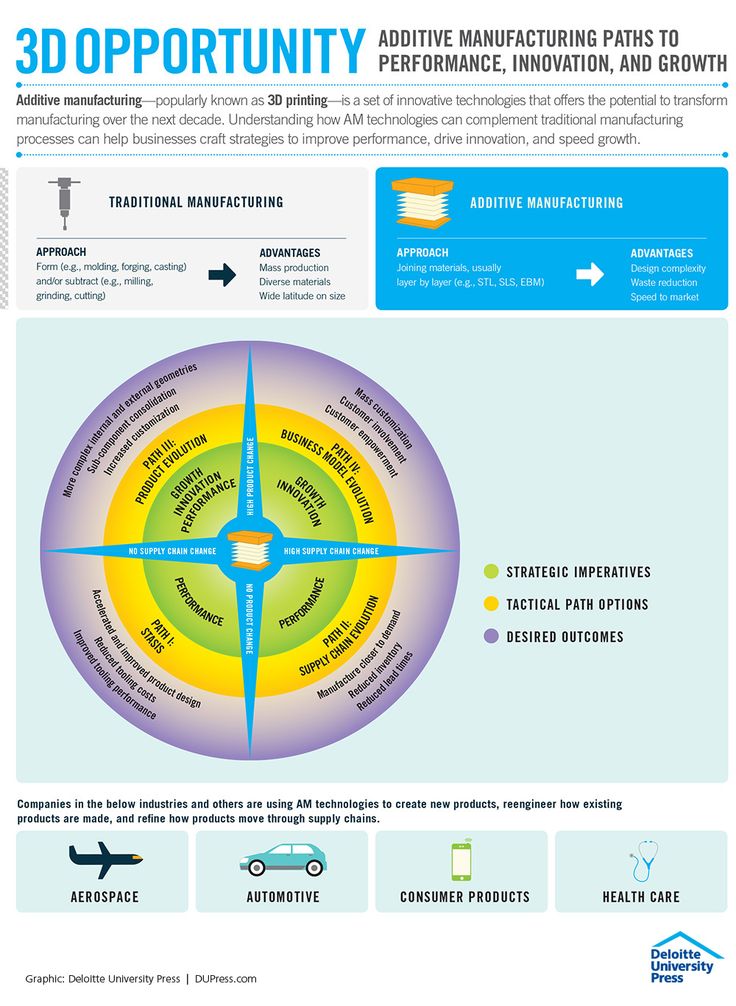

Traditional manufacturing vs 3d printing

3D Printing vs. Traditional Manufacturing: Differences and Comparison

RECENT STORIES

Video: 10 Design Tips for Sheet Metal Bending

December 16, 2022

4 min read

10 Best Metal 3D Printers: Buyer's Guide

December 16, 2022

11 min read

What Are Counterbore Holes in Machining?

December 16, 2022

6 min read

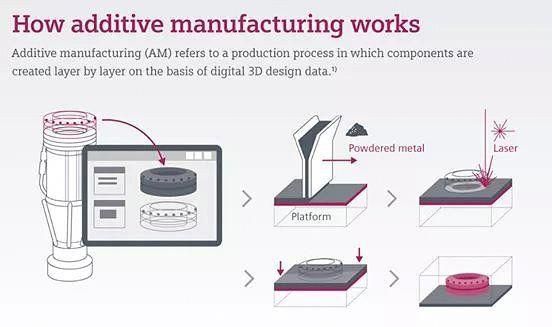

3D printing, or additive manufacturing, is a process in which 3D models are constructed from a CAD or digital 3D model. During the process, the material is deposited layer-by-layer to form the desired object. Traditional manufacturing processes, by contrast, refers to established manufacturing techniques whereby material can either be removed through grinding, drilling, or machining or cast into a mold.

Besides being different in their working principle, 3D printing and traditional manufacturing have other differences. Traditional manufacturing requires mass production to amortize the upfront and running cost of production, tooling, and labor for assembly. Whereas, with 3D printing, the manufacturing cost is independent of the quantity, making it more economical for smaller volumes. 3D printing also offers more design flexibility and the ability to manufacture a product using only one machine, which is not always the case with traditional methods. 3D printing is much faster than many traditional manufacturing methods when producing small to medium objects. This speed improvement is because of the time needed to create the tooling for casts and molds used in traditional manufacturing. However, traditional manufacturing has more material options than 3D printing.

This article will further discuss the differences between 3D printing and traditional manufacturing, present their advantages and disadvantages, and their alternatives.

3D Printing Definition and Comparison to Traditional Manufacturing

3D printing, as a technology, has advanced a lot since its invention by Chuck Hall in 1983. It was initially designed as a rapid prototyping method but has now grown into a true manufacturing process. 3D printing offers many advantages to the manufacturing industry, including design freedom, the ability to create complex designs, mass customization, and a cost-effective, low-volume production method.

3D printing offers many advantages to the manufacturing industry, including design freedom, the ability to create complex designs, mass customization, and a cost-effective, low-volume production method.

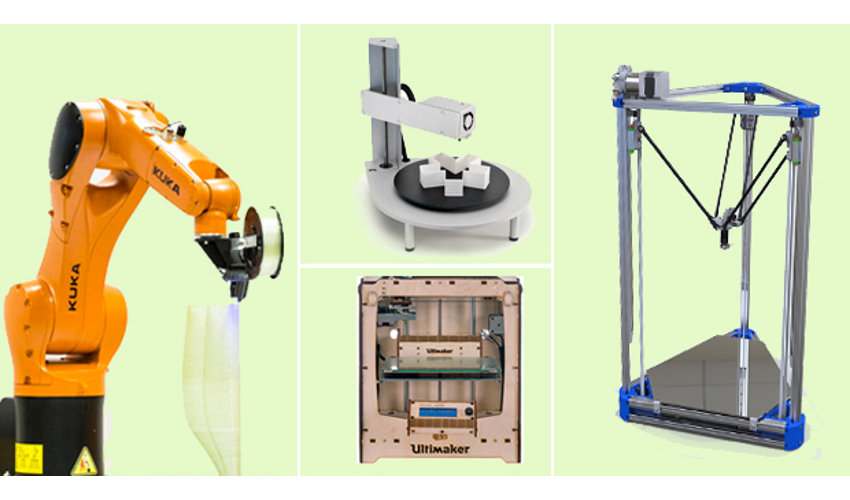

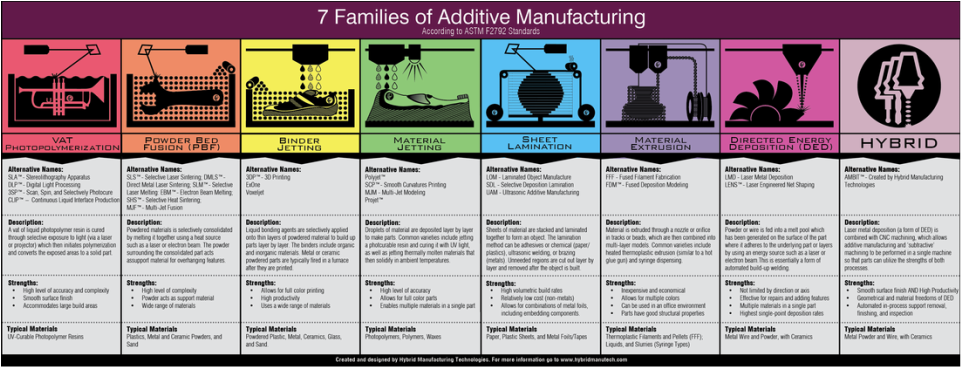

3D printing prints an object layer-by-layer as opposed to subtractive processes—like many traditional manufacturing processes—in which the product is cut out of a larger block of material. As a result, 3D printing creates less material waste. There is a wide range of 3D printing types: direct energy deposition, resin-based printers (or VAT polymerization), binder jetting, material extrusion, material jetting, powder bed fusion, and sheet lamination. All forms of 3D printing fall into one of these categories. 3D printing technology also offers a wide selection of materials that can be used to print objects. Industries that currently use 3D printing include robotics, aerospace, automotive, medical, dental, sports, and other consumer products. For more information, see our guide on What is 3D Printing.

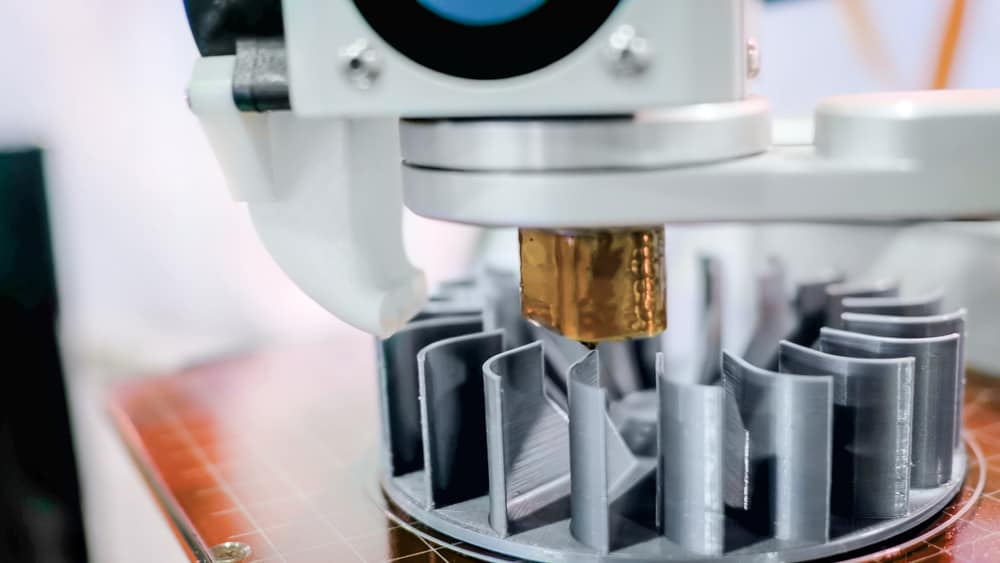

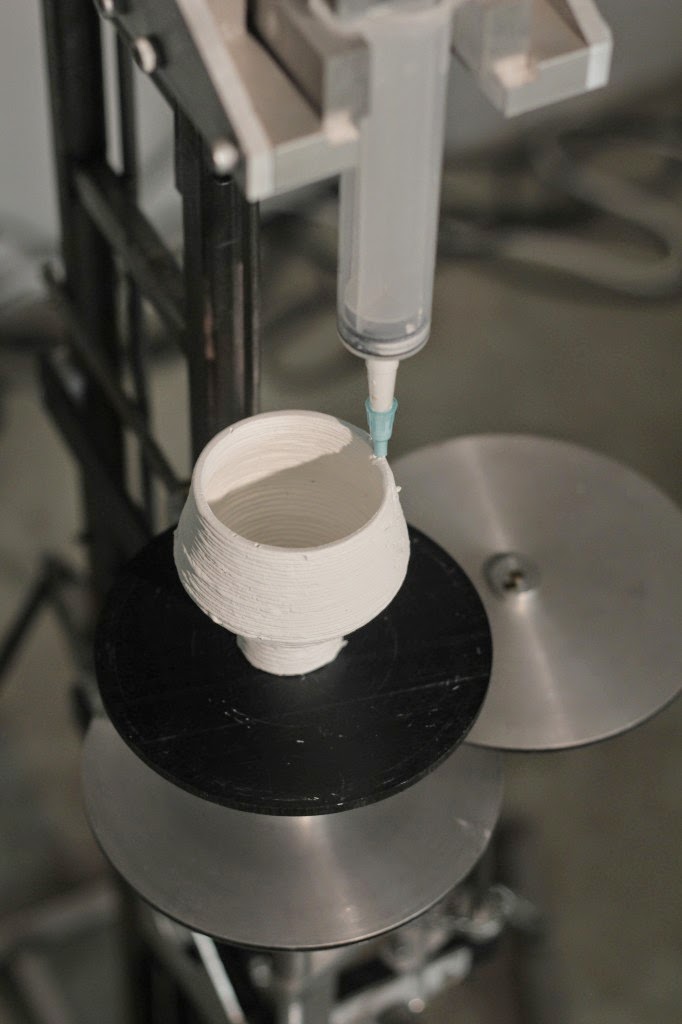

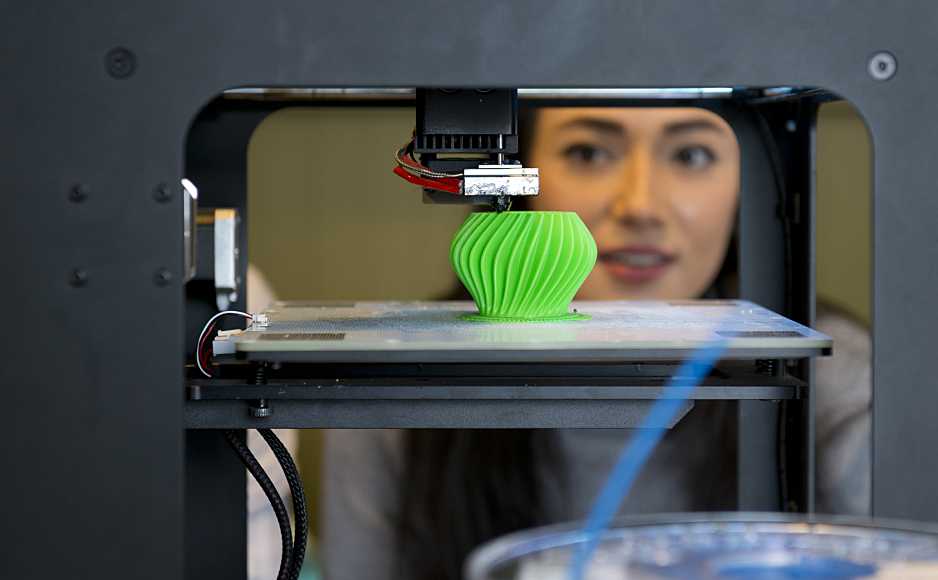

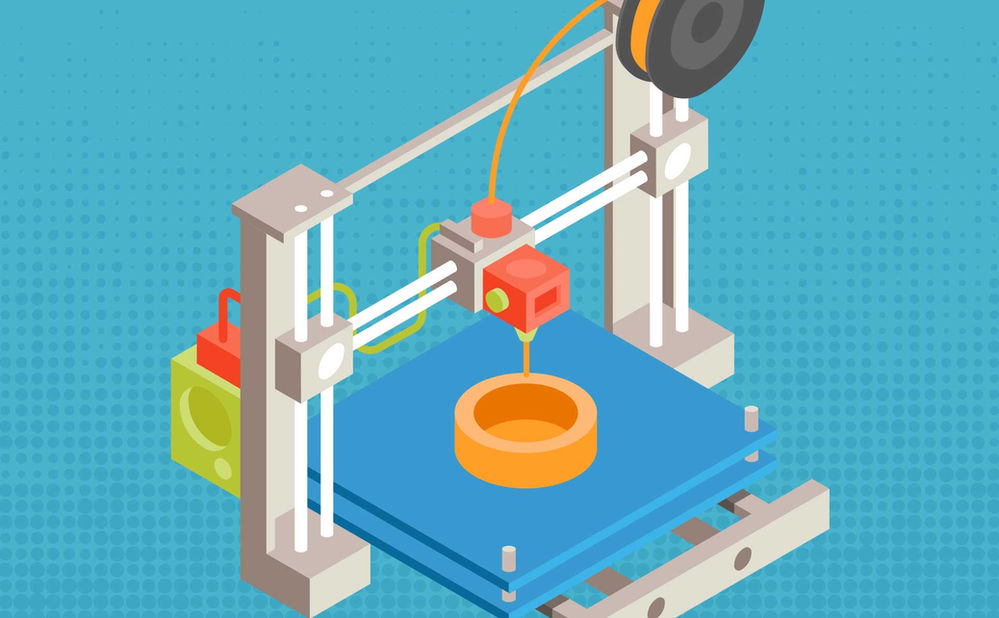

Figure 1 below is an example of an item being 3D printed:

Slide 1 of 1

A red object being 3D printed.

Image Credit: Shutterstock.com/MarinaGrigorivna

What Are the Advantages of 3D Printing Compared to Traditional Manufacturing?

3D printing offers several advantages over its traditional manufacturing counterpart, including:

- More design freedom.

- Able to print complex designs at no additional cost.

- Generally faster, especially for small and medium-sized objects.

- Involves less waste material.

- Can combine the manufacturing and assembly stages of a product.

- Can easily be used to create custom parts.

- It is a completely automated process with limited labor requirements.

- It uses a single device to handle all aspects of creating the object.

What Are the Disadvantages of 3D Printing Compared to Traditional Manufacturing?

The disadvantages of 3D printing vs. traditional manufacturing are:

- It has fewer material options compared to traditional manufacturing.

- The process is less economical compared to traditional manufacturing in large-scale production.

- Batch quality testing cannot be applied to 3D printed products.

- Print quality can be inconsistent and so varies from product to product.

Traditional Manufacturing Definition and Comparison to 3D Printing

The history of manufacturing dates back to the industrial revolution in the 1900s, when raw materials were turned into useful products. During this period, there was a transition away from human labor (at least partly) toward chemical manufacturing and machinery. Traditional manufacturing processes are mainly subtractive. This means that an object is machined or otherwise removed from a larger block of material. Conventional manufacturing methods can be divided into four main families: molding, forming, machining, and joining. These processes are typically more suitable for large-scale manufacturing, primarily due to the tooling, molding, and/or casting costs, as well as the overall limited design flexibility of the processes. Simply put, the cost of a custom product will not be justified if only 50 units are manufactured, for example., as it is difficult to recoup the upfront expenses that are needed for developing the customization.

Simply put, the cost of a custom product will not be justified if only 50 units are manufactured, for example., as it is difficult to recoup the upfront expenses that are needed for developing the customization.

One of the most significant advantages of traditional manufacturing, compared to 3D printing, is that it offers a wide range of material selections. The process is also more established. 3D printing, however, has the upper hand regarding design flexibility, cost, and speed. Traditional manufacturing processes are commonly used in industries that mass-produce products made from materials like wood, steel, or plastic. These include producing furniture, plastic bottles or tanks, toys, textiles, and luggage. Figure 2 below is an example of a CNC milling machine:

Slide 1 of 1

A CNC milling machine.

Image Credit: Shutterstock.com/Pixel B

What Are the Advantages of Traditional Manufacturing Compared to 3D Printing?

Listed below are some of the advantages that traditional manufacturing processes have over 3D printing:

- Best suited for mass production.

- Batch quality checks are possible with traditional manufacturing processes.

- Most traditional manufacturing processes offer good repeatability.

- Traditional processes offer a wider material selection.

What Are the Disadvantages of Traditional Manufacturing Compared to 3D Printing?

Some of the limitations that traditional manufacturing processes have compared to 3D printing include:

- A single part commonly involves the use of many processes and machines.

- Traditional manufacturing is not well suited for low-volume, customized products.

- Subtractive (traditional) manufacturing generally wastes a lot of material.

- Traditional methods are more labor intensive and more expensive.

Comparison Table Between 3D Printing and Traditional Manufacturing

Table 1 below compares 3D printing vs. traditional manufacturing:

Table 1. Comparison of 3D Printing vs. Traditional Manufacturing

| Attribute | 3D Printing | Traditional Manufacturing |

|---|---|---|

Attribute Lead time | 3D Printing Fast | Traditional Manufacturing Slow |

Attribute Material selection | 3D Printing Good | Traditional Manufacturing Excellent |

Attribute Surface finish | 3D Printing Moderate | Traditional Manufacturing Excellent |

Attribute Profitability | 3D Printing Independent from scale | Traditional Manufacturing Large-scale production |

Attribute Design complexity | 3D Printing Yes | Traditional Manufacturing No |

Attribute Customizability | 3D Printing Yes | Traditional Manufacturing No |

3D printing is ideal for low-volume manufacturing, complex or customized parts, fully assembled components, and fast production. However, traditional manufacturing methods have the upper hand regarding surface finish and high-volume production of simple objects.

However, traditional manufacturing methods have the upper hand regarding surface finish and high-volume production of simple objects.

3D Printing vs. Traditional Manufacturing: Lead Cost Comparison

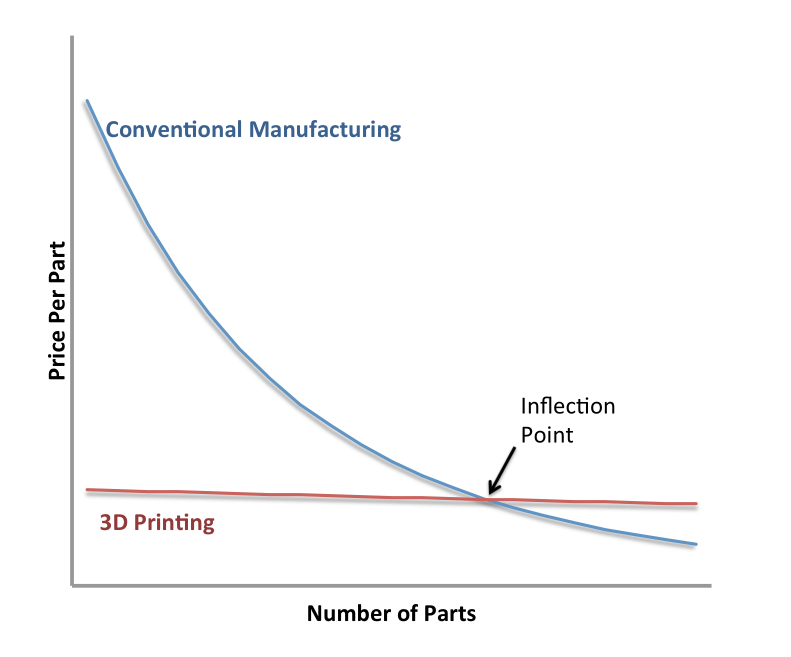

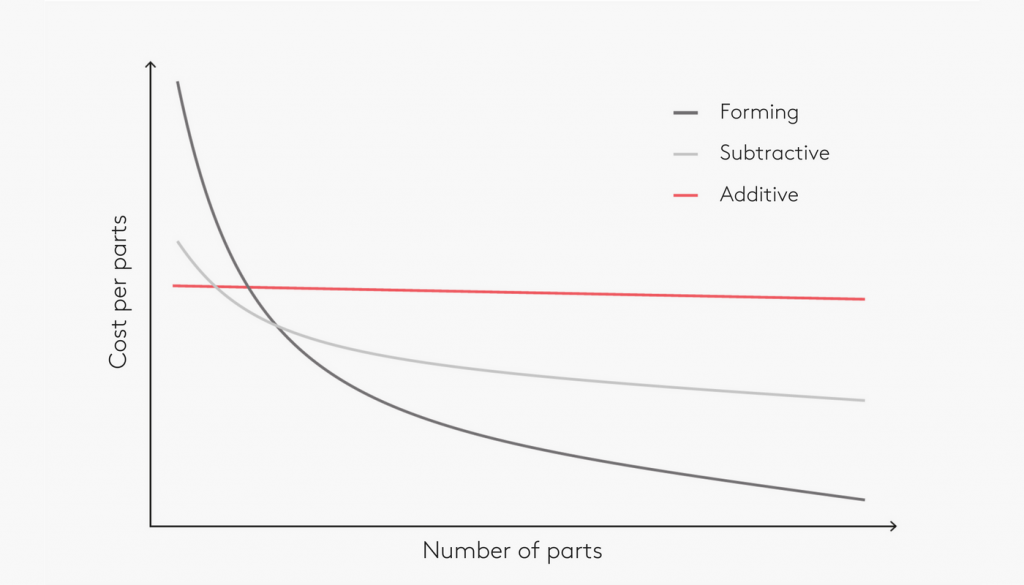

The cost comparison of 3D printing vs. traditional manufacturing depends on the number of units produced. The initial costs of traditional methods are quite high, but large-scale production makes such processes economical. With 3D printing, the cost is independent of the quantity; essentially, there is a flat rate per unit.

3D Printing vs. Traditional Manufacturing: Speed Comparison

3D printing is known to be a lot faster than conventional manufacturing. This is mainly due to traditional processes' molding and casting steps before production can commence. With 3D printing, this is not an issue. Designs are created through CAD or 3D modeling software, and the 3D printer prints the model.

3D Printing vs. Traditional Manufacturing: Volume Comparison

Traditional manufacturing processes are established industrial processes known for their ability to be used in high-volume production, whereas 3D printing is ideal for rapid prototyping or small-scale production. Traditional processes are, therefore, mainly used for batch production of simple designs, such as plastic bottles. 3D printing, on the other hand, offers excellent design flexibility and customization. It can be used to troubleshoot designs and introduce minor tweaks to a design before mass production occurs.

Traditional processes are, therefore, mainly used for batch production of simple designs, such as plastic bottles. 3D printing, on the other hand, offers excellent design flexibility and customization. It can be used to troubleshoot designs and introduce minor tweaks to a design before mass production occurs.

3D Printing vs. Traditional Manufacturing: Materials Comparison

Though 3D printing is broadening its material selection and does offer quite a few options, traditional manufacturing processes provide a wider selection and range of materials. However, the continuing evolution of 3D printing technology makes it almost certain that it will be able to compete with traditional manufacturing processes in terms of material range in the near future.

What Are the Mutual Alternatives to 3D Printing and Traditional Manufacturing?

An alternative to both 3D printing and traditional manufacturing is:

- Rapid Tooling: With rapid tooling, a tool or mold is produced which enables manufacturers to rapidly produce parts that function as a tool.

Low-volume injection molding is mostly used. Rapid tooling is similar to both 3D printing and traditional manufacturing in that 3D printing and CNC machining (one of the main subtractive manufacturing methods in traditional manufacturing) are used to rapidly produce parts.

Low-volume injection molding is mostly used. Rapid tooling is similar to both 3D printing and traditional manufacturing in that 3D printing and CNC machining (one of the main subtractive manufacturing methods in traditional manufacturing) are used to rapidly produce parts.

What Are the Similarities Between 3D Printing and Traditional Manufacturing?

Aside from their ability to produce working parts, there is not much similarity between 3D printing and traditional manufacturing.

What Are the Other Comparisons for 3D Printing Besides Traditional Manufacturing?

Another alternative to 3D printing is:

- 3D Printing vs. Laser Cutting: 3D printing (specifically SLA, SLS, and SLM) and laser cutting are similar in that both technologies use a laser to produce parts.

What Are the Other Comparisons for Traditional Manufacturing Besides 3D Printing?

Another alternative to traditional manufacturing is:

- Traditional Manufacturing vs.

Smart Manufacturing: Smart factories, associated with smart manufacturing, digitize traditional manufacturing processes and machinery.

Smart Manufacturing: Smart factories, associated with smart manufacturing, digitize traditional manufacturing processes and machinery.

Summary

This article contrasted 3D printing and traditional manufacturing processes to see how they differ in approach, material selection, production volume, and other factors. To learn more about 3D printing or traditional manufacturing processes, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Team Xometry

This article was written by various Xometry contributors. Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more.

Traditional Manufacturing VS 3D Printing

Pros and Cons of the Two Methods

A Brief Overview of Traditional Manufacturing and 3D Printing

Traditional manufacturing refers to four main subtractive manufacturing methods – CNC Machining, Injection Moulding, Plastic Forming and Plastic Joining, while 3D printing is an additive manufacturing process that works via depositing material layer by layer until it forms the desired object.

Firstly, CNC refers to Computer Numerical Control. CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts.

Injection Moulding, requires the use of a mould. It is a manufacturing process where parts are produced by injecting molten material into the mould.

During Plastic Forming, some manner heats a sheet of plastic and drapes it over a mould. It then utilizes air pressure and male plugs to form the sheet into a shape.

Lastly, Plastic Joining involves the joining of semi-finished parts. This includes fastening, adhesive bonding, and welding.

1. Time and Cost Considerations

When it comes to production, businesses are most concerned with lead time and costs incurred.

Parts produced by traditional manufacturing generally take a longer time, as moulds are required to facilitate the process. At times, they may take up to months to prepare, costing up to thousands for a single mould. It takes 15-60 days (and sometimes more) to have the first part in hand.

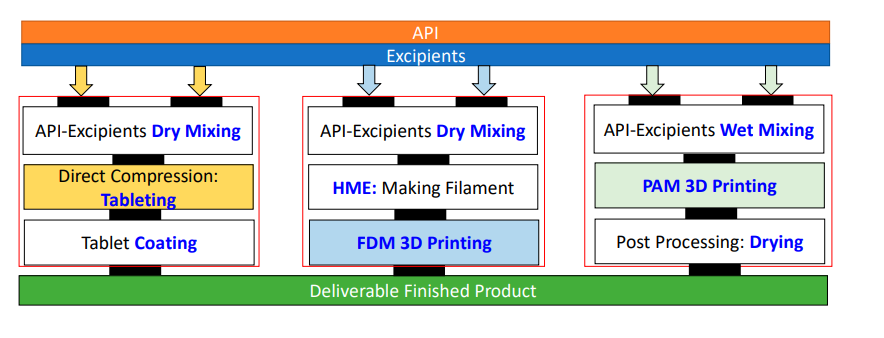

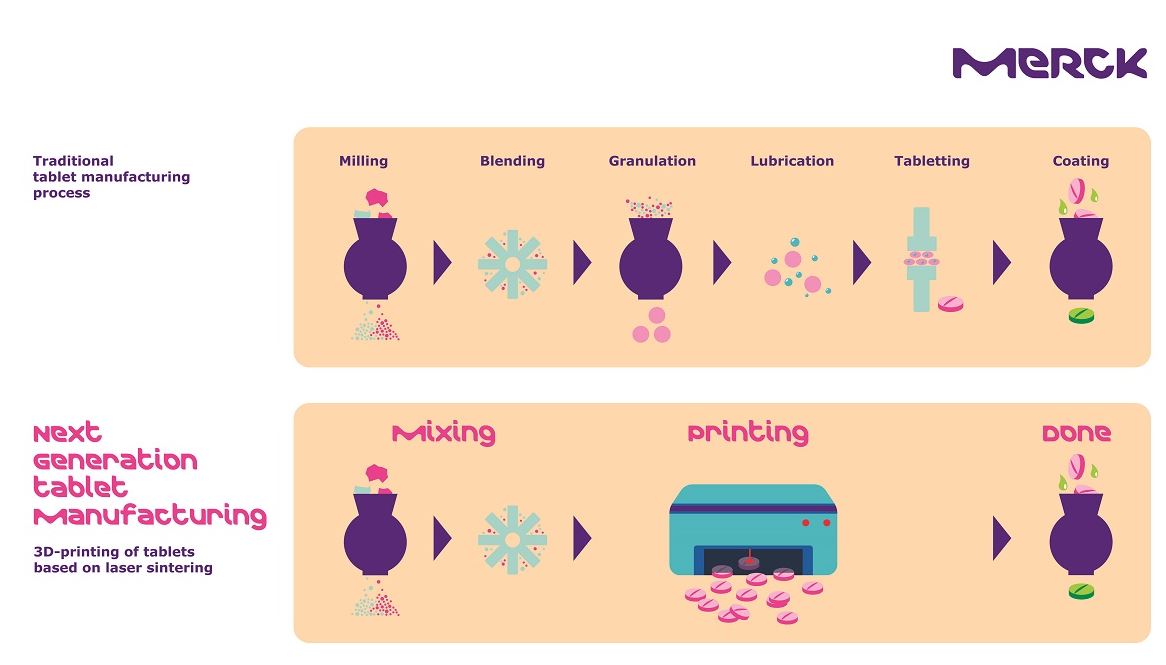

In comparison, 3D printing does not require the use of moulds. This is due to the fact that it is an additive manufacturing process which involves depositing material layer by layer on the printing bed. Lead time can be as short as a few days, while observing a significant reduction in cost as there is no need for moulds.

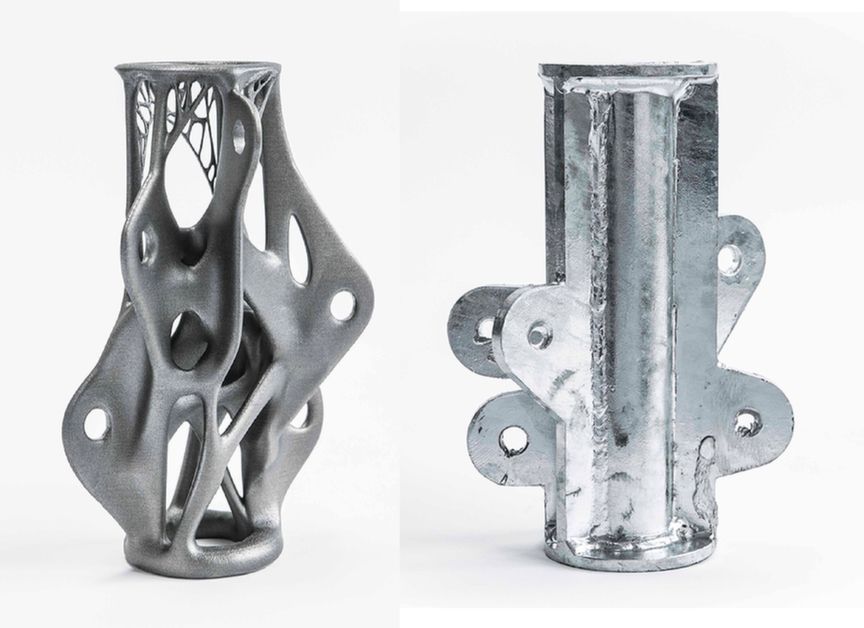

2. Freedom of Design

End-use parts made with traditional manufacturing need to adhere by strict design for manufacturing (DFM) rules. DFM refers to the process of designing or engineering a product in order to facilitate the manufacturing process to reduce manufacturing costs. Therefore, businesses usually discourage producing parts with complex structures as this would result in unnecessary costs.

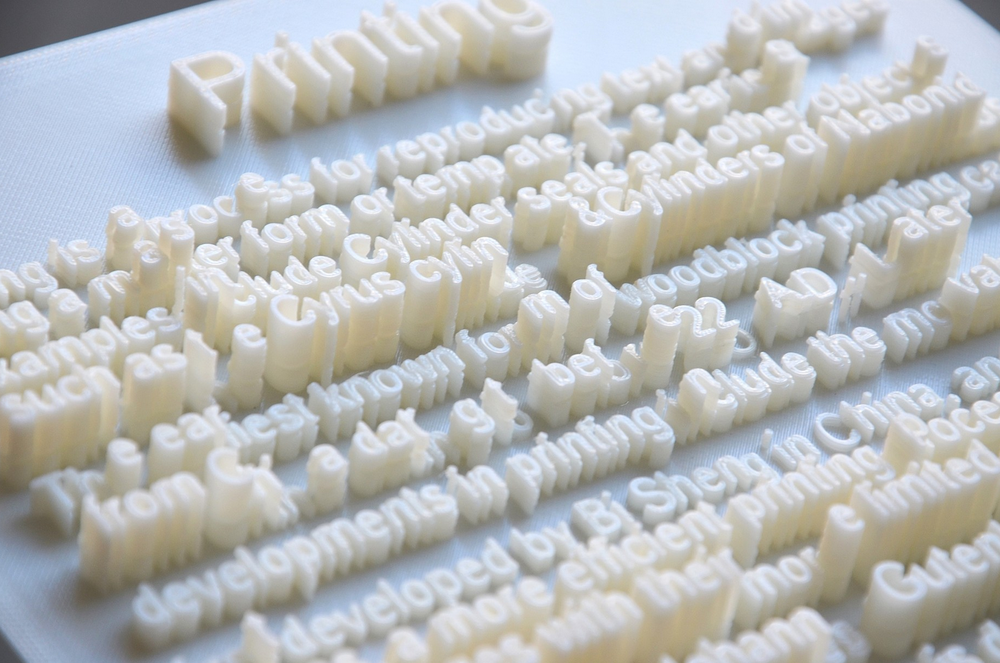

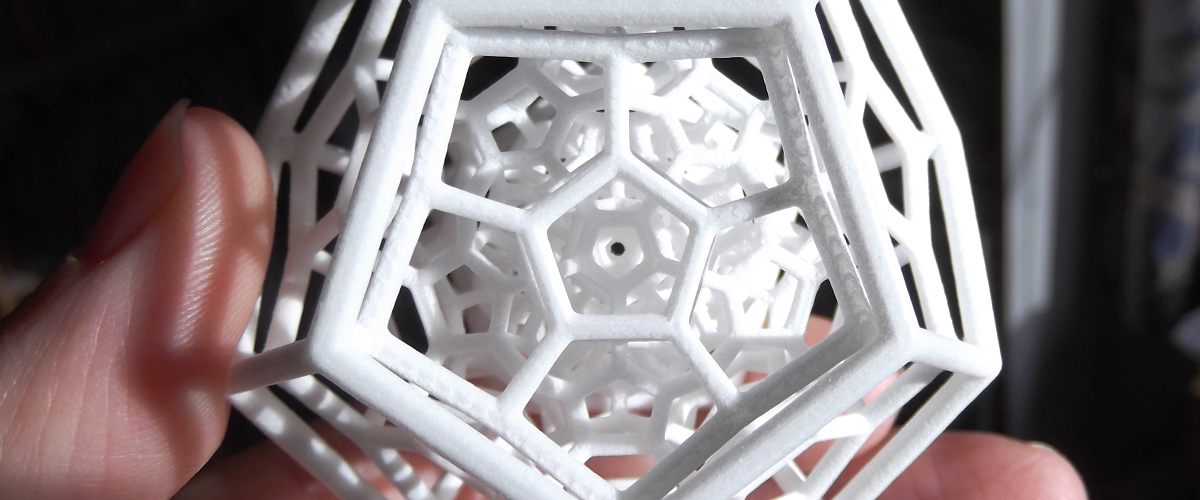

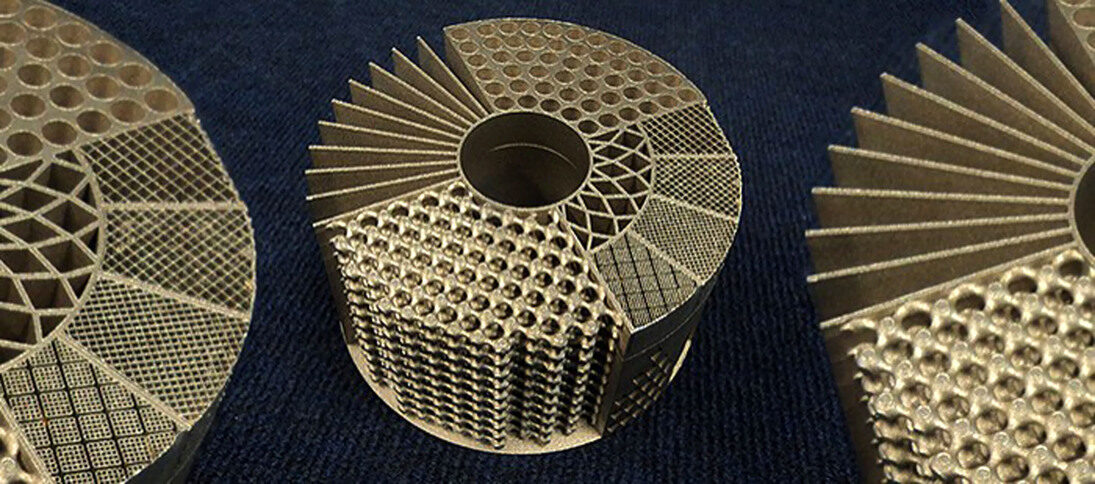

However, 3D printing eliminates this concern. Additive manufacturing processes are able to print complex designs at no additional cost. In fact, any design is possible, as long as you have the right support material! For example, Selective Laser Sintering (SLS) 3D printing technology does not require any form of support. During SLS, the leftover unsintered powder acts as self supporting material. Hence, extremely complex geometries are made possible. Learn more about SLS here.

During SLS, the leftover unsintered powder acts as self supporting material. Hence, extremely complex geometries are made possible. Learn more about SLS here.

3. Quantity of Parts

An important factor to consider when deciding between traditional manufacturing and 3D printing is the number of parts you require. The key difference is that traditional manufacturing is more suitable for mass/large scale production. On the other hand, 3D printing proves to be more economical for low volume manufacturing/short-run production. This is because it doesn’t make sense to create a mould for a production cycle of as little as 50 parts.

4. Materials Offered

Traditional manufacturing options like injection molding and forming can offer a high material selection. 3D printing offers much lesser materials. However, there is still a variety of industrial materials available, depending on the 3D printing technology chosen. For Fused Deposition Modeling (FDM), there is static-dissipative ABS-ESD7, along with ULTEM 9085, ABS-M30 and many more. For stereolithography (SLA), there is Accura25, ClearVue, Taurus and so on. Sinterit Laser Sintering (SLS) offers materials such as PP, PA12 and TPU. VeroClear material is available for Polyjet, while PA12 is offered for Multi Jet Fusion (MJF) technology.

For stereolithography (SLA), there is Accura25, ClearVue, Taurus and so on. Sinterit Laser Sintering (SLS) offers materials such as PP, PA12 and TPU. VeroClear material is available for Polyjet, while PA12 is offered for Multi Jet Fusion (MJF) technology.

How 3D printing complements traditional production

Analytics and business

Rapid prototyping

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

From prototyping to production | Quality | Speed | Efficiency | Creativity | The evolution of additive manufacturing

We live in an era of rapid progress in technology and business processes, but we must admit that manufacturers are still limited by the eternal trinity: quality, speed and cost. Finding a balance between the two is not an easy task, but the good news is that the additive industry is reaching new levels. How exactly can 3D printing complement traditional manufacturing and change business models across industries? nine0003

According to Jabil's 2021 3D Printing Market Trends Survey, additive manufacturing is already helping manufacturers find new and unique approaches to better meet market demands. In recent years, regulated industries with strict safety and quality standards, including healthcare, aerospace, defense and automotive, have enthusiastically promoted the strategic benefits of additive manufacturing. nine0003

In recent years, regulated industries with strict safety and quality standards, including healthcare, aerospace, defense and automotive, have enthusiastically promoted the strategic benefits of additive manufacturing. nine0003

Digitalization will help manufacturers from different industries change the market, and not lose competitiveness in it. Both value metrics and the rapid expansion of digital manufacturing are pushing for the transition to digital technologies. Thanks to 3D printing, companies are better able to respond to changing conditions, complete joint projects and modernize.

The article discusses four key factors that underlie the interaction between additive and traditional manufacturing: nine0003

-

quality,

-

speed,

-

efficiency,

-

creativity.

Can 3D printing help you optimize production in your organization? Order a free consultation with iQB Technologies experts

nine0044 From prototyping to production

3D printing is usually associated with generating ideas, designing and prototyping, but it has long been cramped in this framework. Today, with the help of additive technologies, they create tooling, test products before launching into mass production, and manufacture small series of parts. According to Jabil's 2021 3D Printing Market Trends Survey of over 300 decision makers, 62% of companies use 3D printing for mass production. For comparison: in 2017, only 27% spoke about this. nine0003

Today, with the help of additive technologies, they create tooling, test products before launching into mass production, and manufacture small series of parts. According to Jabil's 2021 3D Printing Market Trends Survey of over 300 decision makers, 62% of companies use 3D printing for mass production. For comparison: in 2017, only 27% spoke about this. nine0003

From this we can conclude that distributed production networks are the reality of today. Global networks of additive manufacturing assets (such as the Jabil Additive Manufacturing Network) enable companies to manufacture products close to the point of delivery. The advantage of this model is "digital flexibility": one participant uploads design files in Chicago, while another prints them at a facility in Singapore, closer to the end customer. With this approach, supply chains are used much more efficiently. nine0003

Significant recent advances in the additive industry are setting the stage for distributed 3D printing manufacturing, accelerating progress and making the technology more practical. To list just a few of the aspects that define how 3D printing complements manufacturing.

To list just a few of the aspects that define how 3D printing complements manufacturing.

1. Quality

3D printing allows manufacturers to produce unique, complex shapes of consistently high quality at a low cost. Thus, the additive method can advantageously produce a small number of parts of different sizes, and in some cases, one part of different sizes. nine0003

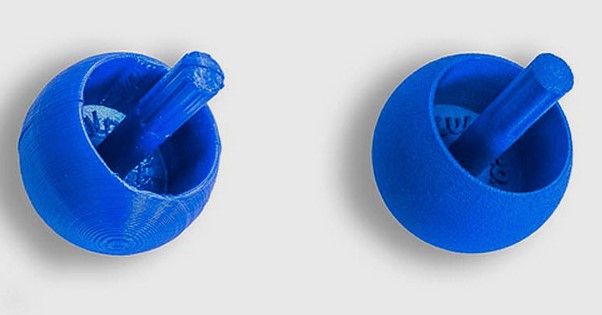

In recent years, the print quality and reliability of 3D printers have improved significantly, and they can now print more precise parts with better surface quality. In 2019, Jabil conducted a print quality survey. About 40% of the respondents answered that they were not sure about the reliability of the parts produced. Just two years later, 27% gave this answer.

In addition, new materials, platforms, and software enable companies to overcome the challenges of making parts repeatable from batch to batch and machine to machine. Thanks to these solutions, the company reduces the time and cost of organizing or reorienting production, which means it can respond faster to changing market requirements. nine0003

nine0003

2. Speed

By using additive technologies combined with smart digital supply chains, virtual teams around the world can work on new projects, compare real product representations, save time along the concept-prototype-prototype-manufacturing chain, and even move production closer to customers. .

Compare this approach with the traditional one (involving investments in tooling, parts, equipment, partnerships and the release of the first production prototype) and see how obvious the advantages of additive manufacturing are: there is no doubt that it can affect all stages of product development. nine0003

Rapid prototyping provides the opportunity to explore different iterations and try out different designs during production. The healthcare, automotive and aerospace industries are undergoing rapid change, and 3D printing has become a key tool without which manufacturers cannot keep up with the most flexible and efficient product lifecycle management strategies.

Another important advantage of 3D printing is the ability to quickly change the range of manufactured products. Each printed item can be made unique, which means that the product can be created according to individual orders. Manufacturers can react faster to market changes and adapt production rates to demand. nine0003

As a result, additive technologies can reduce the time to market for new or upgraded products from months to days.

3. Efficiency

Additive-created products have simpler material specifications, which greatly simplifies supply chain management and speeds up production. An increasing number of businesses are using 3D printing platforms. Design improvements lead to more efficient design, lighter parts, and cleaner production, all of which contribute to an overall improvement in product performance. By simplifying specifications, not only the efficiency of the entire production process, but also the end product itself is improved. nine0003

nine0003

Applying Design for Additive Manufacturing (DfAM) principles to create monolithic parts and system-level design results in merged specifications and reduced parts count, resulting in significant cost savings for companies and often increased product reliability.

3D printing has another economic advantage: various parts with complex geometries can be produced on a single 3D printer. Companies that have adopted the technology are able to save money by increasing the scale of production. The distribution of production along value chains is becoming more real. Rapid production of tooling, spare parts and more can all be done at facilities closer to the end customer, reducing costs all the way from transportation to warehousing. nine0003

Moreover, the digitalization of inventory management allows manufacturers to free up capital and give them more flexibility to develop new products, manufacturing processes and/or investments in other lines of business. Fewer parts in stock means fewer containers on the shop floor and more storage space.

Fewer parts in stock means fewer containers on the shop floor and more storage space.

Reducing bills of materials through 3D printing can reduce the cost of documentation, quality control, mass production planning and inventory management. Fewer parts means less time and labor to create the product itself, which leads to additional savings in production costs. nine0003

4. Creativity

The impressive potential of additive manufacturing cannot be realized without a large selection of materials. At the Jabil Materials Innovation Center in Chaska, Minnesota, designers, chemists, materials researchers and manufacturing experts interact with customers to develop high performance powders and filaments. These custom-designed materials enhance the performance, durability, fire resistance, conductivity and lubrication of the end product. nine0003

As Jabil's report shows, materials for 3D printing are on the rise, with plastics, polymers, composites and, with a slight lag, metals remaining the most common. Metal is less popular in 3D printing than plastic or polymer. This is the situation today, however, it may change, as survey participants said they would like to use more different materials in the future.

Metal is less popular in 3D printing than plastic or polymer. This is the situation today, however, it may change, as survey participants said they would like to use more different materials in the future.

“Innovative materials don't just help increase bottom line. Revolutionary manufacturing approaches using new polymers can address important sustainability, healthcare, transportation, environmental and aerospace issues,” says Elizabeth Gardner, Jabil senior chemist and materials engineer. nine0003

The evolution of additive manufacturing

3D printing will develop dynamically, and in recent years we have seen how the pace of its implementation is growing. The convergence of digital technologies (including 3D scanning, integrated information systems and additive manufacturing) suggests the obvious: manufacturers are looking at digital solutions to increase profitability and accelerate the development and manufacture of their products.

This development will have implications for today's big business. “There is a lot of activity going on in this area, a lot of money and creative resources,” writes Richard D'Aveney in the Harvard Business Review, asking the question, “What is the price of waiting?” Indeed, new opportunities are increasing the speed and efficiency of 3D printing, and there is no doubt that successful companies would prefer to pick up this pace rather than slowly adopting the technology. nine0003

“There is a lot of activity going on in this area, a lot of money and creative resources,” writes Richard D'Aveney in the Harvard Business Review, asking the question, “What is the price of waiting?” Indeed, new opportunities are increasing the speed and efficiency of 3D printing, and there is no doubt that successful companies would prefer to pick up this pace rather than slowly adopting the technology. nine0003

More and more companies are realizing the value and cost-effectiveness of additive technologies for design, prototyping and manufacturing. 3D printing is becoming one of the key tools in the arsenal of a manufacturing enterprise. If you use a 3D printer to streamline the iteration process and improve the product during the prototyping phase, you will ultimately save time and money, as well as reduce the error rate during the manufacturing phase. 3D printing is not just an innovation, it brings tangible benefits. nine0003

Research your customers first. It is essential to understand what they want and how best to meet their needs. 3D printing solutions are revolutionizing prototyping, tooling and product manufacturing. Large companies that actively use these opportunities (including design for additive manufacturing) will be in a better position and will be able to maintain stability.

3D printing solutions are revolutionizing prototyping, tooling and product manufacturing. Large companies that actively use these opportunities (including design for additive manufacturing) will be in a better position and will be able to maintain stability.

D'Aveni recommends reviewing current processes. “3D printing is creating countless new approaches to manufacturing parts, and companies need to understand what supply chain configuration and what combination of old and new processes will become optimal,” the scientist argues. nine0003

Finally, the strategic implications need to be explored as AM will soon be adopted by entire trading platforms. Manufacturing is a 150-year-old industry that is inherently less subject to change. Nevertheless, we see that new technologies are being introduced more and more actively, and more than half of the top managers of companies that took part in the above survey see strategic opportunities in the use of additive technologies. In previous years, this percentage was lower. nine0003

In previous years, this percentage was lower. nine0003

The unique technologies, materials, processes and capabilities of additive manufacturing make it the cornerstone of digital transformation, a process that is already affecting many industries. There is no doubt that additive manufacturing is changing the way companies design and manufacture their products, and Jabil is an example of a business operating at the intersection of additive and conventional technologies.

Source: jabil.com

nine0002 Article published on 03.11.2021, updated on 02.11.2021

metal casting or metal 3D printing?

Additive manufacturing is generally accepted as one of the paths to a new industrial revolution. 3D printing is changing the world around us, making it possible to create a wide variety of products - from car parts to airplanes and houses. However, how does this innovative and still quite young technology compare to the classic metal casting that has been used for centuries? nine0003

Traditional metal casting

The history of classic metal casting technology dates back to the Middle Ages. This process includes several steps. First of all, you need to create a model of the final product. In the manufacture of the model, you can use various materials, including wood. In the design of the model, it is necessary to provide for a gating system and some additional supports. After that, a mold is made on the basis of the model. For this purpose, you can use different molding materials, the most popular of which is the sand mixture. nine0003

This process includes several steps. First of all, you need to create a model of the final product. In the manufacture of the model, you can use various materials, including wood. In the design of the model, it is necessary to provide for a gating system and some additional supports. After that, a mold is made on the basis of the model. For this purpose, you can use different molding materials, the most popular of which is the sand mixture. nine0003

The first step is to prepare the model; this process can be done in different ways depending on the materials used. After creating a copy of the final product, it is necessary to design the gating system. It is important to remember that the model must be free to move out of the sand mold, so the bottom of the model should not be wider than the top.

"Traditional methods are preferred when we are dealing with large parts. However, if you are producing custom precision parts, 3D printing is a better choice.

" nine0126

Parts and gating design should also take into account the fact that, due to the high solidification rate of molten metal, it may solidify before reaching the highest point of your product. To avoid this, it is necessary to provide bulges, which are subsequently separated from the part.

All of this must then be reflected exactly in the mould. It is necessary to prepare two sand molds. Next, the first form is created from a special sand mixture, which exactly copies the object. The second mold is used for the gating system into which the metal is poured; if necessary, it can also be used to copy the second part of the product. After that, the molds are installed one above the other in such a way that the gating system matches the configuration of the object. nine0003

By connecting the two molds together and making sure that the metal does not leak through the two layers of sand mixture, we heat and melt the metal. Since the metal solidifies very quickly, casting processes require the metal to be poured into the mold very quickly through the gating system.

The last step is to clean the product from sand and separate the gating system. After that, you can subject the object to the necessary additional polishing or remove excess material, if necessary. nine0003

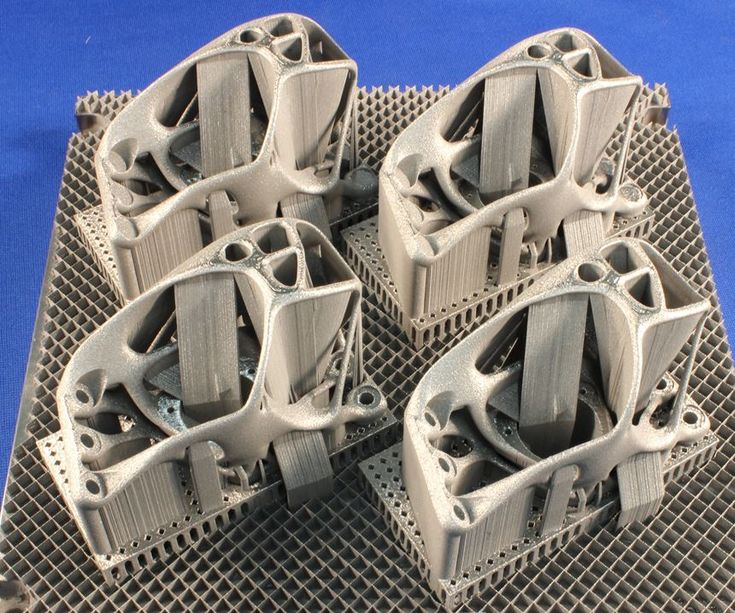

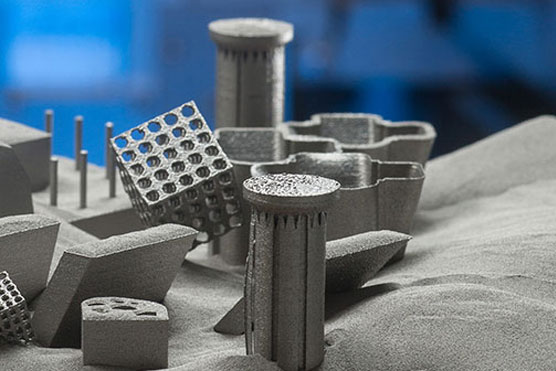

Selective Laser Melting

Selective Laser Melting (SLM) is an additive manufacturing technology that uses metal powder to create parts. A metal 3D printer spreads a thin layer of powder on a platform, after which the laser melts the metal, following the configuration of your 3D model. A new layer of powder is applied and the procedure is repeated again. Since metal melting occurs at a high temperature, the printed parts need some time to cool down. nine0003

SLM technology allows the integration of several components into one object, which reduces costs and reduces the assembly time of parts. The use of selective laser melting for the production of parts also allows you to get very strong products, which at the same time can have thin walls, which reduces weight. In addition, such parts are resistant to high temperatures.

In addition, such parts are resistant to high temperatures.

Metal investment casting

Investment casting is the only 3D printing method that does not use metal powder. This technology is based on the injection of metal into a mold. The master model, usually made of wax, is an exact copy of the final product thanks to 3D printing. The master model obtained by 3D printing is covered with gypsum molding sand. After receiving a plaster mold ready for use, the object is created. To do this, straightened metal is injected into the mold and replaces the wax model, which is melted through a tree-like system. nine0003

Metal casting and 3D printing: cooperation, not competition

Additive manufacturing is not a clear competitor to traditional metal casting: 3D printers can be used to complement and improve on classical methods. A great example of combining additive manufacturing with classic foundry is 3D printing of master models. 3D printing provides a high level of detail that was not available before additive manufacturing techniques. This technology also reduces the pre-production steps of traditional metal casting. nine0003

A great example of combining additive manufacturing with classic foundry is 3D printing of master models. 3D printing provides a high level of detail that was not available before additive manufacturing techniques. This technology also reduces the pre-production steps of traditional metal casting. nine0003

A good example of the combination of two technologies is investment casting. Additive manufacturing provides a high level of customization when printing a wax model of a product. 3D printing allows you to speed up the process, and the wax model is easily removed.

Another way to combine additive manufacturing with classic metal casting is to 3D print plastic models of the final product. Similar to the case of metal investment casting, printed copies are melted down into ideal custom molds that can be applied to traditional casting methods. nine0003

In addition, 3D printed models are ideal for the widely used metal sand casting process. Additive technology allows you to get a highly detailed model that leaves an accurate imprint in the sand mixture, providing high accuracy of metal products. An excellent example of the combination of two technologies is shown in the following video on the use of 3D printing to make a metal hammer:

Additive technology allows you to get a highly detailed model that leaves an accurate imprint in the sand mixture, providing high accuracy of metal products. An excellent example of the combination of two technologies is shown in the following video on the use of 3D printing to make a metal hammer:

When is the best time to use traditional metal casting? nine0117

Classic foundry is well suited for large parts

If you plan to produce large mechanical parts, such as engine components or large gears for machines, classic casting is perfect for this purpose. Additive technologies will not be effective in this case due to the limitations on the size of parts created using 3D printers. The main task in the production of mechanical parts is to provide the necessary functionality. Appearance does not play a big role; the main thing is that the parts have good mechanical properties. And if you also need to produce large parts, then traditional metal casting will give you just what you need. nine0003

nine0003

Traditional metal casting is cheaper in large batches

Classic foundry is also the best choice when you need to produce a large number of parts. The cost of manufacturing decreases as the number of parts increases, whereas in additive manufacturing, the cost remains the same.

How to improve the manufacturing process with metal 3D printing?

Since the application of 3D printing in combination with investment casting metal technology is not much different from traditional metal casting technology, in this section we will focus more on the benefits of additive manufacturing using metal powders.

3D printing opens up new design possibilities

3D printing also offers virtually limitless design freedom, a high level of detail and great customization. If precision is an important factor for your product, additive manufacturing is a better choice. In addition, when using 3D printing, it is possible to design articulated parts, which is not possible with traditional metal casting technology. Additive technologies not only reduce assembly time, but also provide you with completely new design possibilities. nine0003

In addition, when using 3D printing, it is possible to design articulated parts, which is not possible with traditional metal casting technology. Additive technologies not only reduce assembly time, but also provide you with completely new design possibilities. nine0003

3D printing speeds up the production process

If time is a priority in your production, then additive technologies will be the right choice. For a variety of reasons, the metal 3D printing process is much faster than traditional metal casting. All you need for 3D printing, from the preliminary preparation stage to the direct printing of metal parts, is a 3D model. If we compare this with metal casting, where it is required not only to design the part, gate system and riser, but also to create a mold, then it is obvious that a 3D printer provides significant time savings. nine0003

Design freedom: topological optimization and 3D printing allow you to create parts with any complexity of geometry

In the case of 3D metal printing, the post-processing process is also faster. It should not be forgotten that the metal casting process involves machining to separate the gating system and the riser, as well as the manual removal of metal spilled between the molds, and to this you still need to add surface treatment to the part. At the end of the 3D printing process, you only need to remove the supports. nine0003

It should not be forgotten that the metal casting process involves machining to separate the gating system and the riser, as well as the manual removal of metal spilled between the molds, and to this you still need to add surface treatment to the part. At the end of the 3D printing process, you only need to remove the supports. nine0003

Full control of the production process

Although the production process is faster with metal casting due to the rapid solidification of the molten metal, you have no control over the process. Additive technologies offer a much more stable manufacturing process. Of course, it is possible that the 3D printer will fail during printing, but you control the production of each part and can immediately respond in such situations. Metal casting technology doesn't give you that option because you can't see what's going on inside the molds. nine0003

When using traditional metal casting, there is also a risk that the molten metal will solidify before reaching the highest point of your product. To avoid this, it is necessary to create an additional part of the structure, called the sprue. The sprue needs to be subsequently separated from the final product, which increases the post-processing time. In addition, at the stage of pouring into the mold, the formation of bubbles in the metal due to oxidation or the ingress of small particles of the sand mold into the metal can occur, which affects the properties of the product. nine0003

To avoid this, it is necessary to create an additional part of the structure, called the sprue. The sprue needs to be subsequently separated from the final product, which increases the post-processing time. In addition, at the stage of pouring into the mold, the formation of bubbles in the metal due to oxidation or the ingress of small particles of the sand mold into the metal can occur, which affects the properties of the product. nine0003

3D printing allows you to create lighter parts

If you need to make the parts you produce light, then additive manufacturing offers a lot of opportunities for this. To reduce the mass of parts, you can design the walls of parts in the form of cellular structures. It is also possible to create hollow parts, which is not possible in the case of metal casting.

Good mechanical properties

When using additive manufacturing methods such as selective laser melting, the parts produced will also be very strong and resistant to high temperatures.