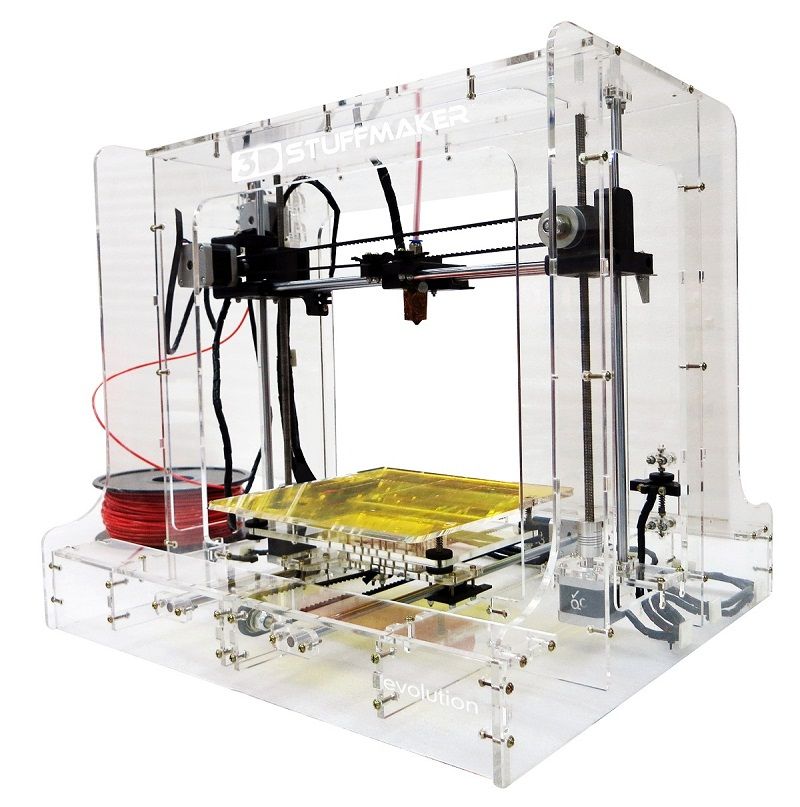

3D printer for prototypes

What is Rapid Prototyping with 3D Printing?

What is Rapid Prototyping with 3D Printing? - Stratasys Stratasys Invests in Axial3D to Make Patient-Specific 3D Solutions Available to All - Learn MoreUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

What is Rapid Prototyping?

Rapid prototyping with 3D printing is the quick, easy, cost effective way to turn great ideas into successful products. Do you need concept modeling to put your newest ideas to the test? What about functional prototyping to gauge performance before committing to costly production tooling? Rapid prototyping solutions from Stratasys will give you the flexibility to create, test and refine in ways you never thought possible so you can go to market faster than ever before.

See how 3D printed rapid prototypes are changing the way the world does business

"Every time we avoid cutting a tool, we save 8 to 12 weeks."

Randy Larson, Polaris Industries

Rapid Prototyping and Manufacturing - Quickparts

US Certifications

ISO 9001: 2015

ITAR Registered

UK Certifications

ISO 9001: 2015

EN 9100:2018

UK AS9100

7.5mil

Parts produced per year

40,000+

Projects completed

75+

Material options

Rapid Prototyping

When a single millimeter could make all the difference in the product development cycle, rapid prototyping services should be your primary choice.

But outsourcing your rapid prototyping needs only works when you partner with a company that delivers laser-focused precision at industry-leading speeds—for single or multiple iterations.

Why choose Quickparts for rapid prototyping services?

Quickparts is the rapid prototyping company you have been looking for!

01.

High Quality

With access to cutting-edge technologies and materials, not to mention our rigorous quality standards, our rapid prototyping services are guaranteed to exceed your expectations.

02.

Speed

With facilities around the globe, we are uniquely positioned to get your parts to you quickly. We even coordinate across multiple facilities- and countries- to get your job done to your specifications as fast as possible.

03.

Experience

Our application engineers have over 10 years of experience on average. This knowledge empowers us to provide accurate and effective 3D-printed prototypes of parts for many industries, all with the quality you expect from Quickparts.

04.

Rapid prototyping options

Rapid Express Metal 3D-Printed Prototypes Rapid Express Plastic 3D- Printed Prototypes

Rapid Prototyping

Metal 3D-Printed Prototypes

Plastic 3D-Printed Prototypes

case study

National Geographic Makes CritterCam Smaller and Lighter with 3D Printing

Crittercam was envisioned and invented by marine biologist and filmmaker Greg Marshall. National Geographic introduced the first generation of the Crittercam back in 1987 and has continually been improving it. The Crittercam has been used in March of the Penguins, National Geographic’s Wild Chronicles and many other National Geographic DVDs.

Read More

Explore Other

Resources

Get Started

You’re seconds away from starting your Quickparts project.

As the ultimate partner for rapid prototyping for your manufacturing needs, Quickparts delivers laser-focused precision at industry-leading speeds for single or multiple iterations. When every millimeter counts in your product development cycle, we stand out from other rapid prototyping companies with our 40,000+ projects, leading-edge equipment, and customized production strategy. The unparalleled speed of modeling and manufacturing, combined with our know-how, makes Quickparts your #1 choice when it comes to prototyping.

Quickparts has the expertise and proven capabilities to serve various applications and industries.

Producing quality parts quickly isn’t just in our name—it’s a vision made possible by an exceptional team and state-of-the-art technology that we’ve spent decades building.

Looking for accelerated prototyping but need help figuring out which method should be used for your items? We have it all to cover your rapid prototyping & manufacturing requirements. Quickparts can create items for your project using the following technologies:

Quickparts can create items for your project using the following technologies:

- Stereolithography: The most versatile and cost-effective solution when you need 3D-printed parts.

- Selective laser sintering: Best for low-volume printing of pieces with complex geometries.

- Digital light processing: The optimal choice when you need durable parts for indoor and outdoor applications and can’t afford to lose time on producing them.

- CNC machining: The most efficient method of manufacturing parts requiring exceptional dimensional accuracy, material-specific properties, and ultimate attention to surface finishes.

- Fused deposition modeling: This technology, along with cost-effectiveness and ultra-fast printing speed, allows for manufacturing temperature-resistant, chemical-resistant, and durable parts.

100% certified for rapid prototyping and manufacturing

US Certifications

| UK Certifications

|

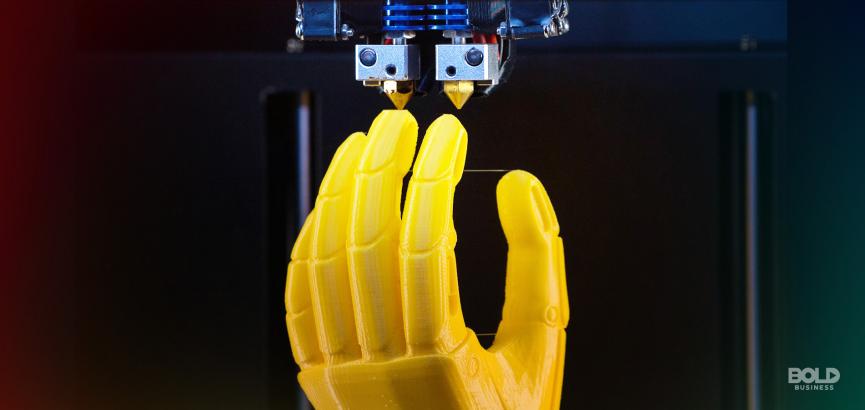

3D printed prototypes for functional testing

Testing product prototypes, individual assemblies and parts is an essential part of any production chain. With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment; nine0008

- test new design solutions;

- test strength, wear resistance;

- blow through objects in a wind tunnel.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment;

- test new design solutions;

- test strength, wear resistance;

- blow through objects in a wind tunnel. nine0008

Benefits of functional prototyping with 3D printing

- Speed.

You don't have to wait weeks for contractors to build a prototype for you.

You don't have to wait weeks for contractors to build a prototype for you. - High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems. nine0015 Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar racing engines

Ford's Nascar racing team is actively using 3D printers to upgrade and test new engine, exhaust and fuel system components.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines. This allows us to change the characteristics of cars incredibly quickly and prepare for the race.

nine0003

Victor Martinez, Chief Engineer, Ford Team

Benefits of Functional Prototyping with 3D Printing

- Speed. You don't have to wait weeks for contractors to build a prototype for you.

- High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems. nine0008

- Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar racing engines

Ford's Nascar racing team is actively using 3D printers to upgrade and test new engine, exhaust and fuel system components.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines.

This allows us to change the characteristics of cars incredibly quickly and prepare for the race. nine0003

Victor Martinez, Chief Engineer, Ford Team

Example: 3D printing a prototype stepper motor for testing

Example: 3D printing a prototype stepper motor for testing

Stratasys F370

Total-Z AnyForm 650 PRO

3DLAM Mid

UnionTech RSPro 800

0003

Stratasys F370

Total -Z Anyform 650 Pro

3DLAM MID

UnionTech RSPRO 9009

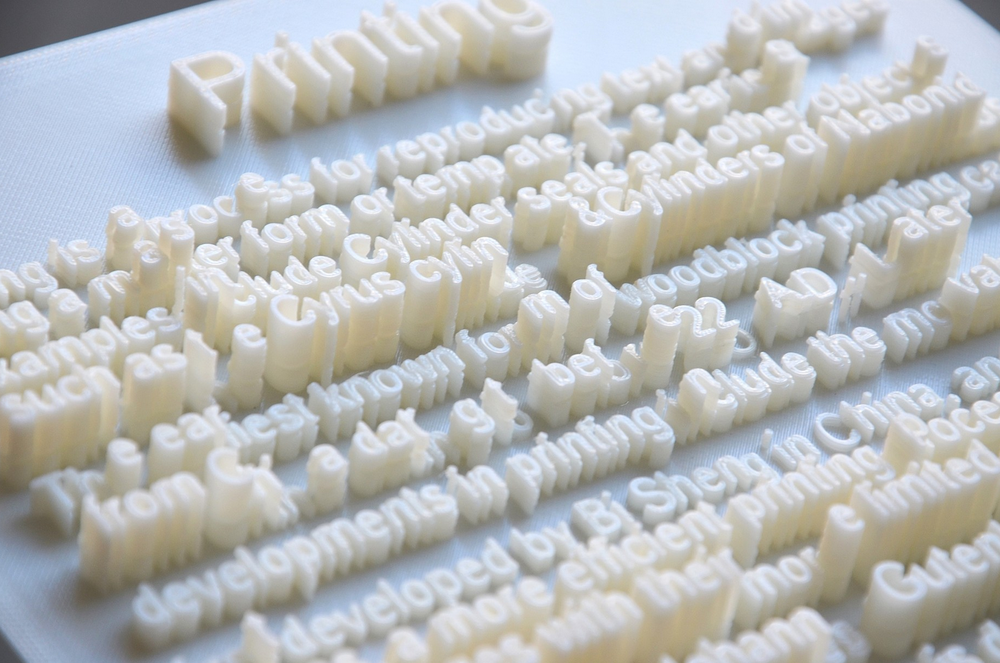

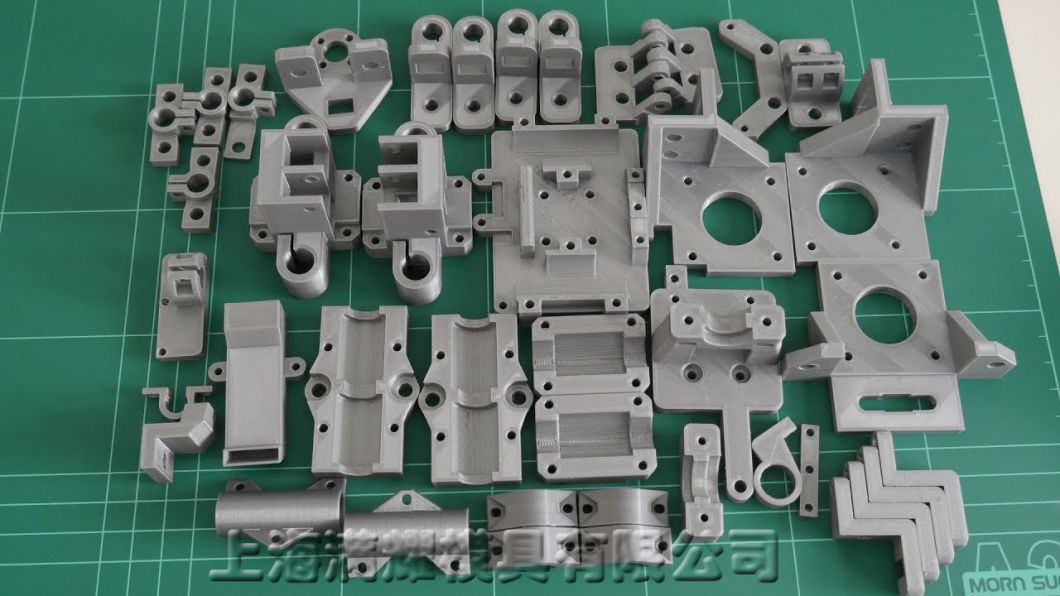

3D CREELIBICS, ADITALS - DDITITIONS OF IDITIONS OF THE DDITITIES worthwhile product without spending a lot of development resources. 3D prototyping is the ability to produce an object according to a drawing or mathematical model in full size or scale, without losing the main functions of the final product. When using metals, thermoplastics, polymer blends and composites, high quality and functionality can be achieved without resorting to classical production.

nine0003

nine0003 Prototyping 3D models eliminates the risk of inaccurate design and engineering calculations and, consequently, unnecessary costs.

3D printing a model from a simplified (non-final) material or mass production material is the optimal solution for product development. You will be able to test a sample, check its functional properties and assembly compliance, make a presentation, and correct shortcomings even before the start of mass production. nine0003

Work stepsPrototyping typesTechnologiesPrices for 3D prototyping

Work steps

3D prototyping allows you to quickly start production in several basic steps: Testing the finished product, adjusting the digital model if necessary

With a prototype, you can appreciate its appearance, ergonomics, and even experience its functionality. If the object meets the requirements of the company, it can be used as a master model or tooling for the first batch of goods - in DDM. Lab you can order the production of products by molding into silicone (from 10 to 1000 pieces) or single- or reusable production tooling.

Lab you can order the production of products by molding into silicone (from 10 to 1000 pieces) or single- or reusable production tooling.

Prototypes are most often ordered by large machine-building and instrument-making companies, developers of innovative products and designers interested in the speedy release of plastic and metal products. Leave a request, and our experts will select for you the best way to introduce additive technologies into production! nine0003

Types of prototypes

Conventionally, prototypes can be divided into several types:

- Industrial - created for large manufacturing enterprises (assemblies, housings, parts and spare parts)

- Transport - such prototypes are used in mechanical engineering, aviation, shipbuilding (from development to individual parts or components of land, water and air transport)

- Product prototypes allow you to work out the format of the future product and its packaging

- Presentation models, for example, a model of an apartment, a building or an entire city, make it possible to convey the project with its architectural features and interior design as clearly as possible.

for solving the problems of orthopedics, endoprosthesis, orthodontics.

for solving the problems of orthopedics, endoprosthesis, orthodontics.

Technologies

- FDM thermoplastic deposition modeling allows you to quickly and inexpensively produce fully functional samples of products and production tooling from a wide range of materials

- Inkjet printing with PolyJet photopolymers allows printing highly realistic color and multi-material products and tooling

- Selective laser fusion of LBM/SLM metals is often used for high-precision manufacturing of end products with complex geometry from metal-powder compositions of small fractions

- Gas-powder jet deposition using directed energy exposure DED/LMD is used for quick repair of worn surfaces of products, as well as for the manufacture of products from "scratch" from metal powder compositions

- 3DMP Arc Welding/Arc Wire Deposition - the most affordable and productive solution for the rapid production of high-stress end metal parts

- BJ inkjet printing by applying material powder and bonding it with a binder to create molds from sand-polymer compositions

- Selective SLS laser sintering for the rapid production of full-featured parts, production tooling from a wide range of polyamide and composite (polyamide-based) powders, and polystyrene powders for creating burnable master patterns for foundries

- SEAM screw extrusion hybrid additive manufacturing for rapid production of large-sized products using granular thermoplastics, including those filled with carbon fibers binder.

Learn more