3D food printer pizza

How the Beehex Pizza 3D Printer Works

How the Beehex Pizza 3D Printer Works Search iconA magnifying glass. It indicates, "Click to perform a search". Insider logoThe word "Insider".US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right. Read in app BeeHex's device that 3D-prints pizza.Today's robots are pretty extraordinary. They can paint incredible works of art, run lettuce farms, and even act like humans (sort of).

One Silicon Valley startup called BeeHex has even invented a bot that can 3D-print pizza.

The inventors received a $125,000 grant from NASA to develop the device in 2016, cofounder Jordan French told Business Insider at the time. NASA was looking for a bot that could easily make something delicious (as opposed to normal, unappetizing space food) for astronauts during future Mars missions.

The startup has since shifted to adapting the prototype for the commercial market. In February, TechCrunch reported that it raised $1 million in seed funding to launch its first product, a pizza printer called the Chef 3D.

Starting later this year, the Chef 3D will appear at select theme parks, sports arenas, and malls. Compared to human workers, the robot is faster, cleaner, and more consistent, French says. Only one person is needed to work the machine, which can lay down the dough, sauce, and cheese for a 12-inch pizza in one minute, before you pop it in an oven for five.

Check it out below.

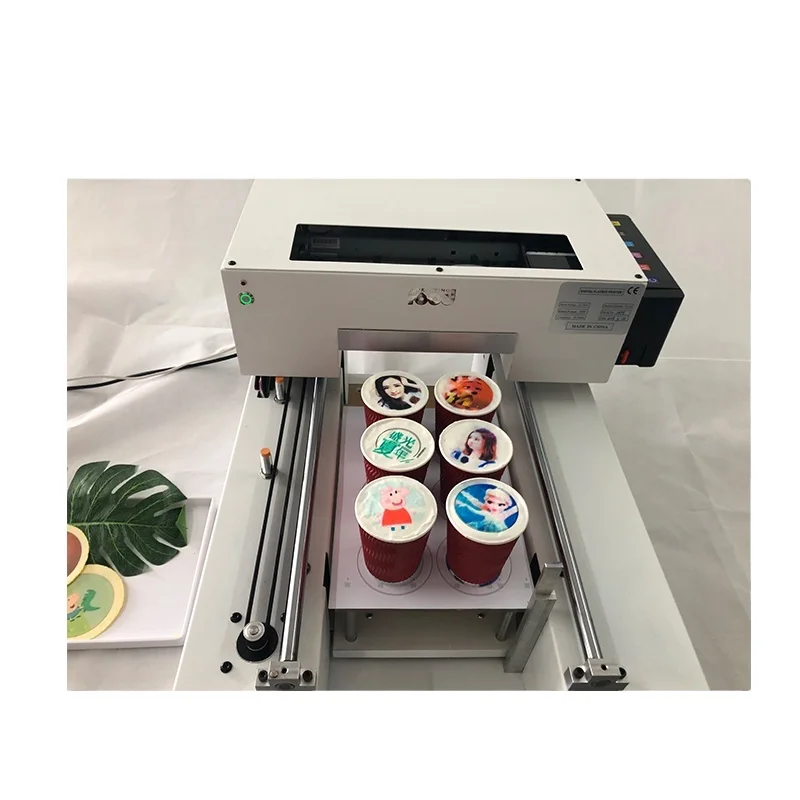

BeeHex's bot, called the Chef 3D, can produce any type of pizza in any shape, French says. Like most 3D printers, it hooks up to a computer that tells it which dough, sauce, and cheese to use.

Beehex is working with world-renowned chef Pasquale Cozzolino (pictured on the right) to design the pizza recipes. Leanna Garfield/Tech Insider

Leanna Garfield/Tech Insider Customers will also eventually be able to order pizzas through the BeeHex app, which will ping them when they're ready. First, you choose the pizza's size (10 or 12-inch), dough (plain, tomato, or gluten-free), sauce (tomato basil, pesto, or vodka), and cheese (mozzarella or burrata).

Leanna Garfield/Tech InsiderDepending on the size, toppings, dough, and location, a Beehex pizza will cost anywhere from $8 to $15. More options will be available in the future, including thicker crusts and larger sizes.

More options will be available in the future, including thicker crusts and larger sizes.

The pizza possibilities are endless, French says. BeeHex's system can take any jpg file and turn it into a pizza shape — even one that looks like Donald Trump.

Leanna Garfield/Tech InsiderEventually, Beehex will experiment with making other foods, like bagels and scones (Pizzas are the easiest food to 3D-print because they're flat).

After you place your order, the nozzle applies a layer of liquefied dough in the shape you want.

A pressurized system pushes each ingredient from the cartridges through the tubes and then out the nozzles. For harder cheeses like Parmesan, the bot knows to release more pressure.

For harder cheeses like Parmesan, the bot knows to release more pressure.

The Chef 3D then repeats the process for the sauce and melted cheese. This process takes about one minute.

Beehex 3D/FacebookWhen it's done, you pop it into a 400-degree oven for five minutes ... and voilá! Time to slice up your 3D-printed pizza.

Jeffrey HosierI tried a slice, which tasted exactly like a normal pizza.

However, the pizza did cool off very quickly due to the ultra-thin crust. After a few minutes, the slices can taste more like crackers than pizza. (BeeHex's creations are served best right after they come out of the oven.)

However, the pizza did cool off very quickly due to the ultra-thin crust. After a few minutes, the slices can taste more like crackers than pizza. (BeeHex's creations are served best right after they come out of the oven.)A post shared by Jordan French (@jordan__french)

When piping hot, BeeHex's pizzas rival those made by real chefs — maybe even better. "It has the potential to create more interesting foods, like, say, a pastry with hundreds of different layers," French says. "These are things that you just can't make with human hands."

Leanna Garfield/Tech InsiderRead next

LoadingSomething is loading.

Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Features Food future of foodMore...

3D Printed Pizza: The Tastiest Projects

If there’s still any doubt that 3D printing can be our best friend in technological progress, let it be washed away with these three words — 3D printed pizza.

The development of 3D printed foods has caught a lot of people’s attention lately, including 3D printing meat and chocolate. But the concept of a 3D printed pizza is a lot more complicated than one might think, given its relative complexity of ingredients and massive variety of styles compared to most foods.

But the concept of a 3D printed pizza is a lot more complicated than one might think, given its relative complexity of ingredients and massive variety of styles compared to most foods.

See also: our ranking of the best food 3D printers.

We also have a ranking of the best chocolate 3D printers.

With efficiency, cleanliness, and, of course, taste being the main priorities of those looking to bring 3D printed pizzas to the masses, it’s interesting to see the advancements in technology that can bring us our favorite foods in a matter of minutes.

From start-ups to NASA, we’re going to look at some of the most promising breakthroughs in 3D printing pizza, amongst other foods, and how close we are to printing one of the world’s favorite foods in our own homes.

Why 3D Printed Pizza?

There are so many different kinds of food, and even more subtypes, so why have innovators taken to 3D printed pizza as a focus? The answer is simple, pizzas are layered!

Unlike other foods that come as a mix of many ingredients, all prepared at different times or needing stirring, mashing, melding, and frothing, pizza is naturally a set of base ingredients layered on top of each other.

Because 3D printing involves depositing materials — called filaments — this makes pizza perhaps the best food to make with 3D printing, not to mention how their customizability make the delicious discs a universal love.

The Benefits of 3D Printed Pizza

3D printed pizzas can also have a beneficial impact on our carbon footprint. The ingredients involved in 3D printing pizzas have a long shelf life, and even commercially they are only ever printed to order.

3D printed foods can cater to almost any taste, too. The ingredients can be made to suit meat lovers, vegetarians, and vegans as required with little more than a flick of a switch and a care to avoid cross-contamination.

This means that there is significantly less wastage making 3D printed pizzas compared with traditional baking, which involves ingredients that need to be thrown out much sooner if they aren’t used. Many of the ingredients can be made from plentiful and sustainable proteins from plants and even insects!

Advances in 3D printed pizzas and other foods can also bring nutrition to the less fortunate. Further advances in 3D printed food technology further cuts the production costs, making the food far more affordable.

Further advances in 3D printed food technology further cuts the production costs, making the food far more affordable.

Are There Other 3D Printed Foods?

3D printed pizzas may be the most popular of the 3D printed foods around, but they are far from the only food being worked on. From ice cream and candy to burgers and steaks, 3D printed food has seen some exciting developments in recent years.

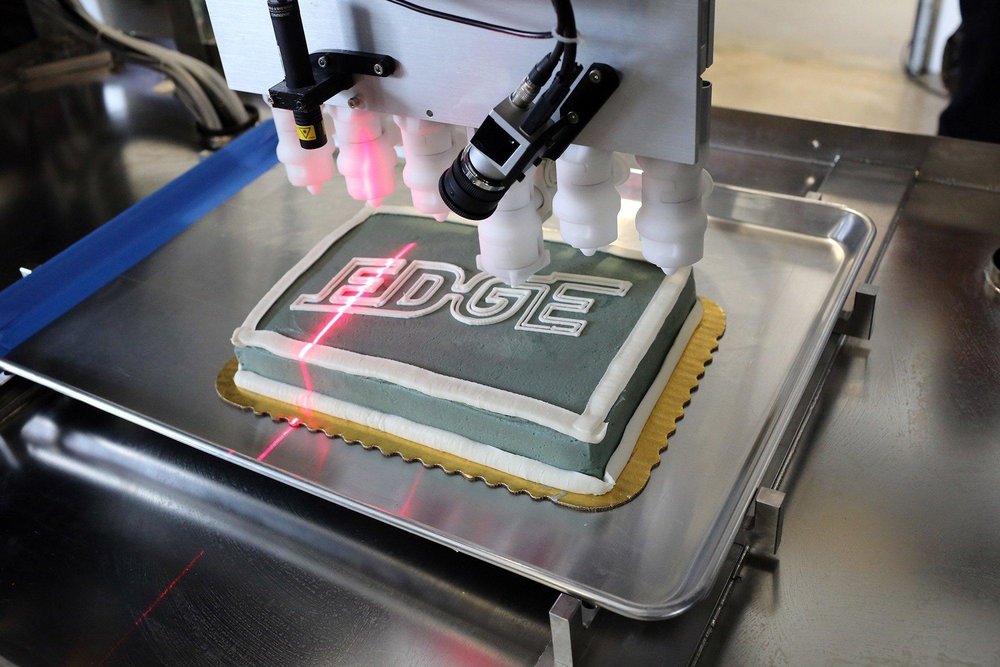

Companies like BeeHex have found a niche in creating 3D printers for dessert baking and cake decoration, and XYZPrinting have debuted a 3D printer that can make a batch of cookies in just over 15 minutes.

We also have an article of 50+ great 3D printed cookie cutters

3D printing has also opened doors for vegetarian and vegan cuisine via the advancement of 3D printed synthetic meat. This means the likes of steaks and burgers as well as pizza toppings can be made with 3D printing for meat-eaters and vegans alike.

In 2018, Starbucks even had a limited run of 3D printed ice cream in a wide variety of flavors.

Even more recently, in 2021 Polaroid launched their CandyPlay, a 3D pen that you can use to draw free-hand sweets or make edible sculptures just like those made with a standard 3D pen!

As you can see, it’s not just 3D printed pizzas that have the technological wizards of the culinary industry buzzing!

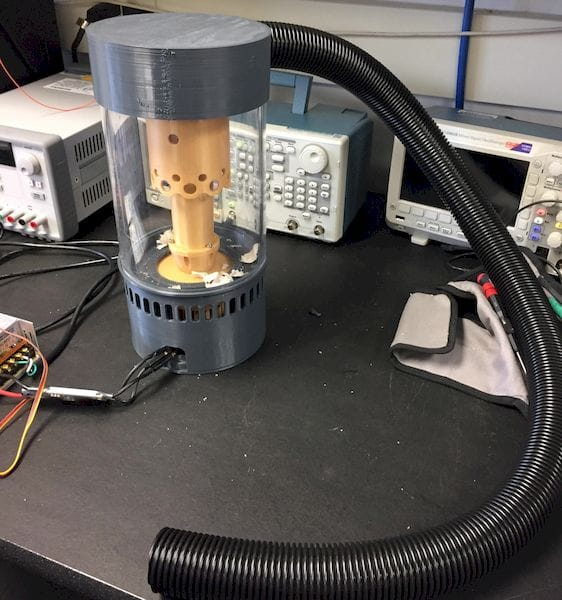

Beehex’s Chef 3D – 3D Printed Pizza in Space?

Let’s face it, no one becomes an astronaut for the food. While these days a space explorer’s diet is similar to that we have on earth, some of the simplest culinary pleasures we enjoy today are simply not feasible in space.

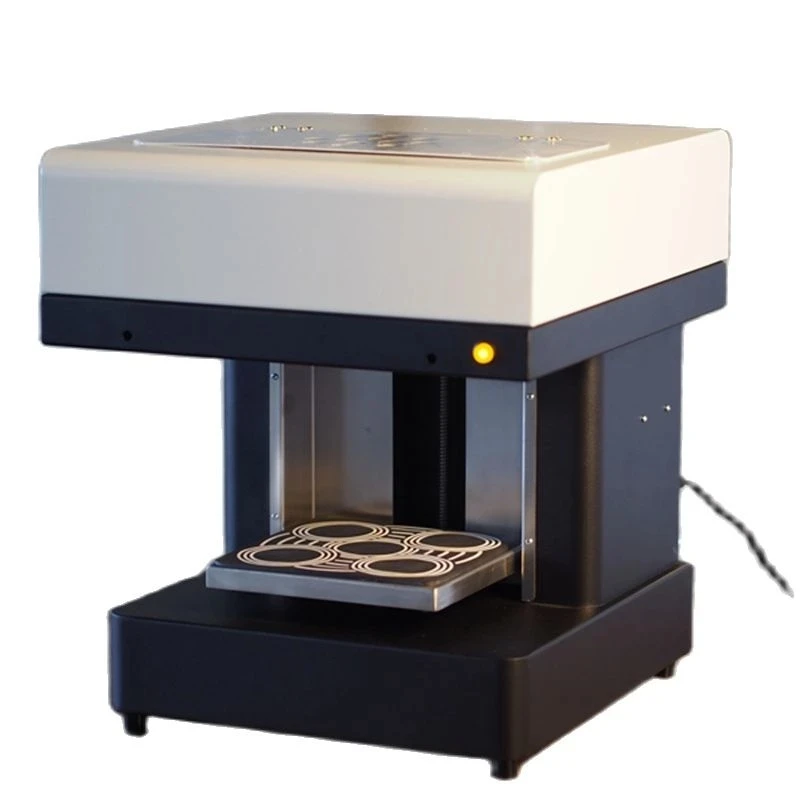

In 2016, NASA took initiative against food-related boredom by funding the now self-titled ‘NASA spin-off company’ Beehex. With a grant of $125,000 to create a machine that could 3D print pizzas in space, Beehex developed the Chef 3D, which is capable of 3D printing a raw 12-inch pizza in under a minute.

Through a crowdfunding campaign that earned a $1,000,000 dollar backing, the Chef 3D became the flagship of the company, and was even being considered for widespread commercial use. The marketability of its cleanliness, speed, and efficiency has sparked interest all over the culinary world.

The marketability of its cleanliness, speed, and efficiency has sparked interest all over the culinary world.

The Chef 3D is also self-cleaning and produces it 3D printed pizzas on the cheap, costing only around $8 per print. While it is to-date limited to only automatically printing the classic margherita, further developments in 3D printed food could see us having our own meat feasts and Hawaiians before too long!

Beehex’s Chef 3D pizza 3D printer.Though it may yet be a little while before complicated pizzas and stuffed crusts can be fully made with 3D printing, it’s easy to see why a lot of people are so excited to get a 3D printed pizza of their own.

The approximate baking time for Beehex’s 3D printed pizzas is only five minutes in a standard oven, meaning that from the moment printing starts, you’re only a maximum of seven minutes away from chowing down.

Today, Beehex prides itself on being the leaders in autonomous bakery and cooking equipment, and has seen great success in its four short years.

As well as NASA, Beehex works with the U.S. Army, the Center for Innovative Food Technology (CIFT), and Donatos; an Ohio-based pizza delivery company with a venue in the Smithsonian National Air and Space museum.

Despite their relatively short active years so far, Beehex foresees great things for the automated culinary industry, and their work on bringing 3D printed pizzas to the public is only just getting started.

Foodini – 3D Printed Pizza at Home

Beehex may be the company on everyone’s radar for their high-profile development in 3D printed food, but they weren’t the first to dabble in the intriguing art of 3D printed pizzas.

Natural Machine’s ‘Foodini’ was a 3D printer that used stainless steel extruders and a bio-safe process to make all kinds of foods, including 3D printed pizzas. It had a limited run back in 2014/2015, but the technology itself is rife for re-use and repurposing into newer machines that could have them as regular household appliances before too long.

Much like the Chef 3D, the 3D printed pizzas created with the Foodini were only capable of simple tomato and cheese, with any other toppings needed to be added manually before the pizza itself goes in the oven.The Foodini, capable of 3D printing pizza.

XYZPrinting Pizza Printer

XYZPrinting’s mantra of making 3D printing affordable to both businesses and private consumers was not to be left out of the 3D printed food market.

The Taiwanese company publicly displayed their 3D food printer during the 2015 Consumer Electronics Show (CES) in Las Vegas. The 3D printed pizzas created with their multi-purpose food printer were reportedly delicious, and was made with the same machine that was designed to make cookies and decorate cakes in any shape.

XYZ’s entry into the 3D printed food market doesn’t seem to have seen the light of day since its debut, they have maintained their status as sellers of affordable 3D printers and 3D printer accessories for both companies and individual consumers.

3D printed pizza in five minutes

News

Modern robots are becoming more diverse and gifted. They paint pictures, build houses, and are responsible for production. Take, for example, BeeHex, a unique robot chef that can print... pizza.

It should be noted that it has a fairly wide range of applications: amusement parks, sports facilities, concert venues and - of course - shopping centers, it remains only to wait until the beginning of 2017. This robot will beat any pizza maker in no time in all respects, because it is faster, more accurate and never gets tired. Only one person is required to serve it, and it will take a couple of minutes to prepare one pizza. nine0003

Now let's see how it works.

BeeHex can print pizza in any shape. Like most other 3D printers, this one is controlled by a computer program that tells it how and when to apply dough, sauce and cheese.

The developers don't say exactly which companies have their eye on BeeHex yet, but we've heard rumors that Six Flags is one of the largest amusement park operators in the world. Who knows, maybe next year we'll be buying pizza from kiosks that look like this:

Who knows, maybe next year we'll be buying pizza from kiosks that look like this:

Pizza can also be ordered through the BeeHex app, which will gladly let you know when it's ready and shipped to your address. In the application, you can choose the size (25-30 cm), dough (no additives, with tomatoes, gluten-free), sauce (tomatoes with basil, pesto or wine) and cheese (mozzarella or burrata).

Depending on the size, topping, dough and delivery address, the cost of a pizza will vary from $8 to $15. More options will become available in the future, such as thick crust pizza or mega-large pizza. nine0003

Pizza decoration options are endless. In fact, you can upload any jpg file to the BeeHex system and get a pizza, for example, in the shape of Donald Trump's head.

In the future, the developers plan to experiment with the preparation of different products, such as bagels and wheat cakes. Of course, pizza is the easiest to print, because it is flat, but no one bothers to apply the same technology to the production of other products and dishes.

Of course, pizza is the easiest to print, because it is flat, but no one bothers to apply the same technology to the production of other products and dishes.

So, let's say you made an order. The chef loads the jpg file into the system, and the dough, sauce, and cheese into the appropriate 3D printer cartridges. First, a layer of liquid dough is squeezed onto the platform according to a given pattern. nine0003

Then BeeHex does the same with sauce…

… and melted cheese.

When everything is ready, the pizza goes into the oven where it is baked at 200°C for five minutes. Now all that's left is to cut the 3D printed pizza into pieces and taste it.

It should be noted that the taste is indistinguishable from pizza cooked in a more traditional way. True, it cools quickly, because it has a very thin crust. After a few minutes, slices of such pizza taste like crackers, so it is better to eat it right away, piping hot. nine0003

nine0003

Source

Follow author

Follow

Don't want

2

“3D printer pizza? Why not?". Bobruisk engineer about 3D printing

2796

Over time, 3D printers will replace multicookers and food processors, becoming common household appliances, Bobruisk engineer Maxim Shevtsov believes.

3D engineer Maxim Shevtsov.

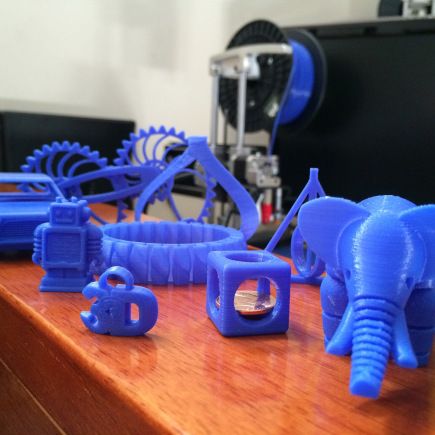

3D printing technology has opened up new possibilities in various fields of production, including gastronomy. But while the Chinese are printing entire buildings, and the British are opening restaurants with food in 3D format, Bobruisk engineer Maxim Shevtsov is using 3D printing to solve everyday problems. He claims that it will take quite a bit of time, and such printers will appear in almost every home. nine0003

First it was a hobby

3D printing Maxim became interested in 2010. I saved up money and bought my first 3D printer from a Chinese online store for $1,500. He says that he invested money in the device out of curiosity - he wanted to understand how it works and what it is capable of. At that time, 3D printing was his hobby.

I saved up money and bought my first 3D printer from a Chinese online store for $1,500. He says that he invested money in the device out of curiosity - he wanted to understand how it works and what it is capable of. At that time, 3D printing was his hobby.

– I myself am a car design engineer by education, I work at Belshina. Therefore, making a drawing of a part in 3D format is not a problem for me. It was interesting whether the printer could print all this, - says Maxim. nine0003

First I printed plastic parts for myself. Then friends and acquaintances began to turn for help, whose household appliances were out of order.

– They asked us to make various small things, without which household appliances do not work, and it is very difficult to find replacement parts, – the engineer recalls.

While we are talking, a printer is making noise behind us, printing another plastic part. Its thickness does not exceed 1-2 cm, and after 20 minutes of operation of the device, it seems that nothing has changed on the pallet where the future parts are fixed. nine0003

nine0003

– The thickness of the layer is only 0.1 mm, so nothing seems to be happening, Maxim smiles.

"Lego" is resting

The movement of enthusiasts who decided to master 3D printing on their own was only in its infancy in Belarus a few years ago. Those who are interested in 3D printers began to gather regularly in Minsk and share their experience.

- At one of these meetings we discussed how great it would be to teach people about 3D printing. By that time, I had already registered as an entrepreneur and printed 3D parts to order. I decided: why not open express courses for those who are interested in this topic? nine0003

According to Maxim, 4 people came to the first lesson. Everyone had their own goals, but in general people wanted to understand what 3D printing is and how it can be used for practical purposes.

- I taught five express lessons and then developed a robotics course for kids. We print parts for robots in 3D format.

Children, according to Maxim, take what adults think of as a fantasy as something for granted. The boys, who are 8-10 years old, under the guidance of Shevtsov, assemble real robots that can perform simple actions - move, move loads, vacuum. nine0003

The boys, who are 8-10 years old, under the guidance of Shevtsov, assemble real robots that can perform simple actions - move, move loads, vacuum. nine0003

- It's much more interesting than assembling Lego, - says Maxim.

Do-it-yourself 3D printer for $100

There are plenty of adults who are interested in 3D printing in Bobruisk as well. For them, at the time club "13:87" Maxim Shevtsov created an engineering school.

One of his students, who is almost twice his mentor's age, was so taken with the idea of 3D printing that he decided to build a 3D printer himself. And collected. nine0003

Knowing the basics of physics and electronics, making a 3D printer at home is not difficult, says Maxim. All parts for the device are freely available on the Internet. Maxim and like-minded people print all plastic components himself and are no longer surprised by the paradox: parts for a 3D printer are made on a 3D printer.

“It costs about $100,” says the engineer, adding that it is the simplest household model for printing plastic parts. Prices for professional high-precision 3D printers today are tens of thousands of dollars. nine0003

Soon people will print food instead of cooking?

The printer, bought by Maxim at one time for $1,500, today, according to him, costs several hundred:

$9-10 - the cost of 1 kg of plastic for printing parts on a 3D printer. 2-3 grams is the weight of the printed part.

5 kopecks - the cost of a part from a 3D printer.

- This technique is becoming available and I am sure that soon 3D printers will be in every home. nine0003

Maxim himself is not averse to continuing his experiments. He is interested in devices that work with polymers, but the Bobruisk engineer is not yet ready to shell out several thousand dollars for such a model.

- I'm also interested in food printers. I took, for example, and printed a chocolate bar. Need a pizza from a 3D printer? Why not?

I took, for example, and printed a chocolate bar. Need a pizza from a 3D printer? Why not?

– That is, soon people will print food instead of cooking it?

- It is possible. I think that over time, 3D printers will replace multicookers and food processors, becoming common household appliances that are available to everyone. nine0003

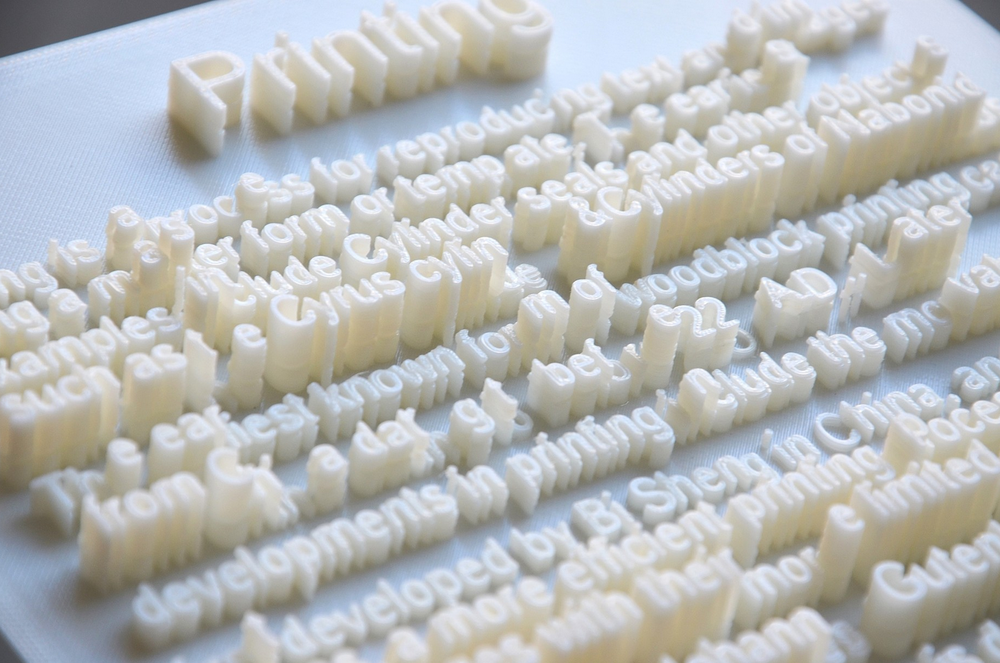

What is a 3D printer: This is a device that creates a three-dimensional object based on a virtual 3D model. Unlike a conventional printer that prints information onto a sheet of paper, a 3D printer allows you to output three-dimensional information, i.e., create certain physical objects.

How it works

3D printed parts look like puff pastry. The minimum layer thickness is 0.02 mm. The smaller the layer, the more accurately the part will be printed. And the more time it takes to make it. It usually takes about 20 hours to print a part. It is made of plastic, which in the form of rods enters the extruder of the printer and, under the influence of temperature, turns into a kind of thick dough.