3D printing supply near me

Staples® Official Online Store

Staples® Official Online StoreSkip to main content

Skip to footer

30% back in rewards on ALL ink and toner

Staples Business AdvantageSearch

Staples has you covered

Get picture-perfect prints every timeWhether working from home or the office, make sure every print is perfect by selecting the right printer and ink for the job. For frequent or high-volume printing, choose a supertank printer or high-yield cartridges to save time and money. Staples has the top brands, technologies, and ink cartridges you need:

- We have a wide selection of HP printers, including HP photo printers, HP inkjet printers and HP laser printers. Already have an HP printer? Make sure to stock up on the most popular HP ink cartridges, including HP 952, HP 63 and HP 902.

- Browse our selection of Brother printers, including Brother laser printers, Brother inkjet printers and Brother photo printers.

If you need ink, stock up on the most popular Brother ink cartridges, including Brother LC103, Brother LC201 and Brother TN350 toner.

- Staples carries the Epson printers you want and need, including Epson inkjet printers, Epson photo printers and Epson dot matrix printers. If you’ve already got an Epson printer, don’t forget to get the most popular Epson ink cartridges, including Epson 252, Epson 127 and Epson 220.

- If you’re looking for a Canon printer, we have a full selection, including Canon laser printers, Canon photo printers and Canon inkjet printers. Don’t need a new Canon printer? Be sure to snag the ink you need; our most popular Canon ink cartridges include Canon 245, Canon 240 and Canon CLI-251.

No matter your printing needs, we have the right printers, ink and toner for the job.

The right paper for every job Wherever your business takes you, we’ve got you covered with the right paper for the job. For menus, signs, invitations or craft projects, choose cardstock. Make your presentation materials stand out or preserve memories with quality photo paper for your printer. For all of your notetaking needs, we have notebooks, binder filler paper and more. Not sure what to get? Pick up some multipurpose paper that can be used for copying, printing or dashing off a quick letter.

For menus, signs, invitations or craft projects, choose cardstock. Make your presentation materials stand out or preserve memories with quality photo paper for your printer. For all of your notetaking needs, we have notebooks, binder filler paper and more. Not sure what to get? Pick up some multipurpose paper that can be used for copying, printing or dashing off a quick letter.

Manila folders are a classic office staple for a reason – they have so many uses from medical offices, to schools, to everyday household management. Keep all of your paperwork at the ready and make it even more convenient by using a hanging file folder system. Don’t forget that folders make excellent presentation packets; use a pocket folder to include supplemental materials or create professional portfolio with a presentation binder or folder.

Send it with care Manage day-to-day office correspondence smoothly with a wide selection of business envelopes, inter-office envelopes, and catalog envelopes. Sturdy manila envelopes are the perfect choice for preventing damage to regular documents or choose a rigid certificate mailer for even more peace of mind. For business or social celebrations, consider invitation envelopes and red envelopes.

Sturdy manila envelopes are the perfect choice for preventing damage to regular documents or choose a rigid certificate mailer for even more peace of mind. For business or social celebrations, consider invitation envelopes and red envelopes.

JavaScript is Disabled

Sorry, this webpage requires JavaScript to function correctly.

Please enable JavaScript in your browser and reload the page.

3D Printer Store in Atlanta – GraysonHobby RC Hobby Store

Posted onAuthorBasil

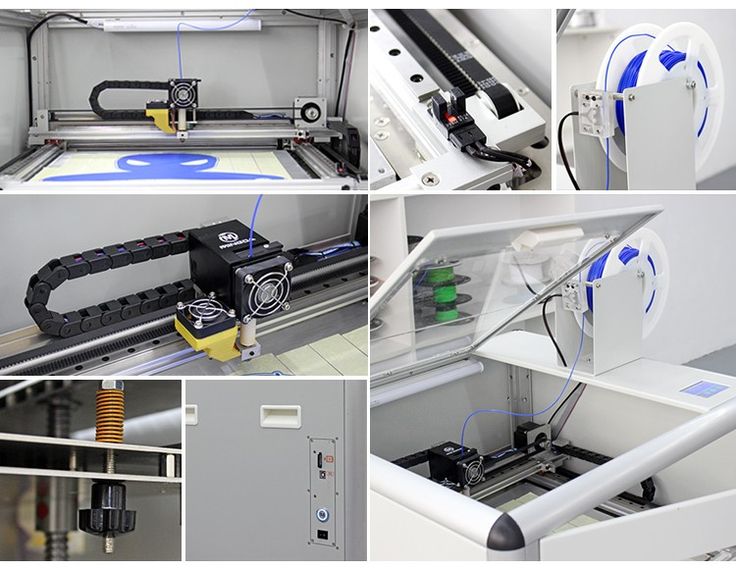

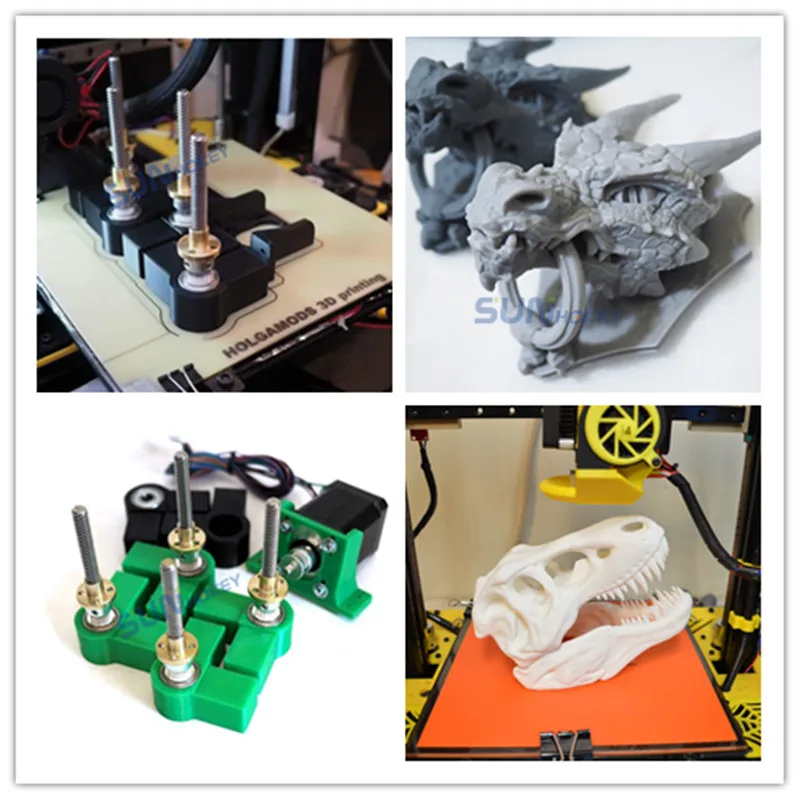

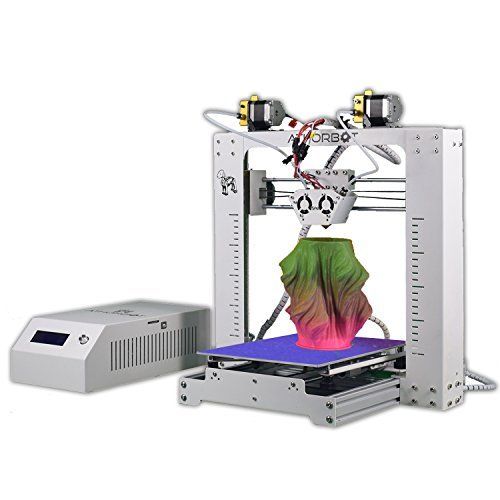

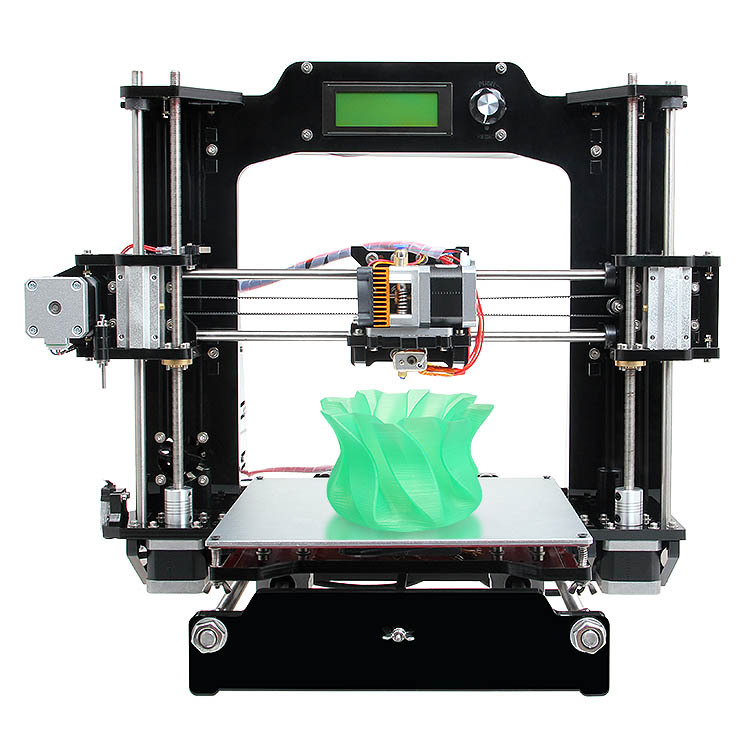

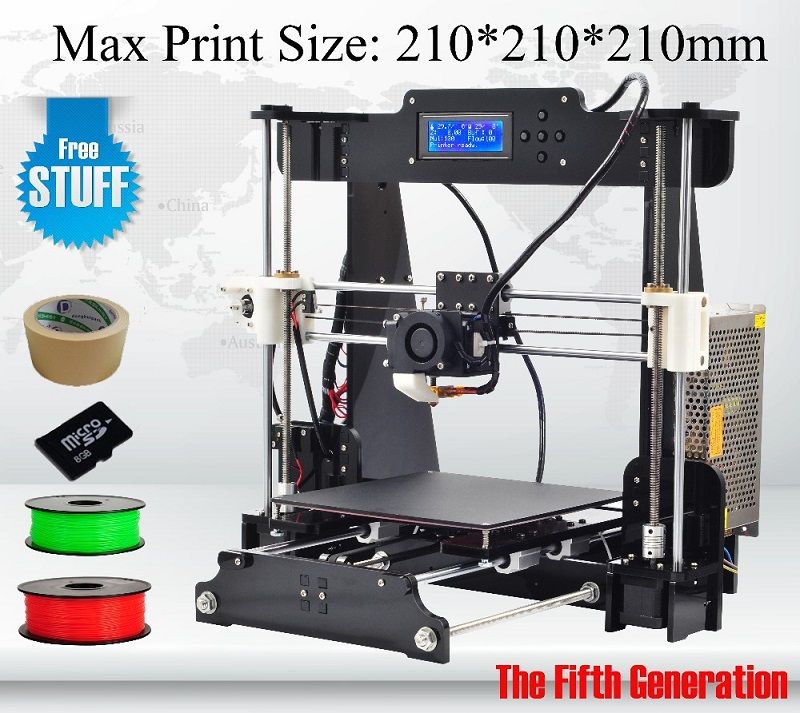

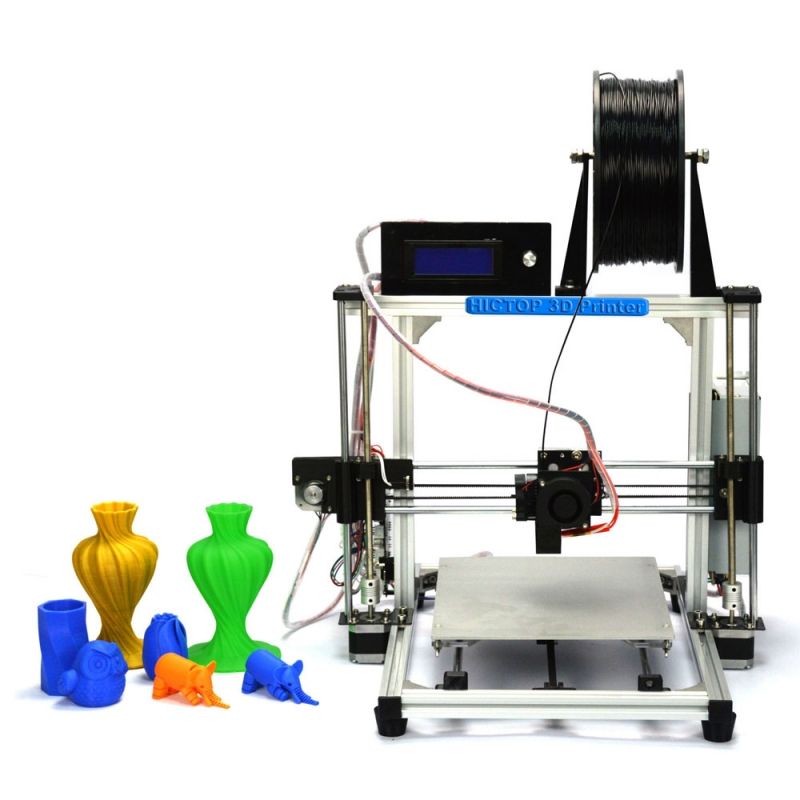

GraysonHobby Shop Now Sells 3D Printers!!! 3D Printer Near Me Atlanta!Located outside of of Atlanta Georgia. Grayson Hobby now sells and supports the Crealty Line of 3D Printers – If you never seen a 3D Printer working before, now you can come see them in action at 220 Old Loganville Road, Loganville GA where we have the most famous Ender 3 printing a 3D model just about every day. Come visit our 3D Printer Showroom where we sell the BEST and MOST popular 3D Printers.

Come visit our 3D Printer Showroom where we sell the BEST and MOST popular 3D Printers.

There’s a novel 3D printer store in town (Atlanta, GA) and it’s here to show you a new dimension of the world.

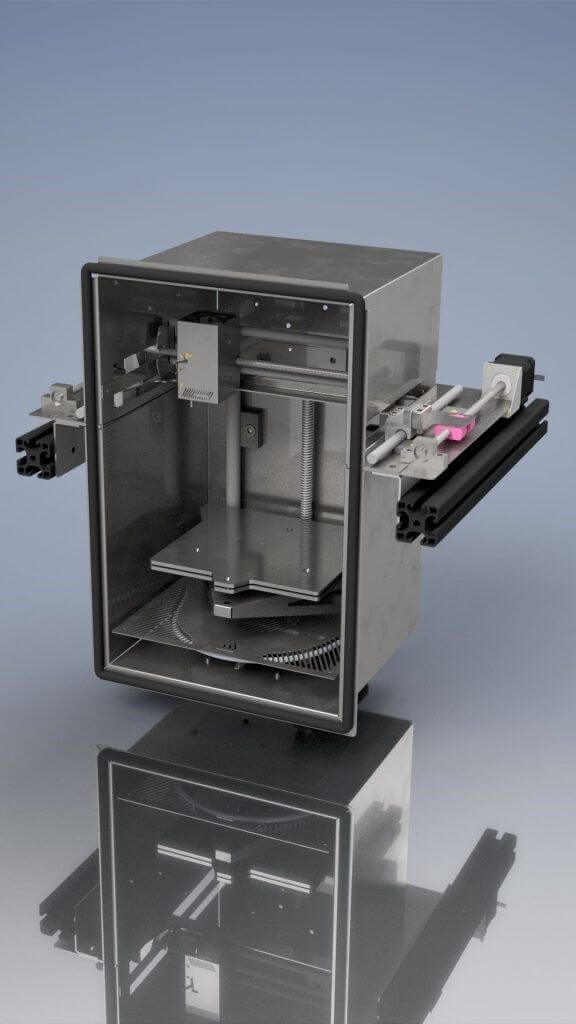

Fully Assembled Models Ready to Take Home

The biggest challenge for new 3D Printer owners is assembly, setup and configuration. Here at Grayson Hobby we several 3D Printers fully assembled ready to take home. So you literally pack it in your vehicle fully assembled. When you get to your home or office, find a sturdy table, plug it in, and print away. Of course the transportation may alter the fine tuning a bit, but for the most part (bed leveling). No hours of assemble, no waste of filament trying to level and tune the configurator. We guarantee you can get to the final location and be printing within minutes, not HOURS.

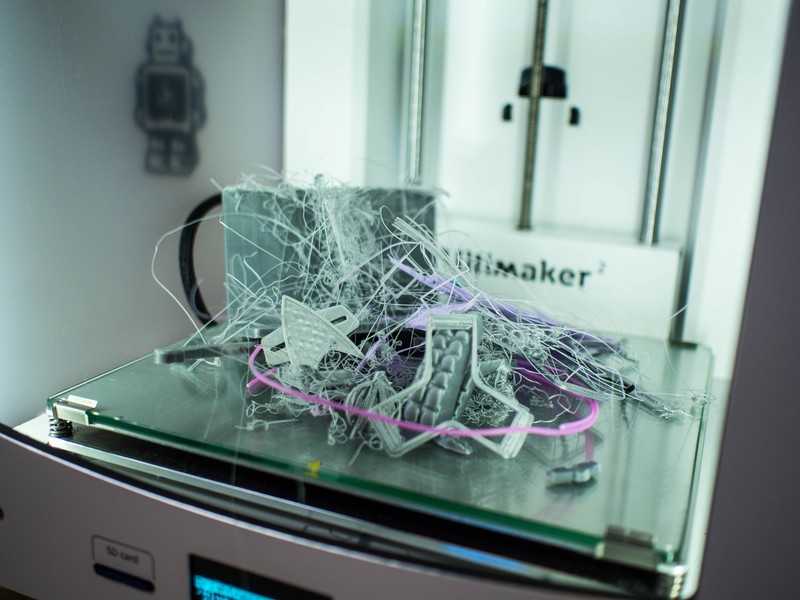

Living in this century, you’ve definitely come across the term “3D printing” one way or another. Several years ago, however, the only place one might have seen or heard of it would have been in a sci-fi movie. But today, 3D printing has become a powerful technology that’s both highly applicable and readily accessible due to various factors.

But today, 3D printing has become a powerful technology that’s both highly applicable and readily accessible due to various factors.

Years ago, 3D printing was only accessible to businesses with large capitals, but with the development of cheaper and easy to use 3D printers, anyone and everyone can benefit from this technology.

3D Printers for the Experienced Person

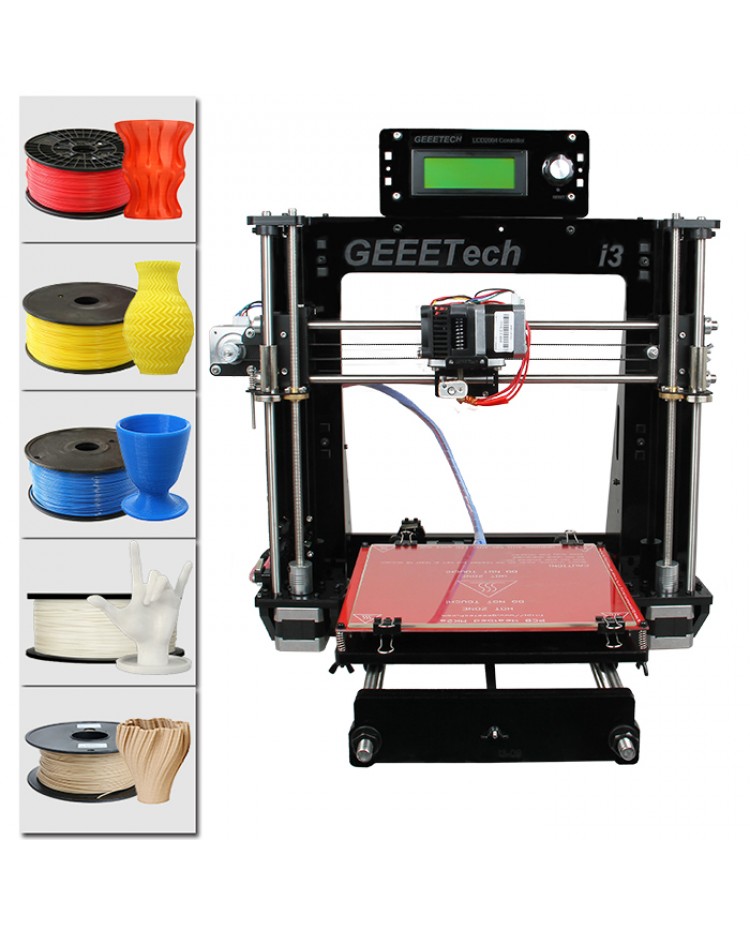

Grayson Hobby also sells 3D Printers still in the factory sealed box. If you are experienced with 3D Printer we have you covered. The Creatlity 10S Pro is the most popular 3D Printer on the market for those wanting a bit more features and for those that have a larger budget. If you want to look at the size of the Ender 3 Pro or the Creality 10S Pro, we have each of these models up and running at Grayson Hobby retail store.

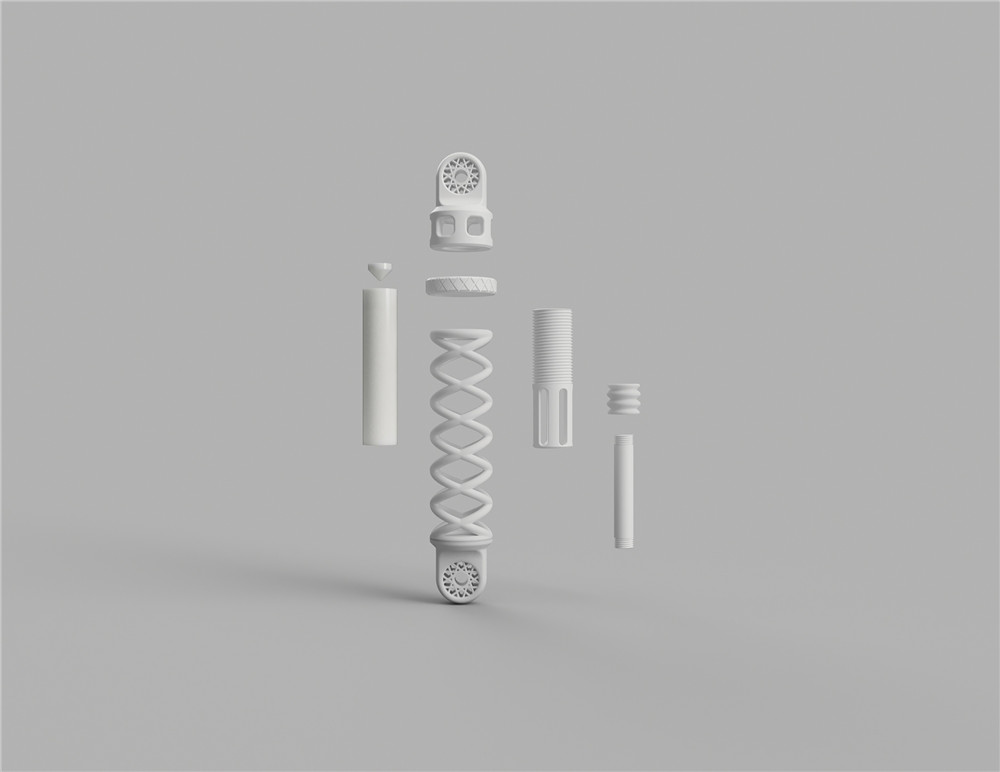

But before we go any further, what exactly is 3D printing?Also known as additive manufacturing, 3D printing is a complex process of creating three-dimensional objects from a computer aided design model, which is usually done by adding materials layer by layer. The machine used to achieve this 3D object is called a 3D printer.

The machine used to achieve this 3D object is called a 3D printer.

Oh, the possibilities are limitless. 3D printers are used for many personal and industrial purposes. Having a 3D printer is like having a device that can make anything you want. Some people use it to make toys for their children, some use it to make missing pieces of an object, while some go to the extent of creating more complex objects like wristwatches.

For industrial purposes and mass production, larger 3D printers are used, while for smaller basic objects, desktop 3D printers can be used.

Aside the ability to just create 3D objects, here are some other benefits of owning a 3D printer.

Benefits of a 3D printer from Grayson HobbyIt’s true that 3D printers will help you create three-dimensional objects, but what’s the difference between getting a 3D printer and just going out to buy the object itself? Well, 3D printers have a lot of benefits and there are many reasons why you’d want get one of your own.

- Get quality objects and save money

Compared to buying items that are lost or items that you might need, a 3D printer offers you a cheaper and more affordable means of getting those objects. Household expenses are drastically reduced because you can easily make spare parts for appliances and even create objects like customized phone casings.

You also have the freedom to choose the kind of material to use for your object, giving you total control over the quality of your object. With your own 3D printer on hand, you can get quality items, avoid the hassle of buying new items and save the cost of transportation.

- Create custom gifts

Many 3D printers come with custom print service for gifts. Why buy a mass-produced coffee mug when you can design and customize one into your preferred unique style? The power of personalization is something that a 3D printer gives, and the objects you make feel special, for sure.

- Make some money

Apart from saving money, you can also make money. Since 3D printers have the ability to create objects with speed, you can develop your printing skills and then engage in 3D printing services. Make that extra buck printing objects for people that are in need.

You need a new doorknob? 3D print it! You want a new cup? 3D print it! All these and more are only possible when you have a 3D printer. Thankfully, you don’t have to look far because GraysonHobby Shop just started selling and fully assembling 3D printers. But if you can’t get one of your own just yet, who’s to say you can’t get your objects custom-made? Yes, the store also offers custom print services for one-off prints and gift items!

So, what are you waiting for? Step into GraysonHobby Shop, and bring your imaginations to life!

Where can I see these printer in action and purchase an Ender Pro 3D Printer.

Grayson Hobby

220 Old Loganville

Loganville, Georgia 30052

tel 678. 682.9123

682.9123

Printing organs: how ears, skin and noses are made with a 3D printer

- Natalka Pisnya

- BBC Russian Service, USA

it will help you sort things out.

Image copyright, Masela family archive

Photo caption,Luc Masela with his parents one month after the artificial bladder transplant. year 2001.

Luc Masela, now 27, is an athlete with a degree in economics, works for a major exhibition company, travels a lot and recently met, in his words, "the most beautiful girl in the world." Both she and most of his current friends were extremely surprised when they learned that 17 years ago he survived a dozen and a half operations.

Luke was born with spina bifida - and although he was able to walk, his bladder was severely damaged. By the age of 10, he almost did not leave hospitals: due to improper functioning of the bladder, fluid began to return to the boy's kidneys, doctors diagnosed an irreversible pathology of the organ.

You need JavaScript enabled or a different browser to view this content

Video caption,"3D printed" organs are here

Doctors offered the family two solutions: lifelong dialysis or the creation of a new bladder from a segment of the intestine. This would guarantee Luke several years of medically supervised life and a high risk of developing cancer.

The urologist in charge of the boy suggested that Masela's family take part in an experimental program to grow a new bladder from his own cells. Then, in 2001, it sounded like science fiction: only nine people took part in the program before Luke. Despite this, his family agreed.

"The essence of the operation was reduced to two stages: first, a piece of bladder tissue was taken from me, and over the next two months, cells were grown in the laboratory in order to grow a new healthy bladder from them," says Luke.

Photo copyright, Masela family archive

Photo caption,Luc Masela, 17 years after the artificial bladder transplant

Next was the transplant operation, which, according to him, lasted 16 hours. “I opened my eyes and saw a cut through my entire stomach, tubes of all possible sizes were sticking out of me, except for them - four IVs and a bottle-feeding machine,” he recalls. “I stayed in the hospital for another month, I was prescribed bed rest, after that I stayed at home for another month.

“I opened my eyes and saw a cut through my entire stomach, tubes of all possible sizes were sticking out of me, except for them - four IVs and a bottle-feeding machine,” he recalls. “I stayed in the hospital for another month, I was prescribed bed rest, after that I stayed at home for another month.

The operation was performed by Dr. Anthony Atala, Pediatric Regenerative Surgeon. In two months, out of a hundred patient cells, scientists created one and a half billion. Further, an engineering structure was created on a collagen frame: the bladder was “sculpted” like a two-layer pie, the core of which dissolved over time, and it started working like a normal organ, taking root thanks to Luke’s own cells.

- An animal capable of regrowing its head

- The birth of a chimera: why do scientists need a human-animal hybrid?

- Swedish company 3D prints body parts

Luke and Dr. Atala haven't seen each other for 10 years after being discharged from the hospital. Once a dying child became the champion of the school wrestling team and went to college.

Atala haven't seen each other for 10 years after being discharged from the hospital. Once a dying child became the champion of the school wrestling team and went to college.

The professor took charge of the Wake Forest Institute of Regenerative Medicine in North Carolina in those 10 years, but Luke was never forgotten: his bladder was one of the most challenging and most successful projects in his early practice.

By 2018, Atala won the Christopher Columbus Award for "work on a discovery that will have a significant impact on society"; The Times and Scientific American magazines at various times named him "Physician of the Year", he was also recognized as "one of the 50 scientists on the planet who in the next 10 years will change the way we live and work."

How to print a new face

Skip the Podcast and continue reading.

Podcast

What was that?

We quickly, simply and clearly explain what happened, why it's important and what's next.

episodes

The End of the Story Podcast

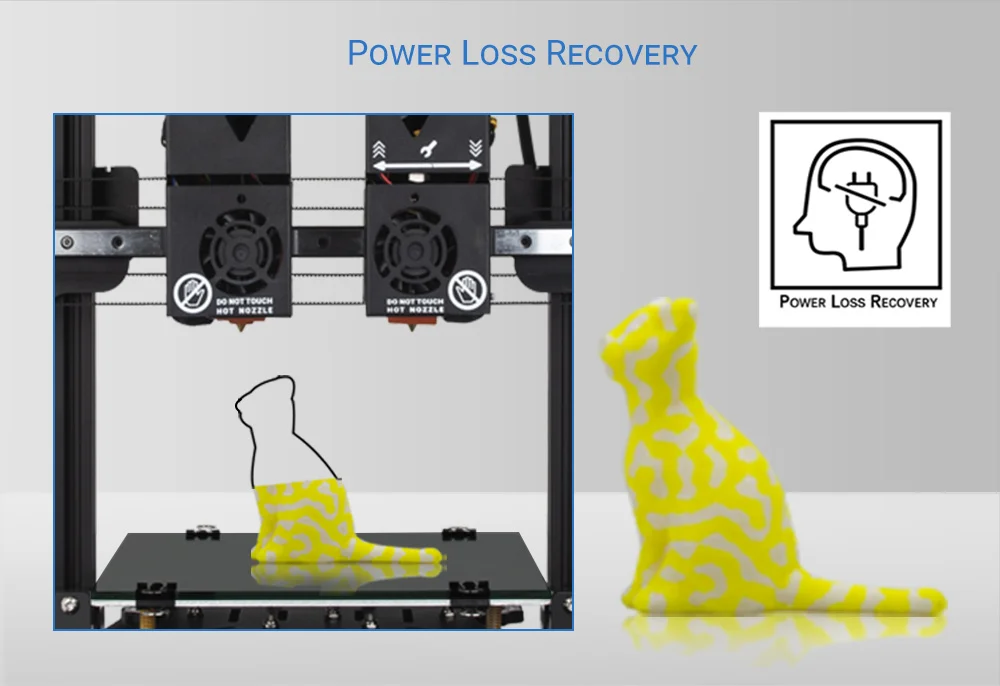

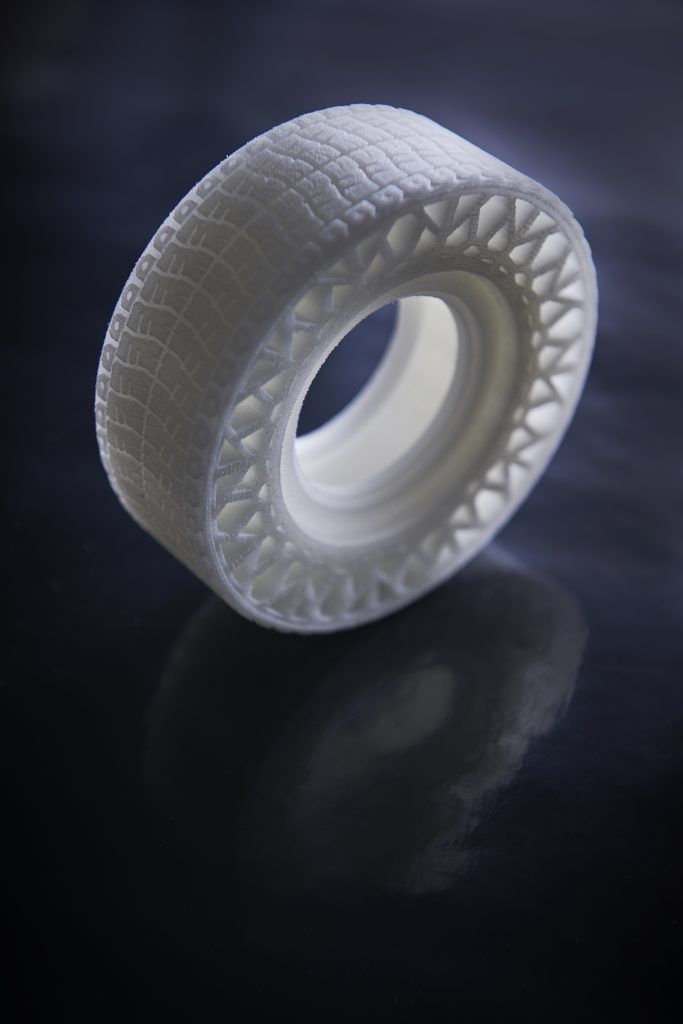

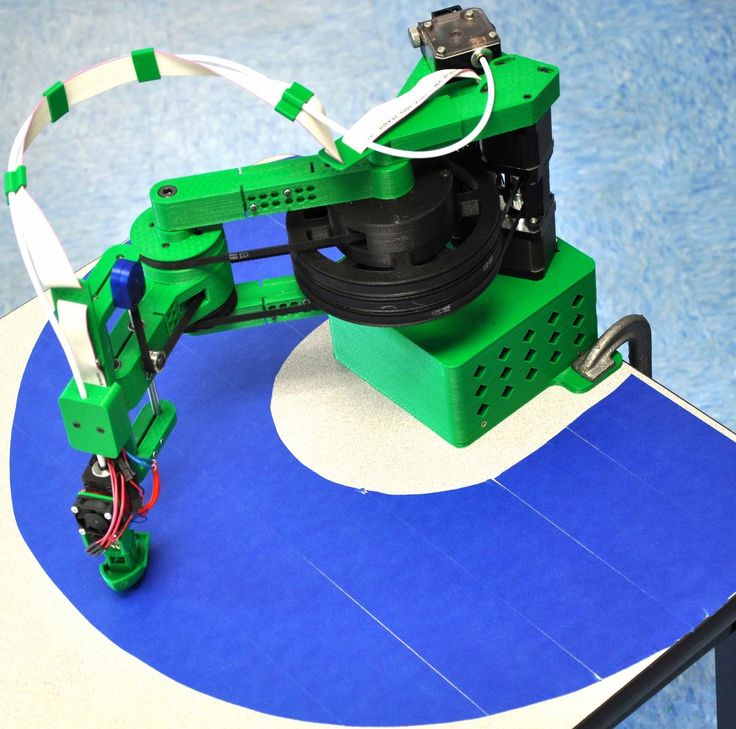

In the mid-2000s, Atala's team turned their attention to an ordinary household 3D printer and wrote special software for it, later specialized machines were created for the laboratory. Now the laboratory "grows" up to 30 different types of cells and organs, as well as cartilage and bones.

One of the team's latest achievements is ears and noses grown outside the human body.

The main customer and sponsor of Atala's developments is the US Department of Defense, and many of the patients are military victims of military operations.

It works like this: first, a CT scan of the ear or nose is done. One of Atala's assistants, Joshua Corpus, jokes that at this stage, people often ask to "improve" the shape of the nose if they thought theirs was too wide or hooked, and the ears if they were too wide.

After that, a special computer code is written, and the printing of the base of the organs begins.

For this, a bioabsorbable polymer, polycaprolactam, is used. At the same time flexible and durable, in the human body it disintegrates within four years.

After printing, the layers of polycaprolactam resemble lace; after transplantation, their place will be taken by a person's own cartilage tissue in a few years after transplantation.

Polycaprolactam is then saturated with a gel created from the patient's cells, cooled to -18 degrees Celsius - so the cells, according to scientists, are not damaged, they are "alive and happy."

Image caption,Printing a test kidney sample on a bioprinter

In order for the polymer and gel structure to take shape and become something more durable, ultraviolet light is used in the laboratory - it does not damage cells.

The future implant is printed for 4-5 hours, then it is finally formed and inserted under the epidermis.

Skin can also be grown: children affected by the fires were the first to participate in the early trials of Atala - after the "printing" of the skin, scientists observed the patients for several more years. The new skin did not crack, did not burst, and grew with the children.

The new skin did not crack, did not burst, and grew with the children.

The most difficult job, according to the scientist, is facial wounds: it’s not enough just to stretch the skin, you need to accurately calculate the geometry, align swelling, bone structure, and understand how a person will look after that.

In addition to the skin and ears, Atala can "print" the bones of the jaws, grow blood vessels and cells of some organs - the liver, kidneys, lungs.

This technology is especially appreciated by oncologists: on the basis of patient cells, it is possible to recreate the body's response to various types of chemotherapy and observe the reaction to a particular type of treatment in the laboratory, and not on a living person.

But the liver, kidneys, lungs and heart are still being tested. Atala says he raised them in miniature, but creating organs from various tissues to real size requires a lot of additional research.

But, according to him, cells were grown in the laboratory and a vagina was created for a girl who was born several years ago with a congenital deformity of the genital organs - several years have passed since the transplant.

Image caption,Bioprinted polycaprolactam ear implant base

Atala smiles and adds that his team is also working on a working penis. This research has been going on for several years, and the most troublesome for scientists is the complex structure of tissues and the specific sensitivity of the organ itself.

Among others, Igor Vasyutin, a Russian post-graduate student of the First Moscow State Medical University (MGMU) named after Sechenov, is working on this under laboratory conditions. He is a cell biologist, Atala's right hand.

Vasyutin has been in the USA for about a year - he came on an exchange. He is ready to talk about the behavior of stem cells for hours, but becomes less verbose when it comes to Russian science.

Vasyutin's alma mater has not reached mass regeneration of human organs and is still training on animals: local scientists "printed" a mouse thyroid gland on a 3D printer.

However, they are also involved in the study of human organs. According to the head of the Institute of Regenerative Medicine at MSMU Denis Butnar, several years ago the Institute recreated a special engineering design of the buccal mucosa. She functioned perfectly for the first six months, but subsequently had to undergo a second operation.

Image caption,Test specimen of an ear implant exposed to ultraviolet light

In Russia, however, over the past few years, the Italian surgeon-transplantologist Paolo Macchiarini has been practicing - the man who was the first in history to perform an operation on transplanting a synthetic organ - a plastic tube that replaced the patient trachea.

- Paolo Macchiarini: the rise and fall of the famous surgeon

However, seven of his nine patients died, and the breathing tubes implanted in the remaining two subsequently had to be replaced with donor ones.

Several criminal cases were brought against him, including on charges of pressure on patients and fraud, and the world's leading doctors called Macchiarini's operations "ethical Chernobyl."

Will printed organs replace donors?

At the zenith of his career, Macchiarini argued that a new perspective is opening up for humanity: you can "print" any human organ on a printer, create an engineering structure from it, enriched with the patient's stem cells, and get the perfect prosthesis.

Be that as it may, complex human organs - the liver, kidneys, heart, lungs - have not yet been grown by any regenerative surgeon.

Bioprinting of the so-called simple organs, however, is already available in the USA, Sweden, Spain and Israel - at the level of clinical trials and special programs.

The US government is actively investing in such programs - in addition to Wake Forest, cooperating with the Pentagon, the Massachusetts Institute of Technology also receives significant amounts to recreate the functioning of the liver, heart and lungs.

Skin application test on a burnt wound

According to Professor Jorge Raquela, a gastroenterologist at the Mayo Clinic Research Center, "Bioprinting is one of the most exciting branches of modern medicine, it has huge potential, and the turning point of the most important discoveries is already close."

Meanwhile, Pete Basillier, head of R&D at analytics firm Gartner, insists technology is advancing much faster than understanding the implications of 3D printing.

Such developments, according to Basilière, even if created with the best of intentions, give rise to a set of questions: what will happen when "improved" organs are created, the basis of which will not only be human cells - will they have "superpowers"? Will a regulatory body be created to monitor their production? Who will check the quality of these organs?

More than 150,000 Americans are on the waiting list for organ transplants every year, according to a report from the US National Library of Medicine. Donor organs will receive only 18% of them; every day in the United States, without waiting for a transplant, 25 people die. Organ transplants and subsequent rehabilitation cost insurance companies and patients $300 billion in 2012 alone.

Donor organs will receive only 18% of them; every day in the United States, without waiting for a transplant, 25 people die. Organ transplants and subsequent rehabilitation cost insurance companies and patients $300 billion in 2012 alone.

- A 3D printer helped a cyclist who lost his jaw

- Genetically modified pigs - human organ donors?

- The world's first child who received both hands transplanted plays baseball

Most Americans are potential donors: upon obtaining a driver's license, they voluntarily answer the question of whether they agree to donate their organs in the event of a car accident or other dangerous incident . In case of consent, a small "heart" and the word "donor" appear in the corner of the document.

Professor Atala's driver's license is the same - despite all his achievements and faith in the press, he is ready to share his with others.

Neither the professor himself, nor his subordinates hide the fact that science is not yet able to "print" organs for thousands of those who need transplantation right now. According to him, it will take several decades to replace donor organs with grown ones at the mass market level.

The work of Atala and others in the field of regenerative medicine remains more probing than mainstream, and still tailored to the individual patient.

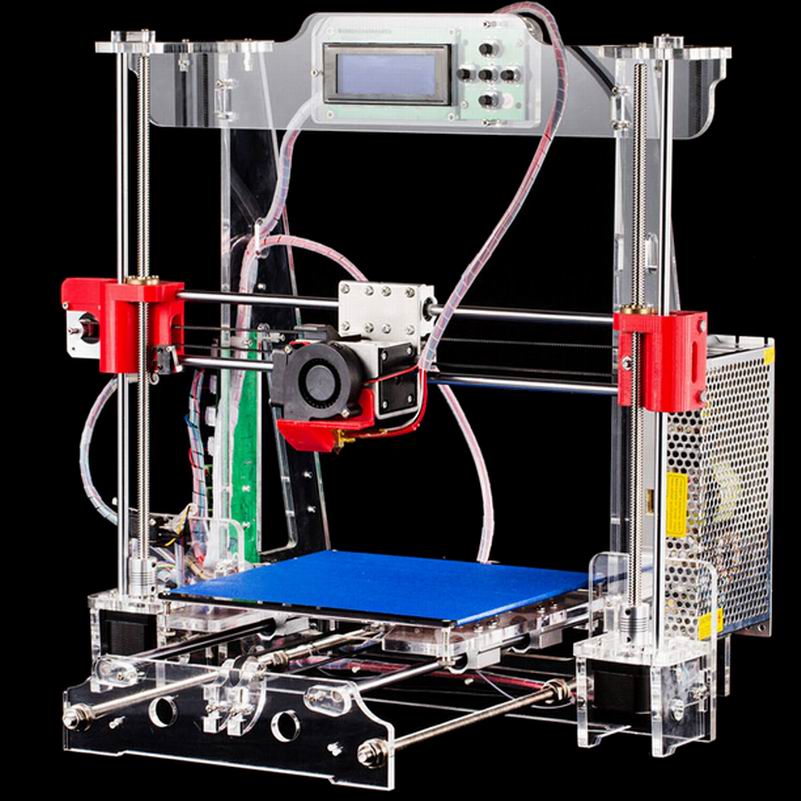

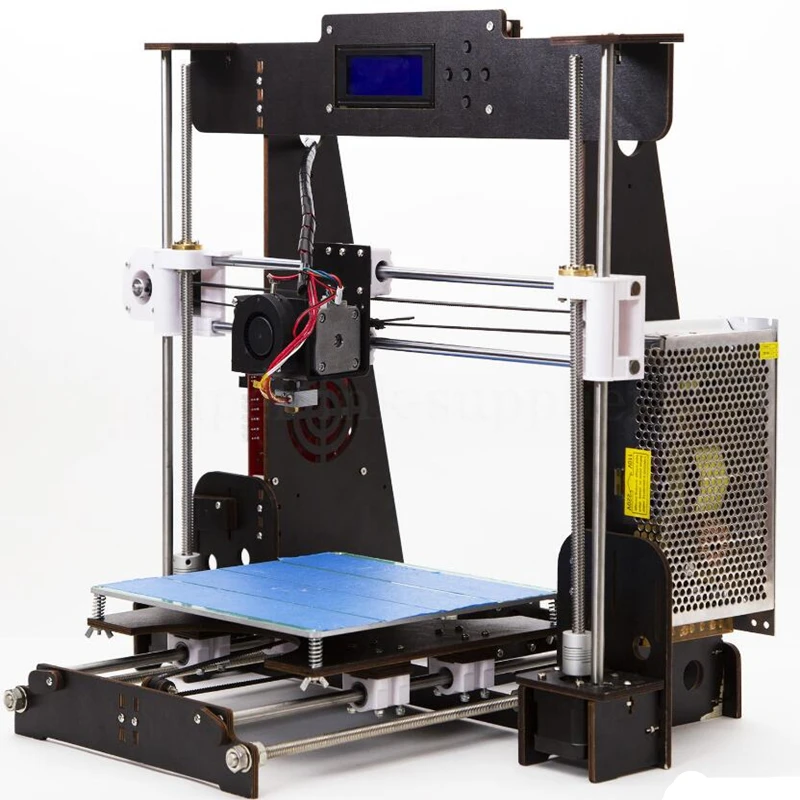

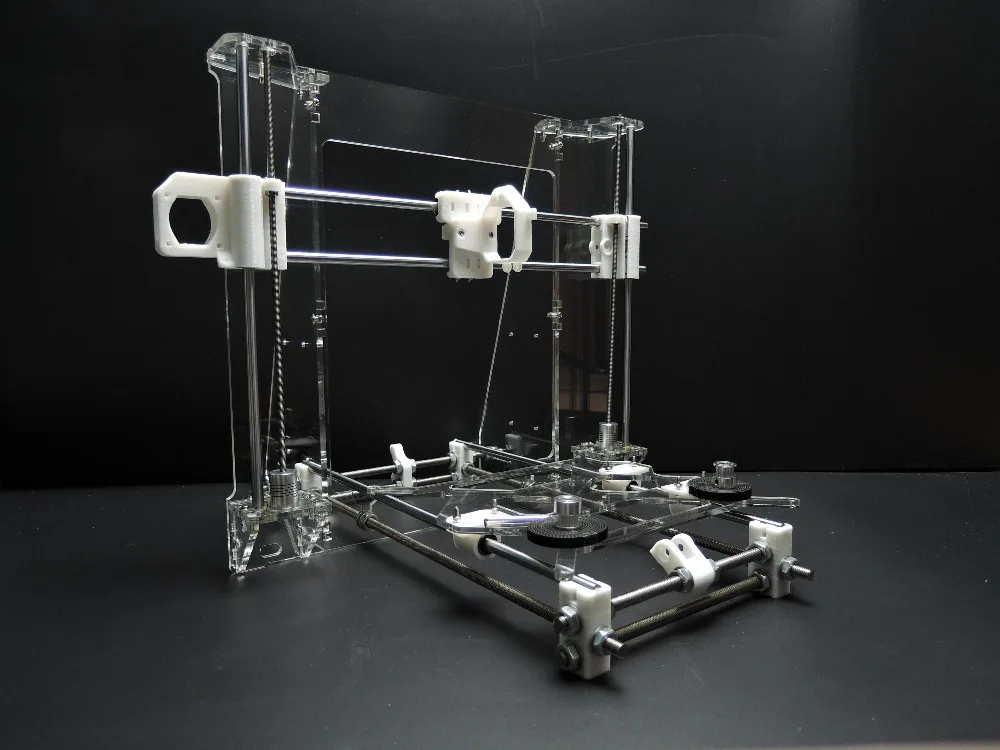

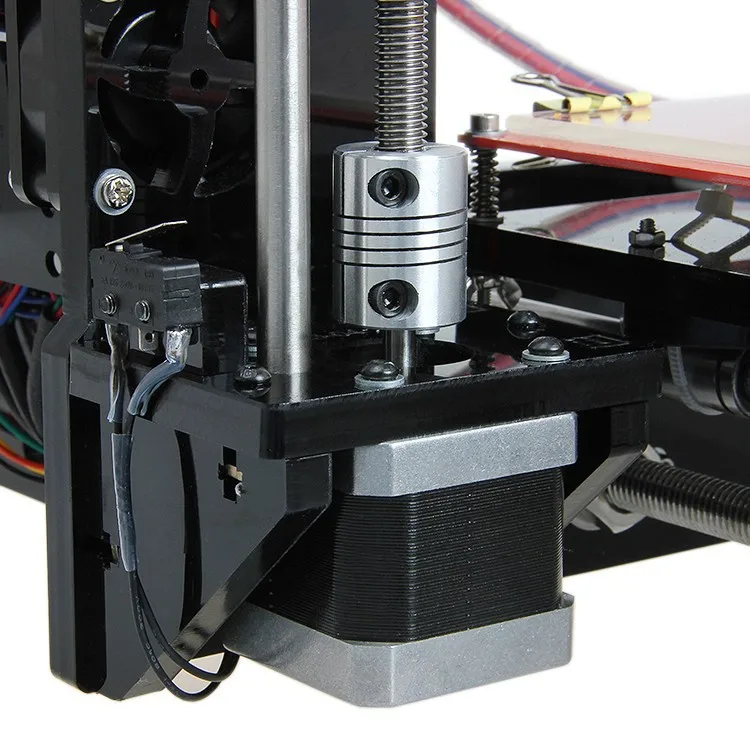

Why do I need a 3D printer? A little later, the thought was reshaped into "Buy", and a little later, "What for it to me." But the interest in the technology did not give me rest, and when I coincided with the holiday, I still bought myself a miracle of the Chinese industry, an Anicubic Kossel 3d printer.

I bought it because it was one of the cheapest (15t.r.) but at the same time, according to the descriptions, it was quite strong. In the most common review, it is delivered as a kit of parts for assembly, and according to reviews, the biggest difficulty is calibration, since this type of printer belongs to Delta printers with unusual mechanics at first glance.

The seller had several options:

- On rollers - this is when aluminum profiles act as guides, and carriages with plastic rollers ride along them.

- On rails - steel rails (industrial linear guides) and steel carriages with circulating steel balls go along them.

- Variants 1 and 2 with heated table.

I ordered a version on rails with a table.

Parcel weighing eight kilos arrived by courier in a week. As it turned out, the Chinese do not stand still and do more and more for a person - the Printer came almost assembled, it only remained to connect everything together.

Top and bottom triangles with motherboard mounted:

Rails and uprights, rails separately in dense polyethylene with silica gel:

Table, control panel, power supply, feeder (bowden), all also in separate compartments foam box:

Hot end (second part of the extruder) with rods assembly - it is also called a spider:

Instructions with pictures, all pages are numbered:

The bags with fasteners are numbered with the same number:

Each bag contains exactly one set of fasteners more than necessary.

And as a bonus, a ruler, side cutters, spatula, tube of lubricant and rubber gloves:

As a result, after a couple of hours of pleasure, the finished construction is obtained:

- I was afraid that it would not be enough, as a result, about 10 centimeters remained extra. Everything is assembled with hex keys, but those that are definitely not assembled in the kit - the metal is raw, in the end I assembled it with my old screwdriver with bits. The electrician is assembled according to the picture in the instructions, and on all wires there are stickers with inscriptions corresponding to the inscriptions on the board. The manufacturer also thought about the calibration and made an auto calibration: a limit switch on a magnet is put on the hot end and a special item in the menu is launched.

When you start the calibration, the head rises up to the limit switches, then it starts to go down to the table, touches the table a couple of dozen times and rests on the Z-post!? Restarted - again the same thing, double-checked all connections - again the same thing. Using the

Using the mathematical deduction method , I found out that there is an inaccuracy in the instructions: there are 6 connectors on the board for X +, Y +, Z +, X-, Y-, Z- limit switches, and there are only three limit switches, and a pair of limit switches must be connected to the connectors instead of connectors with the + sign With "-". After the reconnection, the calibration was successful.

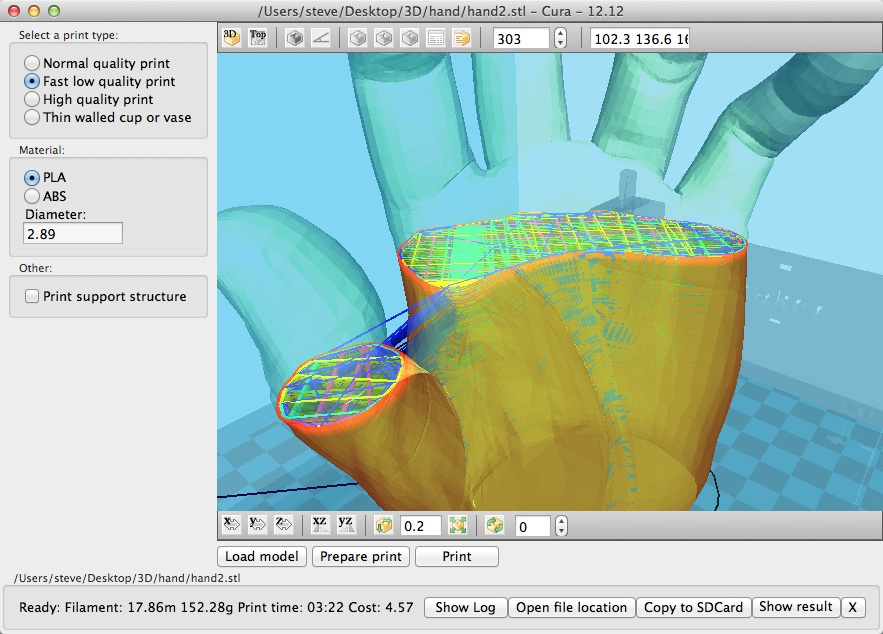

Also included is a memory card with Cura software and test cases. All test cases are in STL format, that is, you first need to install the slicer (Cura) and save the model in gcode format, after which you can insert the flash drive into the printer and start printing. The first such model was printed very poorly and has not been preserved.

Then it was necessary to answer the question: Why do I need a printer? I installed the home version of Compass and in a couple of evenings I was able to draw a few simple models.

Oil probe Mitsubisi Lancer:

Painted without supports

Detle sets for one long -stuck project:

Details Upload:

9000

9000 all PLA, the coil of which came with the printer (1 kilogram).