3D printer hobbyist

Hobbyist vs Professional 3D Printers

Learn Blog

When 3D printing first arose, the imagination of users and producers alike militated against real-world use. Now expectations have slowed down as the technology has sped up to meet in the middle. There are $1,000 printers today that compare favorably to the $50,000 printers of a decade ago.

To maximize the potential of 3D printing, however, users still need to understand how the home hobby maker and the fablab-level printers compare.

Among the several differentiators are two important ones: time and money.

TIME

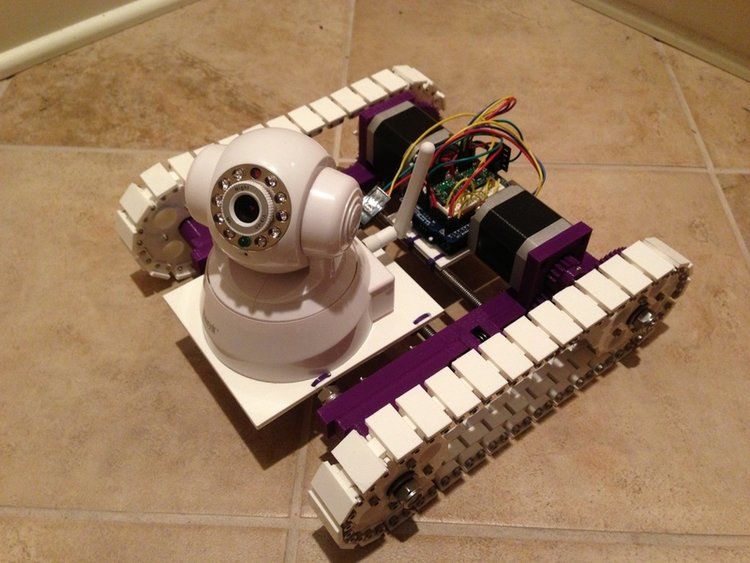

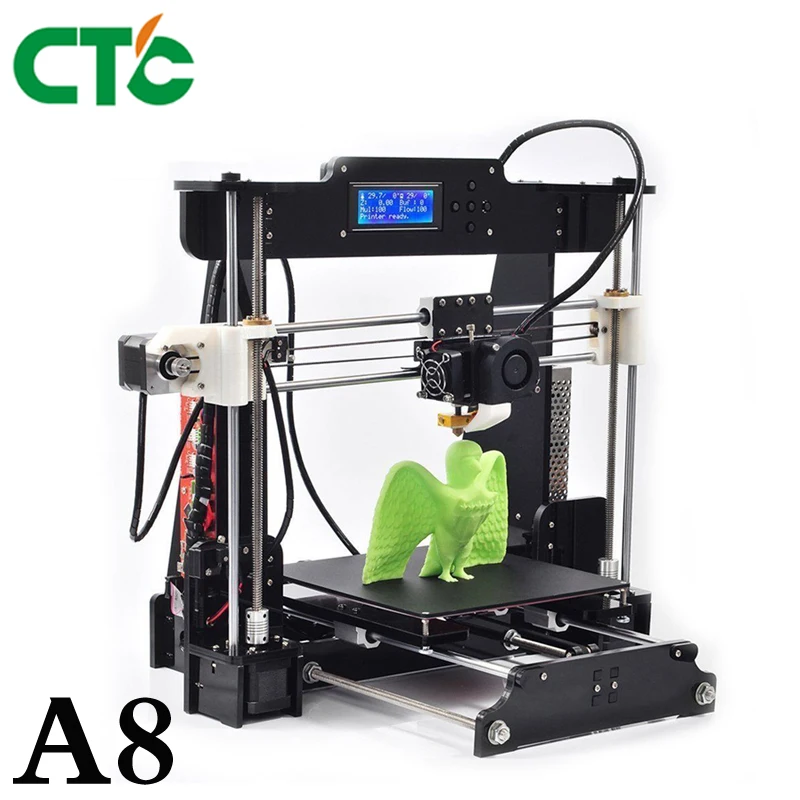

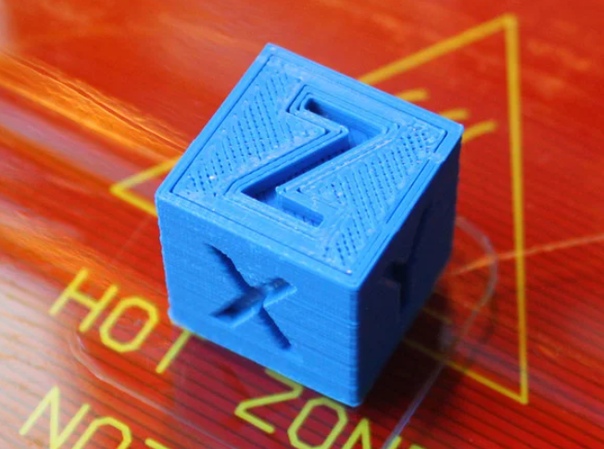

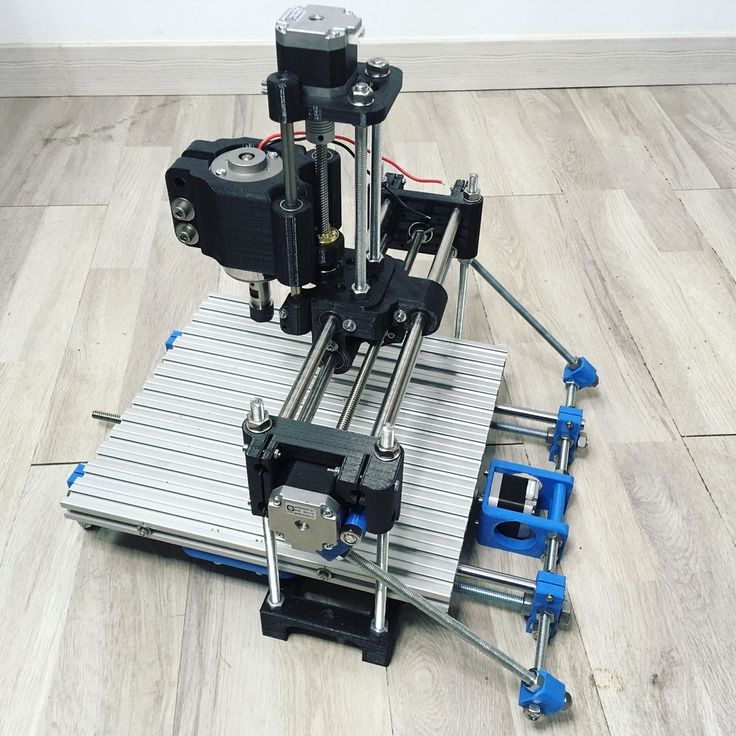

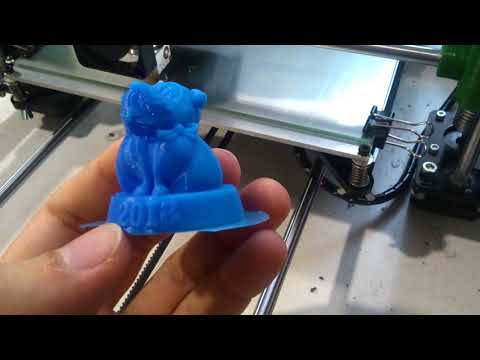

With a hobbyist machine these days, it will feel like you have infinite options for filament, software, and hardware upgrades. Home 3D printers are great for printing a few items such as Benchies or Baby Yodas, but those printers have some drawbacks. Home 3D printers can be difficult to use. You may find yourself reprinting once, twice, three or four times to get it right. Some may find satisfaction in finally getting the perfect print, others may not, but that’s exactly why these printers are perfect for hobbyist applications — they take extra time. Hobbyist users are looking for an activity, a way to spend time.

Conversely, professional 3D printers are built for efficiency, built to save time. With a home 3D printer, spending time is the goal. For a professional printer, time costs money.

MONEY

If you are in a position to decide between a hobby machine for as low as $200 and a $20,000 professional machine, there is a way in which paying more costs less.

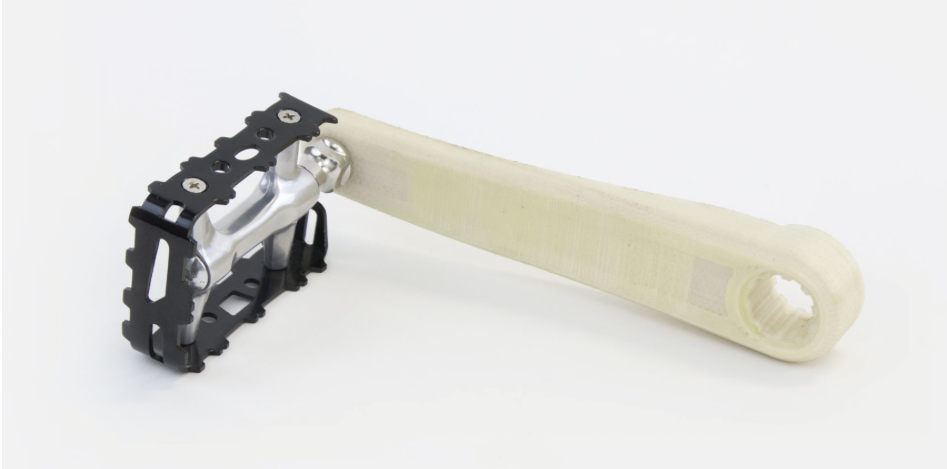

One example is the Markforged Mark Two. This machine enables designers and engineers to replace machined aluminum tooling with stronger parts for a fraction of the price. It combines unique continuous carbon fiber reinforcement and distinctive software with industrial 3D printing, for versatile parts that are ready for immediate use, with up to 26 times the strength of standard 3D printing materials like ABS.

It's not just the materials that save money. It’s also the fact that well-built, stronger products cost less because they need to be replaced less frequently.

So before you decide to buy either a hobby printer for your home shop or a professional printer for your business, listen to what experts from publications like All3DP and TechRadar think and check out the experience of companies like Dunlop Systems and Haddington Dynamics.

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

Subscribe

The Best Cheap 3D Printers for 2023

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

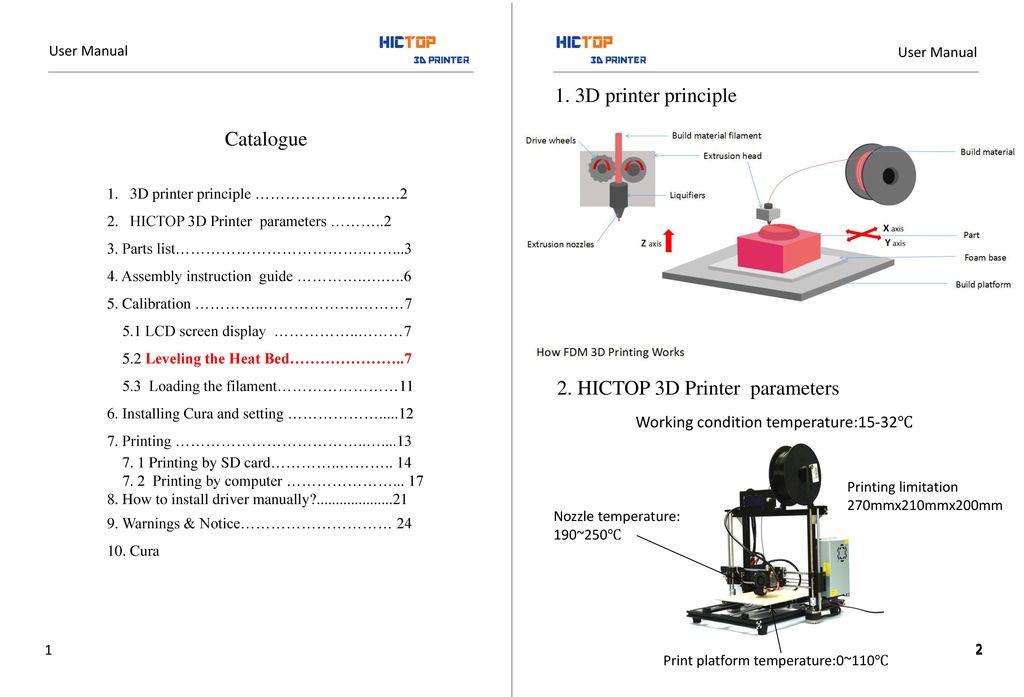

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Deeper Dive: Our Top Tested Picks

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $219.95 | $219.95 | See It (Opens in a new window) |

| Walmart | $199.95 | $198.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

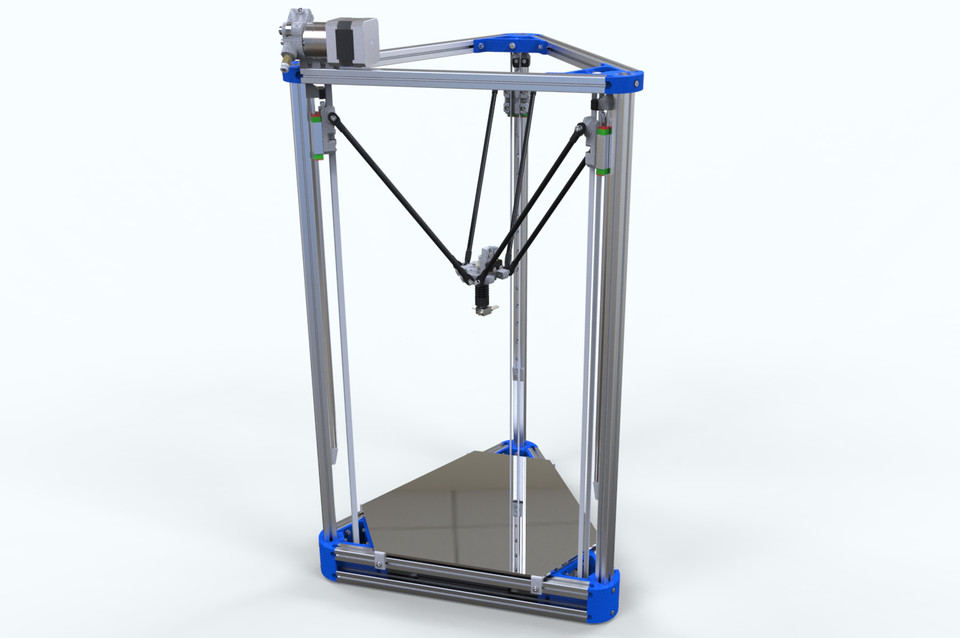

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | Check Stock (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

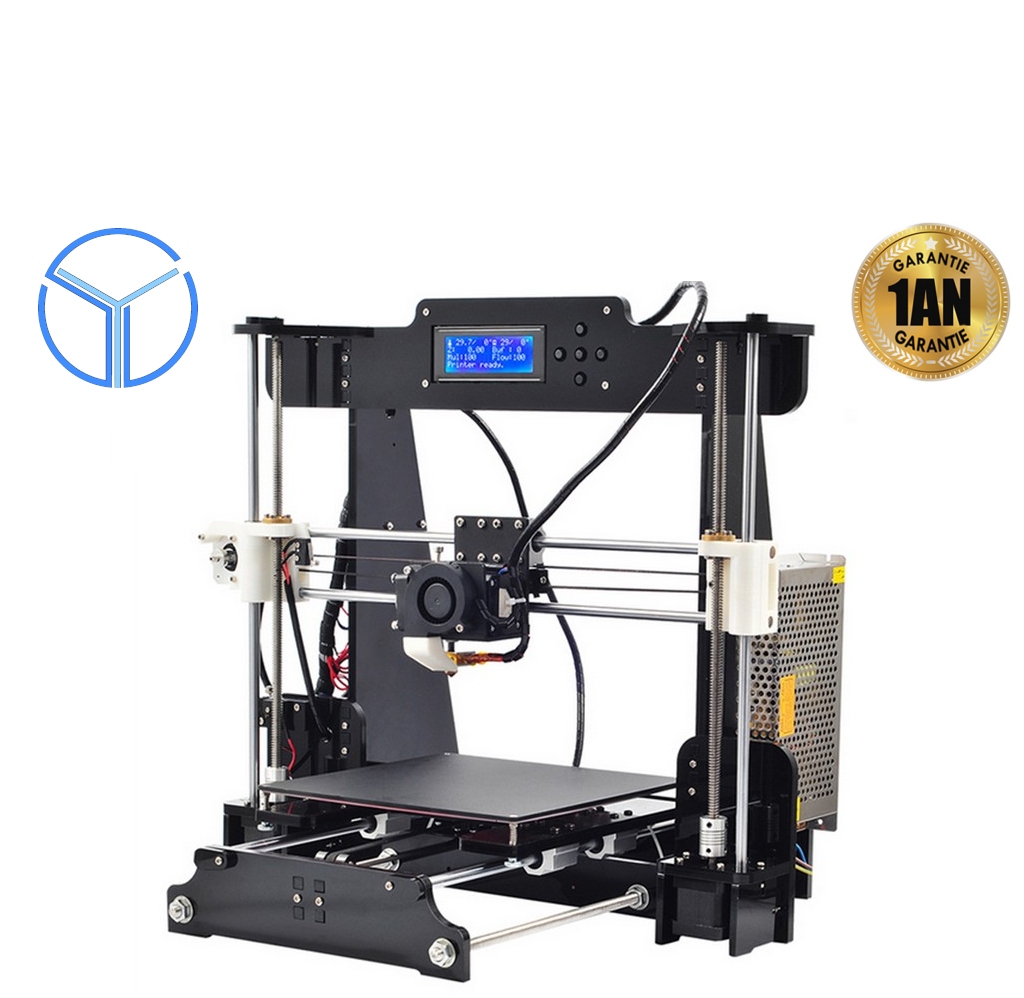

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | See It (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $339. 99 99 | $339.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $499. 00 00 | $499.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

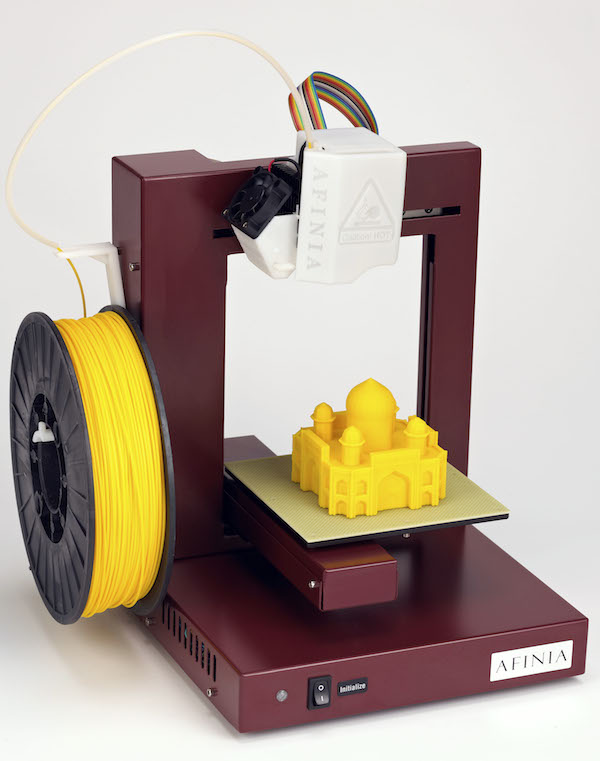

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $259.90 | $259.90 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $249.95 | $219.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $583.74 | $583.74 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | Check Stock (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2023

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

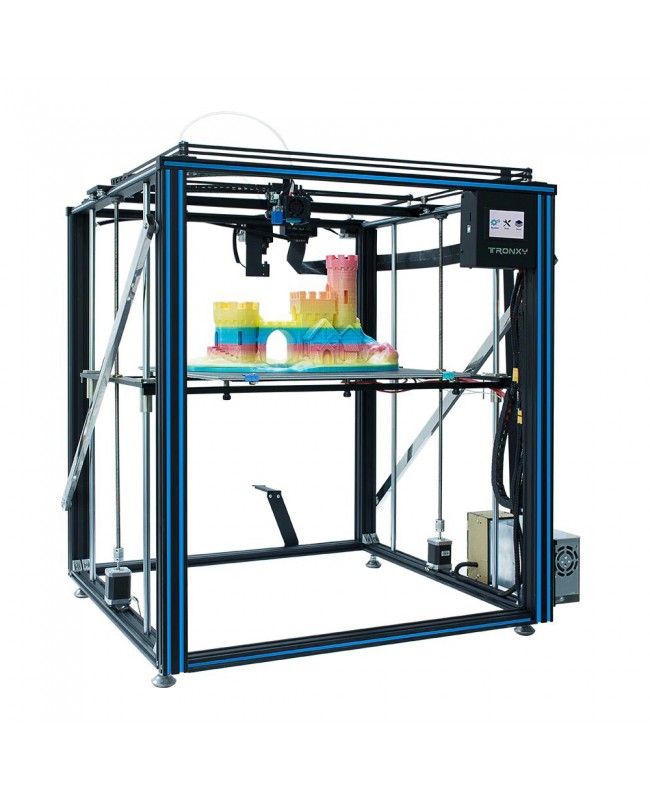

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

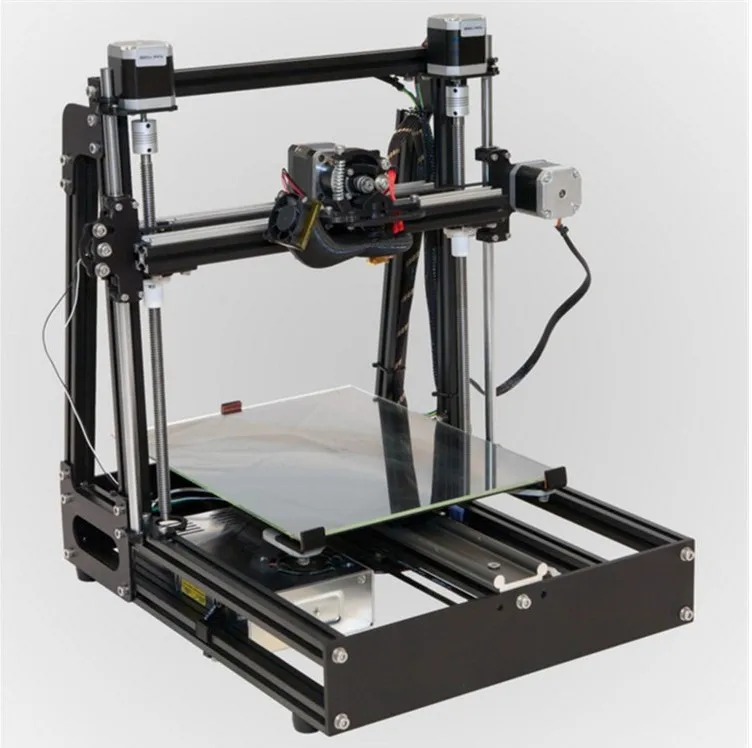

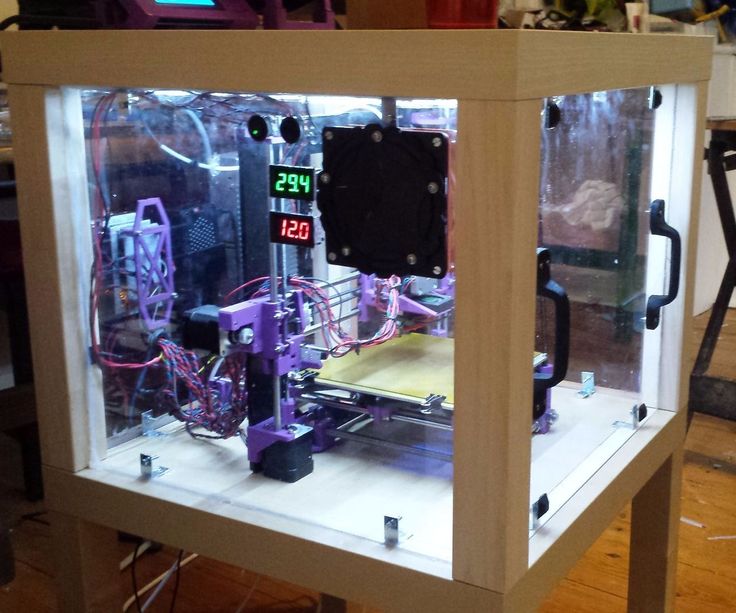

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

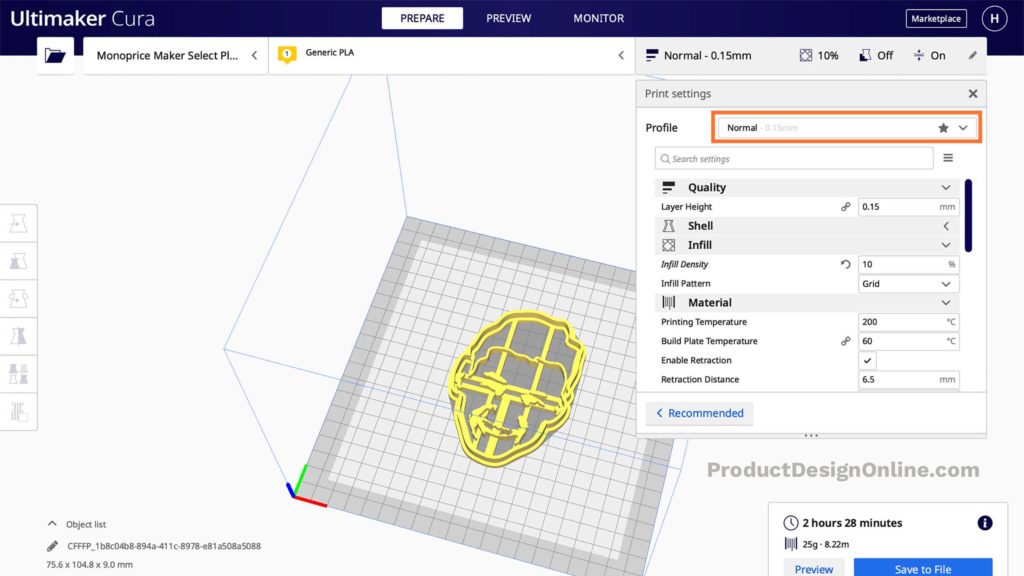

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

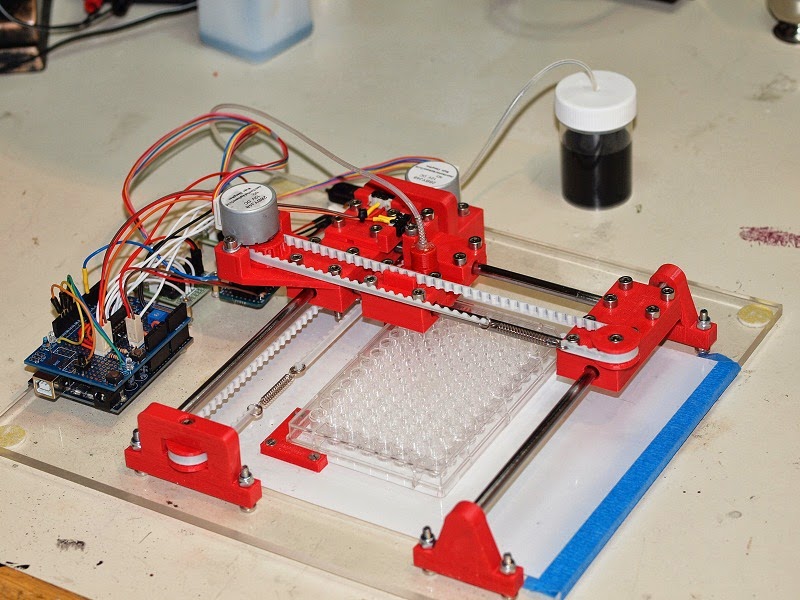

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

Choice of technology and 3D printer for jewelry making, pros and cons

Currently, there are many new technologies that are designed to simplify production in various industries. Progress does not stand still and, despite some opponents, 3D printing has its own niche in the production of jewelry.

Progress does not stand still and, despite some opponents, 3D printing has its own niche in the production of jewelry.

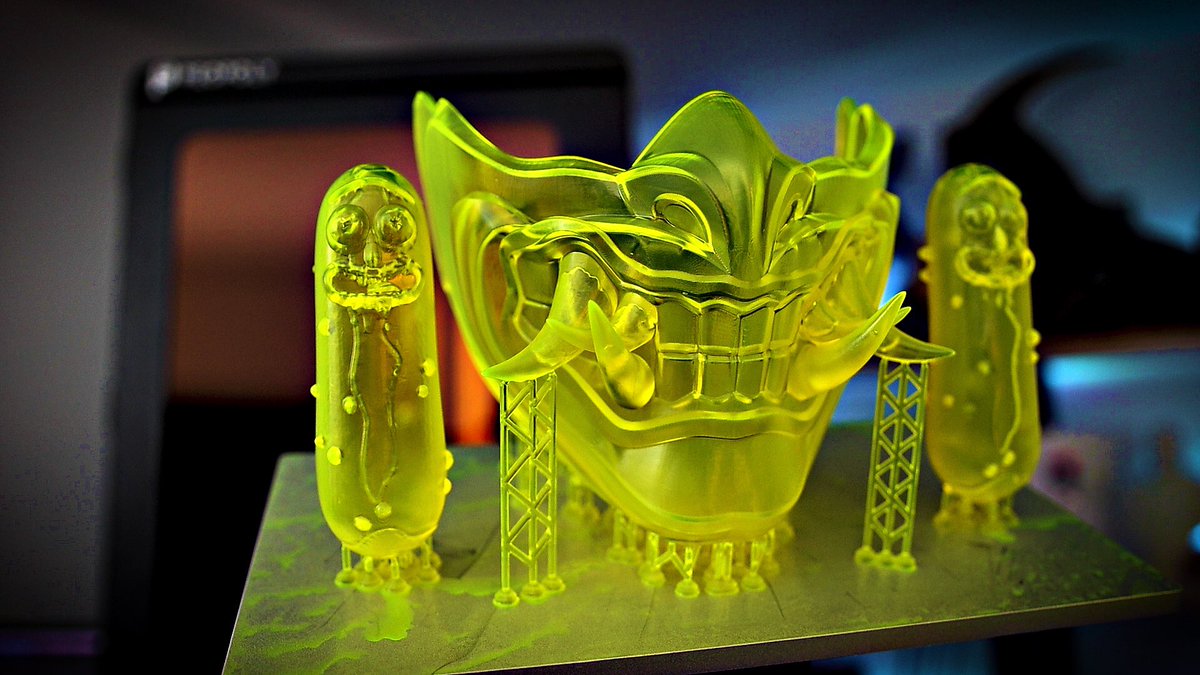

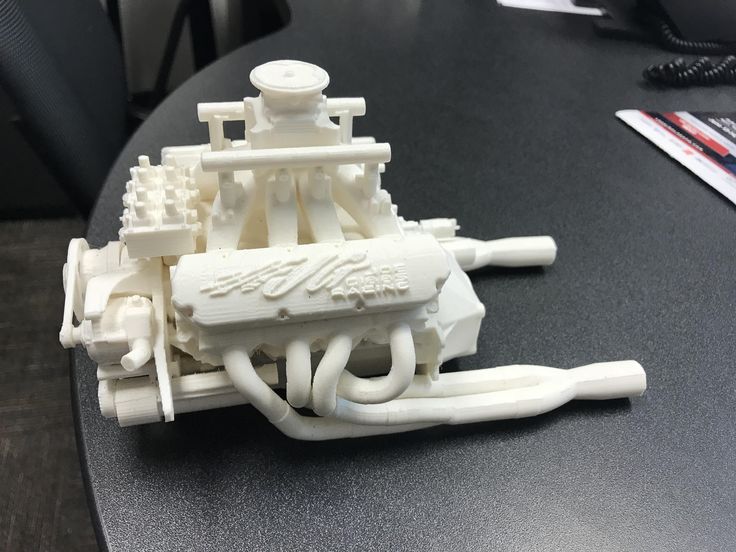

3D printing can speed up and reduce the cost of jewelry production due to the low cost of consumables. With 3D printers, jewelers have the ability to quickly change the design of a product and make prototypes at least several times a day. For many jewelry industries, 3D printing is becoming a good alternative or addition to milling machines and other equipment.

Until now, some believe that handmade is a sign of craftsmanship, especially when it comes to creative work, and models made using 3D modeling and printing are amateurish. But many people forget that behind the computer is the same person who not only mechanically presses the buttons, but also puts his soul into his creation.

Benefits of 3D printing

In order to understand how justified the use of a 3D printer is, you need to know how jewelry is made. This is very painstaking work. No wonder the expression "jewelry work" appeared, denoting a very delicate and complex work.

This is very painstaking work. No wonder the expression "jewelry work" appeared, denoting a very delicate and complex work.

Any decoration begins with a sketch. Usually several sketches are made in order to accurately determine the design and location of the inserts. Not only stones are used as decor, it can be elements made of wood, bone, precious metals, it all depends on the designer's imagination.

At the next stage, the product is drawn in a 3D editor. This allows not only to visualize the future product, but also to correct some errors and inaccuracies made at the design stage.

Ring model

Some craftsmen still carve "stencils" by hand. Such work requires certain skills and perseverance. Usually this is how products are made that will be cast in a single copy.

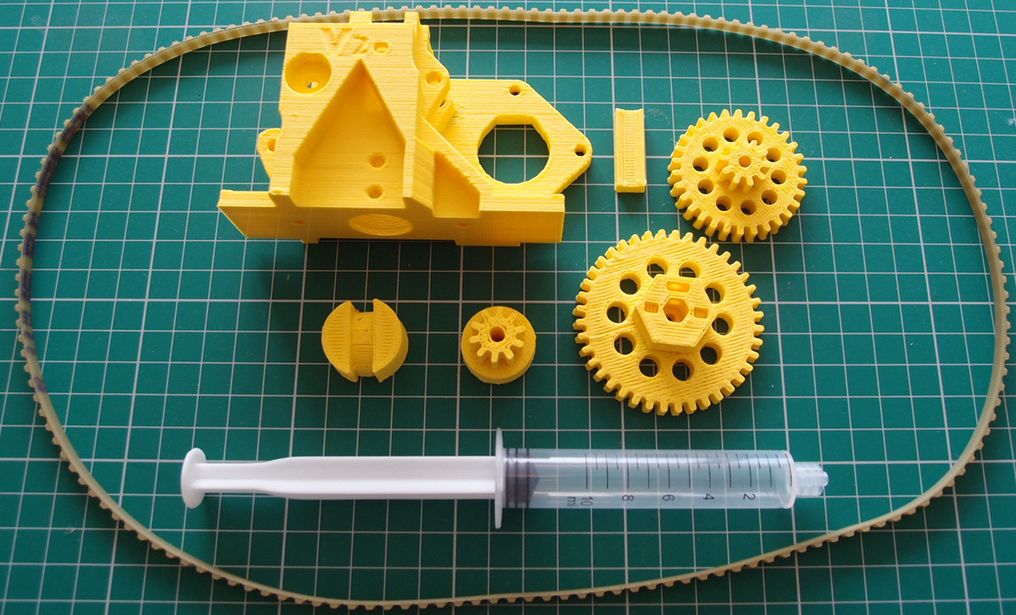

A finished 3D model can have several ways to be implemented in a physical version - this is milling or 3D printing.

Stencil milling

Currently, 3D printing is not much inferior in accuracy to a milling machine and often has a significant advantage in speed, despite the fact that after printing it is still necessary to separate the supports and clean up the points of contact with the model. Once a physical model has been obtained, it can be cast immediately if the material used is wax or a burnable polymer.

Once a physical model has been obtained, it can be cast immediately if the material used is wax or a burnable polymer.

If it is necessary to cast a large batch of products, then a mold is made from the master model made with the help of special rubber for subsequent wax casting. There are many types of rubber that vary in hardness and curing temperature. Rubber is selected depending on the material from which the master model is made.

For pouring molds, a special machine is usually used - an injector. In some models, you can not only heat the wax, but also vacuum it or leave it under pressure. This helps to reduce the number and size of air bubbles for better pouring of the rubber mold.

In home workshops, silicone is used instead of special rubber. After all, a special machine is needed to vulcanize rubber. But rubber molds are too soft and short-lived for making a large batch of stencils.

After making the required number of stencils, they are collected in "Christmas trees". "Elks" are waxes soldered to a wax rod. To save space, the distance between them is very small and they resemble fluffy Christmas trees, hence the name. The finished Christmas tree is weighed to calculate the required amount of metal. In some places, stones are immediately inserted into the stencils, unless another mounting option is provided.

"Elks" are waxes soldered to a wax rod. To save space, the distance between them is very small and they resemble fluffy Christmas trees, hence the name. The finished Christmas tree is weighed to calculate the required amount of metal. In some places, stones are immediately inserted into the stencils, unless another mounting option is provided.

Stencil Christmas trees

Ready "Christmas trees" are placed in a special cylindrical "cassette" without a bottom, which is called a flask, and filled with a gypsum-based molding mass. The flask with uncured gypsum must be evacuated to get rid of unnecessary air bubbles that can lead to defects on the surface of the finished casting.

After hardening, the gypsum flask is sent to a muffle furnace to melt the wax.

The calcination mode is selected depending on the material of the wax. For wax or burnout polymer, different modes are needed in order for the material to be completely removed from the gypsum!!!!!!

When all the wax is melted, cavities are formed inside the gypsum, repeating the contours of the wax. Metal is poured into these voids. After casting, the flask is cooled and the gypsum mold mass is washed out under the pressure of water. The result is a metal Christmas tree.

Metal is poured into these voids. After casting, the flask is cooled and the gypsum mold mass is washed out under the pressure of water. The result is a metal Christmas tree.

Herringbone after casting

Finished castings are cut from the Christmas tree and washed, polished, if necessary, blackened by the master until the desired appearance is achieved.

3D printers for jewelers

There are several 3D printing technologies that may be suitable for the needs of jewelers. Each has its pros and cons. Some 3D printers are ideal for a large workshop, and some are ideal for a small workshop.

SLA

SLA or stereolithography is based on the principle of layer-by-layer solidification of a photopolymer resin under the action of a UV beam. The UV beam is focused by means of mirrors on the surface of the resin and illuminates the model in layers.

How the SLA Printer Works

SLA 3D printers were the first to be noticed by jewelers. SLA devices are compact, while they have high printing accuracy.

SLA devices are compact, while they have high printing accuracy.

Pros and cons

pros

Minuses

Print examples

From prototype to finished product

Cast and printed ring

Rating of printers.

Leadership among the production of SLA 3D printers is held by Formlabs.

Formlabs Form 3

Formlabs Form 3

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 14.5×14.5×18.5cm

Layer thickness: 25 – 300 µm

A professional 3D printer that is popular with professional jewelers and dentists.

Formlabs Form 3L

Formlabs Form 3L

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 33. 5×20×30cm

5×20×30cm

Layer thickness: 25 – 300 µm

Form 3L differs from younger models in its large print area, which allows you to produce truly large products without losing quality and accuracy.

DLP/LCD

DLP is very similar to SLA, only as a source of UV radiation, to illuminate the photopolymer resin, not a directed beam of light is used, but a DLP projector. DLP printers illuminate the entire work area at once, so they greatly outperform SLA in print speed.

How a DLP Printer Works

Today it is one of the most affordable photopolymer 3D printing technologies. In terms of cost, LCD printers have caught up with the price level of amateur FDM. DLP printers are much more expensive due to the use of an expensive projector as a UV source.

The projector is of course more expensive, but more durable, on the other hand, the LCD display is not so expensive and can be easily seen, unlike the projector. What to choose each user decides for himself.

What to choose each user decides for himself.

Pros and cons.

pros

Minuses

Print examples

Comparison between 3D printed master model and molded part

Burnout resin model and finished product

Demonstration of products cast with burnout resin

Rating of printers.

The print accuracy of LCD printers depends on the pixel size, so you should pay attention to this parameter when choosing a printer.

Anycubic Photon Mono

Anycubic Photon Mono

Specifications:

LCD display resolution: 2560x1620 (2K)

XY Positioning Accuracy: 0.051mm

UV wavelength: 405 nm

Working area size: 130x80x165 mm

Layer thickness: 0.01-0.15mm

The Anycubic Photon Mono is an inexpensive LCD machine ideal for hobby printing. The monochrome display allows you to reduce the exposure time and speed up printing.

The monochrome display allows you to reduce the exposure time and speed up printing.

Phrozen Sonic 4K

Phrozen Sonic 4K

Specifications:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x200 mm

Layer thickness: 0.01-0.30mm

Phrozen Sonic 4K is specifically designed for use in the dental and jewelry industry. Despite its compact size, the printer is not inferior to professional machines in accuracy, and the exposure time of one layer is only a few seconds.

Phrozen Sonic Mighty 4K

Phrozen Sonic Mighty 4K

Specifications:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0. 01-0.3mm

01-0.3mm

Phrozen Sonic Mighty 4K is a professional device with a large print area. This allows you to quickly produce small batches of models.

Phrozen Sonic XL 4K

Phrozen Sonic XL 4K

Specifications:

LCD resolution: 8.9" 4K Mono-LCD

XY positioning accuracy: 50 microns

UV wavelength: 405 nm

Working area size: 190x120x200 mm

Layer thickness: 0.01-0.3mm

The Phrozen Sonic XL 4K is a professional machine with a large print area and a high resolution monochrome LCD display. This allows you to quickly produce batches of products with high accuracy.

Peopoly Phenom XXL

Peopoly Phenom XXL

Specifications:

LCD display resolution: 3840x2160 (23.8", 16:9, UHD 4K)

XY positioning accuracy: 137 µm

UV wavelength: 405 nm

Working area size: 527x296x550 mm

Layer thickness: 0. 01-0.3mm

01-0.3mm

The Peopoly Phenom XXL is a device with a huge build area, which is ideal for serial production of not only jewelry.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Specifications:

LCD resolution: 15" 8K Mono LCD

XY Positioning Accuracy: 43 µm

UV wavelength: 405 nm

Working area size: 330 x 185 x 400 mm

Layer thickness: 0.01-0.3mm

This is the first LCD printer with 8k monochrome matrix resolution, and a huge working area allows you to produce large batches of products in one print.

MJM/MJP

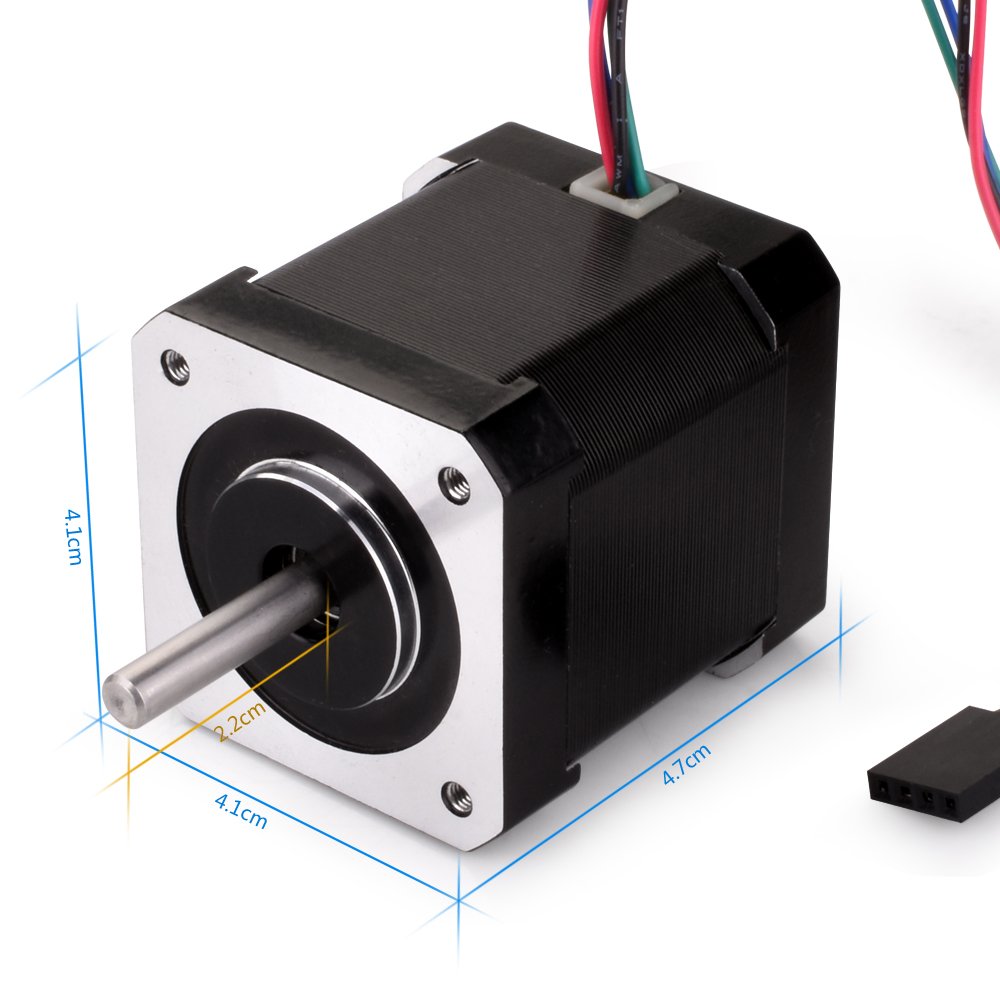

MJM (or similar PolyJet technology) is a technology for layering photopolymer or wax through many fine nozzles. Typically, the print head is located from 96 to 448, depending on the printer model.

If a photopolymer is used as a material, it is immediately cured by a UV lamp, which is located on the printer's head.

How the MJM printer works

In addition to photopolymer, MJM 3D printers can use wax as a material for printing.

MJM printers can print multiple materials at the same time. This allows you to print complex models with soluble or investment supports. This makes it possible to produce complex models with a smooth surface quickly and easily.

Pros and cons

pros

-

Ability to print multiple materials at the same time. This means that another, soluble material can be used as a support. This allows you to save a lot of time on removing the support from the finished model and cleaning up the places where the supports come into contact with the print.

Minuses

-

To install the printer, most likely, you will need a separate room. 3D printers based on MJM technology are quite bulky in their dimensions, this is not a device that can simply be placed on a desktop or nightstand.

Print examples

Seal of a lot of stencils

Ring printed with wax

Master models made on MJM printer

Lot of jewelry stencils for further casting

Printer rating

FlashForge WaxJet 410

FlashForge WaxJet 410

Specifications:

Materials: Wax, support material.

Resolution: 1200*1200*1600

Building area size: 289*218*150mm

Layer thickness: 16 microns

Accuracy: ±0.04mm / 20mm

The FlashForge WaxJet 410 is an industrial machine designed for serial printing of wax models, which will then be cast from metal. Machines of this class can be useful not only in jewelry production, but also in the dental industry, aerospace, mechanical engineering, prototyping, etc.

Totals

Photopolymer 3D printers are no longer inferior in detail to professional milling machines. The main advantage of a 3D printer is the ability to produce models of complex geometry with many internal cavities that are physically impossible to produce on a router.

Large firms will appreciate the flexibility that allows them to quickly adapt to customer requirements, as well as quickly produce large and small batches of products due to the shortening of the production chain.

And for a small workshop, a small photopolymer printer with a can of burn-out resin can be a good help, eliminating the need to purchase some expensive machines.

4 reasons why it's a waste of money / 3D printers, machines and accessories / iXBT Live

iXBT.com projects require cookies and analytics services. By continuing to visit project sites, you agree to our Cookie Policy

Are you interested in 3D printing? Do you have a 3D printer? If you answered yes to both questions, then it can be assumed that you understand the advantages and possibilities of using a 3D printer.

Knowing how to use a 3D printer helps you create your own prototypes, designs, or samples of accessories and other products. Given all its benefits, does that mean everyone should get one? Not necessary.

https://ru.pinterest.com/pin/297659856593251184/There are several good reasons why you shouldn't buy a 3D printer. Below, I will detail four reasons and explain why buying a 3D printer is not the best decision.

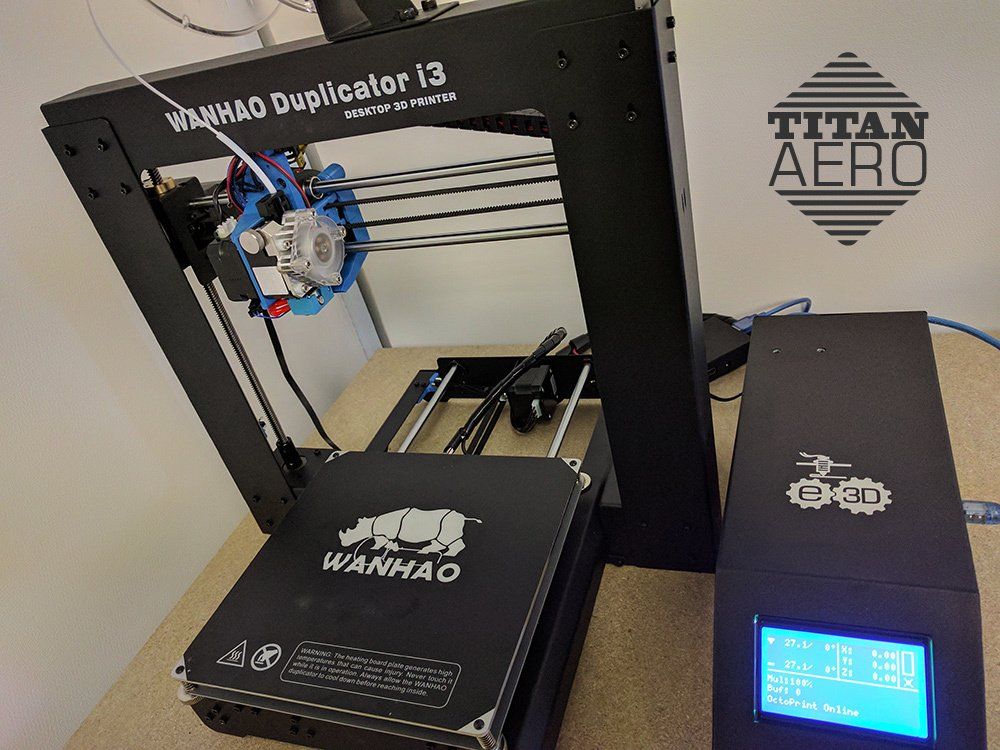

At the time of this writing, there are many different types of 3D printers on the market. While many of them have been around for almost a decade, the technology is in a state of flux.

www.slav-dvor.ruThe best 3D printers of today will be significantly different from the 3D printers of a decade ago, but they still can't give good results without pre-configuration, while most people buy 3D printers because I heard they are easy to use.

This may be true, provided that you are already familiar with the technology firsthand, 3D printing is still at a relatively early stage, and even the most expensive models will not give you perfect results right out of the box, which is an additional expense on the material for the duration of the training and it depends only on you how quickly you master 3D printing and stop translating the material for printing.

3D printing is great technology, but not for everyone. If you are an engineer or "creator" you might be a great candidate for 3D printing. But if you don't plan on making a living as a designer, or just love making things, it might not be worth investing in a 3D printer.

The cost of a 3D printer is significant. Although the price of consumer-grade 3D printers has dropped significantly over the past few years, they are still a luxury. If you just want to occasionally create products for your personal use or print souvenirs for your family, it's best not to invest in a 3D printer.

We all know that 3D printing is a relatively new product. This can lead to the misconception that you can just buy a 3D printer and print whatever you want. But it's not.

The only way to know if a 3D printer is right for you is to explore different models and then buy the one that suits your needs. For many people, this means buying a basic 3D printer with the features you need.

This does not mean that you should buy the printer as cheaply as possible. You just have to make sure the printer has the features you need. This may mean investing in a printer with a high print volume, that is, the maximum distance at which an object can be printed.

We all know that 3D printing can be used to create amazing things. However, many do not use the full potential of their 3D printer. Many people, for example, see 3D printing as a way to print plastic guns. Although this is far from the only high-quality application of 3D printing.

stockimg.netOne of the best uses for 3D printing can be found on Kickstarter. Kickstarter is a site where creators can post projects they are trying to fund. These projects can range from new products to new ideas and new technologies.

Taken from https://www.kickstarter.com/projects/rocket1/kirin-ultimate-dsp-4k-light-engine-for-3d-printing?ref=discovery&term=3d%20printer Projects posted on Kickstarter often are inspired by someone's immediate needs: a designer who needs funds to create a product, a scientist who needs funds to create a new product, or a person who simply needs funds to help bring their idea to market.

These projects are also a great way to learn what kinds of products are made with 3D printers. By studying the types of products people create with 3D printers, you can get a better idea of what a 3D printer is capable of.

3D printing is a great technology. But she's not for everyone. If you just want to make "fun stuff" use a 3D printing service instead of buying a full 3D printer if you don't have a clear goal, you'll just be wasting your money on training materials and the 3D printer itself.

stockimg.netWhat do you think about this issue? Write in the comments.

Also recommended reading:

Cheap and Toxic: ABS Plastic Review

Hi-Tech Plast Filament Review: Cheapest PLA Plastic I've Seen

Is colorless PLA stronger than colored PLA? How the color of a PLA filament affects its physical properties How the cable will feel during real use, as well as its...

Life is multifaceted, and everyone makes mistakes sometimes.