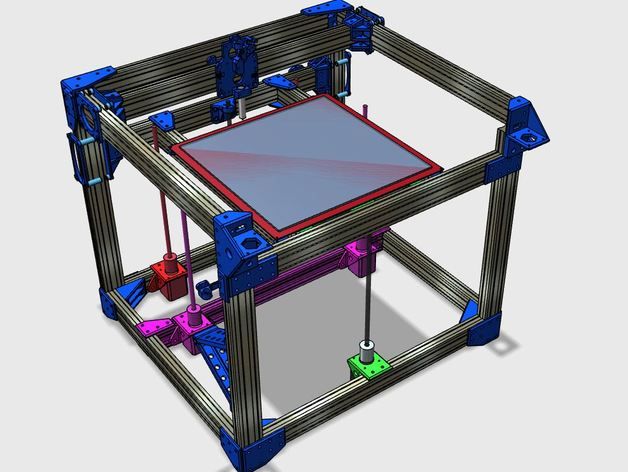

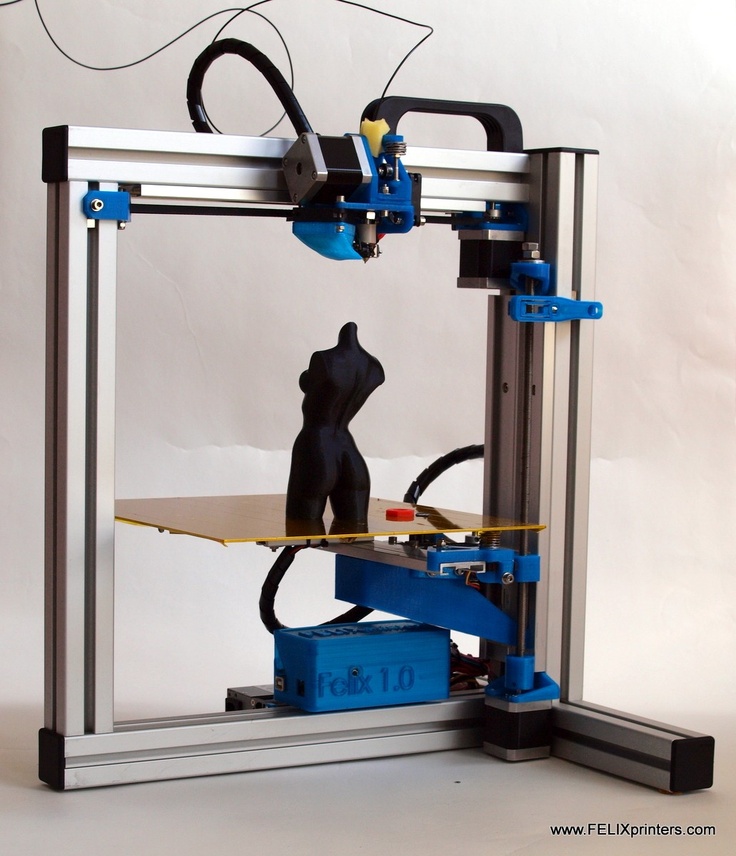

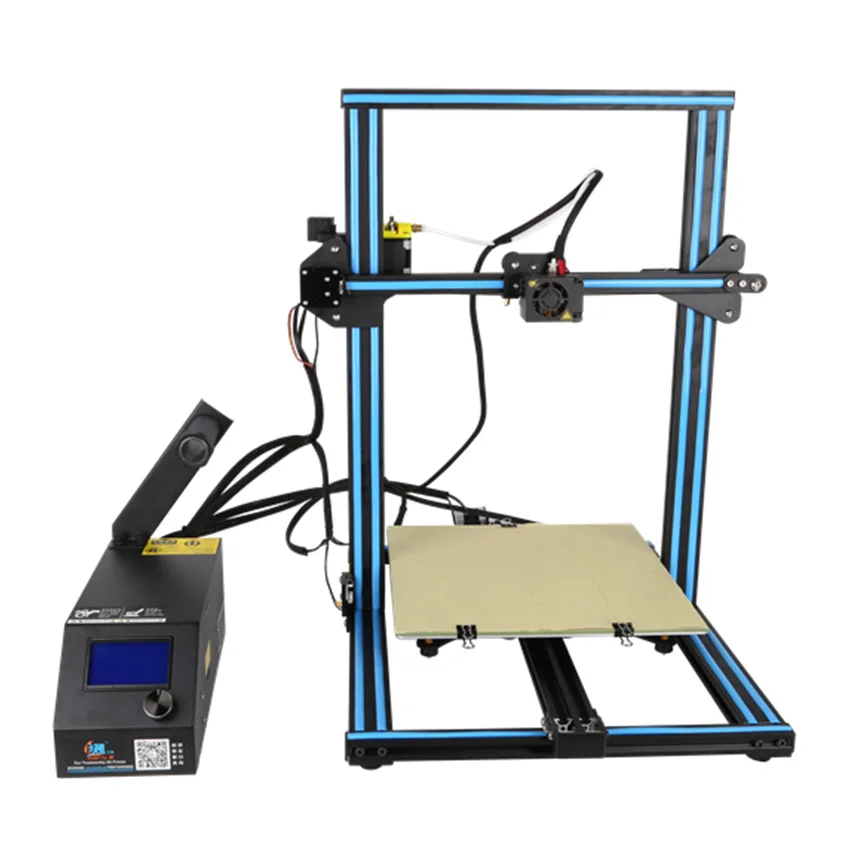

3D printer 300x300x300

The Best Cheap 3D Printers for 2022

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

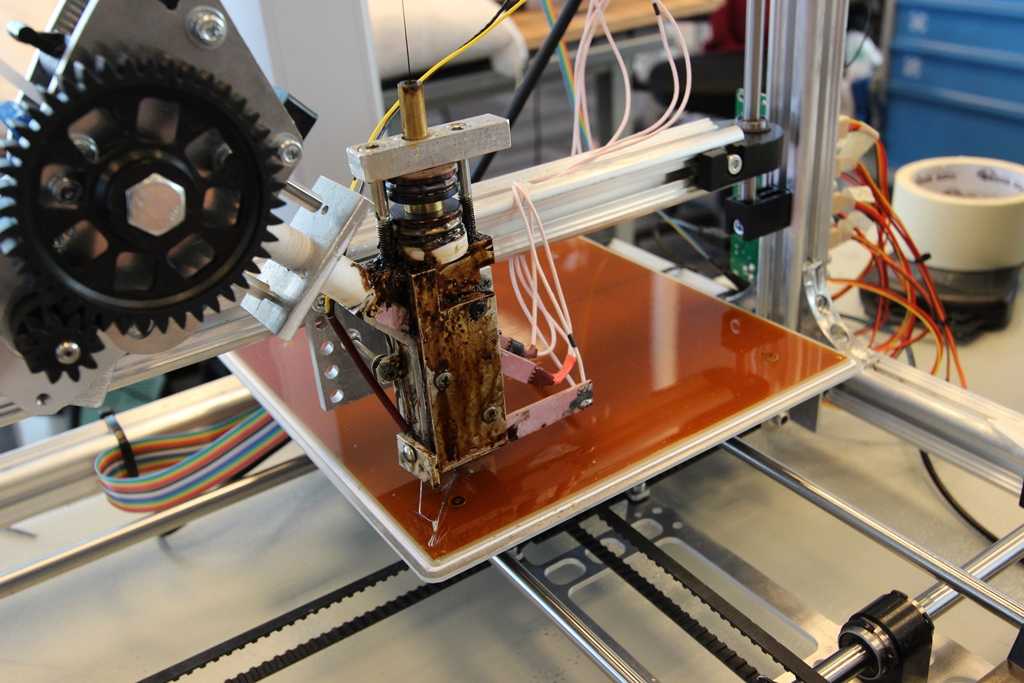

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

More About Our Picks

Original Prusa Mini

4.5 Outstanding

Best Overall Budget 3D Printer

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

Pros

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

Cons

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

4.0 Excellent

Best Budget 3D Printer for Schools, Community Centers

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

Pros

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

Cons

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

4.0 Excellent

Best Budget 3D Printer for Children

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

Pros

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

Cons

- Tiny build area

- Not ideal for importing 3D files created elsewhere

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

4. 0 Excellent

0 Excellent

Best Budget 3D Printer for Beginners, Non-Techies

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

Pros

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

Cons

- Tiny build area

- So-so print quality

- Mere one-year warranty

Read Our Monoprice Mini Delta V2 3D Printer Review

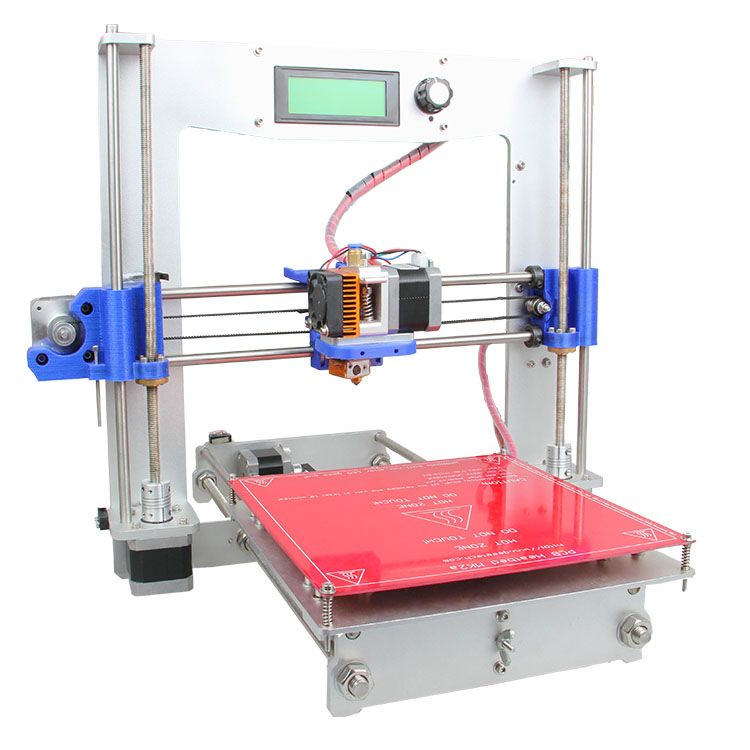

Anycubic i3 Mega S

3.5 Good

Best Budget 3D Printer With an Open Design, Big Build Area

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

Pros

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

Cons

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

3.5 Good

Best Budget 3D Printer for the Biggest Build Area Possible

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

Pros

- Relatively large build area

- Automatic bed leveling

- Simple assembly

Cons

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

Read Our Anycubic Vyper Review

Creality Ender-3 V2

3. 5 Good

5 Good

Best Budget 3D Printer for Tinkerers and DIY Types

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

Pros

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

Cons

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

3.5 Good

Best 3D Printer for the Very Tightest Budgets

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

Pros

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

Cons

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

3.5 Good

Best Budget 3D Printer for Dabbling in Small Objects

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

Pros

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

Cons

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

3.5 Good

Best Budget 3D Printer With Closed Design, Roomy Build Area

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

Pros

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

Cons

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

3. 0 Average

0 Average

Best Budget 3D Printer for Cheap Filament

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

Pros

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

Cons

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

Read Our Monoprice Voxel 3D Printer Review

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together. ) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

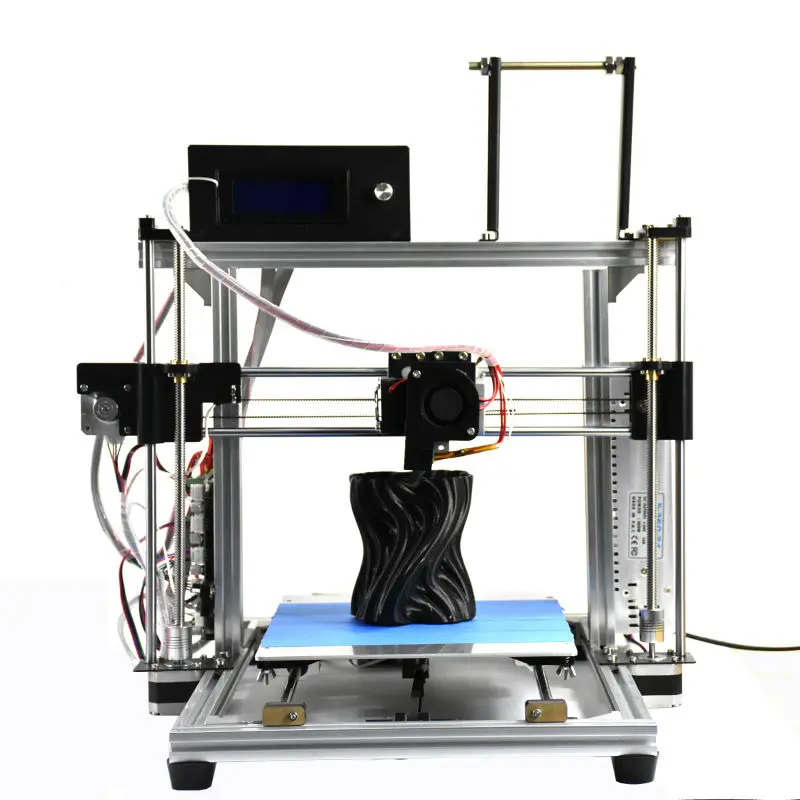

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

3d printer 300x300x300 - Buy 3d printer 300x300x300 with free shipping

Brands

SEE MORE

Working Type

Plug Type

Printing Size

3D Printer Function

Application

Bag Type

-

Home

- "" 519 Results

Price -

OK

Ship From

1 2 3 4 . .. 9

.. 9

Total 9 pages

Go to Page

Go

Confirm your age

You must be at least 18 years of age to enter this section.

I AM UNDER 18 I AM OVER 18

Review of the 3D printer Zortrax M300

Home / Blog / 3D reviews / Review 3D Printer Zortrax M300

01/23/2018

Content

In 2011, the development of the M200 3D printer started, and in 2013, the Polish company Zortrax became known throughout the 3D world thanks to its Kickstarter campaign. The aim of the campaign was the launch of the M200, which promised ease of use and professional quality. The campaign raised $180,000. In 2014, the first Zortrax store was opened, and at the moment the brand is already represented in 50 countries with 160 partners.

The Zortrax M300 is the older brother of the M200. In the M300, the print area has become much larger (300x300x300 mm). Zortrax M300 is a really big printer for printing large items =)

Initially, Zortrax was optimized for printing only with its own production of plastics. Despite the rather large assortment (at the moment, Zortrax has about 9 types of plastic), many were repelled by the impossibility of printing with third-party plastics. In the new versions of Z-Suite proprietary software, the developers have solved this problem - the ability to print materials from other manufacturers has been added.

Appearance

The printer is made of durable aluminum and looks very solid and reliable. Despite the impressive size, there were no distortions, cracks or backlash anywhere. Build quality is top notch.

Zortrax M300 looks exactly the same as the M200, differs only in size) The same strict black color, smoothed corners. The design of the printer can be called minimalistic and concise.

The printer is controlled through a small display with the already familiar joystick - twist)

Equipment

Perfect set:

- Spool holder.

- Material guide tube and fasteners.

- 2 spools of 2kg Zortax branded material.

- Power cable.

- SD card and card reader.

- Protective gloves.

- Knife.

- Scalpel.

- Hexagon set.

- Nozzle wrench.

- Nozzle cleaning strings 0.4 and 0.35.

- Wire cutters.

- 2 spatulas - large and small.

- Tweezers.

- Lubricant for printer moving parts.

- Safety goggles.

- Side panels and door.

A very worthy set. Zortrax made sure that the user has everything they need at hand and does not have to buy something extra. Presented as many as two coils of plastic, we had HIPS and PETG in the box. Most likely, the types of plastic for printers are selected randomly. Even the nozzle cleaning needle is available in 2 versions - for a nozzle with a diameter of 0.4 and 0.35 (by default, a 0.4 mm nozzle is installed on the printer).

Even the nozzle cleaning needle is available in 2 versions - for a nozzle with a diameter of 0.4 and 0.35 (by default, a 0.4 mm nozzle is installed on the printer).

Another important difference from the M200 is that the M300 comes with plastic side and front panels.

Kinematics

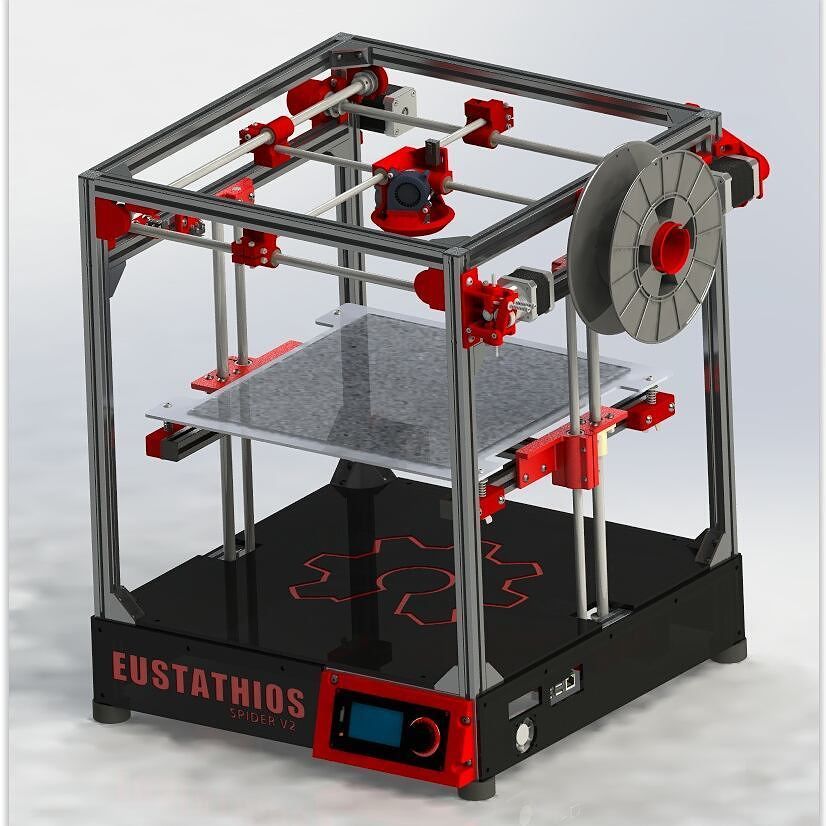

The kinematics of the printer is an enlarged copy of the famous Ultimaker. It turned out to be a win-win solution.

Along the Z axis, instead of the already familiar trapezoidal screw, a powerful ball screw and guide shafts are installed. I was very impressed with the thickness of the shafts - almost with the index finger.

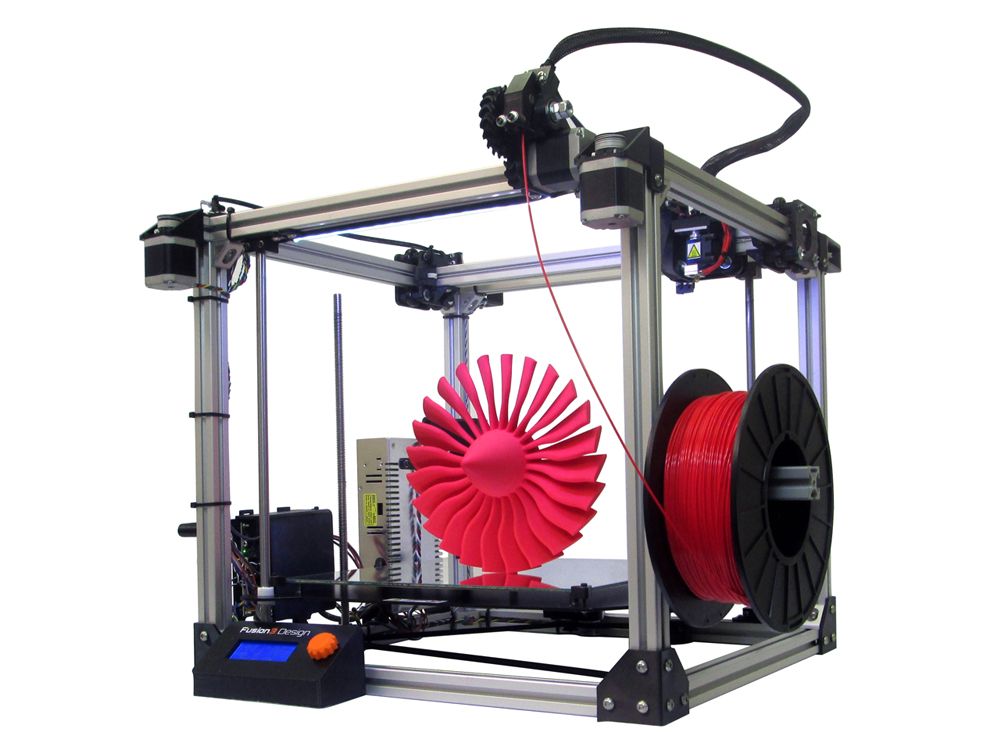

The extruder is exactly the same as on the younger brother Zortax M200. All-metal with a maximum heating temperature of 280 degrees. The “cube” of the heater into which the nozzle is screwed is fixed. A trifle, but, thanks to this, the nozzle is very easily unscrewed, and you do not have to look for ways to fix the heater.

The feed motor is located on the print head. That is, the printer has a direct-feed plastic mechanism. Of course, this solution makes the print head heavier, but it allows you to print all types of plastics, including soft Flex and rubber.

That is, the printer has a direct-feed plastic mechanism. Of course, this solution makes the print head heavier, but it allows you to print all types of plastics, including soft Flex and rubber.

The print platform is a bit unusual - perforated, like on UP printers.

The advantage of this solution is very good adhesion. There is no need to use glue or stickers to keep models from peeling off during printing.

The only inconvenience is that you will always have to print on a substrate (raft).

The board is made and designed specifically for the printer. All wires are shielded.

Preparing for work

After unpacking the printer, the first step is to prepare it for printing:

- connect the extruder cable;

- install and connect the printing platform;

- calibrate the printer.

Connecting the cable is not difficult - you need to open the top of the extruder and plug the cable into the connector. It's nice that the cable is additionally securely fixed with latches.

It's nice that the cable is additionally securely fixed with latches.

We connect the connectors on the platform and install it on magnetic fasteners.

When turned on, the printer asks to download a file from the manufacturer's website and save it to a USB flash drive. Without this, the printer will not start. The M300 does not support Wi-Fi connection, files can only be transferred via a USB flash drive.

After downloading, restart the printer. Everything is working)

The printer menu is ascetic, but very convenient. There are points for loading, unloading plastic and calibration.

Next, we calibrate.

The printer is calibrated "hot". We are waiting for the printer to heat up the nozzle and the table. After that, following the instructions on the screen, we calibrate. The printer will alternately poke the nozzle into the metal squares on the platform and ask you to unscrew or tighten a certain screw at the bottom of the platform.

Calibration completed, you can start printing =)

SW

Zortrax Z-Suite proprietary slicer is used as printer software. The printer will not work with other slicers.

To download and run the program, you will have to enter the serial number of the printer.

Z-Suite has a very nice and intuitive interface. We launch the program and select our Zortrax model.

We load the model and place it on the table.

Preparation for printing takes place in several stages:

- Model analysis. The slicer will show the weak and problem areas of the model.

- Show support. Here you can select the overhang angle of the model, at which the support will be set, and slightly edit the support. Support is edited by "blocks". You cannot add or remove support pointwise.

- Print settings. Here you can choose either a ready-made profile for native Zortrax plastic or set your own settings for any material.

The range of settings is very decent.

The range of settings is very decent.

- Preview. In preview mode, you can add pauses at different heights. This will come in handy if you want to print a multi-colored model.

The file is saved not in the usual GCode format, but in the native ZCode format.

Totals

We have not had time to conduct printed tests yet, but now the Zortrax M300 pleases with its thoughtfulness. The M300 impresses with its reliability and competent design, and, of course, with its really large working area - 300x300x300. The Z-Suite software also pleased us with a friendly interface and the presence of all the necessary functions. Unfortunately, the printer does not have a Wi-Fi connection and the files will have to be transferred via a USB flash drive. The complete set of the M300 includes everything necessary for comfortable work, including material for initial work. The M300 is practically omnivorous, which makes it a good helper for large and small productions.

#3D reviews

Share

all materials

Do you have any questions?

Our specialists will help you with the choice of 3D equipment or accessories, consult on any questions.

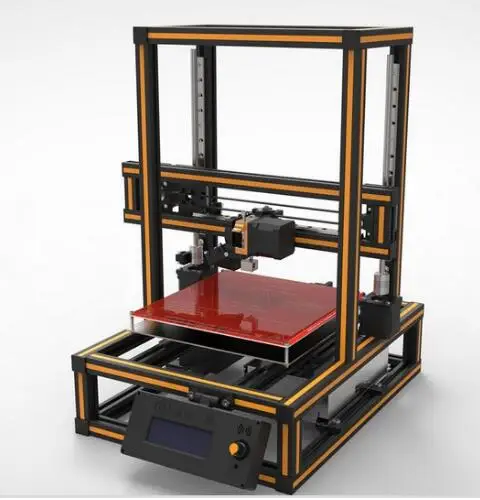

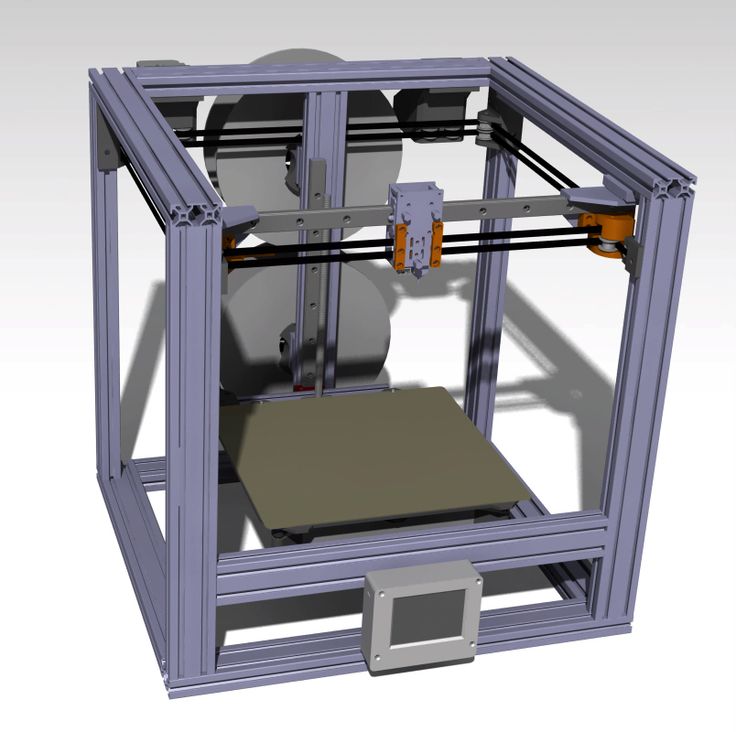

Prime X 3D Printer - 3DPrinter

Prime X 3D Printer

The new Prime X multifunctional 3D printer has a large number of additions to implement the most unusual tasks!

This is a unique 3D printer that can become a full-fledged CNC machine in a matter of minutes, performing laser and engraving work!

In the wake of new technologies and constant progress in the field of 3D printing, 3DPrinter presents its new Prime X printer. This printer combines all 4 years of our company's production experience: improved components are used, the wishes of our customers and new developments are taken into account engineers. The Prime X 3D printer is your new 3D printing assistant.

- Reliable and precise rail guides,

- Two-zone blowing with two turbines,

- All-metal extruder and housing ,

- Closed mechanics ,

- 6-point platform ,

- Possibility to install graphic and touch screen ,

- Available with one, two or three extruders ,

- Filament Break Sensor Support ,

- Color touchscreen display in tandem with MakerBase electronics provide stability and comfort when using your 3D printer.

- Modular extruder design with replaceable heaters, thermistors and fans ,

- Possibility of installation: laser, engraver and chocolate extruder .

Having become the owner of a 3D printer with one extruder, you can expand its functionality by two/three extruders at any time! Laser! Engraver! B even - a chocolate extruder!

*Attention! The color of the case may vary depending on the party

to learn about all the capabilities of Prime X

3D Prime Prime X has several setting options

3D Printer Prime X Standard - one extruder

9000characteristics of the characteristics of the characteristics of the characteristics

Features

Print technology : FDM

*Print area : 300mm * 300mm* 300mm

Z-axis print accuracy : 50-300µm

Print speed : 10-200mm/s

Extruder maximum heating temperature : 275

Maximum heating temperaturetable : 120

Number of extruders : 1

Nozzle diameter (default) : 0. 4 mm

4 mm

Support filament diameter : 1.75 mm

Automatic print recovery after emergency stop : Yes

Input method : 3.2″ touch screen

Interface language : Russian

Body material : steel

Airflow model : Yes

Printer dimensions : 500*500*500 mm

Power consumption : max. 450 W

*Printable area may differ from the maximum size within 10% depending on the configuration, limit switches and 3D printer table settings

Do you want something special? With a mixing extruder, you are guaranteed the most daring 3D print designs.

Mechanics - CoreXY System

Ultra Reliable Linear Motion System: The Z-axis is fixed by 4 hardened shafts that distribute the pressure of the large platform as efficiently as possible. Two 15mm machine rails are responsible for the stability of the extended X-axis. The Y-axis crane beam, on the contrary, is lightened with a light flat rail in order to reduce reversible loads when the extruder moves quickly.

Huge aluminum platform with 6 suspension points. Each corner of the platform rises in sync with the main motor, which ensures perfect stability of the platform and eliminates any vibration in the 3D printing area.

The printer is equipped with two E3D v6 extruders and circular airflow.

I would like to mention airflow separately. To achieve the maximum quality of 3D printing, 3 high-speed turbines are working for you at the same time. Thanks to a powerful cooling system, the temperature of the radiators rarely rises above 30 degrees, which ensures the most stable supply of plastic during printing. Such a reliable and redundant system has not yet been used in any 3D printer.

Metal clamping mechanisms have proved themselves from the best side - reliable and durable! Paired with E3D aluminum heatsinks, this extruder demonstrates the best performance on the market.

Direct Drive Feeding System: plastic is fed inside a Teflon tube fixed on a movable cable channel. No more tubes protruding beyond the 3D printer case, everything is securely and compactly placed inside the Trident

No more tubes protruding beyond the 3D printer case, everything is securely and compactly placed inside the Trident

3D printer case A large color touch screen in tandem with MakerBase electronics ensures stable operation and comfortable operation of your 3D printer. Quick start guide for 3D printer:

View Fullscreen

Video

First run 3D printer

Prime X printer with Engraver.

Laser engraver is an excellent solution for companies specializing in the manufacture of souvenirs, seals, art gifts, promotional items, image products, leather and fur accessories, parts used in modeling, premium commemorative plaques, packaging, accessories, toys, shoes and many other products where high-precision material processing is required, engraving of cylindrical and conical products.

This laser engraver is applicable to processing various different materials such as paper, cardboard, wood, plywood, bone, horn, leather, fabric, acrylic, organic plastics, rubber, glass, anodized, coated or painted metals, etc.

Remember that in the room where the 3D engraver is working, if the user does not cover the working area with a lid, it is necessary to wear protective glasses.

This is a complete CNC machine with a working area of 300*320mm.

Suitable for both entry level and professional engraving applications.

Just a few steps to get started:

- Buy Prime X replacement head

- Remove Head with FDM technology extruder

- Fits replacement head with engraver

- Connect it to a computer (via USB), turn it on and get the finished product.

Features Engraver

| Shade rendering: | Spot, Amplitude, Hybrid. |