3D printing pottery

3D Potter - Real Clay 3D Ceramic Printers

Our line of 3D Clay printers have some unique features when compared to other 3D printers. We use a cardinal axis system, rather than a delta printer configuration. This allows for precise control with minimal effort. Most clay printers use a pressurized system using compressed air, with a 3D Potterbot a high-pressure system is not needed.Great entry-level printer

More info

10 Proreliable and accurate

More info

Full size, Full control

More info

3D Printing Cement is here! We have combined our Scara Elite and Small 50 pump with Sikacrete® 3D printer cement developed by Sika USA. This is a versatile and convenient way of printing large-scale architecture and structures.

The Scara Elite is the first viable large-scale ceramic 3D printer using 3D printing material. It is capable of printing multiple objects non-stop. The Elite with the Small 50 can pump up to 3.5 gallons of material per minute through 85 feet of 1″ hose.

They work together so well, we decided to make them a package.

The possibilities are endless!

PR Articles/Videos

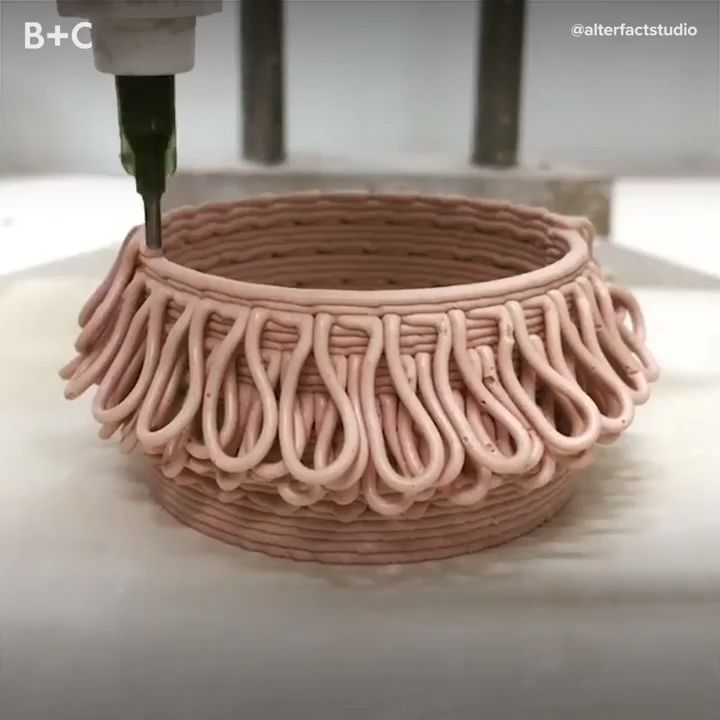

View this post on Instagram

A post shared by Hybrid Objects (@hybrid.obj) featuring non-planar printing.

View this post on Instagram

A post shared by Arina Erdélyi (@arinaerdeyli) featuring a print taken to new heights.

View this post on Instagram

A post shared by Atlas of Lost Finds (@atlas_of_lost_finds) featuring large-scale printing.

See More

3D Potter is proud to offer assembly tutorials and troubleshooting videos for our printers. Our printers can be used with Potterware, a beginner-friendly program to design pots and vases of all shapes, sizes, and patterns. Check out our Youtube channels to see our videos!

Check out our Youtube channels to see our videos!Assembly Videos

Main Channel

3D Potter accepts payment of Bitcoin (BTC) for our products. If you wish to pay by BTC, please contact us.bitcoincash:qr5wmqhnylzr0hcewfrla852xxy9zhp94uugrxy9ay

Here at 3D Potter, we like forward-thinking and preserving the environment. Tesla vehicles are a great example of both. So, if you plan on purchasing a Tesla, use our referral code at checkout and you will receive a discount and charging miles.https://www.tesla.com/referral/dan47410

3D Potterbot Scara V4 Ceramic 3D Clay Printer — Real Clay 3D Ceramic Printer

The Scara V4 is the first viable large-scale ceramic 3D printer using real clay. The advanced design and substantial construction can take on board loads like the 3D Potter 4000ml clay extruder.

The advanced design and substantial construction can take on board loads like the 3D Potter 4000ml clay extruder.

1. Scara v4

2. Closed loop stepper on X, Y, Z, extruder

3. Extruder size of your choice.

4. 5 anodized aluminum nozzles (standard sizes: 3, 4, 5, 6, and 8mm when extruder is purchased)

5. Parts Box: Alan key set, grease, Acme driver tool, tie wraps, extra screws

6. Power Supply

SpecificationsPrinting Envelope:

X/Y- 72" Diameter Circle (1829mm)

Z- 45” (1143mm)

Minimum Printing Envelope:

X/Y- 22" Diameter Circle (558mm)

Printer size:

W-34” L-18” H-44”

Normal operational space needed: W-40” L-36” H-~70”

Maximum operational space needed: W-88” L-88” H-~84”

Height to the top of the extruder fully extended is H~84” (2134mm)

Weight with extruder: 90 lbs. (41kg)

(41kg)

Average speed: 1.2’’ to 3.9’’/s (30 to 100 mm/s)

Power Supply: Output - 24V ~15 amps, Input - 110-220V, 50-60 Hertz.

Power consumption: 24V ~8 amps, ~192 Watt

Main controller board running Duet3D with Atmel SAM4E8E: 120MHz ARM Cortex-M4

Full control through web interface, no apps or software installation. Non-WiFi versions are available, please contact us if you would like this type of connection (Ethernet connection).

* http://www.igus.com

Some components may be re-manufactured

** https://en.wikipedia.org/wiki/Harmonic_drive

Duet Web Control is a fully developed UI for the Scara. Opened in a web browser, it can be used on your laptop, tablet, phone, or other WiFi capable device.

Print StatusOnce a print is started, it shows information about the model being printed. Layer times, estimated time remaining, file information, and more are available for view. It also allows for print and extrusion speed control to be adjusted in real time.

Layer times, estimated time remaining, file information, and more are available for view. It also allows for print and extrusion speed control to be adjusted in real time.

The G-Code Files page allows g-code files for printing to be uploaded, edited, or downloaded. A summary of the file is given such as size, layer height, and what the file was generated by.

Software requirementsNone! The only requirements is a web browser interface.

For object generation, the Scara V4 is similar to the rest of the 3D Potter line ceramic printers. It's is just like any other 3D printer which requires an STL file to be sliced by a third-party program. We recommend Simplify3D or Cura, and then loading the file to the SD card in the printer, which can be done over WiFi.

Build envelope

The build envelope diagrams represent the 45 in Z height. We can do custom Z heights up to 9 feet and diameters up to 8.5 feet.

We can do custom Z heights up to 9 feet and diameters up to 8.5 feet.

The Scara V4 build envelope is quite unique because it's capable of printing 360 degrees with continuous rotation. This means you can create a huge vessel with the printer initially residing inside the vessel or structure. This opens up a whole another opportunity to print small habitat structures (houses). Larger printers are available for this potential habitat project.

Another unique ability is printing multiple objects within the specified envelope in a sequential mode. For instance you could print a particular vessel starting on the far left side and continue to print these vessels until there is no more space left.

Speed and noiseThe Scara V4 is capable of extreme speeds however speed is relative when it comes to ceramic 3D printing. Realistically you probably don't want to exceed 130 mm/s. There are many factors which determine the speed like nozzle size, layer height, and achieving a good adhesion on interlayer of the clay.

The Scara V4 is very quiet, so it can be operated in any area without disturbing the surrounding environment.

Construction and designWe were able to achieve high precision and accuracy with this large Scara arm robot only through diligent design and robust construction techniques. The majority of this structure is out of heavy aircraft grade 6061 aluminum utilizing CNC and welded components for maximum strength and rigidity. The main rail components are from IGUS* which is one of the leading German manufacturers of precision guide rails. The drive motors consist of very sophisticated hybrid closed-loop stepper motors. These have on-board computers with telemetry that continually update their position for zero error positioning.

Drive mechanismsThis is no souped-up 3D printer, this is a dedicated heavy duty purpose-built robot. The main drives are sophisticated harmonic drive units**. These are the same drives used on large industrial robots similar to the ones that are now in most of the large manufacturing facilities. These drives are extremely heavy duty and capable of precision movement down into the fractions of a second of a degree. This means very precise prints with no backlash or jittery movements at realistic speeds. These drives are designed for maximum rigidity with extreme accuracy.

These drives are extremely heavy duty and capable of precision movement down into the fractions of a second of a degree. This means very precise prints with no backlash or jittery movements at realistic speeds. These drives are designed for maximum rigidity with extreme accuracy.

The real advantage is this machine can be positioned on a substantial table top and you can start printing right away within a limited envelope area. Or you can give it its own dedicated space for partial or full envelope.

The space needed is really determined by the end-user and how much of the print envelope they choose to use. Whether on the table top or on the floor, the Scara V4 will require direct mounting for maximum stability. This is achieved with multiple screws to secure the printer to the surface it is on. If you choose to use a tabletop it must be of substantial construction, the minimum is 1.5" thick heavy plywood or wood construction. If a inadequate table is used, the results from the printer will be diminished depending on the build envelope and speed at which the prints are created with.

Overview of 3DCeram ceramic 3D printers

Ceramic is a unique material. Due to its low weight, strength, chemical resistance, toughness and biocompatibility, the resource is in demand in various industries, providing the ability to quickly produce useful things on a 3D printer. Additive manufacturing of ceramic products allows you to create objects of individual configuration. The technique involves the prompt introduction of design changes and helps to achieve the desired characteristics of a part or a finished item. nine0003

Printing technologies used

Ceramic 3D printing is done in different ways: paste extrusion, powder sintering or photopolymerization.

But most often ceramic printers work on SLA technology. The method is based on the illumination of ceramic paste with a laser to form three-dimensional objects or prototypes. The construction is done in layers, and each layer is scanned and drawn with a beam according to the digital model. After building the next level, the working platform is lowered to a given layer thickness, a new portion of the paste is leveled, and the process of scanning the next section of the part is performed. nine0003

After building the next level, the working platform is lowered to a given layer thickness, a new portion of the paste is leveled, and the process of scanning the next section of the part is performed. nine0003

The technique helps to achieve uniform shrinkage during sintering, which guarantees maximum accuracy in the construction of the element.

The Ceramaker 3D printer series is a development of the company that implements the additive technology of layer-by-layer curing of a specialized paste - a composite of a photopolymer substance with ceramic powder. After completion of the model building cycle, the surface is freed from particles of non-polymerized composition and washed in a special solution. Then the object goes through the stage of burning out the photopolymer, which acts as a temporary binder. Next, the final sintering of the workpiece at a high temperature is performed. nine0003

nine0003

Ceramic Printing Materials

3DCeram has developed original formulations that its ceramic 3D printers use. Raw materials are fed evenly, with a given accuracy, which ensures the high quality of the manufactured object and its compliance with strict industrial criteria.

Ceramic resources are neither metallic nor organic. Usually they are molded at room temperature, and acquire special properties during the sintering process. The choice of material for printing a product depends on the conditions in which the parts are to be used. nine0003

3DCeram offers the following options:

Zirconia is a material with excellent mechanical properties that are stable at all temperatures. The composition is characterized by low thermal conductivity and chemical inertness. Products from this resource are hard and wear-resistant.

Alumina is the base material required by the industry. AL203 stands out for its mechanical strength and is a good dielectric. nine0017

nine0017

Silicon nitride - compound resistant to heat and corrosion. The resource is actively used in the manufacture of pumps and valves.

Silicore is a compound used to make blade cores. Porous ceramics with good leaching properties are compatible with various alloys.

Tricalcium phosphate is a biocompatible raw material used for the production of implants;

Hydroxyapatite is a resource in demand in biomedicine for “growing” bone substitutes, since it is characterized by good osseointegration; nine0003

Aluminum nitride - electrical insulator with high thermal conductivity, in demand in the electronics industry;

Cordierite is a low thermal expansion ceramic suitable for vacuum applications.

Raw materials are supplied by means of a hopper filled before starting the printer. However, it is permissible to fill the device during the operation of the equipment.

Ceramic 3D printer software

The company supplies equipment with open source software that allows the buyer to develop and use their own formulations. The printers support Windows, Linux and OSX operating systems.

The printers support Windows, Linux and OSX operating systems.

Overview of 3DCeram ceramic 3D printers

The French engineering company offers interesting solutions for the manufacture of complex ceramic parts for various industries. What can be done with a 3D printer for sale? The possibility of printing finished items and individual elements of ceramics interested jewelers and watchmakers. End products and spare parts are durable, resistant to scratches and chips, hypoallergenic. 3D printing with clay is in demand for creating designer masterpieces, art objects and interior elements. Also, proprietary technology is actively involved in the aerospace and aviation industries, mechanical engineering, and biomedicine. nine0017 The Ceramaker printer series is designed to produce detailed and functional elements with consistently high quality.

Popular ceramic printers

Ceramaker 100 is a design and prototyping device. The printer is easy to operate and uses materials economically. The equipment is equipped with modules of various sizes, which makes it possible to optimize the consumption of paste during printing. Open settings allow you to adapt to personal requirements. nine0003

The printer is easy to operate and uses materials economically. The equipment is equipped with modules of various sizes, which makes it possible to optimize the consumption of paste during printing. Open settings allow you to adapt to personal requirements. nine0003

Ceramaker 900 – industrial technology. The device creates models with high surface quality, is used to manufacture functional elements that have the same characteristics as parts created by traditional methods (pressing, casting). It is the only machine on the market capable of producing objects according to the established specifications and criteria of the end user. This multi-component printer is capable of producing both simple structural elements and full-fledged functional devices. nine0017

Ceramaker3600 Ultimate – mass production equipment. The machine is designed for the production of large-scale batches or large-sized objects. The printer is compatible with a variety of resources.

Thanks to innovative Ceramaker 3D printers and original 3D printing materials developed by 3DCeram, prototypes and functional samples can now be produced quickly, with high precision and surface quality.

Source

Tags:

3D printers Ceramaker, 3DCeram company, Ceramic 3D printing, 3D printer, Ceramic additive manufacturing, paste extrusion, powder sintering, photopolymerization 3D Printers

Ceramic Oxide Compounds

Ceramic Non-Oxide Compounds

Read More

To accompany our customers, we offer maintenance operations combined into offers tailored to each of our machines. nine0003

We offer 3D printing training that allows you to control the process on Ceramaker machines to successfully complete your projects.

3DCeram provides tools for integrating 3D printing solutions into ceramic parts projects.

-

The aerospace and defense industries are constantly striving to optimize the performance of their equipment (satellites, measuring instruments, optics, etc.) by exploiting the properties of ceramics and setting new challenges, accompanied by a strong trade-off between performance and cost.

In this context, products should be more technologically advanced and reduce development time. DETAILS

In this context, products should be more technologically advanced and reduce development time. DETAILS Read more

3DCeram offers production lines tailored to the operating conditions of industrial markets (electronics, chemistry, telecommunications, etc.) that seek to integrate this new technology.

More details

3DCeram has been using SLA 3D printing technology for more than 10 years to produce custom or small batch bone implants (intervertebral cages and osteotomy-tibia wedges), as well as cranial and maxillary implants… READ MORE

More

-

3DCeram is the preferred partner of large research groups and universities. Indeed, the resistance and various properties present in ceramic make it the material of choice.

Read more

Aerospace, collaboration between Anywaves and 3DCeram

Anywaves has developed an innovative ceramic antenna concept for the aerospace industry. 3DCeram assists Anywaves with a 3D-AIM service to refine the entire manufacturing process https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/anywaves-designs-new-satellite-antenna-with-3dceram-ceramic -/ https://www.3d-grenzenlos.de/magazin/3d-objekte/prototyp-bandantenne-gnss-l1-e-mit-3d-drucker-hergestellt-27649103/ https://siusystem.ru/news/servis-3d-aim-ot-3dceram-pomog-anywaves-zapustit-vypusk-antenn-dlya-kosmosa

3DCeram assists Anywaves with a 3D-AIM service to refine the entire manufacturing process https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/anywaves-designs-new-satellite-antenna-with-3dceram-ceramic -/ https://www.3d-grenzenlos.de/magazin/3d-objekte/prototyp-bandantenne-gnss-l1-e-mit-3d-drucker-hergestellt-27649103/ https://siusystem.ru/news/servis-3d-aim-ot-3dceram-pomog-anywaves-zapustit-vypusk-antenn-dlya-kosmosa

DETAILS

Additive manufacturing, innovative in nature

3DCeram Sinto, a French company based in Limoges, has 15 years of experience in 3D printing complex ceramic parts, offers a wide range of services and a line of 3D printers. Interceram met with Nicolas Rousselet, Aerospace Segment Manager, and Karen Malsalle, Marketing Manager, to discuss a new service that meets the expectations of aerospace customers. Read Article

DETAILS

3D printed blade cores

3D printing opens the door to mass production of optimized blade cores.