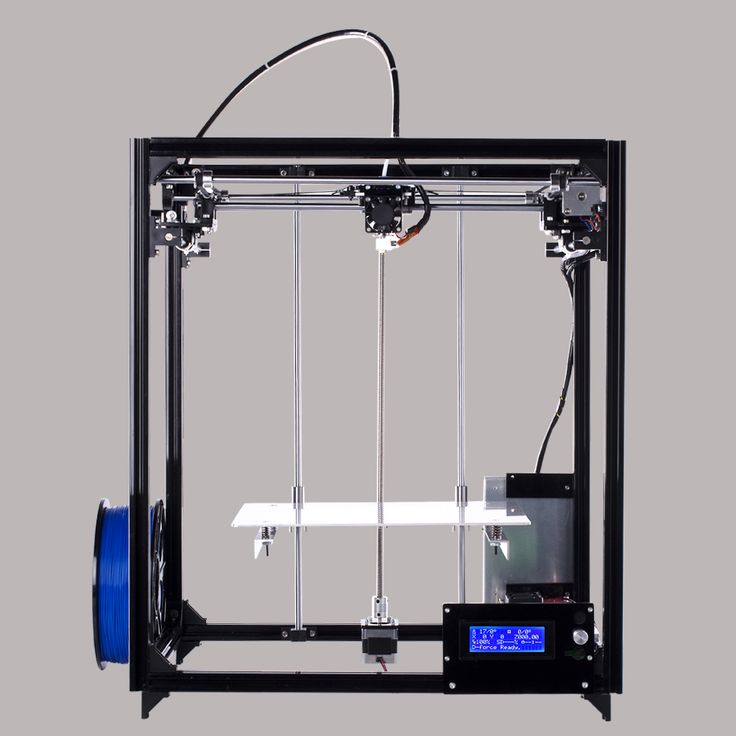

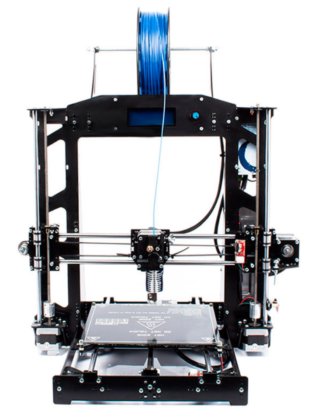

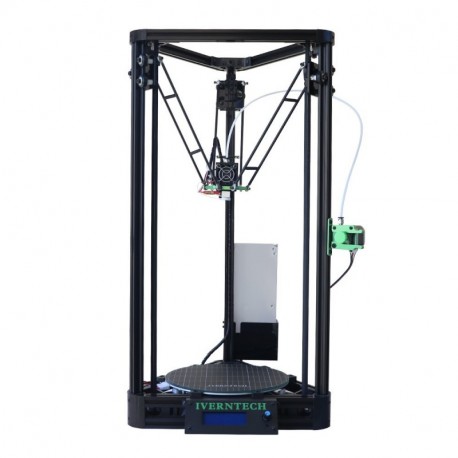

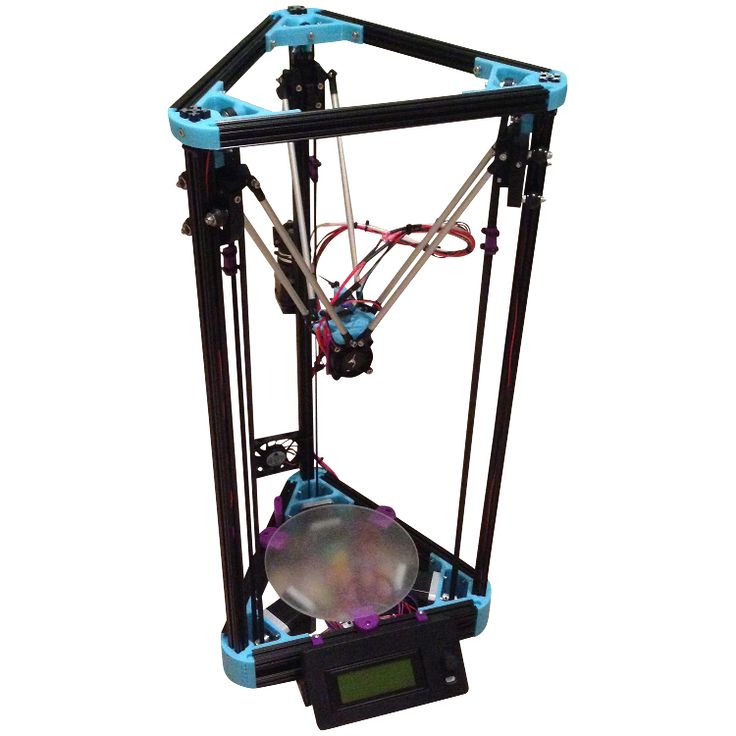

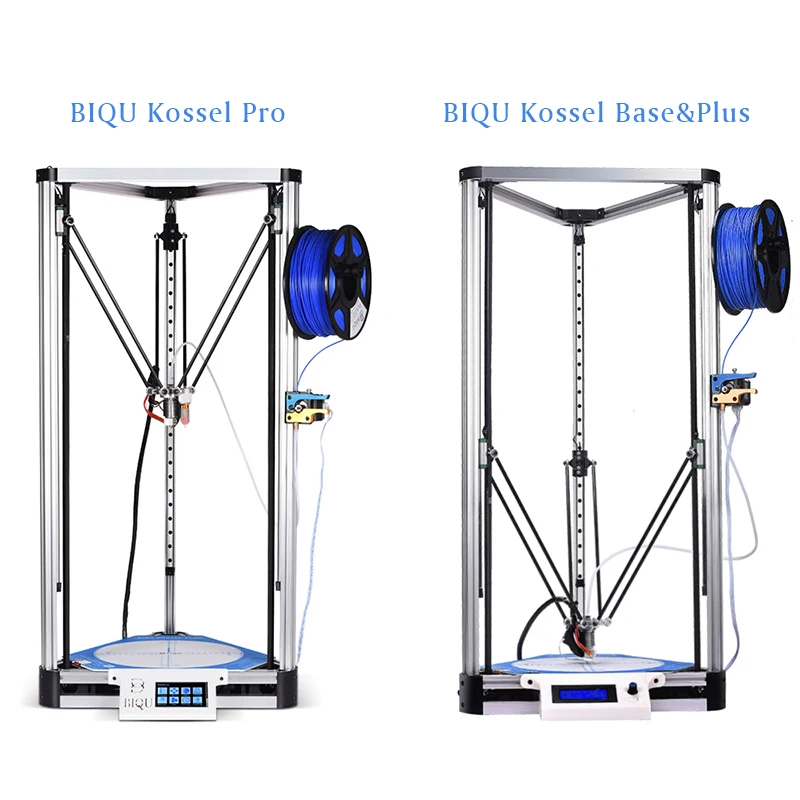

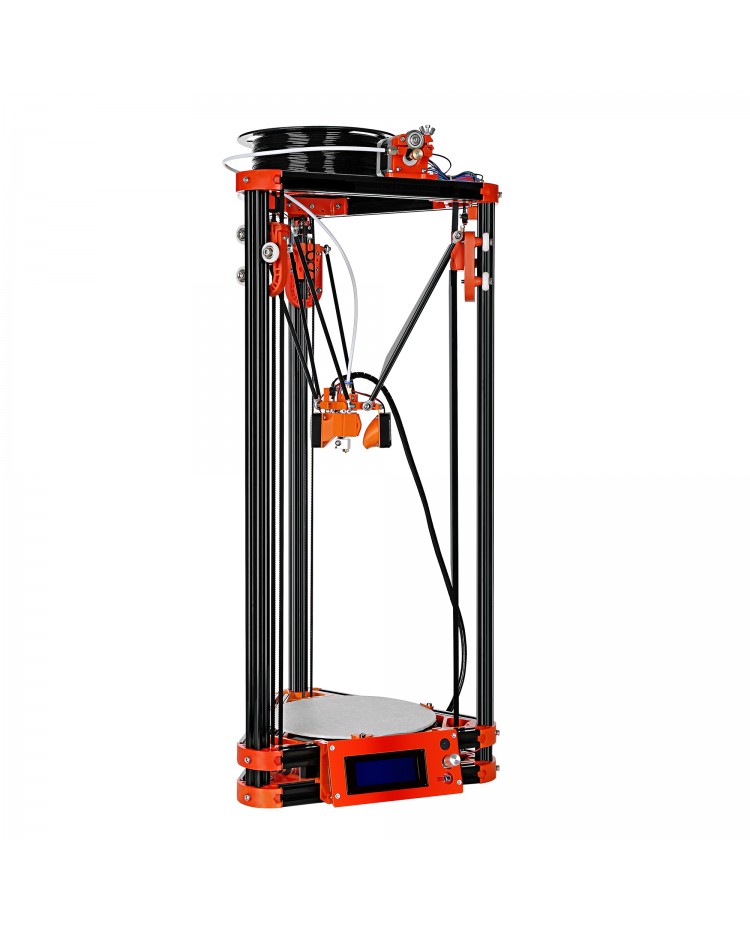

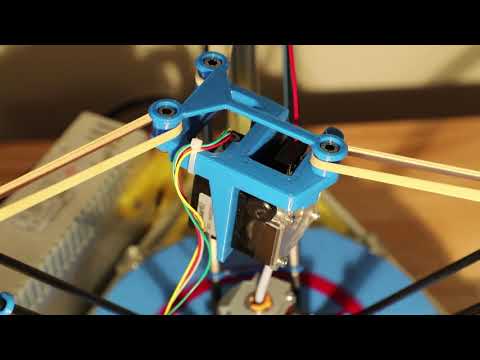

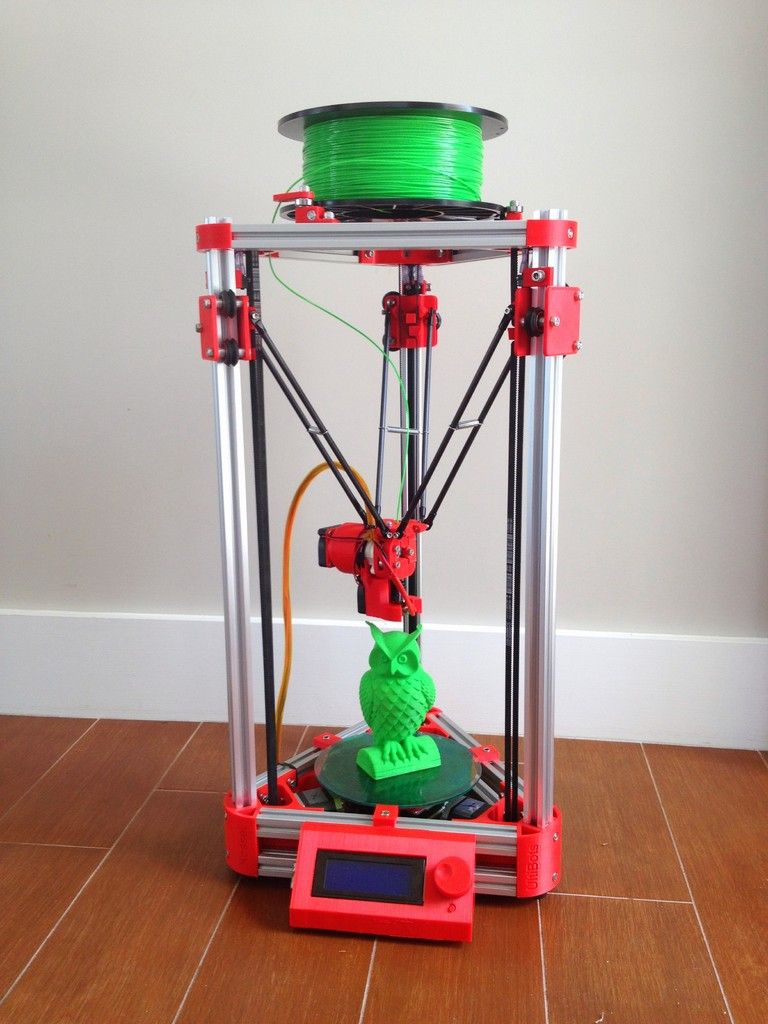

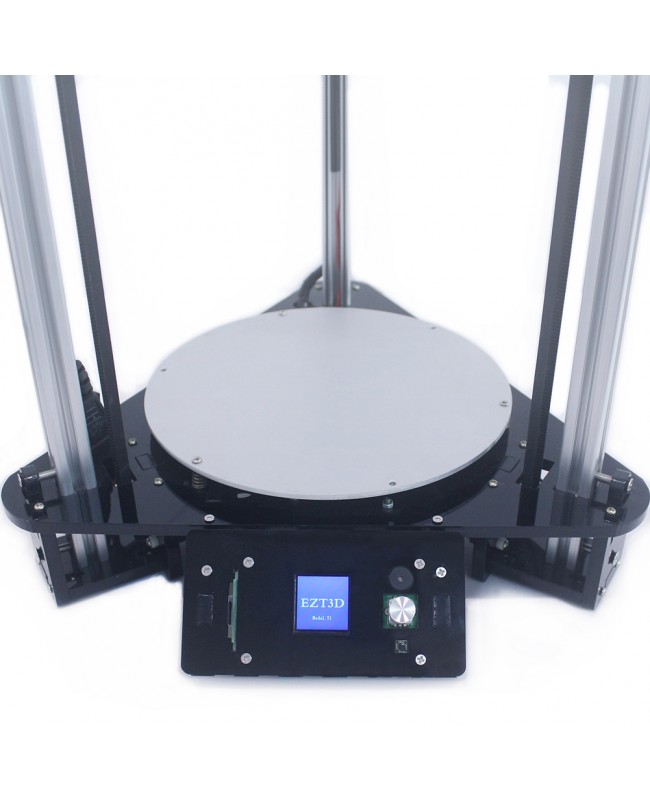

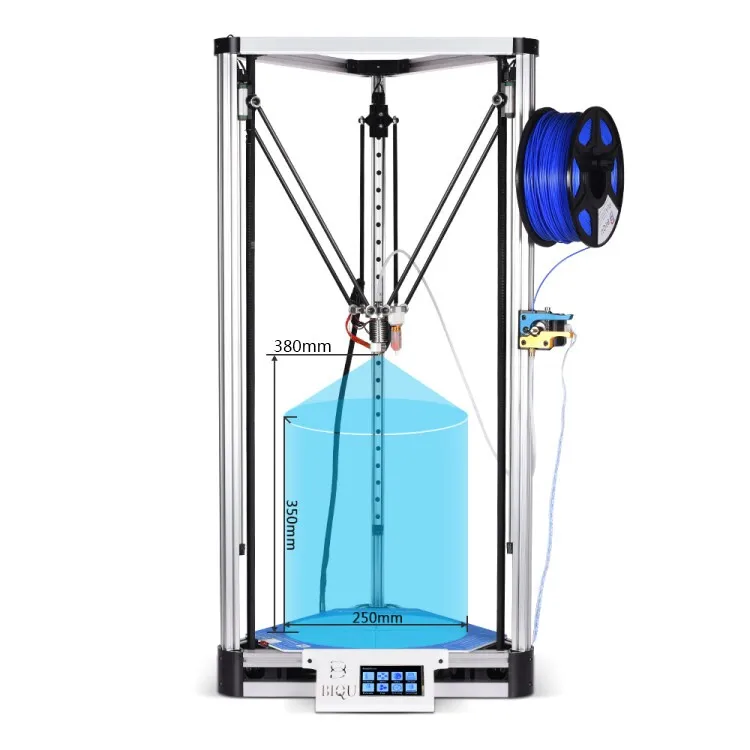

Folger kossel 3d printer

Folger Tech Kossel 2020 suddenly will not print properly? - 3D Printers - Talk Manufacturing

RoboDLC

#1

I finally got my Folger Tech Kossel 2020 delta printer tweaked in. bed flat, zero offset z probe, auto leveling working right, cal cube nearly perfect, lots of prints, including some that use about 75% of the bed working fine, part fan added. Bliss.

And then BANG! Overnight, everything went south.

It now does not reach the bed, first layer isn’t properly “sqashed”, subsequent layers look like they are too high off of the last layer, dogs and cats sleeping together, mass hysteria… (nod to Ghostbusters).

I checked my leveling, everything had moved “up” about .3mm. OK, I releveled, modified the offset from z probe in configuration.h, no good, still the same problem.

Has anyone else seen this? I am using the same firmware, the same slicer/printer (Simplify3D), the same PLA, the same bed and hot end settings.

What gives?

Help?

DLC

Mark_Ingle

#2

Are you homing before the print starts?

Steve_W_Watson

#3

Maybe try a firmware upgrade. Possibly a corruption or bug?

RoboDLC

#4

Answering questions from (appreciated) responses:

Steve: It could be a bug, it is old firmware, but it seems unlikely unless it was a “time bomb”, nothing in any settings changed either in firmware or software.

Mark: Yes, I do home at the start of a script - I am schooled to what happens if you don’t…

Here is a more detailed update of my problem after my investigations:

My setup:

Folger Tech Kossel 2020 delta printer running Marlin firmware ©2011 from the kit maker

Running Simplify 3D on a Win 7 computer

Until yesterday, my delta printer was “dialed in” and printing whatever I threw at it. My bed is flat, auto-leveling was working like a charm. I have a part fan that is off for the first layer and set to 50% at layer 4. My bed is at 60 C and my hot end is at 210 C for the first layer and backs off to 200 C for all layers after that. I work in PLA.

Then, total dysfunction.

Problem one:

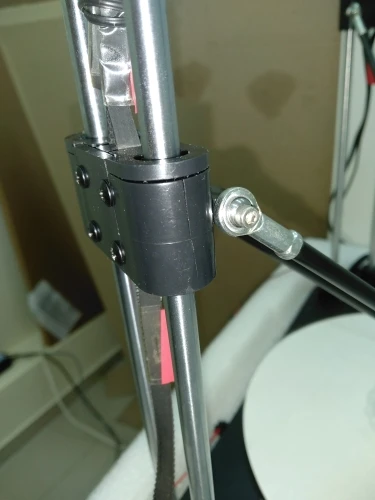

I found that suddenly all my endstops, leveling data changed. My bed used to measure out (X,Y,Z,0) at 1.1, 1.1, 1.1, 1.0. I am using a zero-offset magnetically attached mechanical switch to do the auto bed-leveling. I then measured the “new” bed level stats at 1. 4, 1.4, 1.4,1.3, and the Z offset of the probe obviously moved.

4, 1.4, 1.4,1.3, and the Z offset of the probe obviously moved.

As I re-leveled everything to find the new settings, they changed and finally settled to 1.2, 1.2, 1.2, 1.1.

Huh? Why did these all change, and why did they settle back down (most of the way)?

I updated my configuration.h file and kicked some prints off. This almost worked. If I have flat objects with large contact area-to-height ratios, the print will work. Things that have multiple, smaller contact points will not print, by about the 20th layer the print head will snag on something and pull it off the bed.

This brings up problem 2:

Even flat models now are festooned with “cobwebs”. Gunk gathers and creates “zits” in places and more scars than usual on surfaces. The plastic may warp on a layer and when the print head comes along may hit it and knock it off. Also, it may be dragged around by drools from the hot end. I now see dark sections that look like the plastic got burned while coming out.

OK. I am clueless about Problem 1, I checked my mechanics, no loose or broken rods, my bed springs didn’t suddenly relax and come back, my carriages are solid, no loose screws, my limit switches didn’t move (they’d all have to move at once since the error distribution was consistent at all towers). The belts are the same tension and nothing that I could find was changed on the end effector.

I am clueless about Problem 1, I checked my mechanics, no loose or broken rods, my bed springs didn’t suddenly relax and come back, my carriages are solid, no loose screws, my limit switches didn’t move (they’d all have to move at once since the error distribution was consistent at all towers). The belts are the same tension and nothing that I could find was changed on the end effector.

Problem 2 looks like a classic case of the PLA getting too hot: strings, warping, burned spots, drool dragging. But why all of the sudden? My settings over the last two weeks, when I got my printer working, have not changed. Is it possible that the thermistor is failing and the temperature of the hot end is getting hotter than what is being reported?

regards,

DLC

Mark_Ingle

#5

Have you calibrated your extruder steps and filament multiplier? Also the auto level feature is hit and miss. I ditched it after three weeks of frustration. Doing it manually takes time but it’s worth it in my opinion

I ditched it after three weeks of frustration. Doing it manually takes time but it’s worth it in my opinion

RoboDLC

#6

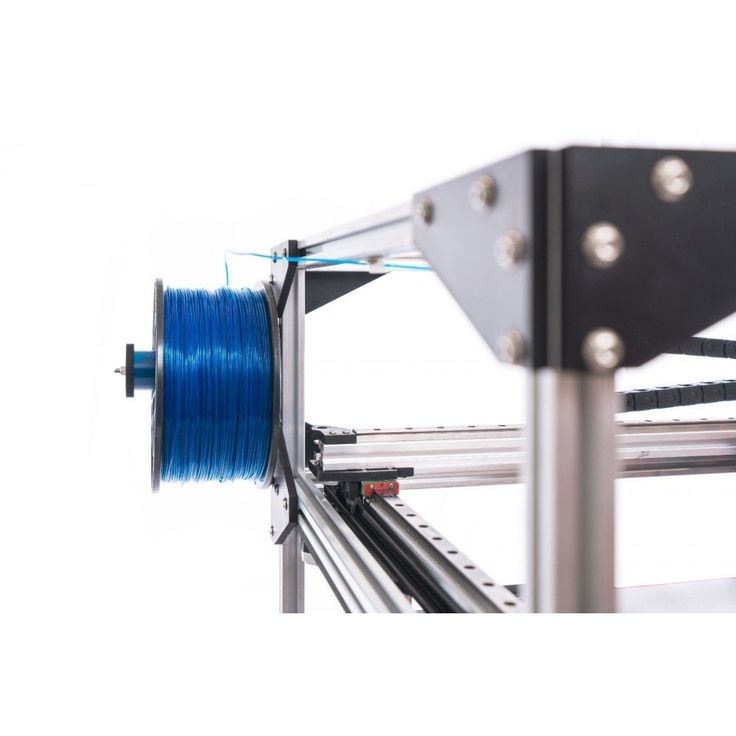

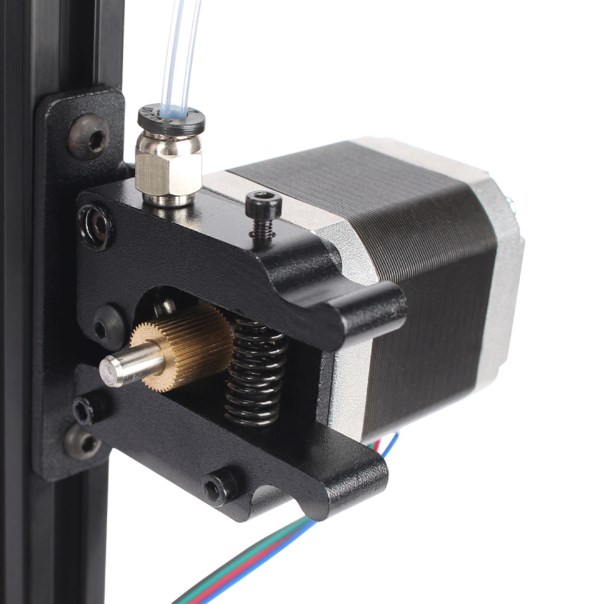

I have not done any calibration on my filament extruder. Up until this point, it was fine. The auto level worked like crap with the included inductive sensor, it works great with my zero offset z-probe that is a mechanical switch, basically the same switch used by the endstops. I have plans for a more sophisticated one later, but not until I get these latest oddities fixed.

thanks,

DLC

Mark_Ingle

#7

Okay…you may have a bad stepper driver board. What kind of controller are you using?

What kind of controller are you using?

RoboDLC

#8

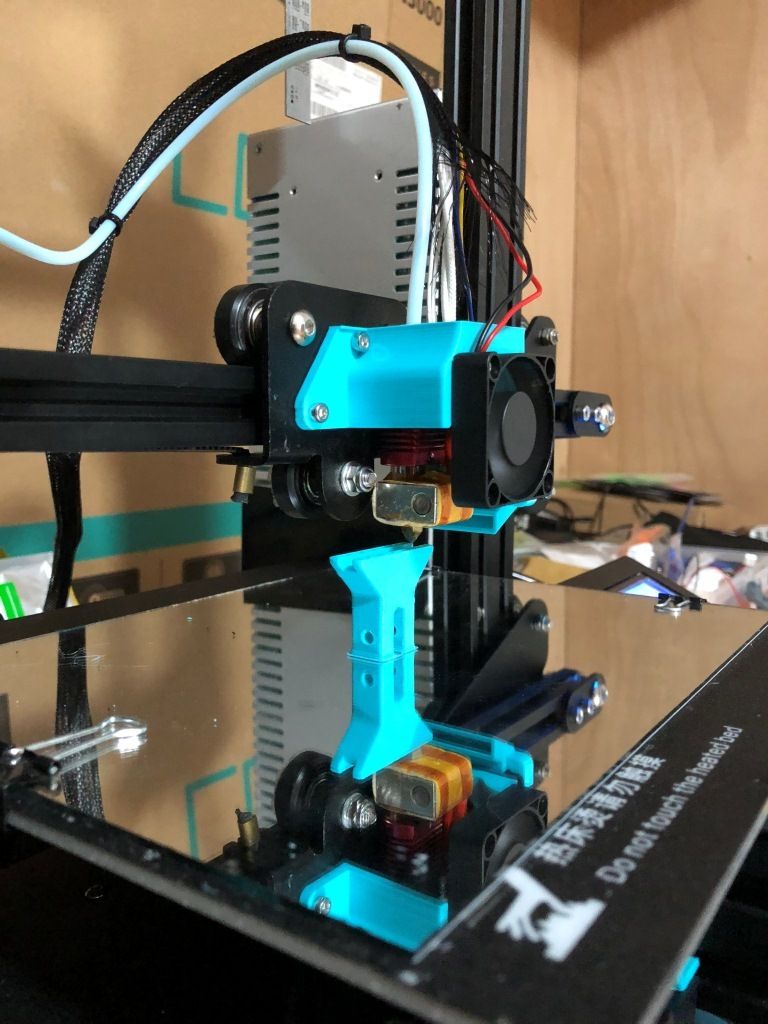

RAMPS 1.4 shield with StepStick stepper drivers.

But, I was looking at goop that had piled up on top of the heater block and realized that there is a simple explanation that explains both the nozzel offset change, plastic goober and burnt PLA patches.

My heater block has come slightly unscrewed. When you install the extruder nozzle you screw that in first, then screw the heater block onto the feeder tube. There is nothing keeping that heater block fixed in place (a mechanical bug if you ask me.) Just before I started having my print problems I had to remove the Bowden tube from the filament feeder. It was a difficult pull and my wiring for the fans and the heater block etc. is zip-tied to the Bowden tube. I probably yanked that tube enough to put tension on that wire harness and the next time the heater block heated and loosened the plastic, that tension may have loosened the block. I have this mental picture of the wires coming out of the block facing a slightly different direction than they usually were. This would cause the nozzle to be a little closer to the bed, it could be sucking in burnt plastic that has oozed out of the tube and onto the block, there to get toasted with long term heat exposure, and it could explain drooling plastic because the “vacuum” of the feeder tube would be broken and get air input from the joint, which is now not sealed.

I probably yanked that tube enough to put tension on that wire harness and the next time the heater block heated and loosened the plastic, that tension may have loosened the block. I have this mental picture of the wires coming out of the block facing a slightly different direction than they usually were. This would cause the nozzle to be a little closer to the bed, it could be sucking in burnt plastic that has oozed out of the tube and onto the block, there to get toasted with long term heat exposure, and it could explain drooling plastic because the “vacuum” of the feeder tube would be broken and get air input from the joint, which is now not sealed.

I will check on this theory and report.

DLC

RoboDLC

#9

Theory Confirmed.

This whole problem was caused by me putting tension on the heater block wiring when I had to pull a broken off strand of filament from the Bowden tube!

I will leave out the string of events leading to the debacle. The key thing was the heater block rotated about 15 degrees loose. This caused a “leak” at the top of the block and stuff to dribble off (after being burned by sitting on the block for a long time) and drool on the print. This also caused the nozzle to drop about .4mm toward the bed, throwing off the print handling and causing the print heat to bash into things. So these two apparently unrelated problems were caused by one issue, a loose heater block.

The key thing was the heater block rotated about 15 degrees loose. This caused a “leak” at the top of the block and stuff to dribble off (after being burned by sitting on the block for a long time) and drool on the print. This also caused the nozzle to drop about .4mm toward the bed, throwing off the print handling and causing the print heat to bash into things. So these two apparently unrelated problems were caused by one issue, a loose heater block.

Let my experience stand as a warning to others, don’t let your hot end come unscrewed.

(Sorry, I couldn’t help myself.

DLC

ProfessorBean

#10

sorry for reviving an old thread, RoboDLC can you upload your firmware, i am experiencing issues printing and having a working firmware to compare to would be of immense help, if you even still have your kossel 2020, thanks

Free STL file Folgertech Kossel 2020 Rev B parts [Revised]・3D print object to download・Cults

Wheels

Free

Random Wheels - 1:64 Scale

Free

Mini Z Truck Body

Free

MAZ Cab

Free

1/87 6x6 Truck

Free

Shooty Spinny Thing

Free

Mini Z Race Pick Up

Free

1/87 APC

Free

Best 3D printer files of the Tools category

Pingpong ball wall holder

Free

M6 Nozzle Box with Skadis Pegboard Inserts

Free

Flexbot Hexacopter V2.

0

0Free

Super smooth universal filament holder

Free

Pegboard mount for Specialized fixed torque wrench

Free

Easy printing face massager - updated with adjustable tension!

€2.42

MAKER'S VALET - Tape dispenser and Cards/parts holder

€2.54

Mini Sword envelope opener

Free

Best sellers of the category Tools

phone ring holder

€0.90

Printer Drawers For Ikea Lack Table

€1.99

BMG E3D V6 Direct Drive for Creality Ender 3 (Pro/V2) & CR-10

€4.49

PRECISION DIAL INDICATOR 3D PRINTING DIY

€1. 90

90

Filament shield

€2.97

PRECISION CALIPER 3D PRINTING DIY

€3.11

Version 2 Alligator 2 || Repeating crossbow || 3d printed magazine || Inspired by Joerg Sprave

€1.50

INDICATOR FOR BEST BED LEVELING FOR ENDER 3 PRO

€3.07

UNIVERSAL INDICATOR FOR BED LEVELING FOR ALMOST ALL PRINTERS

€3.07

NEW GENERATION HOLDER CAR PHONE HOLDER

€2.50

Armadillo - Flex Wire Conduit

€1.84 -20% €1.47

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang.

CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing

CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing€1.68

Grinder | Grinder

€1.50

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020

€2.40 -15% €2.03

SUPERBOX

€1.50

Ender 3 Briss fang Gen2, Red lizard, spider, nf crazy, dragonfly, etc.

€1.87

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

TsMSCh No. 28, Angarsk: Russian 3D printer for work in space was developed by scientists of the Tomsk Polytechnic University Energy", the press service of the university informs.

"Two flight samples of the printer were handed over to the customer. According to Roscosmos, one of them will be sent to the International Space Station (ISS) as early as June 2022. With its help, Russian cosmonauts will be able to make the parts necessary to work with the station equipment. And the second sample will remain on Earth," the message says.

And the second sample will remain on Earth," the message says.

The development of the printer with all the necessary steps took a little over three years. The work was carried out by order of PJSC RSC Energia together with specialists from the corporation and Tomsk State University (TSU).

The printer itself is a device the size of a small analog TV.

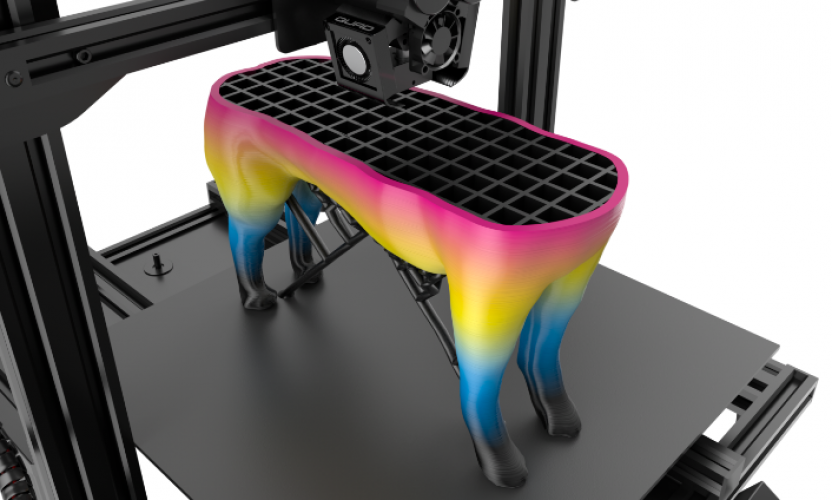

Based on the given 3D model, the printer prints the desired object in layers from thermoplastic polymers.0007

TPU specialists have created a device that will quickly and directly at the station create the small parts needed by astronauts so that they do not have to be delivered from Earth.

"The participation of Tomsk Polytechnics in the project will not end at the development itself. In the future, we plan to participate in the training of astronauts in 3D printing, work with the device. And when the experiment takes place directly on board the ISS, it is planned that polytechnics will participate in processing results," the words of TPU Acting Rector Dmitry Sednev are quoted in the message.

The specialists of Tomsk State University have created the electronic "stuffing" of the printer.

"The software developed by TSU scientists and engineers for the first Russian space 3D printer will allow participants in space expeditions to reach a new level of performing tasks in space using additive technologies," the press service of TSU Rector Eduard Galazhinsky quotes.

As reported, TPU and RSC Energia entered into an agreement on the creation of the first Russian 3D printer for space. First, a model was developed that had to pass a series of tests: vibration, climatic, and others.

Tomsk Polytechnic University was founded in 1896 and is the first technical university in Siberia. In the National University Ranking 2021, prepared by the Interfax International Information Group, TPU ranks eighth.

TSU was opened in 1888. The university took the seventh place in the 2021 National University Ranking prepared by the Interfax International Information Group, retaining last year's position.

Source: Interfax

https://academia.interfax.ru/ru/news/articles/8402/

3D food printer from Moscow scientists prints chocolate, cakes and even nuggets

A 3D food printer with a system of "smart" recipes that prints food products with specified properties was created by scientists from the Moscow State University of Food Production (MGUPP). The new device consists of 99% domestic components and can be used to design vending machines that print products according to the client's order. The 3D printer already prints with dough and chocolate, and in the future it will be able to produce even meat products - nuggets, for example, have already been successfully obtained.

chocolate chess

One of the goals of developing a 3D food printer was to create food rich in vitamins, micronutrients and antioxidants that would be a healthy alternative to traditional meals.

“Today, many are deficient in nutrients and micronutrients that can be replenished with elements in chemical form, but eating foods fortified with them contributes to better absorption. The main goal of creating a food printer was the ability to produce personalized functional products using a system of “smart” recipes, which will be like instructions for the printer,” says Aleksey Kuchumov, Vice-Rector for Research and Development of MGUPP.

The main goal of creating a food printer was the ability to produce personalized functional products using a system of “smart” recipes, which will be like instructions for the printer,” says Aleksey Kuchumov, Vice-Rector for Research and Development of MGUPP.

The main difference between the development of MGUPP scientists and existing 3D printers is the units modified for the tasks of the food industry. The unique technology allows you to take a device for printing with plastic and upgrade it for printing with food raw materials.

“We made one unique extruder (a nozzle through which the raw material exits) of a revolving type. Inside it is a drum into which various raw materials are fed, which allows you to speed up the production process and use fewer parts. This is also our innovation - the use of one powerful drum extruder, into which various raw materials are fed under different pressures and temperatures, ”notes Alexey Kuchumov.

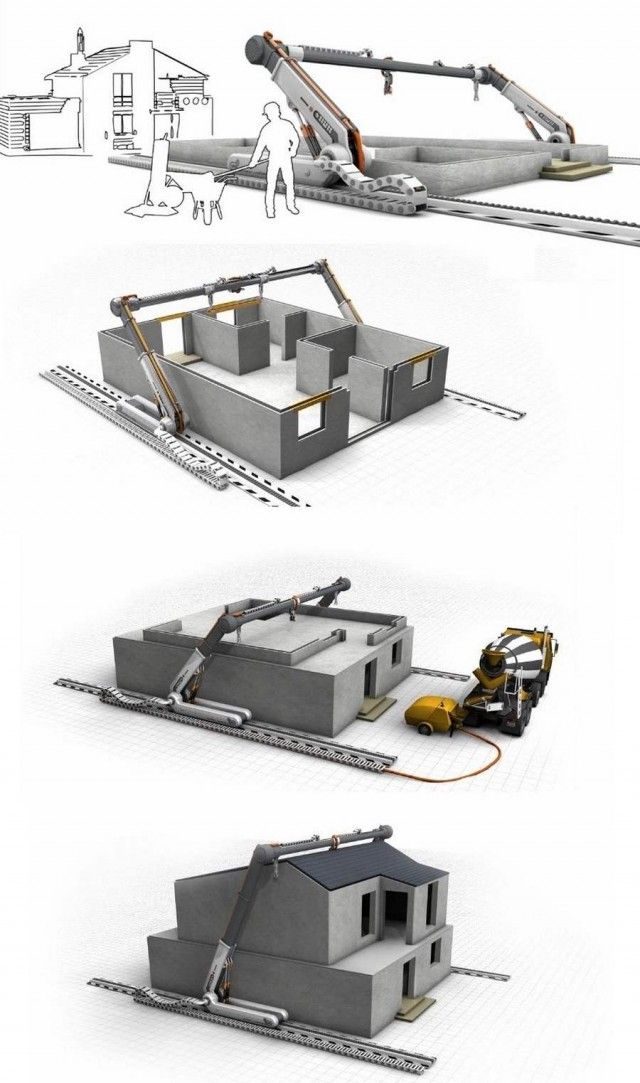

The development of MGUPP scientists allows you to make a 3D printer of any size and for any task, as well as increase the print area to one and a half meters, which is 1. 2 meters more than existing analogues.

2 meters more than existing analogues.

3D printer

In addition, the new device provides the ability to produce artificial meat using bioprinting technology. At the same time, the printer performs the function of a freezer - a refrigerator, and with different setting temperatures. It is designed in such a way that the necessary climatic environment will be formed for each type of raw material: its own temperature, its own humidity, etc. Among other things, a laboratory for the production of “cultured” meat is being opened together with 3D Bioprinting Solutions.

“The bioprinter prints a special plant-based substrate, on which live cells taken painlessly from animals are applied. This device prints according to a given digital model, using special nozzles - devices that allow you to print both cellular material and plant fibers. Such meat can be called “ethical”, and it will be in demand on the market,” comments Alexey Kuchumov.