3D printing georgia

FAQ

How long will my project take?

We turn projects around as fast as possible and can complete some work same-day, but the timeline depends entirely on the scope of work. Here are some averages to give you a better idea:

Single 3D Prints: 1-3 business days if the job is small to medium size, 2-5 business days for large prints, 4-8 business days for SLS prints.

Short-Run Manufacturing: Production runs are heavily dependent on what is bring printed and how many. We oftentimes fulfill as prints are completed if parts are needed ASAP. Contact us for a specific quote.

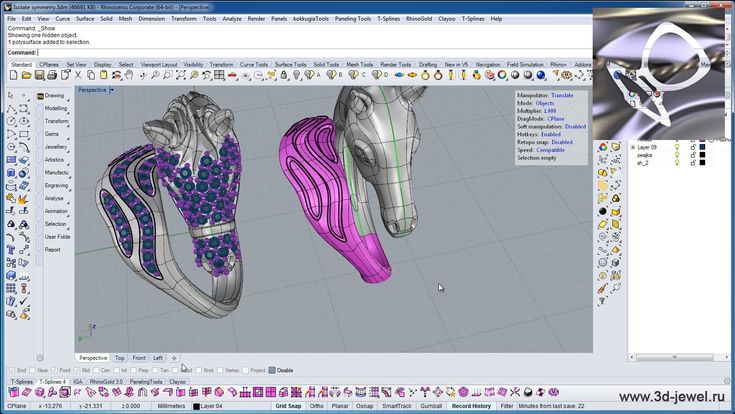

3D Modeling: 1-5 business days, depending on the complexity of the design and the number of concurrent design jobs.

3D Scanning: 1-5 business days.

If you have a tight deadline, please contact us ASAP so that we can make a quick assessment for you.

What is the build size of your printers?

We often build objects that are larger than our build sizes by printing objects in parts and assembling. That being said, we have build sizes as large as 12 feet and as small as 2 inches and are constantly increasing our printing capacity.

How much does it cost?

3D printing, modeling, and scanning projects rely on the scope of work to determine the price, but we have provided some averages below. We offer free consultations in which we can provide a ballpark figure to help determine whether you would like to move forward with a formal proposal.

On average,

3D printing jobs are between $100 and $1000 (with a minimum of $25). Short-run manufacturing and production run prints can cost as low as $1 per unit with an average of $5-25 per unit.

3D modeling is $125/hour and our average modeling projects are 2-6 hours.

3D scanning is $500 for a half-day session which can include multiple parts in that same half-day session, and if the job takes less than two hours we will prorate that down to $250.

How does scanning work?

Currently we are able to scan non-moving objects. Scanning is labor-intensive so we prefer to carve out a half-day session per client, and can typically scan multiple items in that half-day session. The result of a scan is a point cloud file (OBJ, STL, etc.) that can be manipulated in mesh-based software but not directly-edited parametric CAD software. If you need an editable file for reverse engineering or specific changes, the scan data needs to be converted (manually) to a CAD model which would add additional modeling hours to the project.We prefer to know our clients’ end goals with a scan so that we can confirm that the output we provide will meet the needs of the project. For instance, if the scan is intended to then go to manufacturing, a point cloud will not likely suffice and a CAD model will need to be created from the point cloud data.

What materials do you print with?

The most common materials we print with are PLA, ABS, PET, Flexible, Polycarbonate, Nylon, and SLA Resins (standard, tough, high-temp, dental, castable, flexible).

Do you print flyers, signs, shirts, etc.?

We get asked this a lot, but the answer is “no”.

We only print physical objects utilizing various additive manufacturing technologies (commonly called 3D printing) but do not print 2D objects that appear to be 3D.

Printing

$10-40/hr

Pricing dependent on project

Discounts available for bulk orders

Get Started

Scanning

$500/half day

Most projects take one session

Post-scan modeling may be needed

Get Started

Modeling

$125/hr

3D modeling or

file repair

Projects take 2-10 hours depending on complexity

Get Started

3D Printing Service for Atlanta, Georgia

CapabilitiesCustom Online 3D Printing ServiceGeorgiaAtlanta

High Quality Atlanta, Georgia 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Atlanta, Georgia 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

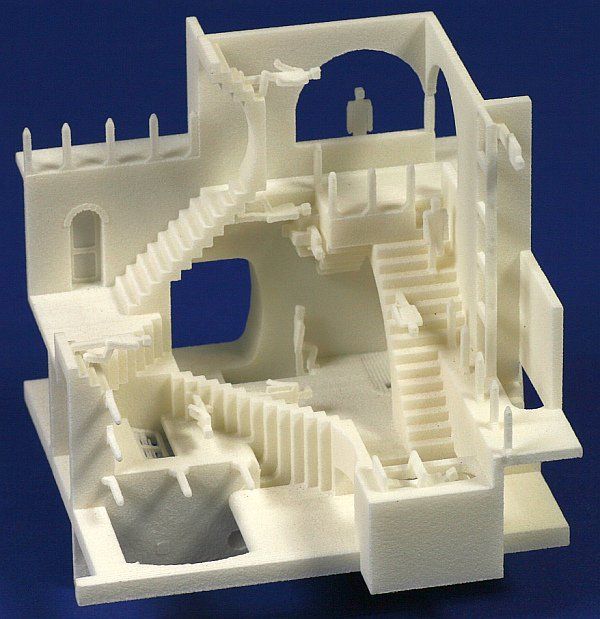

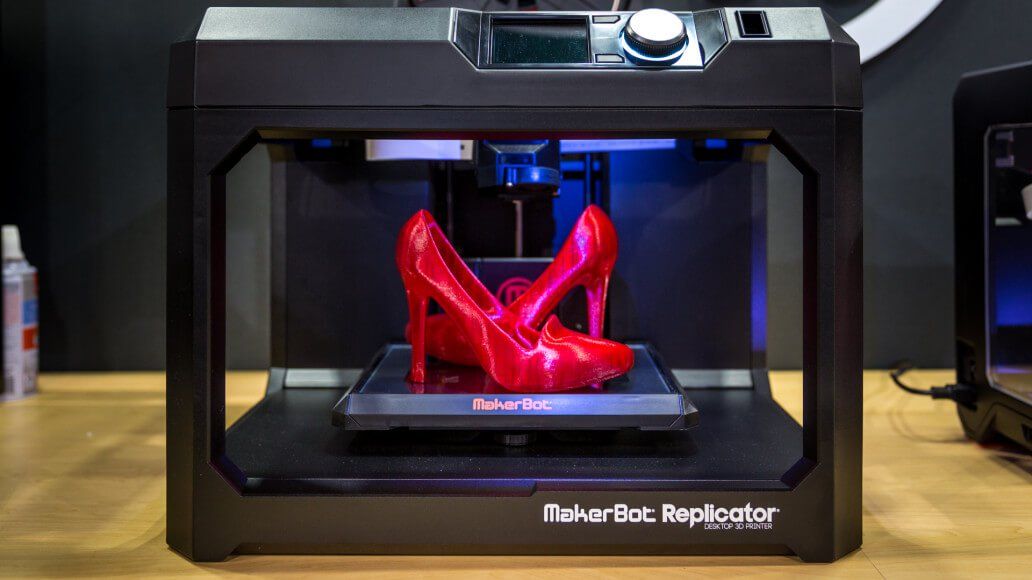

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Atlanta, Georgia

Athens

GeorgiaMacon

GeorgiaChattanooga

TennesseeGreenville

South CarolinaBirmingham

AlabamaAugusta

GeorgiaHuntsville

AlabamaMontgomery

AlabamaKnoxville

TennesseeAsheville

North CarolinaTuscaloosa

AlabamaColumbia

South CarolinaNashville

TennesseeSavannah

GeorgiaCharlotte

North CarolinaTallahassee

FloridaBowling Green

KentuckyCharleston

South CarolinaPensacola

FloridaJacksonville

Florida

Ready to start making custom 3D printed parts?

Custom 3D Printing near you

0 3D Printing service ready to take your order right now and ship parts to Batumi, Adjara, Georgia. Through our platform, you can order 3D printing of prototypes, spare parts and any projects according to your own design without restrictions in size and quantity. If you know exactly which technology, material or application is right for your project, use the filters to narrow your search results. For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of different types.

Through our platform, you can order 3D printing of prototypes, spare parts and any projects according to your own design without restrictions in size and quantity. If you know exactly which technology, material or application is right for your project, use the filters to narrow your search results. For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of different types.

Download files to compare prices of local 3D printing services

Download filesor contact us for a discount on large orders.

Sorry, no matches were found for your search term in your location.

Show international services.

If you are looking for a service for ordering 3D printing with delivery to Batumi, Adjara, Georgia, then you have come to the right place. All companies that provide prototyping and printing services near you are listed above.

How much does it cost to 3D print my products?

To find out the cost of services, select a company and use the "Quick order" button. Based on your 3D model in STL, PLY, OBJ or 3MF format, we will automatically determine the cost of 3D printing. If you are not sure which service to choose, use the order button at the top of the page to compare prices from all eligible print services.

How can I order a print without a 3D file?

3D printing starts with a model, so a 3D file is needed to make the part. Most printing and additive manufacturing companies can help you with a simple 3D design. For more complex modeling tasks, we recommend hiring a professional.

How to choose a 3D printing service?

Treatstock strives to provide a transparent workflow between the 3D printing company and the client for the best result. In order for you to have complete information about the future performer, we show the company's printers and customer ratings. On the public page of each service, you will also find a complete list of their services.

On the public page of each service, you will also find a complete list of their services.

How does it work?

- Download 3D file for instant order;

- Specify order details and delivery address;

- Confirm order;

- Track the progress of your order in the Purchases section;

- Get your finished product.

Our support team is always ready to help. To learn more about the different types of 3D printing, check out our Technology Guide, as well as our Materials Guide for information on them.

Application

- Prototyping

- HD Prototyping

- Jewelry

- Dentistry

- PolyJet and PolyJetMatrix

- Laser stereolithography (SLA)

- Full color inkjet printing (CJP)

- Digital light processing (DLP)

- Direct UV printing (DUP) Biznes,

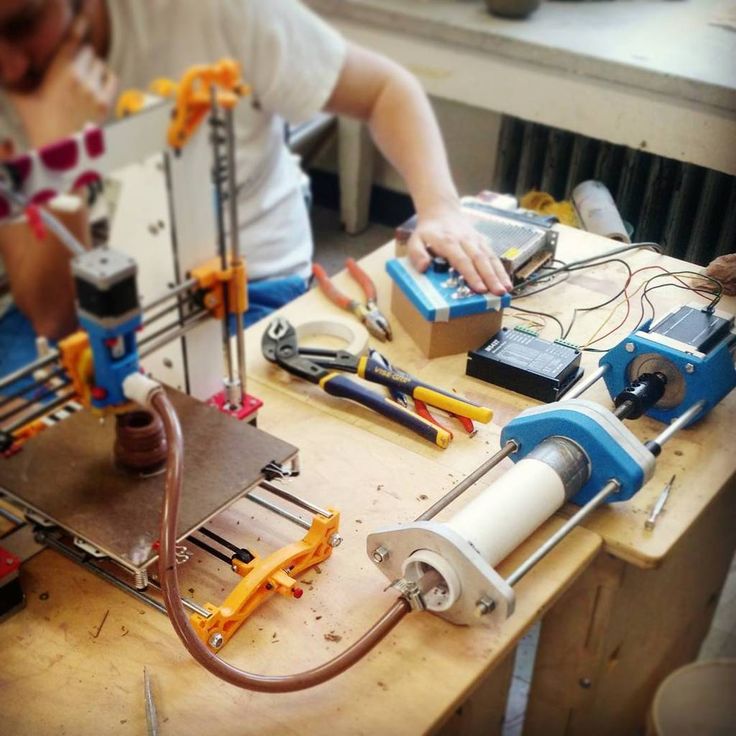

New innovative production has started to work in Georgia. His idea lies in the symbiosis of new technologies and ancient traditions.

We are talking about the production of Georgian clay kvevri on a 3D printer.

We are talking about the production of Georgian clay kvevri on a 3D printer. The author of this idea is the founder of Qvevry, David Mizandari. He was the first to use a ceramic 3D printer to print traditional Georgian Qvevris. His company is the winner of the co-financing grant program of the Georgian Innovation and Technology Agency (GITA). The amount of the grant, GITA, was 100,000 GEL. These funds, as well as personal savings, were invested in the project.

According to David Mizandari, the first high-tech qvevris are already being used for their intended purpose. Now they store young Georgian wine.

- “Our 3D printer was built specifically for printing qvevri. For this, a lot of work has been done. We searched for and ordered parts for the assembly of equipment in various countries of the world. In addition, laboratory studies were carried out on various types of Georgian clay, which is used in the manufacture of qvevri. After all, each type of clay has its own characteristics.

For example, the temperature required for firing depends on this. As a result, we chose the type of Georgian clay that is optimal for printing Qvevri on a 3D printer,” said David Mizandari.

For example, the temperature required for firing depends on this. As a result, we chose the type of Georgian clay that is optimal for printing Qvevri on a 3D printer,” said David Mizandari. At the same time, he noted that in about two months Qvevry plans to start producing relatively large qvevris, with a capacity of one ton. Such vessels are already designed for the needs of wineries.

— “Interest in our products is quite high. Many wineries are interested in purchasing it. However, people want to buy our qvevris not only in Georgia. There is a demand for Georgian qvevri made on a 3D printer even in Portugal and America,” said the founder of Qvevry.

INFORMATION «Smart Press»

Qvevri is a clay vessel resembling an amphora in frome, but without handles. It has the shape of a cone and is used in the process of making, aging and storing Georgian wines in the traditional way.

Qvevris come in different sizes - up to vessels designed for several thousand liters.

The most common type of qvevri contains from 1 to 2 tons of must. The Kakheti region is distinguished by the use of large qvevri, where you can see qvevri with a capacity of 6-8 thousand liters.

The most common type of qvevri contains from 1 to 2 tons of must. The Kakheti region is distinguished by the use of large qvevri, where you can see qvevri with a capacity of 6-8 thousand liters. The oldest kvevri-type pottery discovered in Georgia dates back to 6-5 millennium BC. These are small clay vessels with a height of no more than 1.5 meters, a flat bottom and a wide belly. The ovoid form of qvevri that exists today was finally formed at the turn of the 3rd-2nd millennium BC.

Until the beginning of the 20th century, qvevri were considered the only containers for making and storing wine used in Georgia. Qvevri is considered a symbol of Georgian winemaking. In 2011, Qvevri was recognized as an object of cultural heritage of national importance and included in the intangible fund of the cultural heritage of Georgia. In 2013, the method of making wine in Georgian Qvevri was included in the UNESCO Intangible Cultural Heritage List. Various kvevri-shaped items are popular Georgian souvenirs.

Learn more