3D printing disrupting industries

10 Industries You Won't Believe Are Being Disrupted by 3D Printing

19 July 2018

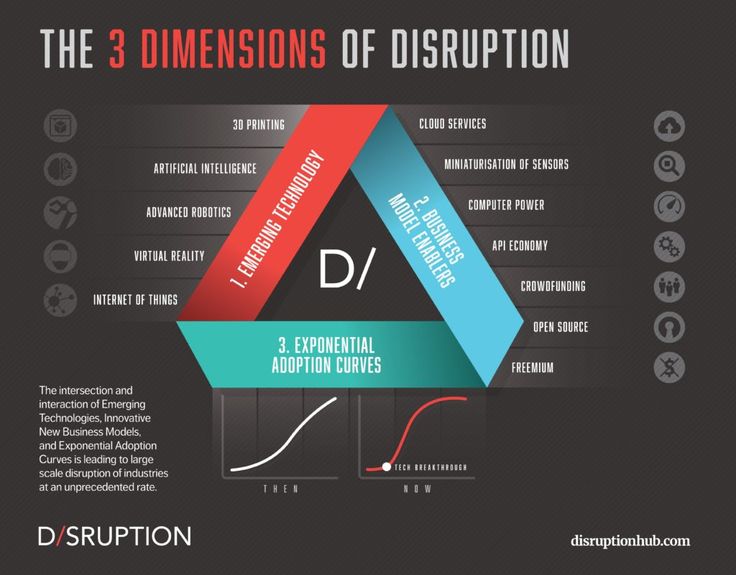

As 3D printing continues to evolve, advancements in the technology have already forged new trends and unlocked new possibilities for key industries like aerospace, automotive and medical. But the disruptive impact of 3D printing is not limited to these well-known cases – the technology also has huge potential in other, perhaps lesser-known areas too.

With that said, let’s take a look at our top 10 unexpected industries set to be disrupted by 3D printing.

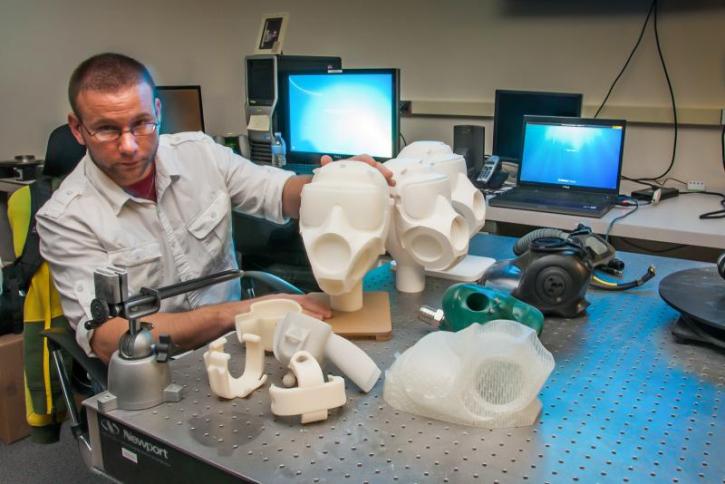

The medical field is among the top industries pioneering research into 3D printing, with the technology already being used to create patient-specific implants, prosthetics and dental devices.

However, advancements in 3D bioprinting and regenerative medicine could be the real game-changer for the medical world. Bioprinting is the process of layering living cells to grow organic structures using 3D printing technology. These bio-printed structures have enormous potential in the field of regenerative medicine, which seeks to restore the structure and function of damaged tissues and organs.

With a great deal of research being conducted in this area, medical researchers have already made strides in tissue and organ engineering. While this seems to be delving into the realm of science fiction, bioprinting has the potential to transform regenerative medicine by introducing a fast and sustainable way of producing complex transplantable human tissues and ultimately organs.

According to a SmarTech report, 3D printing revenues in the oil and gas industry are expected to reach $450 million by 2021, with several key players investigating the opportunities of the technology.

While 3D printing is already leveraged as a prototyping tool in the industry, the most disruptive potential of the technology may lie in the production of spare and end parts. Last year, Siemens Oil & Gas, for example, made headlines when it revealed its production of gas turbine blades, with improved functionality, using 3D printing.

Last year, Siemens Oil & Gas, for example, made headlines when it revealed its production of gas turbine blades, with improved functionality, using 3D printing.

Shell is also investigating 3D printing as a part of its digitisation strategy. Currently, the company uses the technology to test and validate 3D printed prototypes of various components, significantly reducing product development times. However, the company is also recognising the opportunity to use 3D printing opportunities to produce functional equipment components.

3D printing could therefore transform the way in which equipment components are produced and delivered, which could be particularly beneficial in locations where the supply of replacement parts is limited, or where logistical issues is likely to cause delays.

3D printing has taken off in film production, as it provides a way for filmmakers to create realistic and detailed props.

A great example is this year’s biggest superhero blockbuster: Black Panther. Thanks to the freedom of design afforded by 3D printing, costume designers, Ruth E. Carter and Julia Koerner were able to create the impressive crown and a curved mantel worn by Queen Ramonda (played by Angela Bassett), blending the elements of traditional African style and futurism.

The benefit of 3D-printed props is reducing the cost of highly expensive visual effects. This is because in some cases, 3D printing props is a cheaper and potentially faster alternative to creating computer-generated images. As more film studios are actively engaging in 3D printing efforts to meet tight deadlines and provide more realism, the technology has a big future in the filmmaking industry.

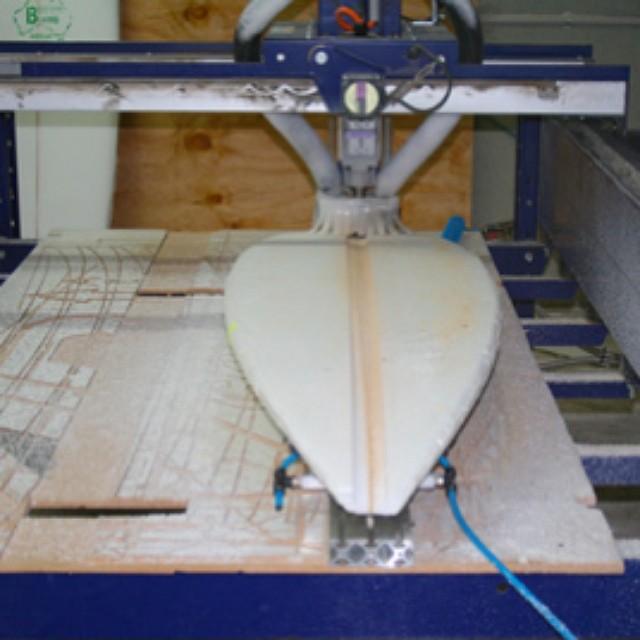

While 3D printing has already revolutionised the production of architectural models, advancements with the technology are pushing the boundaries of what is possible within the construction industry. Now, the prospect of 3D printing bridges and houses may just be a reality, with the benefit of reduced costs and time.

Now, the prospect of 3D printing bridges and houses may just be a reality, with the benefit of reduced costs and time.

One example is Apis Cor, which recently 3D printed a residential house in just 24 hours. To achieve this, Apis Cor used a robot with 3D printing capabilities, coupled with a concrete mixture to create the walls, partitions, and building envelope on site. The cost of the project was just over $10,000. Looking ahead, such technology could potentially offer a solution to the current housing crisis by providing affordable homes in poverty and disaster-stricken areas.

Check out Apis Cor’s building process in action:

Shanghai-based company, Winsun, is another emerging pioneer in the field, having already created several houses using 3D printing technology. The Dubai Future Foundation office building is another Winsun’s projects. Taking just over two weeks to create (17 days), it has achieved the milestone of being the first 3D printed, fully functional office building.

The Dubai Future Foundation office building is another Winsun’s projects. Taking just over two weeks to create (17 days), it has achieved the milestone of being the first 3D printed, fully functional office building.

Will 3D printing completely replace traditional construction methods? We don’t believe so. However, the technology does have the potential to provide greater design freedom and more sustainable processes for the construction sector industry.

5. 3D Printed Fashion

3D printed dress created by designer Michael Schmidt and architect Francis Bitonti, worn by Dita von Teese. [Photo credit: Albert Sanchez]

3D printing is a perfect fit for the fashion industry, as it allows fashion designers to creatively experiment with innovative shapes and designs.

Fashion shows have already begun to showcase the innovation of 3D printed garments. For example, Dutch fashion designer Iris van Herpen exhibited dresses created with the help of 3D printing “Foliage” technique at Paris Fashion Week 2018. The “Foliage” technique, based on Polyjet 3D printing, allowed van Herpen to 3D print intricate and soft leaf patterns directly on a semi-transparent fabric. Three combinations of resin material were used to achieve the colour and transparency.

The “Foliage” technique, based on Polyjet 3D printing, allowed van Herpen to 3D print intricate and soft leaf patterns directly on a semi-transparent fabric. Three combinations of resin material were used to achieve the colour and transparency.

Although for now, 3D printed garments are primarily created for aesthetic purposes rather than for everyday use, companies are working on the development of 3D printers that are able to print with flexible and biodegradable fabrics. As the technology evolves, custom eco-friendly outfits 3D printed at home or in the store might be not so distant future.

The disruptive force of 3D printing has also reached the footwear industry, with major footwear giants such as Adidas already using the technology for prototyping and direct manufacturing. A great example is Adidas’ 3D printed midsoles for its Futurecraft 4D sneakers, set to move into mass production by the end of 2018.

But perhaps the biggest potential of 3D printing for the industry lies in the possibility of mass customisation. Thanks to 3D scanning and printing technology, footwear manufacturers could potentially create custom-fit shoes at scale. With Adidas and others taking the first steps towards this future, this possibility may become a reality faster than we think.

7. Military & Defence

3D printing could potentially have a disruptive impact on military supply chains. The US military spends billions of dollars on logistics and transportation; however, 3D printing could help to drive these costs down by replacing physical warehouses with digital inventories. This means that the need to source spare parts and components could be eliminated and the complexity of supply chains reduced, as physical parts are replaced by 3D printable digital files to be produced on demand.

In addition to simplified supply chains, 3D printing can be used to create customised equipment, from 3D printed drone airframes tailored to the specific function to customised garments for soldiers with built-in sensors and antennas. Ultimately, the technology could provide more flexibility and functionality in the battlefield with on-demand and localised manufacturing.

Ultimately, the technology could provide more flexibility and functionality in the battlefield with on-demand and localised manufacturing.

8. The Toy Industry

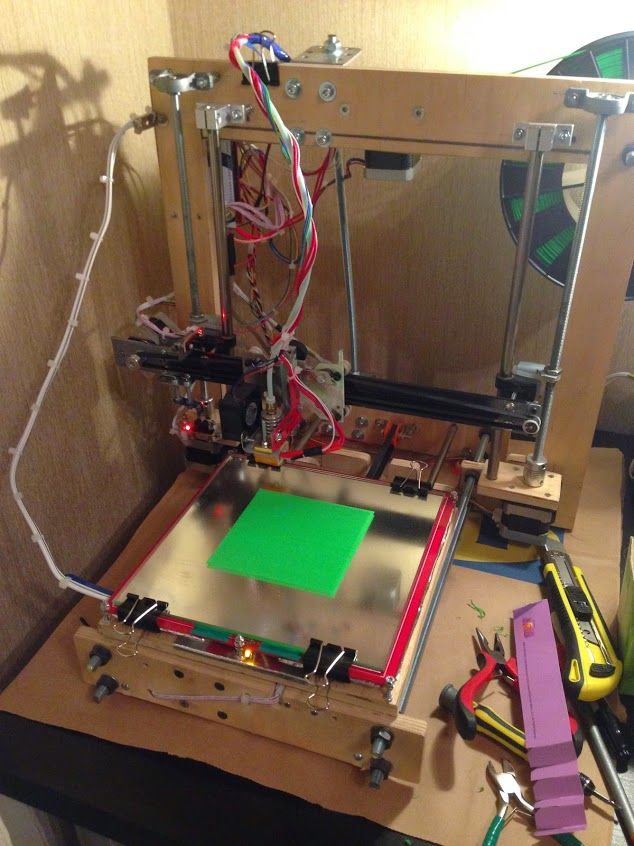

With the cost of desktop 3D printers falling and the emergence of online platforms enabling consumers to share 3D printable designs, the toy industry could see a more “DIY” approach to manufacturing toys. A study conducted by Michigan Technological University and London-based company MyMiniFactory suggests that 3D-printed toys could save consumers millions of dollars per year.

But 3D printing offers other benefits in addition to reduced costs: consumers can also customise toys or create new toys that are not commercially available. Looking ahead, we may even see some toy manufacturers selling 3D designs to consumers instead of the finished products.

3D printing has already made its way into the jewellery industry with 3D-printed wax and resin patterns used for investment casting. However, the next evolutionary step for the technology is direct 3D printing with precious metals.

However, the next evolutionary step for the technology is direct 3D printing with precious metals.

Last, but not least: the education sector. Schools, universities and research institutions are increasingly integrating 3D printing technology into their classrooms and curriculums. As 3D printing provides a cost-effective and relatively quick way to create complex objects from 3D models, students can have access to a technology that fosters creativity and innovation. For example, students at the Oslo School of Architecture and Design (AHO), a long-time user of AMFG, are able to experiment with complex, architectural designs using the technology.

The upswing in demand for 3D printing has led to many universities introduction AM-specific programmes. For example, Loughborough University is among the educational institutions pioneering design for additive manufacturing education through its newly launched Masters’ programme. Ultimately, additive manufacturing is changing the conventional approach to design engineering, helping universities forge the next generation of 3D printing professionals.

To Sum Up

For several of the industries listed above, the advantages of 3D printing are still beginning to be explored. However, as knowledge of the technology increases, it’s clear that 3D printing has the potential to transform the way in which products are produced and distributed. And as the additive manufacturing continues to evolve, the value of the technology will only continue to expand.

3-D printing disrupts $12 trillion manufacturing industry globally

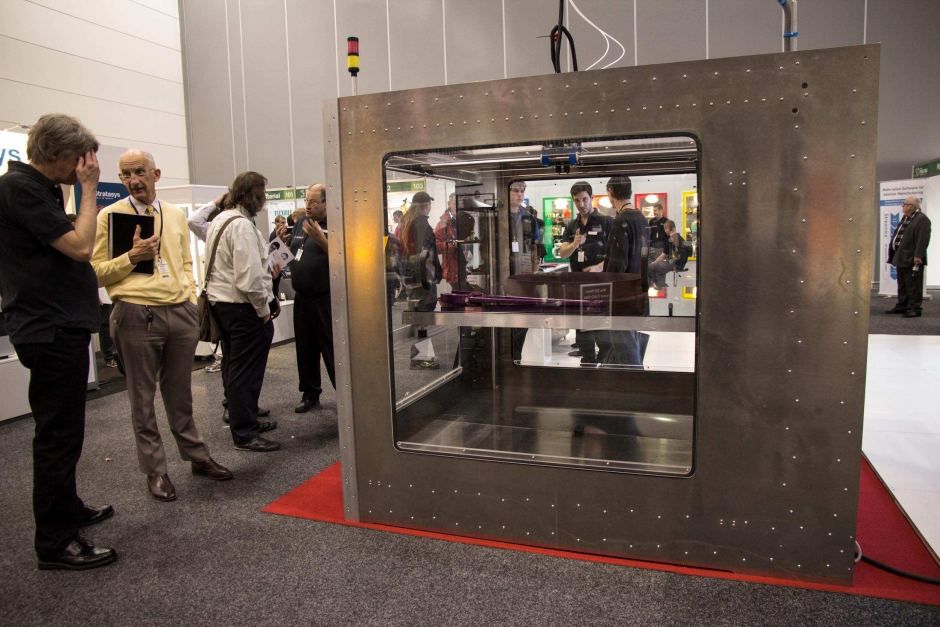

A man is seen admiring 3-D models made with HP printers at Industry Week in Barcelona, Spain. The objective is to accelerate the use of technologies and industrial sectors such as robotics, molds and matrices, new materials and 3-D printing.

SOPA Images | LightRocket | Getty Images

A French cosmetics giant uses one to create artificial skin. A Wisconsin start-up designs ceramic guides that pinpoint tumors in individual cancer patients. Workers on a remote North Sea oil rig make replacement parts on the spot rather than wait days for a ship or helicopter to arrive.

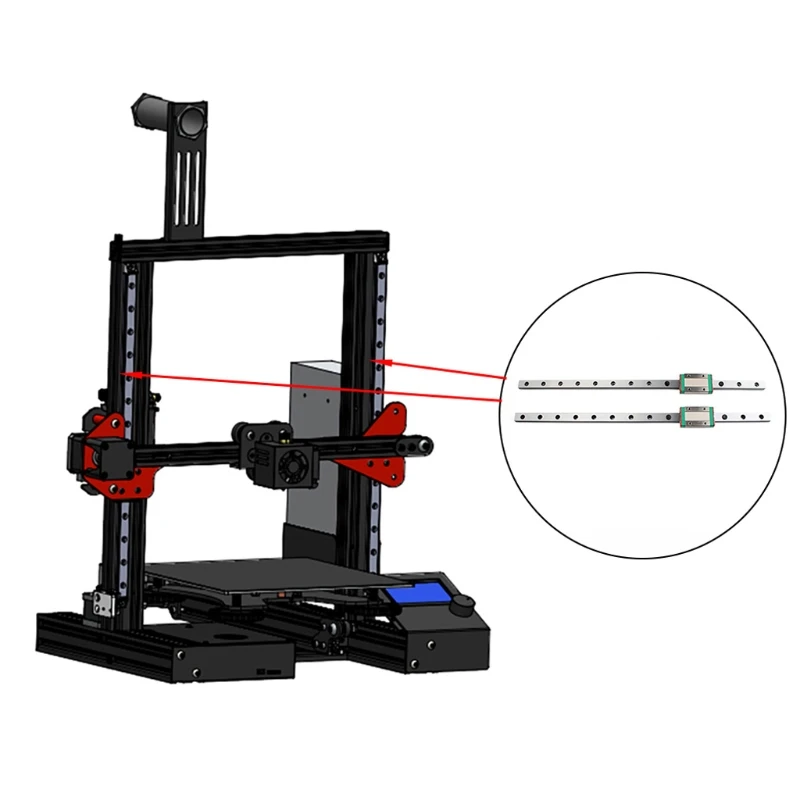

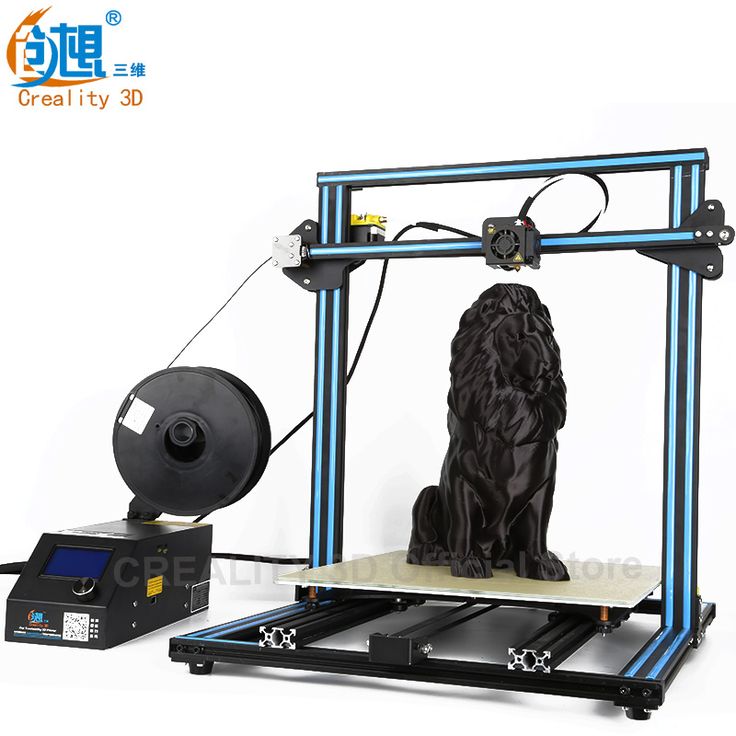

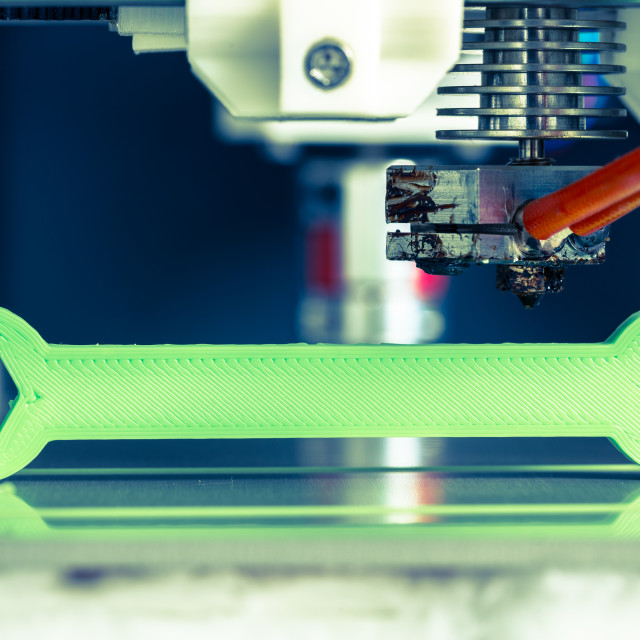

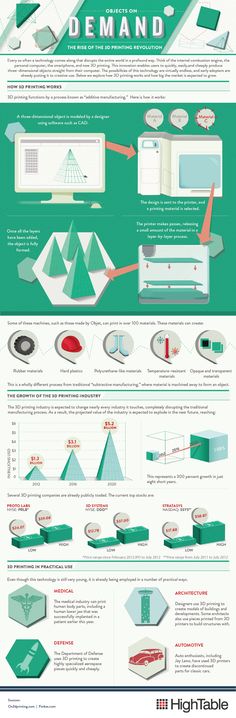

All these actions are made possible by one technology: 3-D printing. Developed in the 1980s, 3-D printers create three-dimensional objects by laying down successive layers of material, a process called additive manufacturing. The technology has evolved to work with different types of substances: plastics, metals and now biological materials.

Management consulting firm A.T. Kearney describes 3-D printing as a technology that is disrupting the $12 trillion manufacturing industry. "3-D printing, or additive manufacturing — will push the production of goods closer to the consumer, democratizing manufacturing on a global scale and allowing products to be cost-effectively customized to consumers' needs," said the firm in a report that described the U.S. as the world leader but with Germany, South Korea and Italy among the countries working hard to catch up.

The adoption is gradual. "3-D printing is having the largest impact on industries which manufacture low-volume, high-value parts which may benefit from mass customization," said Dr. Bryony Core, senior technology analyst at IDTechEx, an independent analyst firm based in Cambridgeshire, England.

Bryony Core, senior technology analyst at IDTechEx, an independent analyst firm based in Cambridgeshire, England.

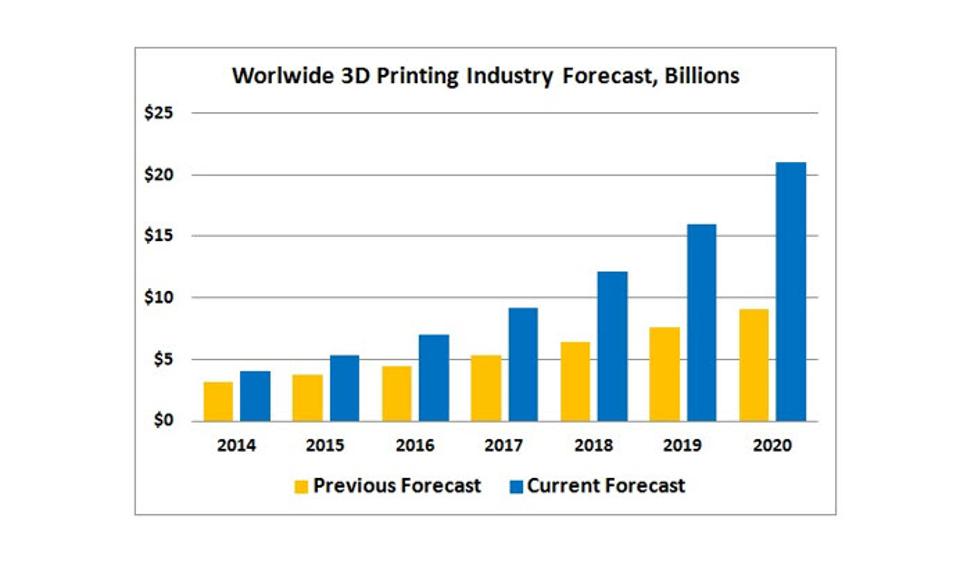

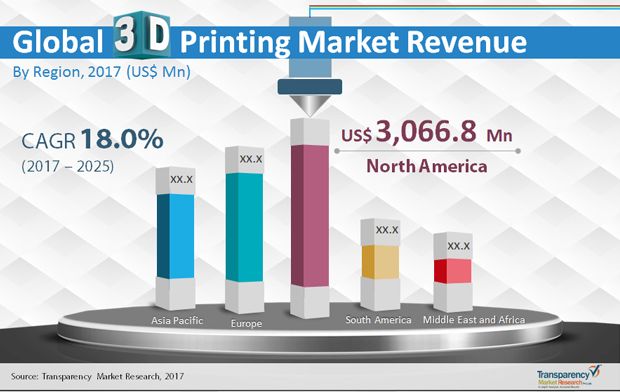

The aerospace and medical industries have been the most enthusiastic adopters, she says, but the list of industries embracing the technology is expanding. They include Boeing and Airbus, Ford and other automakers, consumer electronics manufacturers like Foxconn and brewers like Heineken. IDTech Ex estimates the market for 3-D printing should grow at a brisk 13% rate from $9.87 billion now to $31 billion by 2029.

Ford Motor Company is exploring how large one-piece auto parts, like car spoilers, could be printed for prototyping and future production vehicles, as the first automaker to pilot the Stratasys Infinite Build 3D printer.

Source: Ford Motor Company

The capacity to create 3-D objects immediately is changing manufacturing, said Jos Burger, CEO of Ultimaker, a maker of industrial 3-D printers based in the Netherlands. Customers can go to a dashboard, select a component and send G code (which translates the product specs to a code the printer understands). "The G code is traveling, not an object," said Burger. "That is a revolution growing incredibly fast."

"The G code is traveling, not an object," said Burger. "That is a revolution growing incredibly fast."

French cosmetics maker L'Oreal has been using 3-D technology for more than 20 years, said Anne Debauge, digital director of the packaging and development department. The printers are deployed in 21 of the company's 40 plants worldwide. The availability of 3-D printers in company plants enhances the role of employees, said Debauge. "They become actors rather than coordinators."

The company's original use of the printers was to develop prototypes of bottles and packages for its beauty products, but their use has evolved. L'Oreal is now exploring another capability of 3-D printers: bioprinting. By building layers of living cells, 3-D printers can create human skin.

"Thanks to cutting-edge technological tools, we can print living cells and implant them into other living material," said Jérémie Soeur, head of L'Oreal's cellular and tissue engineering group, in an interview posted on the company's website. The 3-D-printed skin could be used to test products and reduce the controversial use of live animals, for example. (L'Oreal points out it stopped animal testing in 1989).

The 3-D-printed skin could be used to test products and reduce the controversial use of live animals, for example. (L'Oreal points out it stopped animal testing in 1989).

L'Oreal is exploring the use of 3-D-printed skin to test products and reduce the controversial use of live animals. Above, reconstructed human epidermis at the Lyon EpiSkin facility.

Philippe Gotteland | L’Oréal /EpiSkin

Soeur imagined a time when dermatologists could store samples of patient cells and print them directly onto patients after a severe wound or burn. In the long term, scientists believe they will be able to print entire organs from a patient's own cells, reducing the need for donors and the possibility of rejection that now occurs with transplants.

There are two key obstacles to faster growth of the 3-D printer market, says Maikel van Verseveld, global production and operations lead at Accenture's Industry X.O, which focuses on marrying smart technologies to traditional industries. "The majority of our clients are still hesitating," he says. One concern is the disparity in scale between suppliers and customers. Many manufacturers of 3-D printers are small start-ups, while users are often large corporations. "Elephants in the enterprise want to do business with elephants," he said.

"The majority of our clients are still hesitating," he says. One concern is the disparity in scale between suppliers and customers. Many manufacturers of 3-D printers are small start-ups, while users are often large corporations. "Elephants in the enterprise want to do business with elephants," he said.

However, two giants, Siemens and HP, have joined forces to encourage big companies to adopt 3-D printing. In March the two companies announced an alliance that would make Siemens manufacturing software and HP's latest industrial 3-D printers work smoothly together. "We are proud to partner with Siemens to make high-performance parts, personalized products and serialized 3-D production a reality for our customers," said Christoph Schell, HP's president of 3D Printing and Digital Manufacturing, in a press release.

The other big concern is the management of intellectual property rights. A customer may be able to get the specs to create a replacement part, but how will the original manufacturer be compensated? "How do I assure I will get the original design?" explained van Verseveld. He envisions an online marketplace that makes component designs available and handles the financial transaction between the parties.

He envisions an online marketplace that makes component designs available and handles the financial transaction between the parties.

When 3-D printing first burst onto the scene, popular scenarios envisioned a 3-D printer in every garage. But the consumer market never met expectations, because of the limited capability of affordable home printers, said Dror Danai, the chief business officer at XJet, an Israeli manufacturer of 3-D printers.

However, he sees many applications of 3-D printers that will benefit consumers. One example is the creation of more precise crowns and dentures by dentists. Another is the ability to make individualized medical devices for patients. His company is working with a start-up in Wisconsin that uses 3-D printers to create customized ceramic guides to precisely freeze breast tumors identified by MRI machines.

"[3-D printing] works best when parts are impossible to make in a traditional way," Danai said.

How 3D printing is changing the world・Cults

Nearly fifty years ago, the very first concept of what became known as 3D printing was presented to the world. It was created by scientist and inventor David E.H. Jones, who wrote about it in a New Scientist column as a futuristic technology that is coming soon.

It was created by scientist and inventor David E.H. Jones, who wrote about it in a New Scientist column as a futuristic technology that is coming soon.

Today it is undoubtedly with us, helped both by the technological advances of recent decades and the growing availability of inexpensive 3D printers. As a result in 2019The global 3D printing industry was valued at nearly $11.6 billion last year, with huge growth predicted. It is expected to continue to grow at about 14% per year until 2027, as much as current estimates allow. More than 8 million units per year are expected to be sold by then, driven by the need for technology across a range of industries.

Already, 3D printing is having a significant impact on many industries, with the automotive and aviation industries taking the lead. In the first case, companies such as Audi use technology as an important element of the design and development process, as it allows quick and relatively cheap prototyping of models and components. It also provides a quick way to manufacture the machine tools needed in the production process, which is usually a more complex and time consuming process. nine0003

It also provides a quick way to manufacture the machine tools needed in the production process, which is usually a more complex and time consuming process. nine0003

Another, more unexpected, application in the automotive industry is the production of parts for classic or vintage cars. The availability of components that are no longer manufactured extends the life of vehicles that might otherwise end up in scrap metal.

Ever since the first casinos appeared in the 1990s, technology has played an important role in their development. As for how they can use 3D printing as part of their customer offering, there are several options. nine0003

Land-based casinos can be under pressure, and it's understandable that their owners want to make as much money from players as possible. At the same time, if the machine does not work correctly, the potential income is reduced. This is where 3D printing can save the day. Many casino machines contain a complex mechanical design, and breakdowns happen quite often. Having a 3D printer capable of replacing a complex part at a critical moment can be invaluable to a casino at its peak. nine0003

Having a 3D printer capable of replacing a complex part at a critical moment can be invaluable to a casino at its peak. nine0003

Land-based casinos are under constant pressure from their online competitors these days, so it's even more important that all machines are always up and running. Of course, online casinos don't have to worry about their machines breaking down and needing to be repaired quickly, allowing for a wider range of games. A prime example is 888 Online Casino which offers an impressive 15 different online roulette options including French, American, European and of course live roulette. When used correctly, 3D printing can help bridge this gap when things go wrong. nine0003

Medicine and healthcare in general is another area where this technology plays a decisive role. The growing complexity of the technology means that it is invaluable in the production of prosthetic limbs and other body parts that would otherwise take much longer to produce to very precise specifications. Currently, it is possible to make copies of bones, organs and blood vessels, taking into account the individual characteristics of the patient. nine0003

Currently, it is possible to make copies of bones, organs and blood vessels, taking into account the individual characteristics of the patient. nine0003

This clearly improves the quality of life for many patients, reducing costs and waiting times. Industry officials claim that medical errors are minimized by the fact that it is easy to make adjustments before the product is printed. The ability to tailor these products based on patient requirements results in improved patient comfort. However, in the trauma situation, this method is not yet considered as an option due to the length of the process, but in the future it is considered as a very real possibility. nine0003

There are even signs that technology is moving into completely unexpected areas, such as food production. A Spanish company called Nova Meat has gone a long way in developing a printer that can use plant-based protein raw materials to create realistic plant-based steak substitutes. The company aims to create a more sustainable alternative to traditional meat farming and hopes to become a major food supplier not only in its own country, but around the world with EU funding within five years. nine0003

So, it is clear that 3D printing technology is becoming relevant in more and more areas of the world around us, and this trend will undoubtedly continue. The ultimate goal, of course, will be to develop a 3D printer that can replicate itself, producing other, identical devices at the push of a button!

This post was published in accordance with the disclosure policy of cults3d.com

This page has been translated using machine translation. Suggest the best translation nine0003

Previous

ShareNext

Opportunities of 3D printing in the promotional industry - News - Corporate Gifts (Souvenirs) with Logo

3D printing changes traditional production methods! She did not bypass the promo industry and business gifts. 3D printing can be used to produce unique, non-standard products, be it toys, clothes, shoes, auto parts and even edible products.

3D printing also known as layer-by-layer synthesis technology: the elements it creates are produced layer by layer on digital three-dimensional models. It's faster and more economical standard production methods, such as casting or sculpting milling. The most commonly used material is plastic, melted and applied layer by layer. Producing promotional products with 3D printing technology, fulfill absolutely any order, regardless of the circulation and complexity of the product. nine0003

It's faster and more economical standard production methods, such as casting or sculpting milling. The most commonly used material is plastic, melted and applied layer by layer. Producing promotional products with 3D printing technology, fulfill absolutely any order, regardless of the circulation and complexity of the product. nine0003

Corporate gifts — more than just gifts you give to employees or customers. promo products are used to create brand awareness. These gifts can be an item necessary in everyday life (for example, a case for a smartphone) or for the home (plaid, mug), but they all have marketing goals.

Of course, we often give standard positions, and they will always be relevant, but sometimes it is necessary show that your brand keeps up with the times and is interested in new technologies. An extraordinary souvenir will be remembered by the consumer, effectively rebuilding your company from competitors. nine0003

3D printed you can make individual promotional products: it's fast, simple and technologically.