3D printer open source projects

10 Challenging DIY Open-Source Projects that Use 3D Printing

Apart from being one of the booming manufacturing methods in recent times and its increasing industrial usage, 3D printing also seeps into the workflow of the hobbyists and enthusiasts. This article overview 10 interesting and challenging DIY open-source project ideas, where you can use the huge power of 3D printing.

1. OpenRC Formula-1 Toy CarThis 3D printing project is a complete open-source remote operated toy Formula 1 car that can take you and your printer off to the races. This community fun project unites many people who provide various mods, tutorials and insights. This can be modified according to your specifications and print it as big as you want(largest one being just more than 150cms in length). Open RC F1 can be a great project to learn about remote control systems and can take you and your printer off to the track. Here are the detailed instructions on how to build and assemble your 3D printed car.

More information: https://danielnoree.com/the-openrc-f1-build-guide/

Design files: https://www.thingiverse.com/thing:1193309

Image source: ThingiverseMaterial and process recommendation: It is better to use ABS for its durability and high-strength and processes like FDM and MJF as they are cheap and efficient.

2. Dragonfly ScienceThe 3D printed dragonfly is one of the best open-source projects to make good use of your free time. This small machine is inspired by the odd aerodynamics of dragonflies. The flaps are powered by twisted rubbers. This project is designed to allow enthusiasts to know more about the flying properties. Here is the link to project design files and the further information.

More information: https://www.thingiverse.com/thing:951687

Material and process recommendation: We would recommend PP or PLA for the light weight and flexibility and processes like FDM and MJF as they are cheap and highly durable.

Started as a basic student project, this DIY project is the first step in establishing hovercraft as a cheap mobile research station for the Arctic. This is one of the significant 3D printing projects as most of it is 3D printed. However, the base is cut from Styrofoam.

More information: https://makezine.com/projects/3d-print-rc-hovercraft/

Design files: https://www.thingiverse.com/thing:901976

Image source: ThingiverseMaterial and process recommendations: For a durable and robust build, it’s better to employ ABS and technology can be either FDM or MJF.

4. DIY QuadcopterThis exciting 3D printed FPV Quadcopter is lightweight and designed to be crash-resistant and offers good protection for onboard gear. While this is certainly not a cheap 3D printing project, as many as 24 options for this design can be found on Thingiverse to accommodate most budgets. Here is the link to the project description and files.

Here is the link to the project description and files.

More information: https://www.instructables.com/Micro-105-FPV-Quadcopter-3D-Printed/

Design files: https://www.thingiverse.com/thing:1221911

Image source: ThingiverseMaterial and process recommendations: PLA can be used but ABS will give you more crash resistance. In the photo, the top is printed in PLA and the bottom in ABS. FDM or MJF is recommended.

5. Strandbeest- Beach BeastStrandbeest is a cool 3D printed kinetic sculpture that combines engineering and art. They roam mysteriously in the beaches of Netherlands, propelled by the power of wind. You can build your very own DIY Strandbeest just for fun. It has eight individual components, assembled repeatedly in a sequence to get the Strandbeest.

More information: https://www.instructables.com/3D-Printed-Theo-Jansen-Strandbeest/

Material and process recommendations: Nylon is recommended for flexible and moving parts and cheap as well. Processes can be MJF, FDM or SLS based on the costs.

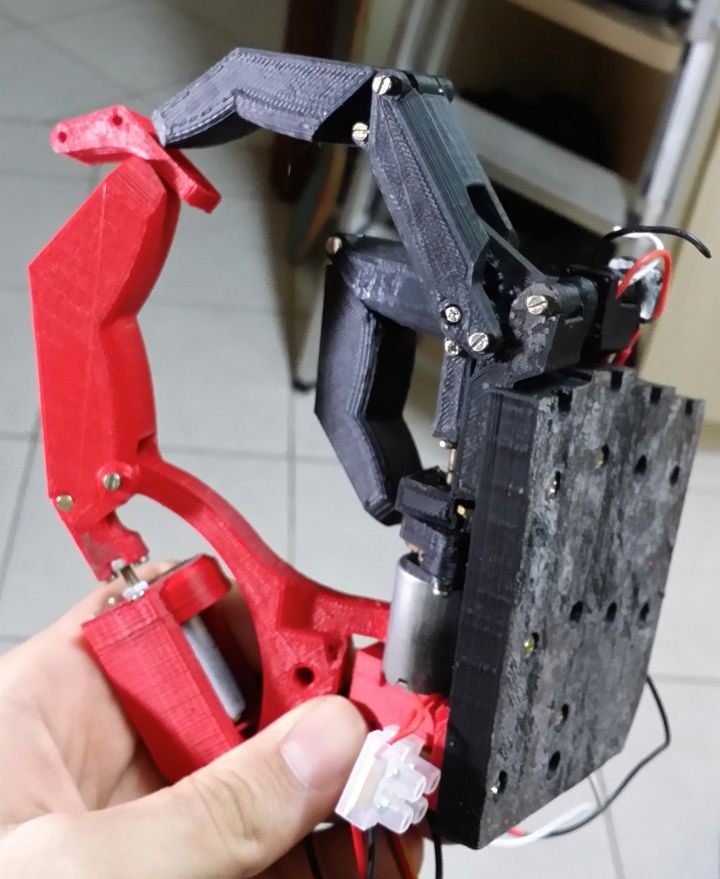

6. Robot ArmAnother interesting, but quite challenging open-source project is a 5-axes robot arm. It was designed by professional engineers and can be 3D printed out of several components. In addition to the printed parts, it requires stepper motors and Arduino. The arm uses Zortrax steppers exclusively developed for robots.

More information and design files: https://www.thingiverse.com/thing:1693444

Image source: ThingiverseMaterial and process recommendations: PLA and PC are the ideal choices for high-strength and functional components. FDM would be the best and inexpensive technology for this project.

FDM would be the best and inexpensive technology for this project.

Worried about watering your plants when you are out on a vacation? Stop worrying and start printing. This simple 3D printing design makes it easier to care of water intensive-plants. All you need in extra is a normal glass jar, fill it with water. Place your 3D printed planter along with soil and plant (seeds or saplings) on the jar. Don’t forget the drainage if your plant needs that. The advantage is that you can see the water level since the glass jar is transparent.

More information and design files: https://www.thingiverse.com/thing:4683066/files

Image source : ThingiverseMaterial and process recommendations: PETG is the most effective plastic when it comes to printing water and moisture resistant components. It is also easy to print with FDM as its filaments are commonly available.

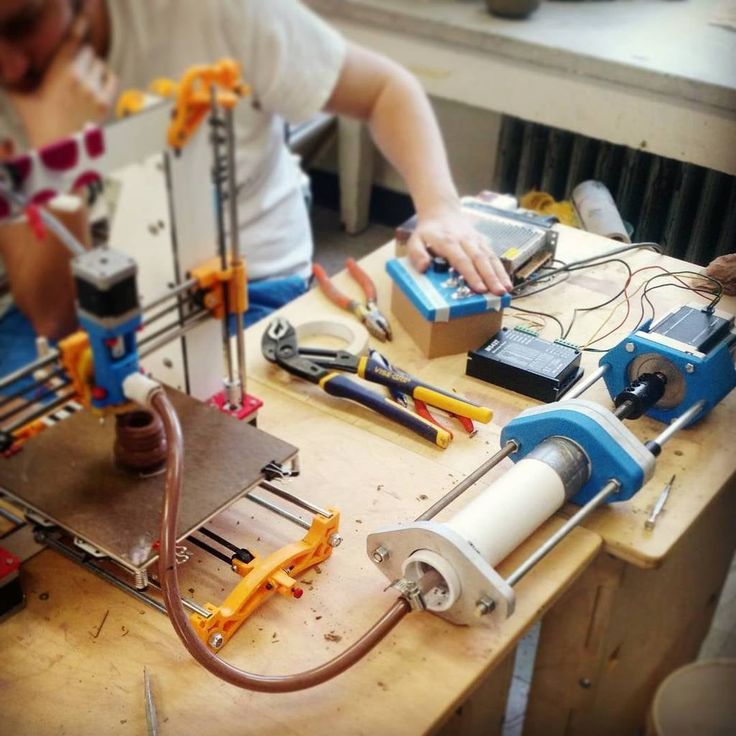

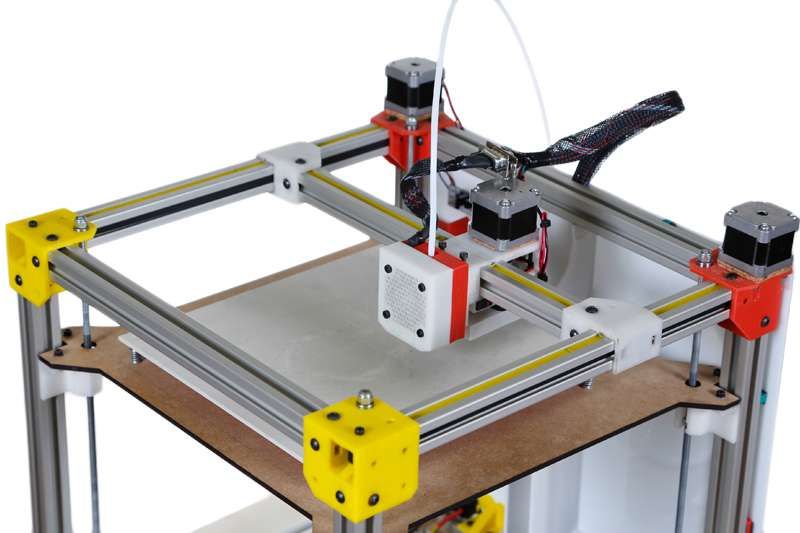

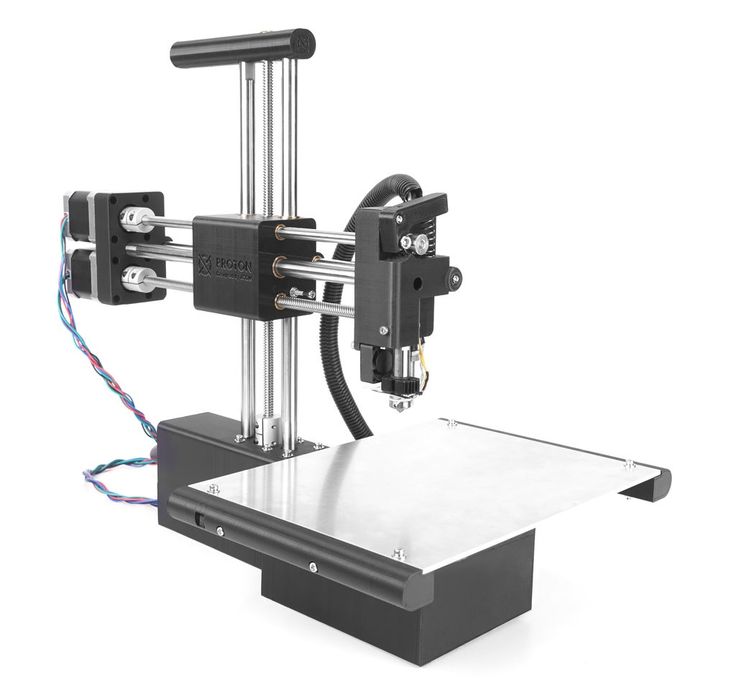

8. Drawing Machine

Drawing Machine A drawing machine is an ideal tool to use for greeting cards, formal invitations and a lot more. This partially 3D printed drawing machine makes your work fun and easy at the same time. Clamp any pen or pencil and create stunning works and cool paper arts from raster files.

More information and design files: https://www.thingiverse.com/thing:1514145

Image source : ThingiverseMaterial and process recommendations: Tough ABS, PC and PLA fits the purpose and process options can be FDM or MJF.

9. PiKon TelescopeAre you a fan of stargazing? If so, this cool project is for you. The PiKon is a 3D printed telescope, powered by Raspberry Pi so you can gaze at the stars on screen while the components are cheaper than earlier.

More information and design files: https://www.instructables.com/PiKon-Telescope/

Image Source: InstructablesMaterial and process recommendations: This project mainly uses PVC pipe as the telescope tube whereas the other components can be made out of PLA for durability and cost-effectiveness as well. FDM or MJF is recommended.

FDM or MJF is recommended.

It’s very expensive to find good equipment for Photographers. This 3D printing project for a motorised camera slider is a fine example of how 3D printing can be effective in producing items that the consumers need and can afford. It employs PVC pipes as sliders and a DC motor.

More information and design files: https://www.instructables.com/3D-Printed-Camera-Slider-Motorized/

Image source : ThingiverseMaterial and process recommendations: Nylon or PLA are the cheapest for making these plastic components and FDM and MJF are the cheap options and can print various colors with its filaments.

There are several other creative and cool open-source projects online on platforms like Thingiverse and Instructables. All these clearly show that 3D printing has already become a part of our daily lives.

Check out the Xometry Instant Quoting Engine to get quotes and order your 3D prints! If you’re curious about the affordable 3D printing materials and technologies, check out our review here.

6 Best Open Source 3D Printers 2022 (With Links To Designs)

Open source previously meant users had permission to use and modify software code, and improve it however they wished. Today, the open source philosophy and community has grown immensely to include physical products, and open source software powers billions of devices worldwide.

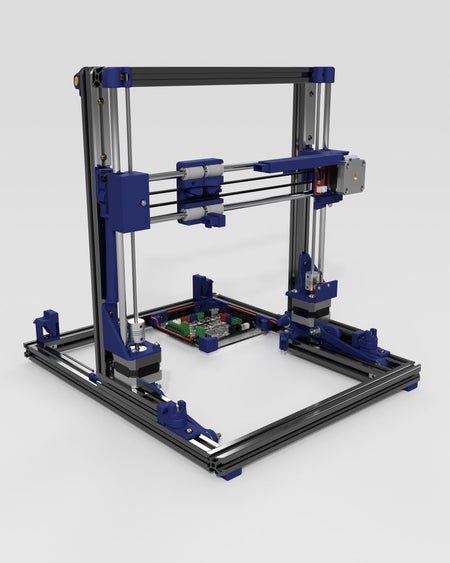

Open source 3D printers helped launch the affordable 3D printer range we have now, starting from the RepRap movement more than a decade ago. Therefore, we ranked our favorite open source 3D printers, with links to the 3D printer source files, and where to buy them.

What is open source?

Open source encourages collaboration and the sharing of improvements with the community, leading to faster innovation and better technology for everyone. Without any IP holding people back from experimenting and improving open source 3D printer designs, fantastic new developments can occur.

- A number of open source software feature in our best free 3D software guide.

- Open source 3D printer software also feature in our best 3D printer software guide.

How can open source improve 3D printers?

An example of this is the development of the Olsson Block. Anders Olsson, in trying to get his Ultimaker 3D printer to print boron carbide, accidentally created a block that made switching a 3D printer’s nozzle far quicker. Now, Olsson Blocks are used by thousands of 3D printers to reduce nozzle switching time.

Best Open Source 3D Printers for all price ranges

| Name | Build Volume (mm) | Price | Best price available at: | Alternative purchase option: |

|---|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | $169 | Amazon here | |

| Anet A8 | 220 x 220 x 240 | $160 | Amazon here | |

| Creality CR-10 / V3 | 300 x 300 x 400 | $499 | Creality Store here | Amazon here |

| Prusa i3 MK3S+ | 250 x 210 x 200 | $749 / $999 | Kit available on Prusa store here | Fully assembled on Prusa store here |

| BCN3D Sigma D25 | 420 x 300 x 200 | $3,995 | Dynamism Store here | Matterhackers here |

| Ultimaker 3 / S3 | 215 x 215 x 210 | $4,080 | Dynamism Store here | Matterhackers here |

At the start of the consumer printing revolution, courtesy of RepRap 3D printers, open source 3D printers were the norm. Passionate makers across the world modified existing open source 3D printer designs or created their own for others to improve. They were effective yet cheap, costing just a few hundred dollars back when an equivalent 3D printer would cost thousands.

Passionate makers across the world modified existing open source 3D printer designs or created their own for others to improve. They were effective yet cheap, costing just a few hundred dollars back when an equivalent 3D printer would cost thousands.

Open Source vs Closed Source 3D Printers

Makerbot, Printrbot, Lulzbot (by Aleph Objects), Ultimaker, BCN3D and several other 3D printer companies were formed championing the open source 3D printer movement. However, some have since struggled.

Printrbot closed down in July 2018 citing low sales, while Lulzbot laid off the majority of their staff in October 2019, facing closure before they were rescued and bought out. Makerbot, perhaps the most successful 3D printer company to emerge from the DIY 3D printer revolution, famously turned their back on the open source philosophy, and now their 3D printers are closed source and IP-protected. The company was acquired for $400M by Stratasys.Makerbot printers are now closed source and IP-protected.

However, some open source 3D printer companies continue to show strong growth and prove that open source is not only well-loved, but also a profitable strategy. BCN3D continue to produce high-quality printers including the Sigma D25 and Epsilon, while Ultimaker have grown to become one of the most respected 3D printer companies in the world.

We have a full list of open source 3D printers at the end of this article. First however, we have our recommendations of the best open source 3D printers with links for purchasing. We also include links to the open source 3D printer designs on GitHub.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Best Desktop Open Source 3D Printers

Monoprice Mini Delta — Introductory open source printer

- Price: $169 — Available on Amazon here

- Maximum print volume: 110 x 110 x 120 mm

- Accuracy: up to 50 microns

The Monoprice Mini Delta is known for being one of the best budget 3D printers around, with great precision (up to 50 microns), speed (up to 150 mm/s) — and it’s open source!

An open source delta 3D printer, this differing type of 3D printer allows for faster print speed, as with less weight on the print head, faster speeds and quicker acceleration can occur without overshooting. Higher print speeds can therefore be maintained without any loss of accuracy.

Higher print speeds can therefore be maintained without any loss of accuracy.

- We also have a ranking of the fastest 3D printers.

Unlike many delta printers, the Monoprice Mini Delta comes fully assembled, so you can get printing in less than an hour from opening the box. The heated bed means you can print ABS and other trickier 3D printer filaments, and you can print via WiFi as well as by USB or SD card. The sturdy metal frame improves part print quality by anchoring the printer down so external factors like vibrations don’t impact quality, and overall it’s a fantastic open source 3D printer for a low price.

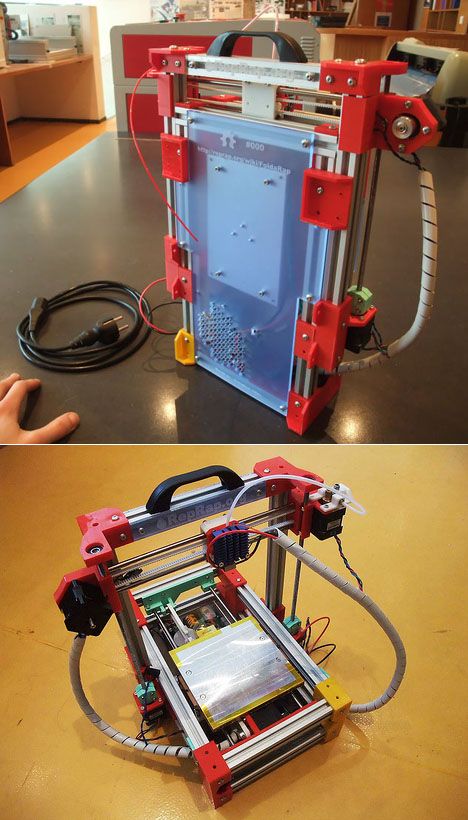

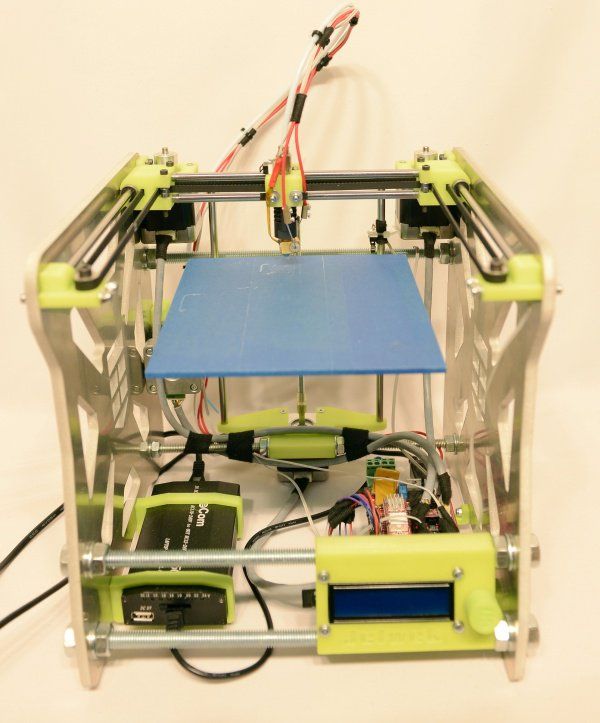

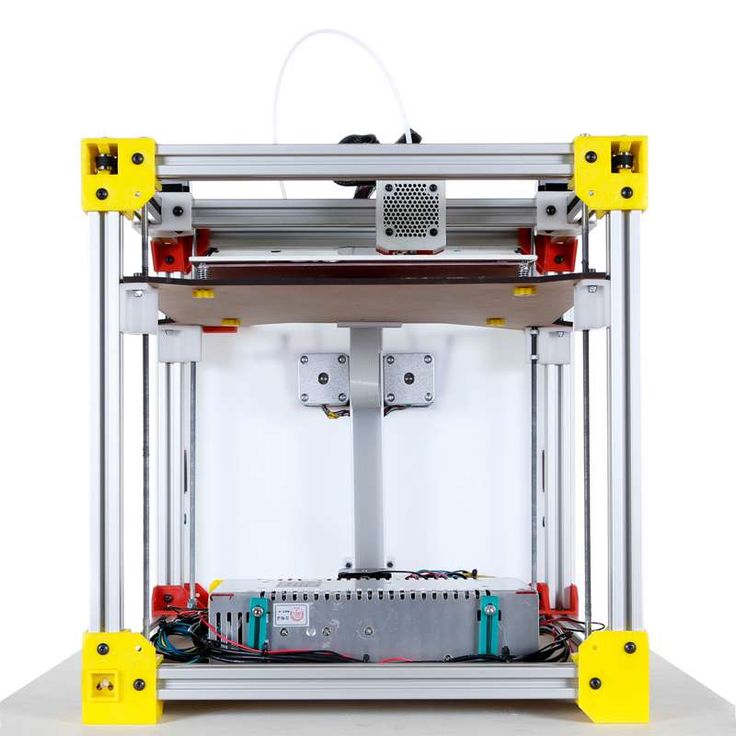

Anet A8 – Low cost open source 3D printer

- Price: $180 — Available on Amazon here

- Size: 220 x 220 x 240 mm

- Minimum layer thickness: 100 microns

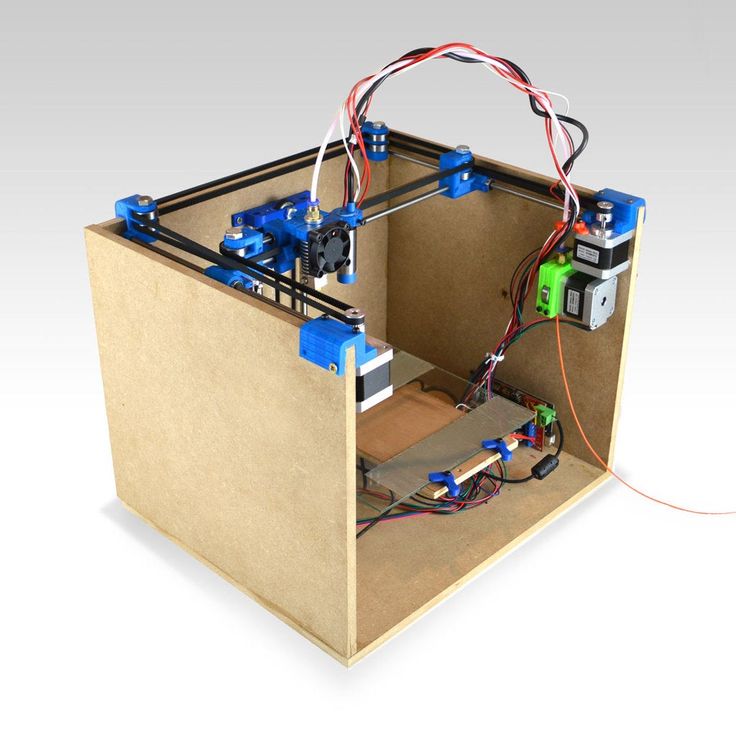

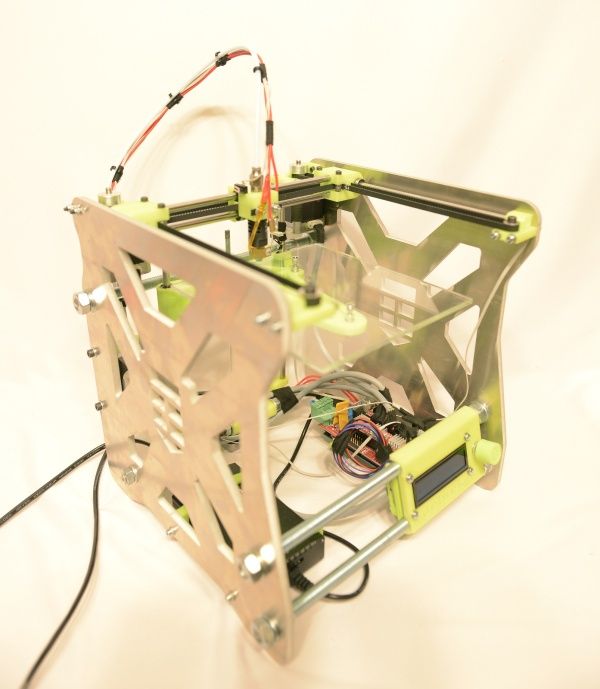

A low-cost open source 3D printer, the Anet A8 is a 3D printer kit that you will have to build yourself. It will take a few hours (up to six, actually), but once it’s up and running, not only will you be able to print magnificent 3D models, but you’ll also feel accomplished and appreciate it more having built it yourself.

Since it requires some tech know-how, this may not be the ideal 3D printer for beginners. But for those with enough experience to handle any issues and who can modify their open source 3D printer based on what they want to print, it’s fantastic for such a low price.

Once it’s up and running, it’s a fairly large 3D printer, able to print 220 x 220 x 240 mm parts without issue. It can print standard PLA and ABS, as well as wood-filled filaments and others including Nylon.

Overall, it’s reasonably reliable, accurate, and does everything you could possibly expect for such an affordable 3D printer. And with the open source firmware, you can unleash your creativity and change anything you want to improve.

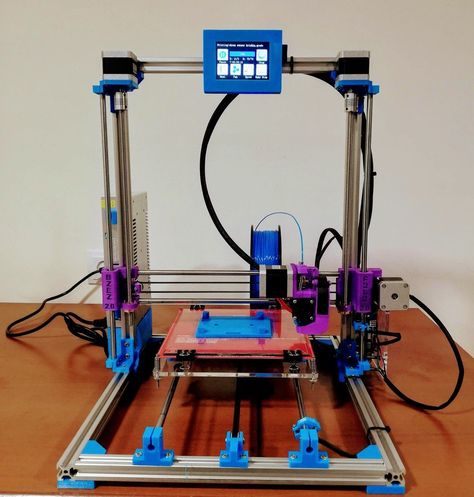

Creality CR-10 / V3 — Great Open Source 3D Printer Kit

- Price: $369 for standard CR-10 / $459 for CR-10 V3 — Available on Amazon here / Available on Creality Store here

- Build volume: 300 x 300 x 400 mm

- Minimum layer thickness: 100 microns

The Creality CR-10 has been one of the best-selling and highest-rated 3D printers under $500 of the last few years, with many iterations and updates continuing to build on the original CR-10’s success.

The original CR-10 is now fully open source, with Creality 3D having released all the files on their GitHub for anyone to view. Though this CR-10 is being phased out in favor of the newer CR-10 V2 models, many 3D printer parts will be identical across models, and the CR-10 V2 files are also available.

The open printing area means there is no protection from unpleasant fumes, and this open source 3D printer can also be fairly noisy, so you may want to keep it in a separate room from the one where you work or relax in. The quality and reliability of the Creality CR-10 however shines through and is the main reason for its popularity, and overall it’s a great open source printer.

Prusa i3 — best open source 3D printer under $1,000

- Price: $749 as a kit — Available on Prusa store here / $999 fully assembled — Available on Prusa store here

- Build volume: 250 x 210 x 200 mm

- Precision: 50 microns

Whereas some desktop 3D printer brands have turned their backs on open source, Prusa is still committed to the open source 3D printer philosophy, and you can access everything you need on their GitHub.

Known as one of the best 3D printer kits ever made, Prusa 3D printers have won boatloads of awards. Solid printing speed, accuracy, great reliability and compatibility with a variety of filaments (especially with the Multi-Material 2.0 upgrade) make it competitive with printers costing far more.

- The Prusa can be upgraded to print 5 colors simultaneously. You can read more in our color 3D printer ranking.

Designed to save you hassle and time, the Prusa i3 printers will save your current progress in the event of a power outage so you can resume where you left off, it will pause in the event of filament running out so the print doesn’t fail, and can even detect when the filament is clogging. Overall, it’s a fantastic open source 3D printer and we highly recommend it.

Professional Open Source 3D Printers

BCN3D Sigma D25

- Price: $3,995 — Available on Dynamism Store here / Available on Matterhackers here / 3DPrima Europe here

- Build volume: 420 x 300 x 200 mm

Barcelona, Spain-based BCN3D remain committed to open source 3D printing since their inception in 2012. All their printers have open source 3D printer files for firmware, process, software, and more published on the BCN3D GitHub.

All their printers have open source 3D printer files for firmware, process, software, and more published on the BCN3D GitHub.

BCN3D printers are known for their reliability, and the Sigma D25, their newest printer, is no different. Featuring their signature IDEX dual extruder system which can print in two special modes, Mirror and Duplication, each extruder can function separately, as either a multi color 3D printer, or for printing with a soluble filament for supports that can be easily removed.

Whereas the Sigmax R19 has a completely closed, enclosed build chamber, the Sigma D25 is semi-open. It’s easy to use, reliable, durable with its high-quality stainless steel frame, and prints very consistently and accurately at up to 50-micron layer heights on E3D hot ends. D25 models now have access to WiFi 3D printing, and can automatically install new firmware updates to keep your printer up to date.

Any keen makers or small businesses looking to print fun projects or accurate plastic prototypes, that is also open source, may find the Sigma D25 the perfect 3D printer for you.

Ultimaker 3 / S3

- Price: $4,080 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 215 x 215 x 210 mm

12 months after the Ultimaker 3’s release, the Dutch company released the hardware source files for both the Ultimaker 3 and Ultimaker 3 Extended here. This was no surprise; Ultimaker had previously released the files to other printers including the Ultimaker 2 Go, leading to innovation breakthroughs such as the Olsson Block. Ultimaker also develops Cura, the popular and open source 3D slicer.

Known as one of the best 3D printers of its generation, the Ultimaker 3 is incredibly accurate and widely adopted for rapid prototyping precise plastic parts. It comes fully assembled and almost ready to print; you can get it all started within just a few minutes.

It works with Ultimaker’s open source 3D printer software, Cura, and features a built-in camera for monitoring your print’s progress remotely. It’s not the fastest, but prints with flawless accuracy for an FDM 3D printer, and the dual extruder also adds to its offering.

Ultimaker has not yet (as of August 2021) released any source files for the Ultimaker S5 or S3, but some of the parts are near identical to the Ultimaker 3.

- BCN3D Epsilon

- Lulzbot Mini

- Taz Pro

- BigFDM

- Creatable 3D

- Hydra Research Nautilus

Other articles you may be interested in:

- How to get a free 3D printer

- Open source CAD software

Created a budget open source 3D printer for working with metal

Navigation

Sergey Skladny 03.12.2013 News 0

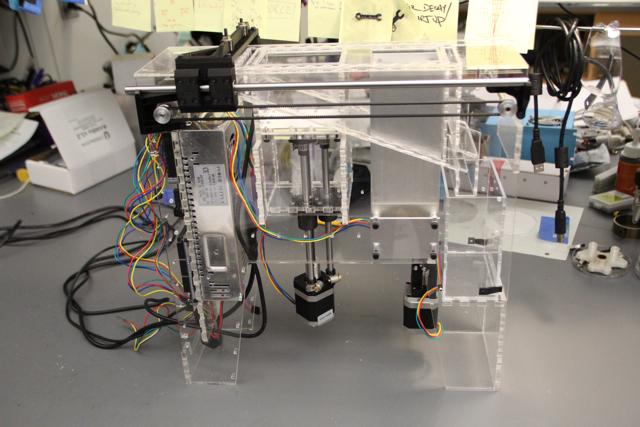

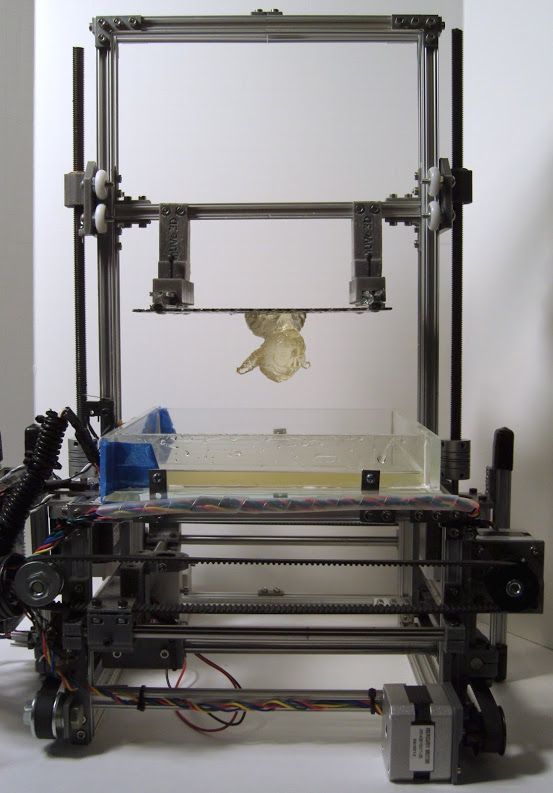

Despite the fact that the technology of ultra-precise 3D printing of metal products has been around for several years, and even actively used by many progressive manufacturing enterprises in the heavy industry, its cost until recently was so high that private users could not even dream of working with it . Only the printers themselves cost more than half a million dollars, and not everyone was suitable for raw materials.

However, those times seem to be over, as a group of young experimental scientists from the University of Michigan, led by engineering professor Joshua Preece, have managed to create their own 3D printer capable of printing metal products. The best part is that talented developers spent no more than one and a half thousand dollars on their creation. It is worth noting that their invention is open source, which will allow hundreds of enthusiasts from all over the world to create a lot of projects, which then each person with a similar printer can download and recreate at home in a matter of minutes.

According to the authors of the project, this breakthrough will bring humanity as close as possible to a futuristic future, which science fiction writers could only dream of a few years ago. Using inexpensive but effective 3D printers, every person will eventually be able to make almost any item at home. And the benefit of this invention for the leaders of small and medium-sized businesses cannot be overestimated. For example, the owner of a car repair shop will no longer have to order some rare parts, and make his own customers wait, it will be enough for him to print them on his printer.

For example, the owner of a car repair shop will no longer have to order some rare parts, and make his own customers wait, it will be enough for him to print them on his printer.

At the moment, the development team is still finishing their project, because, despite the successful testing, they still have a lot of work to set up.

In the meantime, they are actively uploading all their developments and drawings to the network, so that any enthusiast can easily repeat their work and get a personal metal 3D printer right now. The author of the project is sure that in the near future there will be specialists in the world who will be able not only to repeat, but also significantly improve their product, which means that we will soon have a real breakthrough in many areas of production. As a result, all this will certainly lead to a total reduction in prices for many products, and the sphere of consumer goods will become much more accessible for every person without exception.

About Sergey Foldy

View all posts by Sergey Skladny →

3d printers

Command line calculator

Lesson 10: Extracting data from attributes in AutoCAD

Objects printed on open source 3D printers are stronger than on professional equipment

Archive

Subscribe to the author

Subscribe

Don't want to

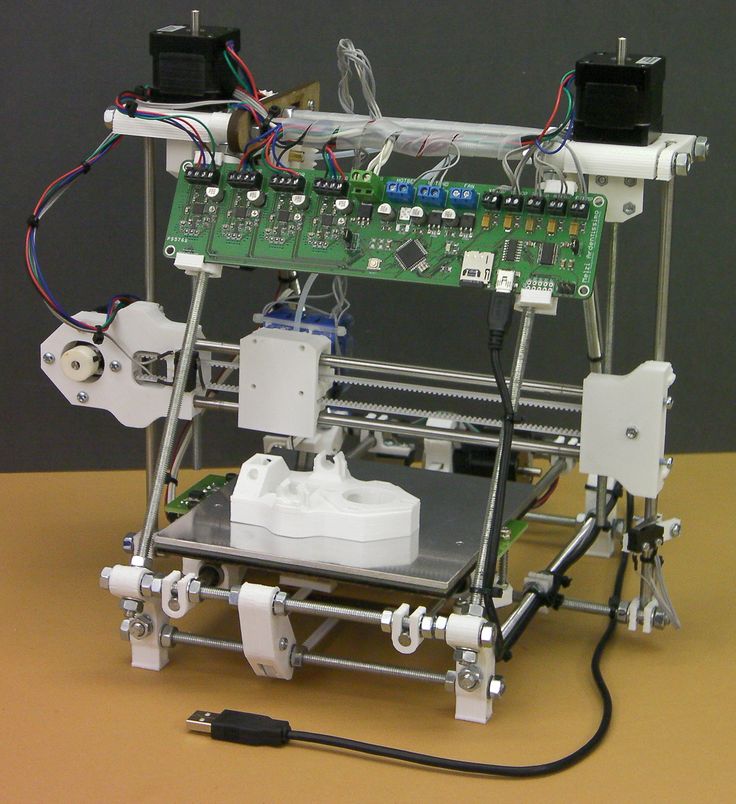

The idea of a manufacturer who can create whatever he wants, independently and at home, is becoming more and more real. The development of the low-cost RepRap, an open source, self-replicating, high-speed 3D printer, has made 3D printing technology accessible to everyone. Mass-produced versions of the RepRap, such as the Lulzbot TAZ, will cost customers $2,000 for a complete device and $500 for a set of parts that you need to assemble yourself.

It is believed that amateur 3D printers, which can easily reproduce any shape and object, can only create fragile plastic knick-knacks, and it does not matter that the finished products look exactly like objects printed on professional equipment. Interestingly, parts printed on RepRap are not inferior in quality to parts printed on professional 3D printers, because the material for printing is the same?

Most owners of amateur printers simply do not have the opportunity to test the resulting objects for strength. And yet no one thought about the mechanical properties of objects created on RepRaps.

“We were also curious. The printed products seem solid, but we wanted to develop reliable scientific equipment for developing countries, so we needed hard, hard numbers,” said Joshua Pierce, associate professor in the Department of Materials Science, Engineering, Electrical and Computer Engineering, Michigan Technological University.

Pierce and his team conducted a study on the mechanical properties of parts printed on open source 3D printers. Standard testing methods were used during the course of the work, with the exception of changes in operating conditions, which were fully consistent with the domestic environment in which such printers are used.

Standard testing methods were used during the course of the work, with the exception of changes in operating conditions, which were fully consistent with the domestic environment in which such printers are used.

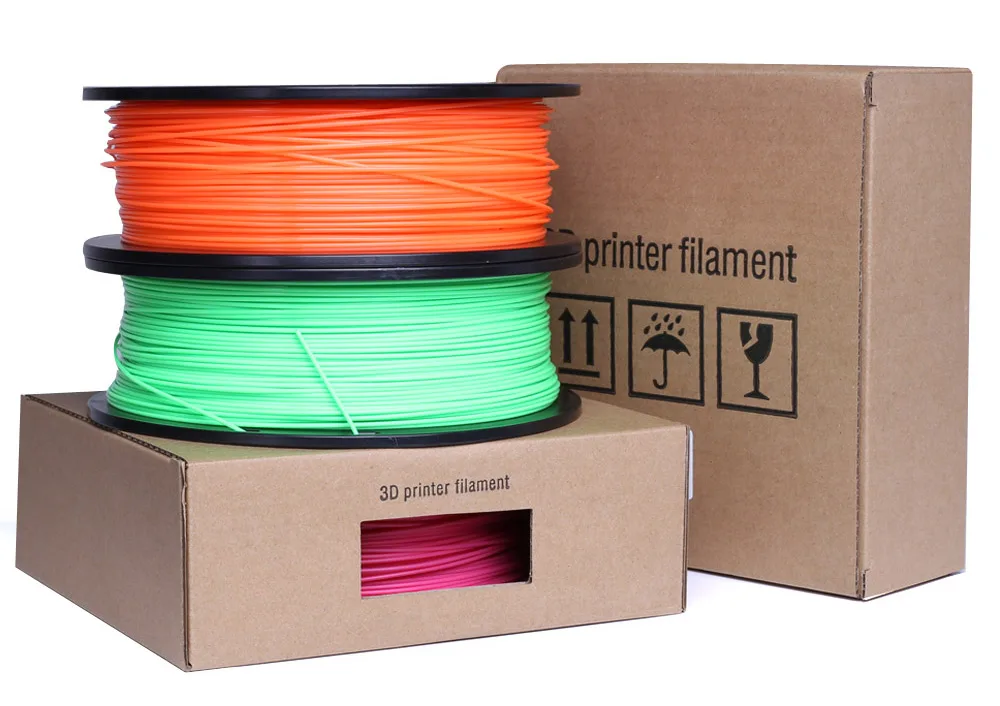

Today, RepRap 3D printers primarily print objects from acrylonitrile butadiene styrene or ABS (the plastic used to make Lego bricks) and polylactide or PLA, a biodegradable plastic that is made from corn. The study assessed the basic tensile strength and elastic modulus of parts printed on a conventional open source 3D printer under realistic working conditions. As a result, it was found that the average strength index is 28.5 MPa for ABS and 56.6 MPa for PLA, and the average elastic modulus is 1807 MPa for ABS and 3368 MPa for PLA.

Pierce says: “The results of the study are clear. Parts printed on inexpensive open source RepRap 3D printers can be considered as mechanically functional as parts made on professional printers. In many cases, they are even stronger than reported. ”

”

“We only tested tear strength on a flat print bed. Now we want to study the interlaminar bond strength.” The researchers plan to continue their work and test other polymers, as the makers of the RecycleBot and commercial open-source printers such as the Filastruder are encouraging consumers to use recycled plastic as a printing fiber.

“The results of our work prove that digital mass production using free 3D printers is technically possible,” concludes Pearce.

You can view the results of the study “Mechanical Properties of Open Source 3D Printed Parts under Realistic Working Conditions” by B. M. Timrak, M. Kreiger and J. M. Pierce.

Article prepared for 3Dtoday.ru

Follow the author

Subscribe

Don't want

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

So, you are thinking about the possibility of making money on 3D printing.