3D printing bio

What is 3D Bioprinting? | Bioprinting Explained

“3D Bioprinting” or “bioprinting” is a form of additive manufacturing that uses cells and biomaterials instead of traditional metals and plastics to create 3D constructs that are functional 3D tissues. These biomaterials are called bioinks, and they mimic the composition of our tissues. Bioprinting can be applied to a variety of areas including but not limited to regenerative medicine, drug discovery and development, and 3D cell culture.

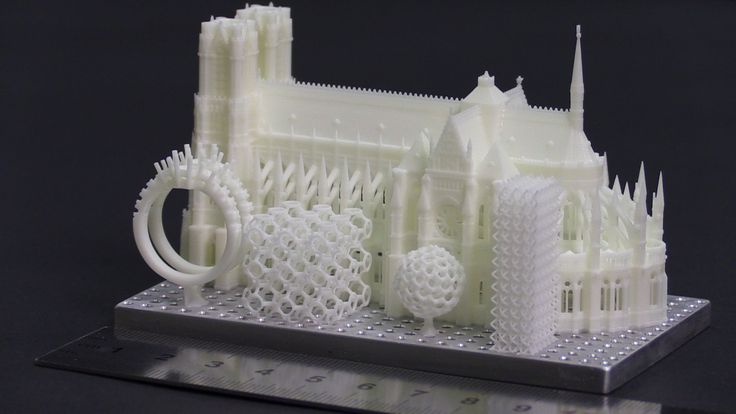

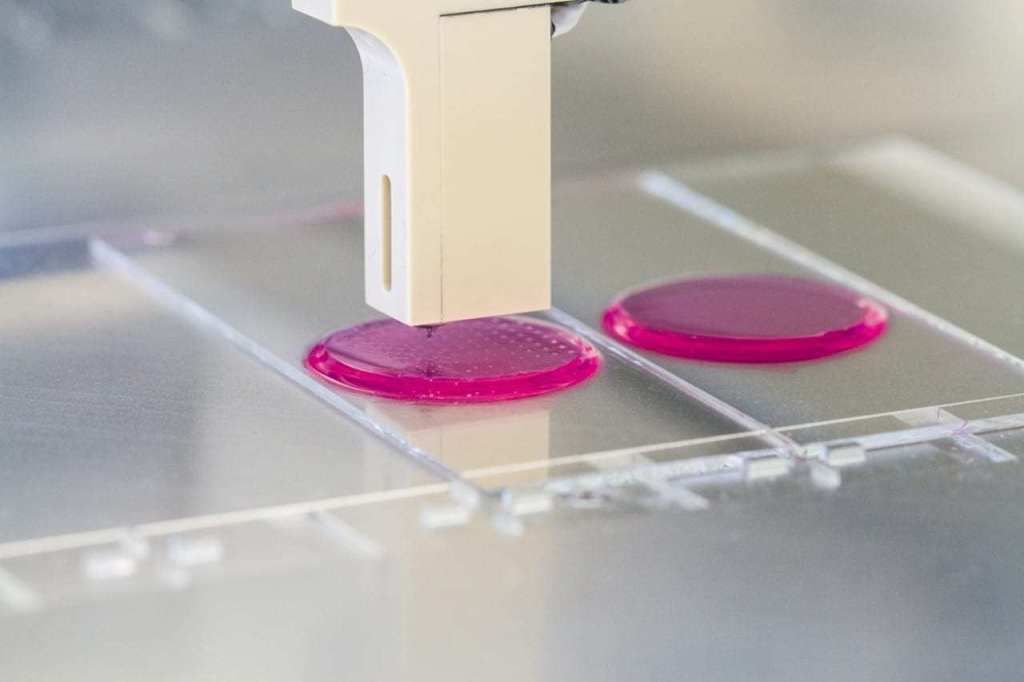

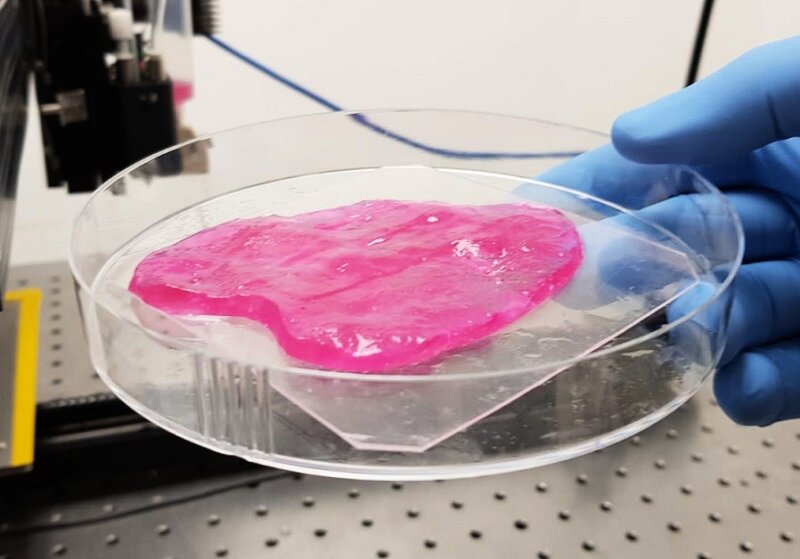

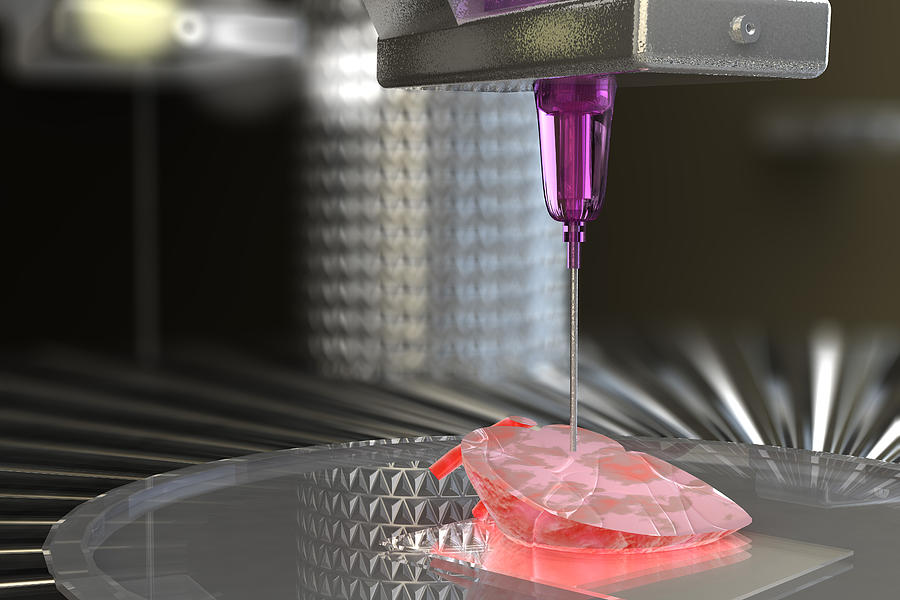

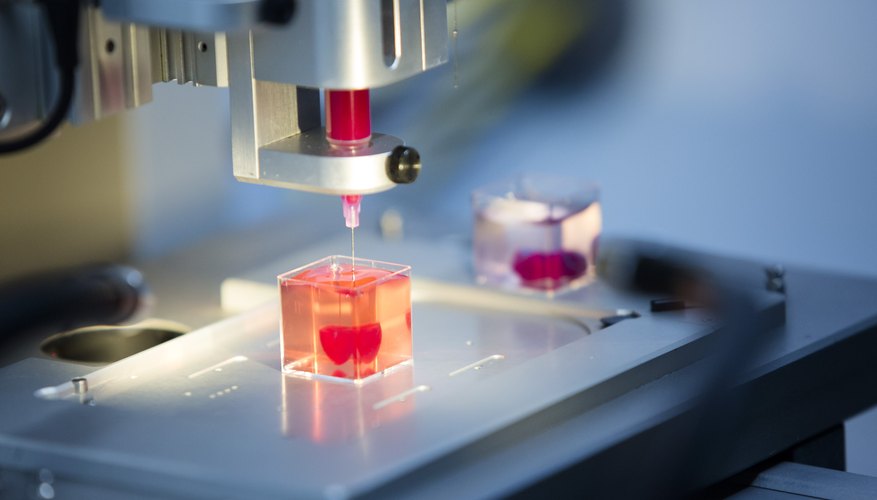

A 3D construct bioprinted on an Allevi by 3D Systems bioprinterBioprinted structures, such as organs-on-chips, can be used to study functions of a human body outside the body, in 3D. The geometry of a 3D bioprinted structure is more similar to that of a naturally occurring biological system than an in vitro 2D model. Structural similarity can in turn lead to functional results that are more physiologically relevant. No other technology enables the level of geometric complexity in engineering tissues that 3D bioprinting enables. That is why this technology has the potential to completely change the way we treat diseases – by replacing animal testing and ending the organ transplant waiting list.

How does 3D bioprinting work?

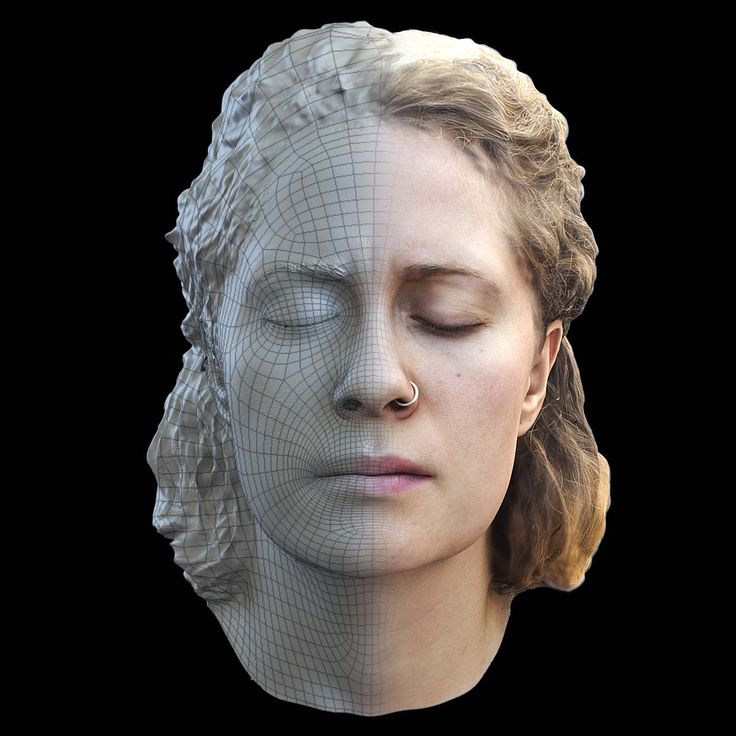

3D bioprinting starts with a model of a structure, which is recreated layer-by-layer out of a bioink either mixed with living cells, or seeded with cells after the print is complete. These starting models can come from anywhere – a CT or MRI scan, a computer generated design (CAD) program, or a file downloaded from the internet.

That 3D model file is then fed into a slicer – a specialized kind of computer program which analyzes the geometry of the model and generates a series of thin layers, or slices, which form the shape of the original model when stacked vertically. Cura and slic3r are examples of slicers commonly used in 3D printing. Allevi also has a specialized slicer, optimized specifically for bioprinting, built into our Allevi Bioprint software.

Once a model is sliced, the slices are transformed into path data, stored as a G-code file, which can be sent to a 3D bioprinter for printing. The bioprinter follows instructions in the G-code file in order, including instructions to control for temperature of the extruders, extrusion pressure, bed plate temperature, crosslinking intensity and frequency, and, of course, the 3D movement path generated by the slicer. Once all of the G-code commands are completed, the print is done and can be cultured or seeded with cells as part of a biostudy.

The bioprinter follows instructions in the G-code file in order, including instructions to control for temperature of the extruders, extrusion pressure, bed plate temperature, crosslinking intensity and frequency, and, of course, the 3D movement path generated by the slicer. Once all of the G-code commands are completed, the print is done and can be cultured or seeded with cells as part of a biostudy.

Why is bioprinting important?

Over 120,000 people in the US alone are on waiting lists for organs, and others experience chronic problems due to the long-term damaging effects of post-transplant immunosuppression. There is a large and growing need for an alternative to the organ transplant waiting list. The scientific community has already succeeded in bringing together multidisciplinary teams of researchers, physicians, and engineers to take on the biggest challenges to human health, and 3D bioprinting is an exciting new tool with the potential to eliminate the organ transplant waiting list.

The scientific community has already succeeded in bringing together multidisciplinary teams of researchers, physicians, and engineers to take on the biggest challenges to human health, and 3D bioprinting is an exciting new tool with the potential to eliminate the organ transplant waiting list.

For pharmaceutical development, 3D bioprinting offers a means of testing drugs faster, at a lower cost, and with better biological relevance to humans than animal testing. In the biomedical devices field, 3D bioprinting has enabled new developments such as sugar stents to help surgeons join veins with fewer complications, and systems for improved drug delivery, among others.

As bioprinting evolves, it will become possible to use a patient’s own cells to 3D print skin and bone grafts, organ patches, and even full replacement organs. Personalized and regenerative medicine continue to grow in popularity, and 3D bioprinting will give doctors and researchers the tools to better target treatments and improve patient outcomes.

Further reading

Bioprinting 101 – Allevi

3D Bioprinting – Wikipedia

3D Bioprinting of Living Tissues – Wyss Institute, Harvard

Bioprinting – NIH Director’s Blog

Comprehensive guide and bioprinter selection

What is 3D bioprinting?

3D bioprinting is a process in which a machine called a 3D bioprinter is used to fabricate tissue structures that contain cells and an extracellular matrix. These structures can have uses in regenerative medicine, pharmaceutical testing, food production, and other areas.

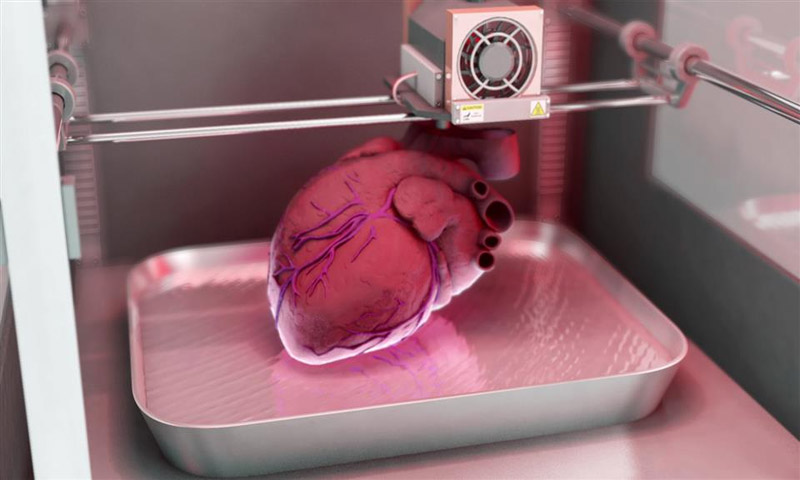

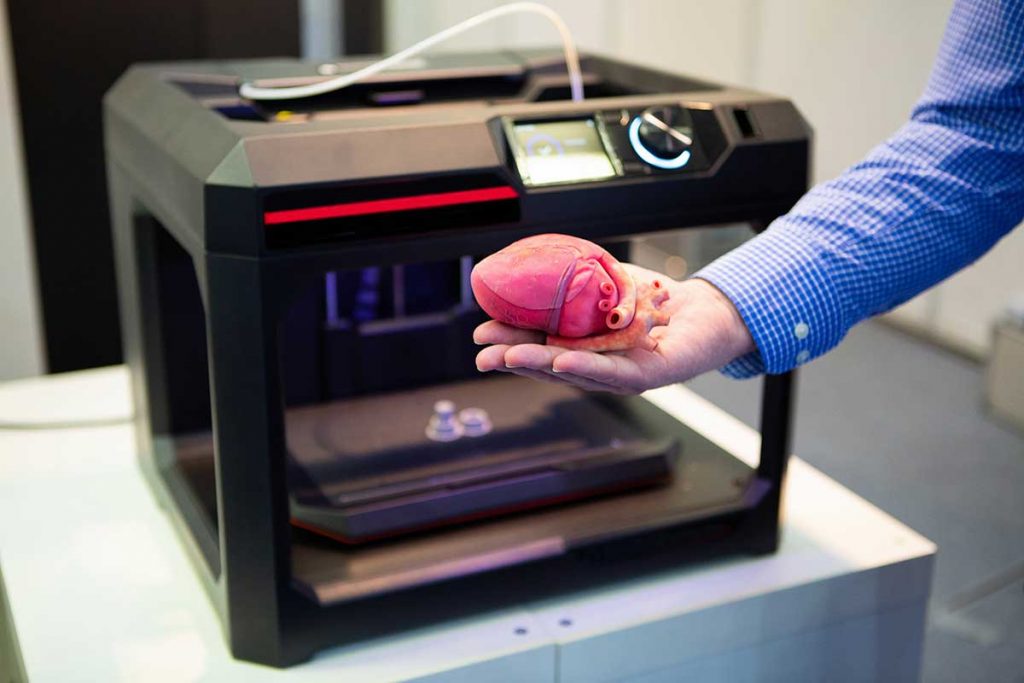

Like regular 3D printing, 3D bioprinting creates 3D shapes layer by layer using a digital CAD file as a blueprint. However, by 3D printing with cells instead of plastics and metals, bioprinting can create precisely engineered tissue structures such as 3D printed organs. At present, these organs can only be used for research; in the future, however, they could be transplanted into human patients.

Although there are many different 3D bioprinting technologies and techniques, most 3D bioprinters print substances known as bioinks. These bioinks contain living cells, in addition to viscous materials like alginate or gelatin which allow the 3D bioprinter to create solid scaffolds on which the cells can survive and interact. Bioinks can contain differentiated cells (specialized, function-specific) or stem cells (nonspecific, later induced to become differentiated).

This guide contains an introduction to 3D bioprinting technologies and their applications, as well as an overview of the best 3D bioprinters on the market.

The top professional 3D bioprinters in 2022

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| REGEMAT3D | V1 BioPrinter | 150 × 160 × 110 mm5.91 × 6.3 × 4.33 in | Spain | $ 25,00025 000 €22,176 £3,726,400 ¥ | Quote |

| Allevi | Allevi 3 | 130 × 90 × 60 mm5.12 × 3.54 × 2.36 in | United States | $ 40,00040 000 €35,482 £5,962,240 ¥ | Quote |

| Axolotl Biosystems | Axo A6 | 130 × 90 × 80 mm5.12 × 3.54 × 3.15 in | – | $ 40,00040 000 €35,482 £5,962,240 ¥ | Quote |

| Brinter | ONE 3D Bioprinter | 300 × 300 × 100 mm11.81 × 11.81 × 3.94 in | Finland | $ 50,00050 000 €44,352 £7,452,800 ¥ | Quote |

| ROKIT | Dr. INVIVO 4D | 100 × 100 × 80 mm3.94 × 3.94 × 3.15 in | South Korea | $ 50,00050 000 €44,352 £7,452,800 ¥ | Quote |

| Advanced Solutions | BioAssemblyBot | 305 × 254 × 178 mm12.01 × 10 × 7.01 in | United States | $ 99,99599 995 €88,700 £14,904,855 ¥ | Quote |

| GeSim | BioScaffold Printer BS3. 2 2 | – | Germany | $ 150,000150 000 €133,056 £22,358,400 ¥ | Quote |

| Poietis | NGB-R | – | France | $ 300,000300 000 €266,112 £44,716,800 ¥ | Quote |

| CELLINK | BIO X | 130 × 90 × 70 mm5.12 × 3.54 × 2.76 in | – | upon request | Quote |

| Fluicell | Biopixlar | – | Sweden | upon request | Quote |

| UpNano | NanoOne Bio | 120 × 100 × 40 mm4.72 × 3.94 × 1.57 in | Austria | upon request | Quote |

Expand to see more specs

Build size: Generally refers to the maximum printable tissue size, which can vary greatly depending on the type of tissue being printed.

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| REGEMAT3D | V1 BioPrinter | 150 × 160 × 110 mm5.91 × 6.3 × 4.33 in | Spain | $ 25,00025 000 €22,176 £3,726,400 ¥ | Get a quote |

| Allevi | Allevi 3 | 130 × 90 × 60 mm5.12 × 3.54 × 2.36 in | United States | $ 40,00040 000 €35,482 £5,962,240 ¥ | Get a quote |

| Axolotl Biosystems | Axo A6 | 130 × 90 × 80 mm5.12 × 3.54 × 3.15 in | – | $ 40,00040 000 €35,482 £5,962,240 ¥ | Get a quote |

| Brinter | ONE 3D Bioprinter | 300 × 300 × 100 mm11.81 × 11.81 × 3.94 in | Finland | $ 50,00050 000 €44,352 £7,452,800 ¥ | Get a quote |

| ROKIT | Dr. INVIVO 4D | 100 × 100 × 80 mm3.94 × 3.94 × 3.15 in | South Korea | $ 50,00050 000 €44,352 £7,452,800 ¥ | Get a quote |

| Advanced Solutions | BioAssemblyBot | 305 × 254 × 178 mm12. 01 × 10 × 7.01 in 01 × 10 × 7.01 in | United States | $ 99,99599 995 €88,700 £14,904,855 ¥ | Get a quote |

| GeSim | BioScaffold Printer BS3.2 | – | Germany | $ 150,000150 000 €133,056 £22,358,400 ¥ | Get a quote |

| Poietis | NGB-R | – | France | $ 300,000300 000 €266,112 £44,716,800 ¥ | Get a quote |

| CELLINK | BIO X | 130 × 90 × 70 mm5.12 × 3.54 × 2.76 in | – | upon request | Get a quote |

| Fluicell | Biopixlar | – | Sweden | upon request | Get a quote |

| UpNano | NanoOne Bio | 120 × 100 × 40 mm4.72 × 3.94 × 1.57 in | Austria | upon request | Get a quote |

How does a 3D bioprinter work?

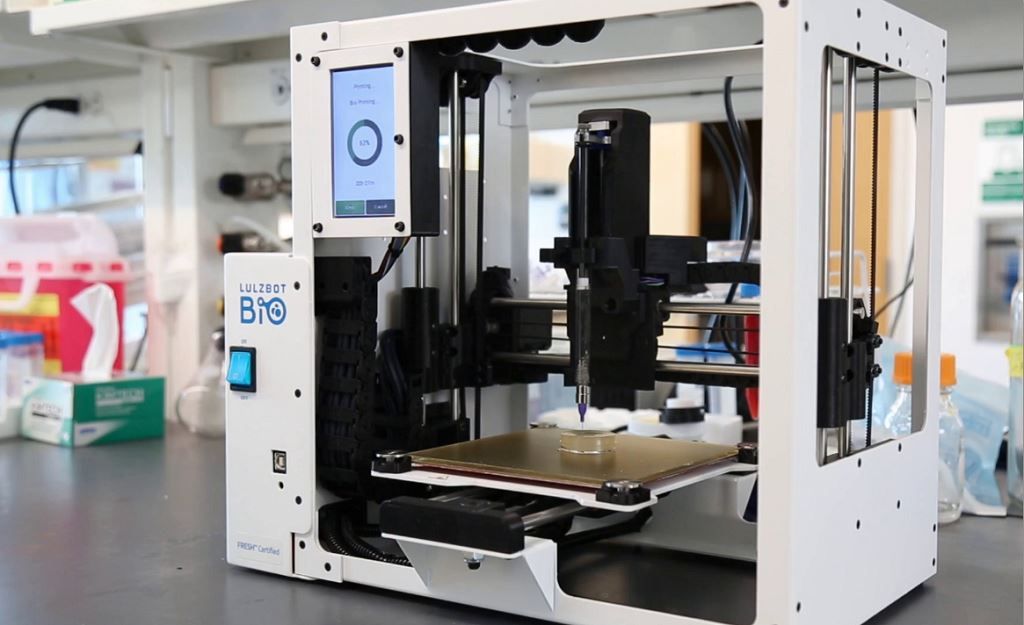

Although there are similarities between a 3D bioprinter and a 3D printer, a bioprinter must ensure the survival of living cells. This means it must have certain unique characteristics, such as the ability to print at mild temperatures.

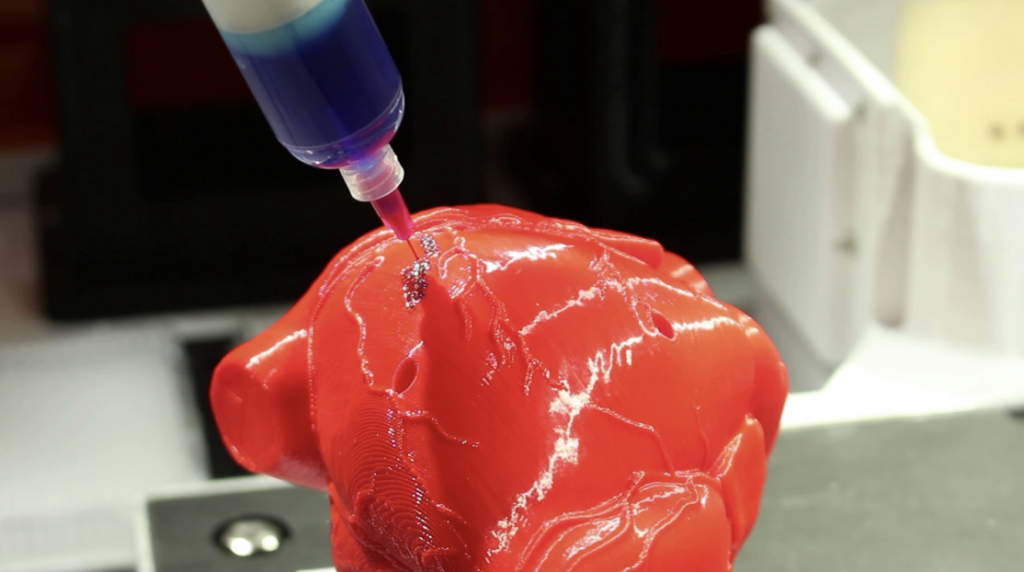

Most bioprinters work by printing a kind of 3D gel known as a bioink, which comprises cells and a printable biomaterial like gelatin. Bioinks are similar to hydrogel biomaterials — which researchers use to create non-printed tissue structures, often in microplates — but with one key difference: bioinks are stable enough to be extruded or deposited from a printer.

How the bioink is manipulated depends on the chosen bioprinting technology.

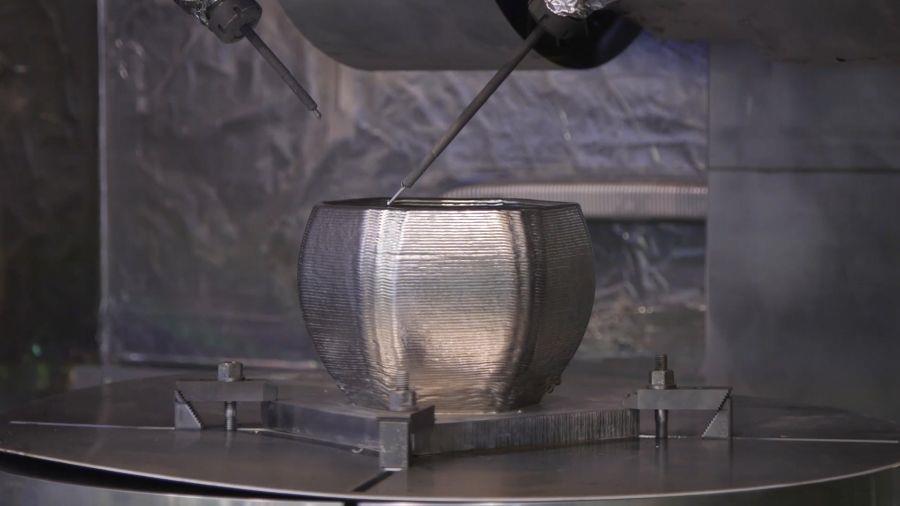

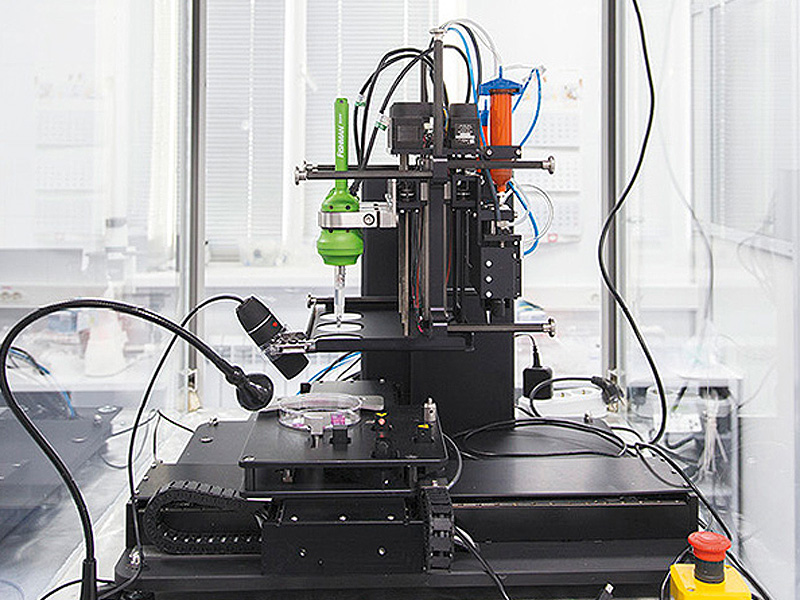

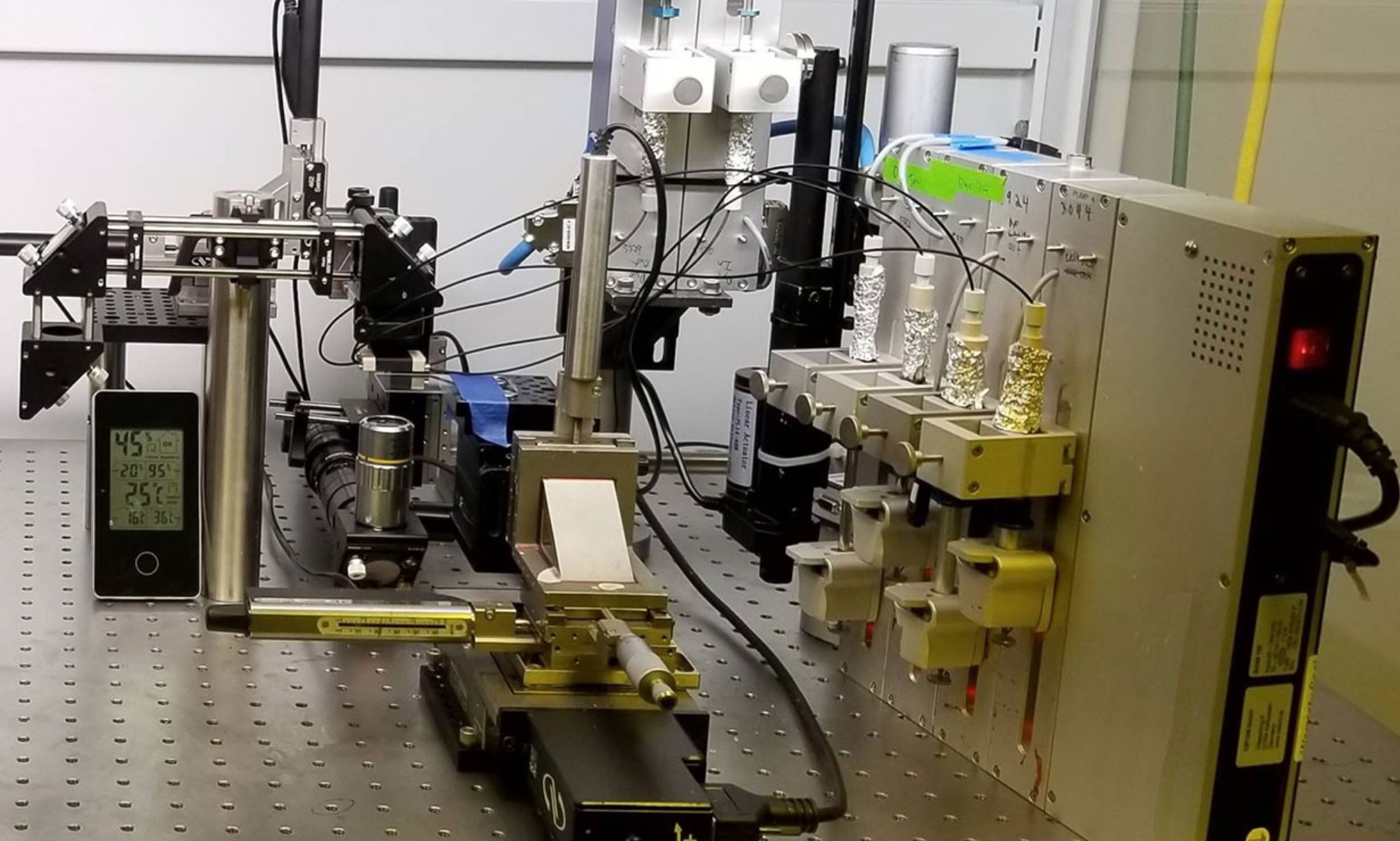

3D bioprinting technologies explained. Source: MerckExtrusion bioprinting

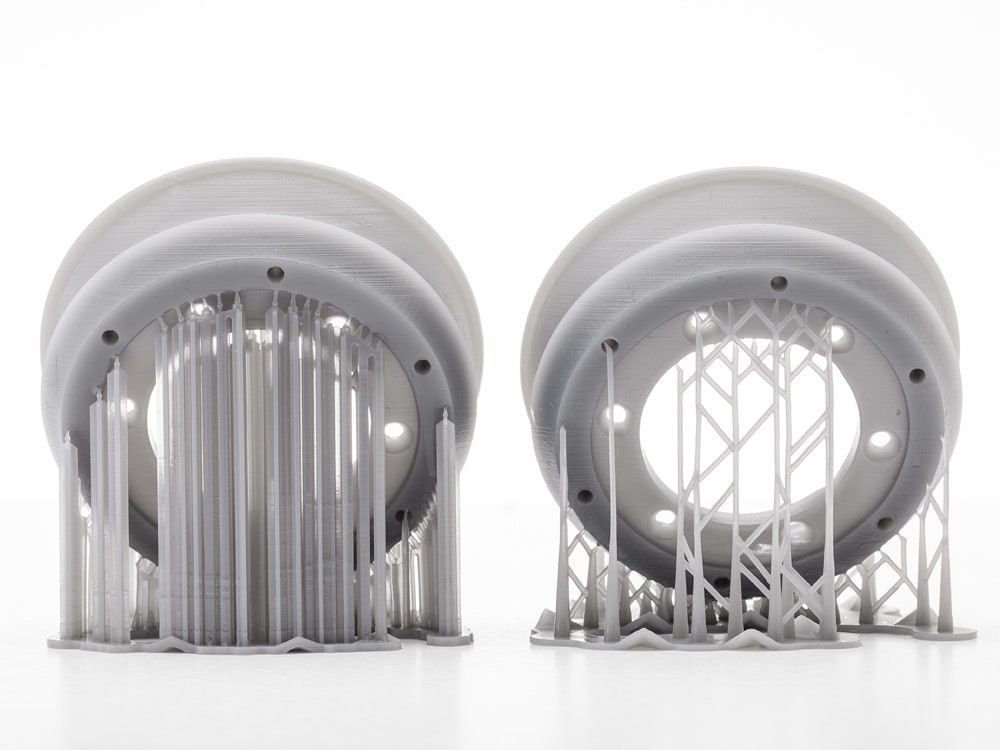

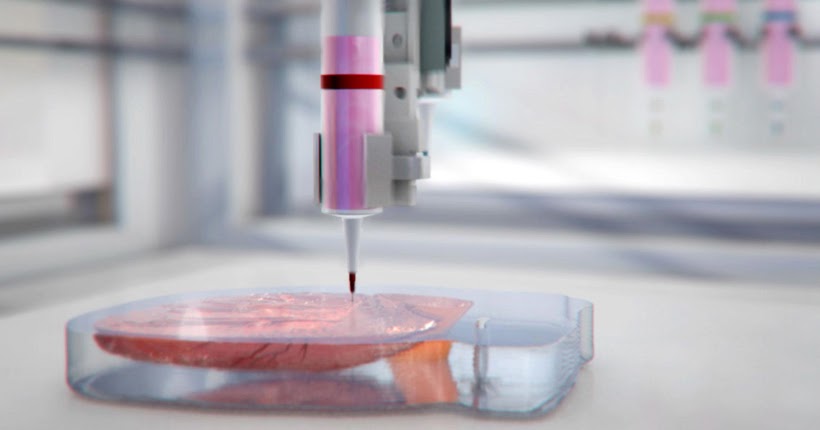

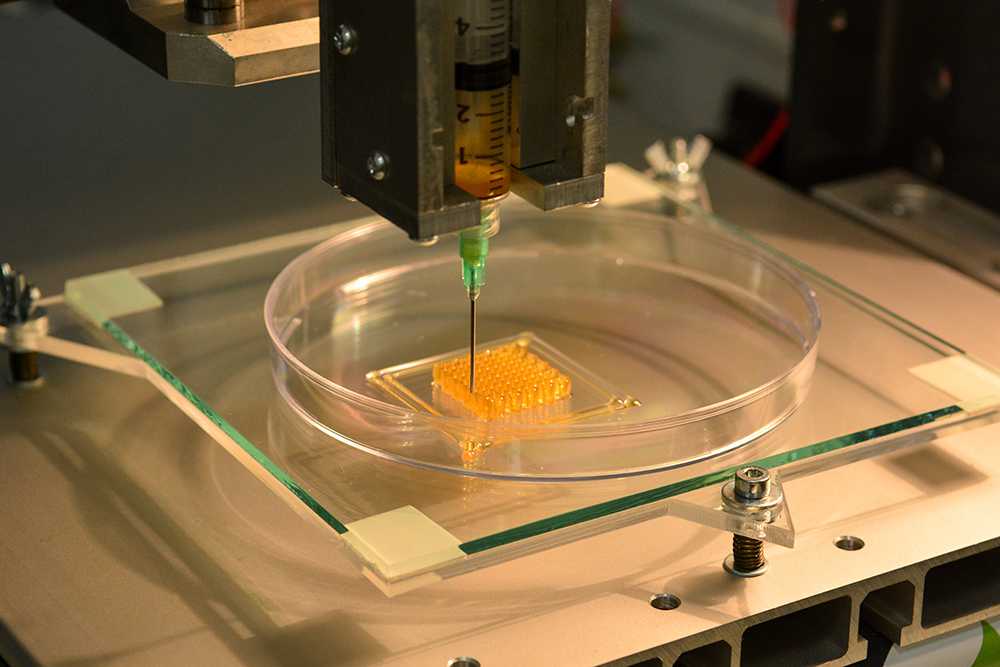

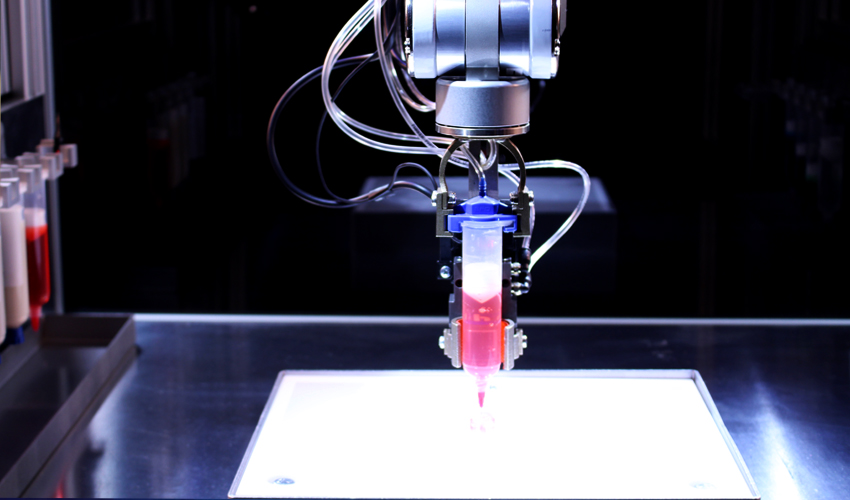

The form of 3D bioprinting most similar to FDM 3D printing is extrusion-based bioprinting. This technology uses a computer-controlled print head to extrude, layer by layer, a highly viscous bioink onto a surface such as a petri dish. The extrusion may be achieved by air pressure, pistons, or a reciprocating screw.

Inkjet bioprinting

Inkjet 3D bioprinting, sometimes called drop-on-demand bioprinting, is a fast and highly accurate bioprinting technique in which a bioink is printed in droplets onto a surface. While inkjet bioprinting allows for the precise control of cells, it is less effective for 3D printing scaffolds, since its bioinks must have very low viscosity.

While inkjet bioprinting allows for the precise control of cells, it is less effective for 3D printing scaffolds, since its bioinks must have very low viscosity.

Laser-assisted bioprinting

Unlike extrusion and inkjet 3D bioprinters, laser-assisted 3D bioprinters do not use a nozzle to dispense bioink. Instead, these bioprinters direct UV light onto a vat of photosensitive bioink, which hardens when exposed to light. Like other Stereolithography (SLA) printers, the bioprinter has a moving platform to enable the printing of subsequent layers.

Misc. bioprinting technologies

Other forms of 3D bioprinting are less easily categorized. For example, some 3D bioprinting companies have developed systems that 3D print cells onto a needle array instead of using a biomaterial scaffold. With this technique, clusters of pure cells– not mixed with other biomaterials– are skewered onto upright needles to create 3D tissue structures.

Overview of the top 3D bioprinters in 2022

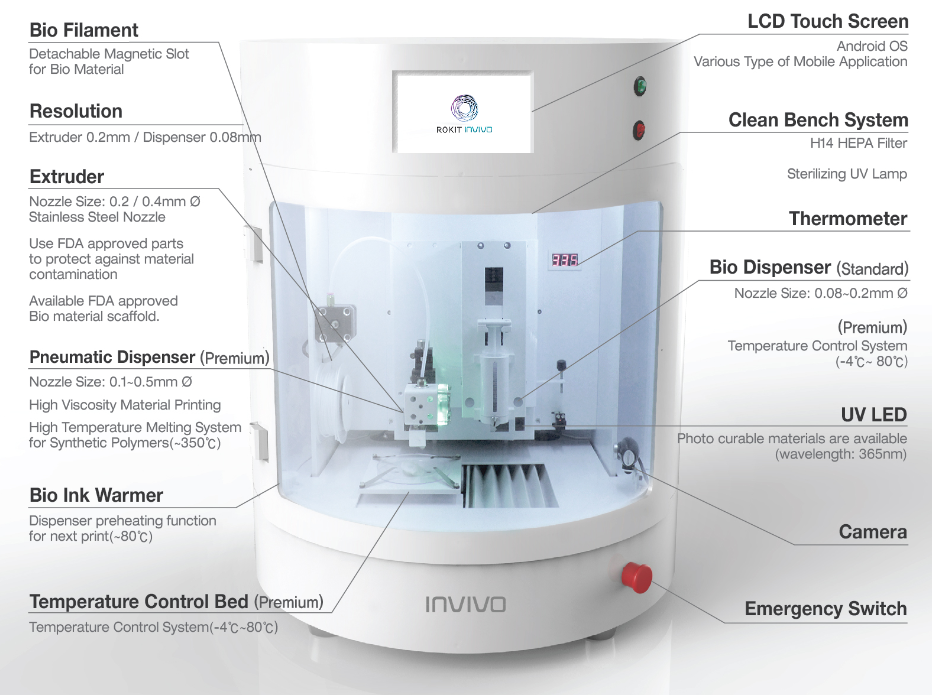

Rokit Healthcare is a biotechnology company based in South Korea. Its product portfolio includes 3D bioprinters, bioinks, skin modeling products and anti-aging solutions.

The Dr. INVIVO 4D is a 3D bioprinter with three extruder options: filament extruder, syringe dispenser and hot-melting pneumatic dispenser. The machine pays extra attention to sterilization, with a h24 HEPA filter and UV lamp included. Compatible materials include bioinks, biopolymers and ceramics.

The 3D bioprinter is sold in three variations: Standard, Upgrade and Premium, with the Premium version offering the widest range of extrusion types.

Contact manufacturer Get a quote Add to comparison

Brinter is a Finnish bioprinting company offering solutions to businesses and researchers in pharmacology, biotechnology and cosmetics.

The company’s Brinter 3D BioPrinter is an extrusion-type 3D bioprinter designed for the easy changing of print heads. It can process materials of varying viscosity, and its integrated camera allows for remote monitoring. Brinter has designed a range of print heads for the machine, including the MicroDroplet tool, Pneuma Tool, and Visco Tool.

Brinter also produces a range of bioinks made from biomaterials like nanocellulose, collagen, and fibrinogen.

Contact manufacturer Get a quote Add to comparison

Regemat is a Spanish biotech company that specializes in creating tailored bioprinting systems for individual companies, researchers and applications.

The Regemat Bio V1 is a 3D bioprinter designed to print osteochondral tissue, but it can also be used in many other tissue applications.

The printer offers three extrusion types — individual pore filling, injection volume filling and fused deposition modeling (FDM) — and works with six unique print heads: extrusion syringe, two-component syringe, UV light curing system, IR light curing system, cold syringe module and heated syringe module.

Regemat’s bioprinting system is used in hospitals and universities in over 20 countries around the world.

Contact manufacturer Get a quote Add to comparison

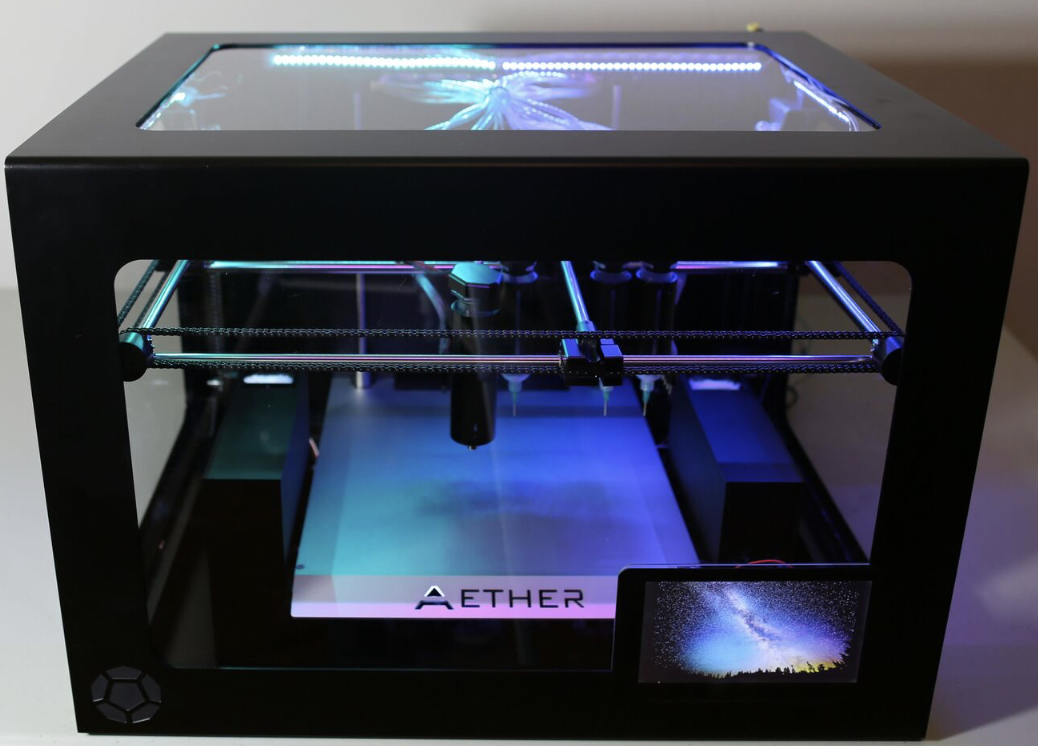

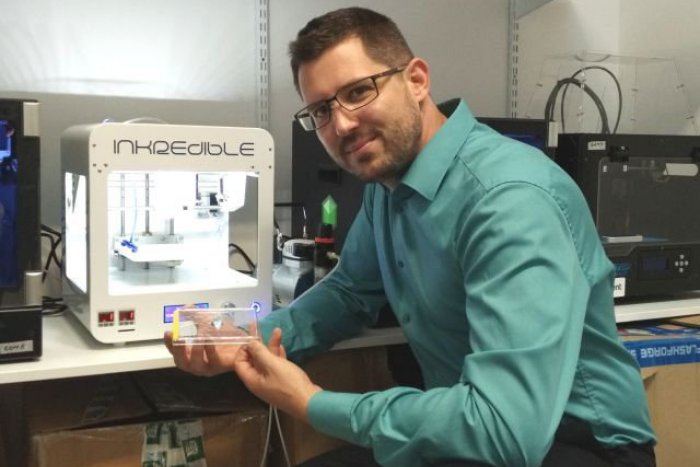

Allevi, an American bioprinting company, creates 3D bioprinters and bioinks for use in medical research and drug discovery.

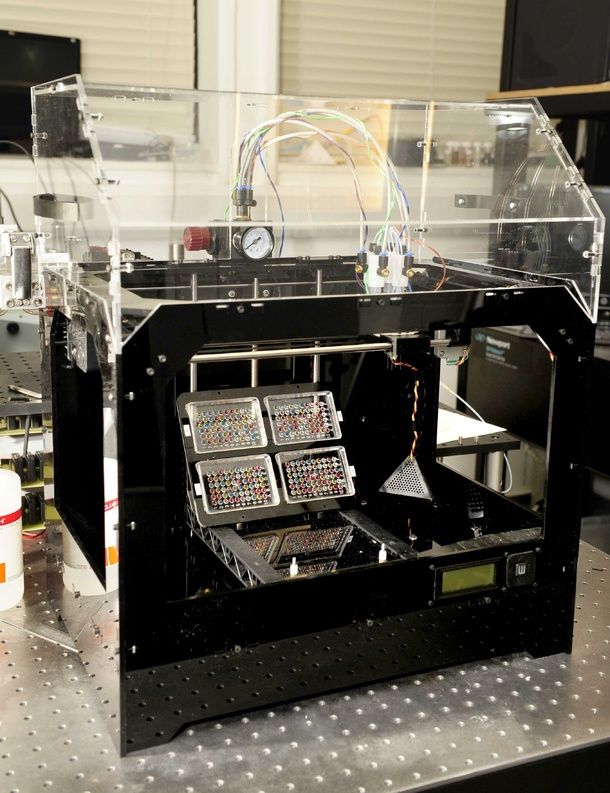

The Allevi 3 is a triple-extruder 3D bioprinter with heated print bed, print head temperature control and photocuring possibilities. The extruders are powered by compressed air, with the pneumatic system suitable for a range of viscous biomaterials.

Recommended applications include tissue engineering, disease modeling, organ-on-a-chip, pharmaceutical development and dentistry.

All Allevi printers are designed with simplicity in mind: the company says its bioprinters are some of the market’s easiest to use.

Contact manufacturer Get a quote Add to comparison

The Axo A6 is a professional bioprinting 3D printer produced by Axolotl Biosystems. Axolotl Biosystems is a 3D printer manufacturer based in Turkey. The Axolotl Biosystems Axo A6 uses 3D bioprinting 3D printing technology. This 3D printer offers a build volume of 130 x 90 x 80 mm.

The Axolotl Biosystems Axo A6 uses 3D bioprinting 3D printing technology. This 3D printer offers a build volume of 130 x 90 x 80 mm.

Contact manufacturer Get a quote Add to comparison

Advanced Solutions is a biofabrication company, initially founded in 1987 as a reseller of Autodesk products.

The BioAssemblyBot is, according to Advanced Solutions, the world’s only six-axis 3D bioprinter, complete with a robotic arm print head for greater mobility and flexibility.

Unlike some other bioprinters, it also functions as a kind of incubator, manipulating printed tissue structures over a prolonged period of time. Advanced Solutions therefore markets the machine as an all-in-one biofabrication solution.

The BioAssemblyBot uses pneumatic and mechanical extrusion technology and is suitable for the fabrication of 3D printed tissue, 3D printed organs, cell spheroids and more.

Contact manufacturer Get a quote Add to comparison

GeSim, based in Germany, is a micromachining specialist that has developed several bioprinting technologies.

The BioScaffolder 3.2 is a pneumatic extrusion-based 3D bioprinter designed for tissue engineering research. When loaded with highly viscous bioinks, the BioScaffolder 3.2 can be used to fabricate 3D printed tissue, while its three extruders allow for multimaterial printing.

Applications include the printing of porous structures, fabrication of metal implants with soft polymer layers and gradient mixing of biopolymers.

GeSim says it can build customized versions of its BioScaffolder machines tailored to specific tissue engineering applications.

Contact manufacturer Get a quote Add to comparison

Poietis is a French biotechnology company that claims to have invented 4D bioprinting technology. Its bioprinters are used by leading pharmaceutical and cosmetic groups for product testing.

The NGB-R is a commercial bioprinter designed for R&D applications. It uses laser-assisted bioprinting technology, offering single-cell resolution and high cell viability. Poietis says the printer provides 4D bioprinting by adapting to the natural timespan of biological processes such as cell proliferation, migration and differentiation.

Poietis says the printer provides 4D bioprinting by adapting to the natural timespan of biological processes such as cell proliferation, migration and differentiation.

The Poietis NGB-R is an all-in-one platform, complete with a robotic arm for automation and additional nozzle-style print heads which complement the machine’s primary laser technology (1 laser printhead and 3 micro-valve heads).

Contact manufacturer Get a quote Add to comparison

The NanoOne Bio is a high-resolution 3D printing system produced by UpNano. This 3D bioprinting solution uses 2-Photon Polymerization (2PP) technology.

Contact manufacturer Get a quote Add to comparison

CELLINK is an American bioprinting company that in 2016 commercialized the world’s first bioink. It produces a wide range of bioprinting systems and materials.

The BIO X is a 3D bioprinter that accommodates various deposition methods, including pneumatic extrusion, electromagnetic dropping and photocuring. CELLINK Has designed eight compatible print heads for the printer, three of which can be used simultaneously, and has fitted the machine with a heated print bed.

Cleanliness is key for the BIO X, which uses a HEPA h24 filter and programmable UV-C germicidal lamps for sterilizing the printing environment.

Contact manufacturer Get a quote Add to comparison

Fluicell is a public biotech company founded in 2012 as a spinoff from Chalmers University of Technology in Sweden. Its products are primarily used by researchers in drug development and cell biology.

The Biopixlar system is a high-resolution bioprinting platform offering a high level of control over individual cell placement. The bioprinter uses “microfluidic hydrodynamic confined flow technology” to dispense cells in 2D and 3D arrangements, and is designed primarily for organ-like tissue structures that can be used in drug testing.

A novel feature of the Biopixlar 3D bioprinter is its control interface: users can operate the machine using a video game-style joypad.

Contact manufacturer Get a quote Add to comparison

Upcoming 3D bioprinters

There are several interesting 3D bioprinting systems to expect over the next few months and years:

- Aspect Biosystems RX1 Bioprinter

- Inventia Rastrum

- WeBio Bioprinter

Alternative 3D bioprinters and special mentions

These 3D bioprinters are either extremely advanced machines or aren’t commercially available:

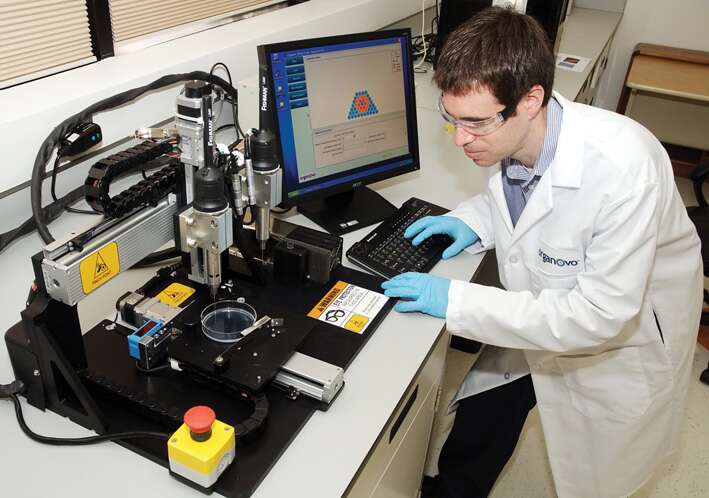

- Organovo NovoGen MMX

- 3D Bioprinting Solutions FABION 2

- Cyfuse Biomedical Regenova

Entry-level 3D bioprinters

Some manufacturers produce relatively affordable 3D bioprinters for educational purposes:

- Hyrel 3D Engine HR ($8,000)

- FELIXprinters BIOprinter ($10,000)

What can 3D bioprinting be used for?

3D printing with cells opens up possibilities in many disciplines, from healthcare to cosmetics. These are some of the most common 3D bioprinting applications.

Healthcare

Perhaps the most significant of 3D bioprinting applications, medical and healthcare research has come on leaps and bounds thanks to bioprinting.

By using a 3D bioprinter to create 3D printed tissue, researchers can carry out drug screening to see how pharmaceuticals impact human tissue — without recruiting humans for potentially harmful medical trials.

Additionally, by 3D printing organs — or miniature approximations of them — with a 3D bioprinter, researchers can perform disease modeling. A tiny 3D printed heart model, for example, can be used to better understand how heart disease impacts the human body.

Another medical application of bioprinting is the 3D printing of skin patches. Medical researchers are developing techniques for bioprinting autologous skin cells in order to treat burns and deep wounds, and because human skin is flat and neatly layered, it is easier to print and develop than other artificial organs.

Cosmetics

Bioprinting can be used to fabricate 3D printed skin, and this process has important uses beyond healthcare — in the cosmetics and beauty industry, for example.

3D bioprinting applications in cosmetics include testing beauty products for allergic reactions and other negative side effects without live human test subjects. 3D printed hair can be used for similar purposes.

A future application of 3D bioprinting in cosmetics could be the use of 3D printed skin for cosmetic surgery and facial reconstruction.

Food

3D printing with cells may soon have important applications in food production. Since a 3D bioprinter can create tissue scaffolds, it can effectively turn stem cells and other biomaterials into lab-grown meat.

Synthetic bioprinted meat is better for the environment than animal farming and involves no harm to living creatures. Several companies and research groups have developed methods for incubating bioprinted structures so that muscle fibers develop, resulting in an edible synthetic product.

Several companies and research groups have developed methods for incubating bioprinted structures so that muscle fibers develop, resulting in an edible synthetic product.

3D printed meat is softer than organic meat, but this is seen as a fairly minor issue for the industry.

Current limitations of bioprinting

The 3D bioprinting of organs has led to major advances in drug screening, disease modeling, and other areas.

However, the holy grail of medical 3D bioprinting is the development of 3D printed organs for human transplantation. In theory, this practice is possible, since researchers can already take a patient’s cells and bioprint them into 3D structures, which can then be incubated to grow into approximations of human organs.

3D printed artificial organs could someday eliminate the need for an organ donor waiting list, as patients could simply “grow” personalized replacement organs using 3D bioprinting techniques. Moreover, since each patient would contribute their own cells, researchers believe the process would sidestep the problem of transplant rejection — something that occurs when a patient receives, for example, the kidney of another human.

Moreover, since each patient would contribute their own cells, researchers believe the process would sidestep the problem of transplant rejection — something that occurs when a patient receives, for example, the kidney of another human.

But 3D printed organs are, at present, too crude to be used for transplantation. In 2022, a 3D printed heart or 3D printed kidney lacks the proper vasculature to function within the human body.

The bottleneck in 3D printed organ development is not so much the 3D bioprinting techniques themselves, but the culture and incubation processes employed after printing, which are not yet advanced enough to turn a bioprinted tissue structure into a fully functional organ.

How much does 3D bioprinting cost?

Commercial 3D bioprinting is an expensive process, with high-end machines like the Poietis NGB-R ($200,000) costing significantly more than even the most high-end polymer 3D printers.

However, some bioprinting systems aimed at university researchers — the Regemat Bio V1 ($25,000), for example — are more affordable.

Other obstacles to commercial 3D bioprinting, beyond the machine unit cost, include the complex process of acquiring human stem cells and the extensive legal effort required to bring 3D bioprinting solutions to market.

Bioprinting regulations: FDA and beyond

3D bioprinting has made huge advances over the last decade, but the legal framework surrounding 3D printed organs and other bioprinted matter is not yet clearly defined.

In the United States, medical products and procedures are regulated by the Food and Drug Administration (FDA), whose Center for Biologics Evaluation and Research is responsible for cell and tissue-based products. When 3D bioprinted organs become marketable, their regulation will likely be assigned to this department.

At present, 3D printed organs do not easily apply to any existing FDA regulations. However, researchers have suggested they would fall under the category of biological products, which include things like therapeutic serums, vaccines, allergenic products, and proteins.

Given their synthetic nature and ultimate purpose, 3D printed organs may even be classified as drugs.

Other global regulatory bodies are also in the early stages of responding to 3D bioprinting. The countries fastest to publish 3D bioprinting guidance have been Japan (Pharmaceuticals and Medical Devices Agency) and South Korea (Ministry of Food and Drug Safety), both of which offered official guidance on 3D bioprinting before the year 2016.

When a research group finally creates 3D printed artificial organs suitable for transplantation, the timeframe for testing and regulating the organs will likely be long.

3D bioprinting FAQ

Is it possible to bioprint an organ?

It is possible to bioprint structures that closely resemble human organs. They can be used for research and testing, but they are not suitable for transplantation into a human body.

They can be used for research and testing, but they are not suitable for transplantation into a human body.

What cells are used in bioprinting?

3D bioprinting has been carried out with a range of cell types. Adult stem cells can be procured by blood apheresis, bone marrow harvesting, and other techniques.

What is bioink made of?

A bioink contains living cells and certain biomaterials – gelatins, alginates, fibrin, etc. – that allow the bioink to be processed by a printer.

Can ordinary 3D printers print cells?

No. 3D bioprinters generally operate at mild temperatures to preserve living cells in the bioink, whereas FDM 3D printers heat filament above 200°C.

Organ printing: how 3D bioprinting technology has advanced and what is hindering its development In research centers and hospitals around the world, advances in 3D printing and bioprinting are providing new opportunities for human treatment and scientific research.

In the coming decades, bioprinting could be the next major milestone in healthcare and personalized medicine.

In the coming decades, bioprinting could be the next major milestone in healthcare and personalized medicine. Let's talk about bioprinting technology, the latest advances in the industry and the limitations that professionals face.

How a 3D printer works

Traditional printers, like the one you have at home or office, work in two dimensions. They can print text or images on a flat surface (usually paper) using the x (horizontal) and y (vertical) dimensions. 3D printers add another dimension - depth (z). During the printing process, the printer heads can move up and down, left and right, back and forth, but instead of delivering ink to paper, they distribute various materials - polymers, metal, ceramics and even chocolate - until the "print" of a holistic, voluminous object , layer by layer in a process known as "additive manufacturing".

To create a 3D object, you need a blueprint for it, a digital file created with modeling software. After its creation, the computer-generated model is sent to the printer. Your chosen material is loaded into the machine and ready to be heated to easily flow out of the printer nozzle. As the printer reads the plan, its head moves, depositing successive layers of the selected material to create the final product.

After its creation, the computer-generated model is sent to the printer. Your chosen material is loaded into the machine and ready to be heated to easily flow out of the printer nozzle. As the printer reads the plan, its head moves, depositing successive layers of the selected material to create the final product.

As each layer is printed, it is solidified either by cooling or by mixing two different solutions delivered by the printer head. The new layers precisely lay down on the previous ones to make a stable, cohesive element. In this way, you can create almost any shape, including a moving one.

3D printing allows you to create objects with geometric structures that would be difficult or impossible to make in other ways. A wide range of products are already being created using 3D printers, including jewelry, clothing, toys, and high-end industrial products. Even a 10-year-old Moscow schoolboy has learned how to work with a 3D printer: he prints 3D figures to order and sells them through Instagram.

How a bioprinter works

Bioprinters work in much the same way as 3D printers, with one key difference - they deposit layers of biomaterial, which can include living cells, to create complex structures such as blood vessels or skin tissue.

Living cells? Where do they get them? Every tissue in the body is made up of different types of cells. The required cells (kidney, skin, and so on) are taken from the patient and then cultured until there are enough of them to create "bio-ink" that is loaded into the printer. This is not always possible, therefore, for some tissues, stem cells are taken that are capable of becoming any cell in the body (organism), or, for example, porcine collagen protein, seaweed and others.

Often used in bioprinting is chitosan, a polysaccharide obtained from the external skeleton of mollusks (eg shrimp) or by fermenting fungi. This material has high biocompatibility and antibacterial properties. Its disadvantage is the low rate of gelation. Another popular material is a polysaccharide isolated from seaweed called agarose. Its advantages are high stability and the possibility of non-toxic cross-linking during research. However, this biomaterial does not decompose and has poor cell adhesion (the ability of cells to stick together with each other and with other substrates).

Its disadvantage is the low rate of gelation. Another popular material is a polysaccharide isolated from seaweed called agarose. Its advantages are high stability and the possibility of non-toxic cross-linking during research. However, this biomaterial does not decompose and has poor cell adhesion (the ability of cells to stick together with each other and with other substrates).

Collagen, a primary structural protein found in the skin and other connective tissues, has a high biological significance. It is the most abundant protein in mammals and a major component of connective tissue. Its disadvantages for bioprinting include the property of acid solubility. More information about biomaterials can be found here.

Based on computer designs and models, often scans and MRIs taken directly from the patient, the printer heads place the cells exactly where they are needed and within a few hours an organic object is built from a large number of very thin layers.

Organovo bioprinter creates tissues that mimic the structure and composition of various human organs

Source: Pbs. org

org

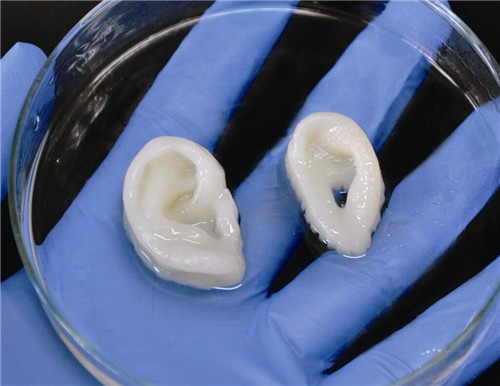

Scaffolding for ear or nose replacement at Wake Forest University in Winston-Salem, North Carolina

Source: CBS News

Computer displays an image of a "scaffold" for the human ear, created in the laboratory of Wake Forest University in Winston-Salem, North Carolina

Source: CBS News

Usually more than just cells are needed, so most bioprinters also supply some kind of organic or synthetic "glue" - a soluble gel or collagen scaffold to which cells can attach and grow. This helps them form and stabilize in the correct shape. Surprisingly, some cells can take the correct position on their own without any "scaffolding". How do they know where to go? How do embryonic cells develop in the uterus, or does adult tissue move to repair damage? Same here.

Universities, researchers and private companies around the world are involved in the development of bioprinting technologies. Let's take a look at some of the amazing things they are working on.

Bioprinting in Russia

3D Bioprinting Solutions is a biotechnology research laboratory founded by medical company INVITRO. The activity of the laboratory is the development and production of bioprinters and materials in the field of three-dimensional bioprinting and scientific research. August 23, 20193D Bioprinting Solutions laboratory sent a new batch of cuvettes to the ISS to continue experiments on bioprinting in space, which began in 2018. This was reported in the press center of the laboratory. This time it is planned to use organic and inorganic components to assemble bone tissue on the world's first space bioprinter Organ.Aut.

Symposium "Biofabrication in Space"

Source: Zdrav.Expert

Organ.Aut magnetic bioprinter

Source: Zdrav.Expert

The astronauts will also grow protein crystals and experiment with printing biofilms of bacteria to study their behavior in zero gravity. Russian scientists expect to receive unique scientific data that can be applied in the development of new drugs.

Scientific director of 3D Bioprinting Solutions and leading researcher of the Institute of Regenerative Medicine, Candidate of Medical Sciences Vladimir Mironov, in his speech at the Department of Anatomy of Sechenov University on September 2, noted: “Living cells, tissues and human organs will be synthesized already in the current century. To do this, morphological sciences, such as microscopic anatomy and histology, must be digitized or digitalized, that is, digitized and made available for computer programs of robotic bioprinters, since without digital models it is impossible to print human tissues and organs.”

Bioprinting around the world

Every year, millions of people around the world need bone grafting. Modern bone grafts often use cement-based synthetic material in combination with the patient's own bone. However, the use of these materials has a number of limitations - some transplants caused rejection and inflammatory processes in patients. Reproduction of the natural bone-cartilage "interface" has also been problematic.

Reproduction of the natural bone-cartilage "interface" has also been problematic.

However, a team at Swansea University in 2014 developed a bioprinting technology that allows the creation of an artificial bone prosthesis in the exact shape of the desired bone, using a biocompatible material that is both durable and regenerative. At the same time, scientists from the University of Nottingham in England were working on similar studies.

It takes about two hours to print a small bone. Therefore, surgeons can do it right in the operating room. This part of the bone is then covered with adult stem cells that can develop into almost any other type of cell. This is combined with bio-ink from the printer, a combination of polylactic acid (which provides mechanical strength to bone) and alginate, a gel-like substance that serves as a shock-absorbing material for cells. The end product is then implanted into the body, where it will completely disappear within about three months and be replaced by new bone.

Researchers hope that in the future, bioprinted bones can be created with sufficient reliability to support complex spinal reconstruction, and that the bone material will be further improved to increase its compatibility with cartilage cells.

Source: ETH Zurich

Successful 3D printing of human cartilage may soon completely replace artificial implants for people in need of reconstructive surgery. Back in 2015, scientists in Zurich developed technology that would allow hospitals to print a full-size human nose implant in less than 20 minutes. They believe that any cartilage implant can be made using their technique.

Researcher Matti Kesti described the technology as follows:

“

“A serious car accident can cause the driver or passenger to suffer complex nose injuries. The nose can be restored by creating a 3D model on a computer. At the same time, a biopsy of the patient is performed and cartilage cells are removed from the victim's body, such as from a knee, a finger, an ear, or fragments of a broken nose. The cells are spawned in the laboratory and mixed with the biopolymer. From this suspension, a model of nasal cartilage is created using a bioprinter, which is implanted into the patient during surgery. In the process, the biopolymer is used simply as a mold. It is subsequently broken down by the body's own cartilage cells. And in a couple of months it will be impossible to distinguish between the graft and the person’s own nasal cartilage.”

The cells are spawned in the laboratory and mixed with the biopolymer. From this suspension, a model of nasal cartilage is created using a bioprinter, which is implanted into the patient during surgery. In the process, the biopolymer is used simply as a mold. It is subsequently broken down by the body's own cartilage cells. And in a couple of months it will be impossible to distinguish between the graft and the person’s own nasal cartilage.”

Matti Kesti

Since the implant was grown from the body's own cells, the risk of rejection will be much lower than for an implant made of, say, silicone. An additional advantage is that the bioimplant grows with the patient, which is especially important for children and young people.

If a person is severely burned, healthy skin can be taken from another part of the body and used to cover the affected area. Sometimes intact skin is missing.

Researchers at Wake Forest School of Medicine have successfully designed, built and tested a printer that can print skin cells directly onto a burn wound. The scanner very accurately determines the size and depth of damage. This information is sent to a printer and skin is printed to cover the wound. Unlike traditional skin grafts, it only takes a patch of skin one-tenth the size of a burn to grow enough cells to print. While this technology is still in the experimental stage, the researchers hope that it will be widely available within the next five years.

The scanner very accurately determines the size and depth of damage. This information is sent to a printer and skin is printed to cover the wound. Unlike traditional skin grafts, it only takes a patch of skin one-tenth the size of a burn to grow enough cells to print. While this technology is still in the experimental stage, the researchers hope that it will be widely available within the next five years.

As already mentioned, 3D printers print products in layers, and since the skin is a multi-layered organ with different types of cells, it is well suited for this type of technology. However, researchers still have a lot of problems to solve, in particular, how to prevent damage to cells from the heat generated by the printer. And of course, like most parts of the human body, the skin is more complex than it first appears—there are nerve endings, blood vessels, and a host of other aspects to consider.

Blood vessels

Biomechanical engineer Monica Moya holding a petri dish with printed alginate-based biotubes. Biotubes can act as temporary blood vessels similar to blood vessels that help create a patch of living tissue.

Biotubes can act as temporary blood vessels similar to blood vessels that help create a patch of living tissue.

Source: embodi3D

With tens of thousands of miles of veins, arteries and capillaries in the human body, researchers are working to replace them if they ever wear out. The creation of viable blood vessels is also essential for the proper functioning of all other potential bioprinted body parts.

Biomechanical Engineer Monica Moya of Livermore National Laboratory. Lawrence uses bioprinting to create blood vessels. The materials created by her bioprinters are engineered to allow small blood vessels to develop on their own.

This development takes time, so vials of cells and other biomaterials are printed to help deliver vital nutrients to the printed environment. After a while, self-assembled capillaries connect with bioprinted tubes and begin to deliver nutrients to cells on their own, mimicking the work of these structures in the human body.

Internal organs

Many researchers hope that in 20 years the lists of patients waiting for organ transplants will become a thing of the past. They envision a world where any organ can be printed and transplanted in just a few hours, without rejection or complications, because these organs will be created from body cells according to the individual characteristics of each patient. Currently, bioprinting of fully functional complex internal organs is not possible, but research is ongoing (and not without success).

Bladder

For example, the bladder is already printed. In 2013, at Wake Forest University in the US, researchers successfully took cells from a patient's original, poorly functioning bladder, cultured them, and added additional nutrients. The 3D shape of the patient's bladder was then printed and the cultured cells soaked through it. The form was placed in an incubator and, when it reached the desired condition, it was transplanted into the patient's body. The mold will eventually collapse, leaving only the organic material. The same team successfully created viable urethras.

The mold will eventually collapse, leaving only the organic material. The same team successfully created viable urethras.

Physicians and scientists at the Wake Forest Institute for Regenerative Medicine (WFIRM) were the first in the world to create laboratory-grown organs and tissues that were successfully transplanted into humans. Right now they are working on growing tissues and organs for more than 30 different areas of the body, from the kidneys and trachea to cartilage and lungs. They also aim to accelerate the availability of these treatments to patients.

Scientists in Australia are doing similar research as well. They used human stem cells to grow a kidney organ that contains all the necessary cell types for a kidney. Such cells can serve as a valuable initial source for bioprinting more complex kidney structures.

MD, Professor of Urology, Professor of the Institute of Regenerative Medicine Anthony Atala shows a kidney created by a bioprinter. A modified desktop inkjet printer sprays cells instead of ink. The cells were cultured from the patient and the structural template for the kidney was obtained from the MRI (so it is the correct size and shape).

A modified desktop inkjet printer sprays cells instead of ink. The cells were cultured from the patient and the structural template for the kidney was obtained from the MRI (so it is the correct size and shape).

Using this technology, back in 2001, Atala printed and successfully transplanted a bladder into a young man, Jake.

Source: TedEd

Heart

Heart cells, laboratory-grown organelles. Source

Surprisingly, it is the human heart that can become one of the easiest organs to print, since, in fact, it is a pump with tubes. Of course, everything is not so simple, but many researchers believe that humanity will learn to print hearts before kidneys or liver.

Researchers at the Wake Forest Institute for Regenerative Medicine in April 2015 created "organoids" - 3D printed fully functional, beating heart cells.

In April 2019, Israeli scientists printed the world's first 3D heart. It is still very small, the size of a cherry, but it is able to perform its functions. The 3D heart with blood vessels uses personalized "ink" of collagen, a protein that supports cell structures, and other biological molecules.

The 3D heart with blood vessels uses personalized "ink" of collagen, a protein that supports cell structures, and other biological molecules.

A Tel Aviv University researcher holds the world's first 3D printed heart on April 15, 2019.

Source: Haaretz

“This is the first time anyone anywhere has successfully designed and printed a whole heart with cells, blood vessels, ventricles and chambers,” said Tel Aviv University scientist Professor Tal Dvir.

So far, scientists have been able to print tissue from cartilage and the aortic valve, for example, but the challenge has been to create tissue with vascularity—the blood vessels, including capillaries, without which organs cannot survive, let alone function.

The Tel Aviv scientists started with human adipose tissue and separated the cellular and non-cellular components. They then reprogrammed the cells to become undifferentiated stem cells, which could then become cardiac or endothelial. Endothelium - a single layer of flat cells lining the inner surface of the heart cavities, blood and lymphatic vessels. Endothelial cells perform many functions of the vascular system, such as controlling blood pressure, regulating the components of blood clotting, and the formation of new blood vessels.

Endothelium - a single layer of flat cells lining the inner surface of the heart cavities, blood and lymphatic vessels. Endothelial cells perform many functions of the vascular system, such as controlling blood pressure, regulating the components of blood clotting, and the formation of new blood vessels.

Non-cellular materials, including a large amount of proteins, were processed into a "personalized hydrogel" that served as "printing ink".

It will be years before this technology can create organs for efficient transplantation. However, the achievements of scientists in Tel Aviv are a huge milestone along the way.

Medical research and pharmacology

One of the key potential uses for bioprinted living materials is in the field of medical and drug research. Bioprinted tissues have several cell types with different densities and key architectural features. This allows researchers to study the impact of various diseases on the body, the stages of disease progression and possible treatments in the natural microenvironment.

One of the most impressive developments in recent years is the development of a desktop brain at the ARC Center of Excellence in 2016. The researchers were able to use a 3D printer to create a 3D printed six-layer structure that includes nerve cells that mimic the structure of brain tissue.

This opens up huge potential benefits for researchers, pharmaceuticals and private companies, because it will allow them to test new products and drugs on tissue that accurately reflects the responses of human brain tissue, as opposed to animal samples, which may cause a completely different response. The desktop brain can also be used to further investigate diseases such as schizophrenia or Alzheimer's.

We are far from printing the brain, but the ability to arrange cells to form neural networks is a significant step forward. By allowing researchers to work with human tissue in real time, testing processes can be greatly accelerated and results can be more realistic and accurate. It will also reduce the need to use laboratory animals for medical tests and potentially dangerous human testing.

It will also reduce the need to use laboratory animals for medical tests and potentially dangerous human testing.

Medical simulators and data registries

Source: Simbionix

About 3,000 medical simulators are currently in use around the world to help doctors practice complex procedures. Virtual blood vessels, 3D printed organs... and no animal suffers!

The American company 3D Systems created an industry segment called VSP (Virtual Surgical Planning). This approach to personalized surgery combines expertise in medical imaging, surgical simulation and 3D printing. Surgeons using the Simbionix medical simulator for the first time often report feeling physical pain while empathizing with their virtual patient - the experience is so realistic. Organs and tissues look completely real. When stitching an organ, the surgeon sees on the screen a needle that enters the tissue, and pulls the thread. If the doctor does something wrong, the virtual blood vessels break and the organ begins to bleed. These simulators were developed by the Israeli company Symbionix, which was acquired by 3D Systems in 2014.

These simulators were developed by the Israeli company Symbionix, which was acquired by 3D Systems in 2014.

On September 3, 2019, the Radiology Society of North America (RSNA) and the American College of Radiology (ACR) announced the launch of a new 3D Medical Printing Clinical Data Registry to collect data on treatment outcomes using 3D printing at the point of care. This information will be a powerful tool to assess and improve patient care in real time, drive ongoing research and development, and inform patients and healthcare professionals about the best course of care.

“

“The creation of a joint RSNA-ACR 3D printing registry is essential to the advancement of clinical 3D printing. The registry will collect data to support the appropriate use of this technology and its implications for clinical decision making.”

William Widock, Professor of Radiology at the University of Michigan and Chairman of the RSNA 3D Printing Special Interest Group (SIG)

According to RSNA, the information in the registry will allow for the necessary analysis to demonstrate the clinical value of 3D printing. Due to the wide variety of clinical indications, different technologies for creating physical models from medical images, and the complexity of the models, it is problematic to choose the optimal treatment method. The registry will help solve this problem.

Due to the wide variety of clinical indications, different technologies for creating physical models from medical images, and the complexity of the models, it is problematic to choose the optimal treatment method. The registry will help solve this problem.

Bioprinting software

Bioprinter and bioprinting software manufacturer Allevi introduced Allevi Bioprint Pro software on September 5, 2019. Built-in model generation and integrated slicing will allow you to focus more on experimenting, rather than setting up the printer. The program runs entirely in the cloud, which means you can create your biostructures, define materials, and track prints right from a web browser on any computer.

According to the development team, the new bioprinter with the above software is powerful and easy to use and represents another piece of the puzzle on the way to 3D printed organs.

At the same time, CELLINK, the first bio-ink company, announced the launch of a new product to become the most flexible bio-printing platform on the market. The BIO X6 bioprinter, which has no analogues at the moment, has the ability to combine more bioprinting materials, cells and tools.

The BIO X6 bioprinter, which has no analogues at the moment, has the ability to combine more bioprinting materials, cells and tools.

Why is this taking so long?

Complex body structure

The human body and its various components are much more complex than a plastic toy. The human organ has a complex network of cells, tissues, nerves, and structures that must be arranged in specific ways to function properly. From placing thousands of tiny capillaries in the liver to actually getting a printed heart that "beats" and contracts in the human body, there is still a lot of research and testing.

Legal regulation

In addition, bioprinting technologies, like all new medical treatments, must pass safety tests and due process of regulation before they become available.

Special software and hardware

It also takes time to develop special software and hardware. These programs can be written only with the appropriate data (medical, clinical, statistical, mathematical, and so on), which someone must first collect, analyze, systematize and digitize.

Working through all of these steps requires the integration of technologies from various fields, including engineering, biomaterials science, cell biology, physics, mathematics, and medicine. So we need to be a little more patient.

The main thing is to know that those who work in the field, doctors and engineers, programmers and scientists are making progress every day both in bioprinting technology itself and in understanding how it can be used and improved. Although we are not quite there yet, there is no doubt that medicine will be very different in 10-20 years, thanks also to bioprinting.

In brief

Bioprinting is an extension of traditional 3D printing.

Bioprinting can produce living tissue, bones, blood vessels, and possibly entire organs for use in medical procedures, medical training, and testing.

The cellular complexity of a living organism has made 3D bioprinting slower to develop than conventional 3D printing.

Bioprinting technology could enable the generation of patient-specific tissues to develop precise, targeted and fully personalized treatments.

We still have a long way to go before we can create fully functioning and viable organs for human transplantation.

Related materials: Russia was the first in the world to print living tissues in space using a bioprinter

5 most amazing things created using 3D printing

A rocket printed on a 3D printerwill go into orbit in 2021 "Exhibits touching is allowed”: how 3D printing is transforming museums

© Rusbase, 2019

Author: Nadezhda Aleinik

Cover photo: etonastenka, Depositphotos

Bioprinter: printing organs on a 3d printer

3D bioprinting is an advanced technology that saves lives and helps create new medicines. What is the peculiarity and complexity of developments, who is engaged in them and what successes have already been made - this will be discussed in the material. We will also get acquainted with all the methods of bioprinting known today.

We will also get acquainted with all the methods of bioprinting known today.

- How bioprinters print and what is 3D bioprinting

- What is printed on 3D bioprinters?

- Where do they print?

- 3D bioprinters in Russia

How bioprinters print and what is 3D bioprinting

3D bioprinting is the creation of 3D models using biomaterial, which includes living cells. It is used to reproduce complex structures such as skin tissue or blood vessels.

Model cells are taken from the patient and cultured until their mass is sufficient to create a bioink. The resulting ink is loaded into the printer, which prints the desired model.

Getting enough cells is not always possible, so seaweed or porcine collagen protein comes to the rescue. Stem cells are also used, which have the ability to become any cell in the body.

The first biological 3D printer

The first serial bioprinter was released by the American company Organovo by the end of 2009. The Australian company Invetech became its industrial partner. Thanks to joint efforts, the machine was born, which in 2010 printed the first full-fledged blood vessel.

The Australian company Invetech became its industrial partner. Thanks to joint efforts, the machine was born, which in 2010 printed the first full-fledged blood vessel.

Organovo representatives decided to move away from the idea of growing organs in a test tube and suggested that it would be much more efficient to print it. They came up with the NovoGen technology, which regulated all the interactions between the biological component of the process and its mechanical part. Invetech was involved to implement the idea. The collaboration resulted in a compact device with an intuitive interface.

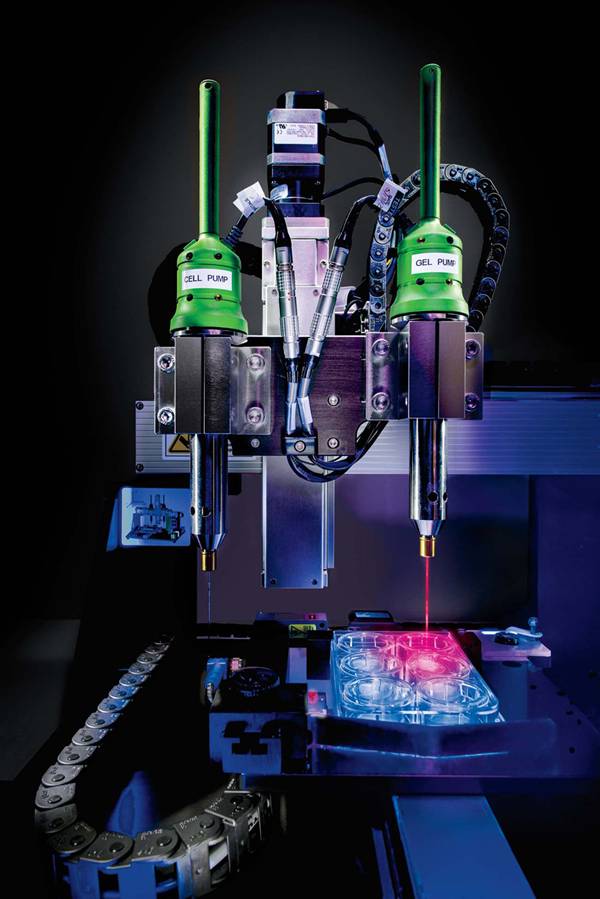

The printer had two printheads. One was filled with the necessary biomaterial, the second - with auxiliary components (collagen supporting the hydrogel, growth factors). Printing accuracy reached micrometers, which played an important role in the correct placement of cells.

3D bioprinting technologies

There are several technologies and approaches being developed and applied in the field of bioprinting. Scientists and researchers from private companies and institutions work on each of them.

Scientists and researchers from private companies and institutions work on each of them.

Multimaterial Multinozzle 3D (MM3D) technology, Wyss Institute

The technology developed at the institute is based on the use of fast moving high pressure valves. The applied method makes it possible to switch between materials up to 50 times per second. This speed is faster than you can see with the naked eye.

The printheads themselves are 3D printed, so they can be easily customized to your specific needs.

The technology is suitable for the manufacture of complex objects, including mobile robots. The method significantly speeds up the creation of complex models, because the printheads can use several nozzles at once.

Sound-Induced Morphogenesis (SIM) Technology by mimiX Biotherapeutics

Swiss technology is based on the reproduction of well-defined biological patterns that self-assemble into functional tissues using sound waves. The method embodies a highly efficient sequence for reproducing organized and dense cellular structures.

The method embodies a highly efficient sequence for reproducing organized and dense cellular structures.

The mimiX technology uses sound waves. The space for growing cells is formed around a given type of speaker. Depending on the shape of the cup and the sound produced, structures of various shapes, such as gratings, are formed.

The creation of this method serves an important purpose - the availability and speed of playback that can be achieved in any room. Prior to the invention of the SIM, bioprinting was available for scientific research. For clinical, it has become too complicated and lengthy. Now this has changed.

Fluicell Biopixlar Bioprinter

Swedish-based Fluicell focuses on creating platforms for studying cell behavior. Her method of work makes it possible to make complex structures that mimic tissue, in which the location of individual cells is controlled by a gamepad. The workflow is similar to a video game.

The company uses the micro-jet technique. Thanks to the micro jet tube and the precision of the pump during the direction of the biomaterial to the printing zone, it gives micro-level control over the material. Because of this, systems scale to the macro level naturally. High resolution prints are produced.

The method makes it possible to reproduce multicomponent structures, while the material can be created in the printer itself. This approach eliminates the need for laboratory preparation. The mixing progress of different materials is controlled in the microfluidic chamber. The result is a 3D printed finished structure, which was created without the use of gels and scaffolds.

The technical capabilities of this method make it ideal for processing scarce materials such as biopsy specimens, stem cells and primary cells.

CELLINK Bioprinters

CELLINK is a Swedish company that develops bioprinting technologies for various applications, including cosmetics and medicine. The principles generated by the organization work to create skin tissue, cartilage, liver and other products.

The principles generated by the organization work to create skin tissue, cartilage, liver and other products.

In 2019, the manufacturer launched two models of bioprinters on the market - Bio X6 and Lumen X. The first one is designed for creating constructs with any type of cells. With it, you can reproduce any tissue found in the body. The company focuses on quick results and combining a large number of materials.

The Bio X6 has 6 printheads built in with CELLINK Clean Camera Technology. It is equipped with a smart interchangeable head method and two powerful fans to create excess air pressure inside the chamber. The user gets the opportunity to combine several materials in one print with a structure of increased complexity.

The second Lumen X unit is the result of a collaboration with the American company Volumetric. This is a startup focused on creating bioprinters using SLA technology. The device has a low cost and modest dimensions. At the same time, it has high printing accuracy and excellent performance. Such characteristics are especially important for the creation of vascular structures. Lumen X gets the job done 10 times faster than its competitors under the same conditions.

Such characteristics are especially important for the creation of vascular structures. Lumen X gets the job done 10 times faster than its competitors under the same conditions.

Bioprinter for Microtia patients creating human ears, University of Wollongong

Myctoria is a congenital defect associated with developmental arrest of the outer ear. It is found during pregnancy. Since the structure of the ear has a specific shape, the treatment of its deformity causes serious difficulties. According to the creators of the bioprinter, the new technology is leading to a revolution in helping children with microtia.

The Australian University of Wollongong created the Alek 3D printer. It prints human ears for further use in reconstructive surgery. Stem cells serve as the basis for bioink. The creation of ears on a bioprinter looks very promising, since the method allows you to design a transplant according to the shape of the patient's face and do it in a fairly short time. The technology excludes the search for donors to take a piece of cartilage, the work is based on the use of the patient's natural tissues.

The technology excludes the search for donors to take a piece of cartilage, the work is based on the use of the patient's natural tissues.

Bioink

Manufacturers are engaged not only in the development of technology and design of printing devices, but also in materials that can be used to create complex structures and entire organs.

Allevi Liver Tissue Ink

The complexity of reproducing the liver lies in the fact that it has many important functions for life. There are more than five hundred of them. A small number of manufacturers are able to create bio-ink for the liver that will meet all the necessary conditions.

The American company Allevi is one such company. The drug, which makes it possible to reproduce tissue-like structures that mimic the natural characteristics of tissues, can be freely purchased through the Allevi online store.

Biogelx Synthetic Bioink

Biogelx is a company from Scotland. It is based in a laboratory at the University of Strathclyde in Glasgow. The direction of the company is the research and creation of artificial materials for bioprinting.

The direction of the company is the research and creation of artificial materials for bioprinting.

Hydrogel ink has a unique chemical and physical variability. It allows you to accurately recreate a variety of tissue parameters. As a result, cells are able to interact in an almost natural environment.

Ink helps keep cells alive. They provide a simple crosslinking technique and viscosity control as well as a high degree of reproducibility. Due to its positive technical abilities, the material is compatible with a wide range of 3D bioprinters.

Hydrogel with mineral nanoparticles, University of Texas

American development from the staff of the University of Texas (TAMU). Scientists have created a material in the form of a hydrogel. It contains mineral nanoparticles. They have the ability to carry out protein preparations to control the behavior of cells. Inks of this kind help in the field of creating tissues containing blood vessels.

Developers have been developing hydrogel bioinks based on the inert polymer PEG (polyethylene glycol). Printing with this type of ink is difficult due to its low viscosity. In the course of research, it turned out that silicate nanoparticles effectively increase the degree of viscosity, while almost not changing the other technical parameters of the printed material. Thus, TAMU workers have created a new class of hydrogels.

Bio-ink for artificial leather printing, Renseller Polytechnic Institute

The production of high-quality imitation skin after burns and other wounds has been on the minds of bioengineers for many years. There are 2 ways to treat serious skin lesions. The first is the use of autologous skin grafts. Healthy tissue is taken from the patient and transplanted to damaged areas, while fresh wounds are formed and, in general, the procedure is quite unpleasant and painful.

The second method is to use skin substitutes made from foreign materials, such as bovine collagen. Such imitations do not completely cover deep wounds and are very different from natural skin.

Such imitations do not completely cover deep wounds and are very different from natural skin.

Skin resurfacing technology from a collaboration between Rensselaer Polytechnic Institute (RPI) and Yale University promises to revolutionize skin grafting. They created bio-ink using living human cells. The material helps in reproducing artificial skin, which later itself recreates the system of blood vessels.

3D Bioprinting Solutions

3D Bioprinting Solutions is the only organization in Russia dealing with bioprinting. The company was founded in 2013. One of the co-founders was the co-founder of INVITRO - Alexander Ostrovsky. His specialty is a resuscitator.

In 2014, the laboratory presented the first bioprinter made in Russia. He received the name FABION. According to the list of the use of various printed materials, this device is one of the leaders in the field of multifunctional devices.

In early 2015, the company created and successfully transplanted a mouse thyroid organ construct. In 2016, researchers produced a printhead that can automatically feed tissue spheroids for 3D bioprinting. The development was applied in the new version of the device - FABION-2.

In 2016, researchers produced a printhead that can automatically feed tissue spheroids for 3D bioprinting. The development was applied in the new version of the device - FABION-2.

After the release of an updated version of the device, the company's specialists focused on creating a printer that uses a new working methodology, different from previous solutions. It was the principle of magnetic levitation and the ability of microtissues to self-assemble from tissue spheroids. A fully functioning magnetic assembly saw the light of day by the spring of 2017.

At the end of the summer of 2017, cooperation with the state company Roscosmos began. The laboratory has signed a contract for the implementation of a space biofabrication experiment aboard the Russian part of the ISS. Scientists have begun to develop the Organ.Avt printer capable of working in zero gravity.

The Magnetic Bioprinter experiment started at the end of 2018. In its course, models of human bone and cartilage tissue, as well as the mouse thyroid gland, were printed. To carry out the work, the Soyuz MS-11 crew members underwent appropriate training at the 3D Bioprinting Solutions laboratory.

To carry out the work, the Soyuz MS-11 crew members underwent appropriate training at the 3D Bioprinting Solutions laboratory.

In addition to bioprinters, the company has developed a line of multifunctional collagen products - Wiscoll. It is suitable for use in any 3D bioprinter. Bioink is used for a wide range of biofabrication experiments. The product is a concentrated solution of collagen of the first type of the highest degree of purification. It is immediately ready for use.

What is printed on 3D bioprinters?

Printing organs

Printing fully functional complex internal organs is not yet possible, although research is ongoing in this area. For example, the bladder has already managed to reproduce. It happened in 2013 in the USA (Wake Forest University).

Scientists have extracted raw material from a patient's poorly functioning organ, nurtured them and added nutrients. Next, they reproduced the shape of the bladder according to the parameters of the patient and cultured cells impregnated through it. The model was placed in an incubator, brought to the required condition and transplanted into a human. Over time, it collapsed, leaving completely organic material in its place.

The model was placed in an incubator, brought to the required condition and transplanted into a human. Over time, it collapsed, leaving completely organic material in its place.

The same team produced viable urethras. Research is ongoing and breakthroughs are being made in the creation of the kidneys, liver and heart.

Printing of tissues and vessels

The human body is pierced by tens of thousands of kilometers of capillaries, arteries and veins. Over time, they wear out, and scientists are conducting research on the possibility of their full replacement. Creating body parts on a bioprinter is impossible without reproducing viable blood vessels. Technologies make it possible to create materials designed for further favorable independent development of blood vessels.

Surgical practice

Surgeons got the opportunity to practice on operations on organs and tissues that look 100% real. This happens both with the help of virtual prototyping and with the use of 3D printed models.

New drug testing

Bioprinted tissue has multiple cell types with different densities and key architectural features. This makes it possible to conduct research on the impact of diseases on the body, as well as to work out various methods of treatment.

Where do they print?

Organizations that offer organ printing or sell bioprinters:

- 3D Bioprinting Solutions - Russia, Moscow. Specializes in frameless printing, created two printers - FABION and FABION-2. Develops his own method of organoprinting.

- Organovo - USA, San Diego. Produces and sells liver tissue to pharmaceutical companies. In 2009, the first mass-produced bioprinter, Novogen, was released.

- BioBots - USA, Louisville. A startup that introduced a cheap bioprinter for commercial use in 2013. Available BioBot BASIC. Work is underway on the second version of the device.

- Cyfuse Biomedical - Japan, Tokyo. The company produced the Regenovo bioprinter, which can be used to create skin tissues and grow blood vessels.

Learn more

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).