3D printing filament for sale

3D Printer Filament | MatterHackers

- Home

- Store

- 3D Printer Filament

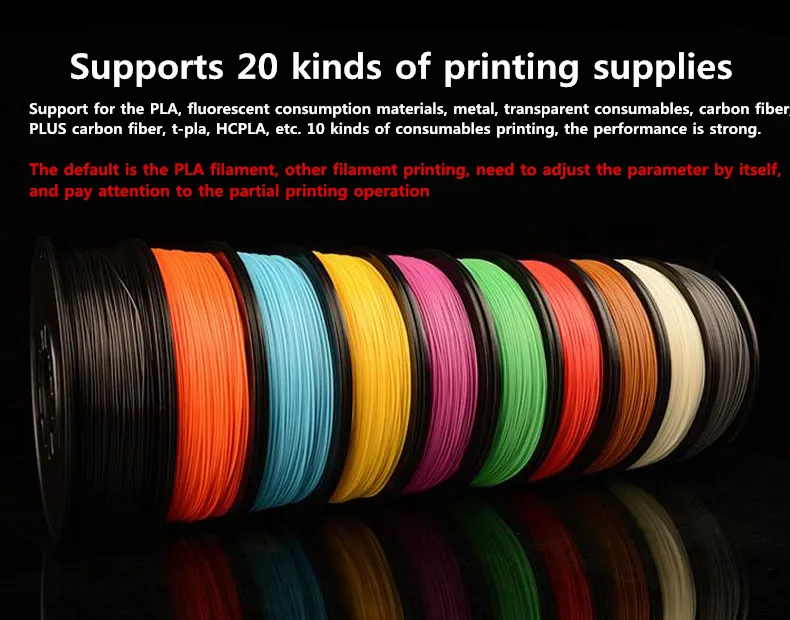

At MatterHackers, we take pride in offering the largest selection of 3D printing filament available. From our affordable MH Build Series filament, to our professional-grade PRO Series filament, you can find any material, like PLA, ABS, NylonX, PETG, TPU, TPE, Flexibles, Polycarbonate, and more! Along with our industry-proven brand of filament, we also carry other top-notch materials from ColorFabb, Taulman3D, NinjaTek, Ultimaker, 3DFuel, and more.

3D Printer Filament Collections

All 3D Printer Filament

Getting Started

3D Printer Filament Comparison Guide

3D Printer Filament

PLA Filament

The most common filament, PLA is a great go-to material for its ease of use.

Metal 3D Printing Filament

Print with real metal on your desktop 3D printer.

ABS Filament

ABS is a durable material perfect for projects that need strength.

PETG Filament

PETG is a strong, reliable material that is great for end-use parts.

Nylon Filament

Nylon and Nylon Composites for strong, functional 3D printed parts.

Quantum Dual-Color PLA

Mind-bending, dichromatic PLA that works on every printer

Support Filament

Dissolvable and breakaway support materials for dual extrusion 3D printing.

MH Build Series Filament

MH Build Series filament is designed and priced for every maker

MH Build Series PLA

An affordable, low-cost PLA filament intended for producing quality, 3D printed parts.

MH Build Series ABS

An affordable 3D printing filament meant for every maker with projects that require durable and temperature resistant parts.

MH Build Series PETG

An affordable, low-cost PETG filament intended for producing tough and sturdy 3D printed parts.

MH PVA Support Filament

MH PVA Support Filament is a dissolvable support material for dual extrusion parts.

PRO Series Filament

When reliability and consistency counts, be a PRO.

PRO Series PLA

PRO Series PLA is intended for producing professional, high quality, 3D printed parts.

PRO Series ABS

A formulation intended to help your prints stand out with a beautiful, glossy, opaque finish.

PRO Series PETG

Temperature resistance and fantastic visual performance with translucent colors

PRO Series Tough PLA

Strong like ABS and much easier to use - it's the best material for reliably printing functional prototypes.

PRO Series Flex

All the benefits of flexible filament together with improved strength over other flexible filaments

PRO Series Nylon

The strength and durability of Nylon now in vibrant colors.

PRO Series Ryno

Excellent at bridging and retraction to keep your parts clean with minimal post-processing.

NylonX

The durability of Nylon combined with the stiffness of carbon fiber

NylonG

Glass infused nylon for strong, functional prints

Carbon Fiber Reinforced PLA

Carbon Fiber reinforced PLA adds more strength and rigidity compared to regular PLA.

ColorFabb

With several varieties available, ColorFabb filament is consistent and reliable.

ColorFabb Fill Series

PLA filaments infused with wood, metal and glow-in-the-dark particles for eye-popping prints.

ColorFabb PLA/PHA Series

A unique 3D printing filament tougher and less brittle than just PLA.

MadeSolid

Affordable materials from MadeSolid - limited time only.

NinjaTek

High quality and industry-leading flexible materials.

PVA (Polyvinyl Alcohol)

Polyvinyl Alcohol, a water-soluble support material that dissolves away in a water bath to leave only your perfectly printed part.

Polymaker Filament

Browse all filament collections from Polymaker!

Polypropylene Filament

Polypropylene (PP) is a semi-crystalline thermoplastic filament used to produce durable and lightweight prototypes through Fused Filament Fabrication (FFF).

Proto-Pasta PLA Blends

PLA filaments blended with metal, wood and glow-in-the-dark materials for cool print effects.

Soft PLA

Soft PLA is a flexible material great for parts that need to bend to fit their environment.

PRO Series TPU

Strong yet bendable filament that has excellent layer to layer bonding.

Taulman 3D

High-strength nylons and engineering-grade materials for functional 3D printing.

Ultimaker ABS Filament

Get beautiful, glossy prints with Ultimaker ABS filament

Ultimaker CPE Filament

Get high impact strength and chemical resistance with Ultimaker CPE

Ultimaker Materials

High-grade filament for any 3D printer from Ultimaker

Ultimaker Nylon Filament

Get impact and abrasion resistance with Ultimaker Nylon filament

Ultimaker PLA Filament

Highly versatile, easy to print and available in a variety of colors.

Ultimaker Polycarbonate Filament

3D Print molds, tools, and functional Prototypes with Ultimaker PC

Ultimaker TPU Filament

Get qualities of rubber and plastic and resistance with Ultimaker TPU

Fillamentum

From ASA to exotic colors, Fillamentum provides a quality 3D printing experience.

3DXTech Filament

Explore advanced manufacturing filament from PEEK to ESD-safe materials.

Proto-Pasta

Metallic filament and unique composites make Proto-Pasta 3D filament stand out.

SpoolWorks

3D printing materials from the creators of the industry-leading All-metal v6 HotEnd.

PRO Series Breakaway Support Material

Provides fast, easy, and clean mechanical breakaway for 3D printed parts.

AprintaPro Filament

3D printing filament with great layer adhesion that produces excellent parts.

Kodak 3D Printing Filament

A wide range of 3D printing materials with a focus on color and quality.

eSUN

Consistent and reliable 3D printing filament for entry-level 3D printing.

BASF Ultrafuse 316L Metal 3D Printing Filament

Reliable metal manufacturing for industrial applications - right from your desktop 3D printer.

FiberForce Pantone (R) Certified PLA

Browse a selection of Pantone® certified colors.

Ultimaker Tough PLA Filament

The ease of PLA printing with the impact resistance and stiffness of ABS.

Kai Parthy Lay Series

Browse unique and experimental 3D printing materials.

DSM 3D Printing Filament

Engineering-grade, advanced 3D printing materials for industrial production.

Engineering Grade Filament

High-temperature and advanced materials used in several industrial applications.

MakerBot 3D Printing Filament

Rigorously tested for quality, and optimized for Method Printers.

Fillamentum ExtraFill Series

An excellent baseline PLA that prints amazingly well.

Fillamentum Extrafill ABS Filament

Premium ABS Filament with a wide variety of vibrant colors.

Fillamentum Crystal Clear Series

An incredible line of semi-transparent, colored materials.

Fillamentum FlexFill Series

Flexfill is rubbery and elastic, making it impact, oil and abrasion-resistant.

Fillamentum Vertigo Series

Vertigo PLA series reflect light and create awesome, eye-catching prints with flecks of gold, silver and blue.

Fillamentum PVC Vinyl Filament

Fillamentum PVC Vinyl Filament

Fillamentum ASA Series

A rugged weather-resistant material that is much more resistant to UV light.

Fillamentum TimberFill Series

Made from a PLA base with wood particulate, Timberfill gives you 3D prints that look like they were carved from wood.

Fillamentum CPE

Fillamentum CPE

Dow OBC 3D Printer Filament

Strength and Flexibility in One Easy-to-Print Material

Raise3D Filaments

Browse Raise 3D selection of 3D printing filaments

Kodak Nylon 3D Printing Filament

Kodak Nylon 3D Printing Filament

Kodak PLA+ 3D Printer Filament

Kodak PLA+ 3D Printer Filament

Kodak Flex 98 3D Printing Filament

Kodak Flex 98 3D Printing Filament

Kodak PLA Tough 3D Printer Filament

Kodak PLA Tough 3D Printer Filament

Kodak PETG 3D Printer Filament

Kodak PETG 3D Printer Filament

Kodak ABS 3D Printing Filament

Kodak ABS 3D Printing Filament

BASF Ultrafuse 3D Printer Filament

Industrial grade filament for technical and engineering level 3D printing.

BASF Advanced Specialty Materials

Sophisticated, advanced materials created by the world's leading chemical company.

Clearance Items - Materials

Filament and resins at reduced prices for great savings.

Metallic 3D Printing Filament

Browse real stainless steel metal filament and metal composites

Guides & Articles

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

How to Succeed when 3D Printing with PETG Filament

This in-depth guide provides everything you need to succeed when printing with PETG filament. Embrace the fantastic properties of durable and easy to print, PETG filament!

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When Printing With Flexible Filament

Let’s take a look at what makes flexible filaments easier to print and how you can add flexible filament to your 3D printing material toolbox.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

How to Succeed When 3D Printing with MH Build Resin

Make SLA resin 3D printing easier with this helpful detailed article on how to successfully fine-tune photopolymer resin to your 3D printer.

How To Succeed: 3D Printing with Nylon and Nylon Composites

Nylon and nylon composites perform exceptionally well in a variety of uses, it just takes a gentler touch to print it successfully.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

What is 3D printing filament?

3D printing filament is a thermoplastic, or polymer, that melts when heated and is extruded through a nozzle layer by layer to create a three-dimensional object. After the filament is extruded, it cools and becomes the surface the next layer is deposited on top of.

After the filament is extruded, it cools and becomes the surface the next layer is deposited on top of.

3D printing filament is sold in spools ranging in weight from 0.5 kg to 10 kg. It comes in two diameters; 1.75mm and 2.85mm.

The most commonly used filaments are PLA and ABS. Both have advantages for different applications.

What types of filament are there?

Below is a chart showing the more common types of filament, along with their transition temperatures, bed temperatures, and ideal printing surfaces.

| Filament | Common Transition Temps | Common Bed Temps | Printing Surface |

| PLA | 205±15 °C | 40±15 °C | Glass |

| ABS | 230±10 °C | 90±10 °C | Glass with ABS slurry or kapton tape |

| PETG | 245±10 °C | 60±10 °C | Blue painters tape or bed adhesive |

| Nylon | 255±15 °C | 70±10 °C | Garolite |

| ASA | 250±10 °C | 90±10 °C | Hairspray, bed adhesive |

| Polypropylene | 250±15 °C | 110±10 °C | Packing tape or polypropylene |

| TPU/TPE | 230±10 °C | 50±15 °C | Glass, painters tape |

| PCTPE | 235±10 °C | 70±10 °C | Glass with kapton tape or hairspray |

| Polycarbonate | 290±20 °C | 130±15 °C | Gluestick/hairspray |

| PVA Support | 180±20 °C | 45±10 °C | LayerLock PEI |

| Breakaway Support | 210±10 °C | 50±5 °C | LayerLock PEI |

| HIPS Support | 230±10 °C | 50±10 °C | Glass with kapton tape or hairspray |

Metal 3D Printing Filament from BASF

- Home

- Store

- 3D Printer Filament

- Metal 3D Printing Filament

BASF Forward AM's Ultrafuse metal 3D printing filament has changed the game for desktop 3D printing. You can now print with real stainless steel metal on even the most low-cost 3D printers. This metal 3D printing filament that can be debound and sintered, leaving your 3D printed part solid stainless steel metal.

You can now print with real stainless steel metal on even the most low-cost 3D printers. This metal 3D printing filament that can be debound and sintered, leaving your 3D printed part solid stainless steel metal.

Using the right design parameters and print settings, along with a simple hardened steel nozzle upgrade, anyone from manufacturers and engineers to research students and hobbyists can successfully print with solid metal on their 3D printer.

Looking for metal composite filament for aesthetic characteristics? Check out our Metallic 3D filament!

Metal 3D Printing Filament Collections

All Metal 3D Printing Filament 3D Printer Filament

Metal 3D Printing Filament

BASF Ultrafuse 316L Metal 3D Printing Filament

Reliable metal manufacturing for industrial applications - right from your desktop 3D printer.

BASF Ultrafuse 17-4 PH Metal 3D Printing Filament

The most affordable way to print with real metal on any desktop 3D printer.

BASF Ultrafuse Metal Processing Tickets

Convenient service process for debinding and sintering Ultrafuse 316L and 17-4 PH.

Metal Filament 3D Printer Adhesives

Browse solutions for getting the best first layer and results when using metal materials.

Guides & Articles

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

BASF Forward AM: A Look at One of Additive Manufacturing's Top Chemical Producers

BASF Forward AM is the production branch of BASF that creates a wide range of additive manufacturing materials for businesses and personal 3D printing.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

Stainless Steel Metal 3D Printing on Benchtop 3D Printers

A MatterHackers presentation on advanced materials and their rising presence in 3D printing and BASF Ultrafuse 316L, a composite filament that yields pure metal components

Casting Metal Parts From 3D Prints

Follow Sylatech as they transform legacy casting processes with 3D printing.

How to Succeed When 3D Printing With Metal PLA

Learn the best tips and tricks for 3D printing with metal-infused PLA 3D printing filament.

How To: Post Process Metal Filled Filaments

While 3D printing in true metal is still cost prohibitive to most people, 3D printing composite materials to achieve the look and feel of metal is easy, and all it takes is time.

Tech Breakdown: A Detailed Account of ColorFabb SteelFill Filament

An in-depth review of SteelFill 3D filament, the next great metallic PLA from ColorFabb that delights users with its metal characteristics and relatively easy printing.

What is Metal filament?A cutting edge new 3D printing filament that has a stainless steel powder embedded within a thermoplastic polyester that provides an easy printing experience, yet can be processed into an actual metal part, with no remaining plastic. For tips and tricks on 3D printing BASF Ultrafuse Metal Filament, check out How to Succeed with 3D Printing Metal on a Desktop 3D Printer.

What are the properties of metal filament?316L and 17-4 PH Metal filament has multiple advantages in 3D printing and digital fabrication:

- Cost-effective when compared to small batch metal injection molding.

- Extremely safe and easy to print

- Simple processing to get metal parts

- Excellent chemical and thermal stability after printing

- Print with 17-4 PH for magnetic reactivity

- High corrosion resistance and toughness

Metal filament requires similar temperatures to PLA for printing. It is also highly recommended that a heated bed and proper adhesive be used.

It is also highly recommended that a heated bed and proper adhesive be used.

- Use a Glass Bed with Dimafix for proper adhesion.

- 225°C +/- 10°C is the optimal printing temperature for most machines. Never exceed 250°C.

- A heated build plate at 110°C +/- 10°C is nominal for improved adhesion.

- Use an abrasion resistant nozzle that's clean of any other material.

- Layer cooling can cause warping during printing, so do not use any part cooling fans.

- A print speed of 15 to 40 mm/s will ensure the highest quality prints.

- Set you Infill to 100%. Voids in your infill could lead to failure during processing.

- We recommend either Lines or Concentric pattern depending on your geometry. These will give you the most uniform and solid infill.

Metal filament can be used to make anything machined from aluminum blanks or injection molded.

- Functional Prototyping

- Medical Equipment

- Automotive Parts

- Pipes, pumps and valves for chemicals, gas, and oils

- Parts for tooling and mold inlays with near-surface cooling

- Weighty, shiny objects

3D Printer Filament Buyer's Guide

6 - Nylon (Nylon), PA (Polyamide)

WHAT IS NYLON?

Nylon or polyamide, a popular family of synthetic resins used in many industrial applications, is the champion in the world of professional 3D printing. Compared to most other types of 3D printer filament, it takes first place in the competition for strength, flexibility and durability.

USER NOTE

Another unique feature of this 3D printing filament is that it can be dyed both before and after the printing process. Nylon also has a drawback - it, like PETG, is hygroscopic, strongly absorbs moisture. Remember to store both materials in a cool, dry place, keep these filaments in perfect condition, and this will ensure the best quality prints. Better yet, dry it before printing.

Better yet, dry it before printing.

In general, there are many grades of nylon, but the most common for use as 3D printer filament are 618 and 645.

3D PRINTER FILAMENT PROPERTIES: NYLON (POLYAMIDE)

-

Tenacity: very high | Flexibility: high | Durability: High

-

Difficulty to use: average

-

Print temperature: 240 ° C

Table temperature: 70 ° C - 100 ° C 9000,000 -

Shrinkage / deformation: Significant

-

Soluble: no

-

Food safety: Consider the manufacturer's instructions

When should the nylon (polyamide) should be used?

Taking advantage of nylon's flexibility and durability, this filament can be used to create tools, functional prototypes or mechanical parts (such as hinges, buckles or durable gears), pattern rigging. nine0004

nine0004

Summary

-

Plus: High flexibility, high flexibility, durability, self -disposable material

-

disadvantages: As a rule, expensive moisture, requires a high nozzle and table

The performance of objects printed from nylon can be significantly improved by using nylon filament made with additional fillers: fiberglass or carbon fiber. nine0004

PA-GF (Glass Filled Nylon)

Glass fiber reinforced nylon. Compared with pure nylon filaments, the mechanical strength, stiffness, heat resistance and fatigue strength of glass-filled nylon are greatly improved, and shrinkage in 3D printing is reduced. Moreover, the hygroscopicity is reduced.

The "trouble" of pure nylon is the relatively low temperature of the onset of softening and thermal deformation under load - total 50 °С. Filling the thread with carbon fiber helps to defeat this effect.

PA-CF (carbon-filled nylon)

Environmentally friendly material based on nylon and 20% carbon fiber . Lightweight, odorless print with a matte finish. High hardness, high rigidity, good toughness, wear resistant material, suitable for printing industrial parts. Deformation temperature 120°C, therefore suitable for high temperature use. Compared to nylon, it has lower shrinkage and distortion. Fire rating: UL94-V2.

The positive experience with carbon-filled nylon has led major filament manufacturers to make the logical decision to launch other grades of thermoplastic filaments enhanced with carbon fiber. An overview of the various proposed options for such composite threads is the subject of the next paragraph of this Guide.

7 - Carbon-filled filaments

When 3D printer filaments such as PLA, ABS, PETG and nylon are reinforced with carbon fiber, the result is an extremely strong and stiff material with relatively low weight. Such compounds are particularly advantageous in structural applications that must withstand a wide variety of end uses. nine0004

Such compounds are particularly advantageous in structural applications that must withstand a wide variety of end uses. nine0004

NOTE TO THE USER

The downside of this material's outstanding properties is increased wear on your printer's extruder nozzle, especially if it is made of a soft metal such as brass. Just 500 grams of this exotic 3D printer filament will noticeably increase the diameter of a brass nozzle, so if you don't like frequent nozzle changes, consider using nozzles made of a more durable material - steel or even ruby.

WHEN SHOULD CARBON FILAMENT BE USED?

Due to its structural strength and low density, carbon fiber is the best choice for mechanical components. Do you want to replace a part in your car or aircraft model? Try this filament.

SUMMARY

8 - HIPS (high impact polystyrene)

In commercial production high impact polystyrene (HIPS) for CDs. nine0004 In the world of 3D printing, HIPS usually plays a different role. Using HIPS as a support material is quite simple. Print support structures on these materials where they are needed, and then carefully break them out with tweezers or other suitable tool. If it is difficult or impossible to get to the support printed with HIPS thread, it can be dissolved with D-limonene. It is also useful to squirt D-limonene at the contact points of the main model and the HIPS support before breaking it out. nine0004 Unfortunately, using HIPS as a backing material limits you to printing the main part in ABS only. Other 3D printing materials may be damaged by D-limonene. But HIPS and ABS print well together because they have the same strength, rigidity and close printing temperature. In fact, despite the fact that HIPS was originally used as a support material, it is a worthy filament for basic printing as well. It is stronger than PLA and ABS, warps less than ABS, and is easy to glue, sand, and paint. nine0004 With many characteristics similar to ABS, HIPS 3D Printing Filament is a good all-round solution for parts that must endure wear or for projects that require post-processing material to achieve the final look. Pros : Can be used as both a support material and a strong base filament for a 3D printer Cons : Requires dilution with relatively expensive D-limonene to remove supports, only compatible with ABS 9 - PVA advantage is fully used for commercial purposes. Common uses include packing dishwasher tablets or fishing lure bags (throw one into the water and watch it dissolve, releasing the bait). The same principle is applied in 3D printing, making PVA an excellent support material when combined with another filament in a dual extruder 3D printer. The advantage of using PVA over HIPS is that it can be used to support more materials than just ABS. The downside of this filament is that it is a bit more difficult to handle. Care should also be taken during storage - moisture in the atmosphere can damage the filament before printing. Silica gel dry boxes and pouches are a must if you plan to store your PVA coil for a long time. nine0004 PVA filament is an excellent choice as a backing material for complex prints with raised features. 10 — Cleaning This filament is unique in its kind because it is the only one designed not to print objects. It is intended solely for cleaning the nozzle of a 3D printer from the remnants of any working material after printing. The usual procedure for using a cleaning filament is as follows: heat the extruder tip to a temperature slightly above the operating temperature for the filament used before. To determine it, before starting the procedure, carefully read the information from the manufacturer of the filament used for printing. First, push the cleaning filament by hand (if your printer is designed to allow this) through the extruder to be cleaned. The “cleaning” temperature depends on what types of 3D printer filament you have used before, and what kind of filament you plan to use next (cleaning filament operating temperature: from 150 to 300°C). It is generally not necessary to use more than 10 cm of cleaning thread at a time. There are other methods of cleaning, such as cold removal of the remaining used filament with a solvent, followed by mechanical cleaning. nine0004 You should definitely clean your 3D printer's extruder between using two materials with completely different temperatures or colors. Generally speaking, it is very useful to regularly run a little cleaning filament through the heating tip of your 3D printer, for example, after a long (more than a day) printing even without a planned filament type change. 11 - Smooth Many 3D printed objects require a glossy finish. These are molds for casting in silicone, finishing elements of furniture prototypes or other details that are sensitive to a smooth look. In such cases, the main disadvantage of filament printing (layer-by-layer deposition) plays a very unpleasant role. How to get rid of the characteristic layered structure without applying laborious and expensive mechanical post-processing? Printed ABS objects can be processed in an acetone bath, but this operation is not the most pleasant for the printer user. How to be? The answer is: use an easily smoothed plastic, for example, eSmooth from the Chinese manufacturer eSUN. nine0004 Smooth filament printing is no more difficult than PLA, temperature characteristics are close, a closed 3D printer chamber is not required. It is enough to treat the constructed object with ordinary ethyl or isopropyl alcohol and leave it for some time, preferably for 8-9 hours. This interesting filament is recommended for applications where a very smooth printed surface is required and mechanical post-processing is difficult or impossible. It is desirable that there are no small significant elements of construction or design on the surface - they can be melted with alcohol. But details with a rounded surface and smooth transitions will turn out very well! Pros: is an easy way to achieve a smooth surface for your print on a less complex 3d printer. Cons: higher price compared to ABS or PLA, inability to process items with fine surface details. 12 - Wax3D (Wax thread) Do you want to get a product made of real brass, pewter or other metal? It's possible! First, you'll print your investment casting pattern using 3D printer wax filament, and after a few extra steps, your idea will be embodied in metal. nine0004 This process is called "lost wax casting" and it works like this: Create a direct wax mold, i.e. a wax copy of the intended final metal product. Dip the mold in plaster or other special compound and allow it to dry and harden. Place an item with a lost shape into the furnace. At a sufficiently high temperature, the wax will melt, leaving a "negative" space inside the shell into which the metal work is to be cast. nine0004 The 3D printer wax filament made the first step much easier. According to traditional technology, first it was necessary to prepare a metal mold on a CNC machine, and then pour wax into it to obtain an investment mold for metal casting. When using this or similar waxy materials, be aware that they are much softer than most types of 3D printer filament. Basic conditions for printing with wax filament: The main condition is that your printer must be able to print at an extruder temperature of 130 o C. The extruder must be built according to the "Direct" scheme (not Bowden!). A Teflon tube up to the nozzle is desirable for good filament glide. Adjustable push wheel pressure in a wide range of settings. It is also desirable that the feed gear should not be on the motor shaft, but through the gearbox. The motor heats up and can additionally soften the thread on the broach. Other measures may require modifying the extruder and applying print adhesive to your printer table. If you are casting metal parts, wax-like filaments such as Filamentarno WAX3D can give you more options, allowing you to print complex 3D objects directly, integrating into your investment casting workflow. Plus: Creation of melted forms using a 3D printer disadvantages: A specific type of extruder design and printed platform, limited use 13-ASA (acrylonitril-stitch Of course, ABS is good, but it has its drawbacks: ABS prints tend to denature and yellow if left outdoors in direct sunlight. That's why plastics manufacturers have found an alternative - acrylonitrile styrene acrylate (ASA), a weather-resistant analogue of ABS plastic that was originally developed for outdoor "street" use. Hence its main application is in the automotive industry. nine0004 ASA has high rigidity, resistance to dilute acids, mineral lubricating oils, diesel fuel. Unlike ABS, ASA plastic is resistant to UV radiation. The material does not turn yellow in the open air, it is easy to process. The ASA range includes high and low gloss grades. The main application of ASA plastic is the production of lampshades, car exterior parts (rear-view mirrors), lighting products. In addition to being strong and relatively easy to print, ASA 3D filament is also extremely resistant to reheating and, most importantly, shape and color changes. Another small benefit of using ASA over ABS is that it warps less during printing. But be careful how you set up your cooling fan - the ASA can easily burst if the fan is set too high during printing. nine0004 For a variety of outdoor applications, from replacement electrical outlet covers and architectural trim to custom garden gnomes and birdhouses. 14 - PP (Polypropylene) Polypropylene (PP) is strong, flexible, lightweight, chemical resistant and food safe, which may explain its wide range of applications including engineering plastics, food packaging , textiles and banknotes. nine0004 Unfortunately, as a type of 3D printer filament, PP is difficult to print, often exhibiting severe deformation and poor adhesion to the table. Because many household items are made from polypropylene, you can recycle your old trash and recycle it into new 3D printing filament. nine0004 If you can get PP warp under control, then for most prints that require a tough, lightweight material, PP will do just fine. However, it is important to note that although the material has found widespread use in food and pharmaceutical packaging due to its safety when used in contact with food, the FDM 3D printing process negates this. Hundreds (if not thousands) of hollow layers are to blame, in which bacteria can start - so it's best not to try. nine0004 pluses : high mechanical properties, chemical resistance  3D printers can't print "over the air" - that's where support structures come in. The protruding elements require some support structure, and this is where HIPS really excels. Together with ABS in a dual extruder printer, HIPS acts as an excellent support material.

3D printers can't print "over the air" - that's where support structures come in. The protruding elements require some support structure, and this is where HIPS really excels. Together with ABS in a dual extruder printer, HIPS acts as an excellent support material.

USER NOTES

WHEN SHOULD HIPS BE USED?

SUMMARY

nine0004

nine0004

USER NOTE

WHEN SHOULD PVA BE USED?

SUMMARY

Please note that cleaning the extruder is required not only when it is already clogged. It is especially useful to clean the nozzle when changing to a build with a different color or from one material to another, especially if they are incompatible due to very different extrusion operating temperatures. How can you continue to work with a filament with a relatively low melting point after printing is refractory without completely removing its residue from the nozzle? It is also helpful to keep the extruder clean to prolong its life. Make regular use of the cleaning floss a healthy habit. nine0004

Please note that cleaning the extruder is required not only when it is already clogged. It is especially useful to clean the nozzle when changing to a build with a different color or from one material to another, especially if they are incompatible due to very different extrusion operating temperatures. How can you continue to work with a filament with a relatively low melting point after printing is refractory without completely removing its residue from the nozzle? It is also helpful to keep the extruder clean to prolong its life. Make regular use of the cleaning floss a healthy habit. nine0004

NOTE TO THE USER

This is necessary to remove the "burned" material residues. Then lower the temperature to operating temperature and feed approximately 10cm of cleaning floss as normal. nine0004

This is necessary to remove the "burned" material residues. Then lower the temperature to operating temperature and feed approximately 10cm of cleaning floss as normal. nine0004 A few additional points to note:

WHEN SHOULD THE CLEANING FILTER BE USED?

SUMMARY

USER NOTE

Alcohol, as it were, melts the outer layer, making the surface glossy. However, during processing, small external parts can “float” or dissolve completely. Therefore, not any geometric shape of a product or tooling can withstand such a smoothing method. This should be taken into account when choosing an object for printing with the Smooth filament. nine0004

Alcohol, as it were, melts the outer layer, making the surface glossy. However, during processing, small external parts can “float” or dissolve completely. Therefore, not any geometric shape of a product or tooling can withstand such a smoothing method. This should be taken into account when choosing an object for printing with the Smooth filament. nine0004

WHEN SHOULD I USE Smooth?

SUMMARY

NOTE TO THE USER

WHEN SHOULD WAX THREAD BE USED?

SUMMARY

NOTE TO THE USER

WHEN SHOULD ASA THREADS BE USED?

SUMMARY

USER NOTE

If not for these issues, PP could seriously compete with PLA and ABS as popular types of 3D printing filament, given its strong mechanical and chemical properties.

If not for these issues, PP could seriously compete with PLA and ABS as popular types of 3D printing filament, given its strong mechanical and chemical properties.

WHEN TO USE Polypropylene Thread?

Summary

..

.. Share article:

What is the best plastic for 3D printing? Let's figure it out together!

3D printing plastic

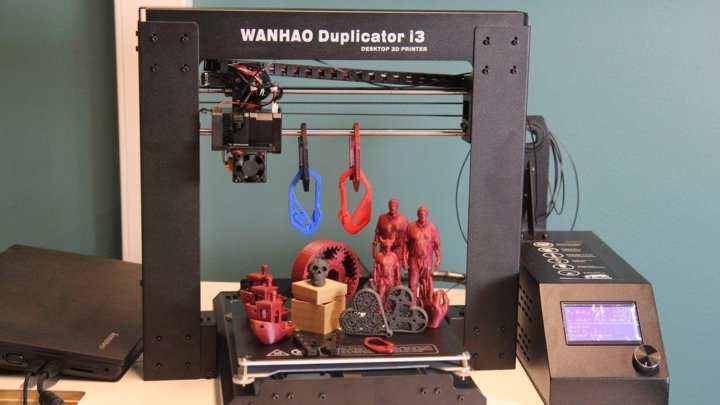

After purchasing your own FDM 3D printer, as well as in the course of choosing it, it becomes necessary to choose the right plastic for 3D printing. But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction. Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing.

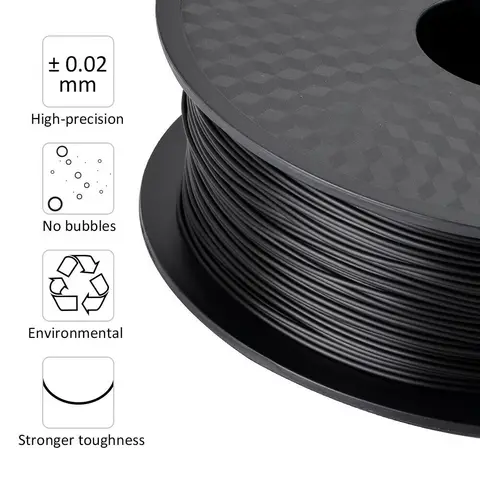

3D printer plastics

First of all, you need to consider the types of plastic for a 3D printer. Plastic for 3D printing, or filament, is produced in the form of a thin thread with a diameter of 1.75 mm and 3 mm. Most often, filaments with a thickness of 1.75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.

Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.

3D printing plastic: 9 varieties0434

In terms of popularity in the Ukrainian market, the following types of plastic for 3D printing can be distinguished:

- PLA (PLA) or polylactide. Organic and short lived. Suitable for 3D printing of decorative products, but not able to withstand high mechanical loads;

- ABS (ABS) or acrylonitrile butadiene styrene. It has a long life and excellent mechanical properties. Heat-resistant and used for industrial purposes. Shrinks on cooling. It is recommended to print in ventilated areas; nine0033

- PVA (PVA) or polyvinyl alcohol. A water-soluble material that is used as a support;

- Nylone (Nylon). An alternative to ABS plastic, suitable for many engineering structures. When printing with nylon, it is recommended to ventilate the room;

- HIPS (High Impact Polystyrene). In terms of physical properties, it is a cross between PLA and ABS.

May also emit toxic fumes when printed.

May also emit toxic fumes when printed.

Other questions and answers about 3D printers and 3D printing:

Which plastic is best for a 3D printer?

In fact, there are many more types of plastic for 3D printing. This can include flexible, fluorescent and luminescent filament, wood and metallized materials. But in practice, such consumables are rarely used and are needed for narrowly specific purposes. Metallized plastics are interesting in their own right, but they are at the initial stage of development and are inferior in performance to ordinary reinforced materials. “And what plastic is best for a 3D printer?” - you ask. You should choose based on specific goals. If you intend to print decorative elements that will not be subject to payload, you can look at PLA plastic. If your goal is to print gears, structural parts and other things, look at reinforced materials for 3D printing. nine0004

What kind of plastic to print?

Please note that not every printer supports the full range of 3D printing materials.