3D printing house uk

Building for Humanity to construct UK's first 3D printed homes in Accrington

0Shares

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

Non-profit housing restoration and construction firm Building for Humanity has announced plans to build the UK’s first 3D printed homes.

As part of the £6 million Charter Street regeneration project in Accrington, the company plans to COBOD 3D print 46 new energy-efficient homes. Once built, the housing is expected to be marketed as more accessible lodgings for veterans and low-income families in the town, who can’t currently afford to rent or buy there.

“Our aim is to ensure quality housing is accessible to everyone through our unique affordable housing model,” said Building for Humanity Founder Scott Moon. “The model is simple, to create a charitable housing institute that is driven by human fulfilment and wellbeing rather than profit. All surplus profits go to our chosen charity partner, Homes for Humanity, meaning it goes into the community to provide housing, support and training.”

Building for Humanity’s proposed Charter Street homes. Image via Building for Humanity.“Ultimately this development is about so much more than housing, it is about people and giving them the opportunity to thrive.”

Building for Humanity

Working from its offices in Accrington, Cornwall and Newark, Building for Humanity is a Community Interest Company (CIC) that’s dedicated to tackling homelessness and assisting those facing fuel poverty. As well as seeking to help families and individuals on low-income, the firm has made it its mission to assist ex-military personnel, by housing them and involving them in its home-building activities.

However, not just satisfied with building homes for the disadvantaged, Building for Humanity prioritizes doing so sustainably. In practice, this has led the company to focus on retrofitting homes with insulation, new boilers and green energy-generating solar panels, to help residents teetering on the brink of fuel poverty.

To assist those already without a home, Building for Humanity has also turned to 3D printing, by pledging to use the technology in the construction of new high-quality, low-cost homes in Accrington. In future, the firm says 3D printing can “reinvent home ownership” by enabling the creation of low-energy, high-performance housing, which is affordable enough to be “in the reach of every person in the UK.”

Building for Humanity’s Whalley Road redevelopment site. Photo via Building for Humanity.A UK-first 3D printing initiative

The Charter Street project will see Building for Humanity work with partner Harcourt Technologies (HTL) to transform a disused piece of land into a ‘Community Hub.’ HTL is a COBOD partner that uses its technologies to offer construction services, such as those related to equipment leasing, servicing, training, R&D and site development.

Working with Building for Humanity as part of its latest project, the firm says it now aims to construct the “largest printed building of its kind in the whole of Europe. ” When ready, the build will be divided up into a mixture of one and two-bedroom apartments and three and four-bedroom houses, interspersed with a communal garden and training hub.

” When ready, the build will be divided up into a mixture of one and two-bedroom apartments and three and four-bedroom houses, interspersed with a communal garden and training hub.

In preparation for the initiative, HTL has worked with partners Lindsay Baxter Design and Harcourt Architects at an R&D facility based inside Accrington & Rossendale College. There, the firms say they’ve managed to develop a means of deploying the technology in compliance with UK building regulations, which could facilitate its wider adoption post-project.

When it comes to the Accrington builds, it’s thought COBOD 3D printing them will reduce their construction cost by 30%, while halving their lead times. Through the efficient placement of materials, HTL also aims to cut the amount of waste produced during construction by 60%, without having to compromise on quality.

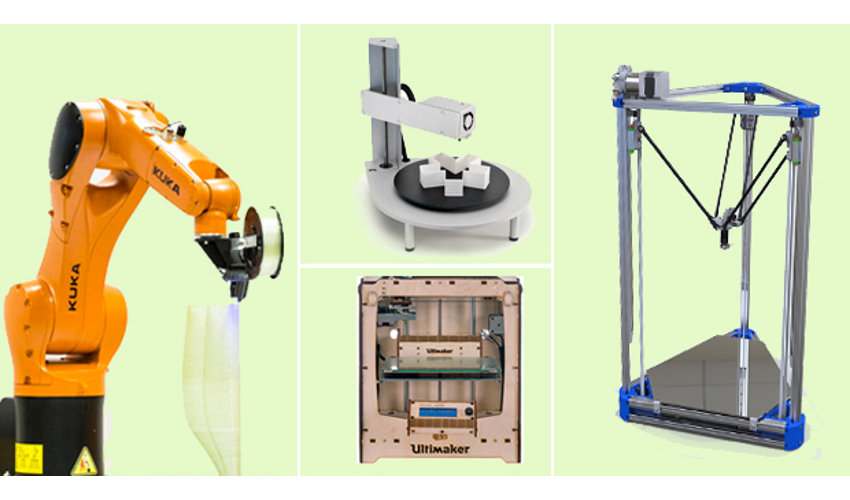

COBOD’s BOD2 3D printer. Photo via COBOD.3D printing affordable housing

Cost-efficiency is often cited as a core benefit of construction 3D printing, and the technology has already been used to build multiple affordable homes. In November last year, Alquist3D, the PERI Group and Printed Farms Florida, unveiled plans to 3D print more accessible US homes for rural communities, using COBOD’s technology.

In November last year, Alquist3D, the PERI Group and Printed Farms Florida, unveiled plans to 3D print more accessible US homes for rural communities, using COBOD’s technology.

Azure Printed Homes has also been contracted by Californian real estate firm ReInhabit to 3D print ten new eco-friendly houses. By 3D printing the buildings from recycled plastic, ReInhabit expects to realize significant cost and lead time gains, in a way that drives up its return on investment (ROI) when they’re rented out to residents next year.

Elsewhere, at the University of Tehran, researchers have proven that 3D printing homes improves energy efficiency. Having developed a novel concrete, the team say it can be 3D printed into housing that generates 400-times less CO2 emissions.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Building for Humanity’s proposed Charter Street homes. Image via Building for Humanity.

Tags Accrington & Rossendale College Alquist3D Azure Printed Homes Building for Humanity COBOD GE Renewable Energy Harcourt Architects Harcourt Technologies Homes for Humanity Lindsay Baxter Design PERI Group Printed Farms Florida ReInhabit Scott Moon University of Tehran

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

3D Printed House - Design & Build It Yourself

Looking to design your house the old fashioned way or are you among the diligent select few seeking a modernised method that is more efficient? ICON have struck the heart of 3D printing by using this advanced technology for home building.

A 3D printed house may have seemed a dream not too long ago, but now an impressive and interesting reality. A new building project has been brought to the public’s attention having been built using nothing but a 3D printer. This 650 square foot home comprises of a bedroom, living room, bathroom and kitchen. It has been put together in just one day for less than £8000! Built from the ground up one layer at a time reduces waste that is produced using conventional methods and provides a more structurally sound finish. It prints concrete which dries quickly and it has been said to be more stable than normal brick houses.

A 3D printed house of this magnitude may not seem all that practical, however this technology can be used to help poor communities in undeveloped countries. This is an unbelievable upgrade from shacks that currently inhabit millions of people in places like El Salvador.

New Story charity are currently working on raising $600,000 in order to provide a 3D printed house for 100 families in poor countries. Instead of waiting for construction advances in the global south, 3D printing is a positive step towards ending homelessness for the less fortunate. 1.2 Billion people worldwide live without adequate housing.

Image credit to Adam Brophy

Benefits of 3D printingCreate complex and detailed models that would otherwise be very time consuming to put together by hand

Architectural practises can improve communication with their clients and win more jobs

Manufactures can speed up their design process by preventing costly mistakes. Redesigning a plastic 3D printed model is far easier than a real prototype.

They are very simple to use and found in schools where students use them for education in art lessons.

Each object is printed individually which gives you maximum customisation potential, however manufactures will not benefit from economies of scale. On the other hand this flaw is offset by its extremely low cost and virtually zero waste.

On the other hand this flaw is offset by its extremely low cost and virtually zero waste.

Convert a 3D house designed in software into a real life 3D printed house model

Arcon Evo is a professional home design software which has an export function with 3D printing capabilities. First off within the software application draw your floor plans to scale using a simple drag and drop environment. The intuitive interface makes this easy, with just a few clicks you can view your new build or house extension project in photo realistic 3D.

How 3D printing can make the UK a world leader in the fourth industrial revolution

How 3D printing can make the UK a world leader in the fourth industrial revolution

The “Industrial Digitalization Review”, a UK government commissioned review on industrial digitization, suggested that The UK could add £455bn ($600bn) to its budget and create 175,000 new jobs by using Industrial 4. 0 technologies such as 3D printing. nine0007

0 technologies such as 3D printing. nine0007

With the UK leaving the European Union, many economists predict a potentially bleak future for the UK. The country is looking for any way it can reduce the damage caused by leaving the European Union. One such way is to use futuristic technology and modernize the manufacturing sector, a tactic that has been strongly recommended by initiatives such as the UK's National Supplement Strategy.

AM UK's National Strategy was only published a month ago, but the scheme's goals are now being reaffirmed by another government-backed initiative: the Industrial Digital Processing Survey.

Conducted by leading business actors on behalf of the UK Government, The Industrial Digitalization Review aims to “assess how manufacturing in the UK can benefit from increased digitalization and technological change” through a concerted effort to bring technology into the industry 4.0

The review was first announced in January and was published today. It contains some impressive numbers regarding the potential growth in the UK if it decides to continue developing areas such as 3D printing , artificial intelligence and various other futuristic technologies that could improve the manufacturing sector.

It contains some impressive numbers regarding the potential growth in the UK if it decides to continue developing areas such as 3D printing , artificial intelligence and various other futuristic technologies that could improve the manufacturing sector.

These figures include a projection that the UK could generate £455bn ($600bn) through Industry 4.0 and also create 175,000 new skilled jobs for workers who can use 3D printers and other related equipment. nine0007

The numbers are not just plucked out of thin air. The review was led by Juergen Mayer, the British and Irish boss of the German engineering company Siemens, a company that knows a thing or two about technology such as additive manufacturing.

"The business and academic community has conceptualized the far greater ambition needed for Britain to become a global leader in the fourth industrial revolution," Mayer said.

Fortunately, the 246-page review should help this organization as it neatly compiles expert advice from industry leaders like Rolls-Royce and Accenture, as well as academic institutions like the universities of Cambridge and Newcastle. nine0007

nine0007

Paper encourages government interest in potentially profitable technologies such as robotics, artificial intelligence, 3D printing , AR and VR, all of which can help the UK ahead of the competition - in China, the US and other European countries - in the race for Industry 4.0.

“The UK manufacturing sector has the potential to be a global leader in the industrial digital technology revolution,” commented Greg Clark, UK Business Secretary. “Government and industry must work together to take advantage of the opportunities that exist in this sector and promote the benefits of adopting new digital technologies as well as advanced business models.” nine0007

The ambitious goal of creating 175,000 new jobs would be achieved by training workers on Industry 4.0 equipment. The review acknowledges that some Industry 4.0 technologies negate the need for manual work in workplaces, but suggests that the net benefits of job opportunities will be significant, allowing workers in redundant positions to be retrained for new roles

Some of the specific proposals made in the Industrial Digital Survey processing, include the development of a national digital ecosystem that would provide collaborative, well-equipped workspaces where small and medium-sized businesses could access to 3D printers and other equipment without having to invest in their own expensive machines.

The government will also provide financial assistance to these small companies that want to gain a foothold in futuristic technology.

UK government to invest $25 million to build 3D printing center

Siemens 3D printer producing gas turbine parts

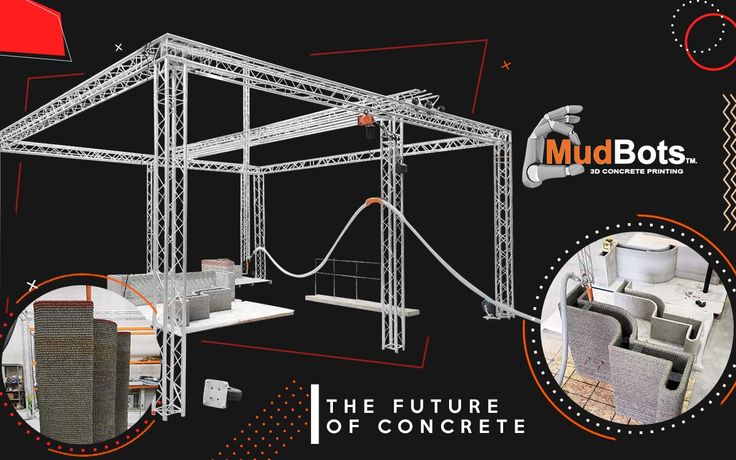

reduce production costs for difficult-to-manufacture products. According to the minister, the state will allocate 15.3 million pounds (about $25 million) for this, the BBC reported. nine00073D printing technology is the build-up of material on an object layer by layer. Historically, production has consisted not of layering, but of removing material, most often by cutting or drilling parts. The UK 3D Printing Center will be located in Coventry next to the Manufacturing Technology Center (MTC), which is funded by both public and private funds and supports new manufacturing technologies.

The 3D Printing Center will, among other things, develop new parts for jet engines, an industry in which the UK is a major player thanks to Rolls-Royce's leadership position. Its creation will also support the automotive and medical industries. However, the aerospace industry will still receive the main benefit - state investment is made as part of the authorities' strategy aimed at supporting this sector, writes the Financial Times. The strategy calls for £2bn ($3.3bn) from the government and industry to go into research to build the next generation of passenger aircraft. nine0007

Its creation will also support the automotive and medical industries. However, the aerospace industry will still receive the main benefit - state investment is made as part of the authorities' strategy aimed at supporting this sector, writes the Financial Times. The strategy calls for £2bn ($3.3bn) from the government and industry to go into research to build the next generation of passenger aircraft. nine0007

The government will also provide £15 million to a new aerospace center at MTC that will develop technologies for new materials such as carbon fiber reinforced plastics for aircraft fuselage and wing parts.

Companies will invest an amount equal to the government allocation. As a result, a total of 60 million pounds ($98 million) will go to finance both projects. The money will also be used for vocational training and advanced training for 1,000 engineers. nine0007

The UK aerospace industry is the second largest in the world in terms of revenue after the US.

The 3D printing center is due to open in 2015. The government will "feel free" to support the success of British manufacturers, Osborne said.

The government will "feel free" to support the success of British manufacturers, Osborne said.

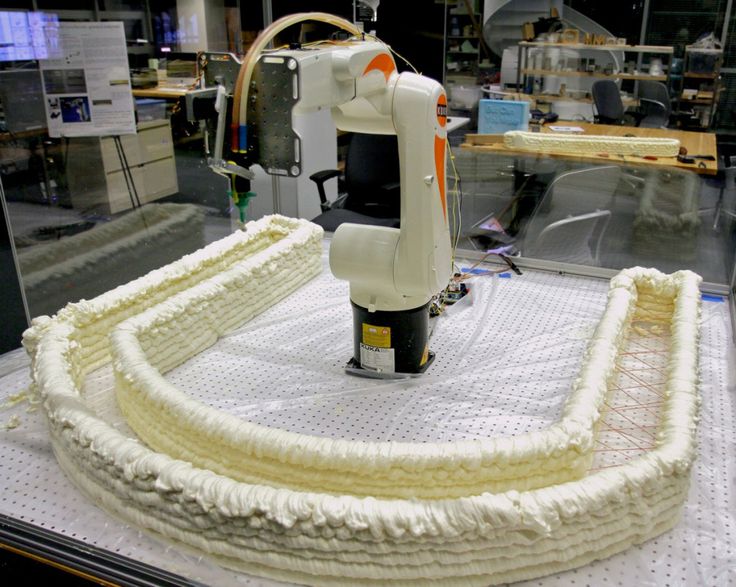

3D printing technology is beginning to be used more and more in production. At the end of last year, the German Siemens announced that from January it would use it to produce spare parts for gas turbines. This will allow it to speed up the repair work (in some cases, for example, when repairing propulsion systems - from 44 weeks to four) and reduce costs. nine0007

Siemens will be one of the first industrial companies in the world to apply 3D printing to everyday metal production. Meanwhile, a number of the largest industrial companies, from EADS to General Electric, are also preparing to introduce this technology into production; the latter said last year that it plans to produce jet fuel injectors in this way.

In July 2013, the US space agency NASA announced that it had successfully tested a 3D printed engine part for a rocket. NASA said in a statement that it normally takes a year to make, but the new technology has reduced that time to less than four months and cut costs by more than 70%.