Iuser 3d printer

The Best Cheap 3D Printers for 2023

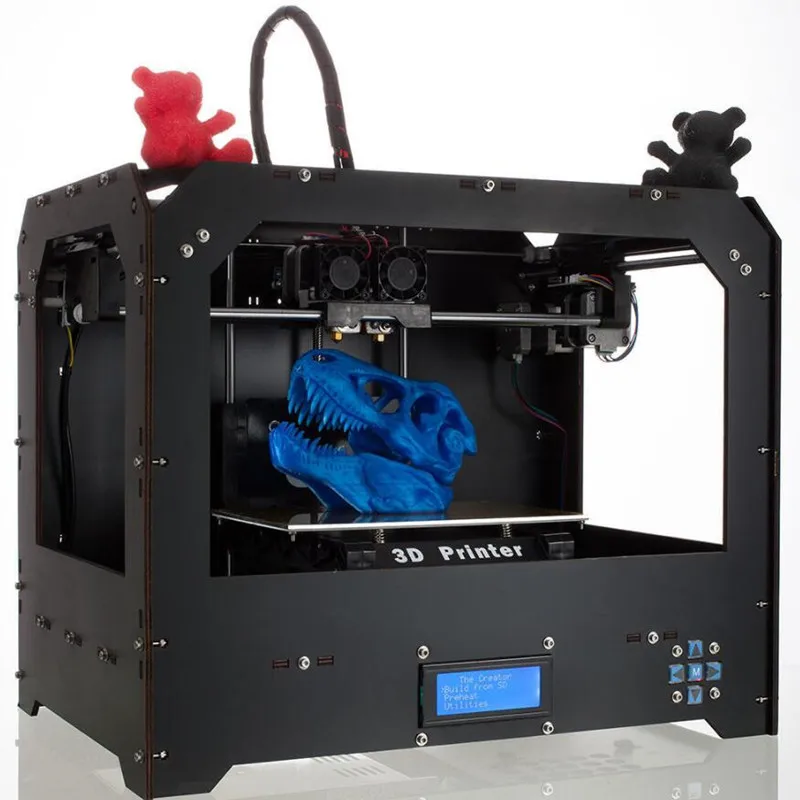

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Deeper Dive: Our Top Tested Picks

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399.00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

| Walmart | $199.95 | $198.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $179.99 | $179.99 | Check Stock (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $499. 00 00 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

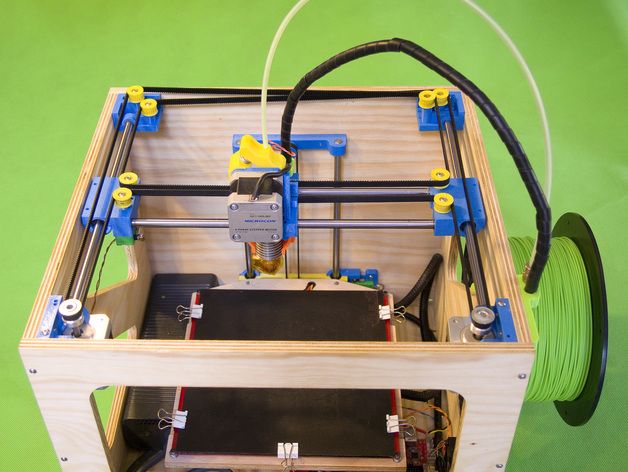

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $499. 00 00 | $499.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $259.90 | $259.90 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $249.95 | $219.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $583.74 | $583.74 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | Check Stock (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2023

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

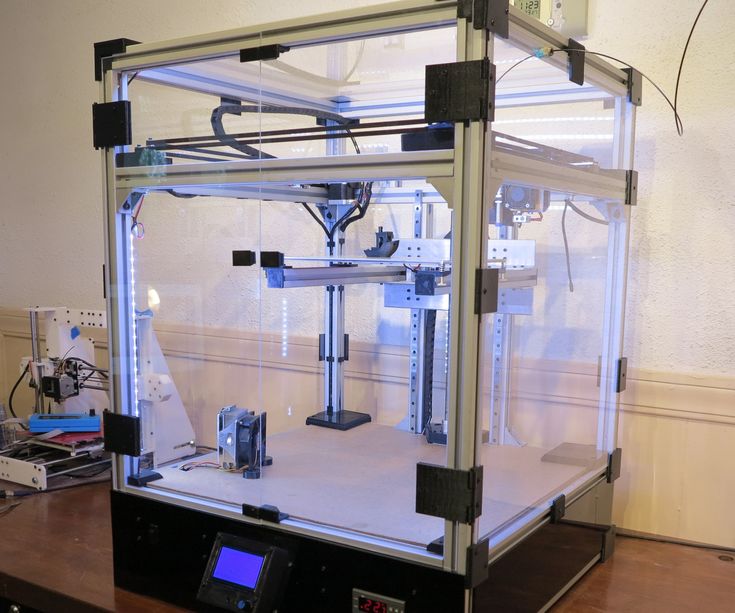

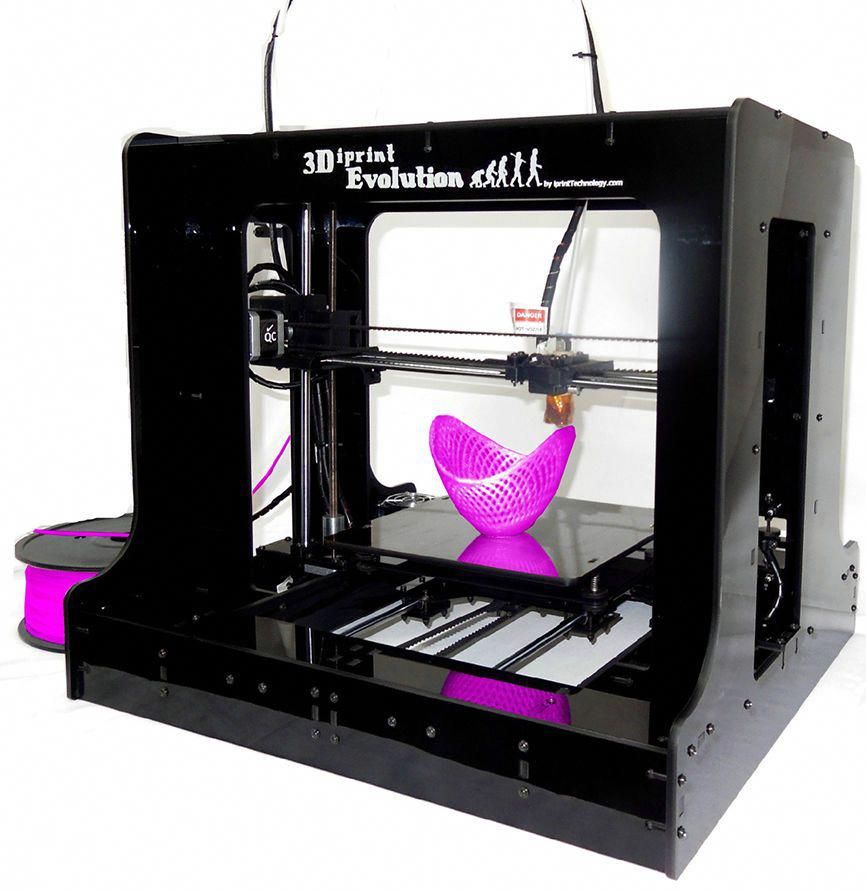

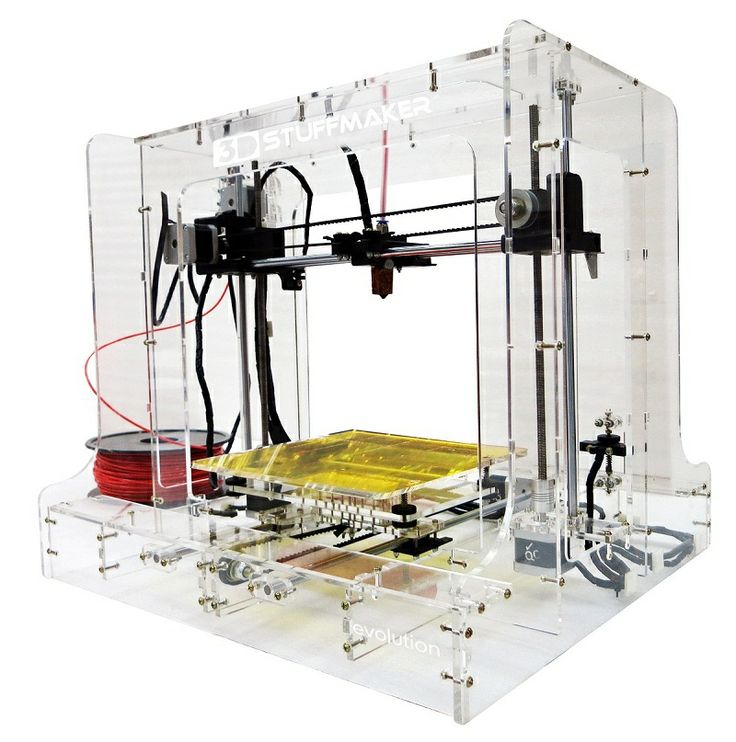

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

The Best 3D Printers for Beginners in 2023

While 3D printing has been around for a while, it’s only recently become more accessible to the mainstream consumer market. Desktop 3D printers make it simple for hobbyists to take advantage of this innovative technology, but those dipping their toes in for the first time may be wary. There’s an enormous variety when it comes to the best 3D printers for beginners, making the process of setting up, printing, and finishing your models a simpler, more digestible process.

Desktop 3D printers make it simple for hobbyists to take advantage of this innovative technology, but those dipping their toes in for the first time may be wary. There’s an enormous variety when it comes to the best 3D printers for beginners, making the process of setting up, printing, and finishing your models a simpler, more digestible process.

3D printers use a process called additive manufacturing to turn digital models into three-dimensional objects. Most often, 3D printers use small nozzles and materials like plastic, resin, polymers, or metal, depositing the material layer by layer, then fusing them with an adhesive or ultraviolet light to create a 3D model.

The things you can create with a 3D printer are almost endless. These desktop devices give you the power to harness your creativity and turn digital prototypes, 3D doodles, and much more into physical objects—all from the comfort of your home. The best 3D printers for beginners will bring your digital dreams to life.

— Best Overall: Creality Ender 3 Pro 3D Printer

— Best for Speed: AnkerMake M5 3D Printer

— Best Resin: ELEGOO Saturn MSLA 3D Printer

— Best Multifunction: Snapmaker 2.0 Modular 3-in-1 A350T 3D Printer

— Most User-Friendly: Monoprice Voxel 3D Printer

— Best Premium: Robo E3 3D Printer

How 3D Printing Works

3D printers use a process called additive manufacturing (more colloquially known as 3D printing) to turn digital models into three-dimensional objects. Most often using small nozzles and materials like plastic, resin, polymers, or metal, the printer deposits the material layer by layer, then fuses them with an adhesive or ultraviolet light to create a 3D model.

The things you can create with a 3D printer are almost endless. These desktop devices give you the power to harness your creativity and turn digital prototypes, 3D doodles, and much more into physical objects—all from the comfort of your home. The best 3D printer for beginners will bring your digital dreams to life.

The best 3D printer for beginners will bring your digital dreams to life.

As with any new consumer technology, 3D printing isn’t exactly cheap, so you’ll have to spend some money for a decent pick. We narrowed down our picks for the best 3D printer for beginners from dozens of 3D printers, paying attention to price, ease of use, and print quality.

Price: 3D printers start at a couple of hundred dollars and can range up to thousands of dollars. Most beginner hobbyists will want a budget-friendly option for testing the waters. We included several printers in a modest price range, skewing towards more affordable prices to appeal to novices.

Ease of Use: User friendliness is one of the most important features when it comes to picking the best 3D printer for beginners. We prioritized features like straightforward assembly and print material refilling, as well as a simple-to-use interface with less of a learning curve required to get started.

Print Quality: Through reviewing product specifications and consumer reviews, we chose 3D printers that create high-quality models, so your design looks exactly as intended. We prioritized 3D printers with good specifications and high user satisfaction. Get started with the best 3D printing software.

The Best 3D Printers for Beginners: Reviews and Recommendations Best Overall: Creality Ender 3 Pro 3D PrinterAn Excellent Learning Resource. Creality EnderWhy It Made The Cut: This beginner-friendly 3D printer is affordable, simple to use, and creates quality prints.

Specs:

— Build Volume: 8.7 inches D x 8.7 inches W x 9.8 inches H

— Weight: 14.6 pounds

— Compatible Materials: PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), PETG (polyethylene terephthalate glycol) plastic

— Print Speed: Up to 180 mm/s (millimeters per second)

Pros:

— Easy to assemble

— Removable, flexible, and magnetic print bed

— Great print quality

Cons:

— Printing bed can be tricky to level

The Creality Ender 3 Pro 3D Printer is a popular 3D printer model for hobbyists, and for good reason. This printer is affordable, easy to use, and comes with several attractive features.

This printer is affordable, easy to use, and comes with several attractive features.

The printer arrives partially assembled with all the necessary tools included for easy setup. Loading the plastic filament is simple. Once assembled and switched on, the device is ready to print almost immediately, with a rapid heating feature that gets the printer ready to go in only five minutes. In case of any pauses in printing, it also has a handy ‘resume print’ function, which restarts the job where it left off.

The heated, removable, and flexible magnetic print bed makes it easier to remove completed models after they’re finished printing, although users will need to take care when re-installing the bed to make sure it’s level. Overall, this 3D printer delivers great print quality, and for its reasonable asking price, it’s our choice for the best 3D printer for beginners looking to dip their toes into 3D printing. For another great option, read out review of the Anycubic Vyper 3D Printer.

Why It Made The Cut: The AnkerMake M5 prints five times faster than some of its competitors and detects errors with an AI camera.

Specs:

— Build Volume: 235 x 235 x 250 mm

— Weight: 27.7 pounds

— Compatible Materials: PLA, PETG, ABS, TPU

— Print Speed: 250 mm per second

Pros:

— Faster than the competition

— AI camera allows for error detection

— Compatible with Alexa

Cons:

— Expensive

If you’re looking to make models fast, the AnkerMake M5 3D Printer is a smart choice. It prints at 250 millimeters per second—five times faster than some other 3D printers. The AnkerMake M5 is a FDM printer that operates on Linux. The integrated die-cast aluminum alloy structure provides a stable base and auto-leveling. The AnkerMake M5 is also designed with an AI camera that helps identify errors such as extruder jams and failure of the model to stick to the print bed. The system sends notifications through the AnkerMake app, a helpful feature for beginners and experienced makers alike.

The system sends notifications through the AnkerMake app, a helpful feature for beginners and experienced makers alike.

The Anker Make M5’s build volume of 235 by 235 by 250 millimeters isn’t as large as some, but it works with a range of materials, including PLA, PETG, ABS, and TPU. In addition to operating the machine through the app, you can also use the AnkerMake Slicer and Amazon’s Alexa.

Best Resin: ELEGOO Saturn MSLA 3D Printer Resin Details. ELEGOOWhy It Made The Cut: This is the best resin 3D printer because it has a relatively large build volume and an accurate printing process to create detailed, sizable resin models.

Specs:

— Build Volume: 7.6 inches L x 4.7 inches W x 7.9 inches H

— Weight: 30 pounds

— Compatible Materials: DLP photopolymer resin

— Print Speed: Up to 40mm/s

Pros:

— Accurate printing results

— Simple to assemble and easy to calibrate

— Large build volume for printer type and price

— Can print multiple miniature models simultaneously

Cons:

— Test model is difficult to remove from the build plate

Compared to FDM (fused deposition modeling) 3D printers, resin printers can print higher levels of detail, which is especially ideal for printing smaller models. Instead of injecting melted materials like plastic layer by layer, resin printers use light (like ultraviolet lights) to cure liquid resin into thin layers. This method allows for finer printing details and a smoother surface. Beginners who want to take advantage of resin 3D printing should consider the ELEGOO Saturn MSLA 3D Printer, a relatively affordable choice with several attractive features.

Instead of injecting melted materials like plastic layer by layer, resin printers use light (like ultraviolet lights) to cure liquid resin into thin layers. This method allows for finer printing details and a smoother surface. Beginners who want to take advantage of resin 3D printing should consider the ELEGOO Saturn MSLA 3D Printer, a relatively affordable choice with several attractive features.

Resin printers tend to be smaller than FDM printers. For its entry-level price, this printer has a large build volume at 7.6 inches long by 4.7 inches wide by 7.8 inches high. This larger size gives the flexibility to create larger, but still very detailed models and miniatures. The ELEGOO also prints 60 percent faster than its predecessor (the smaller Elegoo Mars 2 Pro), while still delivering excellent printing results.

Setup is simple with this printer (although beginners should keep in mind that resin printing requires more post-processing than FDM printing). An easy-to-calibrate build plate and a uniform light source create great print results with few adjustments needed.

Why It Made the Cut: This multifunction 3D printer lets you get everything done with one device, from printing, to laser engraving, cutting, and carving.

Specs:

— Build Volume: 12.59 inches x 13.77 inches x 12.99 inches

— Weight: 61.73 pounds

— Compatible Materials: PLA, Wood PLA, PTG, TPU

Pros:

— Several functions all in one machine

— Compatible with many materials

— Can create larger models with its bigger surface area

— Innovative, sturdy design that’s built to last

Cons:

— Incredibly heavy

— Not a very beginner-friendly price

With a wide array of uses, the Snapmaker 2.0 Modular 3-in-1 3D Printer is a fantastic machine to learn the basics of 3D printing on, and then keep around for the long haul as you master each function. An upgrade to Snapmaker’s previous models, the 2.0 A350T encompasses noise reduction for quieter printing, faster speeds, and precision down to .005 millimeters for a smoother finish.

An upgrade to Snapmaker’s previous models, the 2.0 A350T encompasses noise reduction for quieter printing, faster speeds, and precision down to .005 millimeters for a smoother finish.

This 3D printer is an absolute beast when it comes to material compatibility. Whether you’re printing with PLA, PTG, or TPU; engraving or cutting into plywood, paper, acrylic, fabric, or leather; or carving out shapes and textures with hardwood, PCB, acrylic, POM, carbon fiber sheets, or many more, the Snapmaker can handle the task. This is likely beyond the scope of what you’d be getting into as a beginner, but it opens up the possibilities as you broaden your knowledge and get more comfortable in the realm of 3D printing.

There’s a lot to applaud Snapmaker for, including its incorporation of auto-leveling, filament runout and power loss recovery, WiFi connectivity, and an all-metal, high-strength build that’s designed to last.

Most User-Friendly: Monoprice Voxel 3D Printer Smart and Easy to Use. Monoprice

MonopriceWhy It Made The Cut: A fully-enclosed design, auto-leveling platform, and auto-feeding filament feature make this printer an extra user-friendly choice.

Specs:

— Build Volume: 5.9 inches L x 5.9 inches W x 5.9 inches H

— Weight: 20 pounds

— Compatible Materials: ABS, PLA, wood fill, copper fill, steel fill, and bronze fill filaments

— Print Speed: Up to 100mm/s

Pros:

— Auto-levelling platform

— Full enclosure

— WiFi-enabled

— Built-in camera for print monitoring

Cons:

— Relatively small build volume

If you want to get into 3D printing without the steep learning curve, consider the Monoprice Voxel 3D Printer. This 3D printer features several automated functions that make it extra simple to use.

The printer arrives fully calibrated and ready to print, right out of the box. An auto-leveling feature ensures that the build platform is in the right position, while an auto-feeding filament feature makes loading filament easy. The built-in filament sensor also recognizes low filament levels and pauses prints to notify you that it needs reloading. Once your creation is done printing, lift the heated, flexible, and removable build plate. With a bit of flexing, the model should pop off with ease.

The built-in filament sensor also recognizes low filament levels and pauses prints to notify you that it needs reloading. Once your creation is done printing, lift the heated, flexible, and removable build plate. With a bit of flexing, the model should pop off with ease.

This 3D printer features a closed design to keep hands (or paws) away from hot and moving parts while it’s printing. It is also Wi-Fi-enabled; its functions are controlled and monitored through its color touch screen or through your smartphone (through the Polar Cloud cloud-based platform), and you can check on printing progress through the window or with your phone via the built-in camera. If you're into making miniatures, you may also want to consider the best resin 3D printers.

Best Premium Pick: Robo E3 3D PrinterAll-In-One. Robo.Why It Made The Cut: Robo's E3 is the perfect 3D printer to get if you want to jump into making complex projects right away. It's compatible with over 20 materials, ranging from wood to metal to glass.

Specs:

— Build Volume: 5.9 inches L x 5.9 inches W x 5.9 inches H

— Weight: 19.8 pounds

— Compatible Materials: ABS, PLA, wood fill, copper fill, steel fill, brass fill, carbon fiber fill, magnetic iron, glass fill, bronze fill filaments, and more.

— Print Speed: Up to 100mm/s

Pros:

— Auto-calibrated print bed

— Can store up to 1,000 models on its internal storage

— WiFi-enabled

— Includes two spools of PLA filament.

Cons:

— Expensive

If you're serious about getting into 3D printing, and don't want to go through the process of buying an entry-level printer and then upgrading it in a year or two, Robo's E3 is the one to get. It's roughly the same size and weight as our other 3D printer recommendations, but it can work with a lot more materials.

This gives you the freedom to create 3D prints that wouldn't be possible otherwise, especially if you're making objects that require different elements, like glass and metal. If you plan on printing the same objects over and over again, the E3's built-in storage will come in handy. That's doubly true if you accidentally delete a model on your computer.

If you plan on printing the same objects over and over again, the E3's built-in storage will come in handy. That's doubly true if you accidentally delete a model on your computer.

While these features add to the E3's cost, but it's still a good machine for beginners because of its auto-calibrating print bed, which improves the odds of you ending up with a satisfying print rather than one that's lopsided. By reducing the number of prints you have to discard due to quality issues, the Robo E3 is more forgiving for new 3D printer users, and a lot less wasteful. Novice 3D printers will also benefit from the two-hour online training course that comes with this printer.

It's hard to overlook the Robo E3's up-front cost, but again, it's so capable relative to the other 3D printers we're recommending for beginners that it's well worth the price. This should be the only 3D printer you'll ever get, unless you start needing one for commercial use.

Things to Consider Before Buying a 3D Printers for BeginnersThe best 3D printers for beginners give you the power to create on-demand. But as more 3D printers flood the market, it can be hard to choose the best one for your needs. When shopping for the best beginner-friendly 3D printer, consider the printer dimensions, build volume, compatible materials, and ease of use.

But as more 3D printers flood the market, it can be hard to choose the best one for your needs. When shopping for the best beginner-friendly 3D printer, consider the printer dimensions, build volume, compatible materials, and ease of use.

While consumer 3D printers are heavier than your standard all-purpose printer, they’re still a reasonably small size. Since they’re made for at-home use, most have a compact footprint to fit on a desktop or counter.

Consider the printer size and weight and how it will fit in your space. Keep in mind that the size of the printer is related to the build volume the printer is trying to accommodate; a larger printer will be able to create larger items, and a smaller one will be limited to smaller items.

Build Volume3D printers can be used to create just about anything, from giant 3D models to tiny trinkets, but at-home 3D printers are much smaller than the ones you might find in a design studio.

To help shoppers make a suitable choice, consumer 3D printers include a build volume measurement that describes the maximum width, height, and length of the print area. The build volume roughly determines the maximum size model that the printer can create. Consider the type of items you are hoping to print and choose an appropriate build volume from there.

Compatible MaterialsMost consumer 3D printers available today use fused deposition modeling (FDM), where material (usually plastic filament) is melted and extruded through a nozzle to create thin layers that make up a model. Other 3D printers, like resin printers, use curing processes, like UV light, to harden materials by layer.

The compatible materials vary by 3D printing method, but can include plastics, metals, polymers, resin, ceramics, plaster, and glass. When shopping for a 3D printer, check whether the ones you’re considering allow you to build creations with your preferred materials.

Ease Of Use3D printing can get overwhelming for those who aren’t tech-savvy, so as a beginner, it’s important to find a 3D printer that is simple to use. A beginner-friendly 3D printer should have a simple setup process, easy refilling process, and intuitive controls.

A beginner-friendly 3D printer should have a simple setup process, easy refilling process, and intuitive controls.

Features like a touchscreen interface, print resume functions, robust safety features, and a heated bed (which can ensure a well-made model foundation) can make a 3D printer more user-friendly. Some printers also come with included printing materials, so you can get started right away.

3D printers can include other convenient perks, like quiet operation, built-in cameras to monitor printing, and Wi-Fi connectivity so you can print and monitor progress from anywhere. Buying from a company with easy-to-reach customer support or an active online community is also a nice perk, in case you need to do any troubleshooting down the road.

FAQsQ: What brand of 3D printer is the best?There’s no singular best brand when it comes to 3D printers. We’ve selected our top picks from several reputable brands in the 3D printing industry. The brands on this list create quality 3D printers with user-friendly features that will appeal to beginners.

The brands on this list create quality 3D printers with user-friendly features that will appeal to beginners.

Yes. On a basic level, you’ll want a 3D printer that fits in your space. More specifically, you’ll want a 3D printer with a suitable build volume (the maximum print area) for your needs. Of course, as build volume increases, so does the printer size (and price).

Q: How much does a 3d printer cost?3D printers start at around $200 and can range up to many thousands of dollars. For a decent entry-level 3D printer for beginners, expect to spend between $200 to $400 for a good printer with some user-friendly features. For newbies, it’s best to start with a more basic and budget-friendly printer and you can always upgrade down the line if you decide you need more features.

Q: Is 3D printing an expensive hobby?Compared to many hobbies, 3D printing is a relatively expensive one (although it is much more affordable than it once was). Budget-friendly 3D printers still come in at a couple hundred dollars, which is a somewhat high upfront cost for testing out a new pastime. Ongoing costs include refill printer materials and possible replacements or repairs when something goes amiss. That said, you’ll be able to make some pretty cool and useful stuff, so the hobby is often well worth the price.

Budget-friendly 3D printers still come in at a couple hundred dollars, which is a somewhat high upfront cost for testing out a new pastime. Ongoing costs include refill printer materials and possible replacements or repairs when something goes amiss. That said, you’ll be able to make some pretty cool and useful stuff, so the hobby is often well worth the price.

It depends. Do you plan to print industrial-size parts or small baubles? A good printer size is subjective and will depend on your needs. Most at-home 3D printers are small enough to fit on a desk or counter, and so are often best for smaller projects. When shopping for a 3D printer, consider its build volume, which will give you a better idea of what size models the printer can produce.

Related: Looking for more options? Here's our roundup of the best 3D printers for every kind of project.

Final Thoughts on the Best 3D Printers for BeginnersThe Creality Ender 3 Pro 3D Printer is one of the most highly-rated and popular picks for beginners. It’s a solid, budget-friendly printer that is user-friendly and creates high-quality models.

It’s a solid, budget-friendly printer that is user-friendly and creates high-quality models.

This post was created by a non-news editorial team at Recurrent Media, Futurism’s owner. Futurism may receive a portion of sales on products linked within this post.

Share This Article

3D printing market 2022: 84% of users are optimistic

Analytics and business

Experts recommend

Author: Semyon Popadiuk

Author: Semyon Popadiuk

3D printing is increasingly used in the production of finished parts | Helping Companies Achieve Sustainability | Clear priorities: innovation and flexibility | Unleashing the potential of 3D printing and its reliability | Additive Manufacturing Strategies | Conclusion: main results of the study

Sculpteo, a leader in additive manufacturing and digital manufacturing, has released the eighth edition of its State of 3D Printing report. This annual global survey is conducted to provide information on the state of additive manufacturing needed to inform and improve business strategies. In keeping with its mission of being environmentally responsible, 3D printing attempts to meet the needs of manufacturing by replacing traditional manufacturing resources whenever and wherever the opportunity arises.

In keeping with its mission of being environmentally responsible, 3D printing attempts to meet the needs of manufacturing by replacing traditional manufacturing resources whenever and wherever the opportunity arises.

Each year, Sculpteo collects data from the additive manufacturing industry, which it then analyzes to identify key trends in this rapidly growing industry. In 2022, the report is international, with the majority of respondents based in Europe (63%) and the US (23%). The main users of 3D printers today are management, engineers and designers.

Can 3D technology help you optimize production in your organization? At iQB Technologies you can order the following services : expert advice, ordering and implementation of 3D solutions, training, test 3D printing/3D scanning, site visits.

The survey results reflect a growing level of maturity across sectors, with 39% of users having between one and five years of 3D printing experience, and 27% using the technology on a daily basis.

The industry with the most 3D applications is consumer goods (14%), followed by industrial goods (13%) and education (11%).

The industry with the most 3D applications is consumer goods (14%), followed by industrial goods (13%) and education (11%). “This year we decided to highlight an important issue that concerns all industries and which we ourselves consider one of the main challenges: sustainability,” says Alexandre d'Orsetti, CEO of Sculpteo. “I am glad to say that this technology has great prospects, and I am proud that I can contribute to the future of 3D printing.”

3D printing is increasingly used in the production of finished parts

Additive manufacturing confirms its status as a real manufacturing solution used for research, education, R&D and end use. We see that the majority of respondents use 3D printers when they need less than 1000 parts. Indeed, this technology offers significant advantages when it is intended to create a small batch of products. 40% of advanced users use 3D printing for small series, and up to 18% for mass production.

Goals and results

Detail optimization is becoming an increasingly important task for 3D printing users. One-fourth of those surveyed use additive manufacturing to speed up the product development process, consistent with the heavy use of 3D printers for proof of concept and prototyping.

One-fourth of those surveyed use additive manufacturing to speed up the product development process, consistent with the heavy use of 3D printers for proof of concept and prototyping.

The results also show that 47% of respondents use 3D printers to create mechanical parts, and 28% use them to manufacture consumer goods. This level of growth in 3D printing is a clear indication of the progress being made in technologies, materials and post-processing solutions.

Materials and technologies

When it comes to choosing materials for 3D printing, users are interested in accuracy, special technical properties, and cost-effectiveness. More sustainable materials are also important to 81% of users.

Industrial 3D printing technologies such as those based on sintering or powder melting (SLS, MJF) are increasingly used internally; enterprises are fully aware of the potential of these technologies and are investing in equipment. However, most companies do not own their own equipment and still order 3D printing of plastic, photopolymer and metal parts from contractors.

Helping companies achieve sustainable development

40% of the companies surveyed are looking for more environmentally friendly methods and materials for the production of their products. 41% say 3D printing is helping them achieve their sustainability goals. Another very impressive figure follows from the report. 61% of manufacturers say that a huge advantage of additive technologies is that they help them make products according to individual customer requirements.

Also, with 3D printing, there is no need to resort to many different resources, since it is not necessary to use several materials to create certain products in traditional ways. The need to use multiple materials is contrary to the concept of sustainable production. Most manufacturers find that additive methods help them implement sustainability policies because they make it unnecessary to maintain inventory in the enterprise.

Clear priorities: innovation and flexibility

Additive manufacturing is able to meet any need for product customization. 84% of respondents are optimistic about the future potential of additive manufacturing. When asked about the future potential of 3D printing, 58% of survey participants were optimistic that it would play a significant role in manufacturing, business and everyday life. 26% of respondents believe that 3D printing will only have an impact on manufacturing and business. The flexibility and new innovative possibilities offered by 3D printers have the potential to completely change the rules of manufacturing.

84% of respondents are optimistic about the future potential of additive manufacturing. When asked about the future potential of 3D printing, 58% of survey participants were optimistic that it would play a significant role in manufacturing, business and everyday life. 26% of respondents believe that 3D printing will only have an impact on manufacturing and business. The flexibility and new innovative possibilities offered by 3D printers have the potential to completely change the rules of manufacturing.

Unleashing the Potential of 3D Printing and Reliability

Respondents consider the reliability and environmental friendliness of materials to be priority goals. 61% of users say that custom manufacturing is the most reliable and sustainable benefit that 3D printing provides. 47% of users say that 3D printers reduce the need to use a lot of resources because some designs cannot be implemented using traditional methods.

According to the results presented in the Sculpteo report, 59% of users want to be able to use more sustainable materials. This demand is driven by the growing number of bio-based materials that have emerged in recent years. According to users, three aspects of 3D printing reliability and sustainability need improvement the most:

This demand is driven by the growing number of bio-based materials that have emerged in recent years. According to users, three aspects of 3D printing reliability and sustainability need improvement the most:

-

the availability of more options for recycling printed objects;

-

development of more environmentally friendly materials;

-

greater progress in powder recycling through technologies such as SLS.

Additive Manufacturing Strategies

More and more successful companies will spend more money on additive manufacturing, find exciting new opportunities and break new ground by using 3D printers to make products and not just design them. They consider this technology to be a reliable manufacturing process capable of meeting their requirements.

The majority of respondents actively use additive manufacturing, arguing that 3D printing is partially or fully integrated into their global strategy. In confirmation of the effectiveness of this technology, 89% of users consider 3D printing a strength or competitive advantage.

In confirmation of the effectiveness of this technology, 89% of users consider 3D printing a strength or competitive advantage.

The early adoption of 3D printing allows businesses to be more competitive, according to 61% of respondents who are adjusting their budgets and priorities to keep up with competitors.

Conclusion: main results of the study

-

41% of respondents say additive manufacturing is helping them achieve their sustainability goals.

-

25% use additive manufacturing to speed up product development.

-

33% believe that budget is the main factor limiting the wider adoption of 3D printing.

-

84% of respondents are optimistic about the future of additive manufacturing.

-

63% want to expand their recycling options for 3D printed products.

Material courtesy of Sculpteo. All images © Sculpteo

Free download of the full State of the 3D Printing Market 2022 report in English here

Article published on 12/15/2022, updated on 12/15/2022

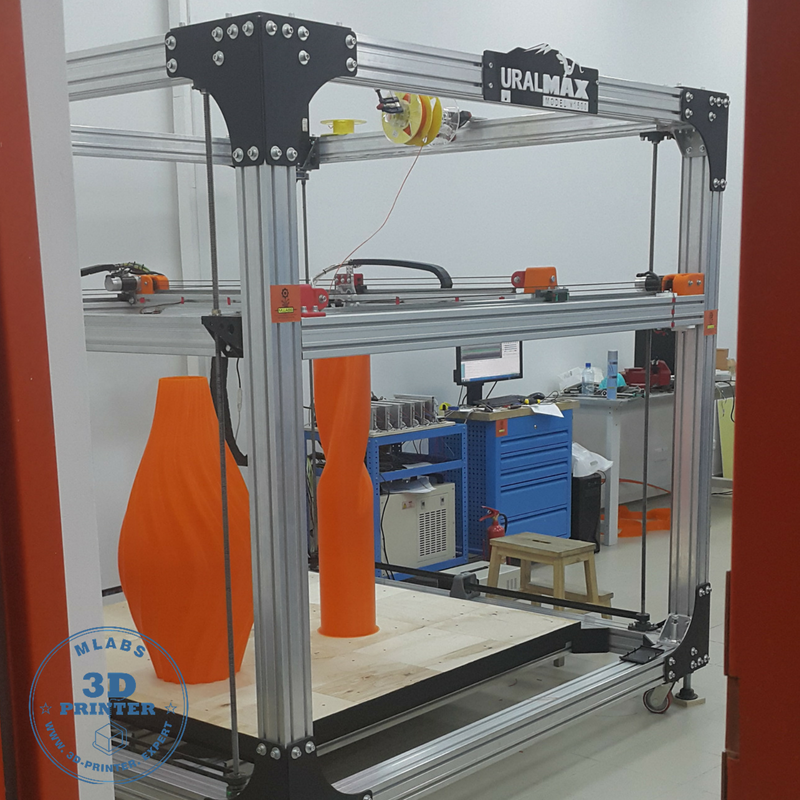

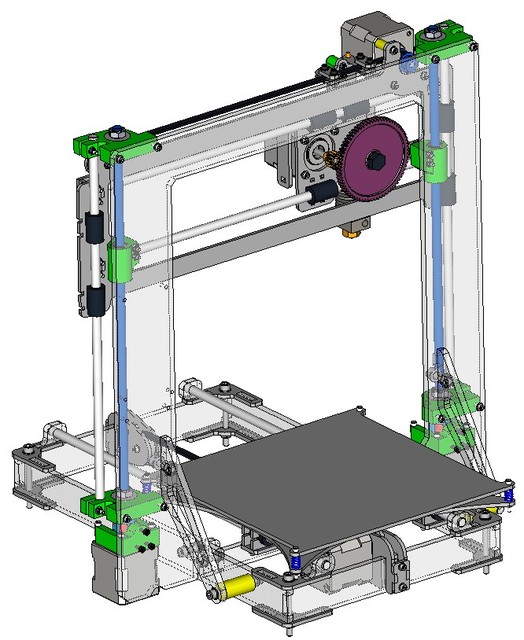

Large Modix 3D printers

Modix Large 3D Printer is the

your best next 3D printer!

- IDEX Dual Head - NEW

- Premium Components

- Heavy Duty Design

- Multiple Extras

- High Resolution

are delivered in the form of sets for independent assembly:

- Manage your configuration

- Independent service

- easily update

- within your budget

- Compact packaging

Modix Large 3D Printer is your next best 3D printer!

- Premium Components

- Heavy Duty

- Multiple Options

- High resolution

are delivered in the form of sets for independent assembly:

- Manage your configuration

- Independent service

- Easy to update

- compact packets 9006

New generation 4 November 22Modix is proud to announce the release of its new unified 3D printing platform called Generation 4 with IDEX dual head technology.

Modix continues its path to market leadership by integrating cutting edge technology while maintaining outstanding value for money.

Modix continues its path to market leadership by integrating cutting edge technology while maintaining outstanding value for money. Generation 4 upgrades the Modix offering with new features such as printing models with internal geometry, faster print speeds, faster post-processing times and higher reliability.

Learn more about the fourth generation of Modix - click here.

IDEX allows you to print models with internal geometry, provides high quality surface finish while reducing post-processing time.

View detailsIDEX Filament Changer saves time and improves print quality by automatically switching filament spools without stopping the printer.

MoreThe Griffin printhead delivers high print quality, impact resistance, easy replacement and higher print temperatures than ever before.

Learn moreA set of reliability sensors designed to save time on print jobs. It can detect filament runout, under extrusion and clogging.

Learn moreFull set of automatic calibration tools including: bed tilt calibration, bed leveling, gantry leveling and z-offset calibration.

Learn moreDon't limit your future ideas, get a bigger printer today!

Premium Components

Controller

UKExtruder Sweden

U.S. Movement

Drivers of the German step engine

power voltage

TaiwanAlignment of the South Korea

Printing Taiwan Movement

Hands Taiwan0003

Signal wires Germany

Professional Features

For more information about our large 3D printer technology, please CLICK HERE

IDEX

Dual independent extruders

Touch screen

7" touch screen and web interface for remote monitoring

Duo Controller

Advanced 32 bit electronics with web based management

Active air filter

Protect your health with a set of charcoal and HEPA filters.

(Optional)Shielded wires

IGUS signal cables for greater reliability.

Magnetic bed

Easily remove printed objects when finished.

(Optional).Fault Detector

Detect hardware failures and prevent failures.

High Quality

One of the most significant advantages of Modix large-scale 3D printers is carefully selected premium components, each of which contributes to high quality printing. These components include: Bondtech Extruder (Sweden Made), E3D Nozzles (UK Made), DUET3D Controller (UK Made), Trinamic Motor Drivers (German Made), IGUS Shielded Signal and Power Wires (German Made), Alcoa Cast Aluminum Plate Mic-6 (made in USA), Meanwell power supply (made in Taiwan) and more. Nearly every component in our large format 3D printers contributes to print quality and reliability, which is why we choose the highest component standards, even for the smallest parts, such as aircraft grade power adapters, durable castors, fiberglass reinforced belts, etc.

Heavy Duty

A key design factor in our large scale printers is the heavy duty design. Because our large format 3D printers are supplied as DIY kits, we place great emphasis on ensuring that the end user achieves the highest levels of accuracy and consistent calibration. This includes a very detailed online build guide with 3D models that can be rotated and scaled, several detailed video tutorials for each step, and more. In addition, we provide our clients with calibration methods and tools that help make this process as successful and as smooth as possible.

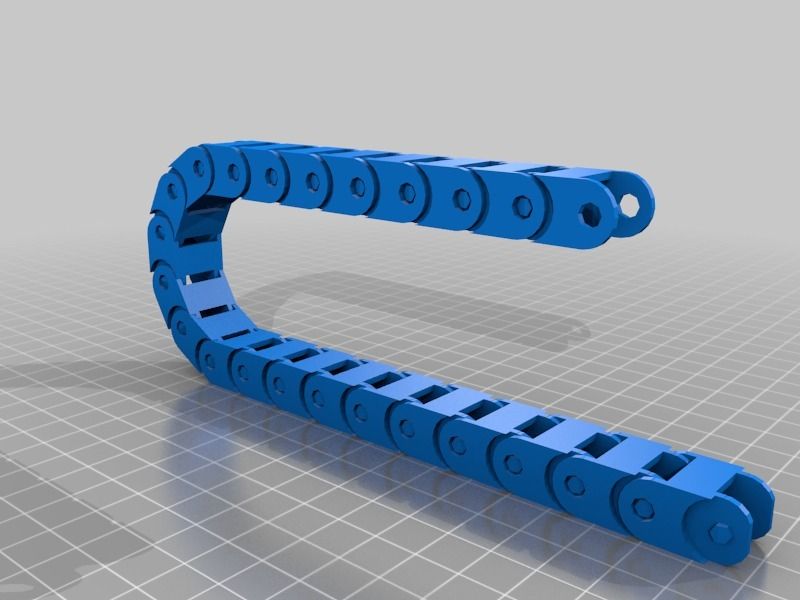

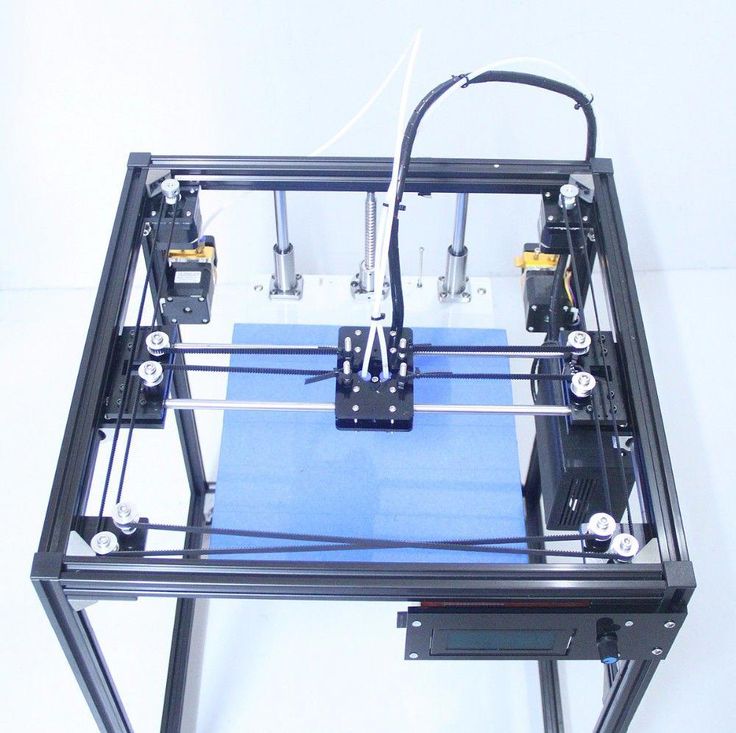

IDEX Dual Extrusion

IDEX's dual print head technology allows internal geometry to be printed using a dissolvable support filament. Once completed, you can dissolve the support material and enjoy high-quality results without the tedious manual removal of the support. With tear-off support, you can quickly remove the support immediately after printing is complete. In addition, you can enjoy the smooth surface of the bottom surfaces.

With a secondary support thread, you can maintain zero distance between dense support layers and the model itself, so the surface will be much smoother than when printing support from the same material.

With a secondary support thread, you can maintain zero distance between dense support layers and the model itself, so the surface will be much smoother than when printing support from the same material. Customizable Platform

Modularity is our flagship concept. In fact, the Modix brand is called "modular technology". At Modix, we're constantly making new optional add-ons available to easily add to your printer, including air filters, multiple printhead configurations, and more. There are several additional setup guides on our customer's online services portal.

Wide Choice

Our Griffin printhead offers a wide range of nozzle and heater block configurations. Modix offers three heat block sizes: the default high performance Griffin hot end, the short E3D-V6 hot end for detailed fine prints, and the E3D Super Volcano for rough and fast 3D projects. Each of the thermoblocks has several options for nozzles, some of them are offered as part of our set.

Other materials can be purchased directly from the E3D online store, such as high-quality hardened steel nozzles that can print with abrasive filaments (such as filament containing carbon fiber).

Other materials can be purchased directly from the E3D online store, such as high-quality hardened steel nozzles that can print with abrasive filaments (such as filament containing carbon fiber). Open Architecture

Our customers are not locked out! Modix believes in freedom of choice, especially for passionate innovators. Users can select filament from any source and use a variety of modeling and slicing software solutions to suit their needs. We recommend the Simplify3D slicing software, but recognize that users may have other software preferences such as Cura and Slic3r. They also work great and are compatible with our larger 3D printers. Our customers are provided with print profiles for each of these slicing software packages.

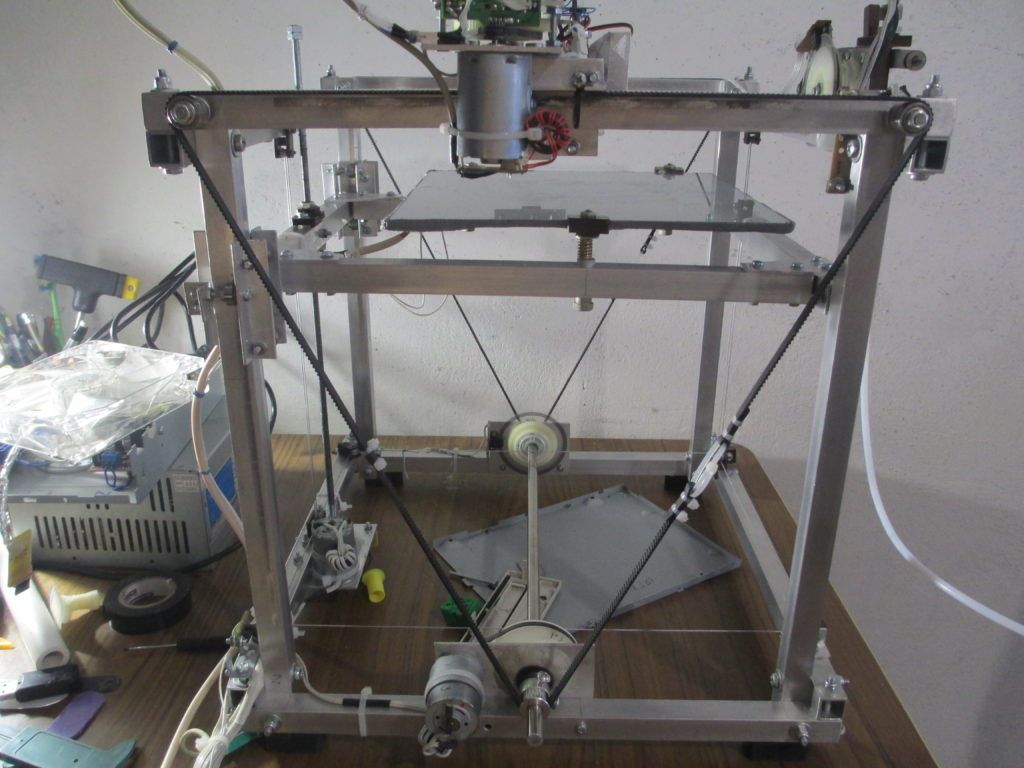

Self Assembly

Self assembly is the preferred method of purchasing a 3D printer for many professionals for several reasons. Practical approach - you build your own machine to better understand the motion system, print head and calibration.

You will gain invaluable insight into how to maintain your printer and how to upgrade it in the future. Just like your PC's operating system, Modix large format 3D printers are specifically designed to be customized and adapted to your specific needs.

You will gain invaluable insight into how to maintain your printer and how to upgrade it in the future. Just like your PC's operating system, Modix large format 3D printers are specifically designed to be customized and adapted to your specific needs. Future Ready

We are constantly developing and innovating, so when you buy a Modix 3D printer, you are actually investing in a platform that can be upgraded from time to time. Owners of earlier versions are now offered the benefits of our latest version (Generation 4.0). This alone improves the long-term sustainable use of the printer and increases your return on investment.

Large Benefits of 3D Printer

Experienced 3D printer users who already own one or more small desktop 3D printers and are now looking to expand their printing capabilities should consider the following unique advantages of large format 3D printers:

1. Printing large, one-piece 3D models makes them stronger.

2. Printing models as one part also saves post-processing time. There is no need to fit smaller pieces together or try to hide a seam.

Printing models as one part also saves post-processing time. There is no need to fit smaller pieces together or try to hide a seam.

3. Another unique advantage of the large printbeds is the fact that you can print several smaller items in one batch. Batch production can be set up to complete one object before starting another ("sequential printing") for greater reliability.Premium Support since 2015

Modix prides itself on its prompt and professional support!

We believe that any product is only as good as its service, and since the beginning in 2015, we have worked hard to maintain this concept. If received, help requests are cleared daily. If necessary, videoconferencing sessions are scheduled to better understand the ground situation. This saves time both in understanding the problem and in quickly finding a solution.Reviews

Mr. Brian Grimm

Engineering Garage USA

BIG-60 B3Mr. James Lowick

Australia

BIG-60 B3MR.

Jeff Raymond

Jeff Raymond

Real Martian USA

BIG-120V3Frank 3D Print

Lab USA

BIG-60 V3 (Open Mode)Use Cases

Canon Restoration 1.6 meters

Made in IrelandRobot housing parts

Made in GermanyMotorcycle engine cover

Made in Czech RepublicBronze cast

Made in TurkeyGoodyear Farm Tire

Made in USACutter cover

Made in IsraelPCB maker

Made in FranceProsthesis cover for high legs

Made in Portugaltrusted By

Aerospace

Automotive

Protection

Production

Production

Educational

Get an overview of our new product:

The product overview includes a detailed technical review, updated specifications and answers to frequently asked questions, including how to print at high temperature, software comparability, and more.

Learn more