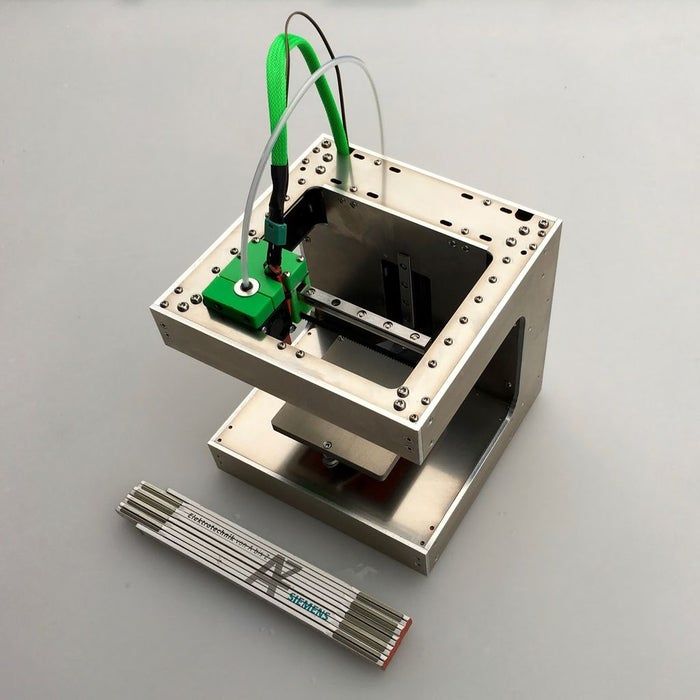

Nema 17 stepper motor 3d printer

What is the Best Stepper Motor/Driver for Your 3D Printer? – 3D Printerly

If you’ve wondering just which stepper motor/driver is best for your 3D printer, you’re in the right place. It’s a quite overlooked part of a 3D printer and it deserves a bit more of an informed decision rather than just sticking with what your printer came with.

Many people have reported prints improving after installing a better stepper motor on their 3D printer so which one is best for your 3D printer?

For such an essential part of a 3D printer, I’ve wondered which stepper motor is the best so I created this post to find that out so read along for the answers.

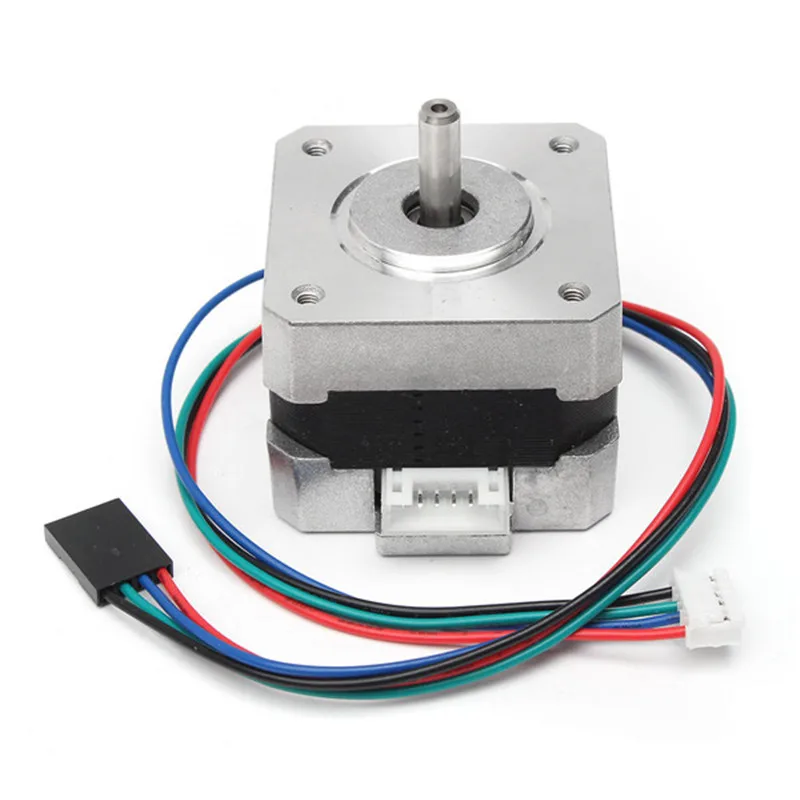

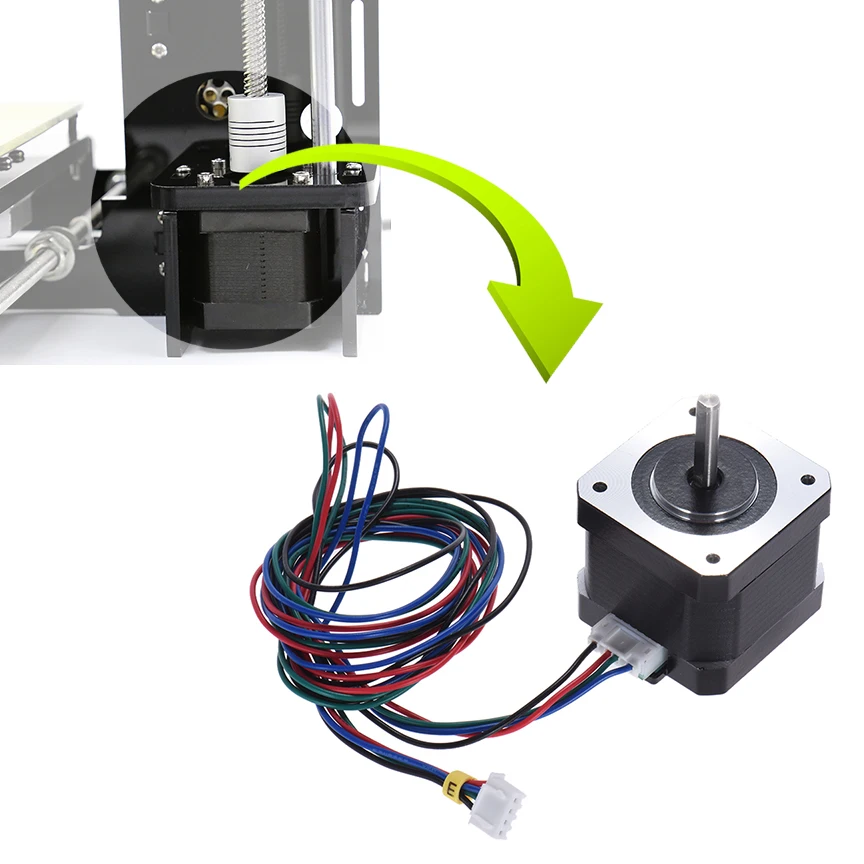

For the people that came for a quick answer, the best stepper motor for your 3D printer is going to be the StepperOnline NEMA 17 Motor. It’s highly rated on Amazon and is the #1 listing for Electric Motor Mounts. Low noise, long lifetime, high performance and no loose steps!

Many have described it as a plug-and-play motor but it does require a bit of know-how, but shouldn’t take too long at all to install. Once you install this stepper motor, any slip problems you’ve had previously should be dealt with easily.

If you are looking for the best stepper motor driver, I’d go for the BIGTREETECH TMC2209 V1.2 Stepper Motor Driver from Amazon. It significantly reduces noise in 3D printers and produces much smoother movements overall.

Now let’s get into what makes a stepper motor so important.

What are the Key Functions of a Stepper Motor?

Under the hood of every 3D printer out there, you’ll find a stepper motor.

The proper definition of a stepper motor is a brushless DC electric motor that divides a full rotation into an equal number of steps. The position of the motor can be ordered to move and hold at certain steps and used at your desired torque and speed.

In simpler terms, stepper motor is what the motherboard uses to communicate to the motors of your 3D printer to make it move around the various axes. It gives the precision, speed and positioning of how things move so it’s a very vital component of a printer.

The reason stepper motors are used in 3D printers is because of their wide range of benefits such as low cost, high torque, simplicity, low maintenance while being highly reliable, and works in just about any environment.

Also on the technical side of things, they are very reliable because there are no contact brushes in the motor, meaning the life of the motor depends solely on the longevity of the bearing.

Stepper motors are also used in medical instruments, engraving machines, textile equipment, packaging machines, CNC machines, robotics and much more.

What Makes a Stepper Motor Better Than Others?

Now it’s important to know that there are many different sizes, styles and characteristics that a stepper motor can give you.

The factors that are important to us are the ones that work best for a 3D printer specifically. Since we need to consider how much work the motor is going to be doing, we take a few things into account.

The main factors that make a stepper motor better than another are:

- Torque rating

- Size of motor

- Step count

Torque Rating

Most stepper motors have a torque rating which roughly translates to how powerful the motor is. Usually, the bigger the size of the motor, the more torque rating you’ll have because they have a better ability to deliver power.

You do have smaller 3D printers such as the Prusa Mini which would require less torque than lets say, an Anycubic Predator Delta Kossel so do keep the size of your printer in mind.

Size of Motor

You have a wide range of sizes for stepper motors, but many can definitely be too strong for a simple 3D printer, which doesn’t require too much performance.

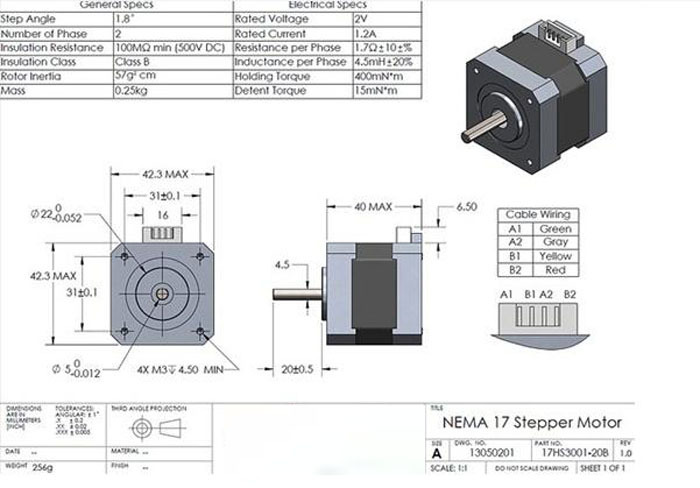

For 3D printers, we generally go for the NEMA 17 (face plate dimensions 1.7 by 1.7 inches) because they are large enough to get the job done.

You would usually use larger NEMA motors in products that require industrial applications or CNC machines. Do keep in mind that NEMA simply describes the size of the motor and not it’s other characteristics. Also, two NEMA 17 motors could be very different and are not necessarily interchangeable.

Do keep in mind that NEMA simply describes the size of the motor and not it’s other characteristics. Also, two NEMA 17 motors could be very different and are not necessarily interchangeable.

Step Count

The step count is what gives us the precision that we need in terms of movement or positioning resolution.

We call it the number of steps per revolution and it can range anywhere from 4 to 400 steps with the common steps counts being 24, 48 and 200. 200 steps per revolution translates to 1.8 degrees per step

For you to get a high resolution, you will have to sacrifice speed and torque. Basically, a high step count motor will have lower RPMs than another motor of a lower step count of comparable size.

If you need higher step rates to turn the motors efficiently, it will require more power so the torque comes in lower and vice versa. So if you want great precision of movement, you will need high step counts therefore reducing the amount of torque you have.

Best Stepper Motors You Can Buy Now

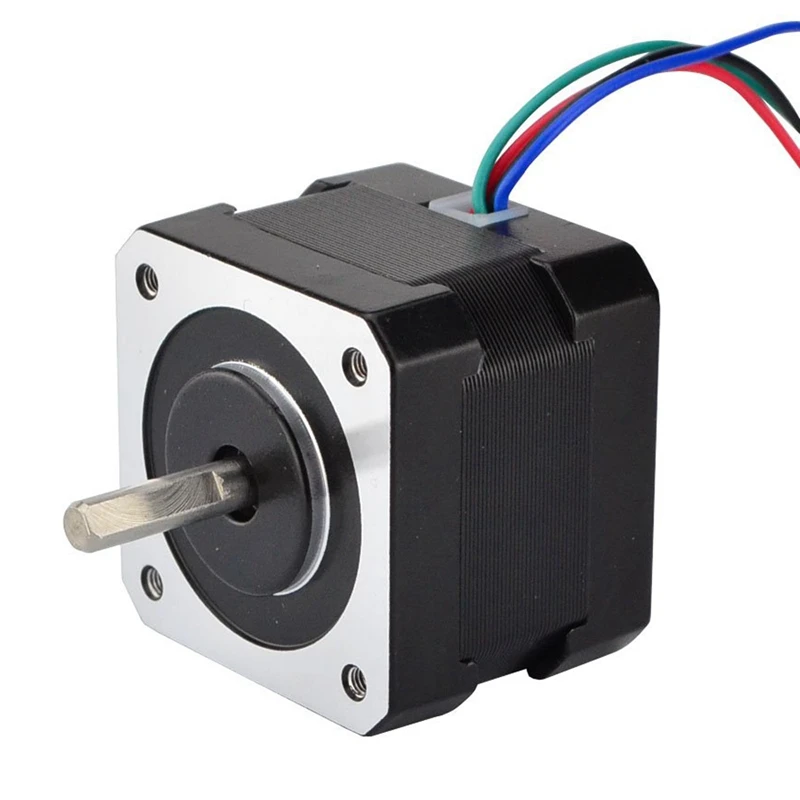

NEMA-17 Stepper Motor

StepperOnline NEMA 17 Motor as recommended at the start of this post is a great choice for a stepper motor. Thousands of happy customers have used this stepper motor with great success with its high quality and flexible customization.

Thousands of happy customers have used this stepper motor with great success with its high quality and flexible customization.

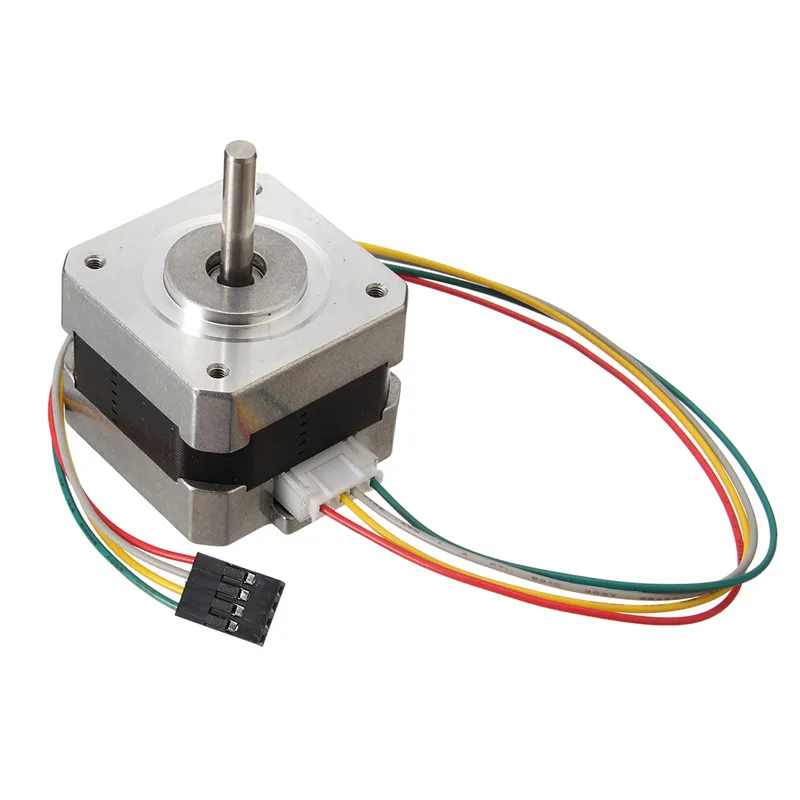

It comes neatly packaged and is a bipolar, 2A motor with a 4-lead and 1M cable/connector. The only downside here are the cables are non-detachable. Do note that the colors of the cables don’t necessarily mean they are a pair.

The way to determine wire pairs is to spin the shaft, then touch two wires together and spin it again. If the shaft was more difficult to spin, those two wires are a pair. Then the other two wires are a pair.

Once you do install this stepper motor, your performance should be second to none and smooth for years to come.

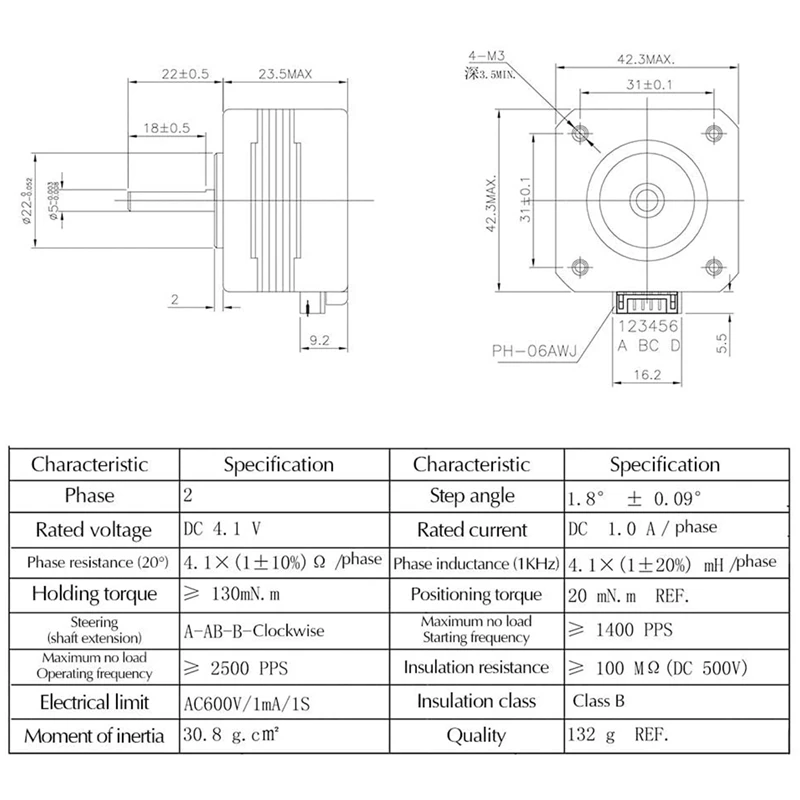

Usongshine NEMA 17 Motor is another choice that is well-liked between 3D printer users and is slightly smaller than the above choice. This high torque stepper motor is made of high quality steel and has great performance.

A few advantages of this stepper motor is its effective thermal conductivity and quality control for each stepper motor that’s sold. You get your stepper motor (38mm), 4pin cable and connector a strong/quiet device to assist you in your 3D printing journey.

You get your stepper motor (38mm), 4pin cable and connector a strong/quiet device to assist you in your 3D printing journey.

The wiring is better set out, with the black and red wires being A+ & B+ then the green and blue wires being A- & B-.

Customer service is also at the forefront of their product so you have good peace of mind after your purchase.

Even at print speeds of 120mm/s+ this stepper driver will deliver amazing performance every time.

Best Stepper Motor Driver for 3D Printers (Upgrades)

Kingprint TMC2208 V3.0

There are many stepper motor drivers out there you can get for your 3D printer, but you’ll want to get one that works well for your particular machine.

The Kingprint TMC2208 V3.0 Stepper Damper with Heat Sink Driver (4 Pack) from Amazon is a great choice that many users have loved using. One user said he went from using standard drivers to these, and the difference in noise and control was astounding.

Previously, he had a very noisy 3D printer that also had jitters throughout the printing process, but now, the printing is silent and really smooth. They have a good large exposed heatsink area, so the installation is made a little easier.

They have a good large exposed heatsink area, so the installation is made a little easier.

The difference between these and classic 4988 steppers are huge. Another nice feature that has been added to this is the pin headers for UART access, so you don’t have to solder them on yourself.

One user mentioned how she didn’t realize 3D printing could be so silent, making a really dramatic difference in noise. If your 3D printer vibrates a lot, even to the point where your table vibrates like another user, you’ll want to get these installed as soon as possible.

After installing this, the loudest thing on people’s 3D printers are the fans.

BIGTREETECH TMC2209 V1.2 Stepper Motor Driver

BIGTREETECH is a very well-known 3D printer accessories company that produces really reliable and useful parts. If you are looking for some of the best stepper motor drivers, you’ll want to look into getting yourself the BIGTREETECH TMC2209 V1.2 Stepper Motor Driver from Amazon.

They have a 2.8A peak driver, made for SKR V1.4 Turbo, SKR V1.4, SKR Pro V1.2, SKR V1.3 Motherboard, and comes with 2 pieces.

- The motor makes it very hard to lose steps; ultra-quiet mode

- Has a large thermal pad area to reduce the temperature of the work

- Prevents motor shake

- Supports stall detection

- Supports STEP / DIR and UART mode

The TMC2209 is an upgrade over the TMC2208 in that it has an increased current of 0.6A-0.8A, but also increases the function of stall detection. It has some cool technology within the part such as SpreadCycle4 TM, StealthChop2TM, MicroPlyer TM, StallGuard3TM & CoolStep.

These do things such as give more control, reduce noise, and provide a smoother operation.

One user said they paired these stepper motor drivers with the SKR 1.4 Turbo, along with a new screen and now their 3D printer is smooth and silent. You won’t regret making this great upgrade if you are facing issues of noise and large vibrations.

NEMA 17 Stepper Motor - gCreate

Definitions

Company – gCreate, LLC, a limited liability company having a corporate address at 141 Flushing Ave., Brooklyn, NY 11205.

Customer – Any purchaser of Company’s products or services, or any entity represented by the purchaser.

Products – Any device or accessory produced by Company, or purchased from Company or from a Company-authorized reseller, including, but not limited to, the gMax 1.5+, gMax 2, and gMax 2 PRO Large Format Desktop 3D Printers and Products purchased via 3D Printing Services.

Services – Any service provided by the Company, or purchased from Company, or from a Company-authorized contractor, including, but not limited to, 3D Printing Services, gMax Printer Tech Support, Consulting Services, and gCreate Customer Service.

Limited Warranty

Company represents and warrants to the Customer that the Products, as defined above, are free of defects and materially conform to the published Product specifications as displayed on Company’s website and associated documentation. Company shall warrant heated pads, solid state relay (SSR), electronic components, BLTouch auto-bed leveling sensor, and other extruder parts for factory defects for ninety (90) days. Company shall warrant all remaining non-consumable components on gMax Printers for any factory defects for a period of one (1) year from delivery. This warranty applies to all original components installed by gCreate as part of fully assembled gMax 1.5+, gMax 1.5 XT+, gMax 2, and gMax 2 PRO 3D Printers. Hot-ends, nozzles, print surfaces (actual build plates, top surfaces, flex plates, adhesives), BLTouch pins, and other consumables are not covered by warranty. Any after-market additions or modifications performed by Customer, or on customer’s behalf by a third party, are not warranted.

Company shall warrant heated pads, solid state relay (SSR), electronic components, BLTouch auto-bed leveling sensor, and other extruder parts for factory defects for ninety (90) days. Company shall warrant all remaining non-consumable components on gMax Printers for any factory defects for a period of one (1) year from delivery. This warranty applies to all original components installed by gCreate as part of fully assembled gMax 1.5+, gMax 1.5 XT+, gMax 2, and gMax 2 PRO 3D Printers. Hot-ends, nozzles, print surfaces (actual build plates, top surfaces, flex plates, adhesives), BLTouch pins, and other consumables are not covered by warranty. Any after-market additions or modifications performed by Customer, or on customer’s behalf by a third party, are not warranted.

For replacement of damaged Products purchased via 3D Printing Services, the Company will cover standard shipping costs within the Contiguous United States. Notification of damaged Products must be made to the Company within two (2) business days from delivery date. Any valid warranty claim must be substantiated with original proof of purchase of the Product, along with a return of the original defective part or Product for inspection by the Company. Company’s liability is strictly limited to the replacement or cost of the Products purchased by Customer. Company is not responsible for delays due to shipping, manufacturing, or other issues outside its control.

Any valid warranty claim must be substantiated with original proof of purchase of the Product, along with a return of the original defective part or Product for inspection by the Company. Company’s liability is strictly limited to the replacement or cost of the Products purchased by Customer. Company is not responsible for delays due to shipping, manufacturing, or other issues outside its control.

For gMax Printer missing or replacement components, the Company must be notified within two (2) business days from delivery. Company shall be responsible for any transportation costs within the contiguous United States associated with replacement of parts covered by warranty. Any valid warranty claim must be substantiated with original proof of purchase of the Product, along with a return of the original defective part or Product for inspection by the Company. Company’s liability is strictly limited to the replacement or cost of the Products purchased by Customer.

No warranty shall apply to any Product: 1) if the Products have been modified by the Customer, including repairs or servicing performed without the permission of the Company; 2) if the Products are misused; 3) if the damage to the Product results from intent, negligence, or carelessness on the part of the Customer; 4) damage resulting from the normal wear and tear caused by use of the Product; 5) if the Product was purchased through a third party; 6) if the Product or component was purchased as refurbished by Company unless otherwise noted; 7) if the Product or the defective portion was lost; 8) if the Product or component has already been replaced under this warranty; 9) if the Product is a previous version that has been upgraded and/or modified by either the Customer or the Company;

For Products shipped outside of the contiguous United States, Customer is responsible for all costs associated with shipping, duties, Value Added Tax (VAT), custom’s fees or charges, taxes, and shipping insurance.

THIS WARRANTY IS THE SOLE AND EXCLUSIVE REMEDY WHERE PERMITTED BY LAW. COMPANY MAKES NO OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED BY LAW, COURSE OF PERFORMANCE, USAGE OF TRADE, OR COURSE OF DEALING, WITH RESPECT TO ANY PERFORMANCE OF ANY PRODUCT. COMPANY MAKES NO WARRANTY OR REPRESENTATION WITH RESPECT TO ANY OTHER MANUFACTURER’S PRODUCT.

IN NO EVENT SHALL COMPANY BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, SPECIAL, INDIRECT DAMAGES (INCLUDING, WITHOUT LIMITATION, CLAIMS FOR LOST BUSINESS PROFITS OR REVENUE, OR THE COST OF THE PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES) OR FOR PUNITIVE OR EXEMPLARY DAMAGES WHETHER AS A RESULT OR BREACH OF CONTRACT, WARRANTY, TORT, STRICT LIABILITY, STATUTE OR OTHERWISE.

Furthermore, any claim against the Company can only be brought by the Customer. Customers cannot assign any rights under this Agreement to another party and in no circumstances shall another party who did not obtain the Products from the Company have any rights or claims against the Company.

Return Policy

Company will accept returns of any fully assembled gMax Printers in new or like-new condition ordered from Company within thirty (30) calendar days after the date of delivery. Accessories that accompany the gMax 3D Printer series, such as the enclosure and rolling cart, are final sale and not eligible for return. Company will not accept any returns of individually purchased components or accessories. Pre-orders are fully refundable up to ten (10) calendar days after purchase unless otherwise noted. After ten (10) calendar days, canceled pre-orders will be refunded less ten percent (10%). No exceptions.

To return a gMax 3D Printer, Customer must request and obtain an official return merchandise authorization (RMA) form from the Company. After thirty (30) calendar days, Customer’s gMax Printer purchase becomes final and no return will be accepted.

To return any other Product purchased from gCreate, Customer must request and obtain an official Return Merchandise Authorization (RMA) form from the Company. Only unused Products in their original packaging will be accepted for return.

Only unused Products in their original packaging will be accepted for return.

Customers will be required to cover shipping costs, as well as a restocking fee equal to twenty five percent (25%) of the returned Products retail price. All gCreate Products must be returned in their original packing material and boxes.

Missing or Damaged Parts

Customer has two (3) business days from delivery to notify the Company if any portion of the Product was missing from shipment or has arrived damaged or defective. This also applies to individual components and accessories. Company will ship replacement parts without cost to Customer at Company’s discretion. All promotional items must be returned in brand new, unused condition with any return or the retail cost of the promotional item will be deducted from the final refund.

gCreate allows returns or replacements for Products purchased via 3D Printing Services if Products contain physical defects or arrive in damaged condition. Products purchased via 3D Printing Services have a seven (7) calendar day return policy from date of delivery. To be eligible for a return, all items must be unused, in their original condition, and returned in their original packaging. Customer is responsible for return shipping. After inspection, approved refunds will be given back to the customer in the manner in which original payment was received.

Products purchased via 3D Printing Services have a seven (7) calendar day return policy from date of delivery. To be eligible for a return, all items must be unused, in their original condition, and returned in their original packaging. Customer is responsible for return shipping. After inspection, approved refunds will be given back to the customer in the manner in which original payment was received.

Company reserves the right to refuse a return of any Product where an authorization form has not been obtained, where the Product has been damaged by the Customer, or where the return is sought beyond the number of days of the return window allotted for the Product. Alternatively, the Company reserves the right to reduce the amount of compensation provided to the Customer for the refund at its discretion upon inspection of the returned Product. Company is not responsible for any damage to Product caused by the return shipping process, nor is Company responsible for providing insurance on any return shipping.

gMax Pro Support Plan Offer

Customers have the option to purchase a gMax Pro Support Plan with their gMax 2 PRO 3D Printer up to thirty (30) calendar days from the delivery date of their gMax 2 PRO 3D Printer for the duration of one (1) or two (2) years.

gMax Pro Support Plan offerings include a free, one (1) hour gMax Printer set up video call, unlimited phone and video technical support, and a ten percent (10%) discount on all replacement parts, including consumables, during the duration of the plan.

Full details of the gMax Pro Support Plan are here: https://www.gcreate.com/pro-support-plan

gMax 2 PRO 3D Printer Standard Technical Support with Enhancement Option

Customers who do not opt-in to the gMax Pro Support Plan are still eligible to receive technical support from the Company. Company offers free phone and video support by appointment for the first thirty (30) calendar days from delivery of the gMax 2 PRO 3D Printer. Phone and video appointment requests can be made via the gCreate ticketing system at the bottom of this page: https://www.gcreate.com/gmax-resources-and-support

Phone and video appointment requests can be made via the gCreate ticketing system at the bottom of this page: https://www.gcreate.com/gmax-resources-and-support

After thirty (30) calendar days, free email support for all gMax 2 PRO 3D Printers will be offered for twelve (12) months from the date of delivery. Support tickets begin via the gCreate ticketing system at the bottom of this page: https://www.gcreate.com/gmax-resources-and-support

If additional phone or video support is requested after thirty (30) calendar days from the delivery date of the gMax 2 PRO 3D Printer and a Pro Support Plan was not purchased during this time, Customers who purchased their machines directly from gCreate or an authorized reseller have the option to purchase enhanced technical support via phone / video call on an hourly basis. The cost for live technical support is one hundred dollars ($100) per hour. While the support technician will do their best to diagnose and troubleshoot any outstanding issue(s) on a call, without having the physical machine in front of them to inspect and work on, results cannot be guaranteed.

The hourly fee covers the live consultation but does not cover the cost of any suggested or necessary components, and/or shipping. There are no refunds for paid technical support calls or used components*, and all calls must be booked and paid in full in advance. Cancellations and rescheduling requests must be made at least twenty four (24) hours before the scheduled call, otherwise the time will be forfeited and billed in full without refund.

gMax 2 PRO 3D Printer Servicing & Repair

Any gMax 2 PRO 3D Printer customers have the option to send their printer(s) back to gCreate for evaluation, servicing, repair, and testing to restore back to factory settings. Upgrades and modifications from original factory settings requested by customer request are subject to gCreate’s approval.

gMax 2 PRO customers who return their printers to gCreate for servicing / repair are responsible for all shipping and shipping replacement costs. Evaluation, servicing, and repair are billed on an hourly basis of one hundred dollars ($100) per hour and parts replacement is calculated on a per part basis and the responsibility of the customer. There is a ninety (90) calendar day warranty for factory defects on components minus consumables for serviced printers. Printers outside of the thirty (30) calendar day return window of the original gMax 2 PRO purchase cannot return their printers. All sales are final.

There is a ninety (90) calendar day warranty for factory defects on components minus consumables for serviced printers. Printers outside of the thirty (30) calendar day return window of the original gMax 2 PRO purchase cannot return their printers. All sales are final.

gMax 2 3D Printer Standard Technical Support, Enhanced Phone and Video Support, and Upgrades

Free, unlimited email support for all gMax 2 3D Printers will be offered for twelve (12) months from the date of delivery. Additional support resources can be found on our Resources and Support page, gMax Articles and Updates page, and the gCreate Online Forum.

Support tickets begin via the gCreate ticketing system at the bottom of this page: https://www.gcreate.com/gmax-resources-and-support

Any gMax 2 3D Printer customers who purchased their machines directly from gCreate or an authorized reseller have the option to purchase enhanced technical support via phone / video call on an hourly basis. The cost for live technical support is one hundred dollars ($100) per hour and while the support technician will do the best to diagnose and troubleshoot any outstanding issue(s) on a call, without having the physical machine in front of them to inspect and work on, results cannot be guaranteed. The hourly fee covers the live consultation but does not cover the cost of any suggested or necessary components, and/or shipping. There are no refunds for paid technical support calls or used components*, and all calls must be booked and paid in full in advance.

The cost for live technical support is one hundred dollars ($100) per hour and while the support technician will do the best to diagnose and troubleshoot any outstanding issue(s) on a call, without having the physical machine in front of them to inspect and work on, results cannot be guaranteed. The hourly fee covers the live consultation but does not cover the cost of any suggested or necessary components, and/or shipping. There are no refunds for paid technical support calls or used components*, and all calls must be booked and paid in full in advance.

Any gMax 2 3D Printer customers, regardless of when or where it was purchased, have the option to send their printer(s) back to gCreate for evaluation and upgrading their machines to a gMax 2 PRO at their own expense. Rebuilt / upgraded printers have a ninety (90) calendar day warranty for factory defects on components with the exception of consumables** for serviced printers. All sales are final.

gMax 1.5+ and Earlier 3D Printer Support

The gMax 1. 5+ 3D Printer Series became a legacy product in 2019. Free resources for discontinued models prior to 2020 can be found and discussed on the gCreate Online Forum.

5+ 3D Printer Series became a legacy product in 2019. Free resources for discontinued models prior to 2020 can be found and discussed on the gCreate Online Forum.

Indemnification

Customer agrees to indemnify, defend and hold harmless Company and Company’s parent, subsidiaries, affiliates, partners, officers, directors, agents, contractors, licensors, service providers, subcontractors, suppliers, interns and employees, harmless from any claim or demand, including reasonable attorneys’ fees, made by any third-party due to or arising out of Customer’s breach of these Terms of Service or the documents they incorporate by reference, or Customer’s violation of any law or the rights of a third-party.

This includes, but is not limited to, any 3D Printers, Accessories, 3D Printed Models, and Personal Protective Equipment (PPE) sold by gCreate.

Limitations

Customers are prohibited from making unauthorized modifications to the Products. Customers are also prohibited from using the Products in any unauthorized manner including using unauthorized parts and materials.

Customers are also prohibited from using the Products in any unauthorized manner including using unauthorized parts and materials.

Severability

In the event that any provision of these Terms of Use is determined to be unlawful, void, or unenforceable, such provision shall nonetheless be enforceable to the fullest extent permitted by applicable law, and the unenforceable portion shall be deemed to be severed from these Terms of Use, such determination shall not affect the validity and ability to enforce any other remaining provisions.

Confidentiality Agreement for 3D Printing Services

Your access and use of any website owned by the Company constitutes your consent to be bound by this Agreement. All 3D models uploaded to websites owned by the Company will be kept confidential and will not be shared without Customer’s written consent. This policy also applies to Potential Customers who upload 3D models to websites owned by the Company but do not complete the path to purchase.

Entire Agreement

The failure of Company to exercise or enforce any right or provision of these Terms of Use shall not constitute a waiver of such right or provision. These Terms of Use and any policies or operating rules posted by Company on Company’s website or in respect to Products constitutes the entire agreement and understanding between Customer and Company and govern Customer’s use of the Products, superseding any prior or contemporaneous agreements, communications and proposals, whether oral or written, between Customer and Company (including, but not limited to, any prior versions of the Terms of Use). Any ambiguities in the interpretation of these Terms of Use shall not be construed against the drafting party.

Governing Law

All matters arising out of or relating to the sale of the Products are governed by, and construed in accordance with, the Laws of the State of New York, United States of America, without regard to the conflict of laws provisions thereof to the extent such principles or rules would require or permit the application of the laws of any jurisdiction other than those of the State of New York. Any and all disputes arising under these Terms shall be decided by a binding arbitration in New York using the American Arbitration Association as the arbitrating entity.

Any and all disputes arising under these Terms shall be decided by a binding arbitration in New York using the American Arbitration Association as the arbitrating entity.

Changes to Agreement

Customers can review the most current version of the Terms of Use at any time at this page. Company reserves the right, at Company’s sole discretion, to update, change or replace any part of these Terms of Use by posting updates and changes to Company’s website. It is Customer’s responsibility to check our website periodically for changes. Customer’s continued use of or access to Company’s website or Products following the posting of any changes to these Terms of Use constitutes acceptance of those changes.

Company reserves the right to modify the Product prior to shipping. Company has the right to change the prices for any Products sold at any time. Orders placed before any price increase or decrease will not be affected by the price change.

*components include any individual portion of any gMax 3D Printer or accessory

**consumables include hot-ends, nozzles, print surfaces (actual build plate, top surfaces, flex plates, adhesives), BLTouch pins, and 3D printing materials.

v.220427

Stepper motors for 3D printers

Stepper motor Nema17 1.8° 40mm

Part Number: Nema17-42J1840-408

Torque 4kg*cm

Phase: 7.5 Omin productivity/phase: 10 mg

Available

1 000 ₽

Step engine NEMA17 1.8 ° 40 mm

Article: NEMA17-JK42HS40-1704

Twist 4 kg*cg

Engine type: hybridulo step:1.8°Rated current/phase:1.7AResistance/phase:1.65 ohm Inductance/phase:3.2mH

In stock

1 300 ₽

Stepper motor Nema17 1.8° 60 mm

Code: Nema17-60mm-6kg

Torque 6 kg*cm

1.5 АHolding torque: 6.0 kg*cm Body length: 60 mm

In stock

Motor type: hybrid Rated voltage: 3.3 V Angular pitch: 1. 8° Rated current/phase: 2.5 A Resistance/ phase: 1.6 ohm

8° Rated current/phase: 2.5 A Resistance/ phase: 1.6 ohm

In stock

3 500 ₽

Stepper motor with two shafts Nema23 1.8° 50 mm

Article: Nema23-50mm-DS-8

With 2 shafts, shaft current 1.0 A, torque*8. 8 mm

Motor type: hybrid Rated voltage: 6.0 V Angular step: 1.8° Rated current/phase: 1.0 A Resistance/ phase: 6.0 Ohm Nema34-150mm-130kg

Torque 130 kg*cm

Motor type: hybrid Rated voltage: 7.2 V Angular step: 1.8° Rated current/phase: 4 A Resistance/ phase: 1.0 Ohm

In stock -Vibro-NEMA17

In stock

1 050 ₽

Extruder cooling radiator MK7/MK8, black

Article: HeatSink-40x40x11-B

Stepper motor cooling radiator In stock NEMA 30 90 90 170002 Holder for the Nema 17

step engine Article: RKP-MB42al-Flat

Aluminum holder for the step engine 42 series

Available NEMA NEMA 17,

Articles: RKP-MB42A

Holder Aluminum for step motor 42 series

In stock

Holder for NEMA 17 stepper motor for extruders BMG/Titan Aero

Code: RKP-MB42-BMG

Aluminum holder for stepper motor 42 series

Available

Stepper motor Nema14 1. 8° 34 mm

8° 34 mm

Code: Nema14-14HY3408

Torque 1.83 kg*cm phase: 6.5 ohm

On request

Stepper motor Nema14 1.8° 34 mm

Code: Nema14-14HY0007-20

Torque 0.91 kg*cm

/Phase:1.25AResistance/Phase:1.86ohm

Under order

1 330 ₽

Step engine NEMA16 1.8 ° 38 mm

Article: NEMA16-FL39ST38-0504A

Twist the moment 2.9 kg*cg

Engine type: hybridomal voltage: 12 Vululovaya step: 1.8 ° Nomalized voltage: 1.8 ° Nomal current/phase:0.5 AResistance/phase:24 Ohm

Custom order

Stepper motor Nema17 1.8° 34 mm

Code: Nema17-17HS1011-20B

°Rated current/phase:1.2AResistance/phase:3.2ohm Holding torque:3.2kg*cm

Under order

1 400 ₽

Step engine NEMA17 1.8 ° 40 mm

Article: NEMA17-17HS4401S

Twist the moment 4.2 kg*cg

Engine type: hybridomal voltage: 3.6 Vulogovo step: 1.8 ° Nominal current/ nominal current/ Phase: 1.5 ASOPENTION/Phase: 2.4 Ohms

On order

1 600 ₽

Step engine NEMA17 0. 9 ° 48 mm

9 ° 48 mm

Article: NEMA17-17HD48002H-22B

Twist the moment of the moment

Engine type: hybridiolo step:0.9° rated current/phase: 1.68 ASOPENTION/Phase: 1.65 Omin productivity/phase: 4.1 mg

On order

1 500 ₽

Medical engine with two shafts NEMA17 1.8 °

Article: NEMA17-40MM-DS

With 2 shafts, current 1.5 A, torque 4.5 kg*cm, shaft 5 mm

Motor type: hybrid Rated voltage: 3.3 Angular step: 1.8° Rated current/phase: 1.5 A Resistance/phase: 2.2 ohm

On request

1 820 ₽

Stepper motor with two shafts Nema17 1.8° 60 mm

Code: Nema17-60mm-DS

With 2 shafts, current 1.5 A, torque 6 kg*cm, shaft 5 mm /phase:1.8 Ohm

On request

2 380 ₽

Stepper motor Nema17 1.8° with screw T8 295 mm and nut

Code: Nema17-42HS40-1004YAL

Engine type: hybrid Rated voltage: 3.9Angular step:1.8°Rated current/phase:1.0 AResistance/phase:3.9 Ohm

On request

3 500 ₽

Stepper motor with two shafts Nema23 1. 8° 76 mm

8° 76 mm

Code: Nema23-3-76mm0DS-3

With 2 shafts, current 2.5 A, torque 17.5 kg*cm, shaft 8 mm

4 100 ₽

Stepper motor cooling radiator NEMA 17

Article: HeatSink-40x40x11.3-B

Cooling radiator 40 x 40 x 11.3 mm

On request

Stepper motor holder NEMA 17 series

Optional

Stepper motor holder NEMA 23

Item: RKP-MB57S

Steel holder for stepper motor 57 series

Optional

choice of stepper motor, which is better

With the advent of 3D printers, people's lives have become much easier. Devices are successfully used in many areas - dentistry, industry, jewelry and medicine. Now a 3D printer is not a luxury item, but a design that is quite affordable. But still there are those who decide to independently manufacture printing presses. Next, let's talk about how to choose a stepper motor for a future 3D printer and what features should be taken into account.

3D printer motor

In the design of a 3D printer, the main function for the movement of the extruder along the axes is performed by stepper motors. They have low weight and high torque.

They have low weight and high torque.

A stepper motor is a motor without a commutator, whose rotation is not smooth, but discrete (in steps). By setting the speed and duration of the pulses, you can make the device rotate in a certain direction. In this case, it is possible to adjust the direction of rotation and the number of revolutions of the rotor.

If we talk about the design of such devices, then there are three main types:

- Motors with variable magnetic resistance - have several poles on the stator and a rotor made of soft material, and 3 windings independent of each other. This type is practically not used.

- Permanent Reluctance Motors - Includes stator and magnetized rotor. Such motors have 24 to 48 steps per revolution.

- Devices combining variable and constant magnetic resistance (hybrids) - combination of the best properties of a variable and constant rotating motor.

The number of steps is from 100 to 400.

The number of steps is from 100 to 400.

The hybrid engine is the most common design, which, in turn, is divided into unipolar and bipolar types.

Which stepper motors to choose for a 3D printer: the best options

When buying a rotator for a 3D printer, you should pay attention to the following parameters:

- rotating structure size;

- holding torque - 2.5-4 kg/cm;

- current rating - 1.7 A optimum version;

- Shaft - Diameter must match the design of the printer.

The most common motors that are installed on the design of the printing device are bipolar with four leads. Such structures in the event of a breakdown are easy to find and replace.

NEMA marked rotary motors are installed in 3D printers.

NEMA is a National Electrical Manufacturers Association that standardizes rotating devices in terms of flange size and fit. This standard allows different manufacturers to produce engines according to certain parameters, depending on the marking.

Most popular models in the NEMA series:

- NEMA 17 with 42*42mm flange;

- NEMA 23 with 57*57mm flange;

- NEMA 34 size 86*86mm.

Stepper motor drivers for 3D printer

To control motors in 3D devices, drivers installed in the board slot were developed.

There are several types of drivers:

- Constant voltage - such drivers are inefficient and are used in a product with low speeds.

- Two-level - These controllers support stepping and half-stepping modes. They reduce engine heat and are efficient in operation.

- PWM drivers are the most popular on the market. They are highly intelligent and have many additional features.

Also, when choosing a driver, you should pay attention to the following parameters:

- current strength;

- supply voltage;

- availability of optoisolated inputs;

- availability of resonance suppression mechanisms;

- availability of protocols required for engine operation;

- surge protection;

- micro stepping;

- driver quality.

Learn more