3D scanner dubai

Artec Leo | 3D Middle East LLC

Artec Leo

Easy 3D scanning: see your object projected in 3D directly on the HD display

A smart professional 3D scanner for a next-generation user experience

The first 3D scanner to offer onboard automatic processing, Artec Leo is able to provide the most intuitive workflow, making 3D scanning as easy as taking a video. As you scan your object, see the 3D replica being built in real time on Leo’s touch panel screen. Rotate the 3D model, check if you have captured all areas, and fill in any parts you may have missed.

Brochure

Breakthrough 3D scanning speed

The 80 frames per second 3D reconstruction rate makes Artec Leo the fastest professional handheld 3D scanner on the market. Furthermore, with its large field of view, Artec Leo can 3D scan and process even large objects and scenes fast and accurately. And for even greater precision, users can point the scanner closer to the object to pick up intricate detail, just as they would zoom in with a video camera.

A fully mobile scanning experience

Thanks to the powerful embedded processor and the inbuilt battery, Artec Leo gives you true freedom in 3D scanning. With no need to connect to a computer or plug into a mains power source, you can hold Leo in one hand and walk around freely, scanning your object unhampered by any wires or additional equipment. Purchase supplementary battery modules for unlimited 3D scanning on expeditions or in remote areas with no power supply.

The smartest 3D scanner on the market

Artec Leo contains state-of-the-art technologies, including the NVIDIA® Jetson™ platform, which is the scanner’s own internal computer, featuring Quad-core ARM® Cortex®-A57 MPCore CPU and NVIDIA Maxwell™ 1 TFLOPS GPU with 256 NVIDIA® CUDA® Cores; a built-in 9 DoF inertial system – accelerometer, gyro and compass – which allows the scanner to understand its position and environment; and a two-in one optical system designed to spec for the most exact texture to geometry mapping.

Designed for usability

With a built-in battery, touch panel screen and wireless connectivity, Artec Leo takes handheld 3D scanning to the next level. Have complete freedom of movement when you scan, stream video to a second device via Wi-Fi or Ethernet, if an additional display is needed, and upload your data at the touch of a button. Add to these features a carefully balanced, ergonomic design, devised to make 3D scanning in one hand easy and comfortable, and you have a next-generation professional 3D scanner, built with usability in mind.

Applications

Since the user is able to capture both expansive areas and fine detail, Artec Leo can be used for scanning a range of objects, from small mechanical parts to the human body, cars, boats or crime scenes. As with all Artec 3D scanners, the applications are wide and far-reaching, including industrial manufacture and quality control, healthcare, forensics, VR and e-commerce. Furthermore, Artec Leo’s new wireless functionality and internal processor allow for a wealth of integration possibilities, making it even easier to streamline your application, regardless of the industry.

3D scan and process even large objects quicker than ever before

With its large field of view, Artec Leo can capture huge volumes in minimum time.

Capture even small details

Sweep over large areas fast, zoom in on detailed areas for increased precision.

The most mobile 3D scanner on the market

With its inbuilt battery and Wi-Fi connectivity, Artec Leo offers true freedom in 3D scanning. Move right around your object, unhampered by any wires!

Built-in touch panel screen and simple interface

See your 3D model being built directly on the scanner itself. Check your model, change the settings or touch it up with some simple tools in the easy to use interface on the touchscreen. Wirelessly connect to a second screen, for ease of scanning or collaborative work.

Built-in 9 DoF inertial system

The internal accelerometer, gyro and compass mean that Artec Leo is the only handheld 3D scanner to be able to precisely pinpoint its position within its surroundings, even differentiating between horizontal and vertical surfaces, such as floors and walls.

Unparalleled texture to geometry mapping

Features a unique optical system developed by Artec 3D, with the 3D camera and color camera combined and directed through the same lens. This technology provides the most advanced texture to geometry mapping.

Large, professional grade lens system

Collects the maximum volume of data with pinpoint accuracy from right across the field of view, resulting in the most precise 3D model.

Enhanced color capture

Using disruptive VCSEL light technology, Artec Leo excels in its ability to digitize hard to scan textures, including skin, and can scan well even in bright conditions. This technology also allows you to regulate the intensity of the flash to improve color capture even further.

No need for targets

As with all Artec’s full powered 3D scanners, Leo uses powerful hybrid geometry and texture tracking, meaning you can really just point at your object and shoot. No need to stick targets on it (and then remove them!).

Built-in SSD drive

Store 256 GB on the SSD drive. You can also extend the capacity, storing unlimited data on micro SD cards. Ideal for 3D scanning in the field!

3D HDR

Scan tricky objects in HDR. For great capture of black and shiny areas, for example, normally difficult materials for 3D scanners to render.

A wealth of integration possibilities

The head of the scanner can be mounted to robotic arm or a conveyor system for automated 3D scanning, or synced with multiple devices and used in multi 3D scanner installations.

Cutting-edge 3D software

Artec Leo uses two powerful 3D programs and the very latest in Artec’s proprietary 3D algorithms. Artec Leo scanning software, with its simple touchscreen interface, is preinstalled on the device for scanning and onboard real-time processing. Once you have finished scanning, the data should be transferred to industry-acclaimed Artec Studio for editing, complex processing and analysis.

Customizing, innovating and streamlining a wide range of different industries

Artec 3D scanners & applications

Industrial design & manufacturing

-

Product design

-

Customisation

-

3D documentation

Reverse Engineering

-

Reverse engineering

-

Quality control

-

Rapid prototyping

-

Aerospace

Healthcare

-

Orthopedics

-

Prosthetics

-

Plastic surgery

-

Custom wheelchairs

Science and Education

-

Research

-

Training

-

Online museums

Art and Design

Artec Studio 17

Smart 3D data processing has never been easier.

Enhance your QI processes with the latest stack of scan-to-CAD features and tools for sustaining the necessary precision levels, even when scanning over long distances.

Enjoy a wide range of innovative features, including the cutting-edge Autopilot mode that expertly guides you through the whole post-processing pipeline, automatically choosing the best algorithms for your data, so you can watch your high precision model being put together before your eyes.

You can also take full control of your results with the wide variety of advanced features available.

Learn More

3D Model Scanning and Printing Services in Dubai

What is 3D Scanning?

3D Scanning is a non-contact, non-destructive technology that digitally captures the shape of physical objects using a line of laser light.

3D scanners create millions of points of data from the upper surface of an object. Basically, 3D scanning is a way to take a physical object’s exact size and shape into a digital file and on a screen as a digital 3-Dimensional image.

3D scanners can measure the finest details and free-form shapes, which are then translated to accurate points. These points are then revere engineered, and the photo is then 3D modelled to a “usable” 3D file, which can then be modified, translated and/or 3D printed.

Benefits of 3D Scanning Services:

3D Scanning Technology has revolutionized the design and manufacturing process in various industries be it shoe designing or supercar manufacturing. Whether for an artistic restoration or engineering prototype, it is an efficient and precise means of manufacturing products on an as-needed basis. With 3D Scanning, you can scan an object multiple times from every angle and turn a tangible product into a virtual design within seconds. Here are five reasons to use high-quality and accurate 3D Model Scanning Services in Dubai from 3DInova.

Save Time at Design Stage

Let’s say a product needs a new part to be designed based on a preexisting object. You can reverse-engineer this new object using 3D Scanning technology. A 3D Scanner is a perfect tool to get into every nook and corner of the existing product and measure the exact dimensions of the area where the new part is required to be fit, and it can do this in no time at all. The same concept can also be applied if the current design needs any alteration or the current measurement of the design needs to be revised. For example, if a ring’s or automotive part’s thickness needs to be changed, 3D Scanners can resolve this way faster than hand-drawn diagrams and manual calculations.

A 3D Scanner is a perfect tool to get into every nook and corner of the existing product and measure the exact dimensions of the area where the new part is required to be fit, and it can do this in no time at all. The same concept can also be applied if the current design needs any alteration or the current measurement of the design needs to be revised. For example, if a ring’s or automotive part’s thickness needs to be changed, 3D Scanners can resolve this way faster than hand-drawn diagrams and manual calculations.

Make the Prototyping Process Faster

Creating an accurate prototype can be a tedious process, but with 3D Scanning technology, it is now a child’s play. 3D Scanning can reduce the amount of prototype cycles required in the design and production stage. A 3D Scanner can not only measure cross-sections but also identify areas where an object may be warped. It has also the unique ability to save all the data in every scan which comes really handy when you need to compare the different versions of the prototypes.

Fast and Comprehensive Quality Control

Did you know that 3D Scanners are so accurate that museums rely on them to preserve world-famous artefacts? 3D Scanning helps them to check the material’s composition and the object’s volume accurately and in a time-efficient manner. The manufacturing industry can also benefit from the same. 3D Scanning facilitates easy checking of a product’s design quality, scale and scalability within millimetres of accuracy. You can even compare the shape of the manufactured product with the original CAD design to find the slightest deviations by simply viewing the data in 3D Colour Map.

Remanufacture Parts without CAD Software

If you ever need to remanufacture a part developed before the widespread use of CAD software, then 3D Scanning is your saviour. 3D scanners can produce accurate reproductions by simply scanning an old part and using reverse engineering software to create a CAD design model of the same, allowing you to compare the newly developed prototype to the 3D scan of the old part to check for accuracy.

Easy to Compare Designs with Manufactured Products

Another advantage of 3D Scanning is the advanced ability to compare the as-designed model to the as-built product model. 3D Scanning can help ensure that the original vision comes to fruition in the end. By comparing the designs to the manufactured product, you can ensure that the product will fit as needed, for example, in an automobile. Similarly, this cross-check could tell a jeweller whether a jewel will fit inside a pendant or ring.

Are you looking to 3D scan?

Please fill out the below form, and our team will be in touch you.

Russian developer of 3D human body scanners Texel will start deliveries of its products to the UAE

News

News

Kirill Bilyk

News editor

Kirill Bilyk

Russian developer of 3D human body scanners Texel will start shipping its products to the UAE. The contract is long-term — within two years, a number of Texel devices worth at least $1 million can be shipped to the Emirates. At the first stage, the deal amounted to $40,000.

The contract is long-term — within two years, a number of Texel devices worth at least $1 million can be shipped to the Emirates. At the first stage, the deal amounted to $40,000.

Kirill Bilyk

The contract between the Russian developer Texel and the managing company of the free economic zone Dubai Internet City was concluded following the results of the Gitex-2021 exhibition, a company representative said. The amount of the first stage of the transaction was $40,000. During 2022-2023, a number of Texel devices totaling at least $1 million may be sent to the UAE.

As part of the contract, Texel will supply Texel Portal MX scanners to the UAE. This is a human-height rotating frame. It is equipped with sensors-sensors and software developed by Russian specialists. The frame wraps around a person in 30 seconds, the system processes the data for about a minute and creates a three-dimensional avatar of a person.

The scanner is able to take measurements that can be compared with the dimensional grid of a clothing store to select the optimal model.

“This technology is unique and can be in demand in a large number of industries such as fashion, entertainment, engineering, design and many others,” said Sergey Klimentyev, co-founder of Texel.

According to the developers, the Texel project has already accumulated a database of more than 60,000 three-dimensional models of people from different countries. The analysis of this data using machine learning and artificial intelligence technologies will further allow obtaining a three-dimensional model of a person from self-made photographs.

Skolkovo resident Texel was founded in 2014. At the moment, the total amount of funds raised by the company, according to Crunchbase, is $2.5 million. One of the investors is the Internet Initiatives Development Fund.

RB.ru was told that in September Texel launched a bot in Telegram, with which you can try on any image on your own or someone else's photo.

Subscribe to our TG-channel to keep abreast of all the news and events!

Photo: Texel

- 3D technology

- Business

- Russia

- Technology

- texel

- United Arab Emirates (UAE)

- Skolkovo Foundation

Found a typo? Select the text and press Ctrl + Enter

Related materials

- one Started accepting applications for the accelerator Industrix

- 2 New technologies, ESG principles and empty houses: how techno-cities are developing in Russia

- 3 Vitalik Buterin: I believe in the future of blockchain in Russia

- four Love and robots: a selection of wedding-tech projects

- 5 "I'm fascinated by the printing process.

" Tenth grader about his passion for 3D modeling

" Tenth grader about his passion for 3D modeling

CAPABILITIES

November 25, 2022

funded, not fired

November 27, 2022

5G SmartTech 2022

November 27, 2022

RuCode 6.0

All possibilities

News

The first Moskvich cars will roll off the assembly line in December

News

Oleg Tinkov decided to renounce Russian citizenship

News

The Bell announced the plans of Alexei Kudrin to discuss with Vladimir Putin the terms of the division of "Yandex"

Speakers

9 promising business ideas after the departure of foreign companies

Speakers

Memory training: tips and exercises to help keep the brain in good shape

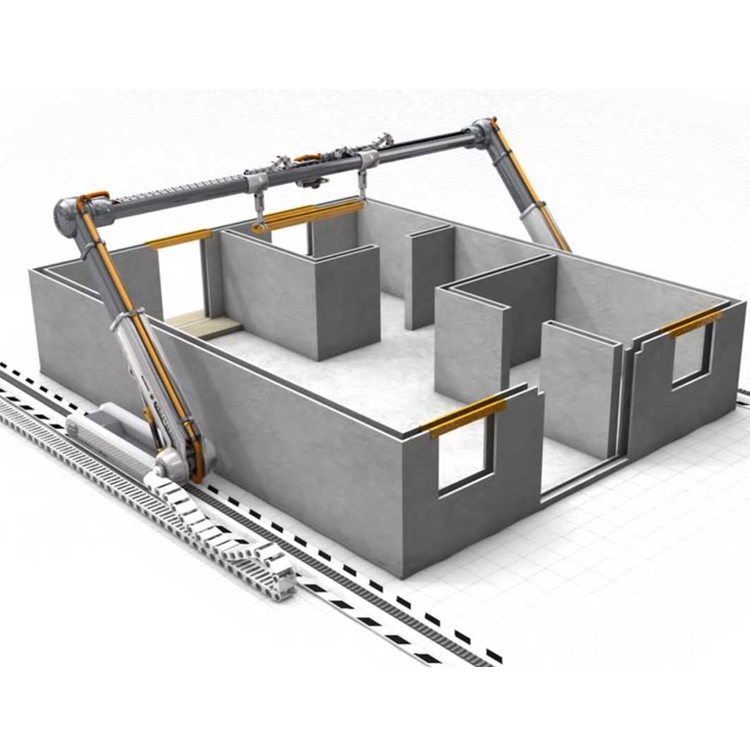

3D printed office in Dubai

First 3D printed office

Just a month ago, Dubai announced its plans to turn the Middle East's largest city into a 3D printing capital by 2030, and the first results of their activities can be seen now.![]() Just recently, the first office printed on a 3D printer was presented. The 3D printed “Office of the Future” covers 250 square meters and is fully equipped to fully function as a temporary Dubai Future Foundation office within the Emirates Towers. This achievement really awakens interest in the further developments of the city in the field of 3D printing.

Just recently, the first office printed on a 3D printer was presented. The 3D printed “Office of the Future” covers 250 square meters and is fully equipped to fully function as a temporary Dubai Future Foundation office within the Emirates Towers. This achievement really awakens interest in the further developments of the city in the field of 3D printing.

The impressive building was built using a special mixture of cement and a combination of various building materials made in the UAE and the USA. All materials have been carefully tested by Chinese and British experts for durability and reliability. A robotic platform 6 meters high, 36 meters long and 12 meters wide was used as a 3D printer.

How the 3D printed office was created

Smaller mobile 3D printers were also used during the construction process to make the tasks easier. Even the electrical wiring, water supply, telecommunications and air conditioning systems have been realized using 3D printing technology, according to the official Emirates news agency WAM.

Moreover, the specific design of the building was not chosen by chance, but for safety and stability purposes. As for the interior, one can observe a smooth transition from a traditional work environment to an interactive environment. According to the concept, the latter will contribute to closer and more relaxed communication between employees. The office printed on a 3D printer provides all the opportunities for the implementation of joint international projects. In addition, its design provides for a special room for exhibitions, seminars and other similar events.

But perhaps the most impressive fact is that all interior and exterior parts were created using additive manufacturing in just 17 days. This is a surprisingly short time, which is simply unrealistic to produce a building in a standard way. It took another two days to finally equip the office. It is worth noting that 3D technologies have reduced production costs by 50% compared to traditional construction methods. It only took one 3D printer, seven installation team members and ten electricians to set up the office, which is an amazing result.

It only took one 3D printer, seven installation team members and ten electricians to set up the office, which is an amazing result.

Highlights of the 3D printed office

The opening ceremony of the 3D printed office building was held on Monday by H.H. Sheikh Mohammed, who also shared several plans for the future of the 3D printing industry in Dubai. According to him, the high pace of development will accompany further projects of the city, with the aim of taking Dubai's scientific and research centers to a new level.

Sheikh also noted the fact that the 3D printed office perfectly demonstrates the competitive advantages of 3D printing. In addition to lowering production costs, it can significantly speed up the delivery of materials, which he says will help make the UAE one of the largest and most sustainable economic centers in the world. Given that 2030 is still far away, we can only imagine what other incredible achievements Dubai will surprise us with.