3D print dentures

Lifelike Digital Dentures at the Click of a Button

Skip to Main Content

Precision and Performance

A directly 3D printed prosthetic means fewer steps and less variability and a quality end product every time

Quick, Repeatable Workflows

Digital denture designs are reusable, shareable, modifiable and easy to reproduce with 3D printing

Improved Efficiency

Economical hardware and materials, providing better profitability than traditional workflows—increase production and profitability at the same time

Once you’ve brought digital technology in-house, you know the transformative potential it has for each part of your business. Your removables department could be next.

3D printed denture workflows are:

- Fast and repeatable, offering optimized profitability and easy replication of dentures.

- Fully customizable to each patient.

- Able to facilitate instant communication between lab and practice.

Learn the workflow from 3D printed denture experts in our Digital Denture Master Class.

Watch the Webinar

With Formlabs, dentures are affordable for the patient and profitable for you. Provide high quality 3D printed dentures at a fraction of the cost.

| Traditional poured | Milled | 3D printed base, stock teeth | Fully 3D printed | |

|---|---|---|---|---|

| Denture base material cost | $2 | $35 | $5 | $5 |

| Denture teeth material cost | $30 | $25 | $30 | $5 |

| Hours of technician labor | 2.5 | 1.5 | 1 | 1 |

| Hourly cost of technician labor ¹ | $25 | $25 | $25 | $25 |

| Material and labor cost | $95 | $98 | $60 | $35 |

¹ NADL 2019 Business Survey

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Calculate Your Savings

Digital denture fabrication removes guesswork and potential for error while retaining room for artistry. Remakes and rush cases are easy for even a junior technician.

Design

Post-Process

Finish

Read Our Step by Step Guide

Virtual seminars, lectures from leading practitioners, and short, helpful videos help you start faster and get the most out of your 3D printer.

Explore More Educational Resources

Formlabs 3D printers enable cost-effective, mass-customized digital production of a wide range of dental products.

Explore Indications

The Form 3B+ and Form 3BL are both available for purchase in packages that include all of the tools required to bring high-precision 3D printing into your lab. Contact Formlabs or an Authorized Reseller today.

Configure Your Printer Package

3D Dentures | Affordable Dentures & Implants

Our Services

- Dentures

- Compare Our Dentures

- Full Dentures

- New Denture Wearer Package

- Partial Dentures

- RealFit 3D Dentures

- Implants

- All-In-One Solution

- Denture Implants (Snap-In)

- Single or Multiple Tooth Implants

- Dental Implants for Seniors

- Mini Dental Implants

- Tooth Extractions

- Denture Services

- Denture Adjustments

- Denture Relines

- Denture Repairs

- Gold Dentures

- Same Day Dentures

- Dental Services

- Crown Solutions

- Sedation Dentistry

- Free Consult X-Rays

- General Dentistry

- Service Costs

- Crowns Cost

- Dentures Costs

- Extractions Cost

- Implants Cost

- Partial Dentures Cost

- Snap-In Dentures Costs

Custom 3D Printed Dentures

Affordable Dentures & Implants is re-imagining dentures with our game-changing, FDA-approved RealFit 3D Denture.

The RealFit3D Denture is the industry’s first premium digital denture that combines accuracy and durability with a computer-aided digital design. The innovative 3D printing and digital design process accurately creates a durable, natural looking denture that feels and fits better than dentures made through a traditional process.

Patients report their RealFit 3D Denture feels comfortable in their mouth and the fit is amazing!

iframe video

What are 3D Dentures?

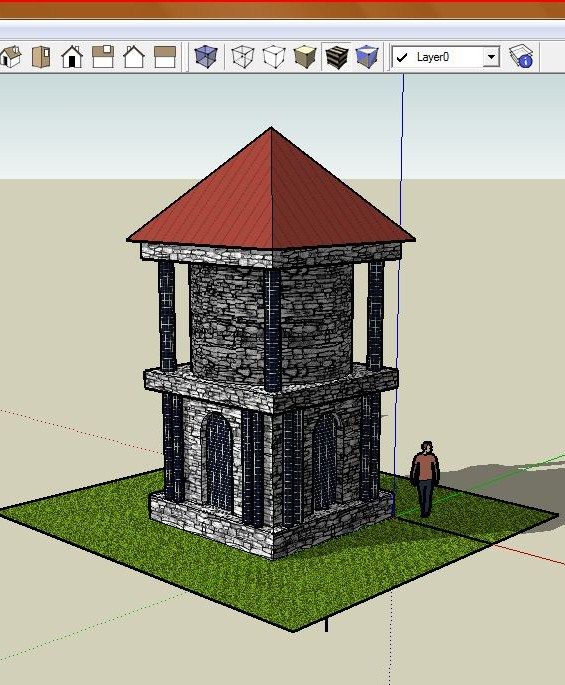

3D dentures are born from a digital scan of your mouth that is then turned into a CAD file. This file is then uploaded to a 3D printer that will build your completely custom set of dentures in as little as hours.

This state-of-the-art technology ensures that your denture will be close to a perfect fit in your mouth when you receive them, and they can be completed in much less time than a traditional denture.

Benefits of 3D Dentures

3D Dentures Last Longer

The 3D dentures are made with a tough resin that won’t break down as fast over time, compared to acrylic or plastic dentures.

Repairs are Faster & More Convenient

Because the scans of your mouth can be saved on our computer, if you need a new pair of dentures we can just send your scans to the lab and have a new set fabricated. You will only need to come back to the office to pick them up!

Little to No Adjustments

You can expect your 3D dentures to fit perfectly and look amazing the first time, without the hassle of creating molds and getting multiple scans of your mouth like with traditional dentures.

Choose How Natural They Look

The 3D printing technology lets you choose the exact color of teeth that you want for your dentures and can even color match with an actual photo of your remaining teeth.

How long does it take to get 3D Dentures?

At Affordable Dentures & Implants, we can usually get you your brand new set of 3D dentures with same-day service. Not all practices offer this option, so contact your local office to see how fast we can get you your new smile.

Are 3D dentures more expensive than traditional dentures?

It is important to consider the value of your time when comparing denture options. While the price point for 3D dentures may seem higher, you must consider the time you will save when you don’t have to come back in for multiple adjustment appointments and relines. You will be able to have your perfectly fit, natural looking dentures in one day at most of our offices. 3D dentures will also last longer than traditional dentures, so it is important to consider these as a strong investment in your future smile as well.

How long do 3D printed dentures last?

10 - 15 years or more with good care habits.

Can I get 3D dentures with implants?

Yes! Your 3D dentures will be placed once your mouth heals completely from the surgery.

Buy With Confidence

Your satisfaction means everything to us! We want you to not only walk out of our practice with a confident, new smile… we also want you to feel confident in the decision you make to trust us with your tooth replacement care. We look forward to serving you.

We look forward to serving you.

Innovative 3D printing technology for removable prosthetics | Dental software Dental4Windows

Japan has invented the world's first technology for manufacturing a complete removable denture using 3D printing with a prosthetic bed made of biocompatible silicone. The technology was called REVA: Digital Soft Lining Denture.

Today, three types of removable dentures are produced using this innovative technology.

1. NREVA silicone relining

Soft biocompatible silicone lining on the surface of the 3D printed prosthesis base. It improves the fit of the prosthesis and dampens occlusal loads, increasing patient comfort.

Note: thickness 3.5 mm.

2. NREVA Hard

3D printed resin base. Recommended for those who want to make a set of digital prostheses. Reva hard is suitable for the upper jaw and Reva silicone relining (with a soft silicone lining) for the lower jaw.

Recommended for those who want to make a set of digital prostheses. Reva hard is suitable for the upper jaw and Reva silicone relining (with a soft silicone lining) for the lower jaw.

Note: thickness 2.5 mm.

3. NREVA White

The prosthesis is used as a temporary to check the parameters of function and aesthetics. The front part of the prosthesis is painted so that the patient can use it without embarrassment during the trial period.

Note: thickness 2.5 mm.

Technology Benefits

1. Easy Ordering

The doctor scans old dentures or uses an intraoral scanner to scan the patient's mouth.

The doctor sends the data to the manufacturer, where they print out the basis of the prosthesis, rebase the biocompatible soft silicone and send the product back to the dental clinic.

2. Short delivery time

After receiving the scan data, all processes (design, printing of the prosthesis, relining of biocompatible soft silicone) are completed in just five working days.

3. Reducing chair time

Reducing patient chair time will save clinic staff time and patient time.

The 3D printed prosthesis is produced from digital data, so the dentist can reduce the visit time from 5-8 visits with a traditional prosthetic method to 2-3 visits with a digital process.

4.Easy Reprint

In case patients lose or break their dentures, they can be reordered through the website. New dentures will be made based on the stored data, so it is not necessary to take an additional impression.

Biocompatible Soft Silicone Pad

Technology Reva uses a unique biocompatible soft silicone pad replacement technology to help patients chew more comfortably.

This is a unique denture with a biocompatible silicone liner on the surface of a 3D printed denture base. The biocompatible silicone has been in development for about 20 years and has gained acceptance by hundreds of thousands of Japanese patients as well as removable denture doctors. We are now incorporating silicone pad technology with the latest 3D printed prosthesis.

We are now incorporating silicone pad technology with the latest 3D printed prosthesis.

The elasticity of Japanese silicone is the highest in the world (0.82 MPa), which corresponds to the elasticity of the thin oral mucosa of the residual ridge. Elasticity does not change with prolonged use of the prosthesis or temperature changes. This silicone allows you to create a strong vacuum connection between the prosthesis and the oral mucosa.

Developed by Japanese denture experts

Japan is considered an overage society. 29.1% of the total population of Japan are over the age of 65. Among them are many owners of dentures. In order to provide oral care for these patients, the Japanese health insurance systems cover orthopedic treatment with removable dentures, as well as denture research conducted extensively in various areas of Japan. That is why Japanese prosthetics (especially complete dentures) are considered the most advanced and richest experience. In addition, a special category of qualified dental technicians is engaged in the manufacture of removable dentures.

Source: https://www.reva-digital.net/

3D printing in dentistry for the manufacture of dentures

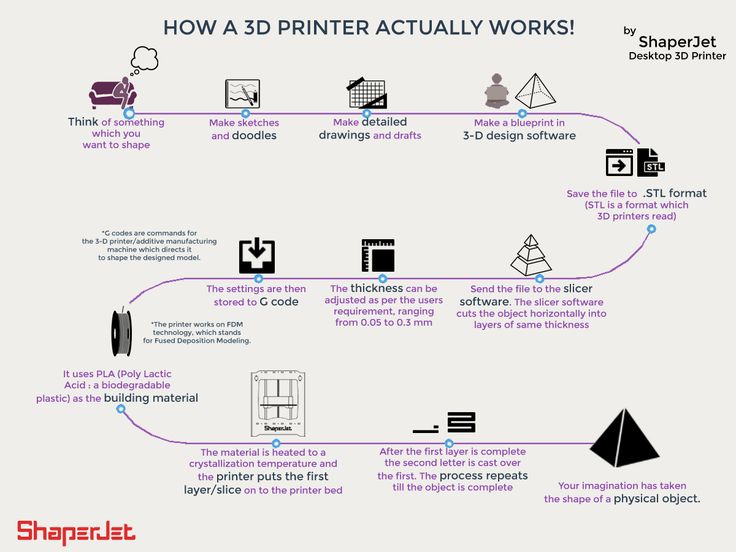

Modern additive printing technologies allow the production of a wide variety of products for an incredible range of applications. Medicine, in particular the field of dentistry, has long been no exception and is using the achievements of technological progress for the benefit of its patients with might and main, becoming digital.

Benefits of using the 9009 3D printer3

Clinics everywhere are switching to intraoral scanning, abandoning the analog, uncomfortable for the patient methods of making an impression. Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Comparison of the main 3D printing technologies used in dentistry

Laboratories do not stand aside and improve the manufacturing methods and range of dental products and services. The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

If we talk about the main methods of manufacturing dental products on a 3D printer, then these will be:

- SLA, or the so-called stereolithography, in which the laser beam polymerizes the material, quickly passing through each point of the object;

- DLP, or layer-by-layer illumination process, in which the projector illuminates the photopolymer layer by layer using ultraviolet radiation, transforming it into a future product.

Regardless of the printing method, the final properties of the work will depend on the material from which it is made, the very "resin".

Speaking of photopolymers, one cannot but mention NextDent. The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

With 30 unique NextDent photopolymers, the widest range of any dental material supplier. A range of aesthetically accurate colors enable dental labs and clinics to achieve a close match of finished products to the patient's teeth and gums. 3D printing materials from NextDent are biocompatible and certified in accordance with the requirements of the European Union, which makes them widely used. Photopolymers meet the requirements of the European Medical Device Directive (93/42/EEC), approved by the Food and Drug Administration (USA) and certified in many other countries.

With such a promising line of dental resins in its portfolio, 3D Systems, as the inventor of 3D printing and a recognized industry leader, could not do without using its own revolutionary technologies in a new field for itself. This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers.

Its hallmarks are speed and ease of use. Incredibly fast in the production of dental work of any complexity, the NextDent 5100 will allow you to print more than 70 temporary crowns in 25 minutes. Or to make a whole prosthesis in front of the patient in just an hour.

NextDent Denture 3D+, a class IIa biocompatible material, was created for the fabrication of removable denture bases. This material has significantly less shrinkage than the already used, standard PMMA materials. Shrinkage can be avoided using software, resulting in a perfectly suitable base for a removable denture. Excellent mechanical properties make it possible to surpass the quality of traditional methods of manufacturing removable dentures.