3D printer that can print tpu

The 7 Best 3D Printers for Flexible Filaments – TPU/TPE – 3D Printerly

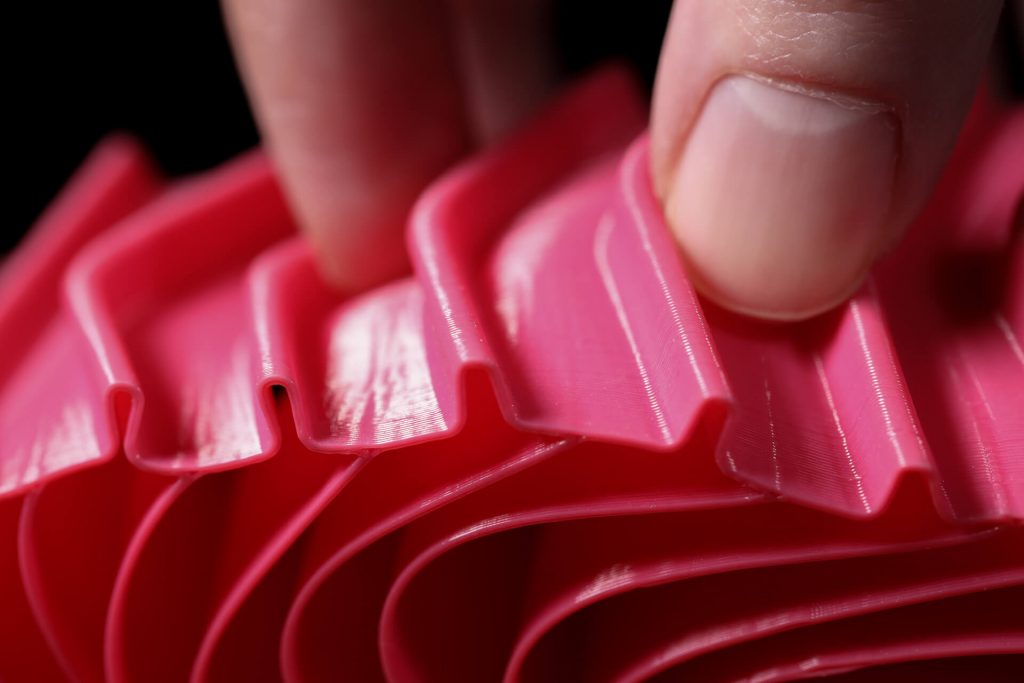

There are tons of amazing materials you can print with and enjoy when 3D printing. One of those materials that are well-loved is flexible filaments known as TPU and TPE.

There is a certain level of ability your 3D printer needs, however, to be able to print with these flexible materials. Rather than purchasing any 3D printer, you’re better off choosing a specific 3D printer which prints flexible material straight away, without any upgrades and tinkering.

This article will list 7 of the best 3D printers out there for printing with TPU/TPE so stay tuned for some great options. But first, let’s take a look at how you can choose the best 3D printer for the type of filaments in question.

QIDI Technology is widely known for its production of premium range 3D printers, and the X-Pro (Amazon) kicking off this list, is no exception to their far-flung excellence.

This machine has a price tag of somewhere around $499 if bought from Amazon and quite honestly has measured to be very affordable for the number of features it has.

First off, there’s a unique Dual Extrusion system that has been mounted on the X-Pro.

This means that instead of one nozzle, you get two at your disposal, both of which are highly suited for the likes for flexible materials like TPU and Soft PLA.

The X-Pro works with the standard 1.75mm filament which is fed to the printhead using the Direct Drive extrusion system – another favourable quality trait for flexible thermoplastics.

Features of the Qidi Tech X-Pro

- Dual Extrusion System

- 4.3-inch Touchscreen

- QIDI Tech One-to-One Service

- Aluminum Build Platform

- Power Recovery

- QIDI Slicing Software

- Magnetic Build Plate

Specifications of the Qidi Tech X-Pro

- Build Volume: 230 x 150 x 150mm

- Layer Resolution: 0.1-0.4mm

- Extruder Type: Dual

- Nozzle Diameter: 0.4mm

- Maximum Extruder Temperature: 250°C

- Maximum Print Bed Temperature: 120°C

- Frame: Aluminum

- Print Chamber: Enclosed

- Bed Levelling: Semi-automatic

- Display: LCD Touchscreen

- Built-in Camera: No

- Print Recovery: Yes

- Filament Sensor: No

- Filament Diameter: 1.

75mm

75mm - Materials: PLA, ABS, PETG

- Third-party Filament: Yes

To help cool the print down, this 3D printer has an Airblow Turbofan which covers all four sides of your printed model.

Although it does require a bit of manual setup, this handy addition pays off well to enhance print quality.

Moreover, the X-Pro arrives at your doorstep with a modernly designed, fully enclosed print chamber. This allows the printer to better maintain the temperature settings while keeping itself free from dust.

An enclosure also helps drastically when printing materials like TPU could really use constant temperature maintenance inside the chamber.

Besides, there’s a swing-open acrylic door where inside resides the heated and magnetic build plate.

The magnetism of the build plate is a catchy feature. It’s capable enough to grasp the prints well and doesn’t turn out to be a hassle when it’s time to remove them.

In fact, all you have to is bend the removable plate a bit outward from both sides, and off comes your print popping.

Specs-wise, the X-Pro’s extruder temperature can go easily up to 250°C which is more than enough to accommodate flexible materials. The heated bed can also heat up to 120°C so TPU adheres even better.

Besides all that, when it comes to the print quality, this beast from Qidi Tech is all about dimensional accuracy.

It might, however, lack some detailing here and there, but it’s still very consistent and printing slow can yield even better results.

Get yourself the Qidi Tech X-Pro from Amazon today.

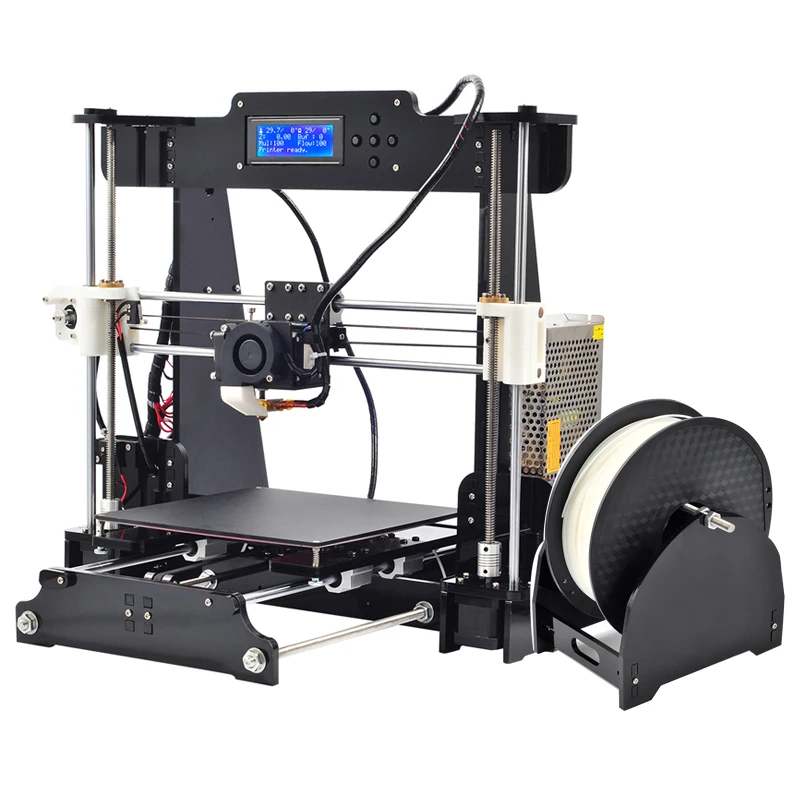

Creality’s Ender 3 V2 is an inexpensive way of introducing yourself to 3D printing and getting close to the very best out of it.

It replaces its predecessor Ender 3 in many ways, both trivial and significant, and measures up to its worth for sub $250.

Some of its prominent features include an appealing new design, a tempered glass print bed, noiseless printing and a spacious build volume of 220 x 220 x 250mm.

Features of the Ender 3 V2

- Carborundum Coated Glass Print Bed

- Quiet Printing

- Coloured LCD Screen

- Belt Tensioners

- Mean Well Power Supply

- Power Recovery

- Built-in Toolbox

- Bowden-style Extrusion

Specifications of the Ender 3 V2

- Extrusion System: Bowden-style

- Extruder Type: Single

- Nozzle Diameter: 0.

4mm

4mm - Build Volume: 220 x 220 x 250mm

- Maximum Extruder temperature: 255 °C

- Maximum Bed temperature: 100 °C

- Maximum Print Speed: 180mm/s

- Enclosure: No

- Bed Levelling: Manual

- Print Bed: Heated

- Connectivity: SD card, USB

- Built-in Camera: No

- Power Recovery: Yes

- Filament Diameter: 1.75mm

- Third-party Filaments: Yes

- Compatible Materials: PLA, ABS, PETG, TPU

The Ender 3 V2 uses a Bowden-style extrusion system which might be questionable when it comes to printing flexible filaments with it.

Usually, a Direct Drive extruder is much more preferred when you have to print materials like TPU or TPE. Bowden tubes are notorious for their incapacity to print with flexible thermoplastics.

However, things could really work out for you and your V2 if you’re using a more manageable type of flexible filament, which some people have had great results with.

One of these is the Semiflex TPU filament, wherewith a slower printing speed and good retraction settings can definitely produce a quality print.

Ninjaflex, on the other hand, would be a little too flexible for an Ender 3 V2 to handle, so I would steer clear from that if you have the stock, single hot end that the printer ships with and the Bowden setup.

It’s all about the hardness ratings of the filament.

A hardness of 95A will do you justice and it’s still pretty flexible, even with 20% infill but only in the direction of the infill itself.

Moving on, there’s also an automatic resume function that allows the printer to pick right where it left from in case of an accidental shutdown or a power outage.

Apart from that, the Ender 3 V2 comes ready for action right out the box and requires a mediocre amount of assembly.

It’s a Cartesian-style printer that has the extruder temperature reaching well above 240°C – a fair extent for printing flexible materials.

To talk about the print quality, the V2 delivers beyond expectations, making its sub $300 price tag hard to believe.

Buy the Ender 3 V2 from Amazon today.

The Anycubic Mega-S is a highly refined upgrade over the original, immensely popular i3 Mega. With both the printers, the Chinese company has surprised everyone with the price point and amazing value for money.

The fundamental reason why the Mega-S deserved to be on this list is because of its Titan extruder.

Unlike the Ender 3 V2, this essential component has received a quality overhaul, making it fit for flexible filaments like TPU, not to mention the added potential with ABS and PLA.

This perhaps is the most important functional improvement over its original counterpart. Therefore, the Mega-S is truly capable to handle flexible printing materials, despite the fact that it has a Bowden drive setup.

Features of the Anycubic Mega-S

- Easy Assembly

- Sturdy Aluminum Frame

- Heated Print Bed

- Fully Colored Touchscreen

- Power Recovery

- Titan Extruder

- Filament Spool Holder

- Filament Run-out Sensor

- Anycubic Ultrabase Build Platform

Specifications of the Anycubic Mega-S

- Build Volume: 210 x 210 x 205mm

- Print Technology: FDM

- Layer Height: 100 – 400 microns

- Extrusion System: Bowden-style Extrusion

- Extruder Type: Single

- Nozzle Size: 0.

4mm

4mm - Maximum Extruder Temperature: 275 °C

- Maximum Heated Bed temperature: 100 °C

- Frame: Aluminum

- Connectivity: SD Card, Data Cable

- Compatible Materials: PLA, ABS, HIPS, PETG, Wood

- Bed Levelling: Manual

The Mega-S is adorned with the latest features like automatic power recovery and a filament run-out sensor that alarms you before your material finishes up and leaves you helpless during a crucial print.

Anycubic has another well-renowned feature that sets it a class apart as compared to 3D printers from other manufacturers. Also prominent in the Mega-S, the Anycubic Ultrabase is what we’re talking about here.

This highly refined, durable build platform has a textured surface that’s able to help thermoplastic filaments with bed adhesion, thus improving the print quality and catering to better user experience.

It’s really something that the Mega-S can brag about.

Furthermore, this 3D printer is a no brainer to fully assemble. Taking about 10-15 minutes at best, setting this machine up is no worry for newbies and professionals alike due to a clear-cut instructions guide.

Taking about 10-15 minutes at best, setting this machine up is no worry for newbies and professionals alike due to a clear-cut instructions guide.

Apart from the assembly, the Mega-S is a treat to have in terms of print resolution. While a lot of 3D printers stand strong between 100 microns of layer resolution, this bad boy kicks it up a notch and works perfectly down to 50 microns. Talk about detail.

I wrote a complete review of the Anycubic Mega-S by going much more in-depth. Be sure to check that out if you want more information on this high-performance 3D printer.

Buy the Anycubic Mega-S directly from Amazon today.

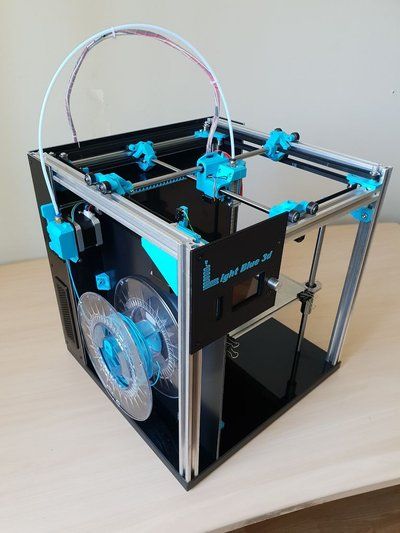

The Creator Pro (Amazon) has been developed by the Chinese 3D printer manufacturer giant known as Flashforge. The company has a knack for producing affordable machines with a bulk of hefty features.

While the Creator Pro is nothing to be taken lightly, let’s briefly review how it takes a robust stance among fellow 3D printers.

First and foremost, the Creator Pro is built with a Dual Extrusion system, just like the QIDI Tech X-Pro. On top of that, it also has a fully enclosed print chamber that allows it to print an extensive array of filaments, let alone flexible ones like TPU and TPE.

On top of that, it also has a fully enclosed print chamber that allows it to print an extensive array of filaments, let alone flexible ones like TPU and TPE.

Unlike the Ender 3 V2, it uses a Direct Drive system that combines ideally with the dual extruder. It’s customary for the Creator Pro to handle flexible filaments like a breeze, as it also has its very own adjustable cooling fan that helps streamline the process even more.

In addition, a heated build plate makes a well-grounded impression for the Creator Pro while adding more to the prospect of using TPU with this 3D printer. You also have to implement a little bit of effort to assemble it up as the printer comes almost ready for action out the box.

Features of the Flashforge Creator Pro

- Dual Extrusion System

- Noiseless Printing

- Enclosed Print Chamber

- Rigid Metal Frame

- Aluminum Build Platform

- Beginner Friendly

- Heated Build Plate

- Direct Drive Extrusion System

Specifications of the Flashforge Creator Pro

- Build Volume: 225 x 145 x 150mm

- Materials: ABS, PLA, and Exotic Filaments

- Printing Speed: 100mm/s

- Resolution: 100 microns

- Maximum Extruder Temperature: 260ºC

- Print Technology: FDM

- Open-Source: Yes

- Filament Diameter: 1.

75mm

75mm - Nozzle Diameter: 0.40mm

- Extruder: Dual

- Connectivity: USB, SD card

By consistent evaluation, the Creator Pro’s print performance has turned out to be quite decent for a printer at its price range. As a matter of fact, you’ll become quite fond of the intricate details this Flashforge workhorse produces.

To talk about the build platform, it’s heated and also consolidated with a 6.3mm thick aluminium alloy. Moreover, its sturdiness allows for an increased thermal conductivity which prevents filament deformation.

While the print bed doesn’t calibrate automatically, there is, indeed, a three-point bed levelling system which makes it comparatively easier to adjust the bed.

Unlike many of the printers listed on here, the Creator Pro is fully open-source, allowing you to experiment with different slicing software and see what suits best.

Also in comparison with the 3D printers above, the Creator Pro reaches the highest extruder temperature of 260°C and that figure bodes very well for flexible filaments like Soft PLA. Like what this printer is packing?

Like what this printer is packing?

Buy the Flashforge Creator Pro it directly from Amazon today.

Enter and embrace the royalty of the MakerGear M2 – a high-end, deluxe 3D printer that settles only for professionals and hobbyists. Beware, you’ll have a very hard time with this beast if you’ve just started out with 3D printing.

Priced at around $1,999, you can expect that the quality of the M2 is going to be nothing short of excellence. It looks like a divine shard of full-metal heaven sitting on your workstation, boasting a sophisticated yet dazzling design with a powder-coated steel frame.

It has its build mostly comprising of steel, but you’ll also observe plastic parts around the extruder. Speaking of the extrusion, the M2 consists of only a single extruder but that’s more than enough to deal with a wide variety of filaments.

From Nylon and ABS to TPU and flexible PLA, multifaceted filament compatibility is not a problem for this 3D printer.

Additionally, it has the maximum extruder temperature going up to a whopping 300°C and as you can comprehend, that’s the highest of all the printers here on this list.

Features of the MakerGear M2

- Fully Open-source

- Spacious Build Volume

- Easy Bed Levelling

- Exceptional Build Quality

- Truly Reliable

- Robust Design

- Very Versatile

Specifications of the MakerGear M2

- Build Volume: 200 x 250 x 200mm

- Nozzle Diameter: 0.35mm (rest are available on the market as well)

- Maximum Print Speed: 200mm/sec

- Maximum Extruder Temperature: 300°C

- Filament Compatibility: ABS, PLA, PETG, TPU

- Built Plate: Heated

- Open-Source: Yes

- Extruder Type: Single

- Minimum Layer Height: 25 microns

- Connectivity: USB, SD Card

- Print Area: Open

This 3D printer doesn’t come with an enclosure and there is a decent amount of learning to pursue if you’re very new to 3D printing.

Furthermore, the M2 might not have the easiest usable interface at all. This aspect of this printer does require a considerable amount of effort.

Nonetheless, it does feature a Quick Start software that makes for an easier time levelling the bed.

If you still don’t get something right, MakerGear has amazing customer support that reaches back shortly, and apart from that, a lot of tutorials teach the essentials of MakerGear 3D printers comprehensively.

With a reliable and precise 3D printer like the MakerGear M2, you simply cannot hope to go wrong when printing flexible filaments.

Get yourself the MakerGear M2 from Amazon today.

The Dremel DigiLab 3D45 (Amazon) 3D printer is another contestant in the first-rate range. It’s priced around $1,900 but it’s safe to say that those figures only do justice to this machine’s remarkable ability and style.

This 3D printer due to its diligent reliability and handiness makes itself very suitable for classrooms and professional usage as well. There’s a reason why it’s regarded so highly in those areas and I’m going to tell you why.

First off, The DigiLab 3D45 works great with demanding filaments such as ABS and Nylon, not to mention the brilliant quality when using thermoplastics like PETG and EcoABS, which is an eco-friendly alternative of ordinary ABS.

Features of the Dremel DigiLab 3D45

- Built-in HD Camera

- Heated Build Plate

- 5-inch Coloured Touchscreen

- Direct Drive Extrusion System

- All-metal Hot End

- Fully Enclosed Build Chamber

- Easy Assembly

Specifications of the Dremel DigiLab 3D45

- Print Technology: FDM

- Extruder Type: Single

- Build Volume: 255 x 155 x 170mm

- Layer Resolution: 0.05 – 0.3mm

- Compatible Materials: PLA, Nylon, ABS, TPU

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Bed Levelling: Semi-Automatic

- Max. Extruder Temperature: 280°C

- Max. Print Bed Temperature: 100°C

- Connectivity: USB, Ethernet, Wi-Fi

- Weight: 21.5 kg (47.5 lbs)

- Internal Storage: 8GB

Focusing on its extrusion sstem, the 3D45 uses a Direct Drive setup. This feature allows the 3D printer to handle flexible filaments extremely well, no matter the brand you’re using.

However, many veteran users of the 3D45 advise starting with Soft PLA. This is because it has a little bit hardness value than TPU, making it easier to print.

In addition, you have to watch out for some important settings like speed, extruder temperature, and retractions.

Beginning your print slow and maintaining a constant speed somewhere between 15-30mm/s (even though the 3D45 goes up to a massive 150mm/s) will get you going in the right direction with flexible filaments.

Apart from that, your retractions have to be short and unrushed.

Next, filaments like TPU should be printed with an extruder temperature that lies between 220-230°C and with the DigiLab 3D45 going up to 280°C, this shouldn’t be a problem for you or this 3D printer.

Besides, the 3D45 doesn’t fail to impress feature-wise either. It’s well-equipped with a heated and removable build platform that measures up to 10 x 6.0 x 6.7 inches – a quite decent build volume. Another noteworthy function is the ease associated with levelling the bed.

The 3D45 uses a two-point bed levelling system that’s as simple as this process could possibly be. This printer even shows you how much the turning knobs should be optimized to level the bed perfectly, all on the 4.5 inch IPS coloured screen.

Lastly, the 3D45 is a concise printer that can form prints of 50 microns of resolution. This makes it highly precise and keen for detail. Moreover, this 3D printer also has an enclosure which helps maintain the internal temperature right when it matters the most.

Buy the Dremel DigiLab 3D45 directly from Amazon today.

Concluding our list of the best 7 3D printers for printing flexible filaments is the critically acclaimed TEVO Tornado.

This 3D printer is famous for the number of possibilities it presents you to extend, customize, and modify its parameters and tinker around to achieve the best results.

In truth, the TEVO Tornado has drawn motivation and is actually based off of Creality’s CR-10 model, which is already quite popular in the printing community.

However, the addition of an E3D Titan extruder made by TEVO themselves just like the Anycubic Mega-S, and an AC-powered heated bed are two features that set it apart from its competition.

With this enhanced extruder, the TEVO Tornado faces no difficulty in printing flexible filaments and numerous Amazon reviews can vouch for this statement as well.

Features of the TEVO Tornado

- Heated Build Plate

- Bowden-Style Titan Extruder

- LCD Control Panel

- Sizable Build Platform

- Effortless Assembly

- AC Heated Bed

- Tight Filament Pathway

- Stylish Colored Design

Specifications of the TEVO Tornado

- Frame material: Aluminum

- Nozzle Diameter: 0.4mm

- Build Volume: 300 x 300 x 400mm

- Connectivity: SD card, USB

- LCD Screen: Yes

- Maximum Print Speed: 150mm/s

- Compatible Materials: ABS, Carbon Fiber, TPU, PETG, PLA

- Filament Diameter: 1.75mm

- Minimum Layer Thickness: 50 microns

- Maximum Extruder Temperature: 260°C

- Maximum Bed Temperature: 110°C

It also hosts a larger than normal build platform that’s about 300 x 300 x 400mm in dimension.

Moreover, Tornado has an all-metal hot end to brag about too. Combine that with the Titan extruder’s constricted filament pathway feed, filaments like TPU and TPE are exceptionally easy to deal with for this 3D printer.

This could be the reason why TEVO Tornado is well-liked among the community.

The AC-powered heated bed is ready for use in less than a minute, which is just a welcome addition to Tornado’s quality of life upgrades. Moreover, you get a maximum print speed of 150mm/s with a very detailed 50-micron layer resolution.

All that for a bit under $350? Seems too good to be true.

Another loveable quality about the TEVO Tornado is its assembly. According to the manufacturers, it arrives “95%” assembled, meaning that you just have to implement a bit of effort here and there and get to printing in under 15 minutes or so.

To speak of the design, it’s obvious how the TEVO Tornado borrows the idea from the famous Creality model, but the South African company has given its own touch of glaring colour apparently.

The Tornado’s frame is as sturdy as they come and feels solidly built too, so the 3D printer gets a good score in this aspect.

You can also get the TEVO Tornado at a really competitive price from Banggood.

How to Pick the Best 3D Printer for Flexible Materials

Flexible thermoplastics can be difficult to print considering their hygroscopic nature and particular sensitivity to rapid movements. This is why the 3D printer you’re going to choose must be well-equipped to handle flexible filaments.

The best 3D printer for flexible materials should comprise the following attributes:

- A print bed that comfortably reaches 45-60°C. Could be a desirable addition if it’s a heated print bed as well.

- A modern extruder system that can handle high temperatures around 225-245°C.

- A Direct Drive extruder is more recommended but a Bowden setup can still get it done!

- A PEI coated print surface for good bed adhesion – although a standard plate with glue stick works wonders

Types of Flexible Materials

Thermoplastic Elastomers (TPEs) are a group of 3D printable materials that are further divided into a few different types.

TPU: Thermoplastic Polyurethane (TPU) is probably the most popular of all flexible printing materials out there that’s highly admired for its exclusive hardness, allowing it to be printed with ease as compared to other filaments of the like. TPU also boasts fairly strong prints with decent durability.

A good example of popular TPU filament is the 1KG Spool of PRILINE TPU that you can get straight from Amazon (rated 4.5/5.0 at time of writing). You might think that this flexible material is much more expensive than standard filament like PLA, but you’d be surprised by the prices!

PRILINE TPU is a top-grade option from a noteworth brand if you have to print with a flexible filament. It can print easily with a nozzle temperature of 190-210°C, which is what most 3D printers can comfortably handle.

The dimensional accuracy of this spool comes in at ±0.03mm, and is backed with a standard 30-day refund guarantee, so you’re sure to be happy.

TPA: Thermoplastic Polyamide (TPA) is a blend of nylon and a co-polymer of TPE. This dual-natured flexible filament exhibits super smooth prints with shining texture. This combination allows it to feature immense durability from nylon and awesome flexibility from TPE.

This dual-natured flexible filament exhibits super smooth prints with shining texture. This combination allows it to feature immense durability from nylon and awesome flexibility from TPE.

TPC: Thermoplastic Copolyester (TPC) isn’t very noticeable around 3D printing enthusiasts and hobbyists, being more suited as an engineering-grade flexible filament. To talk in terms of its physical properties, TPC does, however, feature high-temperature resistance and utterly strong print jobs.

There’s also one more type of flexible material and it’s widely known as Soft PLA. This refers to the blends of PLA in order to make it flexible yet durable and strong.

As a bonus point, you can print Soft PLA similarly as you would with regular PLA. However, you might have to print slowly and opt for a higher bed temperature to rock this flexible filament.

The Soft PLA from Matter Hackers does get relatively pricey!

Flexible Filament Hardness Measures

Flexible filaments, generally, are measured using a Shore Hardness scale. This sets them apart in terms of how much flexibility or hardness they can offer.

This sets them apart in terms of how much flexibility or hardness they can offer.

Relatively softer materials fall in the Shore A scale for 3D printing. Therefore, most of these thermoplastics have a range between 60-90 Shore A hardness.

The higher the value on this scale, the harder the material, while a lesser value will amount to more flexibility.

Lets take a TPU-70A flexible filament.

As the name depicts, this filament would have a Shore A hardness of 70, which means that it is almost in the middle of flexible and rigid, but a little more on the flexible side.

Perfect for the average 3D printer.

The less rigid and more flexible a filament, the harder it is going to be to print with because there is more work and precision needed in controlling that flexible filament.

Rigid filament like standard PLA prints pretty easily, so the further away from that, the harder it will be to print.

How to Print Flexible Filament Effectively

There’s no doubt about the trickiness of printing thermoplastics like TPU and other flexible filaments, but there are approachable workarounds and a little bit attention paying to get this ordeal sorted for you. I’m going to list a bunch of things you can start with today to print flexible filament effectively.

I’m going to list a bunch of things you can start with today to print flexible filament effectively.

Take it Slow

Even when a flexible filament is not concerned, if one hopes to get the best possible results with a lot of detail, printing slowly can’t be overlooked.

This is why a slow speed is recommended for every thermoplastic filament, and not just flexible materials. But for TPU and TPE, there’s no other way if you want to be successful when printing with them.

Slow print speeds prevent pressure from building up largely inside the extruder nozzle and helps negate a plethora of potential problems. When printing TPU, your optimum speed should be no more than 30-40mm/s.

Some people even go as low as 10-20mm/s.

Prefer a Direct Drive Setup

Though it’s not really impossible to print flexible filament with a Bowden-style extruder, it’s definitely more challenging.

Direct Drive setups reduce the distance that a filament has to travel from the extruder to the hot-end. This allows for unmatched convenience when printing with TPU and other flexible thermoplastics. Moreover, the pathway that usually follows is also constricted and narrow, providing for a clear passageway.

On the other hand, we have Bowden-style extruders that simply cannot work well with a flexible filament. This is because these types of filaments tend to bind inside the Bowden PTFE tubing, making the whole process much more difficult and tiresome.

However, there exists an upgrade you can get if possible on your Bowden-style 3D printer. It’s known as Capricorn PTFE tubing.

This upgrade can increase the ability of Bowden setups to print flexible filaments because it just has better control on the filament as it passes through the tubing, preventing it from buckling up.

Additionally, it also has higher tolerance levels over regular PTFE tubes so your Bowden extruder 3D printer is much better off with a premium Capricorn tubing system.

Calibrate Temperature and Retraction

Temperature and retraction both are equally essential when it comes to achieving the desired outcome with flexible filaments. Temperature makes for the smooth sailing of the print operation while retraction helps keep the pressure down to a minimal level.

However, we’re basically oversaturated with different brands of flexible thermoplastics, with each having their own particular properties. The appropriate temperature and retraction settings are mandatory, but we recommend reviewing the guide of your filament to see how your 3D printer can be optimized for it ideally.

Normally, you’re recommended to keep low retraction settings with slight temperature adjustments. Some people have even reported success with 0 retractions, so that’s definitely an area to experiment with as well.

Use Painter’s Tape or Glue Stick

Is material not adhering properly to your non-heated print bed? Try using Blue Painter’s Tape or a standard glue stick and watch how things change for you.

It turns out that TPU and similar filaments can adhere quite wonderfully to these adhesive substances.

In addition, if you have a heated bed, a temperature between 40-50°C should give you the best results. Many people have seen good success with some standard glue on their build plate.

Difficulties in 3D Printing Flexible Materials

Flexible thermoplastic filaments have driven 3D printing into even more far-reaching applications. They’re able to produce strong, ductile prints with terrific resistance to mechanical wear and tear. However, all that comes at a cost, and let’s take a brief look at how.

Problems During the Filament Feed

This is an issue that becomes quite apparent in mainstream Bowden setups that use PTFE tubing. Flexible filament due to its soft physical composition becomes quite a bother to push along the extruder nozzle. Oftentimes, it jams, clogs and gets stuck somewhere in between, causing the print process to fail.

Oftentimes, it jams, clogs and gets stuck somewhere in between, causing the print process to fail.

The only way to proceed is by unclogging and cleaning your nozzle out. Of course, this is not a problem with common filaments like ABS and PLA just because of their hardness, but it is indeed something to attend to with TPU and TPE.

Formation of Bends Due to Pressure

Flexible filament tends to buckle up sometimes, all due to the pressure build-up in the nozzle. This mostly occurs when there’s an absence of a narrow pathway to feed through to the hot end or when you’re printing too fast for your 3D printer to handle the flexible thermoplastic.

This again causes jams in the nozzle where you have to begin everything from scratch.

Follow the video below by Ch4P for a great method to fix this with a standard Bowden extruder.

Stringing

Stringing is one of the most notorious problems with printing flexible filaments. Even if you’ve got all the settings correctly calibrated, you can always expect stringing to come reaping in around the corner. Even the slightest of errors in temperature, speed, and retraction settings could lead to stringing easily.

Even if you’ve got all the settings correctly calibrated, you can always expect stringing to come reaping in around the corner. Even the slightest of errors in temperature, speed, and retraction settings could lead to stringing easily.

This also comes by as a result of the pressure build-up. Stringing will usually create a mess when the extra filament is thrust out the extruder unnecessarily.

Print Bed Adhesion Difficulties

Temperature plays a key role in maintaining the success rate of printing flexible filaments throughout. Flexible filament is known for its difficulties in adhering to the print surface, primarily when the bed isn’t heated or even when the surface isn’t properly levelled.

The Best 3D Printers for TPU

- Author

- Recent Posts

Martin

Besides many test devices, Martin now has his fourth own 3D printer running and prints as a hobby for friends, family and himself. He is happy to share his experience with each new article.

Latest posts by Martin (see all)

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

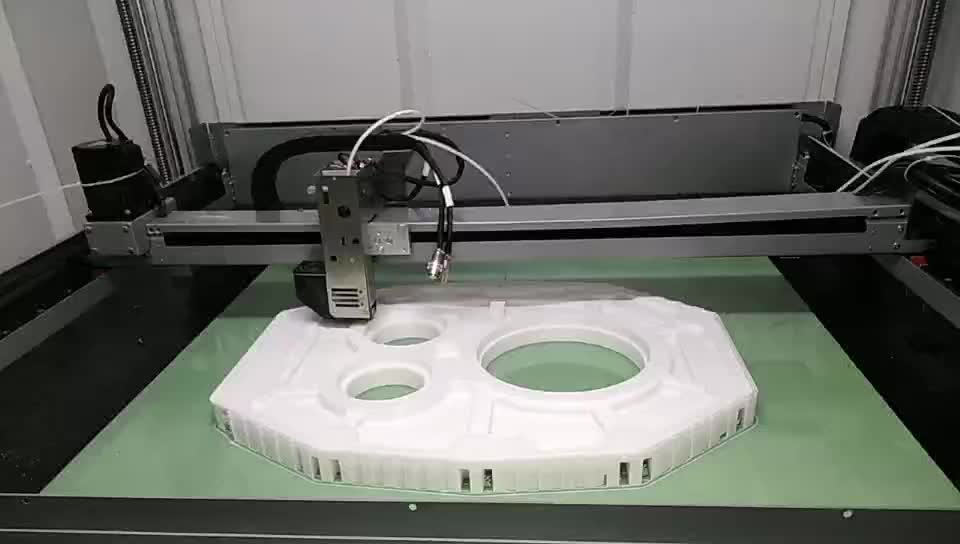

Do you want to be creative at home? With a 3D printer, you have the possibility to produce household utensils, minifigures, toys and spare parts easily in your own four walls. A 3D printer offers a wide range of applications.

While these devices were almost unaffordable for private buyers a few years ago, some top devices are now available for under 300 dollars. Once a casual toy for technology nerds, 3D printers are now becoming popular accessories in the home. Of course, smaller and larger companies are also increasingly turning to these devices. Easy handling and high print quality now characterize the devices.

TPU belongs to the exotic filaments and not every 3D printer can print this demanding filament.

These are the best 3D printers for TPU:

- Creality 3D Ender 3*

- ZD Bravo-I*

- Tronxy XY-2 Pro*

- Elegoo Neptune*

- Monoprice Maker Select Plus*

- Anycubic i3 Mega S*

- TEVO Tornado*

- FlashForge Creator Pro*

- Qidi Tech X-Pro*

- Dremel 3D45*

Table of Contents:

- 1 What is TPU?

- 2 The Best 3D Printers for TPU

- 3 Creality 3D Ender 3

- 4 ZD Bravo-I

- 5 Tronxy XY-2 Pro

- 6 Elegoo Neptune

- 7 Monoprice Maker Select Plus

- 8 Anycubic i3 Mega S

- 9 TEVO Tornado

- 10 FlashForge Creator Pro

- 11 Qidi Tech X-Pro

- 12 Dremel 3D45

- 13 Related Questions

- 13.

1 What are the best settings for 3D printing with TPU?

1 What are the best settings for 3D printing with TPU? - 13.2 How do I prevent TPU Stringing?

- 13.3 What work should I do before I start printing?

- 13.

- 14 Conclusion

What is TPU?

TPU stands for Thermoplastic Polyurethane. 3D printing with TPU offers possibilities that would hardly be feasible with other 3D printing materials such as Nylon*, ABS or PLA. TPU is a clever combination of rubber and plastic. TPU can therefore be used to produce highly resilient, elastic parts. These are easily bendable and compressible.

However, not every 3D printer is suitable for TPU filaments. In this article, we would like to introduce you to the best 3D printers for TPU. After that, you will know which 3D printer is best suited for this material and which technologies support it. You will also learn how to make your 3D printing with TPU as efficient and uncomplicated as possible.

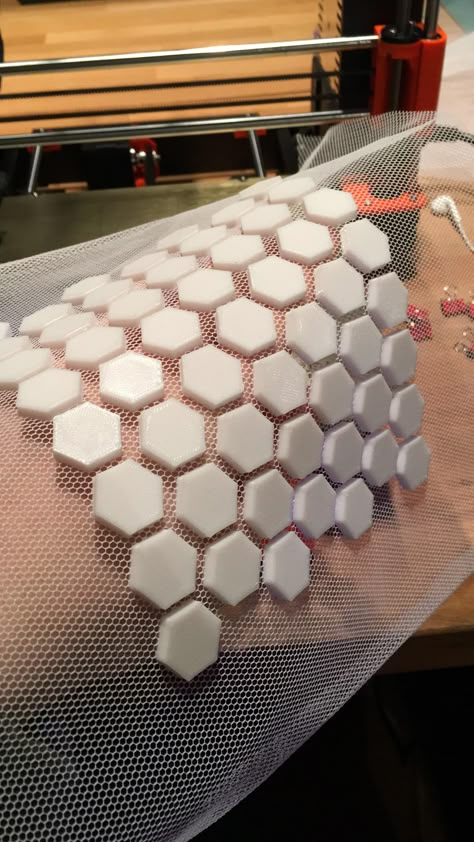

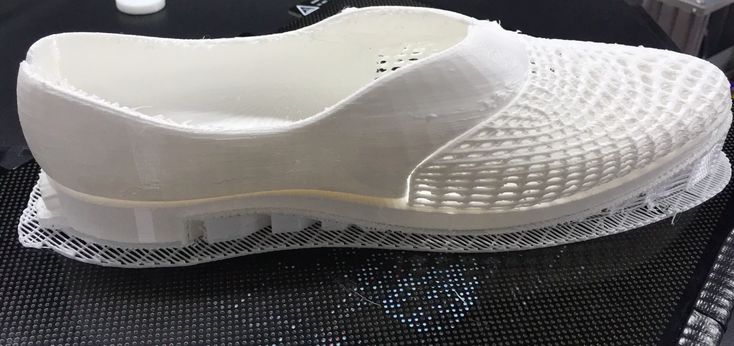

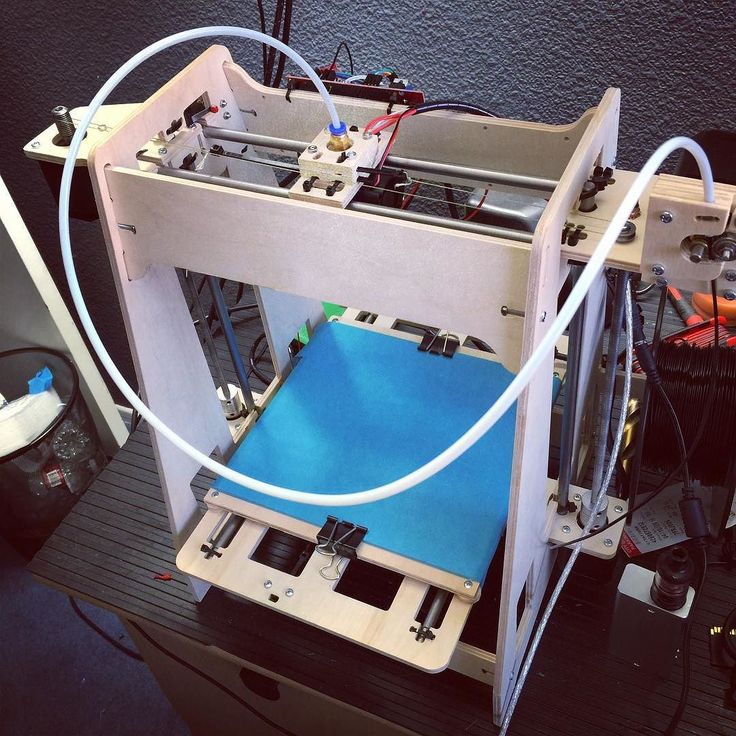

Flexible Filament is Awesome! (source: reddit)The Best 3D Printers for TPU

Although not all 3D printers are suitable for the use of flexible material, there is a very large selection of possible devices. So that you don’t lose the overview, we want to present the best 3D printers for TPU in our opinion.

So that you don’t lose the overview, we want to present the best 3D printers for TPU in our opinion.

Criteria such as purchase price, handling, technology, speed and clogging risk have been included in our evaluation.

However, the order of the devices shown here does not matter – all printers for TPU presented here have our unqualified recommendation.

In order to make the right choice between the following 10 devices, you should rather be aware of what you want to use the 3D printer for in the first place, how often you want to use it and which features you do not want to do without under any circumstances. Of course, a reasonable price-performance ratio also plays an important role.

Creality 3D Ender 3

In 2018, the Ender 3* appeared and caused a small revolution on the world market of 3D printers. The device is now one of the best-selling 3D printers in the world. Since then, the printer has been copied by numerous companies – but never equaled.

Check Price at:

Amazon*

3DJake*

| Print Size: | 220 × 220 × 250 mm | Layer Res.: | 0.1 – 0.4 mm |

| Extruder Temp.: | 255 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 110 °C | Nozzle Ø: | 0,4 mm |

Why this 3D printer for flexible filaments made such a big splash, you can find out here in a nutshell:

- Unbeatable price-performance ratio

- Outstanding results

- Patented extruder technology

- Low risk of clogging

The price-performance ratio of this printer is really top. The results are evidence of high quality. There is little to complain about, even when checking the objects closely. Even the rather difficult use of flexible filaments is easy with the Creality 3D Ender-3. The printer’s extruder technology has been patented by the company. This significantly reduces the risk of clogging. This is an advantage that should not be overlooked – especially when it comes to printing with flexible materials such as TPU.

This significantly reduces the risk of clogging. This is an advantage that should not be overlooked – especially when it comes to printing with flexible materials such as TPU.

Of course, it would be too good to be true if there weren’t a few drawbacks to the device. Here are the drawbacks of the Ender 3 in a nutshell:

- Relatively complex assembly

- Slightly wobbly

- Print bed does not adjust automatically

- Printing plate not completely flat

You should plan about 1 to 2 hours for the assembly. Suitable tools, well-labeled parts and clear assembly instructions are included, but the assembly can still be a bit time-consuming if you are not used to such assemblies. Although the Creality 3D printer is made of aluminum, it is often described as wobbly.

The print volume of 220 x 220 x 250 mm is okay. Although the print bed does not automatically adjust to the print job, beginners can easily lock the print bed. In addition, the printing plate does not seem to be completely flat in some devices. This can sometimes cause trouble with flexible filament.

This can sometimes cause trouble with flexible filament.

All in all, however, we are convinced by the outstanding results, the top price-performance ratio, and the patented extruder technology. These high-quality results are already amazing for the little money.

Related Post:

TPU with the Ender 3 (Pro) Printing – Complete Guide

ZD Bravo-I

The ZD Bravo-I* is far less known than the Creality 3D Ender-3. We think that should change! The 3D printer for TPU offers top performance for little money.

ZD Bravo-I*Check Price at:

Amazon*

| Print Size: | 220 × 250 × 250 mm | Layer Res.: | 0.05 – 0.1mm |

| Extruder Temp.: | 260 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 80 °C | Nozzle Ø: | 0,4 mm |

Here you can see the advantages at a glance:

- Supplied fully assembled

- Ready to go after a few steps

- Compact size

- Print jobs can be submitted offline

- Print bed optionally heatable

- Protection from power outages

- Improved extruder

Unlike the Creality 3D Ender-3, this device is delivered to your home already assembled. After just a few steps, the ZD Bravo-I is ready to go. We also noticed the practical compact size of the device.

After just a few steps, the ZD Bravo-I is ready to go. We also noticed the practical compact size of the device.

Despite its small size, the ZD Bravo-I prints considerable objects with a maximum volume of 220 x 250 x 250 mm. You can also send print jobs offline to the printer via USB or SD card. The print bed can also be heated, which makes the printer suitable for many types of filament.

The powerful printer also convinced us with its protection against power failures. Even without a permanent power supply, the printer terminates every print job once it has been started – which saves you a lot of trouble! By the way, an improved extruder has been installed in the device.

Of course, there are also a few points of criticism with this device, which we would like to go into a bit more detail now:

- First installation costs some nerves

- Finding the right settings is somewhat difficult

- Tricky especially for beginners

A frequently voiced criticism of this device is the complicated initial setup. Especially for beginners, the initial installation is a big hurdle. It can take some time and nerves to find the right settings. However, once you have found the right settings, you are immediately compensated for the effort: In our opinion, the printer delivers a top performance!

Especially for beginners, the initial installation is a big hurdle. It can take some time and nerves to find the right settings. However, once you have found the right settings, you are immediately compensated for the effort: In our opinion, the printer delivers a top performance!

Tronxy XY-2 Pro

Money savers beware! The cheapest 3D printer for TPU in our list is the Tronxy XY-2 Pro*, which is especially suitable for beginners.

Tronxy XY-2 Pro*Check Price at:

Amazon*

| Print Size: | 220 × 220 × 260 mm | Layer Res.: | 0.1 – 0.4 mm |

| Extruder Temp.: | 275 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 120 °C | Nozzle Ø: | 0,4 mm |

These are the many advantages of Tronxy XY-2 Pro at a glance:

- Cheap model

- Excellent for beginners

- Almost completely assembled

- Ready to print after a few steps

- Simple configuration

- Also operable with other 3D printer software

- High construction volume

- Can be heated in wide temperature range

- Automatic leveling of the print bed

When the printer is delivered to your home, it is already almost completely assembled – which saves time and nerves! The Tronxy XY-2 Pro is ready to print after just a few steps. The 3D printer for TPU is also easy to configure. You are thus spared the tedious search for the right settings. Due to the simple initial installation, we recommend this model, especially to beginners.

The 3D printer for TPU is also easy to configure. You are thus spared the tedious search for the right settings. Due to the simple initial installation, we recommend this model, especially to beginners.

The printer can be operated with the manufacturer’s software as well as with other 3D printer software. You can send your print jobs to the device with the USB cable. The maximum possible build volume of 255 x 255 x 260 mm is perfect for hobbyists! And advanced users will also get their money’s worth. Furthermore, we would like to positively emphasize the extruder technology as well as the printer’s wide temperature range. For inexperienced users, the automatic leveling of the print bed is especially a plus.

In general, we have very few things to criticize about this printer. The only small drawback:

- Z-axis a bit wobbly

This is because the Z-axis is not so well connected to the device. On the whole, however, we highly recommend the Tronxy XY-2 Pro! The solid printer at a low price is suitable for beginners and advanced users. Especially for those who are interested in making objects out of TPU, this device is ideal!

Especially for those who are interested in making objects out of TPU, this device is ideal!

Elegoo Neptune

Now that we have presented some models for beginners, we would also like to talk about a great model for advanced users: The Elegoo Neptune 3D printer*!

Elegoo Neptune*Check Price at:

Amazon*

| Print Size: | 205 × 205 × 205 mm | Layer Res.: | 0.05 – 0.3 mm |

| Extruder Temp.: | 260 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 120 °C | Nozzle Ø: | 0,4 mm |

Here are the advantages at a glance:

- Glass printing bed

- High print quality

- Good Adhesion

- Top price-performance ratio

- Automatic filament detection

- Partly ready mounted

- Ready for use after 30 minutes

- Beautiful results with TPU

- Compact, solid device

Even advanced users will get their money’s worth with this device: After all, the print bed here is made of glass, which brings outstanding properties in terms of adhesion. This improves the print quality enormously. Furthermore, the 3D printer impresses with an extremely useful additional function: The automatic filament detection!

This improves the print quality enormously. Furthermore, the 3D printer impresses with an extremely useful additional function: The automatic filament detection!

So if you use TPU or another flexible filament, the Neptune immediately recognizes which material it is – the settings (e.g. regarding the temperature) are then made automatically. This is an advantage, especially in connection with the demanding flexible materials. The printer is delivered to your home partly assembled. The Neptune is ready to start after just 30 minutes. The scope of delivery includes sufficient accessories as well as a large amount of flexible filament to try out. The device is compact and therefore guaranteed to find a place in your four walls.

At this point, we would also like to briefly discuss the device’s points of criticism:

- Adjustment of the print bed complicated

- Must be manually adjusted to the print job

- Installation space with 205 x 205 x 205 mm rather small

Although the print bed has great advantages on the one hand, the manufacturer immediately earns the first point of criticism because of it: Adjusting the print bed is anything but easy! It does not adjust automatically and you have to adjust your print jobs by hand! If you are a particularly experimental user, the installation space might be a bit too small for you.

All in all, however, the Neptune is a solid, compact device that delivers high-quality results. We recommend this printer to anyone who has an affinity for details and is looking for an affordable device.

Monoprice Maker Select Plus

Are you looking for a compact model for little money that still prints TPU in a decent size? Then we recommend the Monoprice Maker Select Plus*.

Monoprice Maker Select Plus*Check Price at:

Amazon*

| Print Size: | 200 × 200 × 180 mm | Layer Res.: | 0.1 – 0.4 mm |

| Extruder Temp.: | 240 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 70 °C | Nozzle Ø: | 0,4 mm |

These are the advantages of the 3D printer in a nutshell:

- Top price-performance ratio

- Open system

- Ready to go after a few simple steps

- Compact size

- Comfortable to use touch screen

- Intuitive operation

- Print jobs via Wi-Fi

This model caught our eye especially because of its great price-performance ratio and the open system. This means that you can also feed the printer with TPUs other than those licensed by the manufacturer. Flexible filaments are expensive anyway – so it’s especially convenient if you can also use no-name products.

This means that you can also feed the printer with TPUs other than those licensed by the manufacturer. Flexible filaments are expensive anyway – so it’s especially convenient if you can also use no-name products.

Another plus point of the device is its high user-friendliness. You only need a few steps to configure the printer. Despite its compact size, the printer can also print a maximum volume of 200 x 200 x 180 mm. Another positive feature is the comfortable and intuitive touchscreen. Printer settings can be easily adjusted and print jobs can be loaded via SD card, USB or Wi-Fi.

There are hardly any drawbacks, except that this model, unfortunately, does not have an automatic print bed. However, the high user-friendliness and ideal settings make up for this drawback. We would like to recommend this model especially to price-conscious and advanced users. The 3D printer can be easily expanded and upgraded and will quickly become your personal expert device. In addition, the printer is very space-saving and you are guaranteed to find a suitable place for it in your home.

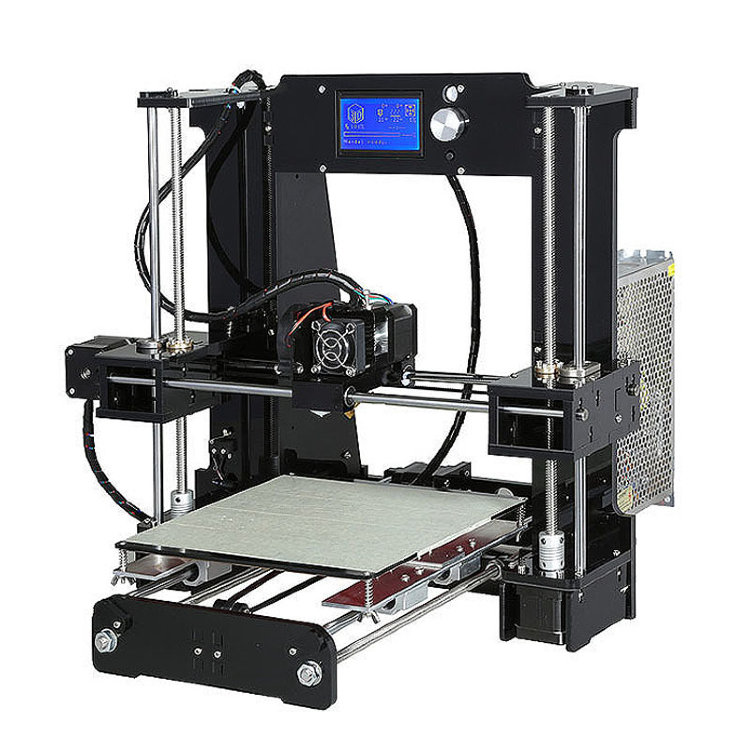

Anycubic i3 Mega S

The Anycubic i3 Mega S* is one of the most popular 3D printers and offers top work quality and functionality.

Anycubic i3 Mega S*Check Price at:

Amazon*

3DJake*

| Print Size: | 210 × 210 × 205 mm | Layer Res.: | 0.05 – 0.3 mm |

| Extruder Temp.: | 260 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 110 °C | Nozzle Ø: | 0,4 mm |

Here you can see the advantages at a glance:

- Quickly built

- Touchscreen

- Intuitive menu navigation

- High stability

- High precision and working speed

- Excellent results

- Open system

The printer can be set up quickly and convinces with a touchscreen and intuitive menu navigation. This means it is quickly ready for use. Furthermore, the printer scores with its stability, high precision and high working speed. The device also delivers excellent results. The open system means that no-name products can also be used.

Furthermore, the printer scores with its stability, high precision and high working speed. The device also delivers excellent results. The open system means that no-name products can also be used.

However, there are also a few points of criticism about the device, which we have briefly listed here:

- Maximum object size slightly smaller

- Only applicable for basics

- Limited applicability of filament types

- High noise level

The i3 Mega S prints objects with a maximum volume of 210 x 210 x 205 mm. This means that the maximum object size is slightly smaller than the other models presented. The model also only accepts 4 filament types. So, those who would like to try exotic material further down the line will unfortunately be disappointed here. Home users should also note that the printer produces a lot of noise.

Despite the limited selection of filament types, the i3 Mega S offers really excellent results. Those who mainly want to produce medium-sized and no-frills basics will definitely enjoy the printer.

TEVO Tornado

The sturdy and heavy TEVO Tornado* is especially suitable for advanced users who want to stay in the lower category in terms of price.

TEVO Tornado*Check Price at:

Amazon*

| Print Size: | 300 × 300 × 400 mm | Layer Res.: | 0.05 mm |

| Extruder Temp.: | 260 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 110 °C | Nozzle Ø: | 0,4 mm |

These are the advantages of the model:

- Solid and robust

- Does not wobble

- Precise results

- Ready for use after just a few assembly steps

- Large construction volume

- Specially coated print bed

Although the Tornado is not particularly compact, but rather makes a heavy impression, this is definitely an advantage: The printer wobbles less, which in turn has a positive effect on the print quality. The model arrives almost completely assembled and it only takes a few steps to get it running. The Tornado also stands out with its high work volume.

The model arrives almost completely assembled and it only takes a few steps to get it running. The Tornado also stands out with its high work volume.

The maximum build volume here is a whopping 300 x 300 x 400 mm. This makes this printer number 1 on our list in terms of possible object size. The print bed can be heated up if necessary. Due to the special coating of the print bed, the objects adhere better.

However, the coating also brings us to our first minus point: Sometimes the adhesion is so strong that it can cause trouble, especially with flexible filaments. Some further points of criticism are:

- No automatically leveled print bed

- Processing of the print bed

Unfortunately, the processing of the print bed does not seem very secure to us. In our opinion, the print bed needs an overhaul. Nevertheless, the Tornado delivers great results and is especially suitable for advanced users who do not want to dig too deep into their pockets.

FlashForge Creator Pro

Now we would like to introduce you to a special treat for professionals: FlashForge Creator Pro*.

Check Price at:

Amazon*

3DJake*

| Print Size: | 227 × 148 × 150 mm | Layer Res.: | 0.1 mm |

| Extruder Temp.: | 260 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 120 °C | Nozzle Ø: | 0,4 mm |

Here you see all the advantages roughly summarized:

- Professional application level

- Sophisticated design

- Dual extruder technology

- Two-color printing

- Fast initial setup

- Heatable and fully automated print bed

- Works very quietly

- Open system

- Excellent quality

The Creater Pro impresses with its sophisticated design and professional application level. Although this printer already belongs to the upper price range, it has some advantages for advanced and professional users. The device convinces with its dual extruder technology, which enables two-color printing. An assembly is not necessary.

The device convinces with its dual extruder technology, which enables two-color printing. An assembly is not necessary.

The printer is quickly set up via quick start. We also noticed the fully automated and heatable print bed. The low noise level of the device and the open system are also worth mentioning. This gives you the option of using no-name products and TPUs from other manufacturers. The maximum build volume is 225 x 150 x 145 mm.

We searched for a long time, yet we could find only a few points of criticism:

- High price

- Data transfer not possible via Wi-Fi

Hobbyists, professionals and others will definitely have to dig deeper into their pockets for this model. But you will be rewarded with excellent results and top technologies. We recommend this printer especially to small and medium-sized companies as well as professional users.

Qidi Tech X-Pro

Another model that definitely belongs in the upper price category now is the Qidi Tech X-Pro*.

Check Price at:

Amazon*

3DJake*

| Print Size: | 230 × 150 × 150 mm | Layer Res.: | 0.1 – 0.4 mm |

| Extruder Temp.: | 250 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 120 °C | Nozzle Ø: | 0,4 mm |

Here you can see all the advantages at a glance:

- Closed installation space

- Ideal for flexible filaments like TPU

- High-quality ventilation technology

- Compact size

- Dual extruder

- Two-color printing possible

- Print jobs via SD card, USB & Wi-Fi

- Magnetic and double-sided coated printing plate

- Two different surfaces

- Fully automatic printing plate

This first-class printer convinces with a closed build space. Especially for the use of sensitive filaments like TPU, a closed build space is ideal.

Another plus point is the device’s four-sided ventilation technology. Just like the Creator Pro, this printer is also equipped with dual extruder technology, which makes two-color printing possible. It is exactly this dual extruder technology that also makes the model more expensive. Cheaper 3D printers usually have to make do with one extruder. We also find the data transfer via Wi-Fi to be top.

By the way, the printing plate was coated on both sides, which results in two different surfaces. You can use these differently depending on the filament used.

We could only identify a few disadvantages:

- More budget needed

- Installation space leaves something to be desired

The maximum build volume of this device is 230 x 150 x 150 mm and could be increased a bit in our opinion. Hobbyists, professionals and the like will have to pay a bit more for the Qidi Tech X-Pro. However, it is basically worth it, since the printer delivers great results and is equipped with top technology. In addition, the device is compact and is still within the hobby budget despite the higher price.

In addition, the device is compact and is still within the hobby budget despite the higher price.

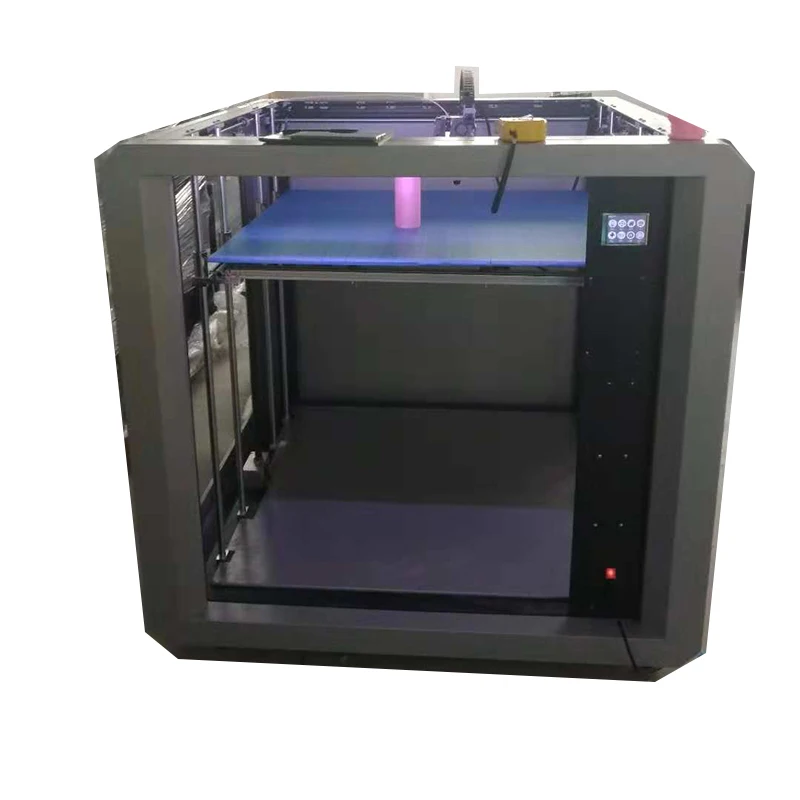

Dremel 3D45

We would like to conclude our buying guide with the following high-end device: The Dremel 3D45*.

Dremel 3D45*Check Price at:

Amazon*

| Print Size: | 254 × 152 × 170 mm | Layer Res.: | 0.05 – 0.3 mm |

| Extruder Temp.: | 250 °C | Filament Ø: | 1,75 mm |

| Printing Bed Temp.: | 120 °C | Nozzle Ø: | 0,4 mm |

These are the advantages of the high-quality model in a nutshell:

- Multifunctional

- Completely enclosed installation space

- Top touchscreen

- Simple initial installation

- Fast, precise & ultra-quiet

- Heated print bed

- Highly professional device

Are you interested in building complex prototypes? Or are you in the middle of your education or training and need a high-end device? Then we can only warmly recommend the Dremel 3D45! The Dremel company is primarily known for its high-quality and multifunctional tools. In the meantime, the company also produces this printer, which really convinces all along the line.

In the meantime, the company also produces this printer, which really convinces all along the line.

As already mentioned above, a closed build space is perfectly suited for the use of flexible filaments such as TPU. This high-end device also convinces with a completely closed build space. This eliminates the need for assembly and the printer is ready for use just a few minutes after unpacking.

The initial installation is really easy and the touchscreen can be operated intuitively. We find the fast, precise and ultra-quiet operation of the device particularly pleasant. The maximum volume is 254 x 152 x 170 mm.

There is hardly anything to complain about in this top high-end device. The only drawbacks we could find are these:

- Printer recognizes only its own brand filament

- Expensive price

Although the Dremel has filament recognition, it only recognizes its own house brand. Besides that, the purchase price is a bit expensive after all. However, this device is absolutely recommendable for all people who have to deal with 3D printers professionally or as part of their education. For us, the Dremel belongs to the top class among 3D printers. So if you have the resources, you will definitely not be disappointed with this device.

For us, the Dremel belongs to the top class among 3D printers. So if you have the resources, you will definitely not be disappointed with this device.

Related Questions

What are the best settings for 3D printing with TPU?

TPU prints can be significantly improved by setting a print temperature between 220-250 °C, never letting the heated print bed get hotter than 60 °C, paying attention to lower fills and airtight storage, printing slowly, and adding adhesive from the print bed for easier removal.

Related Post:

3D Printing with TPU: Features, Tips & Best Settings

How do I prevent TPU Stringing?

3D printing with TPU filament sometimes results in so-called hairy printing. To prevent this, you can try to increase the retraction distance of the filament, increase the retraction speed or minimize the nozzle temperature, among other things.

Related Post:

How to Prevent TPU Stringing – Try these Settings!

What work should I do before I start printing?

Before 3D printing with TPU, you should loosen the tensioning pulley as much as possible. This will prevent the TPU from tangling around the Bondtech. You should also apply a thin layer of glue to the print surface – a normal paper glue stick will do! Also reduce the printing speed.

This will prevent the TPU from tangling around the Bondtech. You should also apply a thin layer of glue to the print surface – a normal paper glue stick will do! Also reduce the printing speed.

Conclusion

3D printing with the flexible filament TPU opens up a whole new world for you: TPU plastics are flexible and elastic and thus offer numerous creative applications.

With the flexible filament, you get enormous elasticity, the greatest possible design freedom and low energy consumption. However, if you want to be flexible with TPU, you need a suitable printer. Not all 3D printers are suitable for printing with flexible filaments.

For beginners on a budget, we recommend either the Creality 3D Ender-3*, the ZD-Bravo-I*, the Monoprice Maker Select Plus* or the Tronxy XY-2 Pro*.

If you’re already advanced in 3D printing, we recommend the Elegoo Neptune* or the TEVO Tornado*.

You want to print mid-sized basics? Then we recommend Anycubic i3 Mega S*.

You are a professional user and want to spend a little more money? Then the Dremel 3D45*, the Qidi Tech X-Pro* or the FlashForge Creator Pro* are the devices of your choice!

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon.com and others. Links marked with * are affiliate links.

how to use flexible materials for 3D printing

3DPrintStory 3D printing process Ender 3 (Pro) and TPU: how to use flexible materials for 3D printing

Newcomers to 3D printing often start with PLA because it's easy to work with. While great models can be printed using PLA, there comes a point in everyone's life when they need materials with specific properties for a particular project.

While great models can be printed using PLA, there comes a point in everyone's life when they need materials with specific properties for a particular project.

This is where flexible materials come in: TPU is an example of a flexible material that can be used to create different types of models. From car tires to cup holders, this material really opens up new possibilities when added to your arsenal.

As always, you have to go through a period of difficulties and frustration to learn something new, and only a few users of 3D printers get excellent results the first time using a new type of plastic. TPU, in particular, can be particularly problematic when using entry-level 3D printers like the Ender 3. Fortunately, the material in this guide can serve as a great base for you to experiment further on your way to 3D printing success with flexible materials.

Is it possible to print with flexible media on the Ender 3?

A common complaint on the forums is that the Ender 3 can't print TPU or other flexible plastics due to design issues. The extruder, the Bowden system and the hot end will probably figure as the main reasons for the impossibility of this noble undertaking.

The extruder, the Bowden system and the hot end will probably figure as the main reasons for the impossibility of this noble undertaking.

However, there are hardware modifications to address each of these TPU-related problems. We are going to look at some of them in the next two sections.

Extruder assembly

Extruder cold end

Discussions around the Ender 3 extruder usually boil down to the likelihood of material bending in the cold end after it has passed through the gear. This is a big problem in the context of flexible plastics like TPU, because... it flexes and the motion of the extruder motor doesn't transfer properly.

All-Metal Extruder

Upgraded All-Metal Extruder can help with potential extruder flex, but if you're on a tight budget, this Thingiverse extruder upgrade can help solve that problem too. Some users even recommend using a straw to keep the thread straight - the main thing is to avoid any kind of kinks.

Direct drive

Another major upgrade to the extruder is the direct drive system. The complete elimination of the Bowden tube will allow your Ender 3 to be much more accurate when using flexible materials and 3D printing in general. Shorter filament paths and increased grip ensure a much better chance of success when printing with flexible materials.

The complete elimination of the Bowden tube will allow your Ender 3 to be much more accurate when using flexible materials and 3D printing in general. Shorter filament paths and increased grip ensure a much better chance of success when printing with flexible materials.

Extruder Hot End

As previously stated, an upgraded all-metal hot end can make 3D printing with TPU easier, as PTFE tubing is completely removed from the design, which causes problems with flexible 3D printing materials. In addition, these types of hot ends can reach higher temperatures, giving you access to a range of other materials.

Bowden tube

Bowden tube can sometimes cause material to flex too much, causing many 3D printing problems. Replacing the Boden type of plastic feed with a direct drive will indeed solve many problems, but if you do not want to deal with such an upgrade in the design of your 3D printer, you can simply try to buy a higher quality PTFE tube. Improving the quality of the tube can make it easier to move the material to the hot nozzle, which can solve the problem even with flexible materials.

Slicer settings

Nozzle temperature when 3D printing TPU plastics is higher than PLA, usually around 220-230°C (at the same time, 3D printing PLA plastic usually occurs at about 200°C). You will also likely find that you will need to raise the temperature of the table and may need to use tape or hairspray to improve the adhesion of the first layer. And all this will have to be done even though you have well calibrated the table and PLA sticks to it without problems.

Also, reduce the 3D printing speed to 40mm/s. If your extruder is clogging or results in poor surface finish, try adjusting the retract to zero. You will also need to adjust the distance between the nozzle and the table since TPU does not require as much pressure as PLA.

As with all slicer settings, the key to success is experimentation. Different brands of TPU may require different settings, but good 3D printed models are just a matter of time, perseverance and intelligent experimentation!

Printing Revolution FLEX, TPU, Rubber

Everyone knows the rather old problem of Bowden printers. I want, for example, to print legs for my laptop, I bought a flex for 3 k and already made a model, but alas, the printer does not chew plastic (although it just chews it)

I want, for example, to print legs for my laptop, I bought a flex for 3 k and already made a model, but alas, the printer does not chew plastic (although it just chews it)

If we search the net for ways to solve the problem, we will find a fairly standard way , sawed the tube under the gear and pushed it deeper. Roughly speaking, they reduced the gap where chewing of the rod is possible.

Eureka... it worked, but now and again, attempt after attempt ends in failure... A little more theory and we reduce the printing speed, and only then we manage to print those same legs. (I’m already silent about how much effort and nerves have been spent)

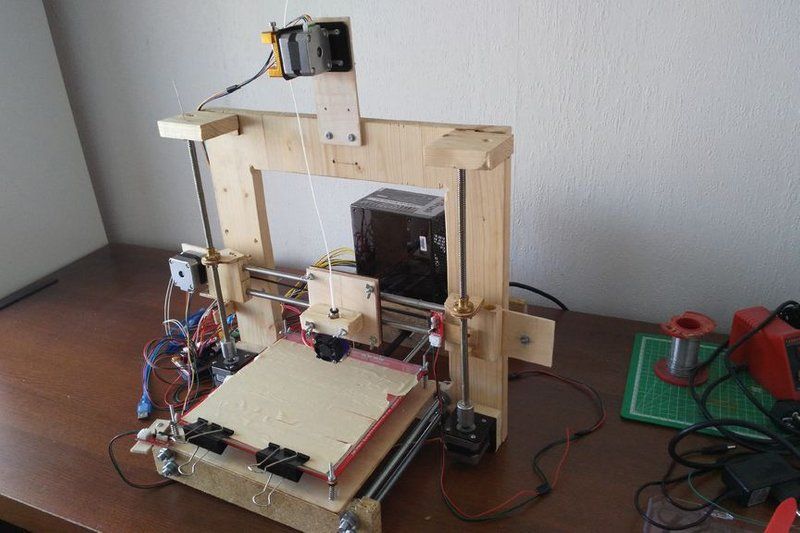

Thus, there are two ways to solve this problem: switch to direct or finish the existing type of feed. Bowden type extruders are mounted on a 3D printer frame. It pushes and pulls the filament through a long PTFE tube directly to the hot end. These extruders are more compact and take up less space than direct feed extruders. The advantage of the direct-c feed is that it is compatible with a wide range of 3D printing materials.

The advantage of the direct-c feed is that it is compatible with a wide range of 3D printing materials.

The disadvantage of feeding through the guide tube is the tension that occurs during printing, which does not allow the use of flexible (soft) materials. The extra mass when mounting the extruder on the print head adds speed limits, causing more wobble and loss of precision in the X and Y axes. For a direct type design, the main problem is heavy weight and limited working space.

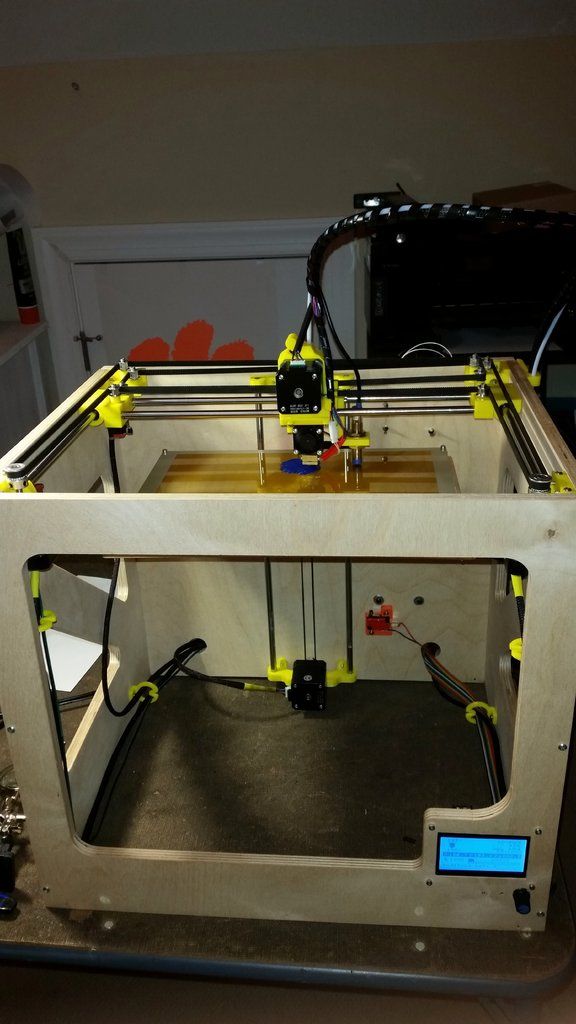

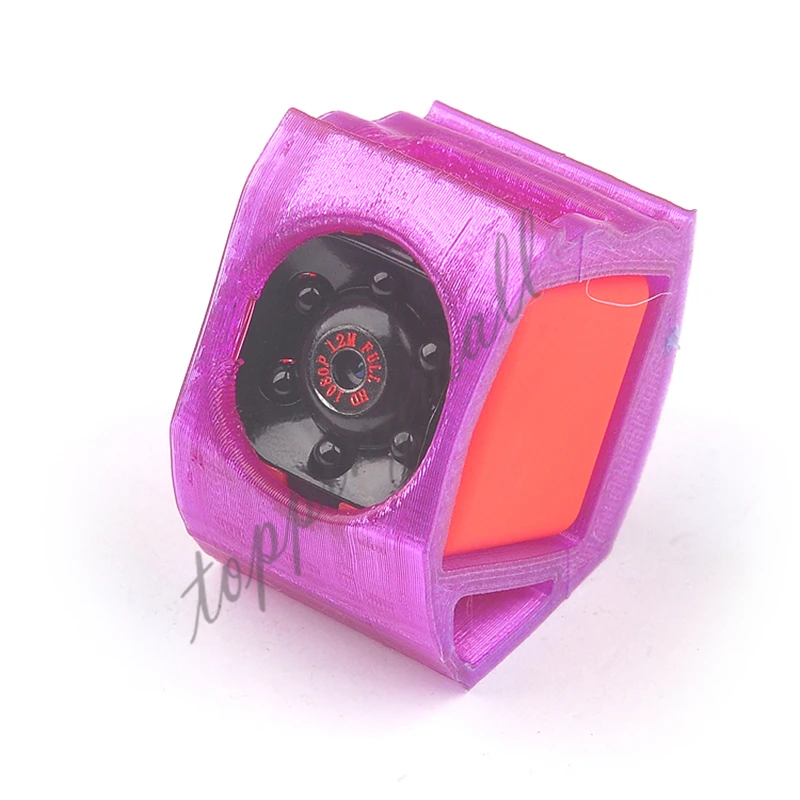

Together with Sapphirus, we solved this case using the possibilities of photopolymer technology. I developed many versions until I reached the golden mean, which showed the best results.

The goal was to make the device as small as possible in all respects.

As a result, we get a direct on a flexible shaft, which is 10 times lighter than the type of feed we are used to.

The device is delivered disassembled with all parts necessary for installation.

The filament is loaded in close proximity to the polymer melting point, the absence of a gap in which the filament can jam makes it possible to print flexible materials at high speeds.

Well, of course, this will affect the quality of the print, since there will be no voltage that occurs in the Teflon tube.

And now the most interesting thing is how to install this device on any printer?!

Can be installed through two fittings and a Teflon tube (for limited space), or installed through a brass adapter directly into the hot end radiator.

The kit comes with a metal adapter that is screwed into the radiator instead of a fitting, and the counterpart is screwed into the device.

So the plastic has nowhere to go other than going directly into the fuser.

Now you need to attach the shaft to the motor and calibrate the steps for the extruder motor.

Calculate a new value using the formula and change it in the printer (how to do this has already been written several times) .

We print the XYZ test cube

And we get a decent result, we need to fix the Z-mechanics and play with blowing, but that's another topic.

Layer laying and feeding uniform, super! And this means that our device, paired with a sapphire die, works flawlessly, which, in fact, we were striving for.

It's time to try flex printing and print the sinister laptop legs

Printing was easy and everything went smoothly

Hooray! I finally printed them)

The extruder device obtained during the design process has the following advantages compared to existing models (directs)

- printing quality is not lost when working at high speeds;

- Significantly improved extrusion unevenness in fine detail printing;

- light weight;

- possibility of using soft, rubber-like materials;

- easy to install and set up;

- the best surface quality of the printed part.