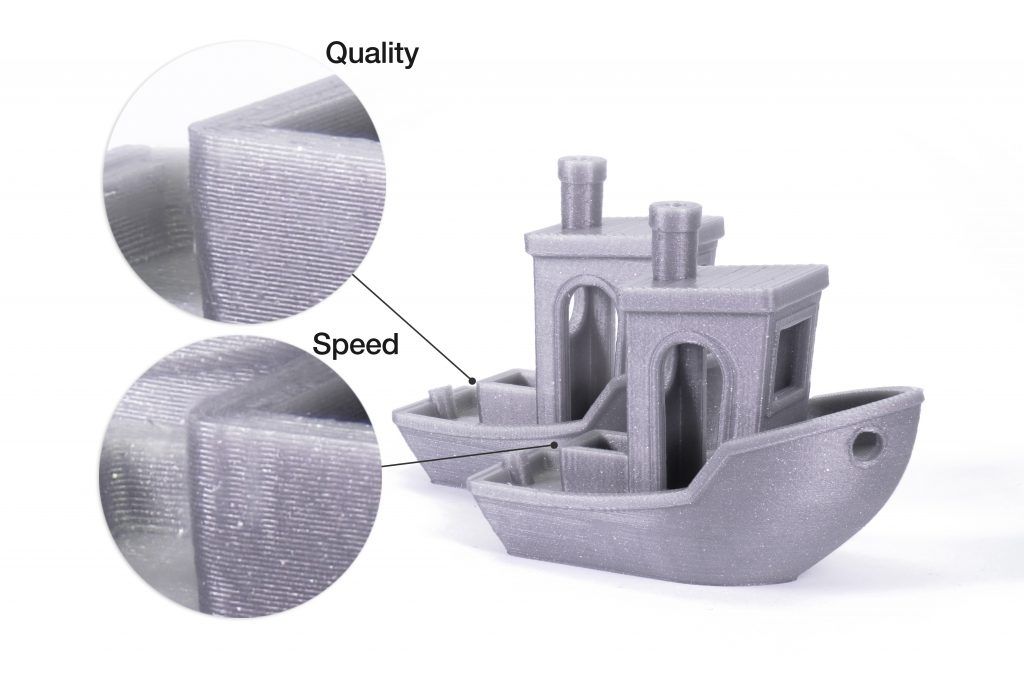

Great Print Quality

The SL1S features a new 5.96'' monochrome LCD with a physical resolution of 2560×1620p. Taking advantage of the completely reworked optics and the new monochrome display technology, the SL1S offers a vastly improved print quality compared to its predecessor.

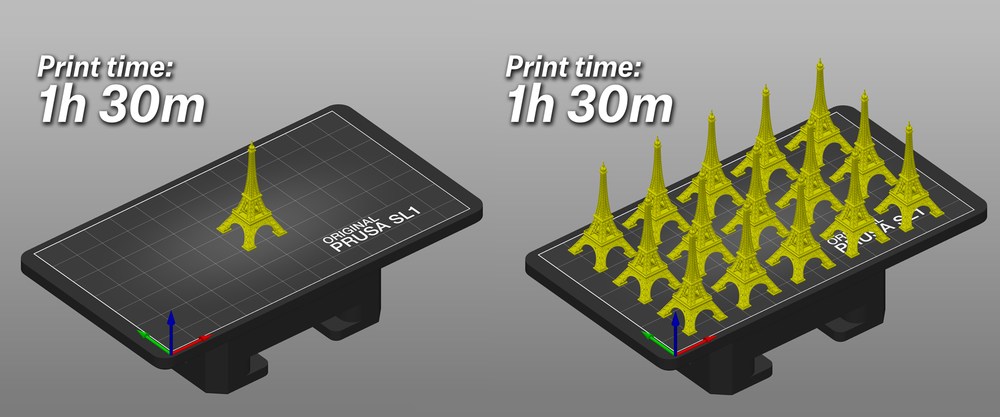

Our Fastest Printer Ever

Configure your 3D printer with ease and see previews of sliced models before you start printing! Thanks to the 2.8’’, 240×320 LCD screen with 65.000 colors, every option is just a few clicks away.

Touch Controls and Network Features

Upload your print files over network and perform over-the-air firmware updates. The SL1S comes packed with modern technologies that make 3D printing easier, safer and more convenient than ever before. On-screen wizard will guide you through the whole setup process. You will be ready to print in no time!

You will be ready to print in no time!

25% Bigger Print Area

The SL1S features a 25% bigger print area compared to the SL1. The largest object that fits in the 127×80×150mm print area can finish under 4 hours (0.05mm layer height) or in 2 hours with 0.1mm layer height. This is also possible thanks to the nearly three times faster tilt compared to the SL1.

For Newcomers and Professionals

The SL1S is more than just a machine for producing figures and statues. With professional-level print quality, extensive documentation, low running costs and 24/7 tech support, the SL1S is perfect for newcomers and professionals alike. Its predecessor, the SL1, already found its way to hospitals and industrial companies.

High-Quality Materials and Rigid Body

We have built the Original Prusa SL1S 3D printer around a rigid, heavy aluminum body, which minimizes vibrations and ensures the best possible printing performance even when printing thin and highly detailed geometry. The SL1S features a quick-release mechanism, which maintains the Z-axis calibration.

The SL1S features a quick-release mechanism, which maintains the Z-axis calibration.

Smart Resin Tank

The new tank from high-quality graphite-reinforced PA6 composite comes with a practical opaque lid that protects the resin from being cured by daylight. Automatic Resin Sensor prevents resin from overflowing or running out mid-print.

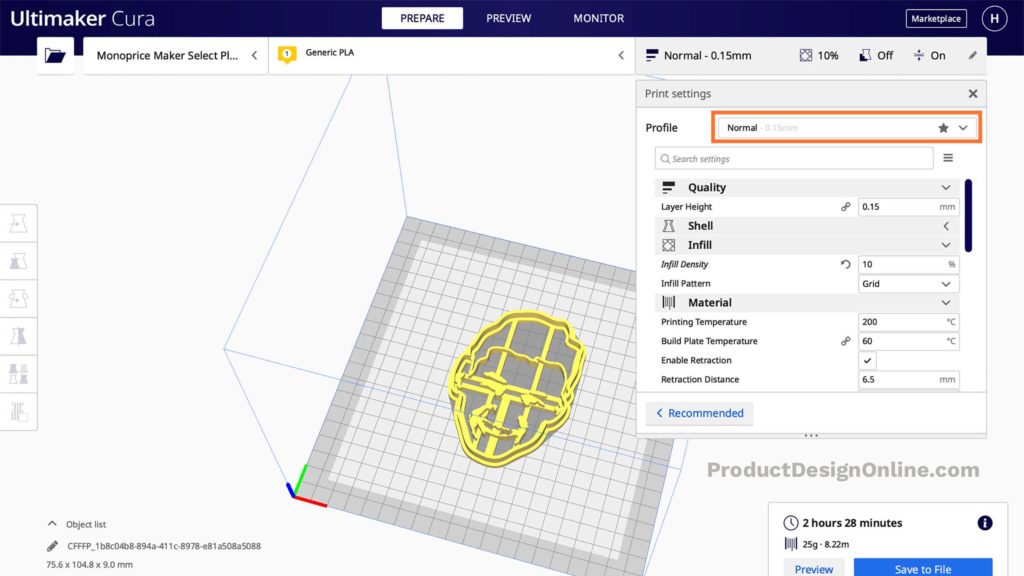

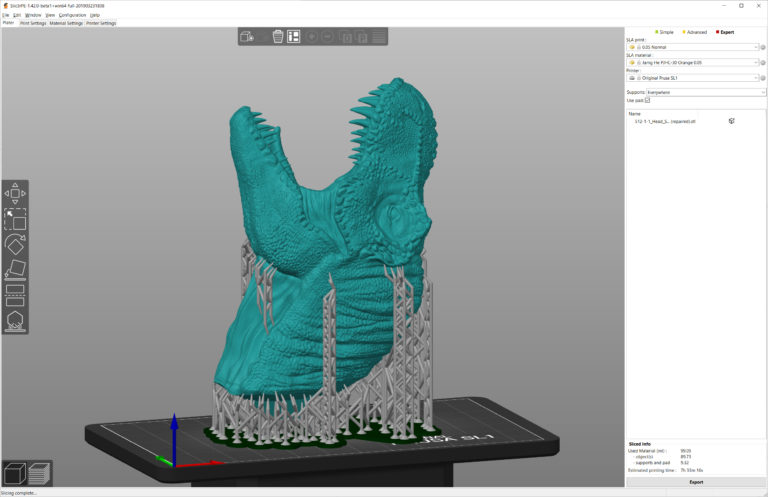

Slice with PrusaSlicer

The SL1S is fully supported in the latest releases of PrusaSlicer, our internally developed and regularly updated slicing software. Take advantage of hollowing, automatic support generation, easy object manipulation and many other tools. PrusaSlicer also contains factory-tested profiles for dozens of resins.

Original Prusa Curing and Washing Machine CW1S

CW1S is a post-processing device for resin-based 3D prints. The CW1S is a 4-in-1 device, which makes the otherwise long and messy process a breeze. What it can do?

Washing

The finished print has to be washed to remove the uncured resin from its surface. CW1S uses a stainless steel tank for isopropyl alcohol and a magnetic propeller. This method is less aggressive compared to ultrasonic cleaning and works very well even with very small objects.

CW1S uses a stainless steel tank for isopropyl alcohol and a magnetic propeller. This method is less aggressive compared to ultrasonic cleaning and works very well even with very small objects.

Drying

Drying a washed model is yet another feature of the multipurpose CW1S. Before the washed model is cured with UV-light, it has to be dried in order to avoid resin residue stains.

Curing

Curing the model with UV-light is an essential part of the resin printing process. Printed objects are usually soft, so treating them with UV light gives them optimal surface properties.

Resin Pre-heat

CW1S can preheat the resin before printing it, thus getting it to the ideal printing temperature and state for the best performance of the SL1S and the resin itself.

Order CW1S in bundle with SL1S Order stand-alone CW1S

Case Studies

Medicine (Surgery)

Neu3D Laboratories, based in Lefkosa, TRNC, operates under the Experimental Medical Research Centre of Near East University. The institute uses 3D printing to advance surgery methods. The SL1 is used to print test models for flexible bronchoscopy simulation.

The institute uses 3D printing to advance surgery methods. The SL1 is used to print test models for flexible bronchoscopy simulation.

Medicine (Dental)

Asana Dental uses a special suction system designed by Dr. Vit Payma and Lukas Pekarek. The system is printed on the SL1 and helps dentists to reduce risks during the Covid-19 pandemic by eliminating potentially hazardous aerosol.

Professional Models

Professional-grade miniatures by David Damek are wonderful recreations of their real-life counterparts. Intricate details and high print quality are an absolute must. "Printing with the SL1 made my work much easier and opened doors to unlimited creativity," Damek says.

Jewelry

SLA printers are precise enough to print even the smallest details. This makes them useful for the process of designing and manufacturing casting jewelry models. SL1S is a perfect match for jewelry professionals all around the world.

Sample Prints

Reviews

Awards

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

Get the Original Prusa SL1S Speed now!

Original Prusa SL1S SPEED 3D printer

The Original Prusa SL1S SPEED is here! Compared to the original SL1, the new SL1S offers vastly improved print quality, a 25% larger print area, and up to three times faster printing with only 1.4 second exposure time per layer. Short exposure times combined with the built-in tilt mechanism enable you to print up to a 150mm tall object in three hours.

The SL1S is the perfect choice for producing extremely detailed 3D prints - fast! No matter whether you want to produce highly detailed sculpts, design and prototype, or you need a reliable workhorse for your workshop or lab, the SL1S delivers outstanding results across the board. We also offer an upgrade kit for your SL1.

We also offer an upgrade kit for your SL1.

Main Features

Great Print Quality

The SL1S features a new 5.96'' monochrome LCD with a physical resolution of 2560×1620p. Taking advantage of the completely reworked optics and the new monochrome display technology, the SL1S offers a vastly improved print quality compared to its predecessor.

Our Fastest Printer Ever

With our custom-made optics system and completely reworked UV LED panel, the SL1S can easily reach a 1.4 second exposure time per layer with standard 405nm resins. This is especially useful for small-scale production or prototyping projects - you can print more in less time.

High Printing Speed, Amazing Details

Featuring a high-resolution 5.96'' LCD monochrome display (2560×1620p) and reworked optical system with four times more powerful UV LED panel, the SL1S produces even more detailed 3D prints. Common 405nm resins require only 1.4 seconds of exposure time per layer. Short exposure times enable much easier use of advanced materials.

Common 405nm resins require only 1.4 seconds of exposure time per layer. Short exposure times enable much easier use of advanced materials.

High-Quality Materials and Rigid Body

We have built the Original Prusa SL1S 3D printer around a rigid, heavy aluminum body, which minimizes vibrations and ensures the best possible printing performance even when printing thin and highly detailed geometry. The SL1S features a quick-release mechanism, which maintains the Z-axis calibration.

For Newcomers and Professionals

The SL1S is more than just a machine for producing figures and statues. With professional-level print quality, extensive documentation, low running costs and 24/7 tech support, the SL1S is perfect for newcomers and professionals alike. Its predecessor, the SL1, already found its way to hospitals and industrial companies.

Full Support in PrusaSlicer

The SL1S is fully supported in the latest releases of PrusaSlicer, our internally developed and regularly updated slicing software. Take advantage of hollowing, automatic support generation, easy object manipulation and many other tools. PrusaSlicer also contains factory-tested profiles for dozens of resins.

Take advantage of hollowing, automatic support generation, easy object manipulation and many other tools. PrusaSlicer also contains factory-tested profiles for dozens of resins.

Touch Controls, Network Features and more

Upload your print files over network and perform over-the-air firmware updates. The SL1S comes packed with modern technologies that make 3D printing easier, safer and more convenient than ever before. On-screen wizard will guide you through the whole setup process. You will be ready to print in no time!

Open-source with Support for 3rd party Resins

Just like all the Original Prusa i3 3D printers, the SL1S is also completely Open Source! This means (among other things) full support for 3rd party resins (405nm). No proprietary vats, resins or FEP films! You can buy 3D printing supplies anywhere you want.

Awards & Press Reviews

Thanks to all of these (and many other) features, the MK3S became the “Best 3D Printer” according to ALL3DP. The MK3S is also the highest-rated 3D printer, and the “Editor’s Choice”, in the prestigious MAKE:MAGAZINE’s Digital Fabrication Guide 2019. The MK3S is also featured in TechRadar's Best 3D printers of 2021 as The best all-around 3D printer. NY Times wrote that "...of the 11 printers we’ve tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints." According to ZDNet, the MK3S is "The best pro-sumer 3D printer under 1000 USD."

The MK3S is also the highest-rated 3D printer, and the “Editor’s Choice”, in the prestigious MAKE:MAGAZINE’s Digital Fabrication Guide 2019. The MK3S is also featured in TechRadar's Best 3D printers of 2021 as The best all-around 3D printer. NY Times wrote that "...of the 11 printers we’ve tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints." According to ZDNet, the MK3S is "The best pro-sumer 3D printer under 1000 USD."

Specifications

Technical Parameters

- Display type Monochrome LCD with high-performance lens system

- LCD resolution 5.96'', 2560×1620p

- LCD lifespan / warranty 2000 hours

- Print volume size 127×80×150 mm

- Layer exposure time 1.3 - 2.4 seconds depending on material and layer height

- Tilt time 3 seconds

- Supported layer heights 0.

025-0.1 mm

025-0.1 mm - Minimal layer height 0.01 mm

- Supported materials UV sensitive liquid resin (405nm), long-exposure materials supported

- Connectivity: USB, Wi-Fi, LAN

- SL1S printer box dimensions: 320×450×500 mm (X×Y×Z)

- SL1S dimensions: 8.8×9.3×15.7 in / 225x237x400 mm (X×Y×Z)

- SL1S energy consumption while printing: ~100W (±5W)

List of Features

- Quick-release platform - maintains calibration. No need to recalibrate the printer when the platform with the print is removed.

- Assisted Wizard for quick and easy setup and calibration

- Motorized tilting bed - prevents layer shifts, stirs the resin, enables faster printing, improves reliability

- Resin tank with non-proprietary FEP films - easy and cheap replacement, low running costs

- Silent operation with Trinamic drivers (auto-homing function)

- Advanced LCD cooling system improves performance and extends the life of internal components

- Rear fan with a carbon filter to minimize odors around the printer

- Safety features: resin level sensor, safety vat under the tilt mechanism to protect the internal parts against minor resin spills

- Fully-featured network interface: control your printer through your web browser

- Free 0,5kg bottle of Prusament Resin Tough included

Original Prusa CW1S

CW1S is a post-processing device for resin-based 3D prints. The CW1S is a 4-in-1 device, which makes the otherwise long and messy process a breeze. What it can do?

The CW1S is a 4-in-1 device, which makes the otherwise long and messy process a breeze. What it can do?

WASHING

The finished print has to be washed to remove the uncured resin from its surface. CW1S uses a stainless steel tank for isopropyl alcohol and a magnetic propeller. The magnetic propeller movement stirs the liquid, so it gets to every part of the model. This method is less aggressive compared to ultrasonic cleaning and works very well even with very small objects.

DRYING

Drying a washed model is yet another feature of the multipurpose CW1S. Before the washed model is cured with UV-light, it has to be dried in order to avoid resin residue stains.

CURING

Curing the model with UV-light is an essential part of the resin printing process. Printed objects are usually soft, so treating them with UV light gives them optimal surface properties.

Resin Pre-heat

Resins tend to change their state while being stored, that is the reason to shake the bottle with resin well before printing. However, CW1S can also preheat the resin before printing it, thus getting it to the ideal printing temperature and state for the best performance of the SL1S and the resin itself.

However, CW1S can also preheat the resin before printing it, thus getting it to the ideal printing temperature and state for the best performance of the SL1S and the resin itself.

Order CW1S in bundle with SL1S Order stand-alone CW1S

Warranty info

The pre-assembled Original Prusa SL1S printer is covered by a 24-month warranty for end customers in the EU and 12 months for businesses and non-EU customers.

Wear and tear category components and consumables are excluded from this warranty. The warranty period begins with the day when the customer receives the goods.

WARNING: The exposure display and the FEP foil fall into the category of normal wear and tear components, which are not covered by our standard warranty. Instead, the warranty of the exposure display covers a maximum of 2000 hours of printing - the SLA 3D printing process on the Original Prusa SL1S is considered the standard way of using and wearing the original display. The warranty of the FEP foil covers 10 cycles (print jobs). When used properly in accordance with the instructions in the official guides (such as the SL1S 3D printing handbook), the life expectancy of the FEP foil is several times longer.

When used properly in accordance with the instructions in the official guides (such as the SL1S 3D printing handbook), the life expectancy of the FEP foil is several times longer.

Neither the Seller's liability for defective products nor the quality warranty applies to printers or parts damaged by handling, which is in conflict with the instructions and recommendations in the official manuals and guides, or improper handling caused by unofficial modifications, such as modifications to hardware or software.

Top 10 Resin 3D Printers of 2022 (each price range)

Resin 3D printers use SLA, DLP, or LCD technology to cure liquid resin, producing sharp, high-resolution prints at high speed. You'd be surprised how many industries use these machines, from jewelry to dentistry.

That's why we've ranked the best resin printers in every price range, from $150 to $5,000+, so you can find the perfect machine for your hobby projects or business.

Contents

- Best cheap resin 3D printers (under a thousand dollars)

- Anycubic Photon Mono is a great low cost resin 3D printer

- ELEGOO Mars Pro / Mars 2 Pro is the best cheap resin 3D printer

- Anycubic Photon Mono 4K

- Phrozen Sonic Mini 4K

- Elegoo Mars 3

- Elegoo Saturn

- Phrozen Sonic Mighty 4K

- Anycubic Mono X is a great budget photopolymer 3D printer

- Curing and Cleaning Stations

- Anycubic Wash & Cure.

- Elegoo Mercury Plus

- Prusa SL1S Speed

- Peopoly Phenom mSLA Printer - large photoresin 3D printer with huge build volume

- Buyer's Guide - What to Consider When Buying a

- RGB Photopolymer 3D Printer vs. LCD Screens - Differences, Advantages/Disadvantages

- Post-processing equipment

- How does a photopolymer 3D printer work?

- Resin 3D printing technologies

- SLA

- DLP

- MSLA/LCD

- LFS

- DLS

- How much does a resin 3D printer cost?

- Resin 3D Printer Applications

- Resin 3D Printing vs. Filament (FDM)

- Resin 3D Printing vs Selective Laser Sintering (SLS)

- FAQ

Best cheap resin 3D printers (under a thousand dollars)

Anycubic Photon Mono is a great low cost resin 3D printer

- Price: $249

- Assembly volume: 120 x 80 x 165 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 6″ 2K monochrome LCD

- XY resolution: 51 microns

- Speed: 50 mm/h

- Cleaning/Cure: Anycubic Washing and Curing Station

The new Anycubic Photon Mono printer adds to Anycubic's reputation as a premium manufacturer of affordable LCD 3D printers. Where you used to pay thousands for an entry-level SLA printer, now printers like the Mono offer great resolution at lower than ever prices. The Photon Mono is a new upgrade from previous models, including greatly increased resin printing speed and other accuracy improvements.

Where you used to pay thousands for an entry-level SLA printer, now printers like the Mono offer great resolution at lower than ever prices. The Photon Mono is a new upgrade from previous models, including greatly increased resin printing speed and other accuracy improvements.

It is equipped with a high quality 2K LCD screen, which is more than enough for most resin projects. But for higher resolution and better quality for really complex figurines or miniatures, we recommend getting the Anycubic Mono X with its 4K LCD screen, which we'll cover in more detail later in this article.

Perhaps the most notable upgrade is speed - up to a maximum of 50mm/h from previous levels of around 20mm/h on older Photon models. Anycubic has also upgraded the Z axis for more stable printing and better surface finish with a new dual linear motion system.

Overall, we rate the Anycubic Photon Mono, as well as its competitors in the Sonic Mini and Elegoo Mars lineups, as the best cheap photopolymer 3D printers. But if you have a few hundred dollars to spare and need a better resolution, go for Mono X.0099 anycubic photon mono cheap photopolymer 3d printer.

But if you have a few hundred dollars to spare and need a better resolution, go for Mono X.0099 anycubic photon mono cheap photopolymer 3d printer.

ELEGOO Mars Pro / Mars 2 Pro - Best Cheap Resin 3D Printer

- Price: $250 / $280 - Available on Amazon here

- Print volume: 129 x 80 x 160 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 6.08″ 2K monochrome LCD

- XY resolution: 50 microns

- Speed: 30-50 mm/h

- Cleaning/Cure: Elegoo Mercury Plus/X 9 Wash and Curing Station0010 The

Elegoo Mars is another cheap resin 3D printer, like the Anycubic Photon, which shocked manufacturers with how good it really is. As LCD 3D printing becomes more affordable, accurate and fast, Elegoo is taking advantage of this advantage to create a low cost resin printer that delivers quality and consistency.

An upgraded version of the Mars Pro printer is more precise with an updated Z-axis linear guide system that smoothes layers and makes each individual layer line less obvious, improving surface quality. There are also a number of safety improvements, such as a silicone seal that prevents resin from leaking on the 3D printer cover.

There are also a number of safety improvements, such as a silicone seal that prevents resin from leaking on the 3D printer cover.

The printer is equipped with a 2K LCD projector and the minimum layer height is only 0.01mm. Elegoo Mars Pro comes with its own 3D resin slicer called CHITUBOX and has a nice max build volume of 115 x 65 x 150mm. It's also fast enough for a budget photopolymer 3D printer.

Elegoo also sells some of the cheapest resins on the market. You can buy them here.

Anycubic Photon Mono 4K

- Price: $289

- Print volume: 165 x 132 x 80 mm

- Screen resolution: 3840 x 2400

- Screen size: 6.23" 4K monochrome LCD

- XY resolution: 35 microns

- Speed: 50 mm/h

- Cleaning/Cure: Anycubic Washing and Curing Station

Equipped with a 6.23″ 4K high-resolution monochrome LCD, the Anycubic Photon Mono 4K is an affordable, performance-oriented 3D printer for the discerning but budget-friendly resin maker.

The construction volume of 165 x 132 x 80 mm is small by FDM standards. Although, as befits resin 3D printers, its volume is slightly larger than most, and it certainly makes up for it with exceptional precision and detail thanks to its 35 micron XY resolution.

In testing, Anycubic Photon Mono 4K proved to be ready to work with any highly detailed models and decorative elements, even quite large ones. Articulated parts, board game figures and even articulated miniatures, the Mono 4K does it all.

Cast on a few copies of a small part and the Anycubic Photon Mono 4K is ready, making it suitable for small businesses and hobbyists alike. The print speed is up to 50mm/h and the printer easily prints layers in less than 2 seconds.

From a usability standpoint, we'd like to see desirable features such as resume printing and Wi-Fi connectivity. Anycubic's Photon Workshop slicing software is a functional, if unremarkable, slicer. Luckily, the Anycubic Photon Mono 4K's compatibility with third-party software such as Lychee and ChiTuBox means you don't have to be tied to Anycubic's slicing software.

If you're after impressive 4K screen fidelity, the Anycubic Photon Mono 4K's delivers hassle-free, high-resolution printing at a great price.

Phrozen Sonic Mini 4K

- Price: $349 - Available at Phrozen official store here / Available on Amazon here

- Print volume: 134 x 75 x 130 mm

- Screen resolution: 3840 x 2160 pixels

- Screen size: 6.1″ 4K monochrome LCD

- XY resolution: 35 microns

- Speed: 80 mm/h

- Cleaning/Cure: Phrozen Cure and Phrozen Ultra-Sonic Cleaner

At an affordable price, the Phrozen Sonic Mini features a powerful 4K 6.1-inch LCD screen that delivers 35µm quality and two-second layering speed.

This is a powerful, inexpensive photoresin 3D printer with everything you need to print, and while if you need more print volume you can go for the Sonic Mighty 4K (more on that later!), if size isn't a big deal, the Sonic Mini 4K is more than fit.

Phrozen claims the Sonic Mini 4K is ideal for resin mold printers, as well as miniatures and desktop models.

Elegoo Mars 3

- Price: $349

- Print volume: 143 x 90 x 165 mm

- Screen resolution: 4098 x 2560 pixels

- Screen size: 6.6″ 4K monochrome LCD

- XY resolution: 35 microns

- Speed: 1.5-3 seconds per layer

- Cleaning/Cure: Elegoo Mercury Plus/X 9 Wash and Curing Station0010

Featuring an Ultra 4K resolution LCD screen and Elegoo's latest mSLA technology, Elegoo Mars now has 30% more accurate XY (35µm) resolution than Mars 2, as well as a 37% larger build volume. For an extra $100, this is a very attractive deal for those looking to get higher-end resin 3D printing.

Other features include an improved light source for more uniform resin curing - even over a larger build area. Built-in 36 high-power LED lamps and a new lens provide higher accuracy, as well as an improved heat sink and cooling fan, which extends the life of the printer and enhances its durability.

Elegoo Saturn

- Price: $499

- Print volume: 192 x 120 x 200 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 8.

9″ 4K monochrome LCD

9″ 4K monochrome LCD - XY resolution: 50 microns

- Speed: 30-40 mm/h

- Cleaning/Cure: Elegoo Mercury Plus/X Cleaning and Curing Station

Featuring an 8.9" 4K monochrome LCD screen for fast layer curing, the Elegoo Saturn greatly outperforms the standard models by printing 60% faster than the Elegoo Mars Pro, printing a layer every 2-3 seconds.

You get a number of other key improvements for your money, the most notable of which is a larger build area that turns the Elegoo Saturn into a 3D printer for printing large hard resin models, as well as the ability to print multiple small models at the same time in one batch.

Improved precision with the Saturn's double linear Z-axis guide makes the Saturn printer more stable than ever, ensuring accurate and uniform printing. And in case you're a fan, the Elegoo Saturn also has an Ethernet port on the back to keep things fast and efficient.

Phrozen Sonic Mighty 4K

- Price: $549

- Printing area: 200 x 125 x 220 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 9.

3″ 4K monochrome LCD

3″ 4K monochrome LCD - XY resolution: 52 microns

- Print speed: 80 mm/h

- Cleaning/Cure: Phrozen Cure and Phrozen Ultra-Sonic Cleaner

If you're looking for an affordable resin 3D printer with a large enough footprint for mass production of models or large resin prototypes, the Phrozen Sonic Mighty 4K even outsizes the Elegoo Saturn.

With a strong and reliable Z-axis that delivers print accuracy up to a maximum print height of 22 cm, it offers good print quality, especially with the 4K resolution LCD screen. It also prints fast, with two-second layer printing.

While Phrozen recommends using proprietary 3D printer resins, the Sonic Mighty 4K is compatible with most third-party resins (but check first). So if you have spare resins left over from a previous 3D printer, you should be fine.

Anycubic Mono X is a great budget photopolymer 3D printer

- Price: $599

- Printable area: 192 x 120 x 245 mm

- Screen resolution: 3840 x 2400 pixels

- Screen size: 8.

9″ 4K monochrome LCD

9″ 4K monochrome LCD - XY resolution: 50 microns

- Speed: 60 mm/h

- Cleaning/Cure: Anycubic Wash & Cure Statio

Anycubic's original budget Photon 3D resin 3D printer is still one of the most popular 3D printers in the world, and now the Mono X proves that the company can compete with higher-end machines. Mono X can print 3 times faster than standard photopolymer printers at speeds up to 60mm/h, and thanks to the 4K LCD screen, it can create very precise and sharp details.

In addition, the upgraded Mono X Z-axis improves stability and makes the surface smooth, unaffected by external factors such as vibrations. The result is jewelry models and miniatures where the layer lines are barely visible.

Another big benefit is WiFi printing, so you don't have to keep unplugging your SD or USB card when printing multiple designs throughout the day. The large 3.5" touch screen makes it easy to navigate, and with a larger build volume, you can print multiple jewelry models or desktop miniatures at the same time. Overall, this is one of the best budget photopolymer 3D printers out there.

Overall, this is one of the best budget photopolymer 3D printers out there.

Curing and Cleaning Stations

Since washing and curing is an inevitable part of resin 3D printing, we have compiled some of the best washing and curing stations to include in your printing system to save you the hassle and mess of subsequent printing. processing.

Anycubic Wash & Cure.

Anycubic Wash & Cure is a versatile station compatible with the vast majority of photoresin printers. Thanks to Anycubic's recent price cut, Wash & Cure is under $100.

The flush mode has adjustable flush cycles including 2, 4 and 6 minutes. Curing mode uses a broad spectrum UV light of 356 nm and 405 nm mounted on a 360° rotating platform to ensure uniform curing of any and all prints 115 x 65 x 165 mm or smaller.

Anycubic has simplified the entire rinsing and curing process with a “set it and forget it” design—select rinsing or curing on the touch button interface and you're done. Station blocks 99.95% UV radiation and has an auto-pause feature if the cap is accidentally knocked off. The station has an adjustable bracket that can be fixed on the Anycubic platform if you are working with a Photon Mono series printer.

Station blocks 99.95% UV radiation and has an auto-pause feature if the cap is accidentally knocked off. The station has an adjustable bracket that can be fixed on the Anycubic platform if you are working with a Photon Mono series printer.

Elegoo Mercury Plus

Another all-in-one station, but this time from Elegeoo, the Elegoo Mercury Plus is an easy-to-use option for hands-free finishing.

The allowed maximum print size is 125 x 85 x 160 mm for washing and 140 x 165 mm for curing. You can either use the included cleaning basket or install the Elegoo build plate with models still attached, making it compatible with most if not all photopolymer 3D printers, not just Elegoo machines.

385nm and 405nm UV lamps and a 360-degree rotatable curing turntable do all the curing work with the ability to enter and control cure times up to 30 minutes on a TFT touch screen. Safety is provided by an anti-UV cap that blocks 99.95% of UV rays and a pause function if the cap comes off during curing.

Anycubic station will cost more, but at around $120 you will complete your 3D printing rig with a quality resin 3D printing station with no mess.

Best desktop resin 3D printers ($1,000 to $3,000)

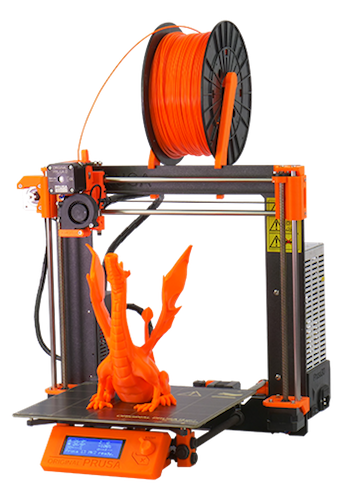

Prusa SL1S Speed

- Price: $1,999 - available at Prusa store here

- Print volume: 120 x 68 x 150 mm

- Screen resolution: 2560 x 1620 pixels

- Screen size: 5.96″ 2K monochrome LCD

- XY resolution: 47 microns

- Print speed: 50 mm/h

- Cleaning/curing: Original Prusa CW1S

Prusa printers are known for being the best RepRap 3D printers. They are so good that over 150,000 printers have been sold, and company founder Josef Prusa has opened his own printer factories to print parts for more printers! Prusa reception.

Prusa has now moved into the SLA 3D printing sector with the launch of the Prusa SL1 printer based on mSLA technology: using LCD and LED panels to cure photosensitive resin layers. As mentioned earlier, this has the advantage of scalability—multiple parts can be created at the same time without additional time—as well as high accuracy.

As mentioned earlier, this has the advantage of scalability—multiple parts can be created at the same time without additional time—as well as high accuracy.

In addition to the printer, Prusa sells a wash and cure machine that helps wash and cure prints, maximizing the surface finish. The Prusa SL1 has a heavy aluminum chassis designed to anchor the printer to the ground and make it more stable for more accurate printing. It seems to me that the phrase “of course, this is good, this is Prusa” is appropriate here.

Peopoly Phenom mSLA Printer - large photopolymer 3D printer with huge build volume

- Price: $1,999 - Available from Matterhackers here

- Print volume: 276 x 155 x 400 mm

- Screen resolution: 3840 x 2160 pixels

- Screen size: 12.5″ 4K LCD

- XY resolution: 72 microns

- Print speed: 75 mm/h

- Cleaning/Cure: Peopoly Curing Box

We already included the Peopoly Moai 130 in our list, a fantastic DIY SLA 3D printer kit. Now Peopoly is back with the Phenom, a large photopolymer 3D printer that combines LCD and LED technology.

Now Peopoly is back with the Phenom, a large photopolymer 3D printer that combines LCD and LED technology.

Peopoly Moai has a huge print volume for a photopolymer 3D printer - 276 x 155 x 400 mm, as well as 72-micron resolution. This is practically unheard of as photopolymer printers typically have a much lower build volume than FDM 3D printers. Peopoly recommends using their own resins for 3D printing, which they sell for about $70 per litre.

Overall, this is an impressive and accurate large format resin 3D printer.

Professional Resin 3D Printers ($3,000+)

Formlabs Form 3 - Best Resin 3D Printer

- Price: $3,499

- Assembly volume: 145 x 145 x 185 mm

- XY resolution: 25 microns

- Print speed: 70 mm/h

- Clean/Cure: Formlabs Form Wash & Cure

Formlabs has made a name for itself in the 3D printing industry since its initial Kickstarter campaign in 2012. An American 3D printer company was selling a Form 3 SLA 3D printer for 3 49$9 and has since become very popular in the dental and jewelry industries.

Formlabs resins available here.

TheForm 3 comes with a ton of new features. It features the new benefits of LFS technology as well as a new Light Processing Unit (LPU) to improve the surface finish of resin parts as well as better layer registration. The Form 2 was already fantastic, and these additional features take the Form 3 to a whole new level in desktop SLA printers.

In addition, the Formlabs Form 3 has an automated resin supply system and uses smart cartridges that automatically fill the resin reservoir, along with many other advanced features. In addition, it is equipped with a resin tray scanning system after each layer and automatically adjusts according to the type of resin used. In addition, the printer has a fantastic touch screen and can be controlled remotely via a WiFi connection.

This UV resin 3D printer has a very good print volume of 145 x 145 x 185mm and is extremely accurate with 25 micron XY resolution. The Formlabs Form 3 is compatible with a wide range of resins, from ceramics, flexible resins, to cast resins, although Formlabs also sells its own high quality resins.

For those looking for third party resins compatible with Formlabs printers, here is a great place to start.

Formlabs has established itself as a leader in stereolithography with the Form 3 printer. It has received rave reviews and is widely used in dentistry. Formlabs also sells a 3D printer for SLS, the Fuse 1.

Buyer's Guide - What to Consider When Buying a Resin 3D Printer

RGB vs. LCD Screens - Differences, Advantages/Disadvantages

earlier models.

This change is only to the benefit of manufacturers, since monochrome screens have many advantages over RGB. Although they are more expensive, they are more efficient, less energy intensive, and print faster due to shorter polymerization times.

Unless you choose an old used model, you will most likely buy a printer with a default monochrome LCD screen.

LCD Resolution - 2K, 4K, 6K

Like computer monitors and TVs, LCD resolution determines the level of pixels and detail.

Higher resolution translates into better XY resolution and lower layer height, which is a critical factor for the fine detail and precision we expect from resin printers.

You'll find 2K, 4K and even 8K resolution printers for those who want the ultimate level of detail and intricate detail in their prints.

However, the print quality of the 2K LCD is far superior to that of FDM printers, so it is more than adequate for most applications.

Build Volume

Photopolymer printers typically have a smaller build volume than more common FDM machines, so manufacturers and professionals use them to create small, intricate parts with high precision.

If you need extra space to print duplicate parts or large figures and models, look to larger format resin printers such as the Peopoly Phenom and Phrozen Sonic Mighty 4K.

Post-Processing Equipment

Resin 3D printing is a messy business and post-processing is a major part of the printing process. Post-processing consists of two parts - washing and polymerization.

Post-processing consists of two parts - washing and polymerization.

Flushing involves removing uncured resin residue from the print with isopropanol.

Polymerization uses additional UV light to complete the polymerization process to improve the finish and overall rigidity of the part.

Do-it-yourself, hands-on processing is one option, but manufacturers now offer versatile wash and curing stations that eliminate many of the hassles associated with this process.

How does a photopolymer 3D printer work?

Each type of resin 3D printing technology cures UV resin, they just differ in how they do it.

Stereolithography (SLA) was the first additive manufacturing technology invented, with patents granted to 3D Systems back in 1986. SLA printing works by using an ultraviolet laser and mirrors (called galvanometers) to selectively cure the resin.

DLP 3D printing was pioneered by EnvisionTEC and uses a projector similar to a movie theater projector. LCD printing uses an LCD screen with individual LEDs that turn on and off to selectively cure specific areas of the resin to form the final object. LCDs are sometimes referred to as MSLA (masked SLA), as in Prusa and Peopoly resin printers.

LCD printing uses an LCD screen with individual LEDs that turn on and off to selectively cure specific areas of the resin to form the final object. LCDs are sometimes referred to as MSLA (masked SLA), as in Prusa and Peopoly resin printers.

Resin 3D Printing Technologies

SLA

Using mirrors, also called galvanometers, an SLA or stereolithography printer directs a UV laser beam at photopolymer liquid resin in cross sections to cure or print layer by layer.

DLP

DLP, or Digital Light Processing, is very similar to the SLA machine and involves emitting digital light (LED in most printers) through an array of micromirrors onto a light-sensitive liquid resin for flash, or in other words, curing the entire image layer at a time in so-called voxels - rectangles that look like pixels.

MSLA/LCD

Like DLP machines, MSLA or stereolithography (often referred to as LCD) printers use a digital light source (usually hundreds of LEDs) to flash an entire layer at once. Unlike DLP, the MSLA printer uses the LCD as a "mask", directing and illuminating a photosensitive liquid resin rather than mirrors. The mask allows the printer to expose only those areas that need to be cured to the light source.

Unlike DLP, the MSLA printer uses the LCD as a "mask", directing and illuminating a photosensitive liquid resin rather than mirrors. The mask allows the printer to expose only those areas that need to be cured to the light source.

LFS

LFS or Low Force Stereolithography is Formlabs patented pot polymerization technology. LFS overhauls the standard SLA process using a custom-designed Closed Light Processing Unit (LPU) that passes a UV laser beam through a spatial filter and an array of mirrors to polymerize the photosensitive liquid resin cross-section layer by layer.

DLS

Another patented technology from Carbon 3D, DLS, or Digital Light Synthesis, uses an oxygen permeable window to cure a photosensitive liquid resin in what is known as continuous liquid interface manufacturing (CLIP). Light from a special LED engine illuminates ultraviolet rays to match the shape and details of the part's cross-section onto an ultra-thin resin layer supported by an oxygen window known as the "dead zone". The resin in the "dead zone" is then cured to create precise, detail-rich layers.

The resin in the "dead zone" is then cured to create precise, detail-rich layers.

How much does a photopolymer 3D printer cost?

Good cheap photopolymer 3D printers start at around $200. Even ten years ago, resin printers cost thousands of dollars, but with great advancement - mainly in the field of LCD printing - the prices have come down!

However, these budget photoresin 3D printers can't compete with more professional high resolution printers like the Form 3 ($3,499) or the Peopoly Phenom (1 9$99). They can still produce accurate models, for example for miniatures and other fun projects, but as a photopolymer 3D printer for business, they may not be effective.

Photopolymer 3D printer applications

Budget photopolymer 3D printers are commonly used by hobbyists to produce precise figurines and miniatures in detail that FDM printers simply cannot match. They are commonly used for 28mm miniatures, D&D figurines and other similar desktop model projects.

However, these inexpensive options can sometimes be used to create wax molds for casting jewelry. However, for higher quality precious metal casting, it is recommended to use a more professional resin 3D printer capable of better resolution and precision.

photopolymer printers are widely used in dentistry, audiology, jewelry and medical industries. For example, in dentistry, photopolymer 3D printers can print orthodontic models and implants, and in audiology, almost 100% of custom-made hearing aids are now 3D printed.

3D resin versus filament (FDM)

Hobbyists usually turn to resin 3D printing when they want higher precision, smoother surfaces and sharper details on small prints such as figurines or miniatures. While FDM is simpler, it cannot achieve these levels of precision and smoothness.

However, the trade-off between FDM and resin is that in terms of filament to resin ratio, filaments are cheaper, easier to use and reuse, come in more materials, colors and types, and tend to be stiffer.

Resins tend to be more expensive (although LCD resins are much cheaper now) and harder to use. They require thorough rinsing and post-processing, and extra care must be taken when printing and during post-processing with a resin 3D printer, including wearing protective gear, as the materials can be corrosive.

Thus, resin and thread are used for different purposes, and are not in direct competition for the same use. For the unrivaled precision of cheap 3D printers, as well as the rapid production of dental, jewelry and medical models, resin 3D printers are the way to go. But for more complex - perhaps with multiple colors - basic prototypes, deposition modeling is best suited.

Anti-selective laser sintering (SLS) resin 3D printing

The trade-off between SLA and selective laser sintering is similar: SLS-printed parts are more rigid, with excellent mechanical properties (and make excellent functional prototypes), although parts printed SLA are characterized by a smoother surface and faster printing.

SLS is also great if you're not a fan of additional support structures and don't like post-processing, because the parts printed in the resin powder chamber don't move or deform during printing. SLS offers better material properties than SLA - for example, it is not as susceptible to UV or sun damage. But they are less affordable—even the cheapest printers start at $5,000.

FAQ

Is resin more durable than PLA?

In general, conventional resin produces brittle, brittle parts that are less resistant to stress and weather than traditional 3D printing materials such as PLA. Therefore, we cannot recommend the resin for making load-bearing, functional, impact-resistant or exterior parts where PLA and ABS work much better, so manufacturers prefer the resin for fragile decorative parts filled with precise detail and a smooth finish.

Increasingly, however, 3D printing media manufacturers are offering "tough" resins such as Formlabs Tough 2000 Resin, which offer superior tear strength and even outperform ABS in some cases. Real world applications in orthopedics (such as splints and braces) and dentistry (aligners and crowns) demonstrate how people are increasingly turning to tough resins to make strong, wear-resistant parts.

Real world applications in orthopedics (such as splints and braces) and dentistry (aligners and crowns) demonstrate how people are increasingly turning to tough resins to make strong, wear-resistant parts.

Is 3D printer resin expensive?

When viewed in the context of 3D printing and compared to other popular materials and filament types, resin is not particularly expensive. A 1 liter bottle of standard resin costs between $20 and $50 depending on the brand, which is more or less the price of ABS and PLA raw materials.

The number and size of prints you can make from a standard 1 liter bottle can vary, with costs skyrocketing for the most prolific producers.

Is the resin print dirty?

While the resin printing process itself isn't messy, post-processing of the finished print is invariably an annoying, sloppy mess, not to mention a potentially dangerous mess of dripping resin and harsh isopropanol. This is not for the faint of heart and not for those who are afraid to get involved in this matter.

This is not for the faint of heart and not for those who are afraid to get involved in this matter.

Luckily, curing and cleaning stations help keep resin processing messy, so you don't get your hands dirty by smearing prints in a vat of isopropanol.

Do resin prints need to be rinsed and cured?

Yes. The resin printing process leaves uncured resin residue on the finished part. Washing off excess resin ensures that all the details and finish of the print remain accurate when you move on to the polymerization process. It's also a safety issue: washing the resin prints removes potentially toxic, uncured liquid resin, allowing the part to be handled safely.

Curing is an equally important part of the process. When the printer has finished printing the part, the resin is in a transitional state: it is hard enough to retain the desired shape and detail, but lacks overall rigidity, making it prone to scratches, scarring, and imperfections. Curing the print with UV, or even sunlight if you have time, allows you to reach the optimal, finished resin state.

Curing the print with UV, or even sunlight if you have time, allows you to reach the optimal, finished resin state.

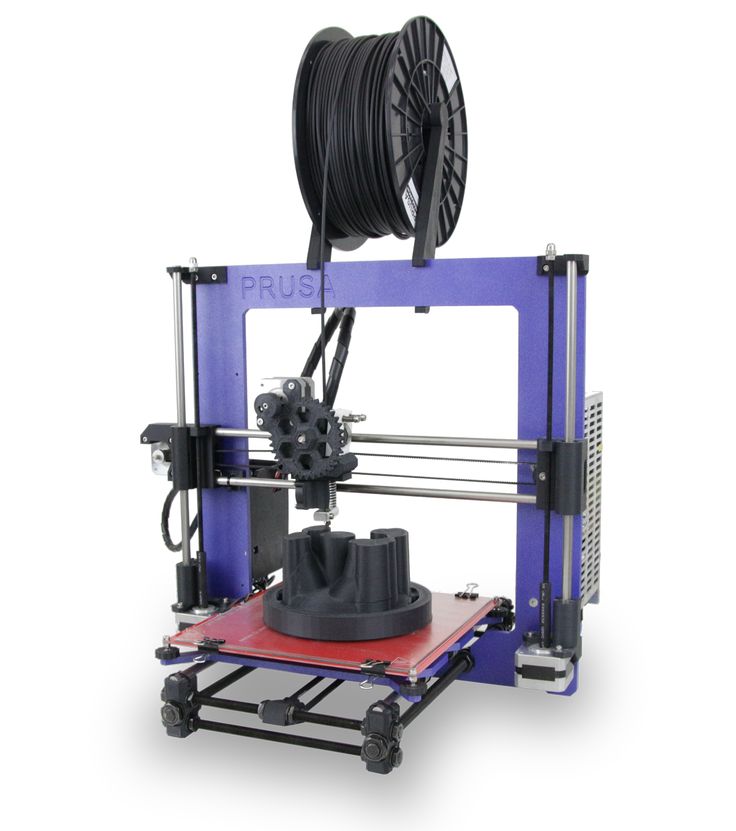

PRUSA produces the new 3D printer Original Prusa SL1

PRUSA produces the new 3D printer Original Prusa SL1

Jozef, the founder of PRUSA REMEARCH, the company was published this week: this week was published by some unexpected News - open source printer, called Original Prusa SL1 .

What do we know about Prusa?

Prusa Research is known for its innovative FFF-based desktop printers. Prusa has been working on 3D printing processes for for the last ten years and has grown its staff to 320 people. Impressively, the company is now producing around 6,000 3D printers per month.

SLA technology

The three main types of SLA processes are Laser (SLA), Digital Light Processing (DLP-SLA), and Masked (MSLA).

In all of these processes, a container of photoreactive liquid resin is exposed to light to create thin, hard layers that eventually form a solid object. The Prusa SL1 uses an MSLA with an LED array as the light source in sequence with an LCD photomask to form a light image.

Like DLP printers, a liquid crystal photomask is made up of square pixels. The pixel size differs depending on the formation of the liquid crystal photomask, and each pixel is deactivated on the LCD to transmit LED light and form the resulting layer. Hence the XY accuracy is fixed and doesn't depend on how you can scale the lens, in theory this means MSLA can work with better accuracy.

In simple terms, an LCD projector projects layers as transparent images while the remainder of the image is black, allowing light to pass only through the layer's transparent form.

Prusa SL1 Specifications Overview

The new Prusa SL1 will use the MSLA printing approach (based on LCD curing) that Prusa adds, is more accurate compared to the DLP process as it avoids the problem with distortion of the latter.

We've put a lot of thought into creating a simple and reliable print bed that doesn't need to be calibrated after each print.

“Because we have a lot of experience with Trinamic drivers in our MK3, we also use them here. Trinity drivers provide silent printing, and also allow automatic calibration . How it works? The print bed is connected to the main ball joint, , so if you loosen it and start auto-calibration, the Z-axis will lower the build bed until it has a gentle impact on the bottom of the resin tank. Once it's there, simply tighten the ball joint and move the platform up. From this point on, the printer is fully calibrated and allows only the print bed to be removed using the quick release mechanism without affecting the calibration."

There are a wide range of connectivity options for the SL1. The whole device is controlled by full color LCD touch screen, and print files can be downloaded via USB flash drive. However, there is also LAN connectivity and Wi-Fi, which allows us to do some interesting things besides downloading print files - for example, allowing you to control the printer via a web browser.

However, there is also LAN connectivity and Wi-Fi, which allows us to do some interesting things besides downloading print files - for example, allowing you to control the printer via a web browser.

Everything, of course, is connected. This means that if the resin level sensor detects that you are out of "fuel", it will send a notification to your phone.

This may be a minor feature for some users, but it's important to note nonetheless: The SL1 is equipped with a sophisticated cooling system, as well as a steam extraction system. In case you didn't know, printing with SLA produces different vapors, which is why the printer also has a cover. However, good airflow is also important, which is why the printer has a fan with a high quality filter on the back of the machine.

In fact, the fan part is removable , so you can, for example, mount a hose on the printer to blow the fumes out of the window.

Another interesting feature of the Prusa AL1 is that the resin tank is removable and has a flexible transparent FEP film on the bottom. It has a motorized tilt function. After one layer has been cured, it does not rise vertically from the bottom of the tank.

It has a motorized tilt function. After one layer has been cured, it does not rise vertically from the bottom of the tank.

A few other notable features:

- Layer Speed : Highly efficient UV light builds one layer at a time, taking about 6 seconds. Then the print platform rises and another layer begins.

- Print size : The maximum printable area is 120 x 68 x 150 mm (or 4.7 x 2.6 x 5.9 inches). It's not much, but generally resin printers like the Prusa SL1 are used to print small models with high detail.

- Aluminum housing : The Prusa SL1 comes with a rigid aluminum housing.

- Power Panic . If the power is interrupted suddenly, the printer may save the last known location of the print platform. After power is restored, the Prusa SL1 continues printing.

- Color screen: 5.5-inch high-resolution LCD with native resolution of 2560 × 1440p.

Learn more