Top 3d printers under 1000

The 10 Best 3D Printers Under $1000 (2022 Update) – Clever Creations

Intended use

Before getting a 3D printer, you must have a clear idea about its intended use. How are you going to use it? What’s the primary purpose? Is it for educational use, professional use, or just for hobby? Where do you plan to use your 3D printer? In your home, office, garage, or school? These are the questions you need to ask to narrow down your options.

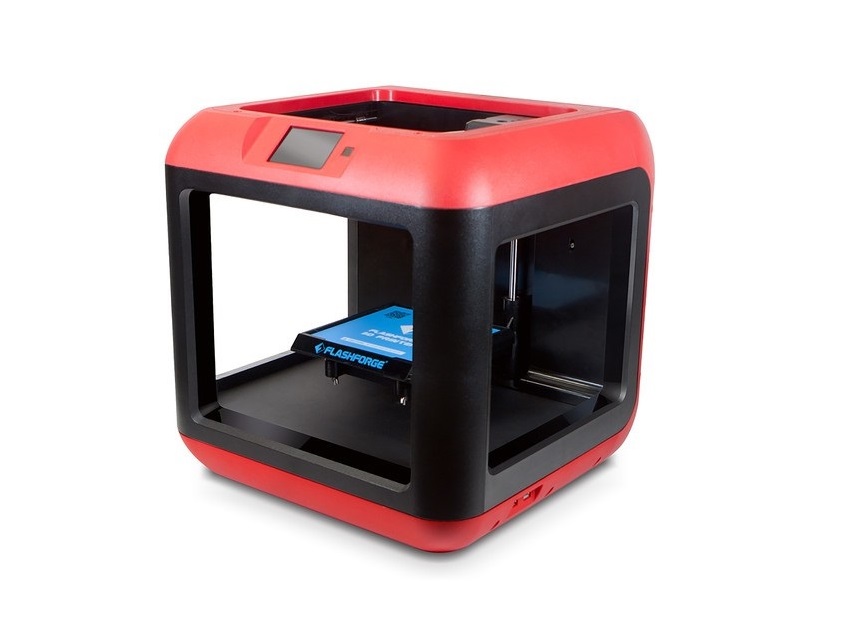

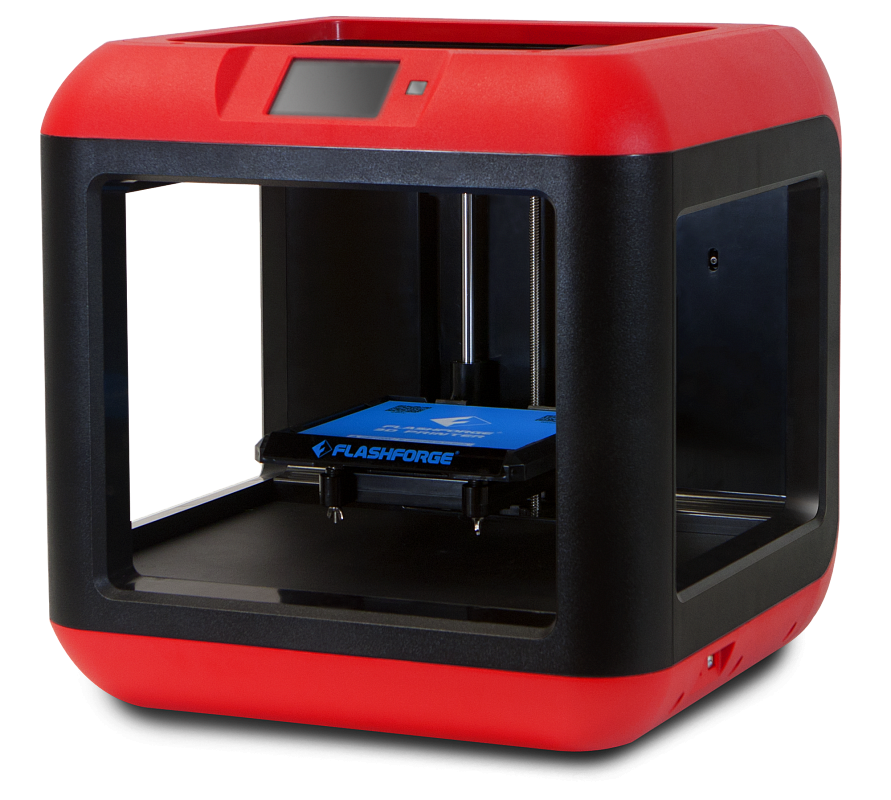

If you’re a beginner or need a 3D printer for kids or educational purposes, focusing on ease of use and safety should be your primary focus. 3D printers like the Flashforge Dreamer, QIDI Tech X-Plus, and the Dremel Digilab 3D20 will be the best 3D printers under 1000 for your use case.

On the other hand, if you are looking for features such as a high-temp hot end, a heated bed, wide material compatibility, and dual extruders, you are better off focusing on a professional high-quality printing experience. In such cases, you should consider the Flashforge Creator Pro 2, Prusa i3MK3S+, or the Matterhackers Pulse XE.

FDM or resin

FDM and resin 3D printers are drastically different in terms of materials, machine setup, workflow, and applications.

Fused deposition modeling (FDM) 3D printers use a solid plastic filament that is melted and deposited, one layer at a time. It’s relatively easy to use and learn, compatible with various materials, and can be used in schools or home environments. You have the advantage of a huge build volume with these machines. However, the quality of FDM 3D printers is comparatively lower than resin ones.

Resin 3D printers are known for their superior quality and smooth surface finish. They use a photosensitive 3D printer resin and cure it with a UV light source, typically that of a UV curing station. It’s mainly suited for applications that require a higher level of detail, surface finish, and precision. For example, if you want to 3D print miniatures, dental models, jewelry, and molds, you are much better off with a resin 3D printer.

The downside of a resin 3D printer is its messy operation due to the resin, expensive material costs, and post-processing of the printed parts. Add to that a relatively small build volume, and you’re limited to smaller-sized objects only. If quality is not the absolute criteria, and you can get away with slight blemishes here and there, an FDM 3D printer is a better option.

Add to that a relatively small build volume, and you’re limited to smaller-sized objects only. If quality is not the absolute criteria, and you can get away with slight blemishes here and there, an FDM 3D printer is a better option.

Build quality

A well-built 3D printer will deliver high-quality, consistent, and reliable 3D prints. 3D printers under $1000 give manufacturers enough room to go beyond the basic materials and use high-end materials, like a metal frame, to improve the build quality of their 3D printers.

3D printers like the Prusa i3, Matterhackers Pulse XE, Flashforge Creator Pro 2 have a solid metal frame and are built to last. The build quality on these machines is top-notch, and as a result, they can deliver high-quality prints for a long time.

High-quality components not only deliver excellent quality but are also more reliable in terms of performance and durability. If long-term reliability is your priority and you want to reduce your downtime, maintenance, and other 3D printing costs, the build quality should be on the top of your list while considering buying a 3D printer.

Features

3D printers under $1000 are more than just basic 3D printers with minimal features. As mentioned above, this budget gives manufacturers more flexibility. Aside from better materials, this also means more and better features in the machine.

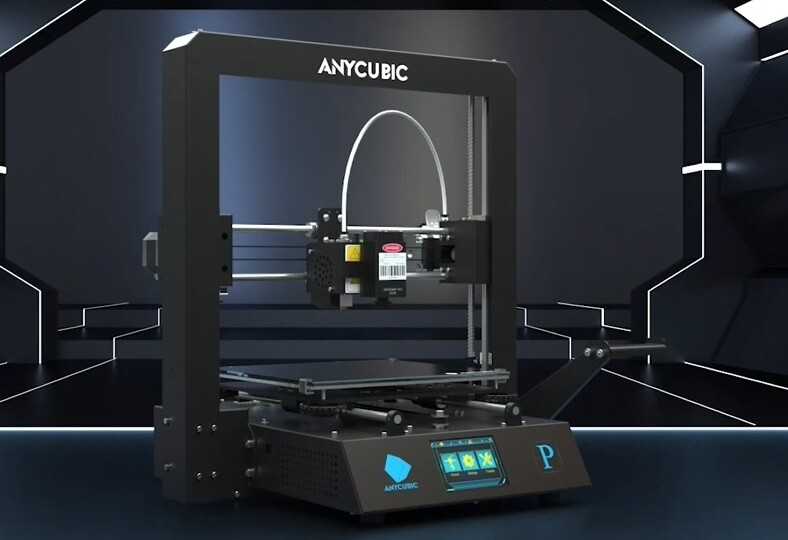

For example, many 3D printers in this category come with basic safety features. For example, an enclosed design, an air filtration system, a top-cover sensor (Anycubic Mono X), and the use of high-quality components promise safe operation and reduce the risk of any accidents.

To avoid getting unsuccessful 3D prints, features like resume printing and filament run-out detection come into play. The resume printing feature helps you resume your print in case of a power failure. And the filament sensor will notify you if the 3D printer runs out of filament. Both these features come in handy during long hours of 3D printing.

You also need to consider the user interface and the workflow of your 3D printer. How intuitive is it to use? Is there any touchscreen, or is it an LCD screen with hardware buttons? If you’re looking for a printer for kids or students, the best 3D printer might be one with an intuitive, user-friendly interface.

Build volume

The build volume of a 3D printer dictates the size of the objects that you can 3D print. If you want to print larger-sized objects, a resin 3D printer will be of little help. You will be better off with an FDM printer that offers ample space.

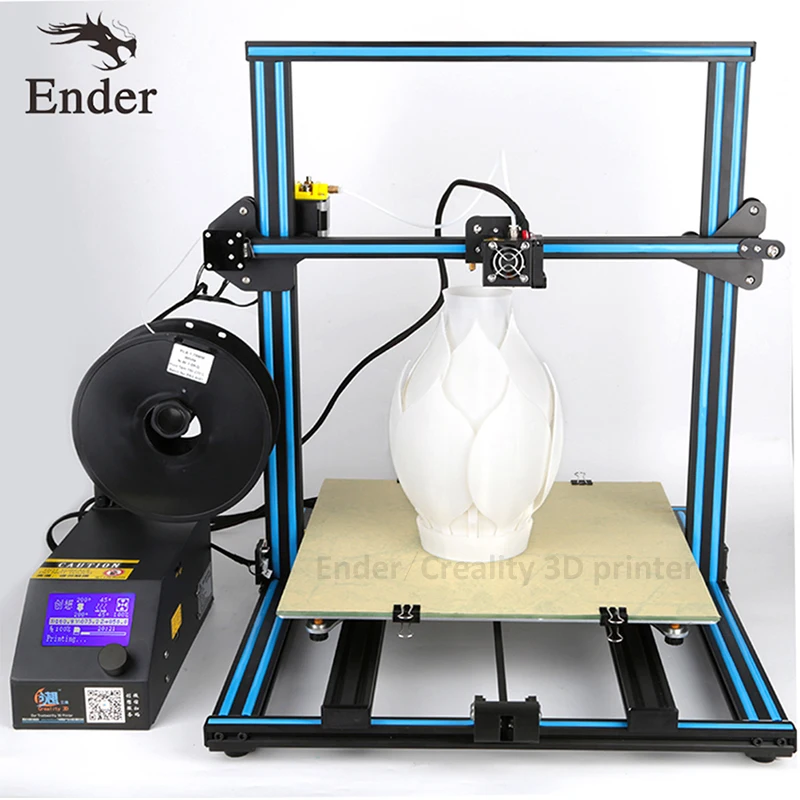

The Creality CR-10 S5 is our recommendation for the largest 3D printer under $1000, with a build volume of 500 x 500 x 500 mm. To put things in perspective, that’s more than enough space to 3D print a full-sized helmet at once.

But if you’re planning on using the 3D printer for educational purposes, or for printing miniatures and figurines, you can get away with a smaller-sized 3D printer. It’ll help you save some costs, or you can choose some other features which are more important to you.

Print speed

Print speed directly affects productivity and your 3D printing experience. If you’re buying a 3D printer for home use or basic hobby purposes, it is likely to not affect you that greatly. But if you’re considering purchasing a 3D printer for your print farm, office, or professional use, printing speed is an essential parameter that dictates your 3D printing output.

A fast 3D printing speed will give you quicker outputs and reduce turnaround times. You will be able to reiterate your designs faster and make the necessary changes at a much faster pace.

To that extent, resin 3D printers have a higher printing speed when compared to FDM ones. Even if you fill up the entire build plate, each layer will take 2-3 seconds to cure. This can come in handy when 3D printing lots of jewelry pieces or miniatures at once.

FDM 3D printers are comparatively slower. Each object you add to the build plate adds extra 3D printing time. Some FDM printers are faster than others. If speed is your priority, the Prusa i3 MK3S+ and Pulse XE offer decent speeds at 200+ mm/s travel speed and offer a printing speed of up to 60-80 mm/s.

Alternatively, you might want to consider a CoreXY 3D printer kit. CoreXY printers have relatively little moving mass due to their stationary motors and are able to achieve high print speeds without sacrificing print quality.

Material compatibility

Material compatibility is one of the primary things to look for when getting a 3D printer. A 3D printer under $1000 offers more flexibility in terms of materials than a 3D printer under $300 does. Except for the Digilab 3D20 and the resin 3D printers, all others have a heated print bed that extends the number of materials that can be 3D printed with.

With 3D printers like the Pulse XE and the QIDI Tech X Plus, which offer a heated print bed and a high-temperature hot end, you can go beyond the basic materials and print with Nylon, Carbon fiber, and Polycarbonate filaments. There is also the Flashforge Creator Pro 2, which lets you 3D print with two materials at once and use soluble supports.

Wide material compatibility will let you utilize your 3D printer in many more applications. You can choose whether to use it only with the basic filaments or use advanced materials without having to change components when the need arises.

Best 3D printers under $1,000 in 2022

We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Learn more ›

Written By Gabriel Morgan

Updated Jul 13, 2022 12:30 PM

Load up the filament, transfer your slices … the best 3D printers under $1,000 have all the tools that most makers will need to give form to their visions. You might be a hobbyist separately printing and carefully-painting each gargantuan wing of the great gold-dragon for your next D&D campaign. Maybe you’re printing a grip for your old film camera to make it more comfortable to hold. Or perhaps you’re creating a custom prop for a photoshoot for much less than the cost of buying it. Whatever your aims, 3D printers at the sub $1000 price point should give you enough power to achieve them. If you want to go even cheaper, you can check out the best 3D printers for kids.

This article focuses on 3D printers at the high-hundreds price-point, that still hover below $1000. At this price point 3D printers get quite capable, delivering some really great features like auto-leveling trays, blistering extruders capable of working with wider sets of materials (such as nylon), extremely high-resolution resin prints, air-filtration, quieter operation, better-connectivity, and dual extruders. Read on for a look at some of the best 3D printers under $1000, and just what it is that makes them so.

Read on for a look at some of the best 3D printers under $1000, and just what it is that makes them so.

- Best overall: R QIDI X-Plus

- Best resin: ANYCUBIC Photon Mono X 6K

- Best dual extruder: BIBO 3D Printer Dual Extruder

- Best kit: Original Prusa i3 MK3S+ kit

- Best budget: Creality Ender-3 S1

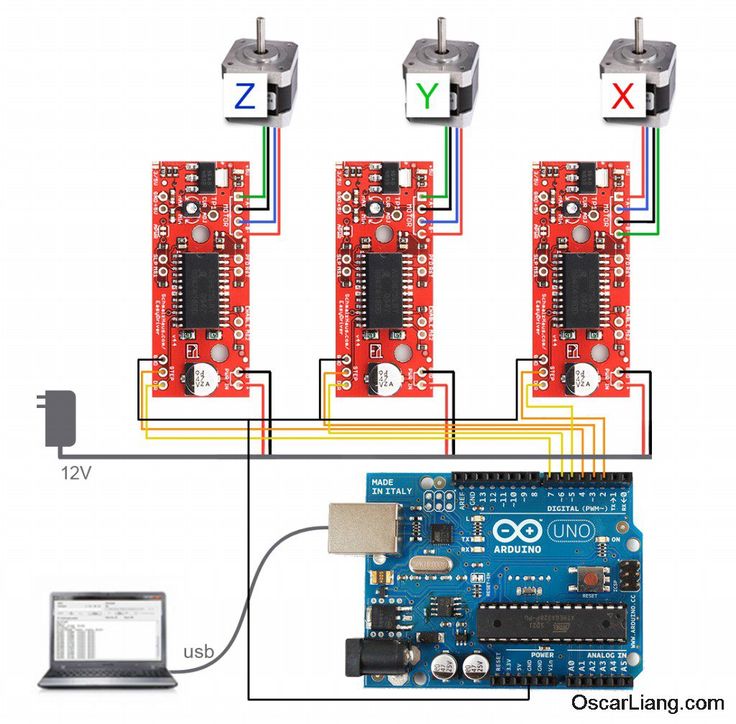

3D printers are stuffed full of tech, from their blistering-hot extruders, to their auto leveling trays, to WiFi, and 4k+ LCD arrays for curing liquid resin, Even the Bowden mechanism that’s often used to channel filament comes from an important invention for bicycle construction. With so many mechanical inventions and systems crammed into one device, 3D printers are inherently technical. Because of this, it’s a good idea to familiarize yourself with some parts of how the technology works before you buy.

With the first functional 3D printers built in the 1980s, 3D printers didn’t begin to pervade the mass market until the 2000s. While a few inventors and scientists were concurrently working on different elements of technology that would be incorporated into the 3D printer systems of today, Bill Masters was the first inventor who filed a 3D printer patent.

The inventor was camping on the banks of the Chattanooga river one night, staring up at the stars, when the idea came to him. He imagined using one star as a seed point, and then combining the other dots of starlight to create any shape he liked. His analogy for the additive manufacturing process that defines FDM printers of now, is great, likening the tech to “spit wads,” similar to the ones so many children familiarize themselves with at a day in the mall, “When you shoot a lot of wads, they begin to take shape. If you can control the direction of the wads and the motion of the device shooting them, you can produce any desired shape.” We love it.

3D Printer typesWhile there are numerous classes of 3D printers, there are three main families. These are fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). Selective laser sintering uses a laser to fuse powdered material, which is distributed across a bed with a roller. SLS printers are capable of delivering strong functional prints that are sturdy enough for immediate incorporation into manufactured systems. However, the SLS process is very expensive, and is out of reach for most DIY tinkerers. At the sub-$1000 price point, this article focuses on FDM and SLA printers.

SLS printers are capable of delivering strong functional prints that are sturdy enough for immediate incorporation into manufactured systems. However, the SLS process is very expensive, and is out of reach for most DIY tinkerers. At the sub-$1000 price point, this article focuses on FDM and SLA printers.

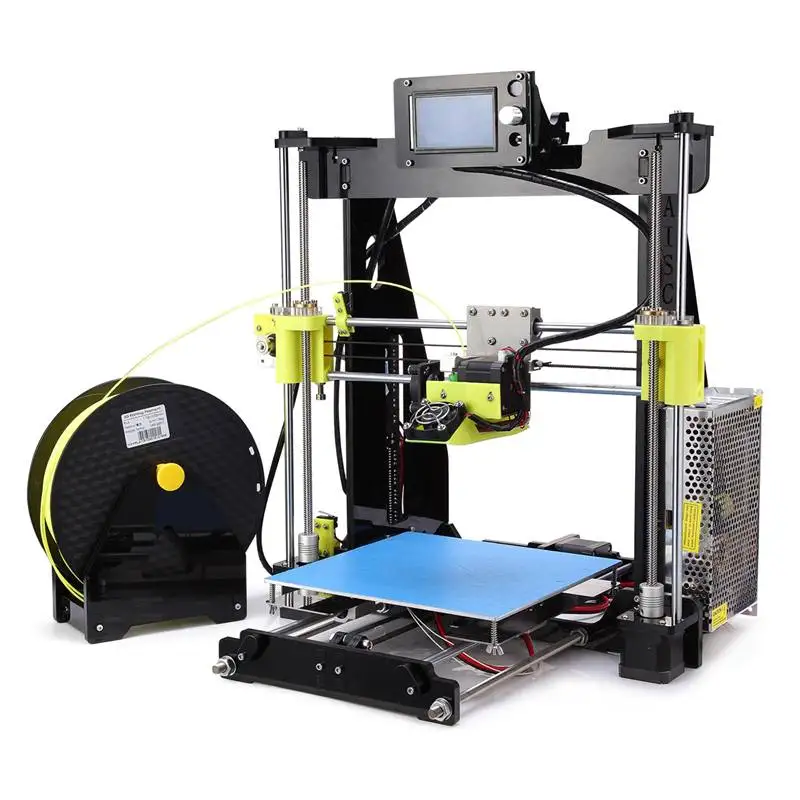

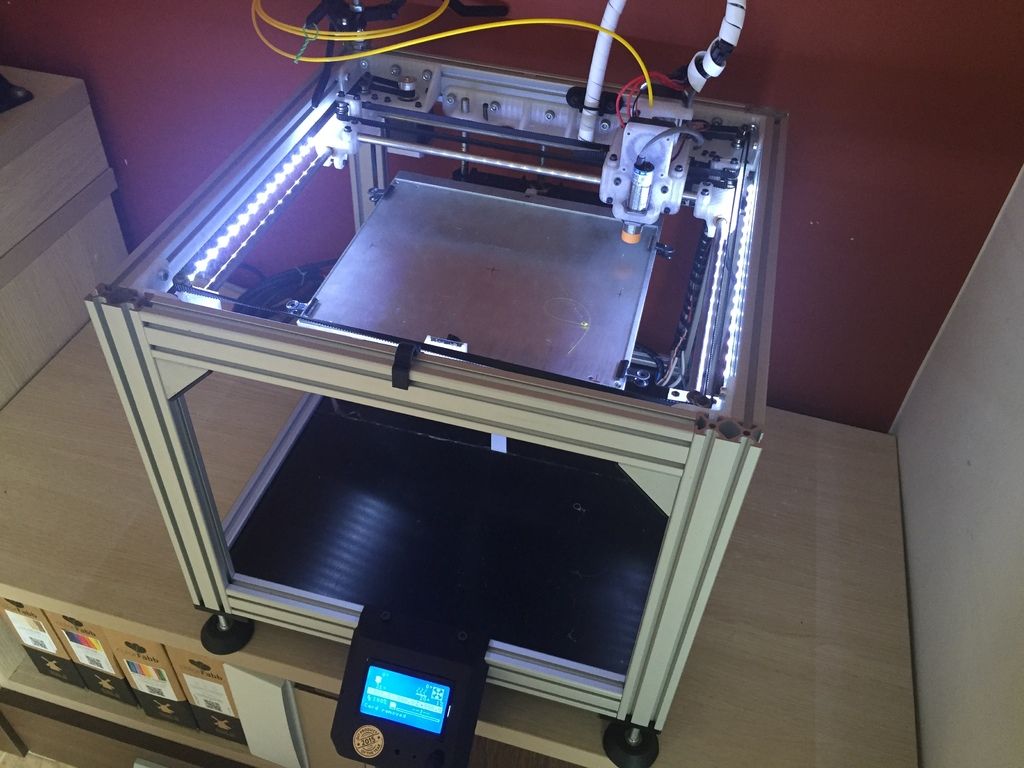

FDM printers are the most common and economical 3D printers on the market. These printers use a superheated nozzle to extrude filament downward onto a heated, leveled tray, building the model up slice-by-slice. FDM printers are suitable for quick prototyping, proof of concepts, and finished projects, and tend to be more economical and user-friendly. FDM printers usually also deliver a greater build area than SLA printers for the price.

Thermoplastics in FDM printersFDM printers create objects out of thermoplastics. These common plastics have chemical properties that allow them to melt, form into a shape, and then melt again. These plastics are inherently recyclable, and many are quite cheap. The most common thermoplastics used in FDM printers include ABS, PLA, PETG, and TPU. Some also print nylon, and more.

These plastics are inherently recyclable, and many are quite cheap. The most common thermoplastics used in FDM printers include ABS, PLA, PETG, and TPU. Some also print nylon, and more.

These thermoplastics have different properties, some are food safe, while others are biodegradable, others are non-toxic for skin contact. However, the manner in which thermoplastic deposits fuse is primarily mechanical, rather than chemical, which runs the risk of leaving voids (or open spaces) in the walls of the print, which leads to inferior structural integrity on the Z axis.

StereolithographySLA printers use a different process from FDM printers, whereby a laser, or LCD array cures resin in a liquid resin bath, and extrudes it upwards slice by slice. These printers fuse the print onto a heated tray, and lifts it, upside-down, from the liquid resin. They are capable of printing parts and models with greater structural integrity and detail. Because of their high print resolution, SLA printers are the go-to for most hobbyists looking to build intricate models and figurines.

SLA printers use thermosetting plastics (thermosets). These resins cure into shape, and cannot be heated to dissolve, rather, heat causes their decomposition. This means that thermosets are not recyclable. However, the curing process of resins give them superior structural integrity to thermoplastics, as the plastic chemically fuses, creating covalent bonds between molecules. These resins achieve prints with better detail, resolution, and strength. Thermoset variety is also wide, including clear resins, wiggly resins, high temp resins, and even dental grade resins.

How we picked the best 3D printers under $1,000MethodologyBecause there’s so much that goes into great 3D printers there were a lot of features to factor when we were researching the five best. We researched numerous printers from multiple manufacturers, looking for the best feature sets, wherein all parts collaborate for a gestalt of function that’s the most useful for the makers of today. Along the way we looked for a few specific features which we detailed below:

Along the way we looked for a few specific features which we detailed below:

Versatility is always nice. At the mid-level price point below $1000, we start seeing FDM printers that are capable of nylon and some more advanced thermoplastics. We also start seeing SLA printers that are capable of more. We noted this wherever it stood out.

Tray functions are so important to overall printer quality. We looked for printers with trays that get hot enough to keep your models well-secured. We also looked for printers that have auto-leveling functionality, or at least excellent semi-auto leveling.

Extruder & LCD (or laser) quality is extremely important for 3D printing. Extruder quality plays a big role in which thermoplastics the printer can handle. Great extruders get hot, and are light enough to work well with the system. Different extruder dimensions also play into their use for different situations. Some systems even use two extruders. For SLA systems the LCD array (or laser) is extremely important in getting good print resolution and smooth forms.

For SLA systems the LCD array (or laser) is extremely important in getting good print resolution and smooth forms.

Overall precision is achieved through lots of factors, but we like to see FDM printers with a multi-column lift system. We looked for FDM printers that don’t leave lines, burrs, or slice edges visible on the sides of the print. We also looked for SLA printers that yield high-res prints with smooth curves.

Connectivity & slicing software can define the quality of your print experience just as much as some of the more mechanical components of your system. Wireless connection is always nice, and printers with a few gigabytes of internal storage also offer a boon. Compatibility with lots of slicing software or one especially good one is also important and we noted this.

User experience and assembly also cannot be overlooked. Some printers get loud — we mean infernal giant-water-bears crawling from the pit sort-of loud (do water-bears roar?). Where we found printers that deal well with sound and fumes, we highlighted them. We also noted the required assembly of each printer. Some want highly customizable printers that might require longer assembly but are capable of modding, but not all do.

Where we found printers that deal well with sound and fumes, we highlighted them. We also noted the required assembly of each printer. Some want highly customizable printers that might require longer assembly but are capable of modding, but not all do.

Best overall: R QIDI X-Plus

R QIDI TECHNOLOGY

SEE IT

Why It Made The Cut: An FDM printer with easily-serviceable standard parts, an optional auxiliary-extruder that enables it to print more technical materials, and outstanding customer service.

Specs:

- Print technology: FDM

- Build size: 10.6 x 7.9 x 7.9 inches

- Supported materials: PLA, TPU, PETG, ABS, Nylon, PC, Carbon fiber, and more

- Best slicer software: QIDI Print Slicer (included free)

Pros

- Second extruder for technical-material free upon request

- Excellent customer service and support

- Very easy assembly & simple repair

- High res-smooth prints

Cons

- Manual bed leveling

- Wifi issues with non-QIDI software

Something of a plug-and-play machine, the R QIDI X-Plus is a highly capable FDM printer that has an expanded range of materials, possible via a free supplementary extruder. With easily repaired standard parts, and great customer support, it’s an easy best-overall choice for most.

With easily repaired standard parts, and great customer support, it’s an easy best-overall choice for most.

Shipped from China, the semi-enclosed X-Plus takes hardly any set up. It comes with a standard extruder suitable for PLA, ABS, and TPU. A second technical-material extruder is also available with your purchase free-of-charge by request (which belies the companies communication-forward ethos), and is capable of materials like Nylon, PC, Carbon fiber, and more. To be clear, this second extruder is swappable, rather than supplementary, this isn’t a dual-extruder rig, and the second extruder won’t work in tandem with the standard. However, the technical nozzle is a nice touch, that firmly differentiates this machine from cheaper FDM’s in the sub-$500 price range.

QIDI is all about customer support and easy repairs. Not only are the majority of the parts in this system standard and easily replaceable, but the majority of replacements are also easy to DIY, with included tools for most hardware in the system. QIDI offers exceptional customer service, with knowledgeable agents ready to send you repair parts as needed, and help troubleshoot issues.

QIDI offers exceptional customer service, with knowledgeable agents ready to send you repair parts as needed, and help troubleshoot issues.

While the X-Plus doesn’t have the automatic leveling you might like at this price point, it does have a semi-auto, single-point quick-level system that is reliable and easy. It features QIDI Print Slicer software, that’s free to use with any QIDI system All-in-all, while this system might not be as appealing to hardcore tinkerers as some, those who want consistent quality with easy set-up, good customer support, and a wider than average range of available materials will love it.

Best Resin: ANYCUBIC Photon Mono X 6K

Why It Made The Cut: 6K LCDs mean better resolution than ever, with more detail and contrast, more build volume, and faster speeds.

Specs:

- Print technology: SLA

- Build size: 9.6 x 7.8 x 4.8 inches

- Supported materials: Resin

- Best slicer software: Anycubic Photon Workshop (free), ChiTuBox, Lychee, more

Pros

- Extreme print detail and resolution

- Great contrast

- Fast, at up to 1s / layer in some instances

- Great out of the box prints

Cons

- Poor connectivity options

- Very smelly

6K — that’s a lot of LCDs, and the ANYCUBIC Photon Mono X 6K leverages them all for extremely high-resolution prints with impeccable contrast. ANYCUBIC is one of the most popular lines of SLA resin printers, and the Photon Mono X is one of the most impressive dogs in the pack.

ANYCUBIC is one of the most popular lines of SLA resin printers, and the Photon Mono X is one of the most impressive dogs in the pack.

With its 6K LCDs the Photon Mono X 6K uses an 9.25 inch monochrome LCD array, with 6% light transmittance, which means quicker printing. The machine is fast, and ANYCUBIC brags up to 1s / layer, in ideal circumstances. Its LCD’s deliver extreme contrast that’s noticeable, and the model sports a much larger build area than its cousins, at 9.6 x 7.8 x 4.8 inches.

ANYCUBIC is compatible with lots of the great slicer software packs, from ChiTuBox, to Lychee, and offers the proprietary Anycubic Photon Workshop free of charge. Sadly, getting your slices to the printer is more difficult than it could be, as the printer’s Wifi is notoriously spotty. It’s built around its LCD screen control and SD card reader, meaning SD is the best way-to-play. Those who like to keep their SLA printer on a well ventilated back porch will appreciate not having to keep their printer connected to a laptop, but those who want to set up a printer farm might groan. Otherwise, it’s a great buy, offering some of the best quality resin prints out there.

Otherwise, it’s a great buy, offering some of the best quality resin prints out there.

Best dxtruder: BIBO 3D Printer Dual Extruder

Why It Made The Cut: Solid dual extruder support means lots of techniques you can’t get at with other FDM printers, plus WiFi and a touchscreen make it easy to use.

Specs:

- Print technology: FDM

- Build size: 8.4 x 7.3 x 6.3 inches

- Supported materials: ABS, PLA, Dissolvable filament (PVA, HIPS), TPU, PETG, Nylon, PC, Carbon fiber, and more

- Best slicer software: Repetier-Host, Cura, Simplify3D

Pros

- Dual extruders

- Minimal easy assembly

- Wifi control

- Good customer support

Cons

- Difficult maintenance and usability

- Bed isn’t easy to level

If you’re moving up from a basic machine, the BIBO 3D’s dual extruders can open doors you didn’t even know were closed. These include printing dissolvable supports, printing with multiple colors, and 3D printing two duplicate objects simultaneously. But these dual extruders aren’t the BIBO 3D’s only bargaining chip.

These include printing dissolvable supports, printing with multiple colors, and 3D printing two duplicate objects simultaneously. But these dual extruders aren’t the BIBO 3D’s only bargaining chip.

BIBO 3D does a good job with a wider range of materials. Beyond the standards like ABS and PLA, it prints more technical thermoplastics like flexible nylon, and carbon fiber. The system uses an easy touch-screen control panel to set up prints, and can also be controlled via Wifi, meaning you can control it from your phone.

The machine does have a couple of blindspots. Its leveling control isn’t as intuitive as you would expect at the price point. The machine is also packed tight with features, with screws in odd places, and somewhat abstract engineering overall. These issues are offset by great customer service from the company, but they do make the machine’s usability somewhat less optimal than some of the competition. It’s a great option for tinkerers who want extra extruders and wider material possibilities, but in spite of its initial assembly, it may be more hands on than some want.

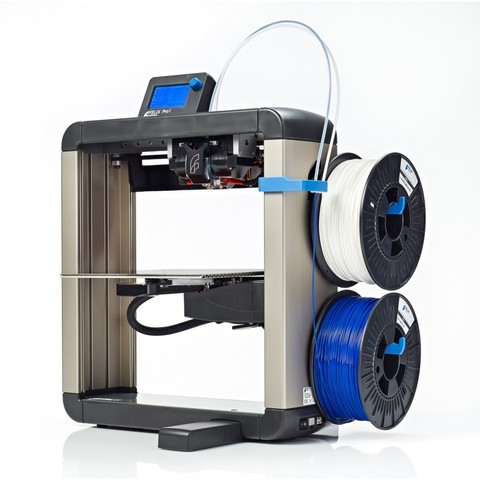

Best kit: Original Prusa i3 MK3S+ kit

prusa3d

SEE IT

Why It Made The Cut: Taking a DIY ethos all the way, the Prusa i3 kit is open-sourced and powerful, with a state-of-the-art-extruder, exceptional leveling, wide filament support and more.

Specs:

- Print technology: FDM

- Build size: 9.84 × 8.3 × 8.3 inches

- Supported materials: PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA / BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill

- Best slicer software: PrusaSlicer (proprietary), open source

Pros

- Mesh bed leveling details leveling for every print

- Excellent extruder that can handle an extra wide set of features

- Open source with strong user base for help with all sorts of mods and use cases

- Easy to remove prints

Cons

- Kit requires detailed and rigorous assembly

- Long lead-times for production, allow weeks before it arrives

You can’t get far into 3D printing turf without hearing the name Prusa, and it’s not hard to see why with the Original Prusa i3 MK3S+ kit (an assembled version is also available for a couple hundred more). This kit is a DIY maker’s dream, including some of the best tools in its class for 3D printing.

This kit is a DIY maker’s dream, including some of the best tools in its class for 3D printing.

There’s a few things that make the Prusa i3 special, but we’ll start with its basics. It features a state-of-the-art extruder, as well as an excellent filament monitor. The extruder can handle a much wider than average set of filaments, including the standards, as well as nice additions such as woodfill, and abrasive nylon carbon-fiber. The printer also features an excellent fully automatic bed-leveling system that checks your bed before every print. If that’s not enough, its removable spring steel-sheets make it easy to extract your finished print.

In the end the Prusa i3 is one of the best options out there at the under $1000 price-point, and debatably beats out our top overall pick, the R QIDI X-Plus. However, for the Prusa to reach its full potential this machine requires an operator and builder who rejoices in getting through the weeds that are a major part of its construction, and making it out the other side. This is a printer for tinkerers and DIY makers, and when it’s well understood and loved, it can do wonders.

This is a printer for tinkerers and DIY makers, and when it’s well understood and loved, it can do wonders.

Best budget: Creality Ender-3 S1

Why It Made The Cut: Markedly more affordable than the rest of the printers on this list, the Ender-3 offers some pro level prototyping features, in an upgradeable build that’s priced for beginners.

Specs:

- Print technology: FDM

- Build size: 8.6 x 8.6 x 10.2 inches

- Supported materials: PLA, TPU, PETG, ABS

- Best slicer software: Open source (No preferred), Cura, Simplify3D, PrusaSlicer

Pros

- Open sourced and upgradeable

- Very precise extruder with dual lift

- 16 point auto level

- Easy assembly

Cons

- Loud prints

- Limited feature set compared to more expensive options

Our pick for the best 3d printer under 500, the Creality Ender-3 S1 is still worth a look, even if your possible budget could maybe allow for something pricier. Alongside Prusa, Creality’s Ender series is ever recognizable, and potentially the best known series for beginners. This open-source and expandable system gives you more room to print with than some systems that cost twice as much. With an extruder that hits 500 degrees Fahrenheit it’s also not that restrictive in comparison. Sure it won’t take care of more technical materials, but it does better than most, and if you’re new that might not matter.

Alongside Prusa, Creality’s Ender series is ever recognizable, and potentially the best known series for beginners. This open-source and expandable system gives you more room to print with than some systems that cost twice as much. With an extruder that hits 500 degrees Fahrenheit it’s also not that restrictive in comparison. Sure it won’t take care of more technical materials, but it does better than most, and if you’re new that might not matter.

One of the S1’s standout features is a 16 point auto-leveling system that makes sure your print bed is up to the challenge every time, it also features a removable spring steel-plate, a power-loss recovery feature, and a filament sensor. It delivers solid precision, with a dual-motor design.

While the S1 doesn’t have some of the top features found in models that retail closer to $1000, it’s still an exceptional hobbyist’s 3D printer that’s capable of doing a lot. It’s a great foundation that can be expanded on significantly with mods.

FDM, or fused deposition modeling 3D printers are usually the cheapest, both in terms of up front cost and the cost to replenish their filament over time. They use an additive manufacturing process whereby they apply layers of molten thermoplastics onto a heated tray.

Q: What is the best 3D printer under 1000?The best 3D printer under $1000 for most users is the R QIDI X-Plus. Arriving pre-assembled, this partially enclosed FDM printer is easily serviceable, precise, good for high-quality prints, and is capable of printing a wide array of filaments. QIDI also delivers great customer support.

Q: Which brand 3D printer is best?There are lots of great 3D printer brands. Creality does a great job with powerful hobbyist printers for affordable prices. Prusa makes incredible open sourced printers with some of the best tech around. QIDI is known for precise, easy to use printers with excellent customer support. ANYCUBIC makes exceptional high-res SLA printers. ELEGOO also makes wonderful SLA printers. The best brand is the brand that brings the feature set you need.

QIDI is known for precise, easy to use printers with excellent customer support. ANYCUBIC makes exceptional high-res SLA printers. ELEGOO also makes wonderful SLA printers. The best brand is the brand that brings the feature set you need.

As with any craft business, 3D printer craft can turn a good profit, however, how profitable it will be will depend upon your business practices. Before you invest in a business based on a 3D printer, consider all the factors that will contribute to your business.

Q: Can 3D printers can be acquired for less than 1000?Yes, there are many excellent printers that can be acquired for under 1000. There are even some good ones that cost less than $200.

Q: Do you need a computer for a 3D printer?In some form, you do need a computer for a 3D printer. However, some work-arounds are possible. If you want to buy a 3D printer and can’t afford a computer as well, consider downloading files from your library or school computer and using an SD card to print them on your 3D printer at home.

In some instances enclosed 3D printers are better. Many enclosed 3D printers come preassembled and are easy for beginners to plug in and get started with. Also, 3D printers can emit harmful fumes and light. Most SLA printers, which use bright curing LCDs and / or lasers, feature a UV shield. FDM printers can also benefit from the protection and structural integrity that enclosures provide.

Final thoughts regarding the best 3D printers under $1,000With so many features and advanced processes spun into one functional system, the best 3D printers under $1000 offer astounding feats of engineering, synergized to work together, to bring wildly powerful tools of creation into your workshop. They are used by everyone from design firms who might be prototyping a new invention, to hobbyists building a fleet of figurines. For the best DIY maker’s tool in its class, we recommend the Original Prusa i3 MK3S+ kit. If you’re looking for top notch resolution, you can’t go wrong with the ANYCUBIC Photon Mono X 6K, which is the best SLA 3D printer at its price point. If you want something that’s a little on the cheaper side, the Creality Ender-3 S1 is the best for beginners, and offers a large build space and solid tools. Finally, if ease of use is your prerogative, we recommend the R QIDI X-Plus, as the best overall 3D printer for most users — it might not offer as much tweakage potential as the Prusa i3, but with the X-Plus you’ll be printing great materials within two hours of the package arriving at your door.

If you’re looking for top notch resolution, you can’t go wrong with the ANYCUBIC Photon Mono X 6K, which is the best SLA 3D printer at its price point. If you want something that’s a little on the cheaper side, the Creality Ender-3 S1 is the best for beginners, and offers a large build space and solid tools. Finally, if ease of use is your prerogative, we recommend the R QIDI X-Plus, as the best overall 3D printer for most users — it might not offer as much tweakage potential as the Prusa i3, but with the X-Plus you’ll be printing great materials within two hours of the package arriving at your door.

Best 3D Printers Under $1000 in 2021 (Review and Buyer's Guide)

Nowadays, 3D printing technology is becoming more and more accessible to any user. Not only because they are being made more intuitive and user-friendly, but also because their prices are significantly reduced to match the economic opportunities of a wide audience in the market.

The thing is, 3D printer prices vary a lot, and if you ask us, we will definitely choose printers under $1,000 but no less than $250. This is the ideal price point where you can find many 3D printer models that can compete with other high quality models. They usually come with a lot of impressive features that might surprise you. For example, the Creality Ender 5 Plus has an astounding maximum build volume of 350 x 350 x 400mm. At this price, it's a very pleasant choice that makes it popular with enthusiasts and professionals who are interested in printing huge models. If you're familiar with the YouTube videos we've reviewed, you've probably come across this model more than once. We often see it being chosen by various generalists and 3D artists for printing life-size helmets onto masks and more.

This is the ideal price point where you can find many 3D printer models that can compete with other high quality models. They usually come with a lot of impressive features that might surprise you. For example, the Creality Ender 5 Plus has an astounding maximum build volume of 350 x 350 x 400mm. At this price, it's a very pleasant choice that makes it popular with enthusiasts and professionals who are interested in printing huge models. If you're familiar with the YouTube videos we've reviewed, you've probably come across this model more than once. We often see it being chosen by various generalists and 3D artists for printing life-size helmets onto masks and more.

Of course there are many other options to consider; especially now, when every year there are many, many new models from leading brands. Some of them come from Flashforge, ANYCUBIC, FLSUN and Snapmaker. The fact is that choosing a 3D printer is not just a game of picking aesthetically pleasing fruit from a low tree. This requires you to evaluate your knowledge as a 3D printer user and the features that will benefit you the most. For example, while the Creality Ender 5 Plus is a great choice, it's not exactly 101% beginner-friendly. For best results, adjustments and correct (AND DETAILED) tuning are required. The same goes for the ANYCUBIC Photon Mono X, which is famous for its detailed prints.

This requires you to evaluate your knowledge as a 3D printer user and the features that will benefit you the most. For example, while the Creality Ender 5 Plus is a great choice, it's not exactly 101% beginner-friendly. For best results, adjustments and correct (AND DETAILED) tuning are required. The same goes for the ANYCUBIC Photon Mono X, which is famous for its detailed prints.

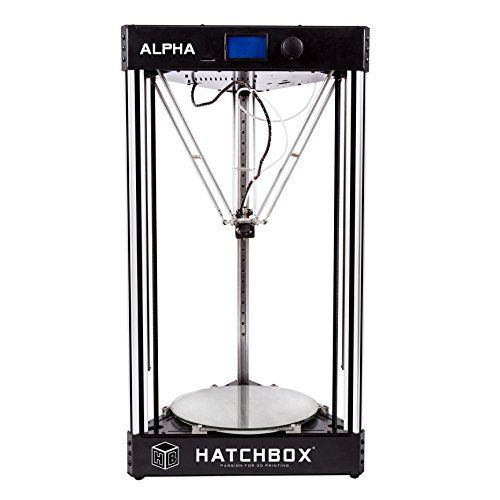

There are also certain technologies you might be interested in. If you're tired of regular FDM printers, a delta model like the FLSUN QQ-S Pro might be a good choice. There are models that are equipped with amazing features such as a laser engraver and Snapmaker Original 3-in-1 CNC carving features. The IDEX Flashforge Pro 2 system also deserves attention.

In order to provide you with more detailed information about them, we conducted a study with the help of our team's experts. After what seemed like an eternity of arguing about which 3D printer is the best, we have prepared a comprehensive review for you. After a series of comparisons and personal observations of the devices, we hope to give you their best moments to help you decide which one to choose. Let's get started:

After a series of comparisons and personal observations of the devices, we hope to give you their best moments to help you decide which one to choose. Let's get started:

The best 3D printers up to $ 1,000 in comparison and rating

| 3D printers up to 1000 US dollars |

| ||

| 4. |

| ||

| Print speed | 200 mm / s, but decreases to 80 mm / s |

Functions

Ease in use

Pros :

- Offers better print volume.

- Offers a great feature set at a great price.

- Comes with a stable print platform and the print quality is consistent.

- The glass print platform is great.

- Can serve larger projects.

Cons:

- Very loud printer.

- Not for beginners; its setup is quite complex and some tweaking (electronics and tubes) is needed to achieve the best results.

Final take:

To get the Creality Ender 5 Plus on our list, our team had a hard time comparing it to the brand's newer model: the Creality Ender 6. It's true that its successor offers a more striking aesthetic, but when it comes to comes down to practicality, we really think the Creality Ender 5 Plus offers a higher value.

First, the Creality Ender 5 Plus has a more impressive and exceptionally high print volume. It offers a maximum build volume of 350 x 350 x 400mm, which is relatively better than the Ender 6's 250 x 250 x 400mm build volume. With it, you can print large models in the Ender 5 Plus, such as helmets and busts, which seems to be simply not possible in other small 3D printers.

It offers a maximum build volume of 350 x 350 x 400mm, which is relatively better than the Ender 6's 250 x 250 x 400mm build volume. With it, you can print large models in the Ender 5 Plus, such as helmets and busts, which seems to be simply not possible in other small 3D printers.

They have almost all the same details like 1.75mm filament diameter, 110°C max print bed temperature, 260°C max extruder temperature, filament types, slicing software and more. Printing accuracy and quality of both models are also practically the same. Apart from the fact that both have a printing accuracy of 0.1 mm, they are also the same in terms of layer thickness from 0.1 to 0.4 mm.

However, in terms of speed, the Ender 6 is a step ahead as it is 3 times faster than the Ender 5 Plus. The latter has a maximum print speed of 200mm/s, which drops to 80mm/s when set for precise models. The Ender 6, on the other hand, delivers a solid print speed of 150mm/s, which is absolutely fast and still acceptable for high quality prints. Hence, if speed is not an issue for you, the Creality Ender 5 Plus is still a good choice.

Hence, if speed is not an issue for you, the Creality Ender 5 Plus is still a good choice.

What's more, the Creality Ender 5 Plus offers a better feature set that we feel is far more convenient than what the Ender 6 offers. speed up printer setup. This is contrary to manually leveling the Ender 6 using the adjustment screws. That being said, if you already have a Creality Ender 5 Plus, there really is no need to upgrade to Ender 6. And if you're planning on choosing between the two, we'd still recommend the Ender 5 Plus because of its amazing features.

Print speed

100mm/s max.

performance and quality

Functions

Simplicity in use

Reason and quality ratio

:

- It is delivered in the collected form, and work with the rest of the case is quite simple.

- The lid is plastic, but there is a solid metal frame underneath that is undeniably durable.

- Has a compact design.

- Has a maximum print speed of 100mm/s.

- Two identical designs can be printed at once.

- Still available with compact body.

Cons:

- Removing the print is quite difficult.

- The filaments are located on the back of the printer and there is no notification feature to tell you if you are out of filament.

Final double:

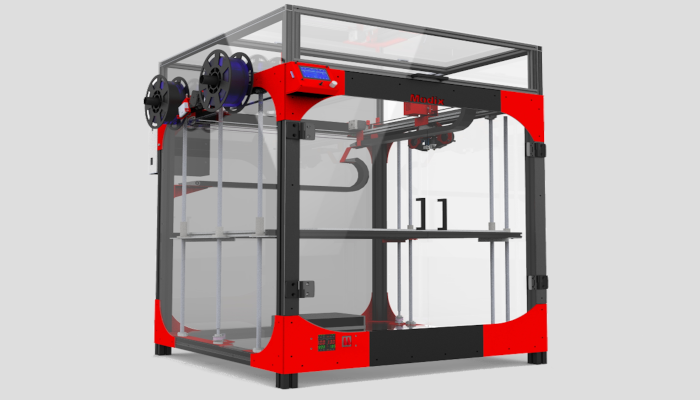

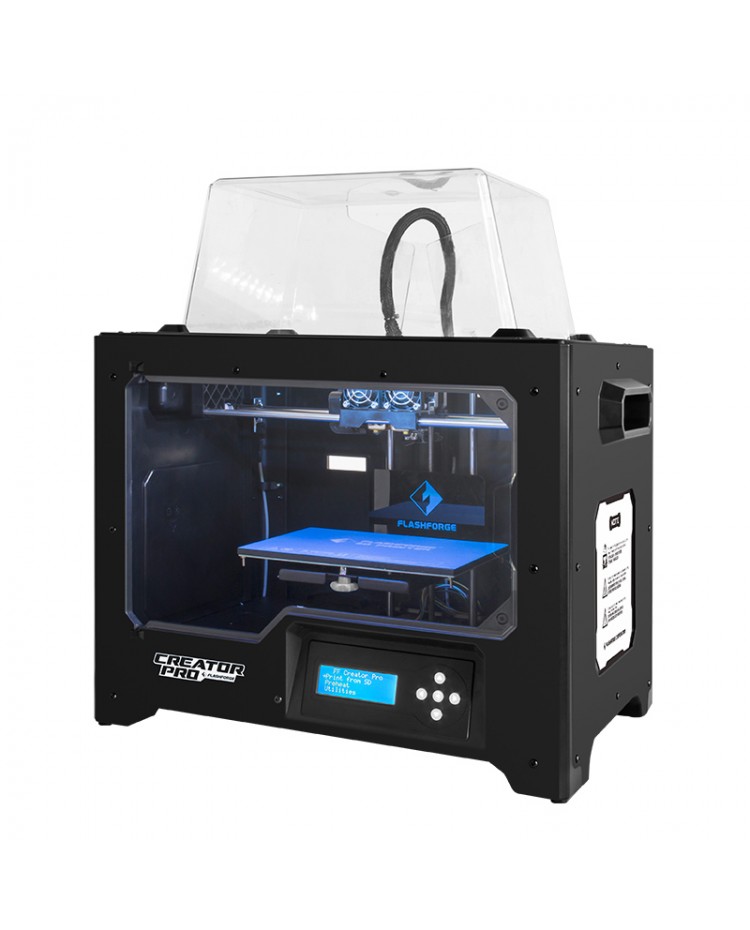

There's just so much to love about Flashforge Pro 2 that sets it apart from its predecessor. Flashforge Creator Pro.

First, it boasts an IDEX system or an independent dual extruder, which you will not see in any other printer on the market. This is a big upgrade from the old model attachments that are attached to each other. Don't get us wrong. We all still love Flashforge Pro dual extrusion, but IDEX Pro 2 is simply unbeatable. Thanks to this feature, which offers you two independent extruders, you can print two identical models at the same time. He can do it even in mirror mode! What's even better is that you can print them in 2 different colors since the machine uses 2 spools of filament at the same time. Sick!

This is a big upgrade from the old model attachments that are attached to each other. Don't get us wrong. We all still love Flashforge Pro dual extrusion, but IDEX Pro 2 is simply unbeatable. Thanks to this feature, which offers you two independent extruders, you can print two identical models at the same time. He can do it even in mirror mode! What's even better is that you can print them in 2 different colors since the machine uses 2 spools of filament at the same time. Sick!

What's more, the Pro 2 still has valuable features and details that we still love in the old version. This includes the closed design of the printer, which makes the printing process still safe and quite attractive. As for the heated aluminum print bed, it's the same as the Creator Pro.

On the other hand, you're getting a huge upgrade in terms of user interface since the Pro 2 now comes with a touch screen feature. The system is quite simple and excellent. All the settings you need can be accessed at once, and the icons and commands are intuitive. No complications.

No complications.

However, we sincerely think that the main drawback of this model is the brand's initiative to create Creator printers with more updated features. For example, it only comes with a maximum nozzle temperature of 240 degrees, which limits its ability to serve other fiber types.

The Pro 2's small build size is also a bit problematic, especially now that it uses IDEX technology. It has a 200 x 148mm base plate with a print height of 150mm. If you use two extruders in mirror mode, this means that the build volume will be reduced even more due to the space between the extruders while working on the X axis at the same time. This gives a maximum width of 80mm for each model. However, this volume should be sufficient for most 3D printing projects. First of all, given the efficiency of printing two models in just one run, you still have a pretty competitive 3D printer with this bad boy.

Print speed

to 60 mm / h at a layer height 0. 05 mm

05 mm

Functions

Ease in the use of

Pros :

- Relatively quieter than other printers.

- Build plate alignment is largely undemanding.

- Print speed up to 60 mm / h at a layer height of 0.05 mm.

- Provides 50 micron XY resolution.

- Supplied with a large build volume.

Cons:

- Not really for beginners, especially since 3D printing results require a steep learning curve.

- The wireless antenna is placed next to the resin tank, which may cause some problems in the future.

Final double:

If FDM isn't your thing and you need more detailed performance, this MSLA printer is worth considering. After all, this is one of the largest printers in its category, with a build volume of 192 x 125 x 245mm. Hence, it can work great with small to medium projects including busts and masks. Good news? Given the nature of the printing process, it can print several tiny models in the entire 192 x 125mm print area. Hence, it can be used to print multiple models at the same time, not to mention faster curing times.

After all, this is one of the largest printers in its category, with a build volume of 192 x 125 x 245mm. Hence, it can work great with small to medium projects including busts and masks. Good news? Given the nature of the printing process, it can print several tiny models in the entire 192 x 125mm print area. Hence, it can be used to print multiple models at the same time, not to mention faster curing times.

The reason for this is quite simple: it is equipped with new features that make it different from the old one. MSLA printers. First up is the 8.9-inch monochrome LCD display, which means improved light transmission, cutting curing time from 6 seconds to 1.5-2 seconds per coat. Also, since the LCD can weaken over time when exposed to ultraviolet radiation, the device allows you to adjust the light so you can extend its lifespan. Apparently this also means longer curing times in each of your projects, and if that's not an issue for you then this feature is a great addition.![]()

In terms of print detail, its 4K resolution with 3840 x 2400 pixels on screen gives it a great experience. In addition, the Z-axis boasts a dual linear guide to keep the printer stable during the printing process. As a result, you will get the highest possible detail on MSLA printers with a smooth surface. Basically, you will get most of what you expect if your sliced model is decent.

However, as is the case with other 3D printers, Mono X is not only about the sun and the rainbow. First, it uses resin to make models that can get really messy, especially if you're trying this type of printer for the first time. Secondly, no offense, adding "wireless" control to the device is almost useless. Yes, we really appreciate the fact that this will allow you to control the printer via your phone via the Anycubic mobile app. This includes starting and pausing the printing process, as well as changing some settings. However, this is similar to controlling the device with built-in controls. Also, setting up the app is tedious, which is why we really think it's almost impractical. However, the great features of this 3D printer can be equated to this small problem. 97

Also, setting up the app is tedious, which is why we really think it's almost impractical. However, the great features of this 3D printer can be equated to this small problem. 97

Press speed

120 mm / sec

performance and quality

Functions

Ease in use

PLANS IN THE RIDED RIDED OF THE RID Composite coating for easy removal of prints. Cons: Final take: The FLSUN QQ-S Pro is way out of the budget range of the other printers on the list. Delta printers are not as popular as their Cartesian counterparts, but in some ways they can offer a number of advantages when it comes to speed. Compared to others, their lightweight printheads allow them to move freely and faster. This is the reason why FLSUN QQ-S Pro provides a reliable print speed of 120mm/s, which is relatively close to the performance of the famous Ender 6. Another distinguishing feature of such a delta printer is the height. In the case of the QQ-S Pro, it has a large Z-height, which means it is capable of printing tall models. It also measures 255 x 365mm, which is impressive given its price compared to other printers. We also really like that, considering its price range, it has an automatic bed leveling. Its print head is equipped with an automatic alignment sensor. The printer uses a titanium extruder that attaches to the frame and feeds filament through a Bowden tube. It provides a maximum temperature of 270°C, allowing you to work with a significant number of fiber types. This includes ABS, PLA, PVA, HIPS, wood and the like, which are relatively flexible. However, this is where we see the main problem with this delta printer model (in fact, this is a problem for all FLSUN printers): there is no filament sensor at all. Luckily, the filament can be easily controlled as it is located at the top of the printer compared to Flashforge Pro 2. Press speed 100 mm / sec Functions Ease in price ratio 9003 value and feature set. Cons: Final take: If innovation and extra features are the main criteria to consider, then the Snapmaker Original 3-in-1 truly is a winner. This 3D printer is one of the most funded 3D printing projects on Kickstarter due to its great features. It will not only be a 3D printer, but also a laser engraver and a CNC carving machine. The general concept of this multifunctional machine is quite simple. It works through the use of three modules, each offering a specific feature. They are easy to replace next to the appropriate beds/platforms needed for the job. The modules are secured with 4 hex head screws and you only need to work on unplugging/plugging in the specific cables you need. In a couple of minutes, you can switch from 3D printing to engraving and cutting. The device's 3D printing feature is not as competitive as other options like the Creality Ender 5 Plus or Flashforge Pro 2. It only has a 125mm square volume. This means that it is only intended for very small projects such as printing small accessories and models. The maximum print head travel speed is 100mm/s, although actual printer performance may vary. However, the nozzle can generate heat up to 250°C, allowing the 3D printer to process a significant number of fiber types. The 125 x 125mm working area laser engraving module provides a spindle speed of 19,000 RPM, which produces excellent details when used with compatible materials such as wood, acrylic, printed circuit boards and carbon fiber sheets. According to our observations, the spindle works differently depending on the material used in the process. While it works great with carbon fiber sheets, it can work more with softwood materials. The same applies to the laser engraving function for selected compatible materials. It uses a wavelength of 405 nautical miles and a power of 200 mW. It can work well with a wide range of materials, including wood, bamboo, leather, plastic, fabric, paper, opaque acrylic, and more. However, for higher performance, users can have an upgraded 1600mW module for the device. print volume This is a must, especially if you often work with 3D prints of different sizes. FDM printing technology is undoubtedly the most convenient technology in the world of 3D printing. Not only because models are usually easy to assemble or because of the unusual features that you often find in such models, but also because of the threads used in them. No mess and no extra steps like resin curing. With SLA printing, the opposite is true. However, while often despised due to the sticky material used in the printer, it should keep you from considering SLA 3D printers. features It's true that there is no perfect 3D printer on the market, but as we often tell our readers, it's all about finding the right set of features that will give you the most value...and the best value for money . It is on this principle that we have made the Creality Ender 5 Plus the leader of our list. There is a newer and "higher" model than this one, the Ender 6. However, after carefully looking at the things the latter loses in order to achieve a more modern look, we think the Ender Plus 5 is still much more practical to have. The printing ability is the same in terms of accuracy. But what really helped was the auto leveling and the sheer volume of printing that most of us often need. There are other 3D printer models that come with other enticing features such as the IDEX system in Flashforge Pro 2, detailed ANYCUBIC Photon Mono X resin prints, the awesome FLSUN QQ-S Pro print height, and numerous Snapmaker features. As mentioned, 3D printers under $1,000 often have great deals for you. They are often equipped with the right set of features to suit most of your project needs. However, it's certainly a good idea to make sure you get the most out of everything. For example, although Ender 5 Plus is an older version, it has a relatively higher price than Ender 6. However, this does not mean that the latter can give you better performance and value. You can add about $30 to enjoy the good old Ender 5 Plus model, but it's worth it in the long run considering it can handle larger projects. So yes, that's the point. Don't mind spending or adding a little more to your budget if you think this model will really benefit you.

it's a lot cheaper than them, but after looking at the other types of printers on this list (and the possibility that some readers might want us to include a delta printer), we decided to include it.

it's a lot cheaper than them, but after looking at the other types of printers on this list (and the possibility that some readers might want us to include a delta printer), we decided to include it.  On the plus side, bed leveling is not only effortless, it also needs to be leveled once, since the machine bed does not move.

On the plus side, bed leveling is not only effortless, it also needs to be leveled once, since the machine bed does not move.

This is the reason many people like it, especially 3D enthusiasts who want to explore other kinds of projects.

This is the reason many people like it, especially 3D enthusiasts who want to explore other kinds of projects.  The layer resolution of the 3D printer is between 50 and 300 microns, and the accuracy of 3D printing is quite decent.

The layer resolution of the 3D printer is between 50 and 300 microns, and the accuracy of 3D printing is quite decent. Best 3D Printers Under $1,000 Buyer's Guide

Medium-sized devices like the FLSUN QQ-S Pro and Flashforge Pro 2 should be enough for most everyday projects, but if you think you need something for larger projects, we recommend the Creality Ender 5 Plus. It can provide a maximum build volume of 350 x 350 x 400mm. While not as fast as its successor, the Ender 6, it can deliver consistent results. The FLSUN QQ-S Pro is also a good choice, especially for vertically long and tall prints considering it's a delta model.

Medium-sized devices like the FLSUN QQ-S Pro and Flashforge Pro 2 should be enough for most everyday projects, but if you think you need something for larger projects, we recommend the Creality Ender 5 Plus. It can provide a maximum build volume of 350 x 350 x 400mm. While not as fast as its successor, the Ender 6, it can deliver consistent results. The FLSUN QQ-S Pro is also a good choice, especially for vertically long and tall prints considering it's a delta model.  The reason is simple: SLA is very good when it comes to details. That is why it is often used not only by enthusiasts, but also by professionals, especially in the field of medicine, who require detailed printouts of objects.

The reason is simple: SLA is very good when it comes to details. That is why it is often used not only by enthusiasts, but also by professionals, especially in the field of medicine, who require detailed printouts of objects.  Original 3-in-1. In addition, each model is complemented with other details that enhance their convenience, from a closed print area to wireless connectivity. However, the bottom line is to find a model that offers the best set of parts that will satisfy you.

Original 3-in-1. In addition, each model is complemented with other details that enhance their convenience, from a closed print area to wireless connectivity. However, the bottom line is to find a model that offers the best set of parts that will satisfy you.

Best 3D Printers Under $1,000 FAQ

Are 3D Printers Expensive?

There are entry-level 3D printer models that range from $200 to $500. They should offer the most basic features you need to 3D print models, but there are better options that cost upwards of $500, like the Creality Ender 5 Plus. However, there are other high-end options from $1,500 to $6,000.

Which filament should I use for my 3D printer?

This depends on the maximum heating power of the device and its compatibility with certain fiber types. However, the most commonly used fibers are PLA and ABS.

Can I leave my 3D printer overnight?

It is never recommended to leave the 3D printer running overnight or unattended. In addition to the danger that the printer may pose to curious children and pets, it may encounter some electronic problems that could lead to a fire.

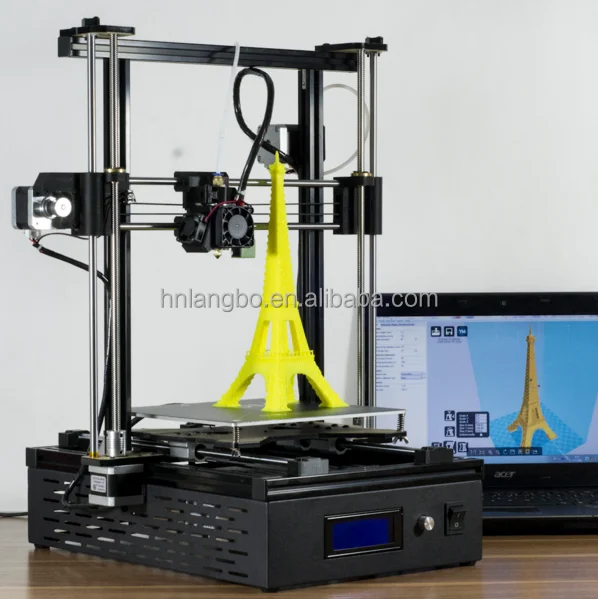

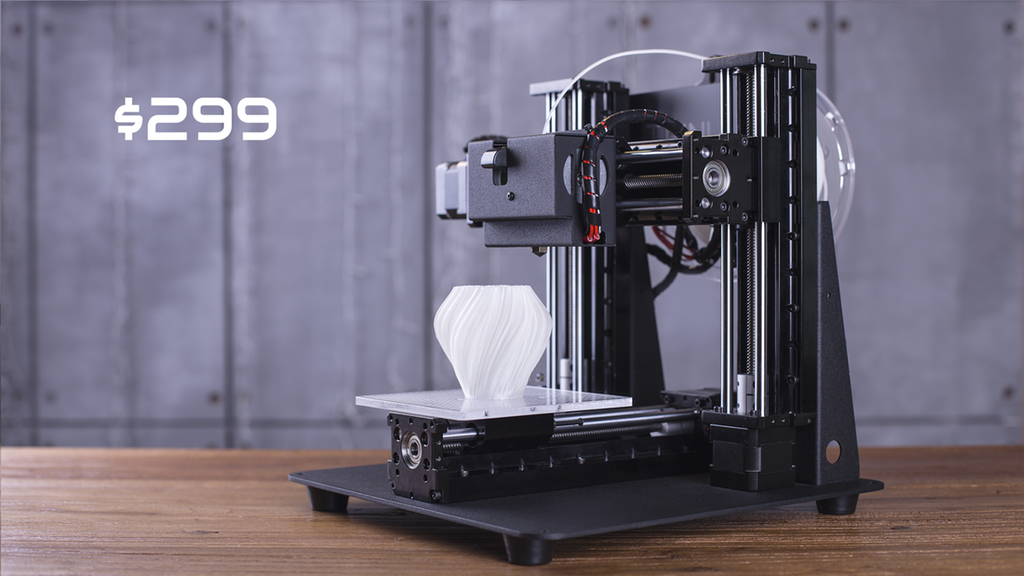

Top 20 Inexpensive 3D Printers ($199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. This is amazing.

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts.

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

And it's really cool!

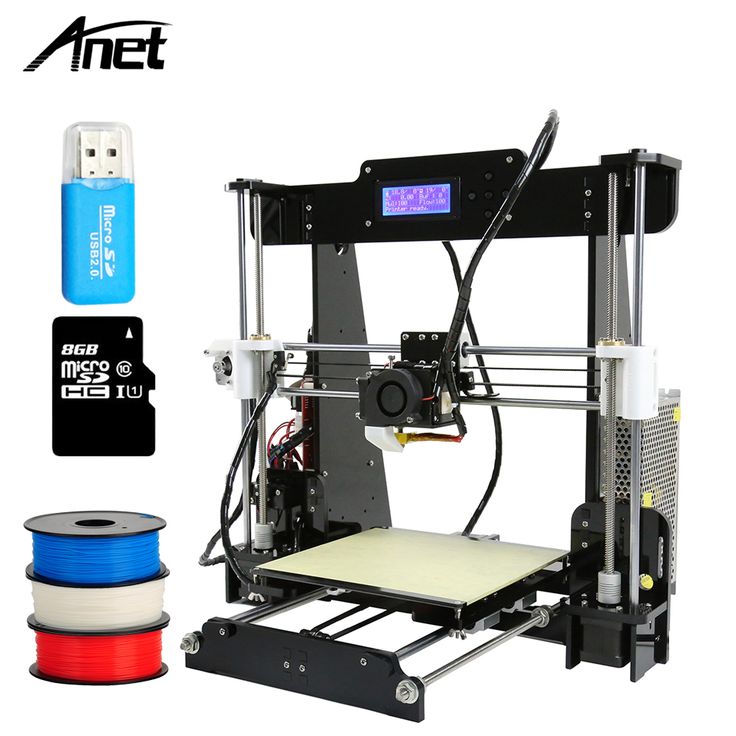

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the price range from $ 200 to $ 1000

| 3D Printer | Material Press | 9076 9076 9071 9076 90EARD0025 | 459 |

|---|---|---|---|

| Flashforge Finder | PLA | 140 x 140 x 140 | |

| XYZ 1.0 Pro | PLA | 150 x 150 x 150 | 499 |

| XYZprinting da Vinci Jr. Mix 2.0 | PLA | 150 x 150 x 150 | 599 |

| Printrbot Simple | PLA | 150 x 150 x 150 | 599 |

| UP mini 2 | PLA, ABS | 120 x 120 x 120 | 599 |

| Monoprice Maker Select Ultimate | PLA, ABS, exotic | 200 x 200770 | 699 |

| ROBO C2 9070 | PLA | X 127 X 127 X 127 X 1270032 | |

| Dremel Idea Builder | PLA | 230 x 150 x 140 | 899 |

| Printrbot Simple Pro | PLA | 200 x 150 x 200 | 999 |

| Prusa i3 MK2 | PLA, ABS, exotic | 250 x 210 x 200 | |

Flsun QQ-S Pro

Flsun QQ-S Pro

This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB.

This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB.  75 mm;

75 mm;  75 mm;

75 mm;  75 mm;

75 mm;  75 mm;

75 mm;  75 mm;

75 mm;

75 mm;

75 mm;  75 mm;

75 mm;  Mix 2.0

Mix 2.0  75 mm;

75 mm;  75 mm;

75 mm;

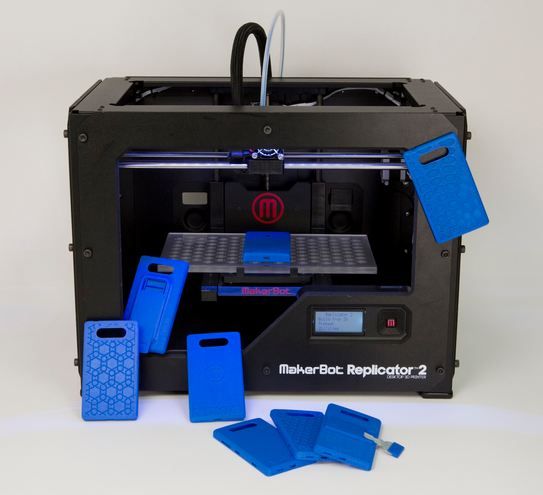

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.  Polar 3D Printer This causes the table to rotate and the print head to move up, down, right, and left.

Polar 3D Printer This causes the table to rotate and the print head to move up, down, right, and left.

75 mm;

75 mm;

75 mm;

75 mm;