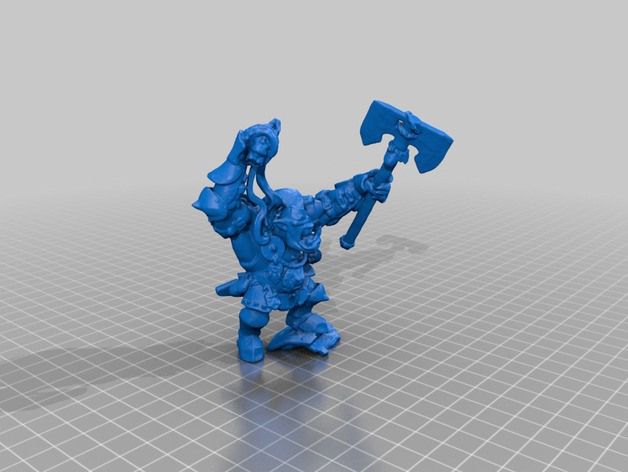

3D printing game miniatures

3D printing is changing tabletop gaming

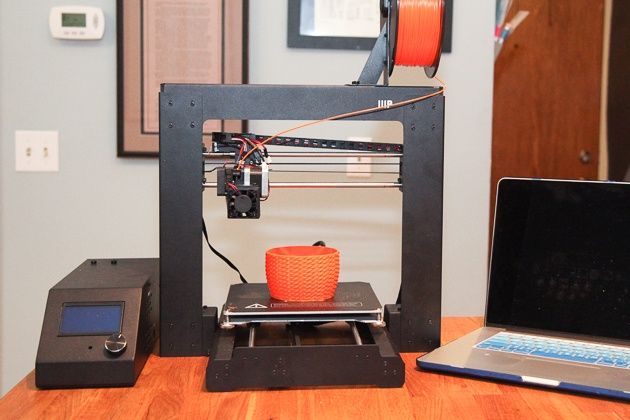

I saw my first 3D printer years ago in a very fancy shopping mall in Tokyo. I watched enraptured as, layer by layer, an early filament printer formed a shoe out of nothing. Since then, 3D printing technology has moved on a lot, becoming more affordable and accessible than ever before. It has particularly exciting applications for the worlds of tabletop wargaming and roleplaying.

Though filament printers, that work by layering plastic from a spool, continue to have uses for tabletop gamers, especially for large terrain pieces, it is the development of affordable resin printing that has greater applications for the tabletop. Resin printers work by pulling a tray out of a pool of liquid resin that cures as it is exposed to ultraviolet light layer by layer. They can produce much finer detail without the streaking common to filament printing. There are many different resin printers on the market ranging in price from a few hundred to thousands of dollars. The printer is not the only expense; prospective printers will also need a curing station and a clean-up station, safety gear and, of course, resin.

Beyond the money, time is a factor that shouldn’t be overlooked. 3D printing is not as simple as plugging in a laserjet and hoping it will work. There is a lot of craft to be learned before you can 3D-print effectively. The maintenance of your printer, getting the setup correct and post-printing work all need to be learned. YouTube is an invaluable resource here, with guides by miniatures hobbyists such as Dana Howl, Squidmar and Miniac and 3D printing-specific channels such as The Maker's Muse, Thomas Sanladerer and 3D Printed Tabletop.

Another consideration is space. As well as not smelling pleasant, uncured resin produces hazardous fumes and irritants. Furthermore, it can be a messy process and not the kind of thing you should be doing on your kitchen table. Good ventilation is a must, in addition to protective equipment. Finally, byproducts of the washing process require proper disposal.

Finally, byproducts of the washing process require proper disposal.

If your interest is just getting exciting new models and parts for your conversions and games, it’s worth paying a 3D printing company to do the work for you, which is generally not prohibitively expensive.

As the technology for 3D printers has developed, a wide range of miniature producers has emerged, selling the STL files needed to 3D print. There are broadly three places to get STLs: crowdfunding, subscriptions or direct sales.

A lot of creators make their miniatures available in a range of places, so if you don’t want to pay for a subscription or crowdfunding project for a complete range, you can usually buy an individual model on an STL store such as My Mini Factory, Thingiverse or Cults, or directly from artists’ web pages.

A bit of 'buyer beware' is prudent when using these services, as some of the sites are not very regulated and customer support can be limited. There are models on these marketplaces that are simple to print. However, there are others that do not work properly, do not come with support or need other modifications to the files to get decent prints. With that being said, 3D printing provides lots of opportunities for all sorts of tabletop games.

There are models on these marketplaces that are simple to print. However, there are others that do not work properly, do not come with support or need other modifications to the files to get decent prints. With that being said, 3D printing provides lots of opportunities for all sorts of tabletop games.

Tabletop roleplaying is one such area. There is a range of character design tools, such as Hero Forge and Anvl, that let you create extensively customised characters and then sell you the STL.

Furthermore, there are miniatures designers that produce models specifically for one RPG - for instance, Lair’s official range of Numenera miniatures. There are also a number of miniatures producers that offer adversaries, NPCs and monsters. The variety out there is stunning. If you want to run a cyberpunk game, there are minis for that. Something based on the Cthulhu Mythos? Perhaps Voidrealm Miniatures has what you are looking for. Cute Redwall-esque critters? Duncan Shadow’s got some. For that or truly depraved demons? Bestiarum Miniatures.

Something based on the Cthulhu Mythos? Perhaps Voidrealm Miniatures has what you are looking for. Cute Redwall-esque critters? Duncan Shadow’s got some. For that or truly depraved demons? Bestiarum Miniatures.

There are vast amounts of 3D-printed miniatures that can be used for tabletop games. Some are conversion bits, heroes, monsters and units for existing games, while others are miniature lines with their own unique game systems, such as One Page Rules.

3D printed miniatures can be used to bolster armies in games such as Warhammer with custom figures, or even used in games with no specific miniatures of their own. Image: alexkorp09/stock.adobe.com

It is no secret that a decent number of miniature producers are making proxies and parts that can be used in the games of wargaming giant Games Workshop. Scout the various producers and you can find a reasonable number of stand-ins - often under legally distinct names like Space Knights, Space Elves and Insect Warriors - compatible with Warhammer 40,000. I play Adepta Sororitas and - though Games Workshop’s own range is great - I get excited by the opportunity to incorporate printed parts into my lineup, both as a modelling challenge and to make my figures look unique.

I play Adepta Sororitas and - though Games Workshop’s own range is great - I get excited by the opportunity to incorporate printed parts into my lineup, both as a modelling challenge and to make my figures look unique.

Printing for Warhammer games is not without its downsides. Games Workshop doesn’t allow 3D-printed components or miniatures at lots of its official events, just as it does not allow traditional miniatures or other parts produced by third parties.

Expansion of 3D printing has also proved to be very useful in the fan revival of dead games such as Mordheim. Older specialist games like Mordheim have been out of production for a long time, making getting hold of the original miniatures hard and expensive - leaving fans with few options. 3D printing has enabled a wide range of new third-party miniatures for the gothic skirmish game, including by companies such as Heresy Lab and Monstrous Encounters. The same is true of Battlefleet Gothic, Inquisitor and Warhammer Fantasy Battle, helping to keep those systems viable.

Watch on YouTube

3D printing has also opened up possibilities for indie and miniature-agnostic games - games designed to be used with miniatures by any company or even just paper cutouts. Producing miniatures using plastic injection moulds is a difficult and expensive process. Because of the expense, smaller games companies tend to have limited plastic miniature lines. 3D printing allows them to produce larger 3D-printable ranges or rely on existing archives of models to fill their games in addition to conventional miniature producers. A recent example is Reign in Hell, Snarling Badger Studios' skirmish game explicitly built to use miniatures produced by other companies. With 3D printing, game designers can produce a game and not worry about the mini lines to go along with it, confident that there will be enough figures from existing miniature companies and 3D printing for people to play their game.

What makes me most optimistic about the future of 3D printing in the hobby is seeing the collaboration between game designers and 3D miniature makers. Odd games like Turnip28 can get miniatures produced independently by artists who get the vision of the game and want to make something for it.

Odd games like Turnip28 can get miniatures produced independently by artists who get the vision of the game and want to make something for it.

This is a really interesting time to be a miniatures gamer or hobbyist. The ability of small artists to create miniatures and get them to market, and for people to print on demand, expands the possibilities for both hobbyists and gamers. As 3D printing technology becomes increasingly affordable and user-friendly, more people will find new uses and its place in the world of tabletop gaming will only grow.

3d Printed Miniature - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

09. 03.2022

03.2022

Content

- How to choose a 3D printer for miniatures

- Advantage of 3D printing for miniatures 9000 9000 FDM 9000 LCD/ DLP

- FDM

- LCD

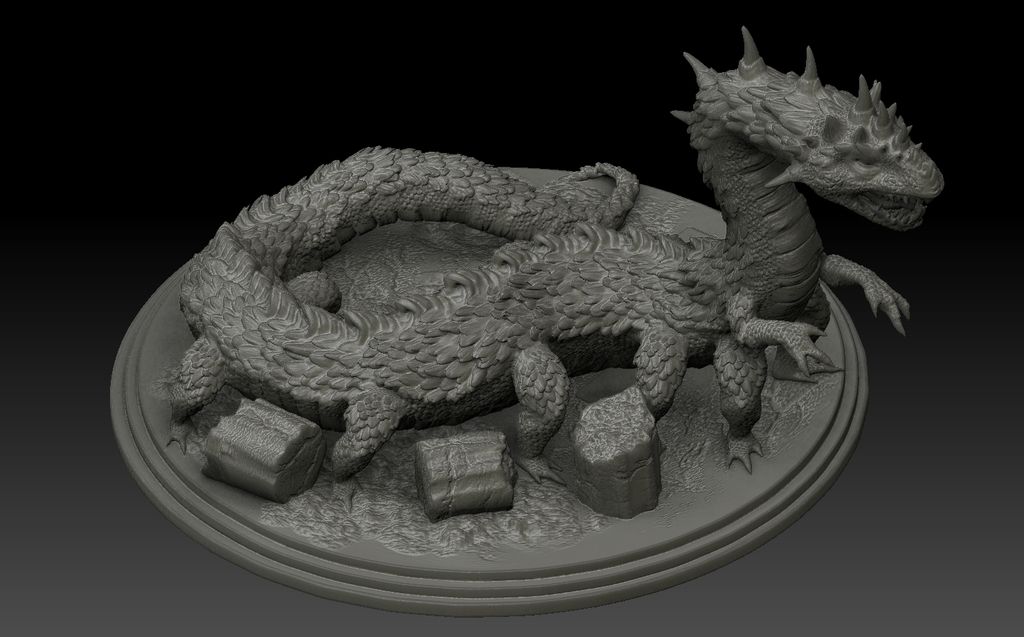

Miniature figurines with amazing detail attract the eye. A little grotesqueness and slightly wrong proportions (otherwise it would be inconvenient to play or transport such a “little one”) are more than compensated by detailed elaboration and an abundance of small, at first glance, insignificant details. These are no longer just small table soldiers, but heroes with their own unique history.

Warhammer 40k 9 miniature soldier0044

Miniatures come in different sizes: from 6mm and more. The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

A 3D printer will help not only in the production of miniatures, but also in related areas, such as the creation of figurines, details of game locations, or, for example, elements of dioramas. To understand the advantages of 3D printing over classical manufacturing methods, it is worth remembering how such models are usually made at home.

Advantage of 3D printing for miniatures

Not everyone was ready to shell out a substantial amount for the purchase of a set of table soldiers, and sometimes the necessary heroes simply were not on sale. Then baked and self-hardening plastics for modeling were used.

First you need to make a wire frame, so the finished figure will turn out to be more durable, and it will be much easier to keep all the proportions. The wire frame can be attached to the stand, which will make the miniature statue more stable, and it can be easily fixed in any position without fear of smearing small parts with your fingers.

Wire frame for miniature

Gradually, layer by layer, the volume of plastic increases on the frame. Each layer must be baked or dried well, depending on which plastic is used - self-hardening or baked.

Gradually, we begin to add small details and work out the details. In fact, this is a very painstaking process that requires perseverance and some sculpting abilities. For a convenient study of small details, you may need special stacks for modeling, but they can be successfully replaced with improvised tools.

Sculpting tool set

The result is such a miniature statue.

Miniature 28mm baked plastic

By the same principle, large table figures, or some elements of dioramas, can be made.

Sometimes a sculptor is more accustomed to working with plasticine. Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

But it is necessary to properly prepare the figurine for casting. The finished "warrior", most likely, will have to be divided into several parts, so that it would be more convenient for the caster to remove the molds and make castings. During the cutting process, it is worth adding a few locks so that the finished castings can be easily assembled, like pieces of a puzzle.

Molded figurine against silicone mold

Some craftsmen have learned to cast metal copies. Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold.

Cast metal soldier

In addition to making figurines from scratch, some craftsmen remake ready-made miniatures. This is called conversion.

This is called conversion.

Conversion in miniatures is a refinement, stylization or alteration of a finished figure. Unfortunately, not every hobbyist has good sculpting skills, and this alteration helps to achieve good results regardless of artistic skills. The main thing is to act very carefully.

Conversion helps enthusiasts achieve amazing figurine detail, add some detail, change the pose, or create a new character that is not yet on sale.

Lord of the Astral Claws turned to Chaos

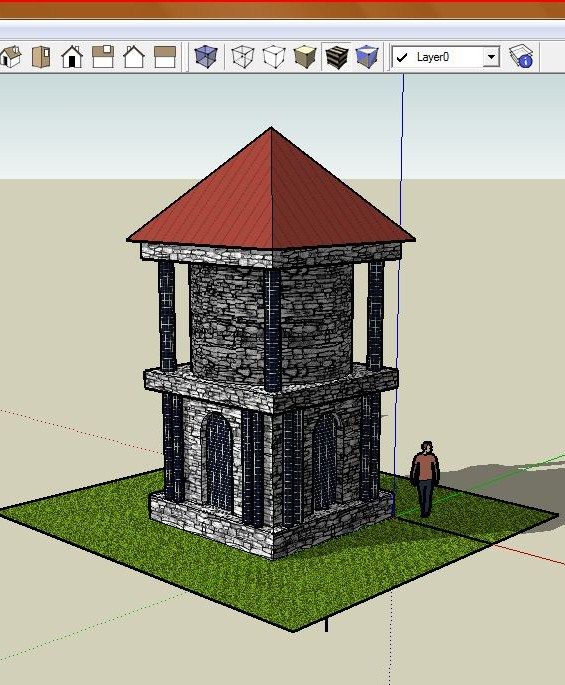

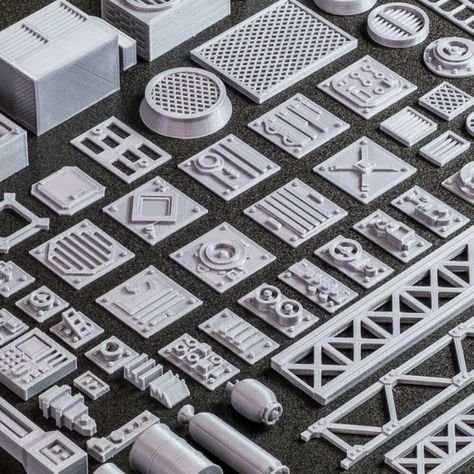

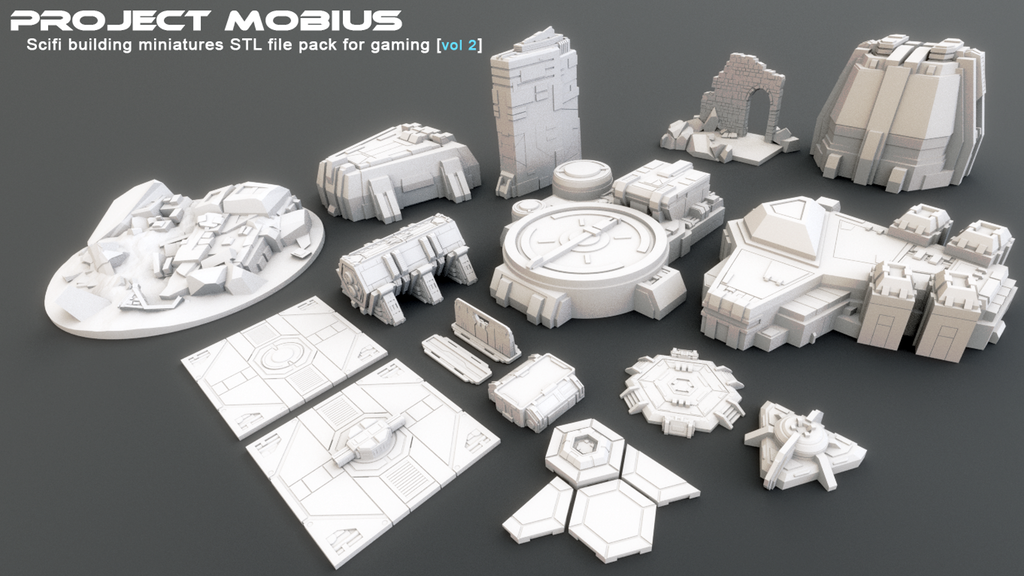

In addition to making the figures themselves, modelers create colorful locations to immerse themselves in the world of their favorite game. This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting.

Game location for board game Warhammer40k

The creation of such locations is painstaking work, and both improvised and special equipment are used as material.

Role play location

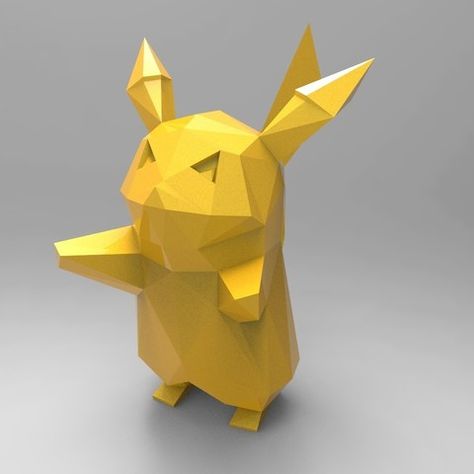

A 3D printer allows you to produce miniature figures and game locations much faster. On the Internet you can find many paid and free models of 28mm figures from different universes or various elements of locations - houses, fences, mechanisms, etc. Adapting or slightly changing the finished 3D model for yourself is much easier than cutting and gluing a finished figure. And creative people with modeling skills are unlikely to have difficulties with the transition to “digital clay”.

Warhammer40k universe 3D miniature model

And of course, dioramas are worth noting. This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

Diorama based on the game STALKER

Each diorama is unique, so the craftsmen use improvised materials to make it. Everything is limited only by the imagination and ingenuity of the artist.

Everything is limited only by the imagination and ingenuity of the artist.

Diorama “Desert Hero”

The main advantage of 3D printing is high detail and repeatability. If you need to make a small batch of miniatures, it will be much easier to print them than to cast, for example. Casting small items is a painstaking process that requires some skill and equipment. It is very difficult to achieve good pourability of small products the first time.

From model to finished figure

And for the manufacture of piece products, such as a diorama element, a 3D printer can replace many materials and tools for modeling. In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass.

Which technology to choose

To begin with, it is important to determine the requirements for the printer - will it be used only for the manufacture of 28mm personal army or should it be a universal printing machine? It is important to understand what size the finished model will be, how detailed it should be, and how much time can be spent on post-processing.

Depending on this, it is worth deciding on the technology by which the 3D printer will work. You can choose one of two technologies - FDM or photopolymer printing (there are several technologies, but DLP and LCD printers are currently popular).

FDM

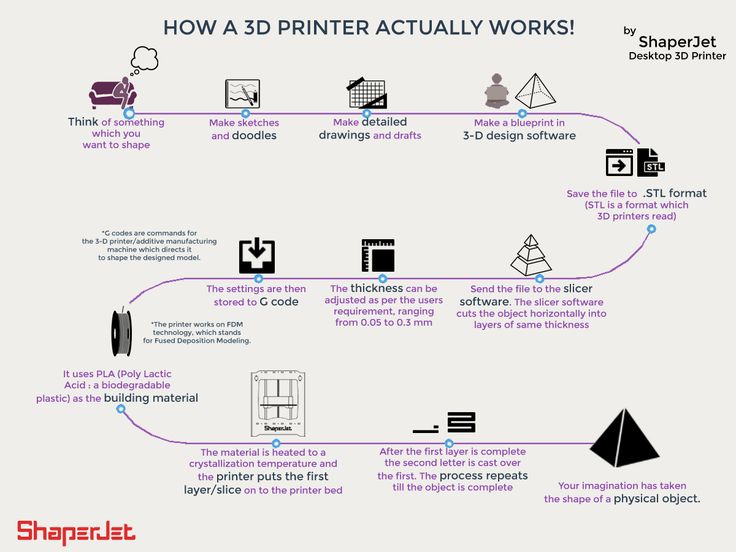

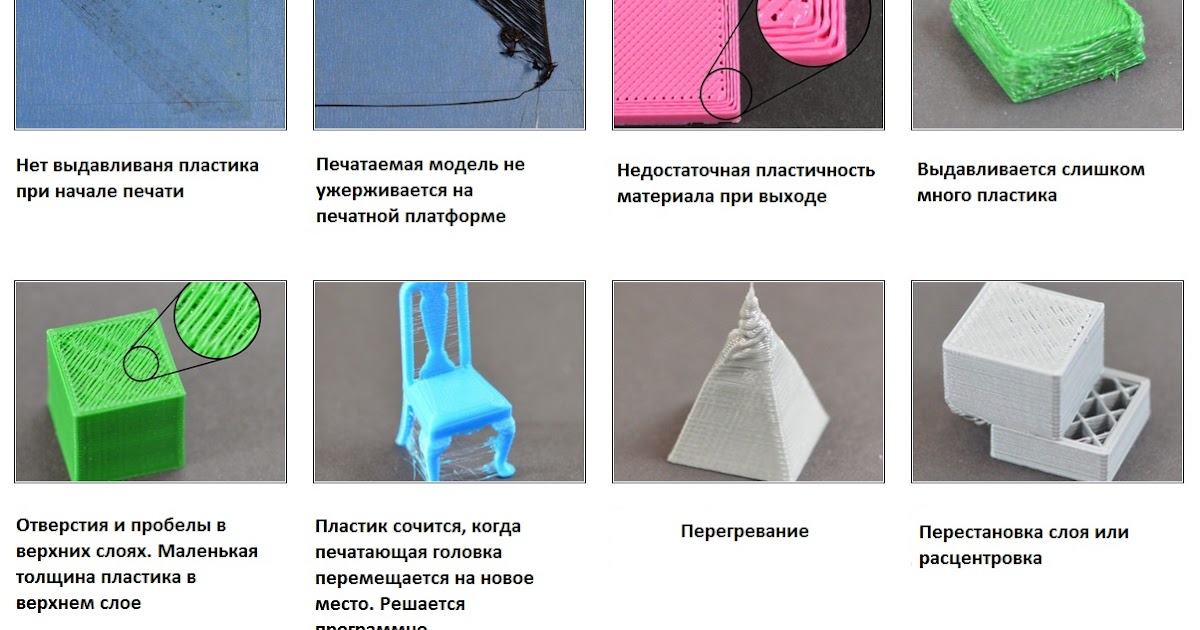

FDM 3D printers use a plastic filament as a material. In a heated extruder, the filament is melted and extruded through a thin nozzle, so layer by layer, a three-dimensional model is grown.

Working principle of FDM 3D printer

Layer thickness and nozzle diameter can be changed in some printer models. The minimum layer is usually 0.1 mm. In some models of 3D printers, a layer of 0.05 is available, but for printing with such a layer, it is important to choose the right many settings and the print speed will be quite slow.

Pros:

-

Large print area

-

Many different materials are available for every “taste and budget”

-

Inexpensive Consumables

Cons:

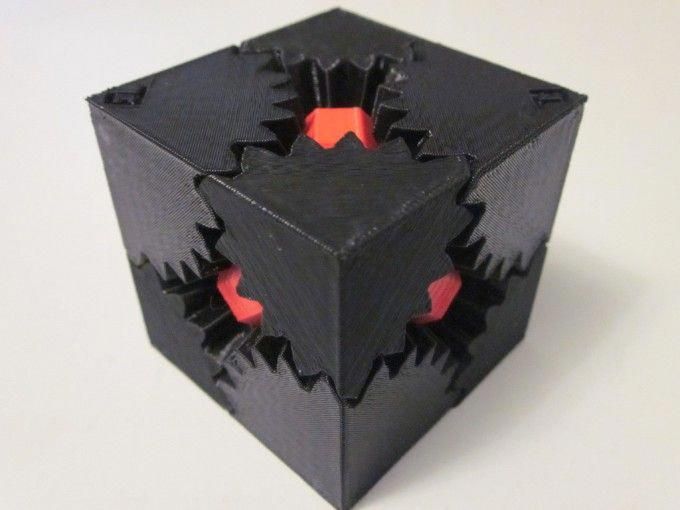

Of course, FDM printers are hardly suitable for making miniature figures, but they can be successfully used to print large souvenir figures, create game locations and some parts of dioramas.

LCD/DLP

The principles of operation of LCD and DLP printers are very similar. The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

Working principle of photopolymer 3D printer

Pros:

-

The ideal surface of the finished figure

-

Many different materials available

-

High print accuracy even for the smallest items

Cons:

Photopolymer 3D printers are able to create miniature products that cannot be made using FDM technology. This technology will be an ideal choice for creating miniatures, small poster models, etc.

Print examples

Robot printed on Asiga Pro 4k

Figurine made with Phrozen Sonic Mini 4k

28mm 3D printed miniatures

3D Printed Halloween Miniature

3D printed play models

FDM Cube Thrower

Figure making process from 3D model to painting

Best Printer Ranking

FDM

Creality3D Ender 3 (Build Kit)

Features:

Print technology: FDM/FFF

Working area size: 220x220x250 mm

Number of extruders: 1

Max. extruder temperature: max. 255℃

extruder temperature: max. 255℃

Closed Camera: No

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

A popular and unpretentious 3D printer that many makers liked. Creality3D Ender 3 is sold as a kit (assembly kit), but thanks to the detailed instructions, there should be no problems with assembly.

Wanhao Duplicator 6 Plus

Features:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: max. 260°C

Closed Camera: Optional

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

Wanhao Duplicator 6 Plus is an updated version of the Duplicator 6. The new modification adds automatic calibration, printing resume after a power outage, and others. You can immediately purchase a printer with a closed case, this will allow you to easily print with composites. Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

FlashForge Creator Pro 2

Features:

Print technology: FDM/FFF

Working area size: 200x148x150 mm

Number of extruders: 2

Max. extruder temperature: max. 240°C

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

FlashForge Creator Pro 2 is an almost professional dual extruder 3D printer. Thanks to the closed body, Creator Pro 2 has no problem even with composite materials, and two extruders allow the use of soluble support for complex models. Moreover, FlashForge extruders are independent, this allows you to print 2 mirror or identical models at the same time. This allows you to speed up the production of the same type of models. FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

LCD

Anycubic Photon Mono 4K

Features:

LCD display resolution: 3840x2400 (4K)

UV wavelength: 405 nm

Working area size: 132x80x165 mm

Layer thickness: 0.01-0.15mm

Inexpensive, but fairly modern 3D printer with a 4K monochrome display. Anycubic Photon Mono 4K will be a good tool for printing miniature models.

Phrozen Sonic Mini 4K

Features:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x130 mm

Layer thickness: 0.01-0.30mm

The Phrozen Sonic Mini 4K is a compact high resolution 3D printer. It allows you to get accurate models even with an abundance of small details. Sonic Mini 4K is a good choice for those who need to print quickly and accurately.

Phrozen Sonic Mighty 4K

Features:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

With a larger work area, the Phrozen Sonic Mighty 4K allows you to quickly produce large models or small batches of small items. Such a 3D printer will be a good help for a small workshop or a hobby circle.

Phrozen Sonic Mini 8K

Features:

LCD resolution: 7.1" 8K Mono LCD

XY Positioning Accuracy: 22 µm

UV wavelength: 405 nm

Working area size: 165x72x180 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mini 8K is one of the representatives of 8K photopolymer printers, which can still be counted on the fingers of one hand. The high resolution LCD-matrix allows you to print figures with amazing surface quality and amazing detail. Such a printer is suitable for demanding printers who care about accuracy and the perfect surface of the finished model.

Such a printer is suitable for demanding printers who care about accuracy and the perfect surface of the finished model.

Totals

3D printers are gradually showing themselves to be great helpers in many areas, not only in medicine and industry, but also in home hobbies. Thanks to 3D printing, it is possible to produce small figurines or elements of dioramas much faster, paying more attention to the elaboration of details, rather than painstaking modeling or the search for exotic materials.

And digitalization makes it much easier to share your work and finished models in the community or adjust them to your needs, for example, change the scale or adjust the pose.

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

#Application

Share

all materials

Choosing the best 3D printer for printing miniatures

3DPrintStory Reviews Choosing the best 3D printer for printing miniatures

The use of 3D printers for printing game miniatures is gaining more and more popularity today. As the price of 3D printers continues to fall, it is likely that the demand for 3D printed game miniatures will only continue to rise.

As the price of 3D printers continues to fall, it is likely that the demand for 3D printed game miniatures will only continue to rise.

If you pick the right 3D printer, you can get amazing 3D models for your board games or to put an inspirational figurine from your favorite game on your desktop.

Today's desktop 3D printers have become reliable, easy to use and deliver decent quality finished products.

How to choose a 3D miniature printer?

There is a wide range of desktop 3D printers that can be used to print miniatures in 3D at home. And if you study the market a bit, or at least the options below, you can get great detailed 3D models.

With the right 3D printer, you can print your own figurines and even create your own board games.

If you don't want to design 3D models of figurines from scratch (and this will really require some skills and time from you), then you can find interesting 3D models on sites with free 3D printable models. After downloading the model, you can immediately print it or edit it before 3D printing for your own needs. We also recommend that you familiarize yourself with interesting 3D models from Dutchmogul. Perhaps in his wonderful collection you will find something interesting for yourself.

After downloading the model, you can immediately print it or edit it before 3D printing for your own needs. We also recommend that you familiarize yourself with interesting 3D models from Dutchmogul. Perhaps in his wonderful collection you will find something interesting for yourself.

To get the same level of detail as the thumbnails above, your 3D printer must meet certain criteria. The most important feature of a 3D printer to consider is the level of detail it can reproduce. This criterion is formed based on the following parameters:

Nozzle diameter

To create a 3D miniature, heated plastic is extruded through a hole. Orifice is the diameter of the nozzle. Make sure the 3D printer nozzle size is less than 0.4mm.

XY Movement Accuracy

The X and Y axis movement accuracy of the 3D printer head should be taken into account. To get a more detailed model, you need to reduce the layer thickness. However, the low thickness means that 3D printing will take longer. In order to print a detailed miniature, you will most likely need a 3D printer that can print with layer thicknesses of 100 microns (0.1 mm) or less.

In order to print a detailed miniature, you will most likely need a 3D printer that can print with layer thicknesses of 100 microns (0.1 mm) or less.

Material type

The most common materials used in 3D printers are ABS or PLA. To get a good surface, after 3D printing, it should be post-processed. If you are using ABS plastic, you can sand the miniature and steam it in acetone to get a smooth surface. It is also worth paying attention to PETG plastics, which are gaining more and more attention and positive user reviews.

Thumbnail size (scale)

If you want to start 3D printing game miniatures, think about the size you would like to get.

A 28mm (~1:58 scale) or 54mm (~1:32 scale) miniature can be made with a standard desktop 3D printer that melts plastic filament. To make a smaller miniature, you will need an SLA Resin printer, which uses liquid resin and strengthens it.

In addition to the figurine, you can also print larger models. 3D printing large models such as houses, huts, castles, trees, and tanks will require more expensive 3D printers that provide faster speeds with good 3D print quality. But there is an important point in the choice. It is better to choose high-quality 3D printing than a large one. You can always separate larger models for printing and then join them together using the same adhesive. The result will be much better than lower quality 3D printing on a 3D printer with a large workspace.

3D printing large models such as houses, huts, castles, trees, and tanks will require more expensive 3D printers that provide faster speeds with good 3D print quality. But there is an important point in the choice. It is better to choose high-quality 3D printing than a large one. You can always separate larger models for printing and then join them together using the same adhesive. The result will be much better than lower quality 3D printing on a 3D printer with a large workspace.

HICTOP CR-10S 3D printer

Value for money, the Hictop CR-10S is one of the best and most affordable budget 3D printers on the market. The Prusa i3 3D printer was taken as the basis for the design.

The Hictop printer uses quality materials for the power supply, motherboard and motion control systems. The metal framework is a rigid and strong design.

The Hictop printer will arrive unassembled, but assembly is easy. You will have to essentially screw in four bolts and connect the necessary wires. That is, you can proceed directly to 3D printing almost immediately after purchase.

That is, you can proceed directly to 3D printing almost immediately after purchase.

The "S" at the end of the CR-10S stands for two Z-axis lead screws and stepper motors.

Dual axis system improves extruder movement accuracy. As a result, you naturally get more accurate 3D printing overall. This is an excellent inexpensive 3D printer that is suitable for 3D printing miniatures and figurines for board games.

The Hictop 3D printer has a mechanism to control the remaining amount of plastic. If the plastic runs out, the printer will go into pause mode and after feeding new material, you can continue printing from the area where you left off. This is a particularly relevant feature for printing large-scale 3D models.

These 3D printers are quite popular, so you will find a lot of information and tips on how to use them online. In addition, thanks to an active community, the Hictop CR-10S has a large number of modifications and upgrades that you can implement yourself and improve its already decent 3D printing quality.

Hictop CR-10S is a quality and affordable 3D printer, which is definitely suitable for 3D printing miniatures and figures of characters from your favorite games or movies.

FLASHFORGE CREATOR PRO 3D printer

FlashForge 3D Printer Creator Pro took inspiration from Makerbot Replica.

A nice feature of the FlashForge 3D printer is that it includes all custom enhancements from Makerbot. These upgrades include:

- Metal worktable supports. Thus, the working table became more stable during heating and assembling.

- Plastic-coated knobs for easy workbench calibration.

- The Central Processing Unit (CPU) supports Sailfish firmware which allows automatic calibration. In addition, the CPU helps regulate heat and delivers higher quality 3D prints.

The above features make the Creator Pro an excellent miniature 3D printer.

In addition, this 3D printer is made in a closed case, which allows you to print ABS plastic with much less difficulty.

Creator Pro allows you to print two colors at the same time. If you plan to paint the finished model in the future, then you don’t really need this feature, but in general it gives you much more options than the standard analogues with one extruder.

Since the Creator Pro is based on the Makerbot Replica, there is a lot of information available on the internet about this 3D printer.

3D printer SINDOH DP200 3DWOX

If you are looking for a reliable 3D printer for printing miniatures, then you should pay attention to Sindoh DP200 3DWOX. This is the best choice if you want to make 3D mini figures.

This 3D printer is easy to use, suitable even for beginners in the world of 3D printing. Below are some of its features:

- 3D printing table covered with aluminum PTFE.

- 3D printing resolution is 50 microns (0.05 mm).

- Equipped with a high efficiency particulate air filter and a closed chamber for 3D printing, which is especially good when using ABS plastics.

- Easy to use material cartridge chamber.

- Sindoh does an excellent job of printing minifigures in high detail.

One of the disadvantages of the Sindoh DP200 printer is that it can only use manufacturer's filament. Consequently, you will pay more money for cartridges because you will not be able to use materials from other manufacturers. The price of these cartridges, of course, is higher than analogues.

Otherwise, the Sindoh DP200 3DWOX 3D printer is a great option for high quality 3D printing of detailed models.

DREMEL DIGILAB 3D Printer

The use of SLA technology for 3D printing helps to obtain miniature products of very high quality. SLA also helps print miniature parts as small as 28mm. The price of this wonderful 3D printer is comparable to the cost of a laptop.

SLA printing differs from FFF printing in the very essence of the processes. During SLA 3D printing, liquid resin is baked using a UV laser. The formation of the part looks like a gradual lifting of the finished model and a bath with liquid material.

Industry-intensive stereolithographic 3D printers are now available at home! The Dremel Digilab 3D printer has proven itself as a hobby printer, which differs from expensive industrial analogues in its exceptionally smaller workspace.

Key Features of the Dremel Digilab 3D Printer:

- The minimum wall thickness of the 3D model is 25 microns (0.025mm).

- Faster 3D printing compared to FFF 3D printers.

- Excellent surface quality of the finished 3D model.

Digilab is an excellent SLA 3D printer. It is easy to use and, according to user reviews, reliable.

With this 3D printer, you can use resins to make investment casting molds. It can also be used to make jewelry by casting metals.

Some disadvantages of using SLA for 3D printing:

- It's expensive. The resin needs to be updated, as over time it ages and loses the necessary properties.

- Resins require maintenance. Make sure you start 3D printing only after the balloons created by adding resin to the tank are gone.

Learn more