3D printing metal gun parts

3D Printing for the Firearms Industry

Forerunner 3D Printing holds a Federal Firearms License for Manufacturing (FFL 07) as well as a Special Occupational Taxpayer for Manufacturing (SOT 02) and specializes in working with firearms customers to produce both their prototype and end use production parts. We offer a wide range of inhouse services to assist our customers with their projects which include Engineering, Reverse Engineering, Metrology / Inspection, Cerakote, and 3D printing.

F3DP Owner Paul DeWys standing in his office displaying FFL07, Paul has always been passionate about designing and building firearms. This attitude extends to the rest of the team at F3DP as well and is the reason we have pursued being a source for 3D Printing for the Firearms Industry.

Why use 3D Printing?

3D printing with polymers eliminates engineering constraints that are prominent in traditional design-for-manufacture projects. The emergence of this new manufacturing technology has lead to innovations that allow for weight reduction, superior performance, and new advancements in firearms and tactical gear. 3D Printing is also a great way to greatly reduce a companies time to market by shortening lead times for prototypes and also allowing for the bridge / low volume production of parts while traditional tooling is built.

“We usually get requests to deliver parts or products yesterday,” Bassoli jokes. “With AM we can now at least deliver them on the same day.” – Marco Bassoli, Firearm Research & Product Development Director, Beretta

We have printed a range of parts for customers in the defense and firearms industry’s over the years including:

- Night vision parts

- Receivers / mag wells

- Optics mounts and accessories (throw levers and dust caps)

- Rubber components like butt stock pads

- Grips

- Magazines (both prototype and production)

- Accessory mounts

- Holsters

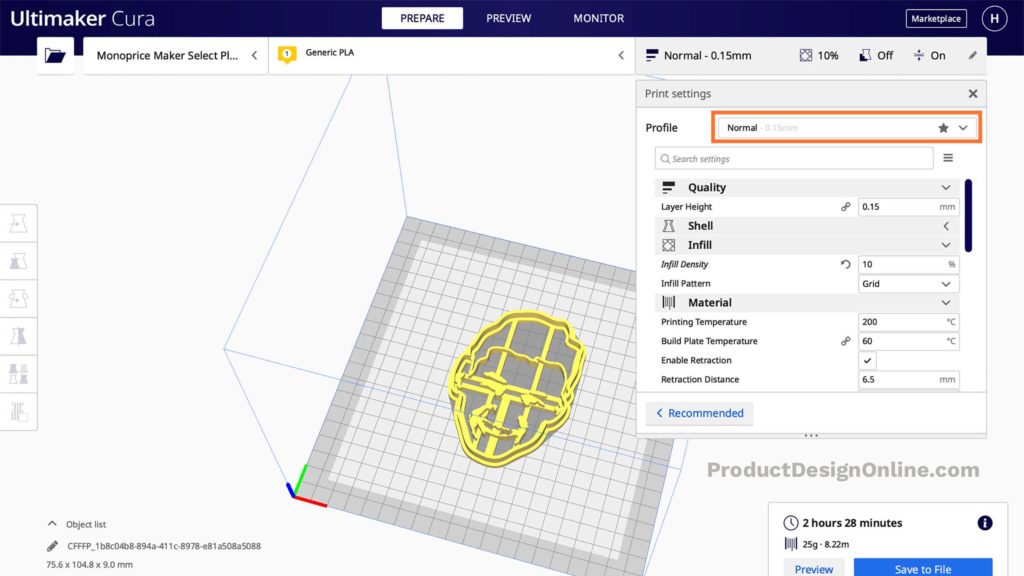

Most of the 3D Printing projects we do for the Firearms Industry is done on our HP MJF Machines using materials like:

- Nylon 12 (PA-12): Strong / wear resistant plastic, good for high temperature applications up to 350F

- M95A TPU Rubber: Durable rubber that is 95A durometer and can be very stiff or flexible depending on part design.

With Forerunner 3D Printing having a Federal firearms License for Manufacturing (FFL 07), as well as a Special Occupational Taxpayer for Manufacturing (SOT 02) we can perform prototyping or contract manufacturing of your serialized or NFA firearm components in compliance with all ATF rules and regulations.

FFL Type Chart

Federal Firearms License for Manufacturing (FFL 07)

There are multiple types of Federal Firearms Licenses each enabling the person or company holding them to transact in different areas of the firearms business. The chart you see to the right (click on it to view in full size) shows all the different types of FFL’s available and gives a summery of each.

At Forerunner 3DP we hold and FFL 07 which is a manufacturing FFL. This allows us to have customers ship their firearms directly to us for use on R&D projects, testing the fit up of prototypes, and for use as check fixtures during production runs. It also enables us to work as a contract manufacture making firearm parts for customers that are considered the registered (serialized) part of the fully assembled firearm. Without an FFL 07 it is impossible to manufacture any firearm part that requires a serial number to meet ATF requirements.

Without an FFL 07 it is impossible to manufacture any firearm part that requires a serial number to meet ATF requirements.

Special Occupational Taxpayer for Manufacturing (SOT 02)

Just like with the FFL system, there are various different classes of SOT as well, each allows the person or company that holds it the ability to transact in different parts of the National Firearms Act (NFA) business.

At Forerunner 3D Printing we hold a SOT 02 which allows us to manufacture and serialize NFA firearms. These include:

- Machine guns

- Full or select fire

- Short-barreled shotguns and rifles

- 18” for shotguns, 16” for rifles

- Suppressors

- Any other weapon

- Or device capable of being concealed on the person from which a shot can be discharged through the energy of an explosive

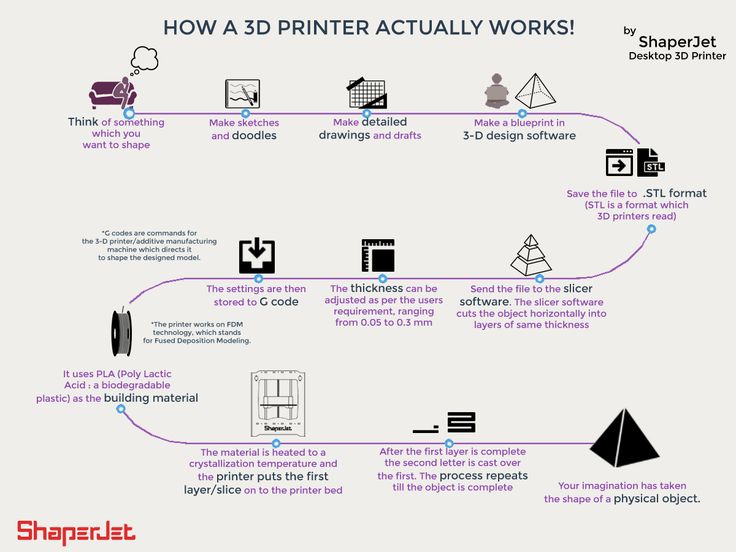

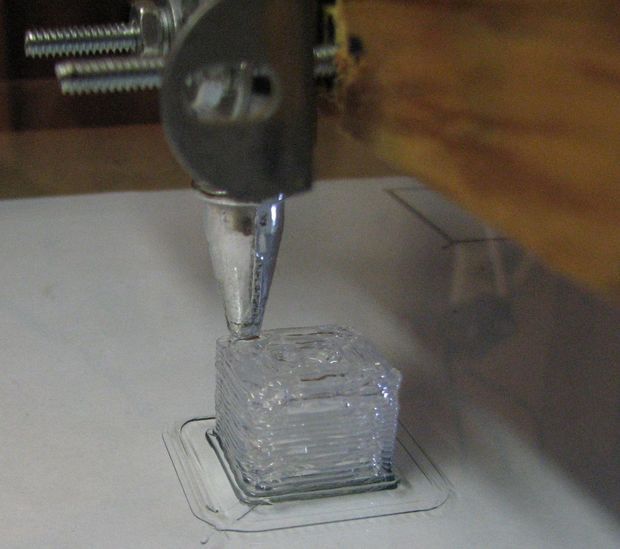

The History of 3D Printing in the Firearms Industry

As 3D printing gained popularity in the early 2000s and desktop printers became more affordable, new possibilities opened for do-it-yourself enthusiasts. Private owners of the first 3D printing machines were able to access CAD files and print simple objects from a variety of plastics. Amid this new wave of 3D printed creations, the first models for firearms and firearm components in polymers began to pop up. However, it wasn’t until 2013 that the first fully functioning 3D printed gun, the notorious Liberator, made its appearance.

Private owners of the first 3D printing machines were able to access CAD files and print simple objects from a variety of plastics. Amid this new wave of 3D printed creations, the first models for firearms and firearm components in polymers began to pop up. However, it wasn’t until 2013 that the first fully functioning 3D printed gun, the notorious Liberator, made its appearance.

The Liberator is a single-shot, polymer-based pistol created by Cody Wilson, founder of Defense Distributed. He published it on the company’s open-source file repository, DefCad, in May 2013. The gun’s publication came in reaction to Makerbot Industries removing firearm blueprints from its popular 3D model repository, Thingiverse in late 2012.

After only two days online, the US Department of State had the files pulled offline on the grounds of an infringement of the ITAR (International Traffic in Arms Regulations) – that the publishing of the files equated to an illicit export of firearms.

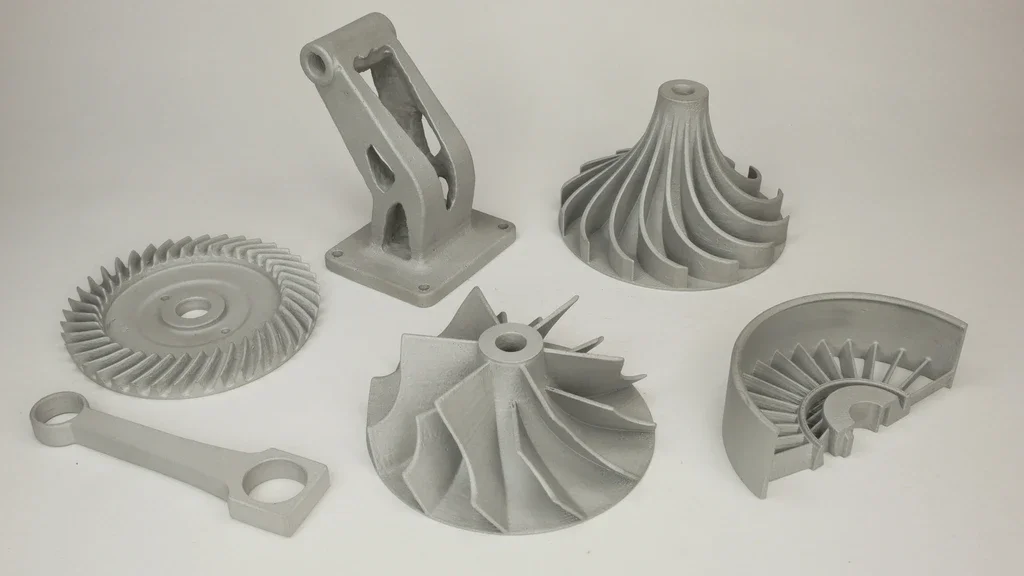

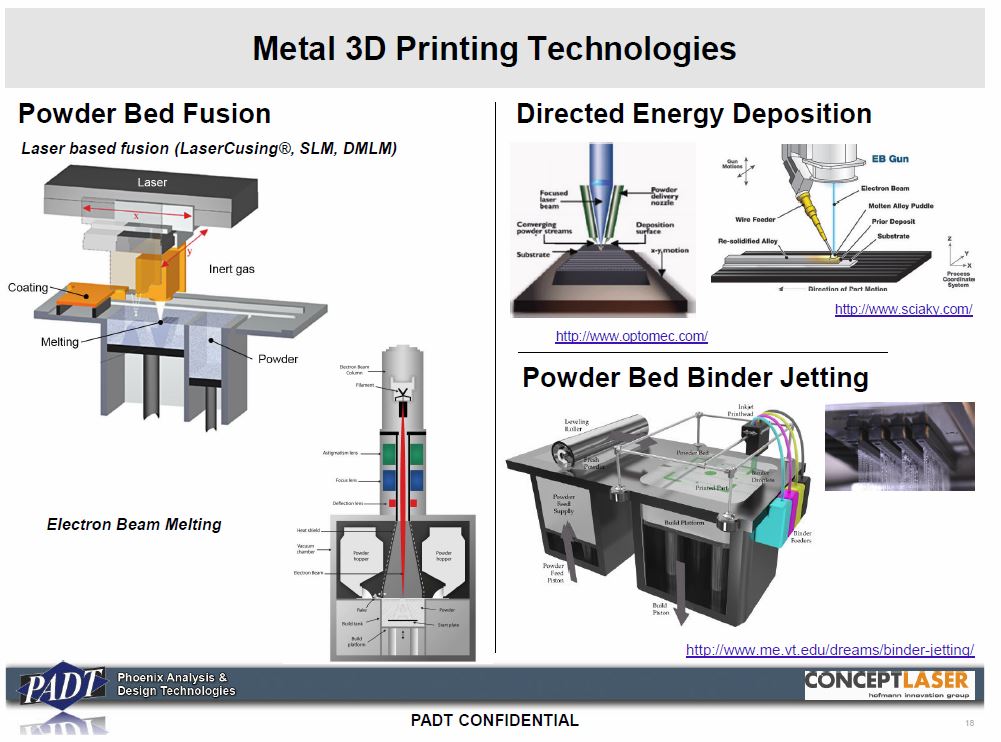

The same year that the Liberator ignited a fiery debate about 3D printed guns, additive manufacturing company Solid Concepts printed what’s thought to be the first industrially manufactured gun. Made from Inconel using the DMLS (Direct Metal Laser Sintering) printing process, the gun is called the 1911 DMLS and is a replica of the Colt Government Model 1911.

Forerunner 3D Printings entry into the world of 3D printed firearms

Fast forward to 2020 and Paul DeWys (owner of Forerunner 3D printing) set out to see if it would be possible to 3D print a homemade functional AR-15 lower receiver out of Nylon 12 on an MJF machine. He started with printing a mil spec lower and put it on a .300 AAC Blackout upper receiver. After 2000rds were fired through it without any issues it was time to take things to the next level and see if the lower would survive firing a larger caliber round.

He started with printing a mil spec lower and put it on a .300 AAC Blackout upper receiver. After 2000rds were fired through it without any issues it was time to take things to the next level and see if the lower would survive firing a larger caliber round.

The mil spec lower was then paired up with an upper receiver chambered in .450 bushmaster, a MUCH larger cartridge. On test shot number 7 the lower broke at the connection point between the pistol grip and receiver. This was not entirely unexpected due to how thin the Nylon 12 material used to 3D print the lower got in this area.

First Mil Spec 3D Printed AR-15 lower paired up with an upper receiver chambered in . 450 BushmasterFirst Mil Spec 3D Printed AR-15 lower after breaking on round #7 of .450 Bushmaster

450 BushmasterFirst Mil Spec 3D Printed AR-15 lower after breaking on round #7 of .450 BushmasterAfter some review of the design of the mil spec lower receiver and how it failed, a new design was made that integrated the pistol grip into the lower receiver which eliminated the failure point. This design passed extensive testing by Paul on the range using the .450 bushmaster round (Paul’s shoulder is still sore).

Redesigned 3D Printed AR-15 lower that has been strengthened to prevent failure when being used with large caliber rounds like the .450 bushmaster.Redesigned 3D Printed AR-15 lowers fully assembled and rocking a fresh coat of Armor Black Cerakote.After these early experiments with using HP MJF Nylon 12 3D Printed lower receiver parts we found them to be not only viable, but quite impressive. At this point the team at Forerunner 3D Printing decided to start pursuing customer projects from the firearms industry. In September of 2022 F3DP pursued and was granted a Federal Firearms License for Manufacturing (FFL 07) in order to expand the range of prototype and production work we could take on from our firearms customers.

In September of 2022 F3DP pursued and was granted a Federal Firearms License for Manufacturing (FFL 07) in order to expand the range of prototype and production work we could take on from our firearms customers.

Our other divisions:

close ×

Get a Quote:

Upload your files and fill out the information below to begin the quoting process.

3D printed guns - what kind of gun can be 3D printed and how it works

3D printing, a considerable shake-up in the gun industry

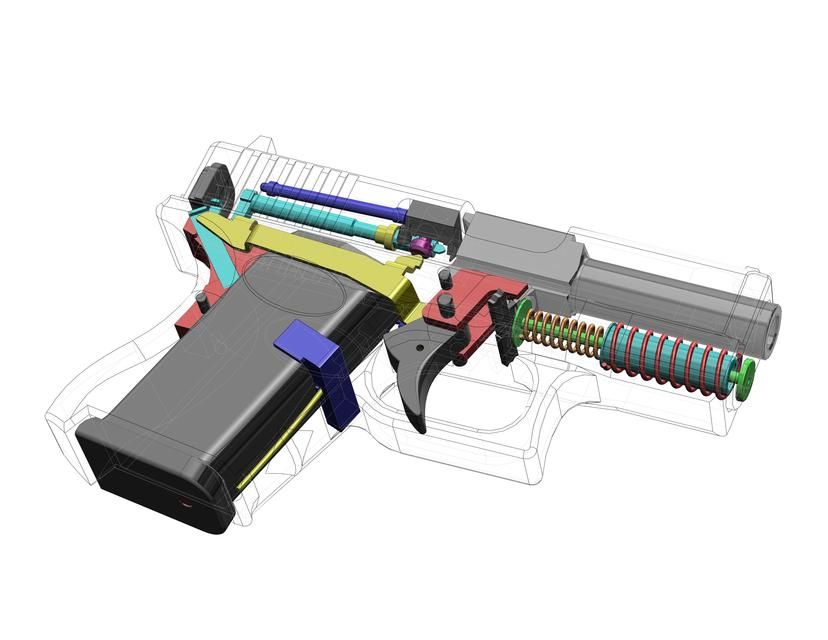

Advanced customization and low production costs are among the advantages of 3D printing for making firearms. Note that it is possible to 3D print gun parts such as the magazine or the handle. 3D printing the most important parts like the chamber or the barrel is a challenge.

The most credible option for homemaking a gun is by crafting a lower receiver as demonstrated in the Wired video below. The machine capable to turn an aluminum block into a gun part is a lot closer to a milling machine than a 3D printer.

The machine capable to turn an aluminum block into a gun part is a lot closer to a milling machine than a 3D printer.

To prove their expertise, some companies like Solid Concepts made metal 3D printed guns. Metal 3D printing technology is far too expensive and complex for individuals nowadays.

The most notable 3D printed firearms

In May 2013, the first 3D-printed gun was test-fired by Cody Wilson. This plastic pistol was produced by internet activists Defense Distributed under the name ‘Liberator’.

The Liberator .038 is made out of 3D printed ABS, with the exclusion of a single nail used as the firing pin.

Cody Wilson, inventor of the 3D printed gun : “the Liberator”In August 2013, a Canadian man going by the name “Mathew” 3D printed an actual rifle, a Grizzly . 22 Caliber Rifle model.

22 Caliber Rifle model.

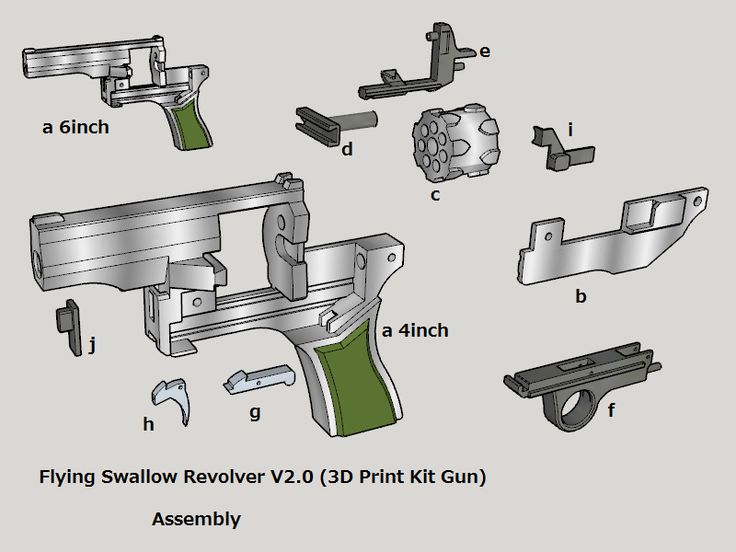

In September 2013, the Hexen organization produces the Reprringer Pepperbox .22 Revolver. The weapon can hold 5 bullets at once in its 3D-printed barrel.

In November 2013 Solid Concepts, now a Stratasys brand, 3D printed an operational metal gun.

The Browning 1911 Metal Replica fired more than 600 bullets without any damage to the gun.

In May 2014, Yoshitomo Imura 3D printed and fired a Zig Zag .38 Revolver. He was later arrested and convicted for owning four 3D-printed plastic pistols at his house.

Seized 3D printed plastic handguns displayed at Kanagawa police station in Yokohama, south of Tokyo, after Yoshitomo Imura’s arrest in 2014.In July 2014, a US citizen nicknamed “Buck O’Fama” 3D printed a receiver for a semi-automatic .22 Ruger Charger pistol.

The Ruger Charger accepts high-capacity mags holding 30 rounds or more. It is capable of shooting a full magazine without issues.

In May 2015, a man nicknamed Derwood, 3D printed the ‘Shuty’, a 9-mm semi-auto based on a combination of parts from a standard AR-15 and a P.A. Luty.

The design for the Shuty combines a metal bolt, an AR fire-control group, and the barrel of a Glock. The magazine, bolt carrier, upper and lower receivers are all 3D printed.

In September 2015, a college student named Chris, 3D printed a semi-automatic revolver called the ‘Yoshee Six Shooter’. The Yoshee Six Shooter is a revolver-style weapon that has multiple barrels and can fire multiple shots without reloading. It includes a 3D printed grip, hammer, spring, barrel, and barrel holder. A metal screw is used as a firing pin to strike the rim of the bullets.

In November 2015, an engineering student called James Patrick has built a 3D printable revolver that uses a rubber band and a nail to fire .22 bullets. The revolver called PM522 Washbear can hold six or eight bullets and can shoot them in a row. This is not the first 3D printed gun made by Patrick who also made a previous model (single shot) called the Songbird.

This is not the first 3D printed gun made by Patrick who also made a previous model (single shot) called the Songbird.

In January 2016, the now-famous Derwood, 3D printed a new gun of its design, the ‘Shuty MP-1’. This 3D printed gun is a 9 mm semi-automatic pistol made from 95% 3D printed parts.

However, the remaining components and most complex parts of the 3D printed gun are made of metal: store-bought Glock barrel, hammer, firing pin, bolts, and springs. Derwood has been able to shot more than 600 hundred cartridges with his Shuty MP-1.

According to him, the plastic holding the barrel starts to melt after about 18 shots so it is better to let the gun cool off regularly.

The legal issues of 3D printing untraceable gun parts and 3D printing gun laws

Most gun parts (magazine, pistol grip, upper receiver) can be bought online without any tracking records. But the receiver stands out as one of the most complex and important parts.

The Ghost Gunner by Defense Distributed is a CNC milling machine capable of making AR-15 lower receivers. The AR-15 is like an AR-10 but uses smaller components for firing 0.223 caliber bullets. Like other CNC mills, the Ghost Gunner uses a digital file to carve objects out of aluminum.

The Ghost Gunner produces an unserialized AR-15 lower receiver from a pre-engineered aluminum part (called 80 percent lower) in a few hours.

As a consequence, the rifle itself is untraceable: it is a ghost gun. Which raises major legal and security issues…

Components of the AR-15 ghost gun made by Andy Greenberg, including the homemade lower receiver. Source: WiredIn 2013, the UK Home Office introduced stricter regulations on 3D printed guns and 3D printed firearms, making it highly illegal to create, buy, or sell them or 3D printed gun parts in Great Britain.

In November 2015, the parliament of the state of New South Wales, Australia, passed one of the strongest prohibition laws against 3D-printed guns. This law called Firearms and Weapons Prohibition Legislation Amendment Bill 2015, intends to penalize both physical and digital possession of 3D printable guns the same way as any illegally owned firearm holder. More information can be found in this 3D printing Industry article.

This law called Firearms and Weapons Prohibition Legislation Amendment Bill 2015, intends to penalize both physical and digital possession of 3D printable guns the same way as any illegally owned firearm holder. More information can be found in this 3D printing Industry article.

California passed a law in July 2016 requiring anyone who makes or assembles a homemade firearm to apply for a serial number or “other mark of identification” from the state Department of Justice.

Around Asia, notable laws on 3D printed guns include Singapore, where possession of a 3D printed gun is punishable by death.

In 2017, China introduced the Chongqing regulation which required manufacturers involved in 3D printing to register with the government to help prevent 3D printing technology from being used to produce illegal items (including blueprints) such as firearms.

As of 1st August 2018, Defense Distributed is again allowed to publish designs for 3D printed guns after the US Department of State agreed to waive its prior 2015 restraint order against Cody Wilson and Defense Distributed. Therefore individuals are allowed to freely publish designs and other technical files about 3D printed guns in the United States.

Therefore individuals are allowed to freely publish designs and other technical files about 3D printed guns in the United States.

3D printed weapons: myth or reality?

Photo: Scott Olson / Getty Images

Is it possible to create a pistol, submarine or grenade launcher using 3D printing and without legal consequences? logos on a 3D printer is gradually entering the industrial circulation. Many are wondering what the potential of this technology is. In September 2020, an underground workshop was found in Spain with two 3D printers, an exact copy of an assault rifle, and parts of other weapons. The trial in this case was classified as “secret” for several months, and the incident became known in early April 2021. Do 3D printers really allow you to create weapons that can be used in practice, or are they just plastic models?

Do 3D printers really allow you to create weapons that can be used in practice, or are they just plastic models?

A real weapon or a plastic toy

Alexander Golovin, a 3D printing engineer, said that the materials used in printers are not engineering materials. They are unlikely to hold the structure in the case of the production of weapons or other heavy items. The maximum that 3D printers are capable of so far is printing key rings, gifts and logos. Of course, you can also print a gun, but functionally it will not differ in any way from a children's plastic toy and it will not work to shoot from it.

The thing is that the material for a 3D printer is fragile and brittle. To create weapons, you need metal parts that could support the main warhead: the receiver, the barrel itself and the bolt. But you should not do this: for a fake design, you can get a real term.

Is it profitable to print weapons

Printed weapons are unlikely to pay off, and their production will take a long time. 3D printing of weapons on a metal printer will cost about ₽100 thousand. Meanwhile, a rifle in a store can be bought for ₽15 thousand. Of course, you will need to spend money on training and a safe, but it will still come out cheaper.

3D printing of weapons on a metal printer will cost about ₽100 thousand. Meanwhile, a rifle in a store can be bought for ₽15 thousand. Of course, you will need to spend money on training and a safe, but it will still come out cheaper.

Even on the black market, the cost of such weapons is much less than the cost of entering the metal printing industry. What's more, it's illegal, so the chance of a 3D weapon maker getting caught increases exponentially.

News about the successful 3D printing of weapons: fact and fiction?

Back in 2013, Solid Concepts printed the Colt 1911 metal pistol. However, this news raises many questions. The classic "colt" has a rifled barrel - it is impossible to print one. Plus, the model requires grinding and processing.

The news that the US Army has built a 3D grenade launcher is a little embellished. It is quite possible to print a model of a grenade launcher, because this weapon is a pipe - it does not matter what it is made of. But it is unlikely that a 3D printer will be able to print explosives or projectiles. Even if this succeeds, when used, the plastic case will scatter in different directions.

But it is unlikely that a 3D printer will be able to print explosives or projectiles. Even if this succeeds, when used, the plastic case will scatter in different directions.

Another 3D printing experiment belongs to the US Navy. They printed a submarine. Alexander explained that, most likely, only some part of the submarine was created - it is impossible to restore it completely without aluminum. The printed boat has a number of limitations related to the strength of the material and the loads it can take. Moreover, it is not known how well such a submarine will be able to dive into the water.

The editors of RBC Trends reminds that the development, production and storage of weapons and their main parts are subject to licensing in accordance with the Russian legislation on licensing certain types of activities. Illegal manufacture, alteration or repair of firearms and illegal manufacture of ammunition are criminal acts .

is it possible to print airguns and firearms

Is it possible to make a gun on a 3D printer and is it legal?

Today's 3D printers offer a lot of possibilities. They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, still fires live ammunition.

They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, still fires live ammunition.

Can firearms be 3D printed?

Back in 2013, a young American gun fighter proved that plastic guns could be 3D printed. He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

Modern 3D printers are capable of printing any CAD model, and firearm models have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

The evolution of 3D printed weapons

Despite all the prohibitions and restrictions, the evolution of 3D printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels. At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube. The weapon was noticeably safer for the shooter compared to previous versions, but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1. It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn't exactly a plastic weapon. The author used some metal parts from factory pistols - a barrel, a firing pin, a bolt and several springs. This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

The main contribution to the development of 3D printed weapon printing technology was made by Defense Distributed, which brought together a group of like-minded activists. First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities. Secondly, they were able to set up a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms - from pistols to carbines. They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of "creativity" of Defense Distributed. At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Where can I get drawings and what should I look for?

Gun manufacturing bans make it much harder to get blueprints and models of guns for 3D printing. The right to free placement of information was achieved only by Defense Distributed. Their website provides free access to drawings, models and technologies. Other information can be found on the Internet, but they are usually illegal.

When choosing a model, pay attention to the following information:

- material used;

- cartridge for which the model is designed;

- number of cartridges in the magazine, rate of fire;

- operating time before failure.

It is important to clarify which metal parts will need to be purchased separately, in addition to plastic for printing on a printer.

What does the law say in different countries?

The only country where firearms can be 3D printed is the United States. Gun Control Act 19 applies here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Should we be afraid of plastic weapons?

The question of how dangerous a weapon printed on a printer is becoming increasingly important. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world. The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

Most experts agree that currently printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots. Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the danger cannot be underestimated. It is easier and cheaper for a "serious" criminal to buy illegal military weapons than to make them on a printer. At the same time, there may be "enthusiasts" who, for their own interest, can make a pistol and try it out in action. Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Important! Plastic weapons have a very small resource. At the same time, sometimes just one shot is enough to kill a person.

3D printed firearms have the following advantages:

- the ability to make military weapons at home;

- light weight;

- availability of materials;

- Ability to copy famous weapon models.

Always remember that there are significant disadvantages:

- illegal production;

- high cost of weapons;

- very small resource and limited rate of fire;

- danger to the shooter himself.

Currently, plastic weapons have more disadvantages than advantages, and most importantly, you can get a real prison term for making them.

Prospects for printing weapons

The potential for 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics. In the future - a significant increase in the resource and the provision of automatic firing.

Significantly increases the reliability of printed pistols and carbines SLS technology using metal powder. Such weapons already differ little from the factory metal models. While it is very expensive, which significantly limits the application. However, over time, the material will become cheaper, which means it will become more affordable.

Printing firearms on a 3D printer has become a reality. Despite its extremely low performance and reliability, interest is growing in it. Experts predict that the printing of weapons will become widespread, and it is impossible to stop such production.