3D printing gaskets

3D Printing Gaskets; Here’s what filament to use! – 3D Solved

One of the reasons I like 3D printing so much, is because of how useful it can actually be to fix things in your own home, such as your bathroom or kitchen sink.

However, not all filament types have the same properties, which begs the question; Which filament is the best one to print gaskets that actually work and last for years?

in short; The best filament to print gaskets with is TPU, not just because of its flexible properties but also because it can withstand 110°C as well as very low temperatures without deforming or getting damaged, and it’s even resistant to abrasions, chemicals and oils, making it the ideal plastic to print objects that go through a lot of wear and tear, such as gaskets.

In this article, I will go over why TPU is the best filament for the subject at hand, the potential problems you could run into when printing with TPU, which brands to get, and even how to print with TPU successfully.

So, without any further ado, let’s get started!

Table Of Contents

- Properties of TPU that make great 3D printing gaskets

- Can TPU withstand high temperatures?

- Potential problems when printing with TPU

- Recommended Filaments for Printing gaskets

- How to print with TPU

- Conclusion

Properties of TPU that make great 3D printing gaskets

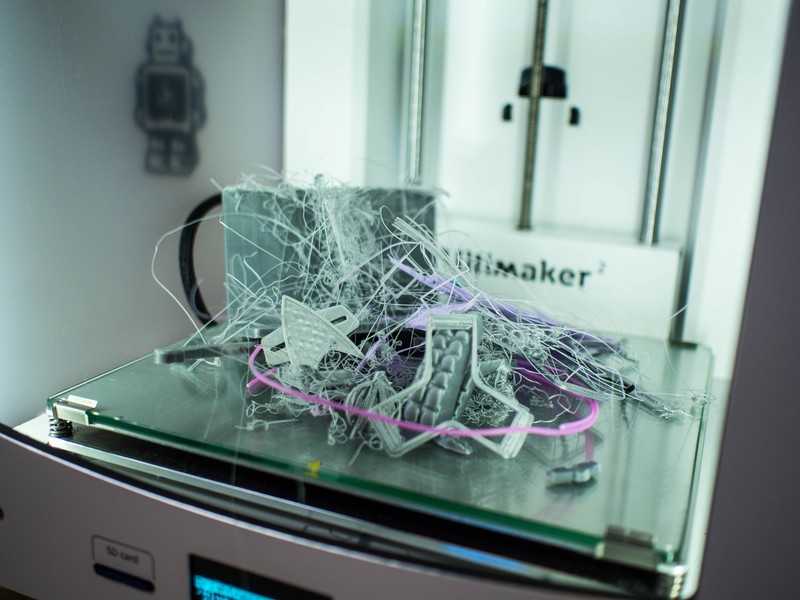

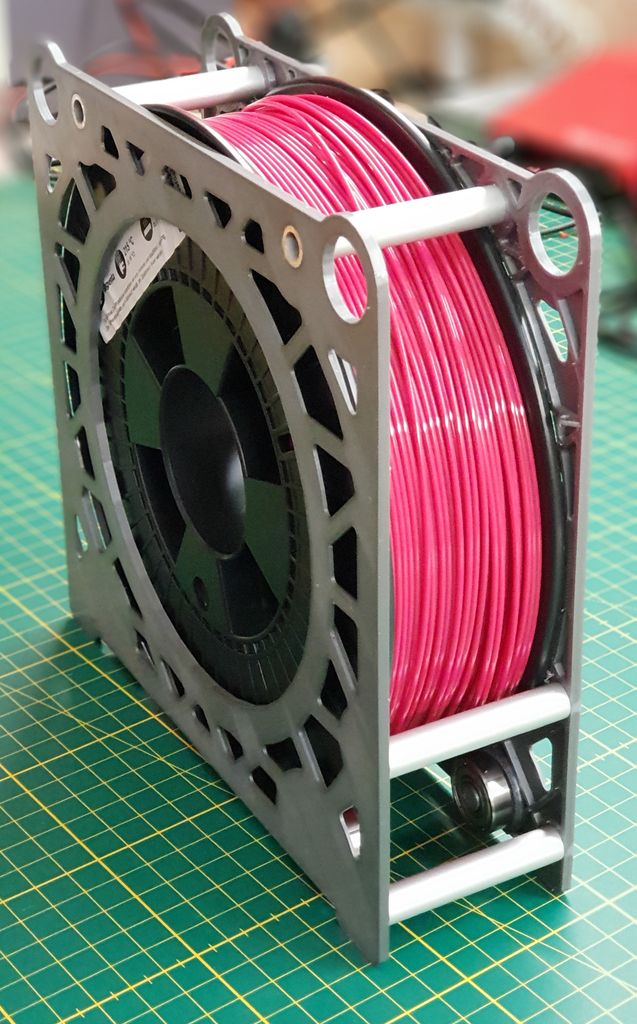

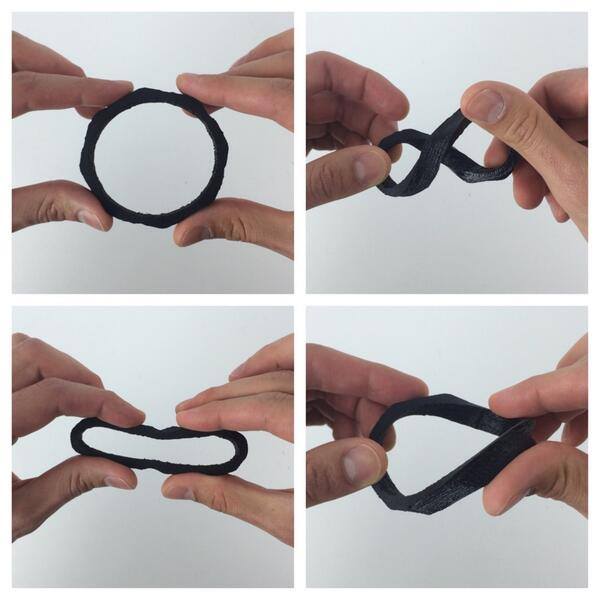

Gaskets printed out of TPU.Thermoplastic Polyurethane (TPU) is a flexible type of thermoplastic that is also highly resistant to abrasion, as well as wear and tear. In the manufacturing process, it’s used for a number of different types of items for both consumer and industrial use. When the right blend is used to make TPU, it can offer a smooth and soft texture, but still maintain the durability to be used in a variety of applications.

3D printing with TPU is ideal for those looking to get soft, flexible and functional prints without sacrificing durability and resistance to abrasions, chemicals, and oils.

TPU can also work without problems at temperatures of up to 110°C, and all of these features make it the ideal type of filament to print gaskets with. Additionally, the fact that TPU is also resistant to extremely low temperatures means that parts printed with TPU will not become brittle and difficult to work with.

TPE filament is a good substitute for TPU, but it tends to deform at lower temperatures and retain less of its flexibility. TPE is also a little more difficult to print than TPU.

Gaskets, O-rings, and seals require high abrasion resistance, long-lasting durability, and resistance to oils and other chemicals. TPU’s High abrasion and chemical resistance accompanied by excellent flexibility, tear strength, and elongation ensure that your gaskets and seals are printed with the same if not higher quality than the commercial ones you buy at any hardware store.

The interlayer adhesion of TPU is excellent, which means that there’s very little curling, warping or delamination during the printing process, and the final product will generally come out great.

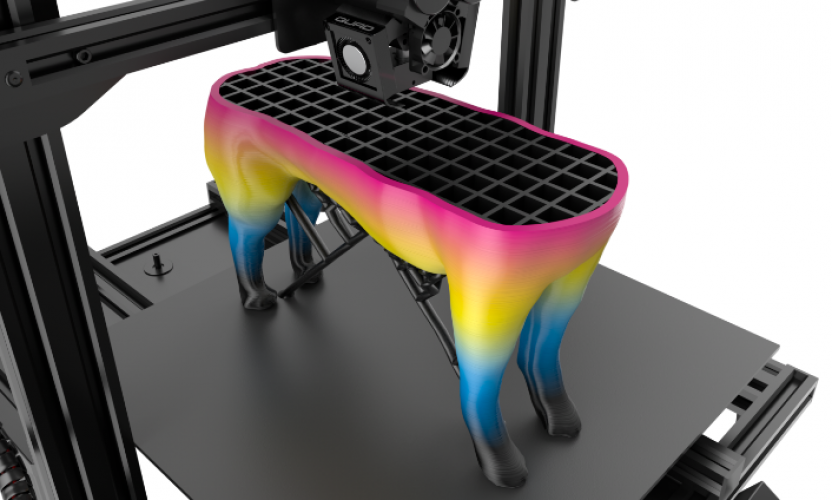

The flexibility of TPU depends a lot on how the 3D printing software is configured; Designs with a lower infill percentage are more flexible as opposed to those with a higher infill, and this allows you to create objects that are slightly more elastic or rigid.

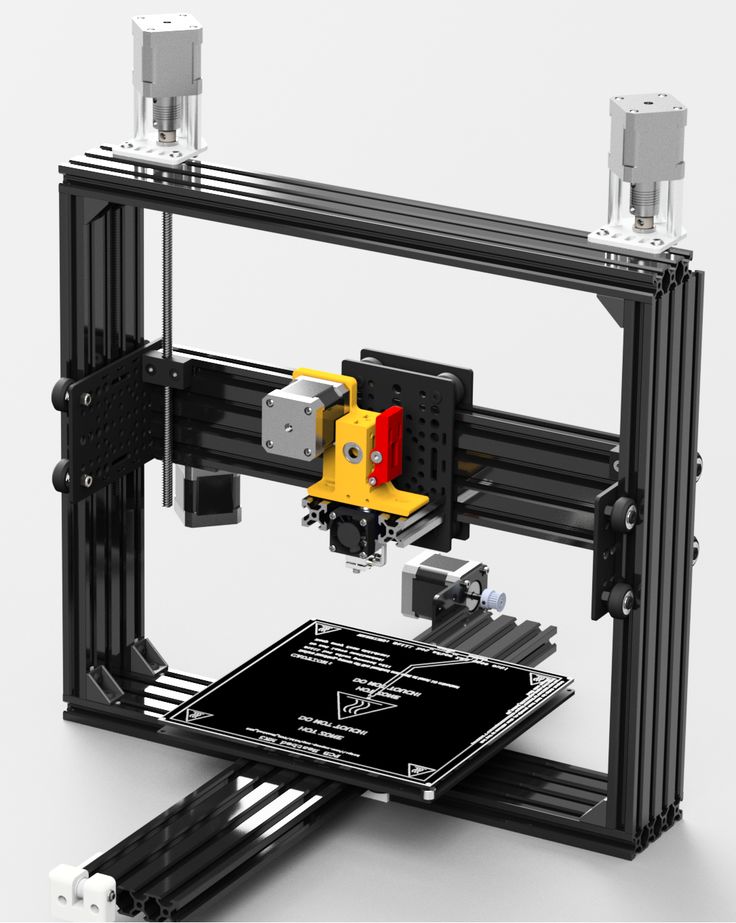

All of this being said, it takes a lot of power for a 3D printer to process TPU filaments since the temperature at which it prints at is 250°C, and most affordable 3D printers aren’t capable of printing TPU straight out of the box and some modifications might be needed.

Can TPU withstand high temperatures?

Given that TPU has a glass transition temperature of up to 60°C only, it begs the question: Is it possible to 3D print gaskets using this filament that will withstand high temperatures?

I did some testing and found that gaskets printed from TPU filament are more than capable of resisting continuous high temperatures of up to 110°C without any problems whatsoever.

It might sound weird at first but the reason behind this is simple: Above the glass transition temperature, 3D printed objects become soft and lose their rigidness, and this is not a problem for parts printed with TPU since they are already soft and flexible even below the glass transition temperature of TPU. It is to be noted here that, while TPU’s glass transition temperature is only 60°C, the melting temperature is 225°C.

It is to be noted here that, while TPU’s glass transition temperature is only 60°C, the melting temperature is 225°C.

So, in short: TPU can withstand temperatures of up to 110°C, or even higher given the right conditions, even despite its glass transition temperature being only 60°C. The reason for this is that since it’s already a flexible material, increasing its temperature won’t make it deform, as it happens with PLA for example.

Potential problems when printing with TPU

When printing with flexible filaments, you’ll want to make sure that the ventilation in your print area is good, as these materials sometimes expel a small amount of toxic fumes during printing, and ventilation can protect users from breathing in those fumes.

All flexible filaments, including TPU, are hygroscopic and tend to absorb moisture from the air and will swell up if they’re not dried before use (of course, the best solution is to store the filaments properly).

When the material is still wet, it can be extruded, but it won’t print well at all you will probably have to clean the extruder afterward. Therefore, using a filament that is completely dry is of the utmost importance.

Therefore, using a filament that is completely dry is of the utmost importance.

If you try to extrude a material before it is completely dry, it will pop and sizzle. The sizzling you hear is caused by the water that was absorbed into the filament and that instantly turns to steam as it hits the nozzle, this usually leaves voids in your print or causes excessive stringing.

When this happens, the quality of the printed part isn’t only visually worse, the molecular structure is also compromised, so it’s not nearly as strong as it would be if it was printed using a dry TPU filament. For this reason, make sure to dry your flexible filaments before printing gaskets if you want them to work properly and last a long time.

Recommended Filaments for Printing gaskets

It’s important to purchase a high-quality TPU filament, especially if you’re thinking of using the printed parts for something that needs to withstand high temperatures and loads of wear and tear, like gaskets. There are many companies that sell low-quality TPU, and this causes problems when they are 3D printed.

There are many companies that sell low-quality TPU, and this causes problems when they are 3D printed.

I’d recommend these two TPU filament brands, and make sure to check out their technical specs before buying and strictly follow their printing guidelines.

NinjaFlex (TPU)

Ninjatek is the premium brand for 3D printing filaments and their flexible filament NinjaFlex is a reliable choice for 3D printing professional-quality seals, gaskets, and plugs.

The NinjaFlex filament has a texture that is much friendlier to extruders than other materials. Their unique technology will reduce the chance of breaking, or jamming your extruder and will print strong parts from direct-drive extruders.

While it may be more expensive than some other brands, if you need to print an object that has to be reliable, I think this is your best bet.

Matterhackers Pro TPU

MatterHackers PRO Series TPU is a great choice for 3D printing gaskets as well, since the parts printed from their TPU have springiness and fatigue resistance.

PRO Series TPU is a versatile material that can be used for a variety of applications, and just like NinjaFlex, I’d recommend it over most other brands.

How to print with TPU

Phone Case made out of TPU.One of the many unique challenges of using flexible filaments like TPU is that they can be tricky to use under certain conditions, and there are several problems that you’ll want to avoid while 3D printing TPU, such as filament clogging, kinking, and stringing. To avoid them, make sure you follow these instructions!

Note: Although not needed, you should print using a heated bed at roughly 65°C for best results and set the printing temperature between 225°C and 250°C.

Use Direct Drive Extruders

Fully flexible filaments are normally used with direct drive extruders because the filament is too flexible for a Bowden extruder. The closer the drive gear to the melting zone, the faster and more efficiently the filament will melt and feed into the nozzle.

The filament also needs to travel through a channel with tight tolerances that prevent it from kinking or coiling. Because of these reasons, a Bowden extruder is typically less practical than a Direct Drive extruder. If you aren’t sure if your printer is ready for flexible filament, make sure to check with the manufacturer.

Note: As I mentioned earlier, most low-end printers can’t print flexible filament.

Use Slow and Consistent Feed Rates

For best results when printing flexible filament, a slow and consistent feed rate is recommended since it’s hard to control a sudden change in the extrusion speed when using an elastic filament.

The faster you try to print an object, the more likely it is that the filament will compress against the extruder and cause a jam. The best approach is to print at slow and constant speeds. You can save yourself time and money by testing various printing speeds and choosing an optimal one based on your findings.

More likely than not, speeds of 20 mm/s can be a good starting point for most materials.

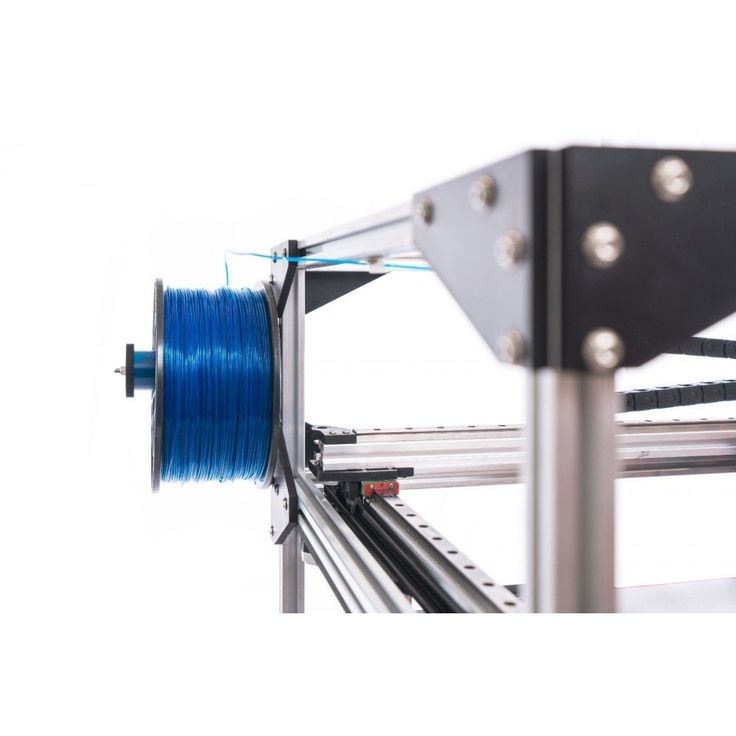

Reduce Resistance from the Filament Spool

If you’re printing with flexible materials, you’ll need to change the way you load your spool: When your extruder pulls filament into the nozzle, the filament spool will unwind a bit of plastic. However, flexible filaments, like TPU, and materials that are high in elasticity will get stretched due to this pulling force and this will result in under-extrusion.

To solve this, mount your filament directly over the top of your printer, it will allow the filament to unwind in a more natural motion in a downward direction and eliminate friction. If the spool hub is mounted on a bearing, it allows the spool to turn far more freely, which can also help the filament unwind easily.

Tune Your Retraction Settings

Flexible filaments are sensitive to quick movements such as retractions. You need to reduce the retraction movements for successful printing by optimizing your retraction settings.

For those who are just getting started with TPU, I recommend that you disable retraction completely so you can focus on optimizing the speed and extrusion rates to print your models reliably.

After you have had more practice with these settings, if you add only a little retraction, you’ll reduce oozing.

Optimize Your Travel Movements

If you’re using flexible materials, you should use as few retractions as possible, because they can cause significant problems for your prints. Check the settings of your slicer to adjust this.

Conclusion

Most flexible filaments should work for printing gaskets, but TPU, especially the ones made by the brands I mentioned earlier, will do better overall.

Printing with it might be a bit tougher than printing will good old PLA, but it’s not as hard to print as some other materials, so give it a try!

I hope this information was useful!

Have a great day!

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

3D Print Rubber - 3D Printing Gaskets

Rubber and rubber-like materials are everywhere in modern industry. Soft materials like latex, silicone, and thermoplastic elastomer are useful in applications that demand flexibility and durability for industrial parts and consumer goods alike.

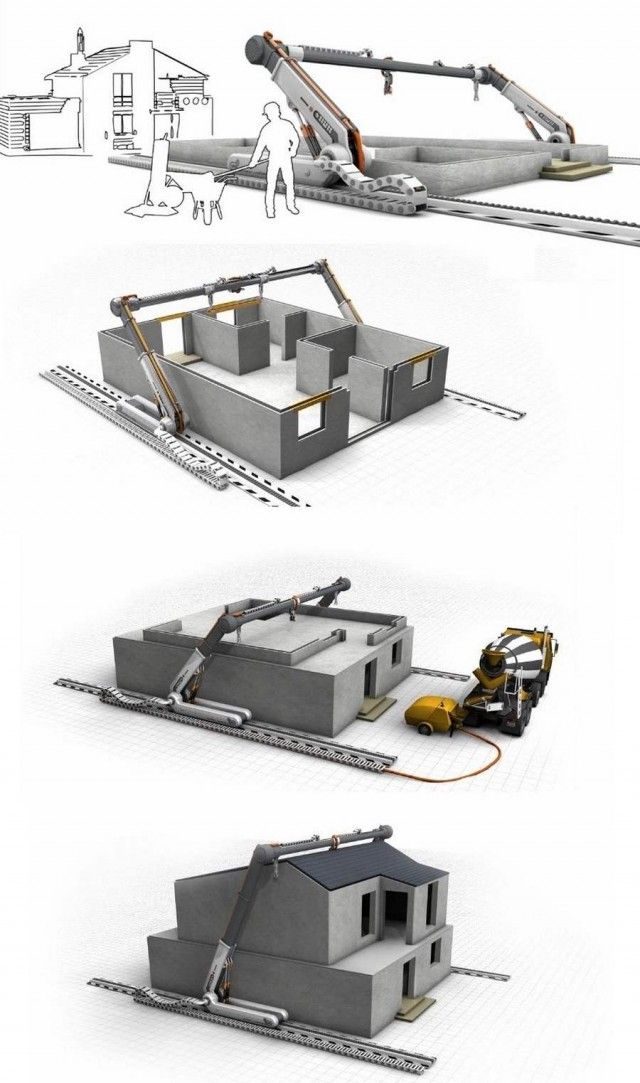

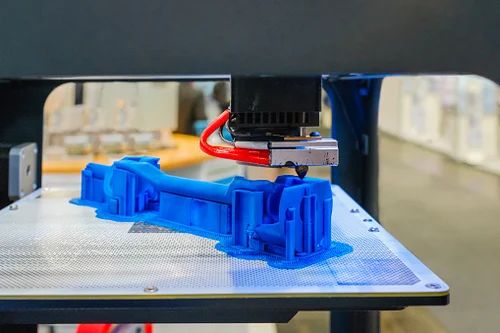

While rubber manufacturing has historically been the domain of casting and injection molding, modern advances in 3D printers and 3D printed materials have made additive manufacturing the ideal solution for producing small to medium quantities of rubber-like parts.

Our 3D printed rubber services can manufacture high-quality rubber-like parts in as few as two days―all you need is a 3D model! Start your project by getting a quote or keep reading to learn more.

Get a quote for your project using our quoting tools. Our engineers will review your project and get back to you 24 hours or less. 3D printed rubber parts ship in as few as two days!

3D Printed Rubber Applications, From Prototyping to Production

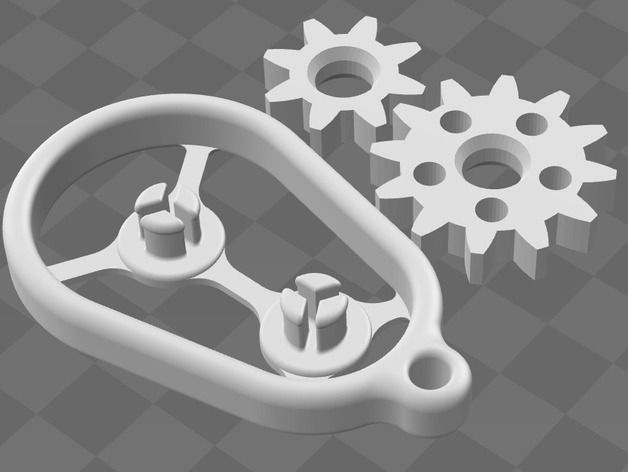

3D printed rubber parts can be used in place of molded rubber for just about any application. Like other methods of 3D printing, rubber prints accurately produce complex internal geometries like lattices and tubes at no extra cost, easily achieving designs that would be impossible with other types of manufacturing.

And because 3D printing doesn’t require any costly molds or tooling, 3D printed rubber parts can be manufactured in just a few days compared to multiple weeks of lead time for injection molding. This combination of high agility and no start-up costs allows rubber 3D printing to excel for both prototyping and small- to medium-sized production runs.

3D printed rubber is ideal for:

Prototypes

Gaskets

Seals

Hoses

Grips

Lids

Plugs

Connectors

Footwear

Tires

Medical Devices

Sporting Goods

Advantages of 3D Printed Rubber vs. Injection Molding

Traditionally, rubber manufacturing has required injection molding, casting, or sheet lamination. Rubber-like materials are far too soft to machine, and 3D printing was restricted to harder plastics for most of its development. Now, new developments in 3D printers and materials have opened up a wide range of new possibilities for 3D printed rubber products. So how does 3D printing compare to casting or injection molding for manufacturing rubber?

Short Lead Times and No Setup Costs

Injection molding requires machined metal molds that cost tens of thousands of dollars and take months to produce. Any design changes require new tools, making adjustments extremely expensive and time-consuming.

Any design changes require new tools, making adjustments extremely expensive and time-consuming.

In contrast, 3D printing requires no tooling or other setup costs and can begin production immediately. This leads to parts that can be manufactured in as little as one day and much greater affordability at low quantities, making 3D printing Moreover, design changes are easy and can be executed at no additional cost.

The Best Choice for Rubber Prototypes

When it comes to product development, 3D printed rubber is a godsend. Even under the most ideal conditions, traditional technologies take weeks of lead time and tens of thousands of dollars for each new design.

Because 3D printing doesn’t require any tooling or setup, 3D printed parts can quickly be designed and redesigned at no additional cost. This agility has made 3D printing an indispensable part of prototyping and product development.

A Question of Quantity

As a result of these differences in lead times and setup costs, 3D printing is much more economical for small- to medium-volume production, while casting and injection molding provide greater value for productions of 1000 parts or more.

Although metal molds are expensive, molded parts become very cheap to produce once the tooling is made. When those initial costs are spread out over thousands of parts, individual part costs plummet, making injection molding the least expensive technology around for high-volume manufacturing.

3D printing, on the other hand, generally stops providing additional per part savings once part quantities exceed the capacity of a single machine. As a result, 3D printing has a much flatter cost curve that makes it a great option for small to medium quantities but significantly less economical for large production runs.

Unlimited Design Possibilities

Rubber 3D printing can easily achieve complicated designs that would simply not be possible with other manufacturing technologies. From interior cavities and lattices to variable wall thicknesses, organic shapes and built-in hoses—all of which are difficult or impossible to create with injection molding—3D printed rubber parts unlock endless new design options. You can even combine multi-part assemblies into single pieces, saving costs and improving functionality.

You can even combine multi-part assemblies into single pieces, saving costs and improving functionality.

Plus, 3D printed parts can be highly customized, down to single parts at a time, without additional costs. This is especially useful for industries like medicine or athletics that have a high demand for products customized to each individual user. Needless to say, this would be extraordinarily expensive with casting or injection molding.

To learn more about the unique design capabilities of 3D printing, check out our Design for Additive Manufacturing (DfAM) Guide.

Is It Really Rubber?

3D Printed Rubber Materials

The answer to whether 3D printed rubber is really rubber depends who you ask. There are a lot of materials that are referred to as rubber: thermoplastic polyurethane, thermoplastic elastomer, silicone, and, of course, natural rubber!

Natural rubber, also known as latex, cannot be liquefied and re-solidified in the manner required by 3D printers. However, thermoplastic elastomers can achieve similar levels of flexibility and softness to rubber and have the thermal properties necessary for 3D printing.

However, thermoplastic elastomers can achieve similar levels of flexibility and softness to rubber and have the thermal properties necessary for 3D printing.

The most effective rubber-like materials for 3D printing are thermoplastic polyurethane (TPU) and thermoplastic elastomer (TPE). It’s important to note, however, that both TPU and TPE refer to multiple materials. In fact, TPU is really a type of TPE―distinguished by its use of polyurethane and increased hardness.

Thermoplastic Polyurethane (TPU)

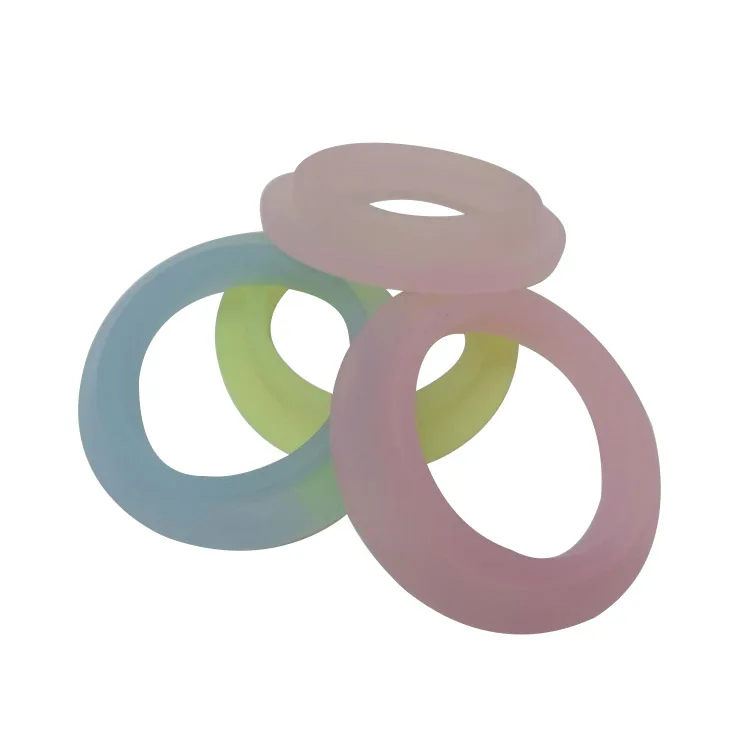

Thermoplastic polyurethane (TPU) is valued by engineers for its flexibility and strength. Not only does TPU’s hardness (Shore 85A to 95A) make it easier to print than TPE, but it also provides higher abrasion, chemical and thermal resistance. Moreover, its resistance to oil and grease makes it a great fit for hoses, gaskets and seals. While not as soft as natural rubber, printed TPU can achieve thinner walls than molded parts to create a similar level of flexibility.

TPU can be 3D printed with Multi Jet Fusion or selective laser sintering and is widely used in transportation, medicine, home goods, consumer electronics, and more.

Thermoplastic Elastomer (TPE)

Thermoplastic elastomer (TPE) is softer than TPU―Shore 40A to 70A—and offers moderate abrasion, chemical and thermal resistance. TPE parts can be trickier to print than TPU due to the material’s softness, but it offers a smoother finish.

Nylon TPE is available for selective laser sintering and is used in many of the same industries as TPU. However, because softer TPE materials are not yet available for Multi Jet Fusion, TPE parts are more expensive and slower to produce.

Rubber Printing Services

Multi Jet Fusion (MJF)

Multi Jet Fusion 3D printing is the fastest, most affordable, and most effective option for most 3D printing projects. It is also the newest printing technology to allow rubber printing, with TPU01 options available in black or gray.

MJF prints combine industrial strength, accurate fine details and a high-quality finish to create parts that are equally suited to industrial parts and commercial products. With lead times as little as one day, MJF is the premier printing option for prototypes and small- to medium-sized production runs.

Selective Laser Sintering (SLS)

Selective laser sintering prints nylon TPE parts with excellent mechanical strength but is more expensive and slower than MJF. SLS parts have a medium-quality finish and larger surfaces can warp.

This technology scales relatively well at medium volumes and is generally cheaper than FDM at those quantities. SLS can achieve slightly larger part sizes than MJF.

Start Rubber 3D Printing Today

If you need rubber manufacturing for your business, RapidMade can help you take your projects from 3D models to high-quality 3D printed rubber parts in as few as two days. When you work with RapidMade, you get a team of 3D printed experts dedicated to helping you succeed.

Learn more about our 3D Printing Services and get started today by requesting a quote. We’ll review your project and get back to you within one day!

90,000 types of plastic for 3D printerContent

-

- Pla

- ABS

- HIPS

- PVA

- Petg

- SBS 9000

Every year 3D printing becomes more popular and accessible. Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink. This makes it easy to build prefabricated or huge models without changing dimensions.

-

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

Cons:

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model made of ABS

ABS+ differs from regular ABS in improved strength characteristics (elasticity, stiffness, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in plain water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

-

slight shrinkage

-

Transparency. After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

-

Easily processed mechanically or chemically.

-

Allowed contact with food.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing.

Perfectly polished and drilled.

Perfectly polished and drilled.

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for switchgear model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

-

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags. It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture.

It is recommended to additionally dry high-temperature plastics before printing to remove excess moisture.

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | Esun |

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

A New Era: 3D Polyurethane Printing

When looking at the global additive manufacturing industry, it's easy to overlook companies working on technologies that may seem small but have huge potential. It's not only about a good idea, but also about finding the real pain points of production. It is important to have the know-how to solve the problem.

A good example is Chromatic 3D Materials' work with the extrusion of thermosets, in particular polyurethanes. The ability to professionally and cost-effectively 3D print one of the most commonly used polymers opens up a huge opportunity that is available to every manufacturer of extrusion 3D printers.

The origins of the development of polyurethane printing

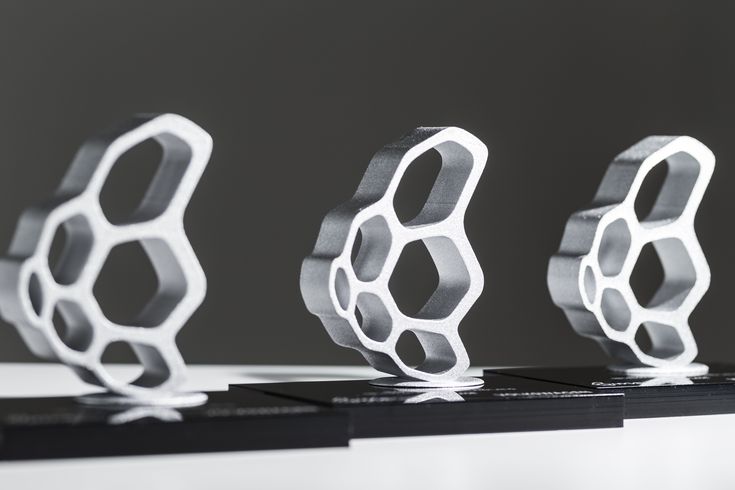

To launch a technology in the world of materials, it is necessary to demonstrate the incredible potential of a new product. 3D printed by Chromatic 3D Materials, polyurethanes are rubber elastomers that provide the desired performance and unique flexibility.

The variety of raw materials previously used for 3D printing was limited. The largest segment that was missing was thermoset plastics, a category that includes polyurethanes as well as silicones and epoxies. This is due to the inherent characteristics of thermosets, which are both very useful and challenging in 3D printing. But difficult does not mean impossible. As with any manufacturing segment, research was required here. The biggest problem with polyurethane 3D printing is that the chemistry affects the printing process more than the mechanics of the processing system.

As with any manufacturing segment, research was required here. The biggest problem with polyurethane 3D printing is that the chemistry affects the printing process more than the mechanics of the processing system.

In a printer with thermoplastic filament, print head and layer temperatures must be matched. For thermosetting plastics, the chemistry must be adjusted. Chromatic 3D Materials tried mixing extruded formulations to solve the problem.

FlexTune's range of polyurethane rubber elastomers range from 40 to 90 Shore A. These materials have been used for decades in non-3D printing applications. They can be bent, stretched, twisted, compressed.

Application examples:

• heels and soles of shoes;

• roller wheels;

• Gaskets in hydraulic seals.

Chromatic 3D Materials has found a way to 3D print these high performance polyurethane elastomers without sacrificing strength and durability.

Chemistry versus mechanics

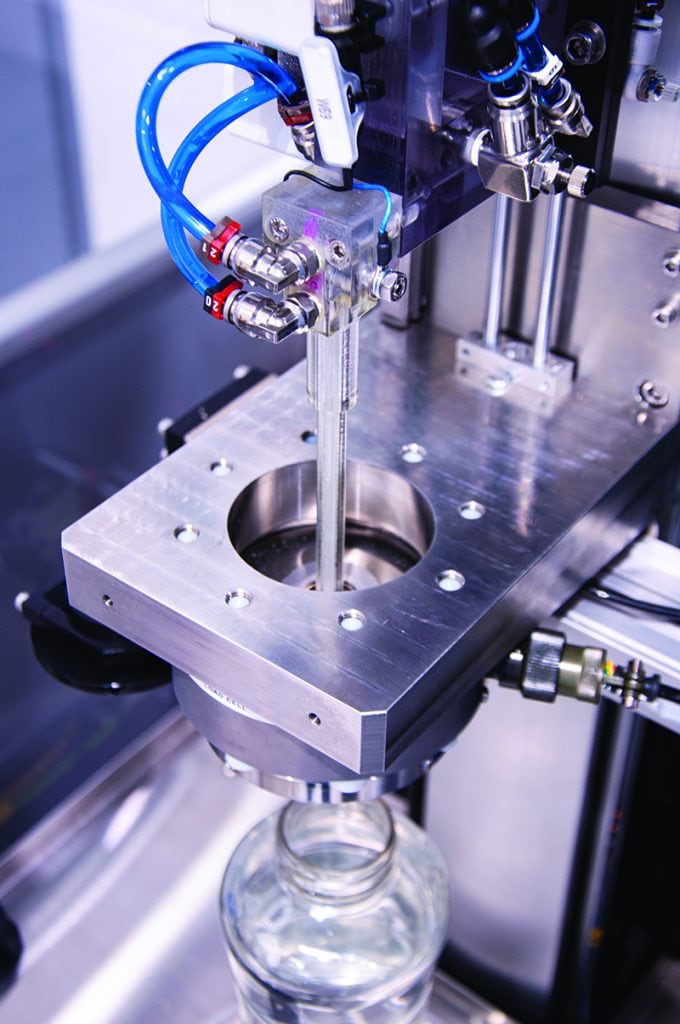

Chromatic's 3D polyurethane printing process can be described as a cross between inkjet and extrusion. When building an object, two liquid components are mixed in the print head, which causes a chemical reaction. By the time the mixture is squeezed out of the print head, the material is a partially polymerized gel. It goes into a stable state in a couple of minutes. The entire process takes place at room temperature.

In other words, while the raw material is melted and reformed in the extrusion of thermoplastics, the thermoset material is actually "created" during the extrusion process. This leads to the formation of strong chemical bonds over the entire surface of the part. The composition leaving the nozzle is about ten thousand times lower in viscosity than the thread. This means you can print at much faster speeds.

This is more of a chemical challenge than a mechanical one, but that doesn't mean it's insurmountable. The advantage is that you can use all the tools that people have used for thermoset chemistry for over 50 years and use them to print polyurethane on 3D equipment.

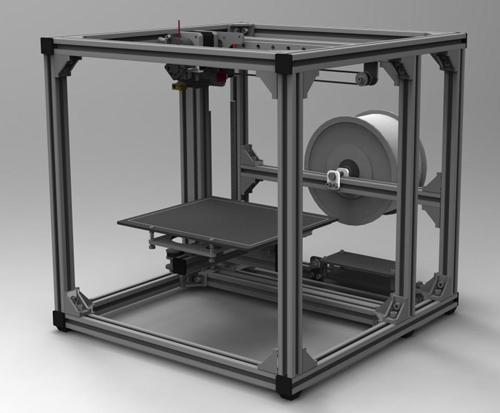

Chromatic extrusion systems can be installed on any extrusion 3D printer by replacing the thermal print head with a thermoset.

Troubleshooting

Chromatic focuses on seals and gaskets for industrial equipment, which are extremely high supply chain value items. An item that requires only a few cents worth of materials can end up costing tens of dollars due to logistics costs.

When the company looked into the supply chain, they found many pieces of specialized equipment that may require less than five hundred parts per year. For injection molding, this is a very small savings. That is, the logistics costs associated with spare parts are up to 90% of the cost of the part and are mainly related to warehousing and distribution.

The logical conclusion made by the Chromatic team was that these parts would be ideal for 3D printing if the initial resources were good enough.

Because FlexTune materials harden during assembly and do not require heat, parts over 20 cm high can be achieved.