3D printers for commercial use

Commercial & Professional 3D Printer Buyer's Guide 2022 (Under $10,000)

Commercial 3D printers are changing how small businesses manufacture, how designers create and iterate, and how schools, healthcare professionals and engineers work.

These professional 3D printers, more expensive than standard desktop 3D printers but less than $10,000+ industrial 3D printers, allow small businesses to be more effective than ever in prototyping and improving their products.

This article focuses on highlighting the best commercial 3D printers, also known as prosumer 3D printers, production 3D printers, commercial grade 3D printers, or high end 3D printers, that are capable of producing professional-grade parts at decent scale, but cost less than $10,000. We therefore categorize commercial 3D printer price as up to $10,000, with no low end price provided it meets professional and small business 3D printer requirements.

What to expect in a commercial 3D printer?

Commercial grade 3D printers can take many forms: some need an FDM 3D printer that can 3D print PEEK or Ultem filaments, create extremely precise prototypes, or create multi-colored architectural models.

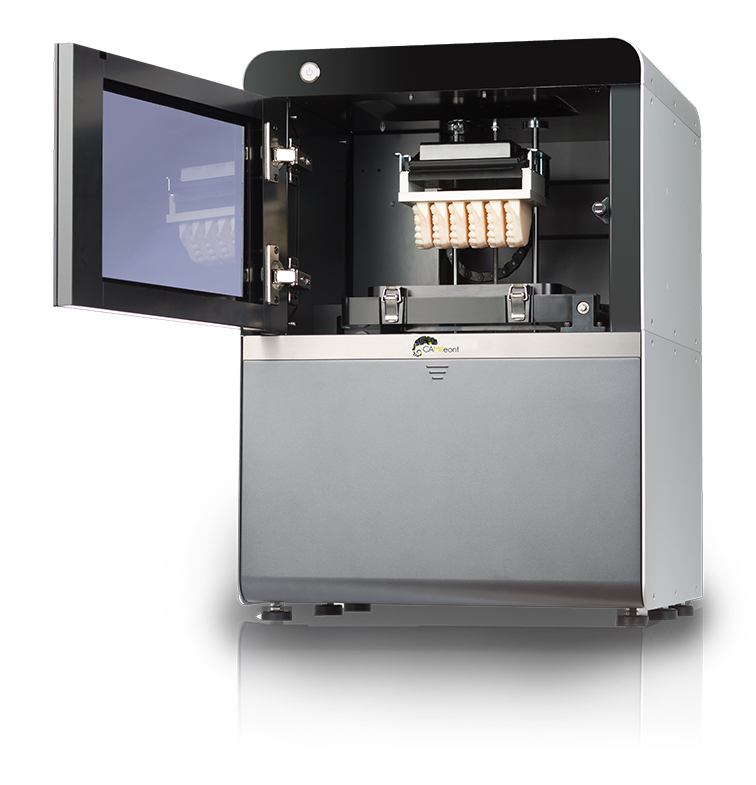

On the other hand, you may need a professional resin 3D printer to create ultra smooth resin prototypes for dental, aesthetic prototypes for items like sunglasses, and much more.

You may also be looking for a professional SLS 3D printer — though they often cost more than $10,000 — for high quality PA12 prototypes, functional parts, and various useful parts for engineers and designers.

Generally however, you should expect the following from a professional 3D printer:

- Commercial grade 3D printing performance: such as powerful heated chambers in FDM 3D printers for tougher material printing and systems for consistent and accurate printing.

- Wide material compatibility: with heated beds and extruders that can reach high temperatures for printing tougher filaments like Nylon, PC, PP, and perhaps even Ultem or PEEK.

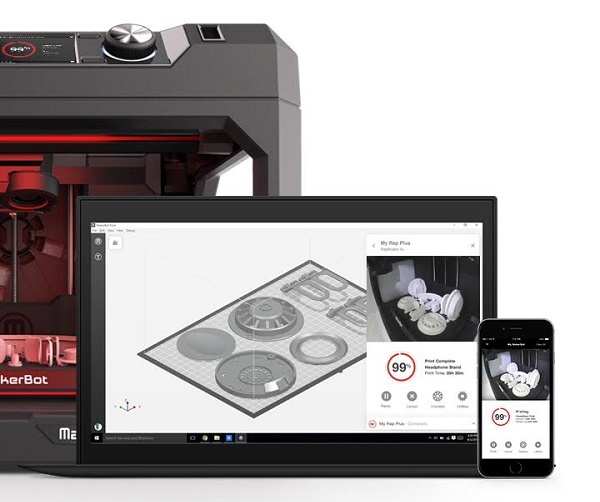

- Fast printing and workflow: the best 3D printers for small businesses not only print quickly (at least twice the speed of desktop printers), but the entire workflow — from CAD software, to slicing, to printing, and then to iterating again — needs to be efficient for overall rapid prototyping.

- Very accurate: where resin 3D printers and SLS printers have advantages are in accuracy and surface finish. Resin printers can reach precisions that FDM printers cannot, so for precise and intricate models, such as characters for films or games, or wax molds for casting into precious metal jewelry, they’re ideal commercial 3D printers. SLS 3D printers require less post processing as they do not print with supports, making them ideal production 3D printers for ready-to-go prototypes made from Nylon.

- Large printing area: commercial 3D printers should have large enough build areas to support either large prototypes, or the printing of multiple small parts simultaneously, as a scalable production 3D printing system. 3D printers for commercial uses we recommend are typically larger for effective batch production 3D printing.

Our commercial 3D printer comparison sorts low to high price, making recommendations on the best 3D printer for business, for production, and many other 3D printers for different commercial uses.

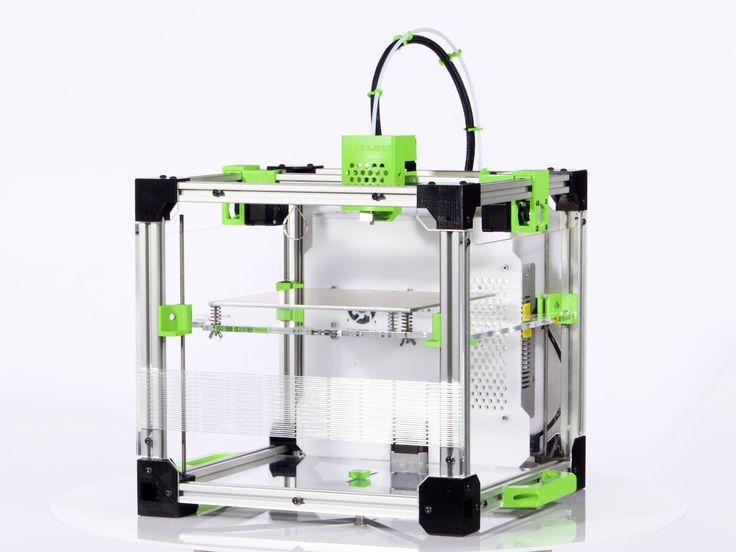

Prusa i3 MK3S+ — low cost commercial 3D printer for small businesses on a budget

- Price: $999 fully assembled — Available on Prusa Store here / $749 as a kit — Available on Prusa Store here

- Build volume: 250 x 210 x 210 mm

With a price of under $1,000 you’d expect the Prusa i3 MK3S to be limited to standard consumer uses like printing fun models from Thingiverse, or fun basic 3D printing projects. However, it excels far beyond this, functioning as one of the best 3D printers for small businesses if you’re on a tight budget.

It can’t compete with higher end 3D printers in some areas, like size of build area, but it’s a fantastic commercial 3D printer for standard size prototypes in materials like PETG, ASA, Nylon, PC, PP, HIPS, and carbon fiber filaments.

Prusa 3D printers are known for their reliability and with an above 200mm/s travel speed, it’s fairly quick for the price. These factors, combined with precise 50-micron minimum layer heights, make it a great overall commercial 3D printer for professional and precise prototype production.

For those looking for a larger 3D printer, a 3D printer for materials like PEEK, or more precise resin 3D printers, keep reading.

Ultimaker S3 — accurate commercial 3D printer for high quality prototypes

- Price: $4,080 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

The Ultimaker S3 follows the incredibly popular Ultimaker 3, and is an effective production 3D printer for small businesses and engineers capable of fantastic 20-micron resolutions. It can extrude composite filaments from either of its extruders, and can easily print soluble filaments with the dual extruder for easier post processing.

Ultimaker created and develop Cura, the world’s most loved 3D slicer, but also offer more professional 3D printer software as part of their Enterprise packages for commercial 3D printing needs. These premium 3D printer options include the ability to open CAD files in Cura, unlimited storage of your parts in their digital parts library, as well as integrating 3D modeling software like SolidWorks and Autodesk Inventor into your workflow with their plugins. All these make for an efficient commercial 3D printing workflow for quick and effective iterating and part production.

All these make for an efficient commercial 3D printing workflow for quick and effective iterating and part production.

The touchscreen is easy to navigate, and WiFi connectivity makes it quick to access and print your files remotely in their digital library.

As a professional 3D printer, Ultimaker serve not just 3D printers for small businesses, but also huge clients like Volkswagen. The German multinational used Ultimaker 3D printers to produce over 1,000 parts, remarking on the productivity and ergonomics of Ultimaker’s printers.

The only factor affecting the Ultimaker S3’s usefulness as a full professional grade 3D printer is the build volume size, which could be larger. However, Ultimaker also offer the S5 for larger print needs, so read on for more information on this.

Ultimaker S5 — all-round excellent production 3D printer

- Price: $6,355 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 330 x 240 x 300 mm

The Ultimaker S5 is the big brother of the already very powerful S3, and a commercial grade 3D printer for high quality engineering parts and accurate prototypes.

The main difference between the S3 and S5 is the larger print volume, a major improvement for those looking for a 3D printer for their small business capable of large prototype printing. It still features the same workflow options, dual extrusion, 20-micron layer heights, and trademark reliability and and precision.

However, you can also turn the S5 into a scalable production 3D printer with the Ultimaker’s S5 Pro Bundle for another few thousand dollars. This bundle adds both a spool holder and top filter. The material handler can hold up to six filament spools, and can automatically change them in and out for different uses as well as protecting filaments from moisture that would deteriorate print quality and protect them from dust, with the environment control filtering out fumes.

- The Ultimaker S5 Pro Bundle costs around $9,550 — Available on Dynamism here / Available on Matterhackers here

The Pro Bundle turns the S5 into the complete commericial 3D printer, able to print continuously, accurately, large parts — everything except super high grade material printing like PEEK and Ultem.

Formlabs Form 3 — precise professional 3D printer for accurate resin parts

- Price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

The Form 3 is sold as a professional quality 3D printer at desktop prices, building on the Form 2’s stellar reputation with incredible resolutions and able to create parts you can barely see the individual layer lines on.

Featuring their LFS (low force stereolithography) tech, layer spot clarity, as well as consistency, surface quality and better translucent material printing are some of the improvements made to the Form 3.

For production engineers looking for a workhorse production 3D printer that can go non-stop, the Form 3 is more than capable, with data on ongoing print performance constantly relayed and alerts if print performance changes so you can make alterations.

You can print in standard resins, or castable wax for jewelry casting, as well as specialized biocompatible commercial grade 3D printing resins for dental uses — which you should instead get the Form 3B for.

Their PreForm software makes preparing your prints easy, and if you’re looking to scale up to a 3D printing factory with multiple printers Formlabs have specialized consulting teams to help, and offer software for managing multiple 3D printers simultaneously.

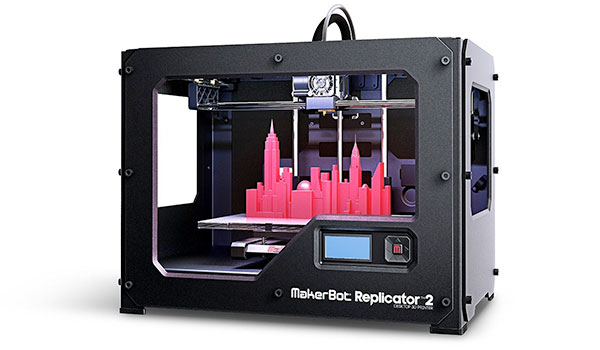

Raise3D Pro2 Plus — large production 3D printer for small businesses

- Price: $5,999 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 305 x 305 x 605 mm

A true workhorse production 3D printer, the Raise3D Pro2 Plus can work 24/7 without much issue. Able to reach 300°C extruder temperatures, printing with filaments ranging from HIPS, ASA, PP, PVA, flexible filaments like TPU and TPE, Nylon, glass, carbon fiber, metal and wood filled filaments is no problem.

As well as the huge build volume and wide material compatibility, the Raise3D Pro2 Plus also offers great precision, with up to 0.01 mm layer heights and 5-micron repeatability. You can change the nozzle out to a smaller or larger one depending on whether your project favors speed or precision.

The large 7-inch touchscreen simplifies your workflow and makes it easy to switch settings or choose your model to print — made easier by Raise3D’s visual model selection previewer. And, if during printing you run into any problems with the power or any other error, the printer can resume from whenever it was stopped without issue.

Marking itself as one of the best 3D printer for business uses, it has some of the largest print areas, as well as an aerospace grade build plate offering excellent adhesion, durability, and preventing warping that can affect or ruin prints — as well as making prints easy to remove. It’s all fully enclosed, so you can effectively maintain and control the chamber temperature to minimize warping and prevent fumes from spreading.

If you want the workhorse benefits of the Raise3D Pro2 Plus, but don’t need the extra Z-axis height building, you can save a couple thousand dollars by going with their standard Pro2 model instead, with a 300mm maximum print height instead of the Pro2 Plus’ 605mm.

Intamsys Funmat HT Enhanced — professional 3D printer for PEEK & Ultem printing

- Price: $7,500 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

For those looking for a specialized PEEK and Ultem 3D printer, the Intamsys Funmat HT Enhanced is the best professional 3D printer for PEEK that’s in most small business’s budget. Costing $6,000 rather than the $20,000+ commonly seen among commercial 3D printers for PEEK, the Intamsys Funmat HT is a great entry-level production 3D printer.

With 90°C constant chamber temperatures, a 160°C heated build plate, and 450°C maximum extruder temperatures from its all-metal hot end, printing PEEK, PEKK, PPSU and Ultem are no problem. However, if you want to use it for printing PEEK as well as more standard plastics you can also do that, with interchangeable nozzles for different printing plastics like PLA and ABS, PC, Nylon, ASA, and more.

Therefore, the Intamsys Funmat HT is a great entry-level production 3D printer for high performance polymer printing. It can automatically level itself with its four advanced drivers offering great precision, and the industrial build platform quality and design features PEI film and glass ceramic materials for great durability and minimal deformation during printing — as well as being safe to use with biocompatible materials like PEEK that may be used to print medical or dental parts.

It can automatically level itself with its four advanced drivers offering great precision, and the industrial build platform quality and design features PEI film and glass ceramic materials for great durability and minimal deformation during printing — as well as being safe to use with biocompatible materials like PEEK that may be used to print medical or dental parts.

With PEEK’s extensive use in medical parts, electrical engineering, aerospace, dental, Ultem’s industrial uses, and PPSU’s medical applications, the Intamsys Funmat HT capitalizes on 3D printing’s fastest growing material segment, but at a low price. Intamsys sell their own Ultem and PEEK filaments, and overall, the Funmat HT Enhanced is one of the best 3D printers for small businesses looking to print high performance plastics to either create parts for other companies, or iterate in-house.The Intamsys Funmat HT Enhanced is an ideal professional 3D printer for PEEK without breaking the bank.

Some other articles you may be interested in:

- The best 3D printers for small business

- Best PEEK 3D printers

- Best industrial 3D printers

- Best 3D printers under $2,000

- Best 3D printers under $5,000

- Best metal 3D printers

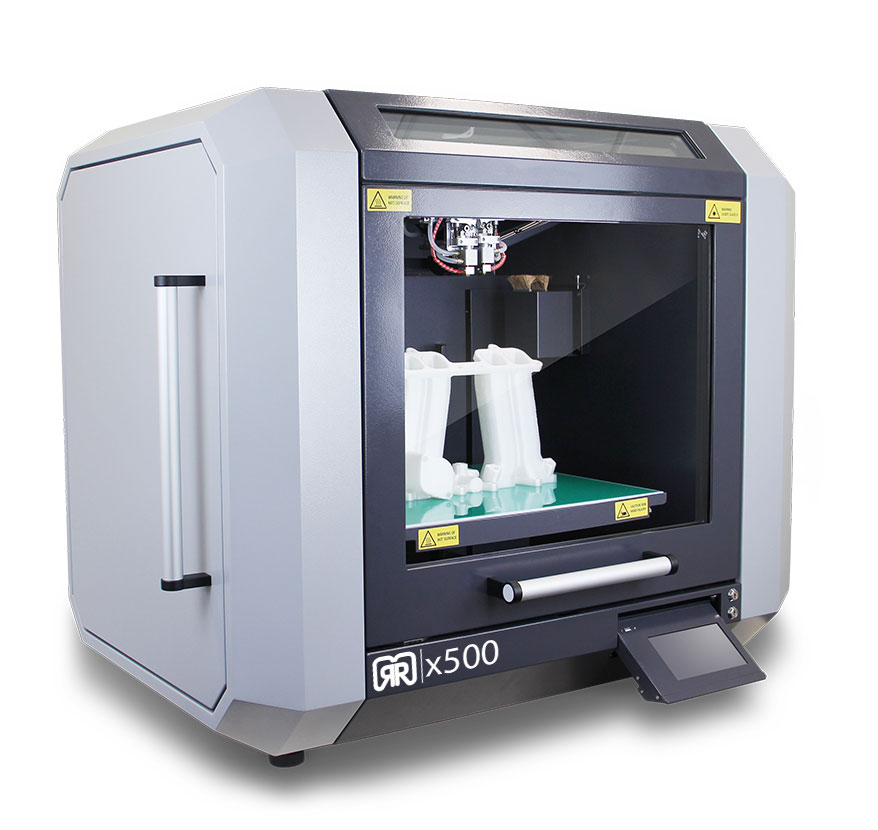

Best Affordable Commercial 3D Printer Fusion3

BEST AFFORDABLE COMMERCIAL 3D PRINTER

The Fusion3 EDGE commercial 3D printer delivers the complete commercial solution: speed, print quality, large build area and service & support that businesses require.

Perfect for prototyping, jigs & fixtures, and the production of end-use parts, the Fusion3 EDGE is the best commercial 3D printer for your business and commercial 3D printing needs.

Many industries are embracing 3D printing, but the most significant that we see here at Fusion3 come from the following: Automotive, Aerospace, Medical Manufacturing, Metalworking, and other related manufacturing fields.

Only $6,999 USD + Shipping World-Wide

REQUEST A PERSONALIZED QUOTE

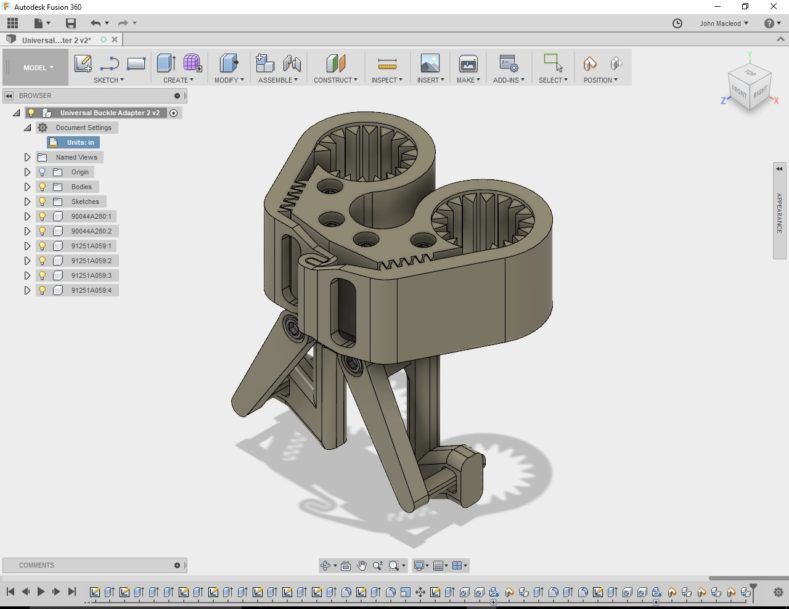

Commercial Parts 3D Printed On the Fusion3 EDGE Commercial 3D Printer

VIEW MORE SAMPLE PRINTS

Affordable, at $6,999 plus shipping, the EDGE Commercial 3D Printer Delivers the Reliability and Performance You Need for the Following Commercial Applications:

With the EDGE commercial 3D printer at your premises, your engineers can now prototype and repeatedly test parts in much less time than using outside vendors.

Injection molding is capital intensive and expensive unless you have a large volume of parts to consume. With its fast speeds, large build area, and low material costs, EDGE provides a cost-effective tool to produce plastic parts inexpensively.

With its fast speeds, large build area, and low material costs, EDGE provides a cost-effective tool to produce plastic parts inexpensively.

Fusion3’s EDGE commercial 3D printer enables manufacturing teams to create tools to quickly improve their performance on the manufacturing line. Companies with innovation programs find commercial 3D printers engage employees and drive rapid process improvements.

Best-In-Class Speed & Print Quality

The Fusion3 EDGE commercial-grade 3D printer features our patented F-Series motion-control system that enables the 3D printing of high-quality objects at layer heights as low as .02mm and speeds up to 250mm/sec.

Don’t waste time waiting for your parts to print. With EDGE you will spend more time designing and testing.

Durable & Reliable

Unlike consumer printers, EDGE is a workhorse using highest quality components and able to withstand use and abuse in commercial environments.

Fusion3 backs our 3D printers with the longest warranty in the industry so you never have to worry about expensive repairs or service contracts.

Enormous Print Volume

The Fusion3 EDGE has the build volume of a true professional 3D printer, with a large 1.64 cubic foot print volume (14.5″x14.5″x13.5″).

Our large printable area enables customers to print large objects in one piece or many smaller items in large batches. It’s important to consider scale for commercial uses of 3D printers, so make sure you have a 3D printer large enough to print what you need.

Affordable Commercial 3D Printing

With a price of only $6,999, the EDGE is your gateway to affordable, professional 3D printing.

Fusion3 offers competitive leasing options and volume discounts for orders of 4 or more. Never before has a commercial 3D printer been so affordable.

FREQUENTLY ASKED QUESTIONS:

COMMERCIAL 3D PRINTERS

What’s the difference between a consumer and a commercial 3D printer?

The difference between a consumer and a commercial 3D printer is in the printing capability, printing speed, and the application itself. Consumer printers are much smaller and slower than commercial-grade 3D printers. Additionally, consumer 3D printers are much more limited with the choice of filaments, while their commercial counterparts can print a wide variety of materials.

Consumer printers are much smaller and slower than commercial-grade 3D printers. Additionally, consumer 3D printers are much more limited with the choice of filaments, while their commercial counterparts can print a wide variety of materials.

What are some of commercial applications of 3D printing?

The most common commercial applications of 3D printing are:

- Prototyping

- Low-Volume Manufacturing

- Supporting the Manufacturing Floor with Jigs & Assembly Fixtures

- Metal Fabrication, including the production of low-volume Press Brakes

- Maintaining production machinery by producing replacement parts

What is typically the price for a commercial 3D printer?

Commercial 3D printers can cost anywhere from $5,000 to $100,000. At $6,999, the USA-Made Fusion3 EDGE is an affordable commercial 3D printer with comparable or greater reliability, durability, and performance to other printers at similar or higher prices.

Is the Fusion3 EDGE a good 3D printer for prototyping?

Yes, the Fusion3 EDGE is a great 3D printer for prototyping. With the Fusion3 EDGE commercial 3D printer, your engineers can prototype and repeatedly test parts in much less time than using outside vendors, at great print quality, tight tolerances and high strength.

With the Fusion3 EDGE commercial 3D printer, your engineers can prototype and repeatedly test parts in much less time than using outside vendors, at great print quality, tight tolerances and high strength.

What should you look for in a commercial 3d printer?

Look for a commercial 3D printer that offers the following features:

- Cost efficient – not only a reasonable initial capital outlay but inexpensive to operate (cost of filament & consumables) and maintain (parts & service).

- Supports a variety of filaments – some 3D printers can only print one or two materials, limiting their utility. Look for a 3D printer that can print a wide variety of different 3D materials.

- A large printing area – a small print area will limit the types or number of items you can print. A larger print surface not only allows for printing of larger objects but allows for large and larger print runs of one part or a set of parts, increasing the 3D printer’s utility.

- Reliable support and extensive warranty – 3D printing is a great technology, but it is closer to a machine tool than a push button appliance. You will need great support to get the most out of a commercial 3D printer.

Click Here

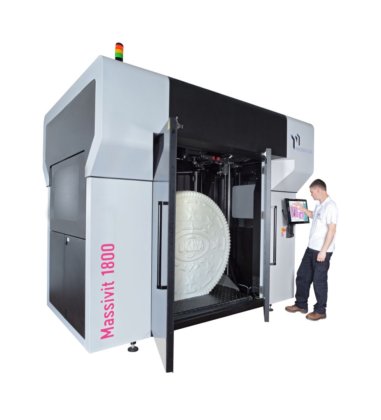

Overview of industrial 3D printers of popular brands

Industrial 3D printers have become popular because of the possibilities they offer. The equipment allows to produce customized products at the stage of product modeling. Users can improve existing CAD models or design entirely new shapes. All this leads to a reduction in the cost of products and prototypes. The market offers a diverse range of devices. The most iconic models are described below.

Overview of industrial 3D printers

3D Systems

The American company 3D Systems is at the forefront in all areas of 3D printing. Brand technology helps to significantly reduce the time for design, prototyping, mass production. Most frequently purchased models:

Most frequently purchased models:

• The DMP Flex 350 3D Printer can print a variety of alloys with high precision. The next generation of equipment is characterized by high performance and accurate reproduction of the digital model. The machine works on DMLS technology and is able to operate around the clock. The technique is equipped with the option of rational use of raw materials, the work is automated at each stage of printing. Unused powder is reused, reducing the cost of the final project. Embedded software controls the entire production cycle, from parameter setting to material quantification and waste disposal. Finished products are characterized by low weight, strength, it is possible to print specimens with a dense structure, identical in properties to cast ones.

Photo: 3DSystems

Features:

| Country | US |

| Applications | foundry industry, automotive industry, medicine, jewelry industry, automotive industry, medicine, jewelry industry |

| Housing color | gray |

| Construction area | 275x275x420 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm |

| Platform | metal |

| Print material | metal |

| Print Technology | DMP |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Minimum wall thickness | 150 µm |

• The DMP Factory 350 3D printer has incorporated the advantages of the previous model, supplementing the list of advantages with an automatic powder circulation module. The car is supplied with an option of cleaning of a working platform at the closed chamber. The upgraded laminar airflow system of the printable area allows you to create models of higher quality. The user interface is equipped with a touch screen that simplifies interaction. The use of DMLS-technology and modern powders of the LaserForm series ensures high speed and increased productivity. The model is optimal for commercial use.

The car is supplied with an option of cleaning of a working platform at the closed chamber. The upgraded laminar airflow system of the printable area allows you to create models of higher quality. The user interface is equipped with a touch screen that simplifies interaction. The use of DMLS-technology and modern powders of the LaserForm series ensures high speed and increased productivity. The model is optimal for commercial use.

Photo: 3DSystems

Features:

| Country | US |

| Applications | aviation and space, automotive industry, foundry industry, mechanical engineering, medicine, jewelry industry, automotive industry, foundry industry, mechanical engineering, medicine, jewelry industry |

| Housing color | gray |

| Construction area | 275x275x420 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm |

| Print material | metal |

| Print Technology | DMP |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Minimum wall thickness | 150 µm |

• The DMP Factory 500 3D printer is a machine optimized for industrial scale. The equipment is a scalable design consisting of several special modules. An integrated metal production system provides a controlled environment for building objects, enabling continuous operation. The right combination of modules can help optimize an existing factory line or start a new product line. The 3DXpert software allows you to grow large seamless elements.

The equipment is a scalable design consisting of several special modules. An integrated metal production system provides a controlled environment for building objects, enabling continuous operation. The right combination of modules can help optimize an existing factory line or start a new product line. The 3DXpert software allows you to grow large seamless elements.

Photo: 3DSystems

Features:

| Country | US |

| Applications | foundry industry, jewelry industry, mechanical engineering, medicine, metal industry, mechanical engineering, medicine |

| Housing color | white-grey |

| Dimensions | 3010x2290x2820 mm |

| Construction area | 500x500x500 mm (including build platform) |

| Layer thickness | 30 µm; 60 µm; 90 µm |

| Layer thickness | metal |

| Platform | metal |

| Print Technology | DMP |

| Operating system | Windows 10 Pro, 64 bit |

| Warranty | 12 months |

| Minimum element size | 100 µm |

| Number of lasers | 3 |

| Laser Power | 500 W |

| Laser wavelength | 1070 µm |

• The ProX 800 3D Printer sets the standard for performance and fine detail. The equipment operates according to SLA technology, focused on the construction of one large part or a series of small products in a full cycle. The technical ability allows the production of samples with a smooth surface that exactly matches the 3D digital model. Additional advantages of the device are the ability to select the necessary material, a clear workflow, saving on waste.

The equipment operates according to SLA technology, focused on the construction of one large part or a series of small products in a full cycle. The technical ability allows the production of samples with a smooth surface that exactly matches the 3D digital model. Additional advantages of the device are the ability to select the necessary material, a clear workflow, saving on waste.

Photo: 3DSystems

Features:

| Country | US |

| Application area | architecture, foundry industry, interior design, foundry industry, education, dentistry, foundry industry, interior design, foundry industry, education, dentistry |

| Housing color | gray |

| Communication interface | LANs, IEEE 802.3 using TCP/IP and NFS, USB |

| Dimensions | 1370x1600x2260 mm |

| Construction area | 650x750x550 mm (including build platform) |

| Layer thickness | 125 µm |

| Platform | mesh |

| Print media | photopolymer |

| Print Technology | SLA |

| Operating system | Windows 10 |

| Warranty | 12 months |

| Minimum element size | 125 µm |

| Maximum weight of model | 75 kg |

| Maximum resolution | 4000 DPI |

3DCeram

The French brand 3DCeram offers services and equipment for 3D printing of original ceramic products. For development work, serial production of samples of complex geometry, the following machines are used:

For development work, serial production of samples of complex geometry, the following machines are used:

• 3D printer CERAMAKER 100 is a brand development aimed at additive manufacturing of ceramic products. This modification is actively used in the chemical and aviation industries, the medical field, jewelry, watchmaking. The equipment operates on the principle of layer-by-layer curing by a laser installation of a special composition of ceramic powder and photopolymer. The latter is a binder and is burned out after the alignment of the object is completed.

Photo: 3DCeram

Features:

| Country | France |

| Applications | aviation and space, automotive, nuclear industry, interior design, railway, mechanical engineering, medicine, dentistry, shipbuilding |

| Dimensions | 1000x1500x1900 mm |

| Construction area | 100x100x100 mm |

| Layer thickness | 50 µm |

| Material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

• The CERAMAKER 900 3D printer reproduces objects with a surface roughness of less than 2 µm. Mechanical post-processing of the product is available at every stage of production. The open architecture of the device allows you to customize the work with the necessary materials, and the adjustable size of the platform makes it possible to line up parts of various sizes. Production is carried out without preliminary creation of a form. Evenly distributed UV power over the entire area of the working platform ensures shrinkage is predictable.

Mechanical post-processing of the product is available at every stage of production. The open architecture of the device allows you to customize the work with the necessary materials, and the adjustable size of the platform makes it possible to line up parts of various sizes. Production is carried out without preliminary creation of a form. Evenly distributed UV power over the entire area of the working platform ensures shrinkage is predictable.

Photo: 3DCeram

Features:

| Country | France |

| Applications | foundry industry, jewelry industry, medicine, mechanical engineering, dentistry |

| Dimensions | 1060x2250x2040 mm |

| Construction area | 300x300x100 mm |

| Layer thickness | 35 µm |

| Print material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

• The CERAMAKER C3600 ULTIMATE 3D printer is a large scale production equipment. The device is aimed at the production of massive products or large batches of products. The device is compatible with materials that are distinguished by chemical, corrosion resistance, as well as formulations used in dentistry. The industrial unit operates according to the stereolithography method, adopting unassisted printing technology.

The device is aimed at the production of massive products or large batches of products. The device is compatible with materials that are distinguished by chemical, corrosion resistance, as well as formulations used in dentistry. The industrial unit operates according to the stereolithography method, adopting unassisted printing technology.

Photo: 3DCeram

Features:

| Country | France |

| Industries of application | foundry industry, jewelry industry, medicine, mechanical engineering |

| Dimensions | 2100x1800x2500 mm |

| Construction area | 600x600x300 mm |

| Layer thickness | 25 to 125 µm |

| Print material | ceramics |

| Print Technology | SLA |

| Warranty | 12 months |

| Number of lasers | 4 UV lasers |

| Laser wavelength | 405 nm |

VoxeiJet

The German company VoxeiJet produces 3D machines for the production of sand molds and cores. The company has developed its own line of polymeric materials, and also produces a diverse range - from small-format research devices to large-sized industrial units. Most famous models:

The company has developed its own line of polymeric materials, and also produces a diverse range - from small-format research devices to large-sized industrial units. Most famous models:

• The VoxelJet VX 200 HSS 3D printer is a compact system based on polymer powder sintering technology. The equipment is used for research purposes and to create new resources for the HSS process. An open system makes it possible to control the settings of print modes and parameters of temperature, layer thickness.

Photo: VoxelJet

Features:

| Country | Germany |

| Application area | interior design, aviation and space, automotive, prototyping |

| Construction area | 290x140x180 mm |

| Layer thickness | > 80 micron |

| Print material | polyamide |

| Print Technology | BJ |

• The VoxelJet VX 1000 HSS 3D printer works with polymers. The high-performance system stands out with a capacious build chamber and high print speeds. The machine is useful for large-scale production of plastic parts that are comparable in quality to samples created by injection molding. The equipment is easily integrated into the existing factory line and adapted to the existing production. Material recycling technology reduces the cost of finished products.

The high-performance system stands out with a capacious build chamber and high print speeds. The machine is useful for large-scale production of plastic parts that are comparable in quality to samples created by injection molding. The equipment is easily integrated into the existing factory line and adapted to the existing production. Material recycling technology reduces the cost of finished products.

Photo: VoxelJet

Features:

| Country | Germany |

| Applications | prototyping, mechanical engineering, interior design |

| Construction area | 1000x540 mm |

| Print material | polyamide, nylon |

| Print technology | BJ |

• The VoxelJet VX 4000 3D printer is a 3D sand mold printing system. The printer is capable of producing large items or a series of small items in a single cycle. The device operates in automatic mode, which guarantees the continuity of the manufacturing process. The car provides fast release of products of the set quality. The capacious space of the construction area allows you to print custom objects with exact compliance with the configuration and plus sizes at high resolution. The technique is in demand in mechanical engineering and the aerospace sector. Finished molds and cores can be immediately used for metal casting.

The device operates in automatic mode, which guarantees the continuity of the manufacturing process. The car provides fast release of products of the set quality. The capacious space of the construction area allows you to print custom objects with exact compliance with the configuration and plus sizes at high resolution. The technique is in demand in mechanical engineering and the aerospace sector. Finished molds and cores can be immediately used for metal casting.

Photo: VoxelJet

Features:

| Country | Germany |

| Dimensions | 20000x7800x4000 mm |

| Construction area | 4000x2000x1000 mm |

| Layer thickness | 300 micron |

| Print material | sand |

| Print Technology | BJ |

| Maximum resolution | 600 dpi |

Inss Tek

The Korean company Inss Tek has focused on working with alloys. DMT 3D printing technology has found its way into various industries. The most popular models working with metals:

DMT 3D printing technology has found its way into various industries. The most popular models working with metals:

• The MX-Lab 3D printer is designed for the manufacture of functional devices, remodeling, reconstruction and restoration work, special coatings. The device uses DMT technology, which provides the necessary mechanical characteristics of the finished product, a unique density, the finest microstructure. Entry-level DMT machine with 3-axis laser system is suitable for material properties study, prototyping, alloy development. 9Feature:

| Country | South Korea |

| Applications | aviation and space, metallurgical industry, mechanical engineering, foundry industry |

| Dimensions | 700x700x860mm; 200 kg |

| Construction area | 150x150x150 mm |

| Layer thickness | 150 micron |

| Print material | metal |

| Print Technology | DMP |

| Operating system | Windows 7 |

• InssTek MX-600 3D Printer - The machine is configured to produce small objects with specified mechanical characteristics. Using this technique, you can repair various devices, modernize mechanisms, and create industrial alloys. The technique is able to quickly convert a complex CAD model into a finished part, which is in demand in medicine, electronics, defense and manufacturing industries. The advanced CVM powder feeding system operates at a stable, adjustable speed.

Using this technique, you can repair various devices, modernize mechanisms, and create industrial alloys. The technique is able to quickly convert a complex CAD model into a finished part, which is in demand in medicine, electronics, defense and manufacturing industries. The advanced CVM powder feeding system operates at a stable, adjustable speed.

Photo: InssTek

Features:

| Country | South Korea |

| Applications | foundry industry, metallurgical industry |

| Dimensions | 2000x2900x2550mm; 6.5 t |

| Construction area | 450x600x380 mm |

| Layer thickness | 250 micron |

| Print material | metal |

| Print Technology | DMT |

| Operating system | Windows 7 |

• The InssTek MX-Grande 3D Printer is an industrial system designed for producing large objects. The equipment adopts gravity feeding method or direct powder delivery method with gas. The capabilities of the device are used in the nuclear and oil industries, metallurgy, and shipbuilding.

The equipment adopts gravity feeding method or direct powder delivery method with gas. The capabilities of the device are used in the nuclear and oil industries, metallurgy, and shipbuilding.

Photo: InssTek

Features:

| Country | South Korea |

| Applications | automotive industry, nuclear industry, foundry industry, mechanical engineering, metallurgical industry, oil and gas industry, shipbuilding |

| Construction area | 4000x1000x1000 mm |

| Layer thickness | 750 micron |

| Print material | metal |

| Print Technology | DMT |

| Operating system | Windows 7 |

Conclusion

Large-scale manufacturing giants actively use additive technologies, while developed countries open large research centers and develop state programs. Industrial printers become more affordable every year, pay off faster. All this significantly affects the production process, making it efficient, environmentally friendly and profitable.

Industrial printers become more affordable every year, pay off faster. All this significantly affects the production process, making it efficient, environmentally friendly and profitable.

Source

Tags:

Industrial 3D printers, 3D Systems company, DMP Flex 350 3D printer, DMP Factory 350 3D printer, DMLS technology, 3DCeram brand, CERAMAKER 100 3D printer, CERAMATE3AKER3AKER60 3D printer VoxeiJet, 3D printer VoxelJet VX 200 HSS, Inss Tek

Other materials:

- Zortrax 3D Printed Sports Helmet for Cats

- QIDI TECH S-Box 3D Printer - Reliable Heavyweight!

- 3D Scanner Review: RangeVision PRO5M, Shining 3D PRO HD, Calibry, KSCAN20, Shining 3D HX

- Go!SCAN SPARK vs HandySCAN SILVER/BLACK: which scanner is right for you?

- Printing with nylon (Nylon) on a 3D printer technology features

Attention!

We accept news, articles or press releases

with links and images. [email protected]

[email protected]

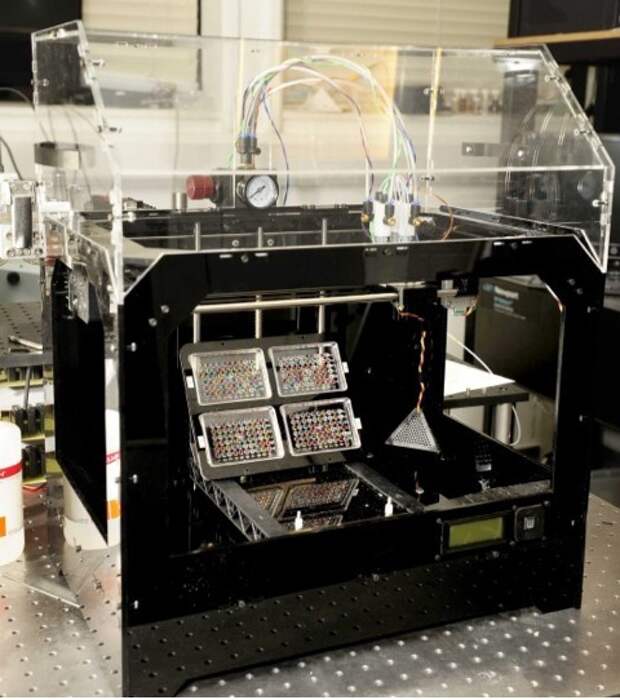

3D printers in the production of electronics

Supplier of 3D equipment since 2010

+7 495 646-15-338 800 333-12-82

3D scanners3D-printer Support

Contact

Manufacturers of consumer electronics and commercial devices are actively using the possibilities of 3D printing to optimize development time and cost.

- What to print

- Advantages 3D

- Case: Microphone for U2

- Select 3D Printer

- use common types of plastics (for example, ABS), commonly used in instrumentation. Polymer resins are also used to print high-precision prototypes and test samples.

Which products are 3D printed by electronics manufacturers:

- concept models for appearance evaluation or market research;

- test prototypes to test the functionality, ergonomics, assembly of complex structures;

- ready-to-use products or individual items;

- silicone casting master patterns.

Many 3D printers use common types of plastics (such as ABS) commonly used in instrumentation. Polymer resins are also used to print high-precision prototypes and test samples.

What products are 3D printed by electronics manufacturers:

- concept models for visual evaluation or market research;

- test prototypes to test the functionality, ergonomics, assembly of complex structures;

- ready-to-use products or individual items;

- silicone casting master patterns.

Why use 3D printers in production

- Reduce time. It takes only a few hours to create a prototype of a new device using a 3D printer. You no longer have to wait 2-3 weeks for a contractor to make a sample for you.

- Reducing the cost of production. The cost of manufacturing an object on a 3D printer is several times lower than if you create a mold for this.

- Preservation of trade secrets. 3D printer in the office will allow you to save all the details of new developments within the company. You do not need to share information with third-party customers to produce the desired part.

- Extensive testing and development options. You can make as many prototypes as you need quickly and cheaply. Test, make improvements - until you reach the ideal.

3D Printing Use Cases for Electronics Manufacturing

How Logitech Uses 3D Printing

A major personal electronics manufacturer uses various types of 3D printers to design and test new products.

For example, Logitech creates prototypes of computer mice from a translucent photopolymer in order not only to evaluate the ergonomics and appearance of a new product, but also to analyze the location of components inside the design.

3D printing was also used to assemble test samples of one of the company's headsets.

Comprehensive testing allowed us to release the most convenient, durable and functional product in a very short time.

Comprehensive testing allowed us to release the most convenient, durable and functional product in a very short time. Why use 3D printers in production

- Reduction of terms. It takes only a few hours to create a prototype of a new device using a 3D printer. You no longer have to wait 2-3 weeks for a contractor to make a sample for you.

- Reducing the cost of production. The cost of manufacturing an object on a 3D printer is several times lower than if you create a mold for this.

- Preservation of trade secrets. 3D printer in the office will allow you to save all the details of new developments within the company. You do not need to share information with third-party customers to produce the desired part.

- Extensive testing and development options. You can make as many prototypes as you need quickly and cheaply.

Test, make improvements - until you reach the ideal.

Test, make improvements - until you reach the ideal.

3D Printing Use Cases for Electronics Manufacturing

How Logitech Uses 3D Printing

A major personal electronics manufacturer uses various types of 3D printers to design and test new products.

For example, Logitech creates prototypes of computer mice from a translucent photopolymer in order not only to evaluate the ergonomics and appearance of a new product, but also to analyze the location of components inside the design.

3D printing was also used to assemble test samples of one of the company's headsets. Comprehensive testing allowed us to release the most convenient, durable and functional product in a very short time.

Unique microphone for group U2

A specially designed and 3D printed microphone with LED inserts for U2's world tour. Due to the complex internal structure, it was able to accommodate not only a large amount of electronics, but also to make it strong enough to support the weight of the vocalist.

Learn more