3D print house mexico

World's 1st 3D Printed Neighborhood Being Built In Mexico

Advertisement

Home//Radio//Here & Now

06:40

DownloadCopy the code below to embed the WBUR audio player on your site

<iframe scrolling="no" frameborder="no" src="https://player.wbur.org/hereandnow/2020/02/06/worlds-first-3d-printed-neighborhood-mexico"></iframe>

Play

February 06, 2020

- Robin Young

- Serena McMahon

In rural Tabasco, Mexico, a community of 50 3D printed homes is now under construction.

The U.S.-based nonprofit New Story has teamed up with the tech company ICON to build the world’s first 3D printed neighborhood. It’s part of their project working to combat global homelessness.

Brett Hagler, the company’s CEO and co-founder, says a machine that’s on an X-Y axis will ooze proprietary cement mix out of a nozzle.

“It looks almost like soft-serve ice cream,” he says.

The machine starts at the very bottom of the home, layering the cement all the way to top where a roof is then placed. Start to finish, the entire process takes just 24 hours to print.

The company hires local workers to do the necessary labor, Hagler says. The 3D technology and automation makes building homes faster, but workers are still required to attach the roof and doors, and install plumbing.

“We bring in the technology to make it faster, cheaper and ultimately a better product,” he says, “and then be able to have local labor to add on the other components that are necessary.”

Each 3D printed home will have two bedrooms, a living room, kitchen and bathroom. Each home can withstand hurricanes and are seismic-approved in case of an earthquake, Hagler says. Being strong enough to stand against natural disasters has a “generational impact,” he says, because families can pass the home down from generation to generation.

New Story started in 2010 after a catastrophic 7 magnitude earthquake devastated Haiti, leaving millions injured and homeless. Seeing the damage “broke my heart,” Hagler says. He says when he went to donate, he couldn’t identify a forward-thinking charity that was pioneering innovative technology and development work in the region.

Instead of traditional methods, he founded New Story to be able to face large scale disasters with new robotic technology that can quickly rebuild communities in dire need. In the case of residents of Tabasco, families there are living for less than $3 a day.

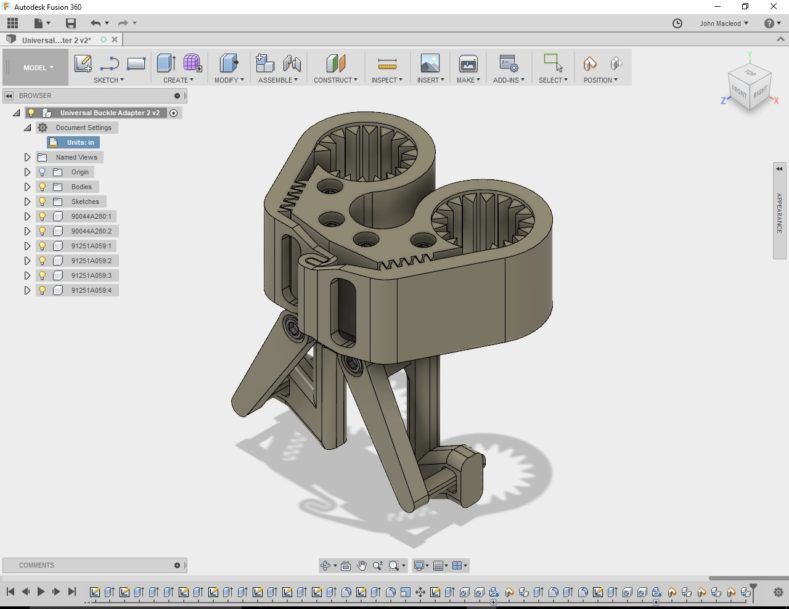

Now, using New Story’s printer, known as “Vulcan 2,” they are able to quickly build safe shelters. For now, Hagler says they are not publicly revealing how much the operation costs. However, he says they don’t want to keep this innovation to themselves.

After their project in Tabasco, they hope to service other nonprofits who are working toward ending global homelessness.

“The big idea is to open source and democratize,” he says, “and try to get this technology into the hands of other housing non-profits and other governments that have agendas to solve very serious problems in their towns and their cities.”

Marcelle Hutchins produced and edited this interview for broadcast with Peter O'Dowd. Serena McMahon adapted it for the web.

This segment aired on February 6, 2020.

new story's 3D-printed neighborhood in mexico has its first houses

Nov 17, 2022

itaca eco-sustainable 3D printed house ensures off-grid living in a 33-meter diameterNov 13, 2022

minimax: a 3D printed handheld projector integrated with open source technologyNov 10, 2022

a fleet of robots is building largest community of 3D-printed homes outside austinNov 10, 2022

michael hansmeyer's 'digital grotesque III' fabricates 3D-printed ornamental column using AINov 02, 2022

‘jabeprode’ cage jails asian hornets for 48 hours until they perishNov 17, 2022

gabriela carrillo's 'casa piedra' lightly hovers over the boulders of its cliffy siteNov 10, 2022

'el aguacate' weekend house composes off-the-grid living experiences in mexicoNov 09, 2022

geometric activity pods welcome young students into renovated school playground in mexicoNov 08, 2022

pininfarina architecture designs 'aldea uh may' wellness community for tulum, mexicoNov 07, 2022

héctor coss arquitectos conceals ribbed concrete villa cubes among mexican desert creektopNov 18, 2022

satoru ito architects builds a japanese timber farmhouse in kashimaNov 18, 2022

'house on a house' steel roof extension pops up in hague's brick cityscapeNov 18, 2022

apollo architects brings visual and spatial duality to 'ESPRIT' house in tokyoNov 17, 2022

itaca eco-sustainable 3D printed house ensures off-grid living in a 33-meter diameterNov 17, 2022

gabriela carrillo's 'casa piedra' lightly hovers over the boulders of its cliffy sitePRODUCT LIBRARY

a diverse digital database that acts as a valuable guide in gaining insight and information about a product directly from the manufacturer, and serves as a rich reference point in developing a project or scheme.

ARCHITECTURE NEWS

Nov 18, 2022

satoru ito architects builds a japanese timber farmhouse in kashimasatoru ito architects & associates' organizes its house in kashima to integrate the large, surrounding garden.

connections: +4710

Nov 18, 2022

world online movie premiere: bêka & lemoine and boonserm premthada on their bangkok journeydesignboom speaks with ila bêka, louise lemoine and boonserm premthada ahead of their film's exclusive online premiere.

connections: 45

Nov 17, 2022

crowned with diamond spires, the world’s tallest residential tower breaks ground in dubaiburj binghatti emblemizes binghatti and jacob & co's design ethos for a soaring ultra-luxury living experience.

connections: +3310

Nov 16, 2022

wooden boat sauna by sandellsandberg sails on stockholm archipelagothe floating sauna invites guests to enjoy the hot steam while sailing.![]()

connections: +620

designboom will always be there for you

milan, new york, beijing, tokyo, since 1999Mexico has the world's first 3D printed residential area

Not far from a city in southern Mexico, a ten meter printer has recently printed walls for the world's first 3D printed residential area.

In early December, the printed houses received a roof, windows and interior decoration. New Story, a charity behind the project, believes 3D printing can bring affordable housing to people in the poorest parts of the world. “We believe we were able to prove the reality of this idea by bringing this device to rural Mexico where there is seismic activity and being able to print the first houses with it,” says Brett Hagler, CEO and co-founder of New Story.

Founded five years ago, his company provides housing for people living in extreme poverty. The organization has already built more than 2,700 houses in the traditional way in Bolivia, Mexico, El Salvador and Haiti.

Photo: New Story

After the 2010 earthquake in Haiti, it was difficult to rebuild houses after the destruction, but New Story improved the construction process so that housing could be built faster. The organization realized that with the help of new technology, it was possible to work faster and at less cost. Two years ago, she partnered with Icon to develop a 3D printer capable of printing even under the most difficult conditions.

The printer is called Vulcan II. This is not the first device that can print an entire house. However, a new residential area in Mexico of 50 printed houses will be the first place where this technology has been used on such a scale. Other companies have experimented with building printed houses, but all trials have been conducted in controlled environments or locations with a low risk of natural disasters.

Initially, the New Story team planned to print houses in another part of Mexico, but ran into difficulties - for a long time the organization could not obtain a building permit from the government. Therefore, it was decided to print houses further south, in Tabasco, a state bordering Guatemala. The new location had a higher risk of earthquakes, so the design of the houses had to be finalized.

Therefore, it was decided to print houses further south, in Tabasco, a state bordering Guatemala. The new location had a higher risk of earthquakes, so the design of the houses had to be finalized.

Photo: New Story

After successful testing, the printer was trucked to the state, but it got stuck in customs for three months. “The device is brand new, obviously it doesn’t exist [in the database],” Hagler explains. When the 3D printer arrived at its destination, the rainy season began. At some point, the entrance to the construction site was flooded, and no one could get there for a week.

However, the most important test—whether the printer can print on site at home—succeeded. The printer lays out the concrete mixture in layers, and the floors and walls are obtained. The program monitors the weather conditions and adjusts the mixture accordingly. “The weather can be dry in the morning and wet in the evening, so you have to change the viscosity of the mixture to keep the print quality the same all day,” explains New Story co-founder Alexandria Lafzi.

The printing process is autonomous, the team can only make minor adjustments to the scheme. In this case, you can print several houses at the same time. The first two houses printed at the same time, the total printing time was 24 hours, but it lasted several days because the team only wanted to work during the day. In the future, the authors of the project hope to be able to run the printer for longer periods to speed up the construction process.

The resulting houses have two bedrooms, a living room, a kitchen, and a bathroom, much better than the simple huts the locals live in. Families who will live in printed houses earn an average of $76.50 a month. “For many families, this will be the first home with a toilet outside the yard and a full sewer,” says Lafzi. And, unlike huts, such houses are able to withstand an earthquake. The charity is partnering with the local government to provide land and infrastructure to build roads and provide electricity to 50 families who need housing the most. When New Story finishes printing all the houses, new tenants will immediately move into them.

When New Story finishes printing all the houses, new tenants will immediately move into them.

Photo: New Story

Some families have already inspected the resulting houses and noted that they do not leak during heavy rain. “When it rains, the roof of our house starts to leak, and the worst thing is when it happens at night,” says Candelaria Hernandez, who lives in a one-room hut with seven members of her family. “We have to wake up and arrange the pans so that things don’t get wet.”

“The construction industry needs a paradigm shift,” says Alex Le Roux, co-founder and CTO of Icon. “We don’t have to choose between affordability and reliability.” The company plans to print more new houses and develop its technology. Many representatives of local governments in Latin America have already shown interest in the project and even visited the current construction site. “Once people see our project with their own eyes, it no longer seems like a crazy idea to them,” says Hagler.

Source.

World's first 3D printed houses built in Mexico

Two houses in a poor rural part of Mexico were built using a giant ten meter wide 3D printer. They were built in the state of Tabasco in a seismic zone, which is also often prone to flooding.

According to CNN, developers hope to build fifty of these houses by the end of 2020, which will form the world's first 3D-printed-only residential neighborhood. At the same time, the houses were built taking into account the wishes of the people who will live in them, and will replace the shacks of the poor, made from pieces of wood, metal and any materials that they could afford. In this rural area of Mexico, its inhabitants have the lowest income in the country and live on an average of three dollars a day. The houses have already been supplied with water, inside they are equipped with a bathroom and electrical wiring, and, according to the developers of the project, they are able to withstand floods and earthquakes.

"These families are the most vulnerable. They live in shacks and when it rains for days during the rainy season, these buildings are knee-deep in water for months," Brett Hagler, CEO of a non-profit organization that helps families, told the broadcaster. in need of housing. Since its founding in 2014, the company has built over 2,700 homes in South America and Mexico. However, this is the first completed 3D printed house construction project.

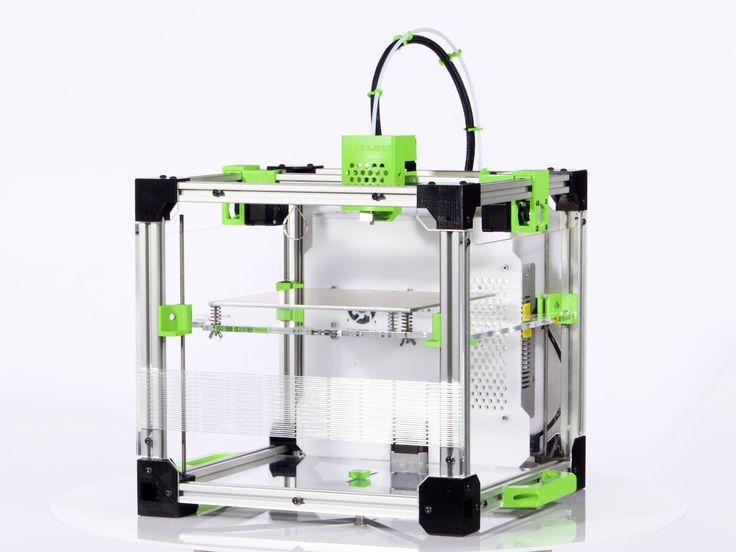

The organization teamed up with a construction technology company that, with input from Silicon Valley engineers, developed the 3D printing robotics used in the project. First, the 10-meter Vulcan II printer, which took three years to build, produces a concrete mix that hardens as it dries, building walls one layer at a time. Building two houses at the same time requires the printer to run around the clock for 3-4 days, which is about twice as fast as building a similar house using traditional technologies. The authors of the project claim that the concrete mixture produced by the printer is stronger than traditional concrete.