3D printing overnight

3D Printing When Not at Home – Printing Overnight or Unattended? – 3D Printerly

3D printing when you are not at home seems like the normal thing to do, but I started to think whether it was actually a good idea. I’ve done some research to find out if it’s something that can be done without issues.

3D printing when not at home: should I do it? You should not leave your 3D printer unattended while printing as it is not safe. Many examples show fires breaking out and spreading around the room. There are ways to make it more likely to be safer such as using a full metal enclosure and having upgraded safety firmware.

There are a lot of things to take into account when deciding to print while away from home. In this post, I’ve described many safety precautions that will make things a lot more feasible for you to print at home when you aren’t there.

3D prints can take many hours, even more than a day to complete a print. So, it’s pretty unlikely that people haven’t left their printer running while asleep, overnight or while they were out.

How much are you willing to risk your house burning down? It just isn’t worth printing while not at home unless you have real preventative measures in place. It seems to be a risk many people seem to take on regularly.

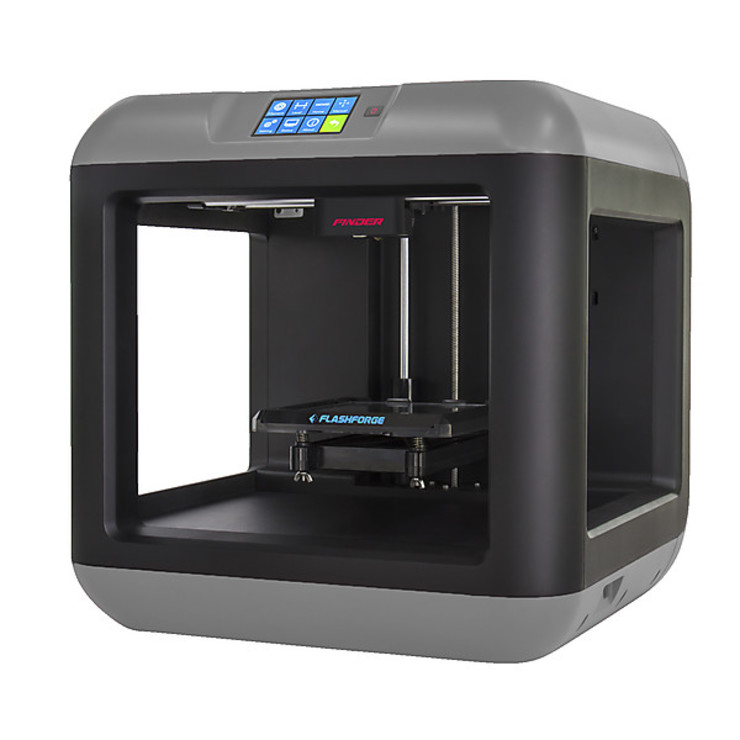

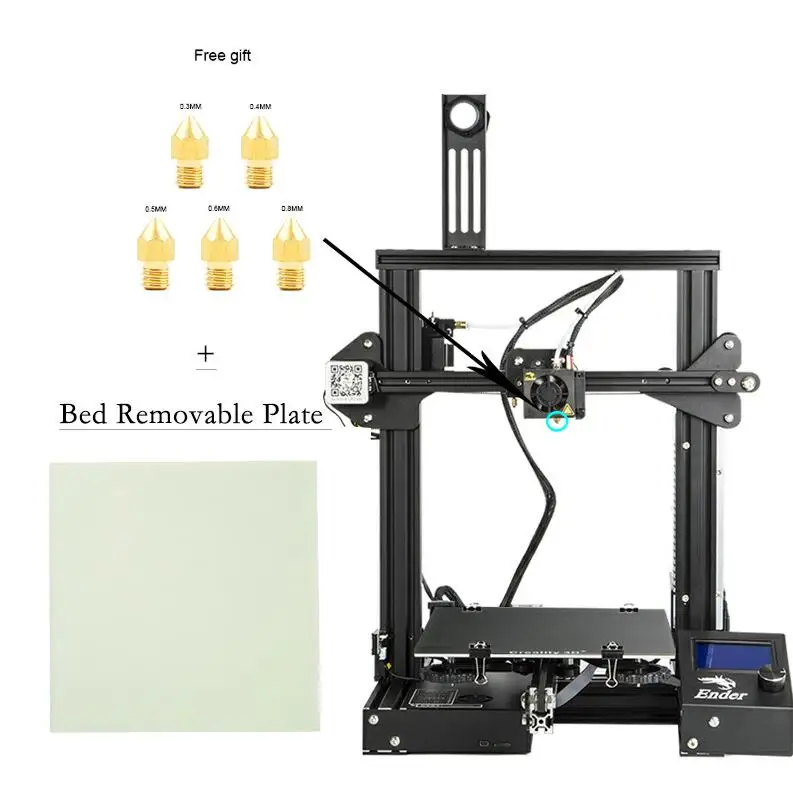

Getting yourself a reliable 3D printer is essential in 3D printing comfortably at home. You can’t go wrong with the Ender 3 V2 3D Printer (Amazon). It’s been growing in popularity massively in the past few months because it does everything so well!

It has:

- Silent motherboard – gives strong anti-interference, faster and more stable motion & silent printing

- Safety UL Certified Meanwell Power Supply for long print times – concealed within the machine for increased safety.

- New 4.3″ UI User Interface – simple and clear operation and improved user experience

- Easy filament feeding with the rotary knob on the extruder

- Carborundum Glass Platform – fast heating bed, prints stick better, and ultra-smooth bottom layers

You can also get the Ender 3 V2 from BangGood for cheaper! (Delivery make take longer)

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

What Can Go Wrong If I’m Not At Home?

A lot can happen from the time you leave home and come back when 3D printing. It makes sense, if you have a 10-hour print and leave for work or head out for a day to come back to a lovely final print.

Unfortunately, there are some issues to keep in mind when leaving 3D printers active when not at home.

There are many ways to protect your 3D printer from fire but with these hot temperatures, electric currents and DIY nature of 3D printing, there’s always a way that fires can occur without triggering some preventative alarm systems.

3D printing mostly comes with experience, knowing how your prints will process over a certain period of time. For example, if you wanted to leave your 3D printer running while you left the house, you may opt in for a print lasting a few hours rather than a 10-hour print.

The longer your printer is running, the longer it has for something to go wrong with potentially damning consequences.

For the most part, it’s not a great idea to leave your home with the washing machine, oven or dishwasher on but people still do it. The usual home appliances don’t have failures as often as 3D printers do.

There are many elements to a 3D printer that make it complex and therefore, less safe than common household appliances. It is, however, quite rare for a 3D printer to fail in a dangerous way and most of the time it just results in a bad quality final print.

The most popular and well-respected 3D printer is the Ender 3 V2 (Amazon or from BangGood), one of the best beginner 3D printers out there and produces high quality prints.

You are unlikely to experience many issues with a well put together Ender 3 printer.

From the high temperature extruder, to heated beds to motors and fans there are many issues that can occur. The problems come in due to the nature of how 3D printing processes are set up.

You have very high levels of control to set your 3D prints up, whereas household appliances operate how the manufacturer intended for you to operate, with knobs and switches.

The main serious failures that occur with a 3D printer is electronic fires, due to electric currents and heat building up in the wiring.

Most people aren’t electrical engineers so might not be clued-up in knowing what to check and look for, but this side of things is very important.

Electronic fires can easily spread around a room, even if the chances are small of it starting are small. An example of a way a flame can start is a connector not being able to handle the current from the heated bed.

If you want to 3D print when you are not home, make sure you are knowledgeable on the wiring aspect of your printer.

If you have a 3D printer which was built up from a kit, the electrical safety standards are your responsibility, and not the manufacturer of the kit.

This means if you are not an expert and put together a kit, it’s definitely not something you want to leave on while not at home.

I think once you’ve established that your printer isn’t faulty, and has printed many times without issues (especially longer prints), then you have a much better idea on how safe it will be but this isn’t 100% accurate.

Your normal 3D printer operation doesn’t usually start fires, neither does cooking but we all know it can happen. Knowing things can go wrong is a risk that people are willing to take responsibility for.

Preventative Measures For Printing When Not At Home

If you ever want to entertain the idea of 3D printing when not at home, you need to have several safety measures in place. Before every print, make sure to do a visual inspection of your components and make sure things are where they should be.

A few tips for you to follow:

- Check if your machine has an auto-shut off function.

- Research your thermal runaway settings.

- Get fire/smoke detection shut-off switches that cuts off power when something is detected.

- Isolate your printer from any flammable objects. (Filament is flammable).

- Consistently operate your printer and know that it works well.

- Print at lower speeds and lower temperatures as well as using PLA without a heated bed if possible.

- Get a camera set-up going so you can always check into your 3D printer.

- Make sure all your wiring and screws are secure and nothing is loose.

At the end of the day, all fires that have happened are because of operator error and a lack of maintenance. On top of that, not monitoring a printer in action.

Even if you have a high-quality printer, there is still the possibility that something could go wrong.

This is similar to having an expensive, well-made car but not maintaining it, you wouldn’t be surprised if you have some serious deterioration over time.

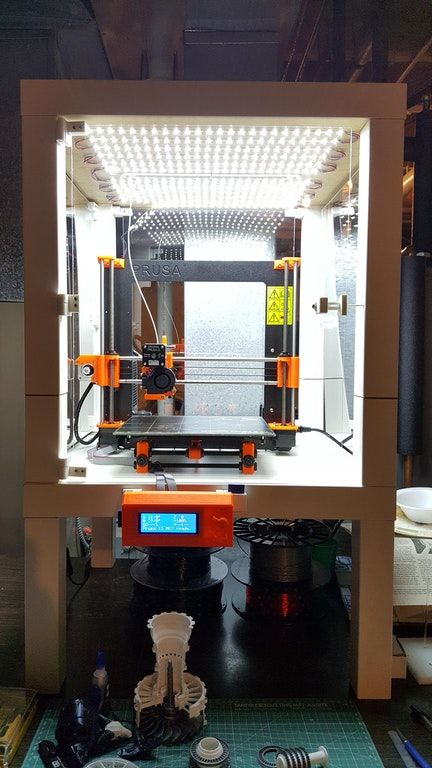

Enclosure

In the unlikely case that any fires occur, it’s best to have an enclosure which can cut off the oxygen a fire needs to grow.

Using software and hardware can assist you in having a safer environment for your printer. Also having flame retardant enclosures such as drywall, fibreboard or metal. A full metal cabinet seems to be a great solution to combat this.

Also having flame retardant enclosures such as drywall, fibreboard or metal. A full metal cabinet seems to be a great solution to combat this.

There is an added advantage of maintaining the temperature around your prints making it more stable, and reducing warping. Many times with longer prints, it just isn’t feasible to be able to constantly watch it.

Creality have manufactured a pretty cool fireproof enclosure for 3D printers which you can purchase straight from Amazon, but they are pretty premium.

Get the Creality Fireproof 3D Printer Enclosure for your 3D printer for maximum safety! It fits the Ender 3, Ender 5 and other similar sized 3D printers.

If you need a larger version, they have you in mind. The Creality Large Fireproof 3D Printer Enclosure is also available from Amazon for a slightly higher price.

These enclosures will give you that necessary peace of mind to be able to print when your not at home. They make things a lot more safe if you decide to leave your 3D printer running overnight or while sleeping.

It also has many added benefits such as:

- Keeping a constant temperature printing environment to improve printing stability

- Flame retardant with pure aluminum film – will melt rather than catch fire and stops the spread.

- Quick and easy installation, just like everybody loves!

- Also reduces noise for those pesky loud 3D printers and provides dust protections

- Very stable iron pipe structure so it can withstand plenty

Smoke Detector & Fire Extinguisher

Having a smoke detector which is linked to a sprinkler system is a great idea to combat fires. If a fire does occur, the speed at which they can spread is just too fast for you to be able to do anything if you are not present.

A great method to combat fires is to have an automatic fire extinguisher mounted above your printer in the case that a fire breaks out.

There are some automatic fire suppression systems which can react to nearby fires by dousing them and putting them out. Also having a smoke detector/relay combo to cut power if any smoke is detected.

Also having a smoke detector/relay combo to cut power if any smoke is detected.

Smoke will usually come before a fire starts so having the power cut out before anything catches or spreads is a good idea.

One of the causes of fires starting can be from using too much hairspray or other substance on the heated bed to stabilize a prints first layer. If you want to run a printer while you aren’t at home or sleeping, definitely don’t use these substances.

Glass build plates are your best bet, and have a fire extinguisher nearby in case.

The Automatic Self-Activation Fire Extinguisher Ball is a great device that gives you an important safety feature and peace of mind in the rare event of a fire. It’s lightweight and promptly triggers in 2-3 seconds to suppress a fire, as well as sounding off a 120 decibel alarm.

At minimum you should have a smoke detector, a good one from Amazon is the Combination Smoke & Carbon Monoxide Detector.

You should also have a fire extinguisher on hand, the Kidde Fire Extinguisher has great reviews from people and fights class A, B & C fires. It’s quick and powerful with a discharge time of 13-15 seconds, as well as being lightweight.

In the case of fires, wooden printers or plastic printers should be totally avoided as they will add to the fire. The printers you want should be made from some kind of metal such as aluminum.

Just because the chances of fires breaking out are rare, doesn’t mean you should assume it won’t happen to you. 3D printing, especially in a bedroom is a bad idea because there are usually many flammable items in a bedroom.

These things won’t just affect you, but everyone around you.

Webcam Viewing Tool

Webcams can be set up so you can monitor your 3D printer remotely while it’s working but you may be helpless to stop it if something went wrong. A popular choice for 3D printer users is the Jun-Electron 5MP 1080P Video Camera Module for Raspberry Pi 4.

This module also requires a Raspberry Pi, the Model B is a great choice.

Having a live-feed camera on your 3D printer, with temperature readings being sent to yourself could combat this. Then in addition to this, having an emergency stop feature on your phone.

There is software out there that allows you to pause/cancel prints if something is going wrong, such as the MakerBot Desktop or Belkin App.

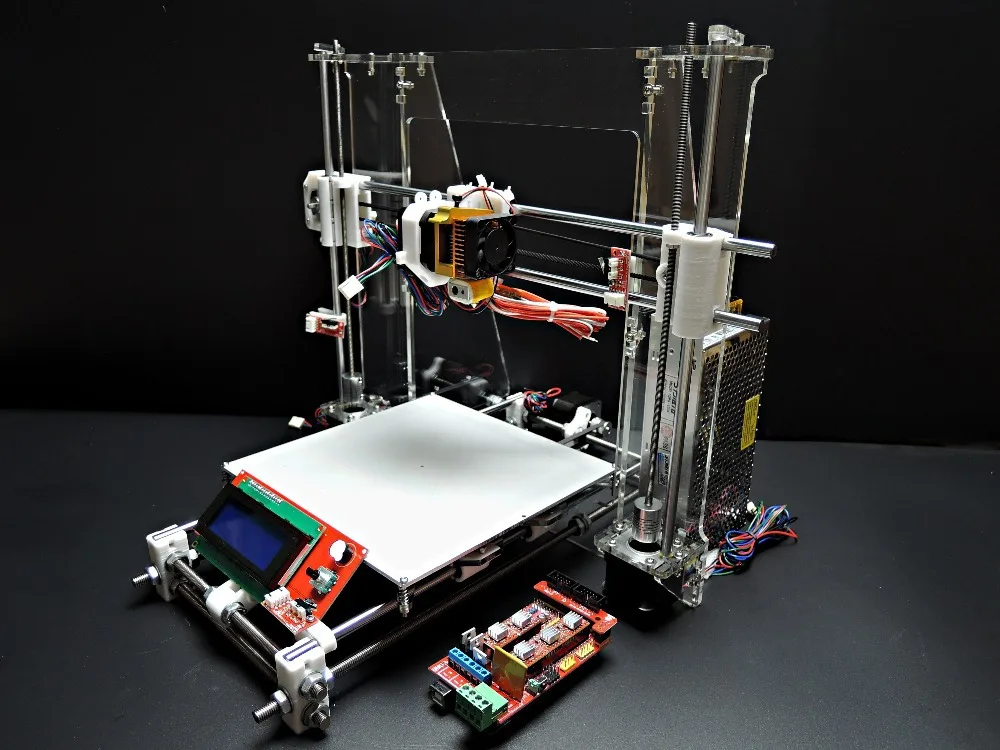

Not All 3D Printers Are Built The Same

There’s a huge variety of 3D printers which are built differently, with some being flagged for having issues. Most 3D printers tend to use many universal parts, but there’s a distinction between high-quality and low-quality 3D printers.

There’s been stories about certain printers which are notorious for causing issues.

The Anet A8 is one of the main culprits which have caused fires to break out, whereas the CR-10 is seen as a safe option. I think it mainly comes down to the wiring and currents running through the wires which cause fires.

In all fairness, the main issues that caused this have been patched up so an Anet A8 isn’t the worst 3D printer you can get but it definitely has a reputation.

Wires heat up and expand which results in more resistance and more resistance means more heat which continues into a cycle of overheating. The solution is to have high-quality, larger wires and connectors which can help withstand these currents.

This post here explains that even after many ‘standard’ upgrades and safety features were installed a fire still managed to break out. In this case, it wasn’t the usual culprits that cause fires such as the power supply, control board, or hot bed.

It was actually the hot end where the heat element actually detached from the hot end block. The firmware which was installed didn’t actually have the thermal runaway protection to shut off the system when temperature readings don’t match up.

You definitely do not want to leave a cheap Chinese model 3D printer unattended because there is so much that can go wrong.

Practically speaking, there is a very rare chance that a manufactured 3D printer to cause a fire, but that small chance is enough to be wary about it.

3D printer manufacturers are constantly putting more emphasis on safety features so over time it will get better.

3D printers that are ‘hobby-grade’ can fail and result in fiery disasters. This is why you definitely want a metal enclosure as a safety measure. Even with all the safety methods you implement, if a fire does break out you won’t be able to do much if you aren’t there.

Some 3D printers are very low-power and so are much less likely to become a fire hazard. These can be a much better option if you wish to 3D print over long periods of time or overnight.

When looking online about fires from 3D printers, there’s a whole host of examples where people have walked into terrifying situations. This alone is enough to be informed that 3D printing when not at home is not a good idea.

The Ender 3 V2 (Amazon or from BangGood cheaper) as previously mentioned is going to set you in the right direction for a high quality, popular 3D printer that has a serious focus on safety. Long printing times and safety features are up-to-date and reliable.

Can a 3D Printer Start a Fire?

A 3D printer can start a fire if thermal runaway protection and other safety features haven’t been installed properly. It’s rare for a 3D printer to start a fire though, but it’s important to run checks on your 3D printer to ensure it is up to standard. I’d recommend using a 3D printer from a trusted manufacturer.

The video below by TeachingTech shows you how to test your 3D printer for thermal runaway protection.

As previously mentioned, as long as you have a reliable machine, you’ll be safe from 3D printer fires. There hasn’t been much news about 3D printers starting fires in recent times because companies have gotten their acts together.

There hasn’t been much news about 3D printers starting fires in recent times because companies have gotten their acts together.

These events mainly occurred from poorly put together machines and unfortunate circumstances with use. These days, even cheap machines will have the proper quality control, wiring, and safety features to prevent fires from happening.

How Long Can 3D Printers Run?

If you are wondering whether 3D printers can run 24/7, you aren’t alone. Even though you may not want to do it yourself, it’s still a question many people ask.

3D printers can run 24/7 successfully as shown by many print farms around the world. Printers that run constantly do have failures from time to time, but generally speaking, they can run for several hours concurrently without issues. Some single large 3D prints can run for over 2 weeks.

Related Questions

Will My Pets Be Safe With My 3D Printer? Pets can be very curious so if your 3D printer is not in an enclosure, it can be dangerous but not life-threatening. Most safety issues will be possible burns from high temperatures. Having your printer in an isolated room or out of reach should make it safe.

Most safety issues will be possible burns from high temperatures. Having your printer in an isolated room or out of reach should make it safe.

Are Cheaper 3D Printers Safe to Leave Unattended? Even though 3D printers are getting safer, I wouldn’t leave cheaper 3D printers unattended as they do have more problems. These may be manufactured without as many trials and testing than more expensive printers, so not the best idea to leave these unattended.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish

- Become a 3D printing pro!

Is It Safe to Leave A 3D Printer on Overnight? (Answered)

If you have a 3D printer, chances are you want to make the most out of it. Letting it print overnight is one of the easiest ways to speed up builds. But, the question is, should you?

Letting it print overnight is one of the easiest ways to speed up builds. But, the question is, should you?

Unfortunately, no matter how tempting it is to leave a 3D printer on overnight or unattended, it can create risks. Most manufacturers strongly advise against doing so. While there are some management and risk-reduction steps you can take, leaving a 3D printer on overnight always creates risk.

Can You Leave a 3D Printer on Overnight?Most 3D printers are not made to run without supervision. In addition, 3D printers can present a fire hazard. In fact, there are many examples of 3D printers left alone to print which turn into a fire hazard. While that isn’t always the case, your 3D printer may not be safe to leave alone. That’s especially true if you’re printing in an enclosed room. Here, fumes can build up overnight so that your room is unsafe to enter.

However, there is a large community of people who do run their 3D printer overnight and without supervision. In fact, most manuals suggest not leaving your 3D printer unattended for long. However, many still do so. Most use mitigating efforts such as 3D printer fire suppression tents. These can reduce the risk of fire and of dangerous fumes. However, no printer manufacturer will recommend this. Instead, most strongly recommend against running your printer without real-time supervision. This advice stems from the fact that any 3D printer can snag, catch, fall, or otherwise burn out – creating a potential fire hazard.

In fact, most manuals suggest not leaving your 3D printer unattended for long. However, many still do so. Most use mitigating efforts such as 3D printer fire suppression tents. These can reduce the risk of fire and of dangerous fumes. However, no printer manufacturer will recommend this. Instead, most strongly recommend against running your printer without real-time supervision. This advice stems from the fact that any 3D printer can snag, catch, fall, or otherwise burn out – creating a potential fire hazard.

3D Printers and Fire Hazards

3D printers are a fire hazard. That is true of any device with working temperatures that sometimes exceed 250 degrees. However, some 3D printer models are more susceptible to combustion than others. For example, the Anet A8 3D printer has a history of combustion – and you can easily find photos of the model burnt out on Google Images. On average, 3D printer fires are rare.

Here, several things impact fire hazards in 3D printers. The first and most important is build quality. Every 3D printer has a thermistor to measure the operating temperature of the 3D printer. Most include a thermistor and heat cartridge instead of a bulkier thermostat. With poor build quality, the thermistor sensors can come loose – which may result in the 3D printer overheating and combusting.

The first and most important is build quality. Every 3D printer has a thermistor to measure the operating temperature of the 3D printer. Most include a thermistor and heat cartridge instead of a bulkier thermostat. With poor build quality, the thermistor sensors can come loose – which may result in the 3D printer overheating and combusting.

That also holds true with wires and cabling. 3D printers can run very hot. Over time, cables can weaken and reach melting point. If you leave your 3D printer running for 18-20 hours, including a long stretch of unsupervised time, those cables could damage to the point of baring wires. That might not result in a fire right away, but eventually, it will.

An electrical fault, such as a short in a wire can also cause a fire. Here, a short causes a spark, usually in a motor. It keeps sparking because the motor keeps running. Eventually, the motor catches fire – which can spread to other parts of the room. That’s especially important as many people leave 3D printers sitting on wooden tables. Because many people leave flammable agents such as lubricants, cleaning agents, paint, resin, etc., near their 3D printer, even a small printer fire can quickly get out of control.

Because many people leave flammable agents such as lubricants, cleaning agents, paint, resin, etc., near their 3D printer, even a small printer fire can quickly get out of control.

It’s highly unlikely you’d get a fire from the 3D print process. Plastics are both not very flammable and more likely to melt if left in contact with the extruder tip while it’s still warm.

8 Safety Measures to Take Before Leaving Your Printer Unattended

It’s never advised to leave your printer unattended. However, if you do, it’s important to take safety measures to reduce any potential risk.

Machine Auto-Shut FunctionMost 3D printers have an auto-shut-off function. It’s important that you use them. This requires checking the manual and potentially creating a script to automatically turn the 3D printer off when the build is complete. In most machines, this will be relatively easy. However, it varies per machine, and may be more difficult depending on the strength of the firmware that comes with your printer.

This varies per printer. Check your manual and set it up.

Remote Monitoring SystemsRemote monitoring systems like webcams and software can offer a lot of assurance when you leave your 3D printer unattended. For example, a webcam allows you to check up on the visual status of your webcam on demand. That won’t do much good if you’re going to sleep, however, it will if you’re going to work. Applications like Octoprint offer dependable remote monitoring for most 3D printers. This allows you to monitor, control, and shut off your 3D printer if it exceeds certain settings. That adds a good measure of safety, providing your hardware is measuring properly. Octoprint also offers remote monitoring, including an embedded webcam feed, progress updates, and GCode visualizers, so you can see what your printer is doing at any time. And, with remote start/stop/shut down functions – you get more control over turning the printer off even if you’re not in the room. While that doesn’t help much if you are sleeping, it is a good additional control if you’re leaving the house or going to work.

While that doesn’t help much if you are sleeping, it is a good additional control if you’re leaving the house or going to work.

Thermal runaway protection is a setting on most 3D printers that allows you to reduce or prevent most fire hazards. Here, the printer simply stops the print in case anything is unusual about the readouts from the thermistor. For example, if the readings are too high, if the readings are too low, or if the readings stop altogether. That prevents issues like a dislodged thermistor or sensors resulting in a fire.

Thermal runaway normally happens when the thermistor is misaligned, dislodged, or faulty. Luckily, many 3D printers actually have it activated by default. For example, Prusa and MakerBot use thermal runaway protection by default. Others, like Marlin and Endor 3D printers require you to turn the function on. Make sure the function is on and check your manual to see what thermal runaway protections your printer actually comes with.

If you don’t have thermal runaway protection active, it can result in issues like fire. Thermal runaway protection is designed to shut down prints if something is off. That means it will react to faulty hardware. Otherwise, you are relying on the thermistor being in good working condition. You also need it to be properly aligned.

Common Problems That Trigger TRP

Thermal Runaway can be triggered by a lot of things, primarily faulty hardware. These triggers include:

- Electrical shorts

- Plastic sticking to the hot end and catching fire

- Faulty wires or cables melting

- Electrical surges

- Misaligned thermistor

- Loose thermistor

- Faulty thermistor

- Broken heat cartridge

- Mistakes with heat settings

Many printers are hot. In fact, some print at temperatures similar to an oven. It’s important to keep them away from flammable objects. That means putting 3d Printers on a ceramic or metal surface or tray in a well-ventilated room. You also want to ensure that paint, resin, cleaning supplies, etc., are not stored nearby. If you do store these kinds of materials in the same room, try to store them in a metal or other filing cabinet, where they will be less affected if something does go wrong.

In fact, some print at temperatures similar to an oven. It’s important to keep them away from flammable objects. That means putting 3d Printers on a ceramic or metal surface or tray in a well-ventilated room. You also want to ensure that paint, resin, cleaning supplies, etc., are not stored nearby. If you do store these kinds of materials in the same room, try to store them in a metal or other filing cabinet, where they will be less affected if something does go wrong.

A smoke detector will let you know if something goes wrong, so you can react quickly if there is a fire. Even if you have a smoke detector and carbon monoxide detector in the house. Here, you’ll want to install both or a dual detector in the room with the 3D printer. This ensures you’re alerted of a problem as quickly as possible in case something goes wrong.

If you do plan to leave your 3D printer on overnight, you might want to consider a smart smoke detector. These devices send alerts to your phone – which can wake you up. Then, you can react as quickly as possible to a potential fire and avoid disaster.

These devices send alerts to your phone – which can wake you up. Then, you can react as quickly as possible to a potential fire and avoid disaster.

It’s important to have a Class C Fire Extinguisher on hand whenever running potentially flammable machinery. Class C fire extinguishers use dry powder chemicals or carbon dioxide to suffocate a fire, which may still be connected to live power. If you do have a fire, it’s also a good idea to first cut power to the room using the breaker box. This ensures that any electrical power which might be feeding the fire is cut off. It also reduces the risk of the fire causing shorts and potential fires in other parts of your home.

For the best results, buy a fire extinguisher and take a class on how to use it. Most local fire departments offer free courses on basic fire management including the proper use and storage of a fire extinguisher.

EnclosureEnclosing your 3D printer in a fire-resistant cabinet or tent can do a great deal to reduce the risks associated with leaving it unattended. These are often sold commercially. However, you still have to make sure your 3D printer gets enough ventilation. In addition, it’s almost always a bad idea to store a 3D printer in a cabinet, where it might overheat wood or composite. 3D printer enclosures:

These are often sold commercially. However, you still have to make sure your 3D printer gets enough ventilation. In addition, it’s almost always a bad idea to store a 3D printer in a cabinet, where it might overheat wood or composite. 3D printer enclosures:

- Reduce the risk of fumes escaping into a room. You can vent into a controlled area

- Keeps humidity away from the printer

- Helps control the temperature of the print

- Minimizes heat loss from the heat bed, which can reduce energy usage

- Prevents objects or pets from damaging the printer

Printing at a lower speed allows you to reduce the temperature of the print – to a certain point. However, this reduction will not be enough to make it safe to leave your printer alone without taking safety precautions. On the other hand, it will reduce the potential risks of faults and issues from overheating. In general, the slower you print, the better it is for the machine and the higher quality the print will be. However, you may also want to choose to print with something that becomes workable at a lower temperature – such as PLE instead of ABS. For example, PLE allows you to print as low as 180 C if you have a heated bed. ABS usually requires at least 240 C.

In general, the slower you print, the better it is for the machine and the higher quality the print will be. However, you may also want to choose to print with something that becomes workable at a lower temperature – such as PLE instead of ABS. For example, PLE allows you to print as low as 180 C if you have a heated bed. ABS usually requires at least 240 C.

You Can Pause It Overnight Instead

Most 3D printers come with built-in start/stop and pause functions. Providing you don’t cut power or lose the saved print data, your printer can then pick back up where it left off. That allows you to safely print larger projects, even when they take more time than you have in one day.

That’s also a much better alternative to fully stopping the 3D print mid-way. For example, if you do so, you’ll likely lose the print. It’s almost impossible to pick back up where you left off, unless you’re using multi-part files.

How Long Can You Pause a 3D Print?Theoretically, there’s no limit on how long you can pause a 3D print. However, your printer has to maintain power to retain the saved file and progress unless your printer has a save function or you can save to your computer. In addition, it’s important that the print is not removed, moved, or jolted. If it does come loose, you’ll likely have to restart the print.

However, your printer has to maintain power to retain the saved file and progress unless your printer has a save function or you can save to your computer. In addition, it’s important that the print is not removed, moved, or jolted. If it does come loose, you’ll likely have to restart the print.

In addition, the longer you wait, the more likely you’ll have to clean the print before continuing. To do so, carefully wipe the top of the print down with an alcohol wipe to remove any built-up dust. Make sure you don’t jostle it loose. Then, allow it to dry and pick up from there.

Related Questions

If you still have questions, these should help.

How often should I give my 3D printer a break?Most 3D printers do not need breaks to run properly. In fact, many people run printers 10+ hours per day, every day. However, the more you use your 3D printer, the more important it is to run maintenance to ensure everything is aligned and in place. A misaligned belt can do a small amount of damage on a 1 hour print. On a 10 hour print, it can ruin your machine.

A misaligned belt can do a small amount of damage on a 1 hour print. On a 10 hour print, it can ruin your machine.

Temperature settings should wholly depend on the material you are printing. Check what you are printing, your bed heat, and your ambient temperature. Then set the temperature accordingly. In most cases, you can get away with a lower temperature by running a slower print. However, running your 3D printer too cold can cause under extrusion and extrusion skipping – which will ruin your print.

How long to let 3D print cool?It’s normally recommended to let a 3D print cool for 5-10 minutes after the print finishes. However, recommendations change per material and based on your fans. For example, if you have low ventilation and a heated bed, you might want to give it a few minutes longer.

Final Thoughts

If you still want to run your 3D printer overnight, it’s important to understand that you are taking on a risk. Make sure you take steps to reduce risks before 3D printing overnight. In addition you should notify a family member or friend as a precaution if no one is in the home to attend the printer.

Make sure you take steps to reduce risks before 3D printing overnight. In addition you should notify a family member or friend as a precaution if no one is in the home to attend the printer.

It’s never recommended to run a 3D printer unattended and that includes overnight or when you are not at home. If you do so anyway, make sure you try to reduce that risk as much as possible.

The night 3D printing was born: the story of inventor Chuck Hull

The night that 3D printing was born

3D printing

the story of inventor Chuck Hull

March 9, 1983, San Gabriel, California. In the evening, the telephone rang at Engineer Hull's house. Antoinette picked up the phone and heard her husband's excited voice. Mrs. Hull was not too surprised by the call - her husband was constantly late at work until late at night. But instead of the usual apologies, the engineer insistently asked his wife to drop everything and urgently come to the laboratory. Antoinette stood in her pajamas and was already getting ready for bed, but she could not refuse. She only replied, "It's in your best interest to make it worth my attention."

Antoinette stood in her pajamas and was already getting ready for bed, but she could not refuse. She only replied, "It's in your best interest to make it worth my attention."

New Gutenberg

The night 3D printing was born.

Part 1

In the early 1980s, the US economy was in recession: unemployment was rising, incomes were falling, and a third of industrial enterprises were idle. The economic crisis shook faith in traditional technologies - enterprises needed modernization, unexpected and fresh solutions. It was obvious to everyone that the future belongs to computers and microelectronics - it remains to find people who would combine IT technologies and conveyor production. The world needed inventors again.

In 1983, Charles "Chuck" Hull worked for Ultraviolet Products (UVP). Unlike the eccentric geniuses of that era, Steve Jobs and Bill Gates, distinguished by anything but patience, Chuck did not seek to conquer the world at all costs. His path to invention was reminiscent of the life of Johannes Gutenberg, a German jeweler and minter whose inquisitive mind led to the creation of the first printing press. Like Gutenberg, until the age of 40, Hull was a typical modern "craftsman" - an engineer with a good university education and a standard career. After traveling around the country, in the late 70s, Chuck and his family settled in San Gabriel, a small town in California, where he took the position of vice president of UVP development.

His path to invention was reminiscent of the life of Johannes Gutenberg, a German jeweler and minter whose inquisitive mind led to the creation of the first printing press. Like Gutenberg, until the age of 40, Hull was a typical modern "craftsman" - an engineer with a good university education and a standard career. After traveling around the country, in the late 70s, Chuck and his family settled in San Gabriel, a small town in California, where he took the position of vice president of UVP development.

Ultraviolet Products focused on ultraviolet solutions: equipment, lamps, photosensitive polymers. Furniture factories bought UVP technologies - such materials replaced conventional varnishes and paints for wood. A special polymer was applied to a countertop or wood slab and then cured under ultraviolet light. It turned out a strong plastic frame, an analogue of wood veneer.

While testing another polymer, Chuck Hull wondered what would happen if successive exposure to ultraviolet light was applied to not one, but several layers of the polymer.

At UVP, Hull worked on the production of those UV curing furniture paints. While testing the next polymer, Chuck Hull thought: what would happen if not one, but several layers of plastic were successively exposed to ultraviolet radiation. If the layers are formed by curing them in turn with UV radiation, it is possible to arrange a plastic product of absolutely arbitrary shape. For this, it is necessary that the process be controlled by a computer - then the probability of marriage will be negligible. This is how the first idea to combine computer modeling and photochemistry appeared.

Post-apocalyptic

kluge

The night 3D printing was born.

Part 2

Chuck needed a lab to get started. With only service equipment on hand, the engineer turned to his boss for help. The UVP president didn't share his subordinate's enthusiasm: after all, his firm makes ultraviolet lamps, not Star Trek replicators. If Hull wants to invent, let him do it in his spare time. So they agreed: during the day, Hull performed direct duties, while he devoted his nights and weekends to independent research.

So they agreed: during the day, Hull performed direct duties, while he devoted his nights and weekends to independent research.

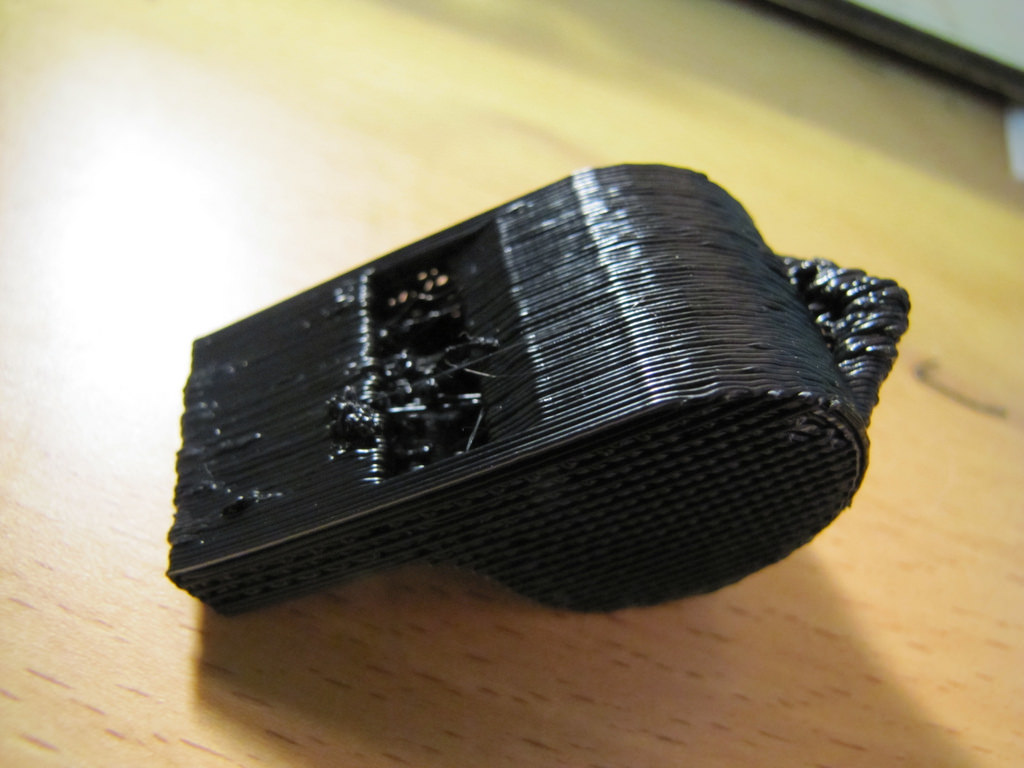

The first 3D printer turned out to be a kludge — that's what technicians call mindless-looking but workable junk.

The engineer was assigned a small room for research. It was there that 3D printing was born in experimental pains. Chuck set up equipment, tested polymers, and wrote programs. Hull later admitted that, as a discoverer, he made every mistake he could. But after months of work, Chuck was lucky - the inventor finally designed a working system in which an ultraviolet lamp illuminated a container of photopolymer.

Hull wrote the code that tells the printer how many layers to use on his own. Therefore, initially the device could only produce structures of a very simple form. And in appearance, the world's first 3D printer did not shine with grace. Chuck described it with the word “kluge,” the technical term for mindless-looking but workable junk: “The 3D printer looked post-apocalyptic, like a piece of equipment from the Water World movie.

March 9, 1983 is considered the birth date of 3D printing - on this day, Hull's "monster" produced something similar to the first 3D model. Then Chuck, as usual, stayed up late in the laboratory, experimenting with the settings of the device. Recently, the polymer, although it hardened evenly, turned into spaghetti due to the low sintering of the layers. But not at this time. The settings were correct, the kluge did not fail, and after 45 minutes of buzzing, the device reproduced a small bowl.

Hull recalled in an interview: “I called it the eye cup because it looked like the eyedropper my wife wore all the time. It appeared to Antoinette as a communion cup. It must have been God directing my efforts.” But Chuck didn't exactly feel like a monk that night, more like a medieval alchemist who created a piece of gold from liquid slime.

The accomplished “father of 3D printing” called his wife and urgently asked her to come to the laboratory. In response, he heard Antoinette's angry voice: "It is in your interest that this be worth my attention. " As his wife entered, Chuck showed off the first 3D printed object. It was an ordinary cup, unremarkable, except for the circular sections on the walls. Years later, Antoinette recounted the events of that night: “He held this cup in his hand and said, “I did it, now the world will never be the same.” We laughed and cried and stayed up all night just fantasizing about the future.”

" As his wife entered, Chuck showed off the first 3D printed object. It was an ordinary cup, unremarkable, except for the circular sections on the walls. Years later, Antoinette recounted the events of that night: “He held this cup in his hand and said, “I did it, now the world will never be the same.” We laughed and cried and stayed up all night just fantasizing about the future.”

First patent

The night 3D printing was born.

Part 3

Hull called his brainchild stereolithography: “I sat at night and tried to come up with a name for a new technology. I wanted the title to necessarily include the term "lithography", as a synonym for printing, and the Greek word "stereo", which means "volumetric", "spatial". Then I just put those two words together.”

U.S. Patent 4,575,330 titled "Apparatus for creating three-dimensional objects using stereolithography" was filed August 8, 1984 years old.

Convinced of the viability of the method, Chuck worked on the device in his small laboratory. A year later, he managed to bring the development to patenting: “As soon as I got a normally working machine, I immediately turned to a lawyer. He wrote a document for the patent office." U.S. Patent 4,575,330 entitled "Apparatus for creating three-dimensional objects using stereolithography" was filed August 8, 1984. In the application, Chuck described stereolithography as a technique for creating solid objects by successively printing thin layers of material and treating them with ultraviolet radiation. Hull was listed as the author of the development, the rights to the invention were transferred to UVP.

A year later, he managed to bring the development to patenting: “As soon as I got a normally working machine, I immediately turned to a lawyer. He wrote a document for the patent office." U.S. Patent 4,575,330 entitled "Apparatus for creating three-dimensional objects using stereolithography" was filed August 8, 1984. In the application, Chuck described stereolithography as a technique for creating solid objects by successively printing thin layers of material and treating them with ultraviolet radiation. Hull was listed as the author of the development, the rights to the invention were transferred to UVP.

The largest manufacturer of 3D printers in the world could well have been called Ultraviolet Products, but it turned out differently. The company was affected by the economic crisis - sales fell sharply, and in order to preserve the core business, the management decided to sacrifice promising areas. During a meeting with the president, the inventor insisted on continuing research, but he could not allocate funds for the refinement of the apparatus and marketing. Then Hull suggested that the boss register a new company and become partners: overall management and promotion fell on the shoulders of Chuck, while the president was entitled to a share of the profits. Seeing the seriousness of the intentions of the already former subordinate, the boss agreed and ceded the license to the invention to Hull.

Then Hull suggested that the boss register a new company and become partners: overall management and promotion fell on the shoulders of Chuck, while the president was entitled to a share of the profits. Seeing the seriousness of the intentions of the already former subordinate, the boss agreed and ceded the license to the invention to Hull.

Founding of 3D Systems

The night 3D printing was born.

Part 4

In 1986, the partners founded the first 3D printer company and named it 3D Systems. Since Chuck had never been in business, he had to put in a lot of time and effort to get his name out there: “I was calm about the technology, I never doubted that 3D printing would become popular. But I was never very confident in myself, so at first it was difficult. He attended scientific forums, consulted with colleagues from leading US universities, traveled to social events to make useful contacts. His activity paid off - a Canadian investor agreed to invest $6 million in 3D Systems.

The first mass-produced 3D printer was released in 1987 and was named SLA-1.

Refinement of the original device to marketable form lasted another year, until 1987. The first mass-produced 3D printer was named SLA-1. The huge and heavy cabinet was not very suitable for presentations, so Hull recorded short videos to demonstrate the capabilities of the 3D printer: “These films were quite corny, but we got a huge response from our customers.”

Hull had high hopes for automakers. In the 1980s, the US auto industry lagged far behind Japan's, and American companies were desperate for a secret weapon. They became a 3D printer. With the help of 3D printing, engineers could quickly prototype small parts such as door handles and gear levers. Hull's predictions were fully justified: General Motors and Mercedes-Benz soon introduced stereolithography for the manufacture and testing of prototypes.

American companies were desperate for a secret weapon. They became a 3D printer.

Hull later found out that 3D printing was applicable not only to liquids, but also to any gradually solidifying materials that could change their physical state. Over the course of several years, he patented dozens of new solutions and technologies, including STL, a new data format for digital models. This format represents the object as a set of triangular faces and supports layering.

Despite the success of 3D Systems, the invention of 3D printing did not initially cause the industrial revolution that computers did. The real boom in additive manufacturing (as well as the recognition of the merits of the inventor himself) occurred later, in the 21st century. But fame and fame never bothered Hull - he was always distinguished by patience. At one time, the developer told his wife that 3D printing technology will take 25-30 years to take its rightful place in the market, but after that it will play an important role in the industry. Both of Hull's predictions turned out to be correct.

Today, 3D Systems is one of the largest 3D printer manufacturers in the world with a market capitalization of $1.1 billion. 78-year-old Chuck Hull continues to work in his native company, combining the positions of executive vice president and chief engineer. He has over 100 patents in the US, Europe and Japan, including 7 3D printing technologies. In 2014, Hull was inducted into the US National Inventors Hall of Fame, placing his name alongside other notables such as Henry Ford, Nikola Tesla, and the Wright brothers.

2018 Project of the Information and Analytical Agency 3Dpulse.ru .

Marketing group " Tekart ".

We thank 3D Systems for providing access to photo and video materials.

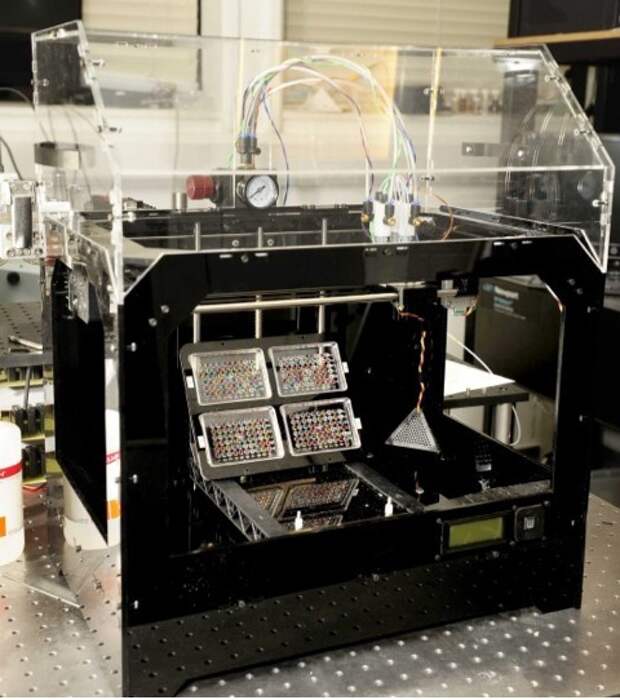

10 reasons to use OctoPrint for 3D printing

3DPrintStory Reviews 10 Reasons to Use OctoPrint for 3D Printing

Surely everyone had problems with 3D printing, which was left overnight in the hope of getting a finished 3D model in the morning. Or it was simply not possible to constantly monitor the 3D printing process in order to stop it in time. e in case of an error. It is this problem - the problem of monitoring 3D printing - that is solved with the help of the wonderful free and open source software OctoPrint.

Or it was simply not possible to constantly monitor the 3D printing process in order to stop it in time. e in case of an error. It is this problem - the problem of monitoring 3D printing - that is solved with the help of the wonderful free and open source software OctoPrint.

OctoPrint is a Raspberry Pi-based 3D printer application that allows you to remotely control your 3D printer. Created by Gina Heusge in 2012, the software is constantly being improved with new versions and new features (via plugins) coming out regularly.

In this article, we highlight the top 10 reasons to use OctoPrint. Some of the problems in this list are solved with the help of additional plugins. By the end of this list, you'll probably want to try OctoPrint if you haven't already.

Wireless 3D printing

Many budget 3D printers do not provide the ability to control or monitor the 3D printer wirelessly. Models must either be downloaded to an SD card or transferred directly via cable. These connection options have their limitations. OctoPrint offers an excellent solution to this problem.

These connection options have their limitations. OctoPrint offers an excellent solution to this problem.

As we briefly mentioned earlier, OctoPrint provides software that is installed on the Raspberry Pi and then connected to the 3D printer. Thanks to the wireless capabilities provided by Raspberry Pi, you can control your 3D printer wirelessly via LAN.

OctoPrint allows you to remotely send G codes, control the temperature of the extruder and hot end, monitor the 3D printing process, and much more. Thanks to OctoPrint's wireless 3D printing capabilities, you can always control your 3D printer, even if you are not physically present.

3D printing from anywhere in the world

As you know, wireless 3D printing is convenient if you are at home and on the same network. But what if you left home and wanted to start printing and was finished when you got home? Or what if you want to keep an eye on the 3D printing process when you're not at home?

Plug-in OctoPrint Anywhere allows you to manage (start and stop) and control 3D printing from literally anywhere. This is a website that can be accessed from your computer or mobile device.

This is a website that can be accessed from your computer or mobile device.

This plugin has a lot of fans, but keep in mind that the OctoPrint developers recently announced that it will eventually be replaced by a more elaborate and updated plugin called Spaghetti Detective.

View G-code

Typically, OctoPrint users monitor the 3D printing process via a webcam connected to their Raspberry Pi. However, if you don't have a webcam or just want to check your 3D print in a different way, the G-code viewer is a great tool.

This underrated OctoPrint feature shows nozzle position and layer number in real time. You can also find the status of your 3D print in the window just below the renderer, which shows the current G-code commands being sent to the 3D printer.

Commands from the terminal

The ability to send commands from the terminal is a great feature for more advanced users. You can view the codes sent to the 3D printer in real time.

One of the most useful features is sending custom G-code commands to your 3D printer. Instead of relying on another program to communicate with your printer, such as Pronterface, you can directly send commands to the OctoPrint terminal.

This feature can be useful in a number of scenarios. If you need to calibrate your 3D printer, you can view the existing system presets in a terminal command. Some commands also allow you to enter and save new calibrated values. This is a very handy feature for those who like to tinker with their 3D printer at a deeper level.

Slow motion

You know that 3D printing is a long process, it can take hours to print one model. Setting up a time-lapse video allows you to view the entire 3D printing process, which lasts several hours, in a matter of seconds.

With OctoPrint and with a camera connected to your Raspberry Pi, you can capture great 3D printing time-lapse video by setting the frame rate and interval between shots. For true enthusiasts, there are also more advanced customization options.

For true enthusiasts, there are also more advanced customization options.

OctoPrint stores the timelapse locally on the Raspberry Pi and you can download it to your computer. Another useful feature of time-lapse video is the ability to determine the exact cause of a 3D print failure, or at least the point at which the failure occurred.

Octolapse is a plug-in that builds on the functionality of OctoPrint's Timelapse section to produce cleaner, crisper videos.

Slicing 3D Models in the Cloud

Cloud Slicing, as the name suggests, is a remote slicing feature that allows you to slice your 3D models without actually installing the slicing software on your computer. Model slicing is performed using a plugin installed on the Raspberry Pi.

Consider the scenario where your laptop is full of applications and you can't/don't want to install a new slicer. Or imagine not wanting a slicer for every computer you use. This is where the Cloud Slicing plugin fits in perfectly. This feature uses the Cura or Slic3r engine plugin.

This feature uses the Cura or Slic3r engine plugin.

Touch screen for user interface

Touch screen user interface has become the norm for many everyday devices. However, many 3D printers still lack this useful feature.

With the OctoPrint TouchUI plugin, you can add this feature and display the OctoPrint interface on the touch screen. This plugin will allow you to use OctoPrint without connecting a computer. The user interface on the touch screen is very similar to that in the browser, so the transition in terms of learning a new interface will not be difficult.

Installing a touch screen can seem like a tedious task, but there are plenty of tutorials and videos to help you through the process.

Open-source community

Individual developers have spent hours of their time improving 3D printing, including free and open source software such as Marlin, Cura, and OctoPrint itself.

OctoPrint's popularity is largely due to open source and free access. All source code is available on the GitHub page. Thanks to this, many users and developers have shared their ideas and brought them to life. User-developed plugins greatly extend the functionality of OctoPrint.

All source code is available on the GitHub page. Thanks to this, many users and developers have shared their ideas and brought them to life. User-developed plugins greatly extend the functionality of OctoPrint.

Manage multiple 3D printers

As you can imagine, this function is useful if you are working with more than one 3D printer. You can connect multiple webcams to one Raspberry Pi.

The video below provides instructions (in English) on how to install three printers on a Raspberry Pi:

Another option is to use OctoFarm, a free and open source service that allows you to control and monitor multiple 3D printers on a single Raspberry Pi. With it, you can monitor multiple 3D printers on the same screen, send files for 3D printing, and monitor the printing process.

List of useful plugins for OctoPrint

In general, it is quite difficult to make the top 10 useful OctoPrint features, since the list is really huge. So below is a small selection of additional plugins that will help you simplify and secure the 3D printing process.

So below is a small selection of additional plugins that will help you simplify and secure the 3D printing process.

- Pushover: This plugin sends you push notifications when a print is completed or 3D print fails for some reason. A simple and very practical plugin.

- Heater timeout: It often happens that the 3D printer stays on and the extruder is still hot, which can cause a fire. This heater timeout plug-in disables hot end heating after a set amount of time. This will help you avoid potential fires and excessive electricity bills.

- Emergency stop: there is always a possibility that something might go wrong during 3D printing. This plugin adds a large red bar at the top of the OctoPrint user interface which, when clicked, will stop the 3D printer from working.

- Bed level visualizer: This plugin is great for those who have installed a bed level visualizer on their 3D printer. This plugin allows you to view the table level measured by the sensor.

Learn more