3D printing newbury street boston

3D Printing Company MakerBot Is Opening a Store in Boston

Brooklyn-based MakerBot is opening a new store in the Back Bay.

Get a compelling long read and must-have lifestyle tips in your inbox every Sunday morning — great with coffee!

Photo Courtesy of MakerBot

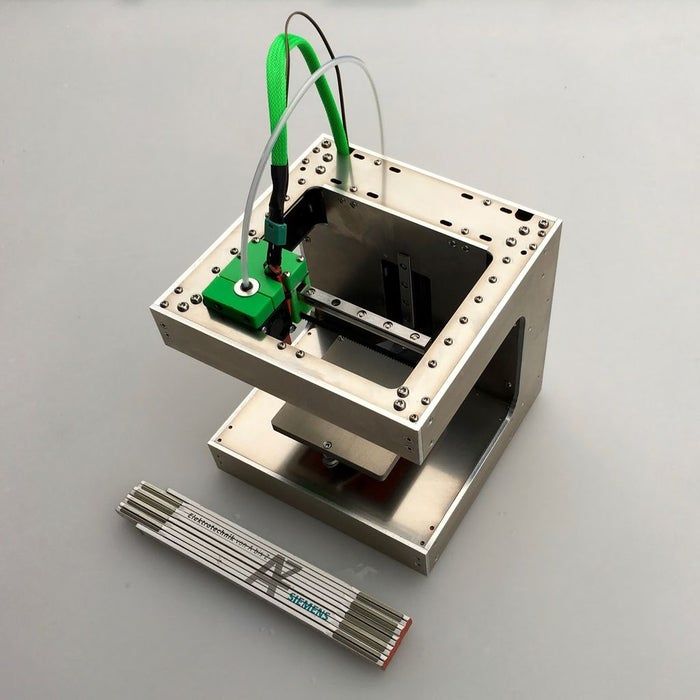

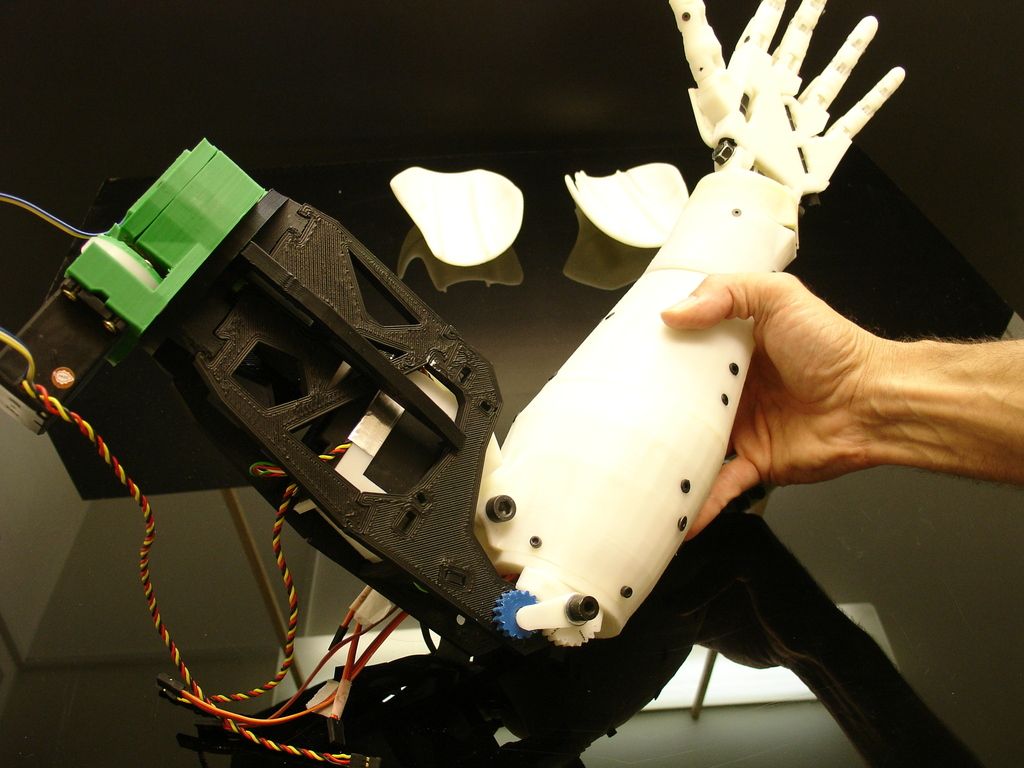

In a short amount of time, 3D printing—while sometimes controversial—has gone from being exclusively used in high-tech laboratories, to being sold for commercial use, and a Brooklyn-based company is aiding the transition by bringing the technology to the retail market.

As the holidays approach, MakerBot, a company that specializes in 3D printing and scanning, will be opening an in-store location on Newbury Street, allowing customers to both drop by and purchase the printers, as well as get demonstrations on how to use the devices. They can even scan, print, and purchase objects created onsite. The New York company will also be opening a store in Connecticut at the same time.

Bre Pettis, CEO of MakerBot, said the Boston shop will be somewhat of a “homecoming,” because the company’s president, Jenny Lawton, once ran her own tech company in the area.

“Boston and [Greenwich, Connecticut] are both terrific, tech-savvy communities, so it seemed natural to expand the MakerBot Store presence in these two areas,” said Lawson in a statement about the new retail spots opening up. “We considered locations all around the world, but knew these two neighborhoods offered vibrant retail communities.”

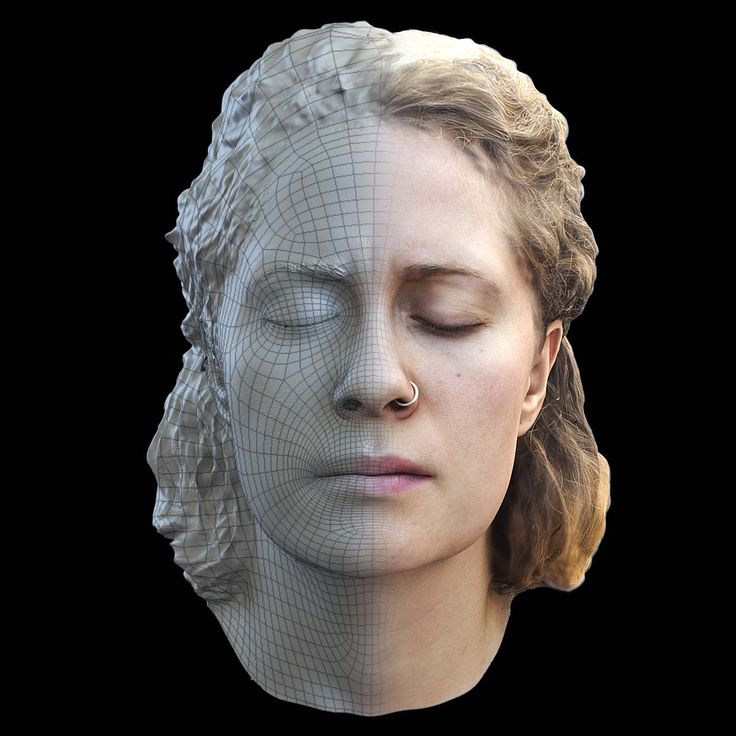

The newest Newbury Street location will also be home to a MakerBot photo booth, where customers can snap a picture of themselves, and then get a 3D rendering of the image printed out on the spot. The technology uses digital cameras to capture the subject matter instantaneously in high-resolution data. “The images are then combined to create an accurate three-dimensional model of the face, including textures,” the company explains. The first 3D photo booth was introduced in New York one year ago.

There will also be a MakerBot Gum Ball machine selling miniature trinkets with Boston-based themes, created by the printers. Installations will be going up in the store’s windows, featuring displays made on MakerBot devices.

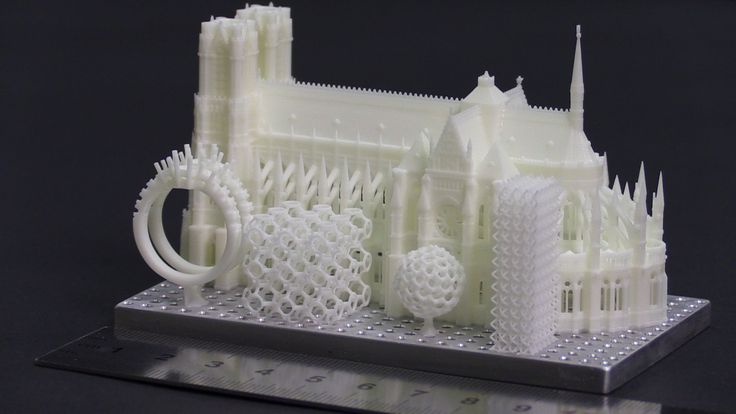

In 2012, Pettis told Wired.com that he believes the small-scale 3D printers, like the MakerBot Replicator 2—which retail for around $2,100—will start becoming household commodities in no time. The pint-sized devices are capable of spitting out everything from toys, to desktop items like puzzles, and even jewelry—all made from the special eco-friendly, plastic-like material used to construct products when scanned and 3D printed. “This is MakerBot’s Macintosh moment. Just as nearly 30 years ago Apple made desktop publishing mainstream, the aim with the Replicator 2 is to take something new to the masses: desktop manufacturing,” Wired wrote.

Read More About:

- Back Bay

FabLabs | The BAC

Fabrication is an integral part of studying at the BAC. The process of converting two-dimensional drawings and sketches, sketch models, or digitally drawn ideas into relatable physical objects for exploration and study is a vital element in the design process. The BAC FabLabs offer many resources to bring your ideas to life.

The BAC FabLabs offer many resources to bring your ideas to life.

- 3D Printing

- CNC Routing

- Laser Cutting/Engraving

- The Shop

What: 3D Printers are available in the CODER Lab on a first-come, first-served basis, seven days a week to all BAC students, faculty, and staff. You must model your idea in 3D modeling software such as SketchUP, Rhino, 3DS Max, etc. Once your file is ready to print, we add it to the queue. Jobs cannot be started later than 1 hour before CODER closes.

You must model your idea in 3D modeling software such as SketchUP, Rhino, 3DS Max, etc. Once your file is ready to print, we add it to the queue. Jobs cannot be started later than 1 hour before CODER closes.

Where: CODER Lab (Room 405) at 320 Newbury Street

How: Users should visit the CODER Lab in person, with their digital files available. A CODER staff member will review the files and make suggestions regarding edits, file clean-up, orientation, and more. Once the file is approved for printing, it will be added to the print queue. During midterms and finals, the queue can be up to 4 or 5 days long. However, while turnaround times can't be guaranteed, most prints can be completed within 24 hours.

More:

- Rules: To ensure equitable use, only BAC-related objects can be printed on the 3D printers. These include studio work, Gateway work, and independent study work. This does not include objects for your office or independent business.

In addition, your files must be 3D compatible and if deemed non-printable, will be returned for revision.

In addition, your files must be 3D compatible and if deemed non-printable, will be returned for revision. - Pricing: 10 cents per gram for the Zortrax printers and 50 cents per gram for the Form Labs printers. Most prints end up costing $7 or less and are deducted from your student printing account. Similar prints at commercial shops are often two to five times more costly.

Questions: Please contact [email protected].

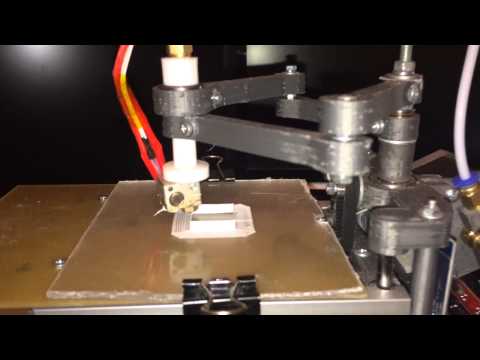

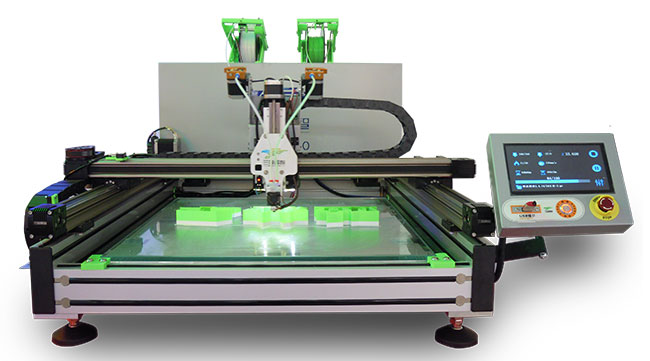

What: A CNC router is a computer-controlled 3-axis (x, y, z) digital fabrication tool used for cutting sheet stock such as plywood or foam. It can make 2D cuts similar to a laser cutter and can also create 3D contours, as the router bit can move in all dimensions. Our CNC machines have a 2'x4' bed size and a 2'x3' bed size, and can be used to produce furniture, signage, site models, pavilion scale projects, and much more.

Where: Basement (Room 003) at 320 Newbury Street

How: The CNC machine is available by appointment to all BAC students and faculty via scheduling at baccnc. 10to8.com.

10to8.com.

- Orientation (1 hour): To learn how to use the CNC machine. First-time users should book an orientation meeting for their first appointment.

- Preparation (1–2 hours): To review my toolpaths or ask questions about my project, the software, etc. All students and faculty must schedule and attend a Prep Appointment prior to scheduling a Cut Appointment.

- Cut (1–3 hours): To create the project. Prep meeting has been completed and project has been reviewed by CNC Operators or Computing Assistants. Appropriate materials are in hand.

Questions: All questions/concerns should be sent to [email protected].

What: All laser cutters at the BAC are Universal Laser System VLS 6.6 60-watt metal-tube CO2 lasers. They can accommodate sheet material up to a maximum of 18 inches by 32 inches with a thickness of up to 6 inches (for etching) and 1/4 inch for cutting (depending on the material).

Where: The BAC has three laser cutting devices located in room 412 - The Laser Lab - on the fourth floor of 320 Newbury Street.

How: The laser cutters can now be reserved online. Those who have completed the orientations will be able to book the laser cutters through the BAC's online booking portal at booking.the-bac.edu. If using a mobile phone, it is recommended to select "Desktop View" prior to logging in. Your login is your standard BAC user name and password.

More:

- Safety and Operation Orientation: Before using either laser cutter, students are required to attend a two-part Safety and Operation Orientation.

- Part 1 is an online (Moodle) self-guided course that takes approximately 1 hour to complete. It contains two quizzes that must be passed at 100% to continue to Part 2 of the training. To have the online course assigned to you, if you are a current student or faculty, please email coder@the-bac.

edu.

edu. - Part 2 is an in-person safety and operational review. These take place every Friday during the semester and begin at 5 pm sharp. Reservations are not required, but attendees arriving late will be asked to join a future session.

- Part 1 is an online (Moodle) self-guided course that takes approximately 1 hour to complete. It contains two quizzes that must be passed at 100% to continue to Part 2 of the training. To have the online course assigned to you, if you are a current student or faculty, please email coder@the-bac.

- Prior Knowledge: Students should know how to draft and print 2D vector linework from AutoCAD, Rhino, or Illustrator to make best use of the laser cutters.

- Allowed Materials: The laser cutters can be safely used on most tree-based products: cardboard, chipboard, museum board, paper, thin wood, and wood veneer. Some plastics such as acrylic, pet-g, and styrene are allowed, but you must consult with an application support specialist at the CODER LAB (room 405 @ 320 Newbury) before cutting any other plastics or unknown material. Inappropriate materials may result not only in poor results, but damaging fires, toxic fumes, and poisonous gasses.

Questions: Please contact help@the-bac. edu.

edu.

What: The Shop houses tools appropriate for milling and shaping wood and other non-metallic materials. It features a full suite of power and hand tools, including:

- 10″ table saw with fence

- 3-Blade Counter-Top Planer

- Band Saw

- Drill Press

- Benchtop Disc Sanders

- Jointer/Planer

- Rasps

- Hand Saws

- Orbital Sanders

- Chisels

Where: Basement of 320 Newbury Street

How: The Shop is available to all BAC students and faculty after they have successfully completed a safety orientation. Current Shop Hours can be found in the FabLabs & Technology Course in Moodle and on the BAC Portal under Fabrication.

More:

- Safety Orientation Sessions: All students and faculty are required to complete a safety certification to use the shop. The orientation schedule will be posted in the FabLabs & Technology Moodle Course each semester.

- The Shop Manual: Prior to using the lab, orient yourself to shop logistics and workflow by reviewing The Shop Manual for information. The manual contains suggested usages and mandatory safety precautions.

- Shop Monitors: The woodshop is operated by highly trained staff who are able to assist you with your project and keep you safe. We advise that you visit the woodshop and discuss your project in advance of purchasing expensive materials.

Questions: All general questions or concerns can be sent to [email protected]. David Hansen is the BAC's Director of Fabrication and Academic Technology and can be reached by email at [email protected].

What: 3D Printers are available in the CODER Lab on a first-come, first-served basis, seven days a week to all BAC students, faculty, and staff. You must model your idea in 3D modeling software such as SketchUP, Rhino, 3DS Max, etc. Once your file is ready to print, we add it to the queue. Jobs cannot be started later than 1 hour before CODER closes.

Once your file is ready to print, we add it to the queue. Jobs cannot be started later than 1 hour before CODER closes.

Where: CODER Lab (Room 405) at 320 Newbury Street

How: Users should visit the CODER Lab in person, with their digital files available. A CODER staff member will review the files and make suggestions regarding edits, file clean-up, orientation, and more. Once the file is approved for printing, it will be added to the print queue. During midterms and finals, the queue can be up to 4 or 5 days long. However, while turnaround times can't be guaranteed, most prints can be completed within 24 hours.

More:

- Rules: To ensure equitable use, only BAC-related objects can be printed on the 3D printers. These include studio work, Gateway work, and independent study work. This does not include objects for your office or independent business. In addition, your files must be 3D compatible and if deemed non-printable, will be returned for revision.

- Pricing: 10 cents per gram for the Zortrax printers and 50 cents per gram for the Form Labs printers. Most prints end up costing $7 or less and are deducted from your student printing account. Similar prints at commercial shops are often two to five times more costly.

Questions: Please contact [email protected].

What: A CNC router is a computer-controlled 3-axis (x, y, z) digital fabrication tool used for cutting sheet stock such as plywood or foam. It can make 2D cuts similar to a laser cutter and can also create 3D contours, as the router bit can move in all dimensions. Our CNC machines have a 2'x4' bed size and a 2'x3' bed size, and can be used to produce furniture, signage, site models, pavilion scale projects, and much more.

Where: Basement (Room 003) at 320 Newbury Street

How: The CNC machine is available by appointment to all BAC students and faculty via scheduling at baccnc. 10to8.com.

10to8.com.

- Orientation (1 hour): To learn how to use the CNC machine. First-time users should book an orientation meeting for their first appointment.

- Preparation (1–2 hours): To review my toolpaths or ask questions about my project, the software, etc. All students and faculty must schedule and attend a Prep Appointment prior to scheduling a Cut Appointment.

- Cut (1–3 hours): To create the project. Prep meeting has been completed and project has been reviewed by CNC Operators or Computing Assistants. Appropriate materials are in hand.

Questions: All questions/concerns should be sent to [email protected].

What: All laser cutters at the BAC are Universal Laser System VLS 6.6 60-watt metal-tube CO2 lasers. They can accommodate sheet material up to a maximum of 18 inches by 32 inches with a thickness of up to 6 inches (for etching) and 1/4 inch for cutting (depending on the material).

Where: The BAC has three laser cutting devices located in room 412 - The Laser Lab - on the fourth floor of 320 Newbury Street.

How: The laser cutters can now be reserved online. Those who have completed the orientations will be able to book the laser cutters through the BAC's online booking portal at booking.the-bac.edu. If using a mobile phone, it is recommended to select "Desktop View" prior to logging in. Your login is your standard BAC user name and password.

More:

- Safety and Operation Orientation: Before using either laser cutter, students are required to attend a two-part Safety and Operation Orientation.

- Part 1 is an online (Moodle) self-guided course that takes approximately 1 hour to complete. It contains two quizzes that must be passed at 100% to continue to Part 2 of the training. To have the online course assigned to you, if you are a current student or faculty, please email coder@the-bac.

edu.

edu. - Part 2 is an in-person safety and operational review. These take place every Friday during the semester and begin at 5 pm sharp. Reservations are not required, but attendees arriving late will be asked to join a future session.

- Part 1 is an online (Moodle) self-guided course that takes approximately 1 hour to complete. It contains two quizzes that must be passed at 100% to continue to Part 2 of the training. To have the online course assigned to you, if you are a current student or faculty, please email coder@the-bac.

- Prior Knowledge: Students should know how to draft and print 2D vector linework from AutoCAD, Rhino, or Illustrator to make best use of the laser cutters.

- Allowed Materials: The laser cutters can be safely used on most tree-based products: cardboard, chipboard, museum board, paper, thin wood, and wood veneer. Some plastics such as acrylic, pet-g, and styrene are allowed, but you must consult with an application support specialist at the CODER LAB (room 405 @ 320 Newbury) before cutting any other plastics or unknown material. Inappropriate materials may result not only in poor results, but damaging fires, toxic fumes, and poisonous gasses.

Questions: Please contact help@the-bac. edu.

edu.

What: The Shop houses tools appropriate for milling and shaping wood and other non-metallic materials. It features a full suite of power and hand tools, including:

- 10″ table saw with fence

- 3-Blade Counter-Top Planer

- Band Saw

- Drill Press

- Benchtop Disc Sanders

- Jointer/Planer

- Rasps

- Hand Saws

- Orbital Sanders

- Chisels

Where: Basement of 320 Newbury Street

How: The Shop is available to all BAC students and faculty after they have successfully completed a safety orientation. Current Shop Hours can be found in the FabLabs & Technology Course in Moodle and on the BAC Portal under Fabrication.

More:

- Safety Orientation Sessions: All students and faculty are required to complete a safety certification to use the shop. The orientation schedule will be posted in the FabLabs & Technology Moodle Course each semester.

- The Shop Manual: Prior to using the lab, orient yourself to shop logistics and workflow by reviewing The Shop Manual for information. The manual contains suggested usages and mandatory safety precautions.

- Shop Monitors: The woodshop is operated by highly trained staff who are able to assist you with your project and keep you safe. We advise that you visit the woodshop and discuss your project in advance of purchasing expensive materials.

Questions: All general questions or concerns can be sent to [email protected]. David Hansen is the BAC's Director of Fabrication and Academic Technology and can be reached by email at [email protected].

You can find more information regarding all these resources, including operational hours and access prerequisites, in the FabLabs & Academic Technology online Moodle course. Generally, all current and recently active students and faculty should automatically be enrolled in this course on Moodle.

If you do not have access to this course in your Moodle account, please email David Hansen, Director of Fabrication & Academic Technology, at [email protected].

Newbury Street, Boston: details with photos | Tourist Guide

Newbury Street's Most Beautiful Buildings

The street is part of the Back Bay Historic District and boasts some very beautiful 19th and early 20th century buildings.

Emmanuel Episcopal Church

The church was built in 1861 by Alexander Rice Esty in the Gothic Revival style. It is famous for the beautiful stained glass of Emmanuel's Land that adorns the central window of the sanctuary, as well as the Leslie Lindsey Memorial Chapel.

Charles Amos Cummings House

Beautiful brick building in the Queen Anne architectural style with a distinctive use of contrasting finishes and several types of brickwork. Its unusual roof with conical towers, several dormers and a pediment attracts attention.

360 Newbury Street

Until 1989 it was an unremarkable yellow brick building. But after it was renovated by architect Frank Gehry, it turned into a deconstructivist architectural masterpiece and won the Parker Award for the most beautiful new building in Boston.

Best shopping on Newbury Street

Luxury connoisseurs will appreciate the huge choice of luxury brands - Burberry, Chanel, Giorgio Armani, Bvlgari, Cartier and others. Those who prefer great shopping at more affordable prices are waiting for Diesel, AllSaints, H&M, Forever 21, Uniqlo and Zara. And be sure to check out the stores of local manufacturers - Bobbles and Lace, Alan Rouleau Couture, Firas Yousif Originals and Johnny Cupcakes. The hunt for art objects should start at the legendary Newbury Comics, continue at the equally interesting Arden Gallery Boston, Childs Gallery, Pucker Gallery and DTR Modern Gallery, and end with a cup of coffee at the unusual bookstore Trident Booksellers and Cafe.

Newbury Street on the map

Newbury-attractions near

Harvard Square

Conservatory of New England

Capitol Massachusetts

Grace arts

BUSTIC ACCOMI

Quincy Market

Beacon Hill

Boston Common

Boston Harbor Islands National Park

Boston Community Garden

Bar-restaurant Chirs Bikon

Market Fanel Hall

Federal Reserve Bank New York

Freedom trail

Cruise terminal Black Falcon

House of Revira

9000 PlymouthBerial Hill Cemetery

Plymouth Plantation

Martha's Vineyard

Rose Wharf Pier

Popular Tours

3 hours

9 HOURS

1 to 2 HOURS

2 HOURS

4 HOURS 30 MINUTES

1 HOUR 30 MINUTES

2 HOURS 30 MINUTES

2 HOURS 9000 9000 2 HUURS 15 MINUTES 30 minutes

1 hour 10 minutes

1 hour 10 minutes

10 hours

1 hour

1 hour 20 minutes

Hotels near Newbury Street USA 9009

Popular Attractions0010Morikami Museum and Japanese Gardens Coral Castle Old Spanish Monastery Everglades National Park KennedyMcCormick Place Exhibition CenterNewberry LibraryBuckingham FountainMuseum of Science and IndustryChicago Cultural CenterMetropolitan MuseumCentral ParkStatue of LibertyBrooklyn BridgeNational MallWashington Museum of Natural HistoryCapitolWhite HouseLibrary of CongressBrooklyn Botanical GardenBrooklyn Art MuseumBrooklyn BridgeConey IslandDisney World Park

Travels

News

News

News

10. 2022

2022

Visit Orlando Retrains trips to the 50th anniversary of Disneyland

Watch all

3D 3D printing next to you

715 3D Printing Services are ready to accept your order for your order right now and send the items to Boston, Massachusetts, United States. Through our platform, you can order 3D printing of prototypes, spare parts and any projects according to your own design without restrictions in size and quantity. If you know exactly which technology, material or application is right for your project, use the filters to narrow your search results. For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of different types.

Download files to compare prices of local 3D printing services

Download filesor contact us for a discount on large orders.

If you are looking for a 3D printing service with delivery to Boston, Massachusetts, United States, then you have come to the right place. All companies that provide prototyping and printing services near you are listed above.

All companies that provide prototyping and printing services near you are listed above.

How much does it cost to 3D print my products?

To find out the cost of services, select a company and use the "Quick Order" button. Based on your 3D model in STL, PLY, OBJ or 3MF format, we will automatically determine the cost of 3D printing. If you are not sure which service to choose, use the order button at the top of the page to compare prices from all eligible print services.

How can I order a print without a 3D file?

3D printing starts with a model, so a 3D file is needed to make the part. Most printing and additive manufacturing companies can help you with a simple 3D design. For more complex modeling tasks, we recommend hiring a professional.

How to choose a 3D printing service?

Treatstock strives to provide a transparent workflow between the 3D printing company and the client for the best result. In order for you to have complete information about the future performer, we show the company's printers and customer ratings.