3D printer indianapolis

3D Printing Service for Indianapolis, Indiana

CapabilitiesCustom Online 3D Printing ServiceIndianaIndianapolis

High Quality Indianapolis, Indiana 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Indianapolis, Indiana 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

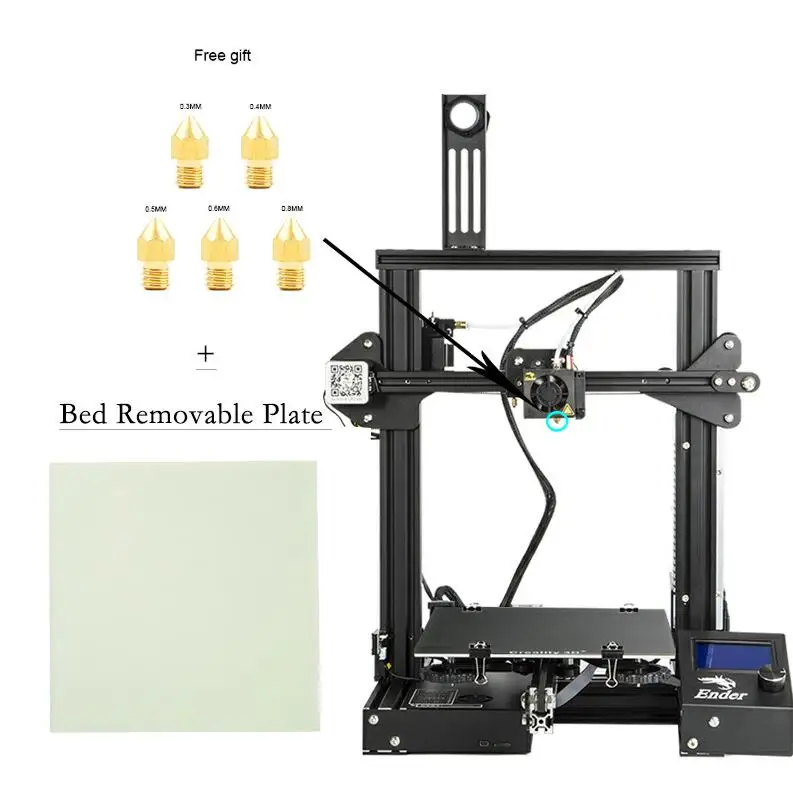

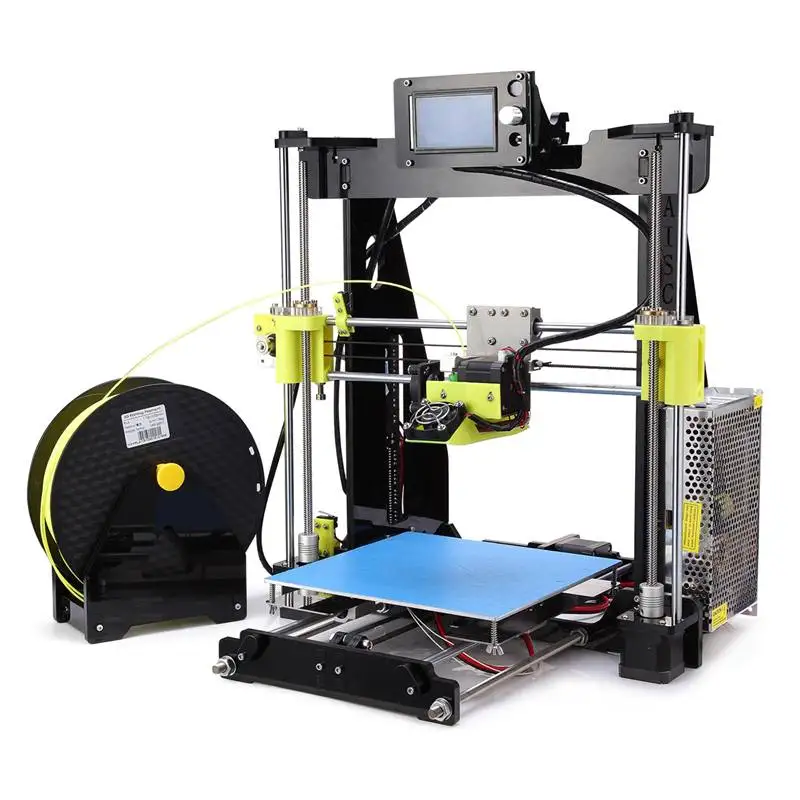

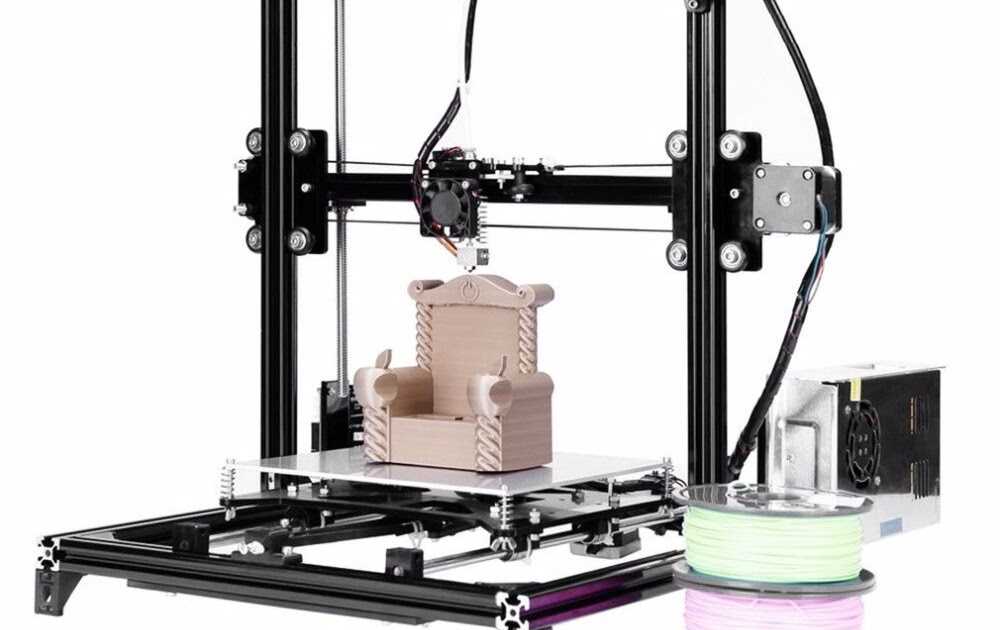

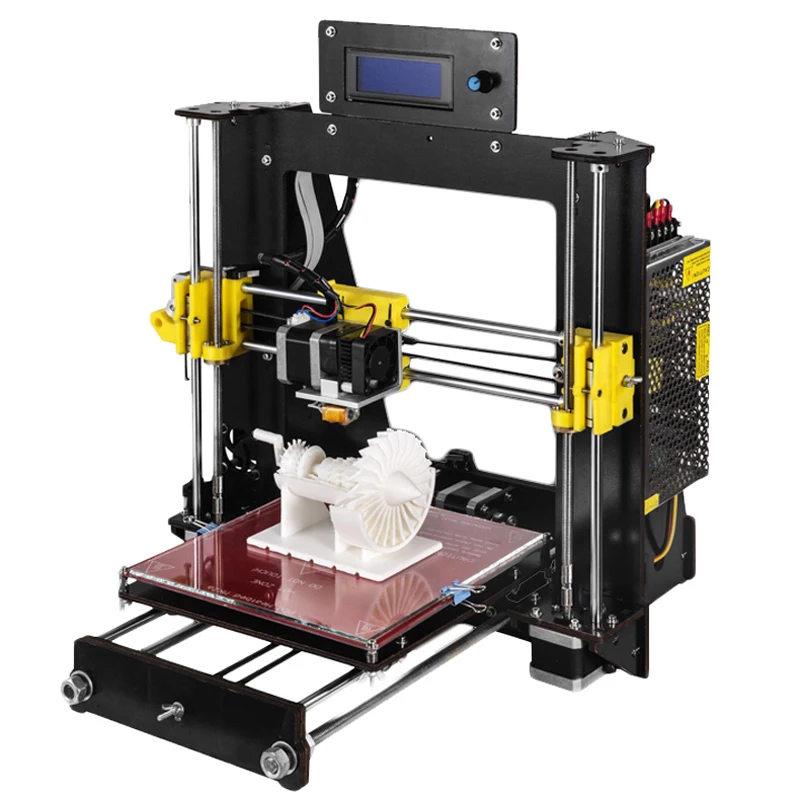

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Indianapolis, Indiana

Bloomington

IndianaWest Lafayette

IndianaTerre Haute

IndianaCincinnati

OhioDayton

OhioLouisville

KentuckyFort Wayne

IndianaSouth Bend

IndianaElkhart

IndianaEvansville

IndianaOwensboro

KentuckyLexington

KentuckyChicago

IllinoisColumbus

OhioEvanston

IllinoisAurora

IllinoisToledo

OhioPeoria

IllinoisBowling Green

KentuckyAnn Arbor

Michigan

Ready to start making custom 3D printed parts?

3D Printing Service Indianapolis, IN | Instant Quotes

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

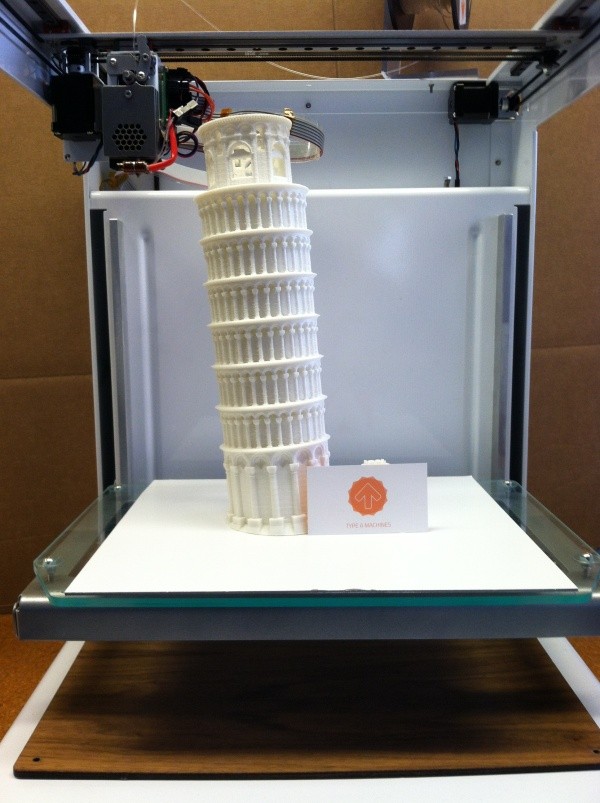

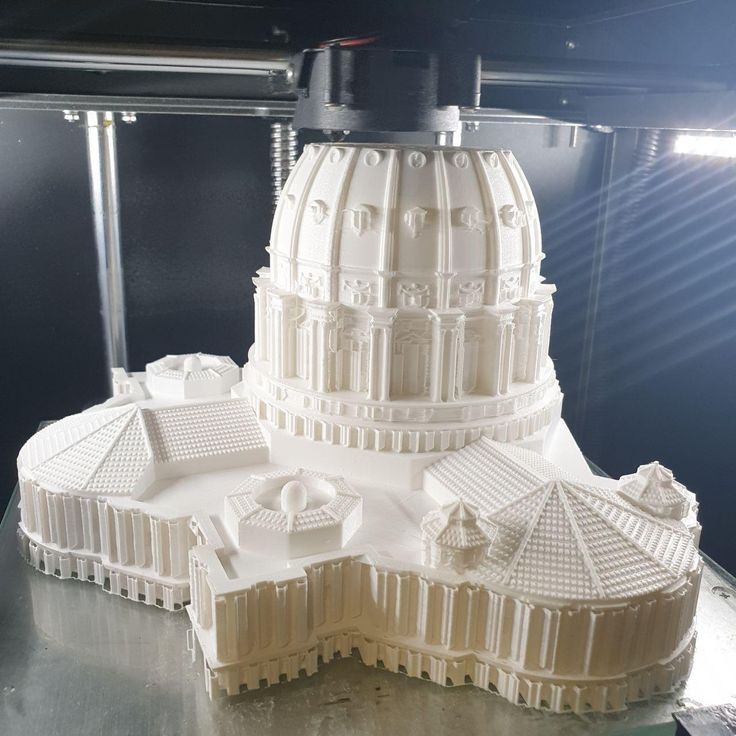

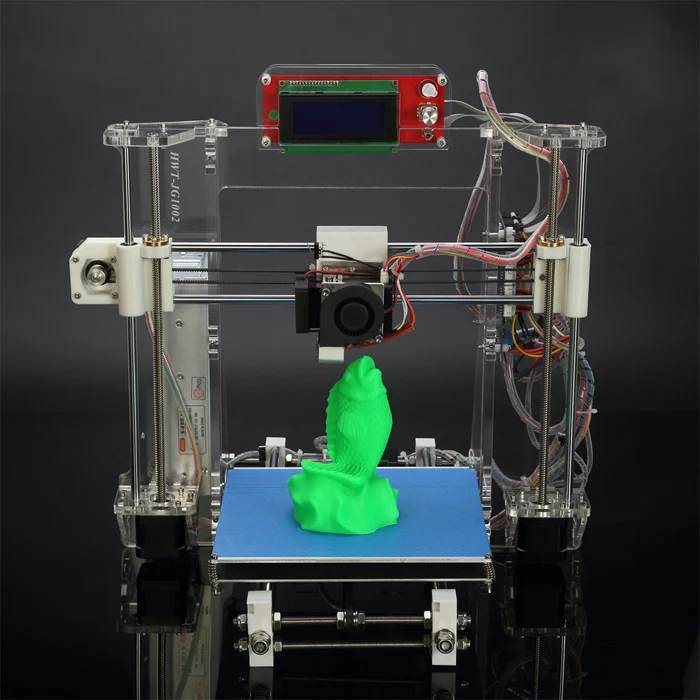

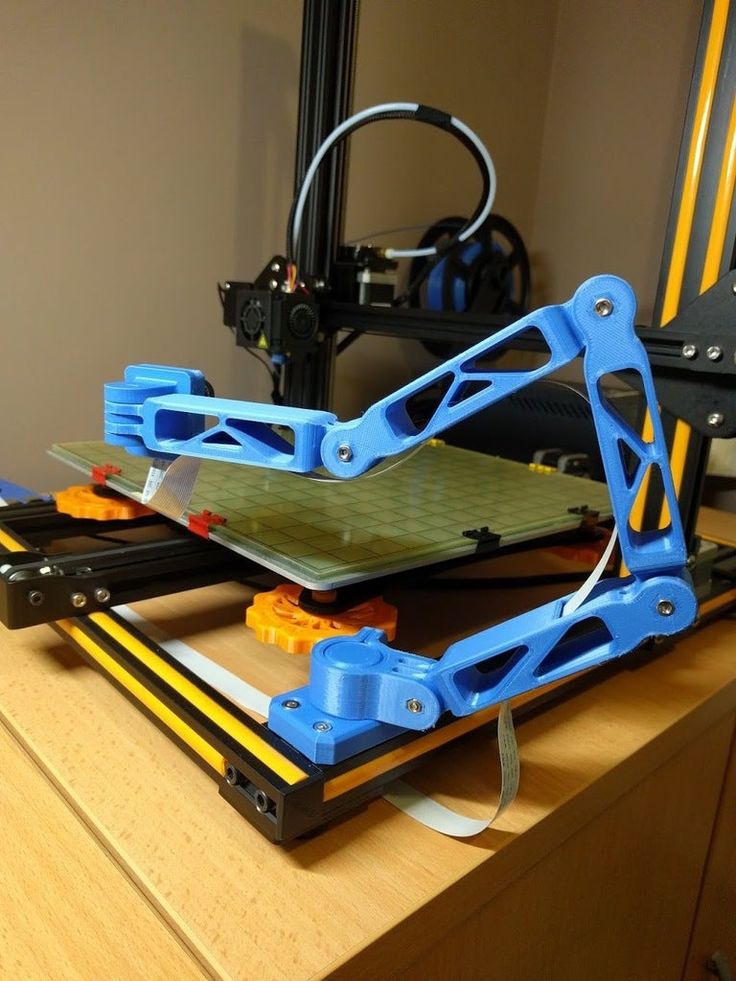

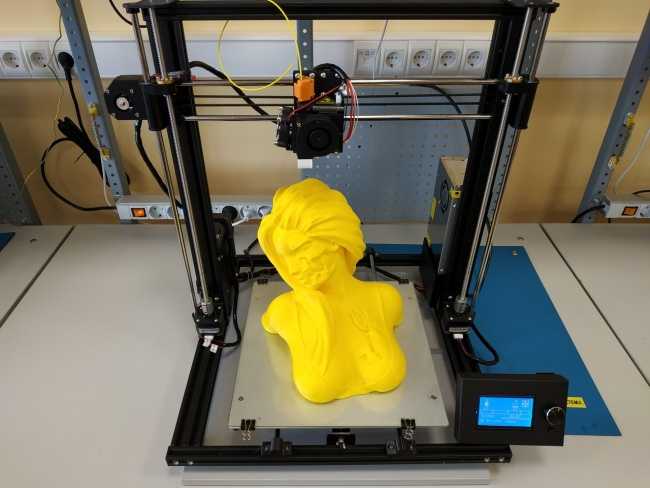

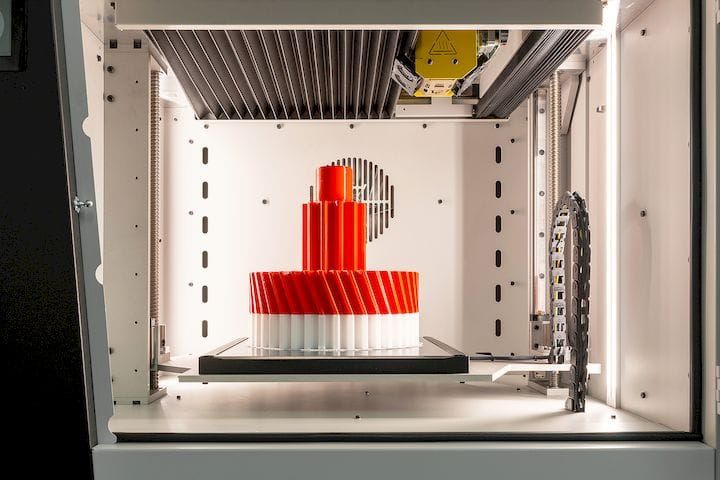

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 213 customers are satisfied with our 3D printing service.

“Prompt and friendly communication. Prints arrived as expected and ahead of schedule”

“Very good communication, extremely fast turnaround.”

“Had a fairly large print - turned out great!”

“Everything came back perfect! Great experience!”

“Awesome service and great help with technical issues!”

“I was very happy with the parts, These were Prototypes and we found a dimension problem with our print because the parts were exactly what we ordered. This was a perfect prototype run, Proof of concept verified and part file was tested out.”

“Great print, parts fit together very well and look nice. Thanks!”

“great service, and communication! thank you”

“The parts arrived quickly and of good quality!”

“An overall fantastic experience from design discussions to quality parts in hand!”

“Excellent service! Ordered on May 31 and delivered via mail just a couple days later. Party looks good and material looks sturdy. This was my first time ordering a print and if given the opportunity I would use this printer again”

“Very quick turnaround, notified me of a part that would be problematic to print and had me update the sketch before printing”

“Excellent provider, extremely communicative and helpful!”

“Good quality print, tiny bit of stringing on one side but causes zero issues. ”

”

“I'm very happy with the results. Will use this service again! ”

“Very happy with speed and quality of the print. ”

“I hate repeating myself but I have to say that EVERY print I get is top notch!”

“Shipping method and timeline worked out fine”

“Great experience! Prompt response to any questions and very knowledgeable! Easy to work with and will definitely use again!”

“Got here faster than expected and split my two orders so I didn't have to pay extra shipping. Print quality was excellent as usual.”

“Very good prints with fast turn-around time. Highly recommended!”

“OUTSTANDING!!! My new "go to" source for 3D printing. Thank you so much, and I look forward to working with you in the future. ”

“Another fine job. Perfectly printed and delivered quickly. Thank you. ”

“Wonderful service and extremely convenient. The staff were very helpful.”

“Highly recommend !! Great Service overall. ”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Indianapolis, IN

Noblesville, IN Fishers, IN Carmel, IN

Indianapolis, IN Anderson, IN Greenwood, IN

Kokomo, IN Muncie, IN Columbus, IN

Lafayette, IN

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

The ISS will start recycling plastic into raw materials for a 3D printer The printer itself is also made by their company and is already on the ISS.

The launch is reported by Space.com.

The launch is reported by Space.com. From the description of the Made In Space Plastic Recusler device on the manufacturer's website, it follows that it is semi-autonomous and can process polyethylene into a thread for the Additive Manufacturing Facility, a 3D printer on the ISS. The reprocessing station is scheduled to launch on November 2 and will be placed aboard Northrop Grumman's Cygnus space truck.

Plastic Recycler was developed by Made in Space in collaboration with Brazilian thermoplastic resin company Braskem. Thanks to the Made in Space partnership, Green Plastic, a resin based on sugar cane, has been adapted for printing tools and spare parts.

AMF has since printed a variety of parts for the station's needs. Dr Julilene Wong used laser scans of astronauts' hands, which are made to fit spacesuit gloves, as well as AMF, and printed splints for injured fingers right on the ISS.

One of the main tasks for AMF was the production of protection for the sensors of the experimental deployable residential module BEAM (Bigelow Expandable Activity Module) by Bigelow Aerospace. A 3D printer printed caps of various thicknesses that covered REM (Radiation Environment Monitor) sensors that measure radiation.

A 3D printer printed caps of various thicknesses that covered REM (Radiation Environment Monitor) sensors that measure radiation.

Source: 3dprint.com

Astronauts have printed a shell for the MakerSat-1 cubesat satellite at AMF - the electronic filling for them is gradually delivered from Earth. The MakerSat-1 was developed by Idaho students as part of a project to study 3D printing in space. The satellite is designed so that its body can be printed and assembled on board the ISS without additional tools.

The previous MakerSat-0 cubesat was launched into space on November 18, 2017 - in addition to taking pictures of the Earth, it studies the influence of space on 3D printing materials that are placed on board.

. In the future, the company plans to adapt AMF to work with metals and composites and some other materials, which, in theory, will make it possible to print electronics for satellites on the ISS.

Finally, AMF prints objects without a scientific or practical purpose. In 2017, Made in Space sponsored British professional racer Pippa Mann. She is the first woman to race in the Indianapolis 500. Mann has partnered with the Susan Komen Breast Cancer Foundation and has been racing the Komen Foundation's pink branded car since 2014 to celebrate this collaboration. Made in Space offered to print a pink ribbon - the symbol of the Komen Foundation on their AMF directly on board the ISS, in order to then sell the unique "space" ribbon at auction. The proceeds were sent to the Komen Foundation.

In 2017, Made in Space sponsored British professional racer Pippa Mann. She is the first woman to race in the Indianapolis 500. Mann has partnered with the Susan Komen Breast Cancer Foundation and has been racing the Komen Foundation's pink branded car since 2014 to celebrate this collaboration. Made in Space offered to print a pink ribbon - the symbol of the Komen Foundation on their AMF directly on board the ISS, in order to then sell the unique "space" ribbon at auction. The proceeds were sent to the Komen Foundation.

The most ambitious Made in Space project she is developing with NASA is Archinaut. In general terms, this is a standalone space 3D printer equipped with a robotic arm that can print in outer space. In 2017, Made in Space featured Archinaut renderings and several CGI videos. At the moment, there is no specific information on the developments on Archinaut on the company's website, on the corresponding page you can only find out about the goals and benefits of the project, as well as its grandiose complexity.

Declared capabilities of Archinaut.

- Build antennas, large scale space telescopes and other complex structures remotely.

- Take advantage of large satellite power systems with high surface area and reflectors currently reserved for larger satellites.

- Remove spacecraft delivery volume limits imposed by rockets.

- Prevent the risks of spacewalks by performing some of the tasks currently assigned to astronauts.

Archinaut is the future mission of Made in Space, the immediate task is to launch stations on the ISS for processing plastic waste into 3D printing material and test it in space. The company plans to create an autonomous station for 3D printing on the ISS, which will be minimally dependent on the supply of materials and parts from Earth.

The Impact of 3D Printing on Logistics and Supply Chain Management (Part 1) - Digital Library Article

Innovation Process Management Development Models

Office of innovative processes of innovation

Logistics logistics in the world

B2BDAVICATIVE AND Logistics

Keywords: 3D packet, three-dimensional production, innovation, supply chain

Annotation

3D printing technologies for logistics and supply chain management. The author considers options for additive manufacturing, analyzes its advantages and disadvantages, highlights the conditions for expediency and possible areas of use. Possible changes in traditional logistics functions under the influence of the spread of 3D printing are explored, threats and opportunities for the main links of the supply chain are studied.

The author considers options for additive manufacturing, analyzes its advantages and disadvantages, highlights the conditions for expediency and possible areas of use. Possible changes in traditional logistics functions under the influence of the spread of 3D printing are explored, threats and opportunities for the main links of the supply chain are studied.

Log: "Logistics Today" — №5, 2015 (© Grebennikov Publishing House)

Volume in pages : 11

Number of characters : about 20.078

References: print / internet

Vinogradov A.B. Impact of 3D printing on logistics and supply chain management (part 1) // Logistics today. - 2015. - No5. — P.276–286. URL: https://grebennikon.ru/article-w7qu.html* The activities of Meta (social networks Facebook and Instagram) are banned in Russia as extremist.

1. 3D printing in dentistry. — More .

3D printing in dentistry. — More .

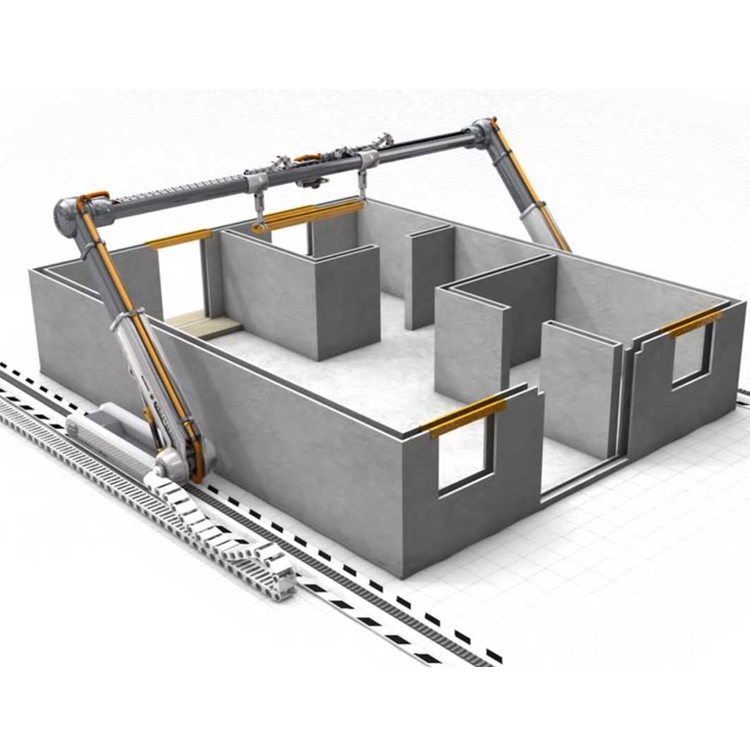

2. 3D printing of buildings. — More .

3. A car printed on a 3D printer. — More .

4. A car printed on a 3D printer in 44 hours. — More .

5. A concrete castle was printed in the USA. — More .

6. Food for US Army soldiers will be printed on a 3D printer. — More .

7. How the Texans taught the printer to shoot. Part two. — More .

8. Kaplan S. How I got my dental crown printed on a 3D printer. — More .

9. Printed world. — More .

10. Plastic bottles will become the raw material for 3D printing. — More .

11. Smirnov N. Things from the printer // Director of the information service. - 2014. - No. 6.

12. Applications of 3D printing in dentistry and medicine. — More .

13. 3D printing will allow organs to be produced on demand. — More .

14. Holweg M. Limitations of 3D printing. — More .

15. What motivates online store customers? — http://4More .

16. McKinsey explained how to survive the 3D revolution. — More .

17. Rolls Royce plans to 3D print aircraft engine parts. — More .

18. 3-D Printing Could Herald New Industrial Revolution. — More .

19. ASTM International. F2792: Standard Terminology for Additive Manufacturing Technologies. — More .

20. D'Aveni R. (2015). "The 3-D printing revolution". Harvard Business Review, May, pp. 40–48.

21. Earls A., Baya V. The Road Ahead for 3-d Printers. — More .

22. E-commerce: Why And How Often Customers Send Stuff Back [Survey]. — More .

23. Fenn J. Applying Lessons from 20 Years of Hype Cycles to Your Own Innovation and Forecasting Strategies. — More .

24. Gibson I., Rosen D., Stucker B. (2010). Additive Manufacturing Technologies. Rapid Prototyping to Direct Digital Manufacturing. New York, London: Springer.

25. Janssen R., Blankers I., Moolenburgh E., Posthumus B. TNO: The Impact of 3-D Printing on Supply Chain Management. — http://3More .

— http://3More .

26. Krassenstein B. Amazon Expands 3d Printing Initiatives, Brings Mixee Labs Team Onboard. — http://3More .

27. Laseter T., Hutchison-Krupat J. A Skeptic's Guide to 3d Printing. — More .

28. Linder B. Amazon Files Patent for 3d Printing Items on a Delivery Truck. — More .

29. Lipson H., Kurman M. (2013). fabricated. The New World of 3D Printing. Wiley, Indianapolis, IN.

30. McKinnon A., Bilski B. (2014). «Innovations in global logistics». In: van den Breemen H. et al. (Eds.). Breakthrough from Innovation to Impact. Lunteren: The Owls Foundation.

31. Petrovic V., Gonzalez V. et al. (2011). "Additive layered manufacturing: sectors of industrial application shown through case studies". International Journal of Production Research, Vol. 49, no. 4, pp. 1061–1079.

32. Research Guide: the Top 10 Strategic Technology Trends for 2015. — More .

33. The UPS Store Expands 3d Printing across the USA. — More .