3D printer supplier philippines

3D Printer Philippines - Norde International

Full Color 3D Printers

Stratasys J55 Prime

Unmatched Design Freedom, Brilliant Color 3D Printing.

- Multiple materials can be loaded at one time.

- Fast, flexible colors can be printed directly from the color information.

- Creates custom jigs, assembly fixtures and tools with ultra-fine accuracy and smooth surfaces.

MORE INFO

Stratasys Objet30 Pro

Desktop Sized High-end Rapid Prototyping.

- Offers great material capacity and hot-swapping capability, empowering you to maximize workflow efficiency.

- Ability to combine up to three base resins in a single build.

- Creates parts that simulate over molding and produces three-material prototypes with minimal post-processing efforts.

- Achieves impressive detail with your choice of 17 photo polymers that offer a wide range of material properties — including rigid and flexible, transparent and simulated polypropylene.

MORE INFO

Stratasys Objet 260 Connex3

Unleash Your Creativity.

- Prints any type of model you may need: from rigid to flexible, transparent to opaque, neutral to vibrant, standard to bio-compatible and durable to high temperature.

- Allows you to be more versatile in your prototyping creation.

- Produces smooth three-color gradients and vivid multi-color models based on the color information in your original CAD file.

- Enables you to create precise threading or crisp lettering directly from CAD.

MORE INFO

Stratasys J720 Dental

Expand your lab’s capabilities with full-color, multi-material 3D printing.

- Prints multiple case types, even multiple materials, at the same time, all on the same tray for faster production compared to smaller single-material printers.

- Increases patient case acceptance and reduce C&B remakes with realistic and accurately colored models of the patient’s mouth.

- Print more cases per shift with 1.75X greater throughput than competing SLA and DLP printers.

MORE INFO

Stratasys J700 Dental

Dedicated to the high-volume production of clear aligners.

- Optimized for out-of-the-box clear aligner implementation.

- Balances speed, quality, accuracy and repeatability with a competitive cost-per-arch.

- No secondary curing so your molds are not compromised by handling or contamination.

- Plug-and-play so no engineering or customization needed to achieve quality aligner arches.

- Capable of 24/7 production for truly lights-out manufacturing.

MORE INFO

Stratasys Objet260 and Objet500 Dental Selection

Achieve maximum versatility in a compact size.

- Increased productivity and capacity.

- Realistic accuracy and detail.

- Ease of use.

- Environmentally safe dental materials.

MORE INFO

Stratasys Objet 260 Dental

Maximum Versatility and Professional Grade Performance.

- Dramatically cut production time by building diverse models on one tray and loading multiple materials at once.

- Ease of use.

- Runs a clean, quiet process.

- Environmentally safe dental materials.

- Individually sealed cartridges with specific lot numbers provide peace of mind and quality standards that your business can count on.

MORE INFO

Stratasys Objet30 Orthodesk

The Digital Future of Dentistry.

- Fully digital process eliminates the need for storing bulky physical models.

- Automated model-making dramatically reduces fabrication times for an exponential increase in technician output.

- Affordability and compact size empower dental labs and practices to increase capacity and accelerate production times.

MORE INFO

Stratasys Objet 30 Dental Prime

Streamline Workflow at Your Small Dental Lab.

- High-quality print mode enables fine-detail applications like diagnostic wax-ups and removable partial-denture casting patterns.

- PolyJet technology automates production for hands-off streamlining of workflow.

- Three dental materials specifically engineered for digital dentistry enable printing of accurate crown and bridge models.

MORE INFO

Industrial 3D Printers

Stratasys F123 Series

Precision printing. As easy as F123.

As easy as F123.

- Minimal setup – simply plug and print. Give your entire workgroup access to professional industrial grade 3D printing.

- Non-stop printing – spend less time troubleshooting and more time getting results.

- Fast and easy material swaps –maximize your team’s productivity.

- Reliable results – high levels of accuracy and repeatability, with engineering grade materials.

- Streamlined workflow – Go directly from CAD file formats to 3D print with GrabCAD Print software.

MORE INFO

Stratasys Fortus 450mc

Advanced Prototyping and Production.

- Embeds hardware, circuitry, and other non-thermoplastic materials into your parts easily, with minimal downtime for changeover.

- Increases your unattended build time up to two full weeks.

- Expands your manufacturing business with speed, agility, and the freedom of your own designs.

- Reduced operation and training time since Fortus systems require minimal training to operate and maintain.

- Can be installed anywhere since they produce no noxious fumes, chemicals or waste.

MORE INFO

Stratasys F900

Built specifically for manufacturing and heavy industries, where you plan and work big.

- Achieve faster build time for large parts

- Enhanced efficiency and visualization

- Production phase optimization with Insight Software

- Automated production and monitoring capability with MTConnect-readiness

- Fewer production system breakdowns

MORE INFO

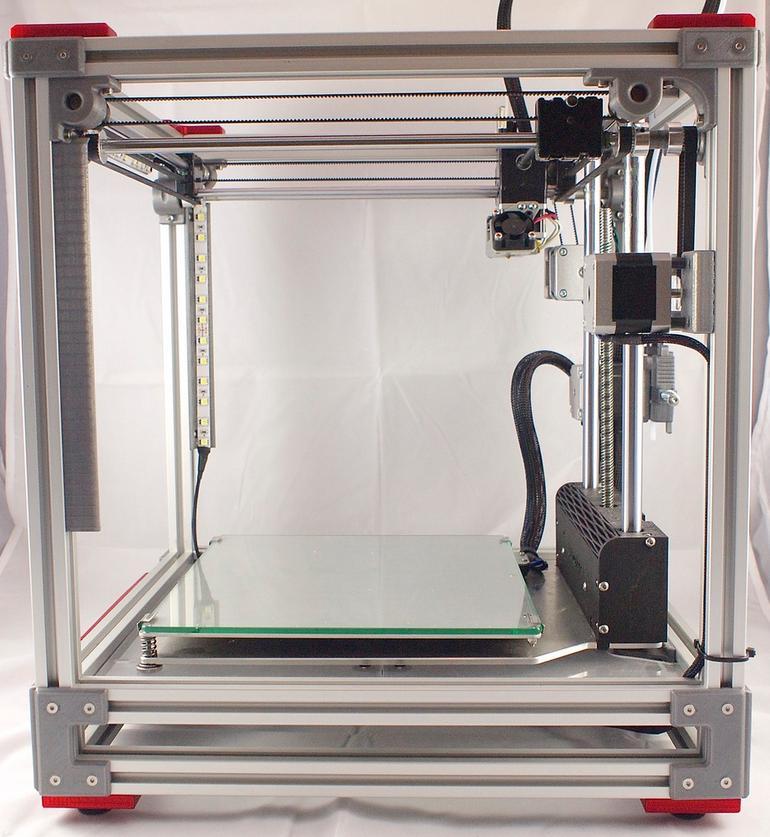

LeapFrog Xcel

Takes large scale 3D printing into the next level.

- Intuitive user interface.

- Auto calibration.

- Huge build volume and extreme strength.

- Closed and controllable heat environment.

- Automatic filament loading and detection.

MORE INFO

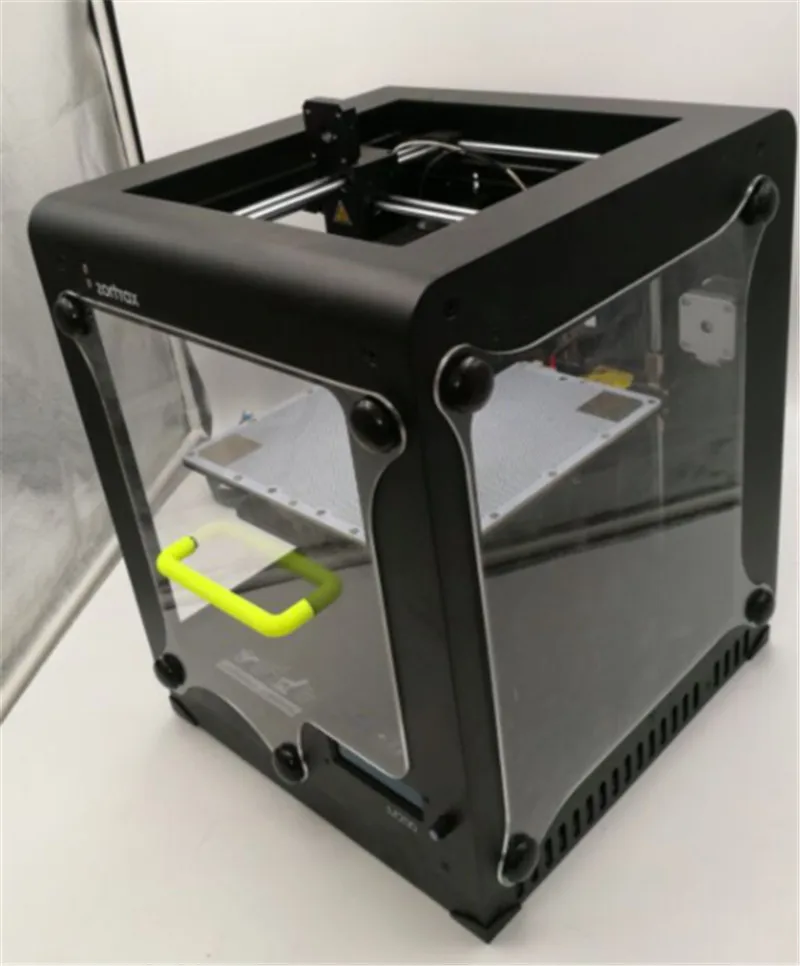

Desktop 3D Printers

Epsilon W50

Powered by our Independent Dual Extruder (IDEX) system, the Epsilon W50 delivers exceptionally strong functional parts with quality and precision.

- Technology: FFF (Fused Filament Fabrication)

- Architecture: IDEX (Independent Dual Extruder system)

Developed and optimized by BCN3D for 7+ years - Print modes: Duplication mode, Mirror mode, Multimaterial

mode, Soluble supports mode - Open filament system: BCN3D certified profiles for: PLA / ABS / PVA / PET-G /

PA / TPU / PP / PP GF30 / PAHT CF15 - Safety features: Hepa filter, Carbon filter, Safety pause, Filament runout sensor

MORE INFO

Epsilon W50 SC

A powerful professional 3D printing solution, designed to deliver large-scale parts with industrial-grade materials.

- Filament diameter: 2,85 +/- 0,05mm

- Hotends: Full-metal designed and manufactured by e3DTM. Hotend Family: 0,4mm (Default) / 0,6mm / 0,8mm / 1,0mm / Hotend X 0,6mm

- Smart Cabinet: Humidity-controlled environment, Uninterruptible power supply (UPS), Tools always in the correct place, Wheels for easy transportation, Load materials from cabinet

MORE INFO

Epsilon W27 SC

Keeping your materials in optimal condition and significantly improving each print’s quality

- Printing volume: W27: 420x300x220mm

- Minimum layer height: 0,05 mm

- Max.printing temp.: 280o°c

- Max. Heated bed temp: 120o°c

- Certificates: CE / FCC

MORE INFO

Form 3BL

The New Standard for High Volume Dental 3D Printing

- Maximize throughput for every print job and print up to 120 models in a day.

- Maintain ideal print conditions with minimal operator intervention with the online Dashboard.

MORE INFO

Sigma D25

Our acclaimed workhorse, engineered for maximum productivity.

- Technology: FFF (Fused Filament Fabrication)

- Architecture: IDEX (Independent Dual Extruder system)

Developed and optimized by BCN3D for 7+ years - Print modes: Duplication mode, Mirror mode, Multimaterial

mode, Soluble supports mode - Open filament system: BCN3D certified profiles for: PLA, PVA, PET-G,

TPU 98A - Safety features: Filament runout sensor

MORE INFO

Form 3+

Desktop Stereolithography 3D Printers for Powerful Prototyping

- Powered by Low Force Stereolithography

- Enhanced Light Touch Support structures that save post-processing time

- Maximize your return, protect your investment, and eliminate unexpected costs

MORE INFO

MakerBot Replicator+

Designed to offer precise and reliable functional 3D printing results.

- Onboard Camera with 640x480p at 4 fps

- Wifi Connectivity

- Remote Monitoring and Printing

- Color LCD Printing Screen

- Flexible Grip Surface Buildplate

MORE INFO

MakerBot Sketch Classroom

Whether it’s back in the classroom, fully remote or going hybrid, we’ve got the ideal setup for you.

- Heated build plate for secure, successful printing and a flexible surface to make removing finished prints a breeze.

- Touch Screen Controls for easy 3D printing navigation.

- Safe Enclosed Chamber and Particulate Filter

MORE INFO

MakerBot Method Carbon Fiber

Replace metal parts with 3D printed Carbon Fiber on METHOD.

- Circulating Heated Chamber

- Includes MakerBot Composite and Support Performance Extruders

- Dry-Sealed Material Bays

- Pre-Print Material Drying

- Post-Wash Part Annealing

- Ultra-Rigid Metal Frame

- MakerBot Cloud Connected

MORE INFO

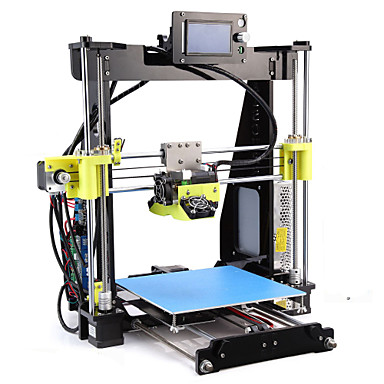

Leapfrog Bolt Pro

Designed to offer precise and reliable functional 3D printing results.

- Built for office and factory floors.

- Built for industrial 3D printing.

- E3D hot ends and extensive filament options.

- Minimum setup with our intelligent user interface.

- Large industrial heated bed with buildtak flexplate.

MORE INFO

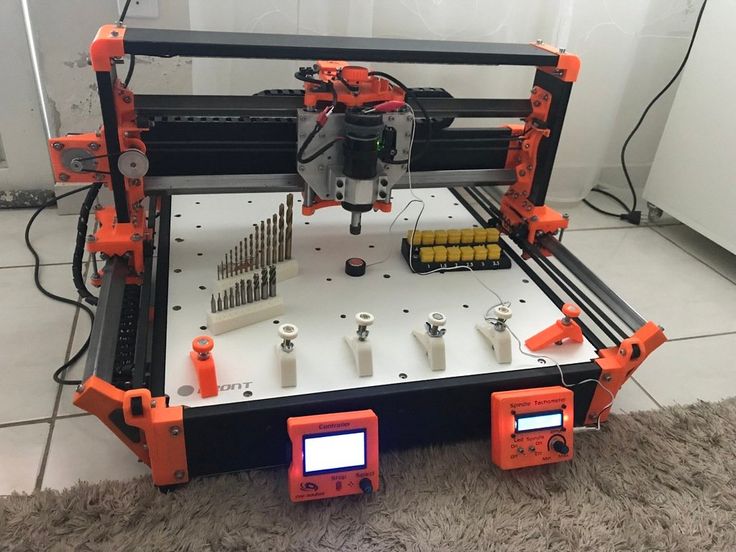

3D Milling Machines

Roland MDX-50

An ideal solution for short-runs and prototypes.

- 4-axis, unattended milling with 5-station

- Automatic Tool Changer for continuous operation

- Mill plastic foam, ABS, POM, hardwood, non-ferrous metals, etc.

- Automated milling and unmatched ease-of-use with precision results— fully-enclosed milling of parts, prototypes and other 3D objects.

MORE INFO

Roland MonoFab SRM-20

A machine with compact size and powerful functionality at an affordable price.

- Multi-axis milling and phenomenal feed rate.

- Mill wax, foam, ABS, chemical wood, acrylic, poly acetate, etc.

- Most user-friendly and precise CNC mill in its class— a fully-enclosed 3D milling device that fits into any office, home, or classroom environment.

MORE INFO

3D Scanners

Artec Eva

Fast 3D scanner for professionals. F119: F123: F138: F119: F124.

- Easier, smoother 3D scanning.

- Faster post-processing.

- Achieve best possible results with geometry and texture data combined.

- Scan even large, featureless objects using color differentiation.

- Option to scan with targets.

MORE INFO

Artec Space Spider

Industrial 3D scanner of metrological accuracy.

- Fast scanning speed.

- High 3D point accuracy.

- Makes full color 3D replicas of your object.

- Captures the geometry of your items with astonishing precision.

MORE INFO

Artec Leo

Easy 3D scanning: see your object projected in 3D directly on the HD display.

- Fastest professional handheld 3D scanner on the market.

- With its large field of view, Artec Leo can 3D scan

and process even large objects and scenes fast and accurately. - First 3D scanner to offer onboard automatic processing, Artec Leo is able to provide the most intuitive workflow, making 3D scanning as easy as taking a video.

- Carefully balanced, ergonomic design,devised to make 3D scanning in one hand easy and comfortable, and you have a next-generation professional 3D scanner, built with usability in mind.

MORE INFO

Artec Ray

High accuracy long-range laser 3D scanner, ideal for precise capture of large objects.

- Lightweight and user-friendly.

- Effortlessly capture difficult to reach areas, e.g. the interior of a car, or to add intricate detail to a large-scale 3D model.

MORE INFO

Artec Micro

Professional ultra-high-precision industrial desktop 3D scanner for small machine parts, jewelry and dentistry.

- Delivers industrial-quality scans with just one click.

- Brings the ultimate scanning solution right to your desktop.

- Up to 10 microns accuracy.

- Create exact digital copies of small objects, tiny parts, jewelry, etc.

- Metrology-grade scans, suitable for quality control.

MORE INFO

The 3D Services Pioneer in the Philippines

The Pioneer of 3D Services in the Philippines

How Can We Help You?

3D2GO is the only one-stop shop for everything 3D printing in the Philippines. We offer end-to-end full-service scanning, prototyping and printing with a streamlined process that guarantees a top quality end product.

We offer end-to-end full-service scanning, prototyping and printing with a streamlined process that guarantees a top quality end product.

3D Scanning

Digital capture an object's physical dimensions so it can be converted into a precise 3D representation.

3D Designing

We conceptualize your ideas into 3D Digitize any object in the form of industrial designs, concept models, and 3D models with texture and color.

3D Modeling

We create a reverse-engineered file using specialized 3d softwares to produce engineering files.

3D Printing

Now let's breathe life into that 3D design. In 3D printing or additive manufacturing.

Benefits of 3D Printing

At 3D2Go, we believe in the power of 3D printing. With our 3D scanning, modelling and printing services, we can help you create products that are both unique and functional. From replacement parts to customized toys, our team is dedicated to bringing your ideas to life. So whether you’re in the market for a new toy or an innovative product, come to us and trust in our expertise.

From replacement parts to customized toys, our team is dedicated to bringing your ideas to life. So whether you’re in the market for a new toy or an innovative product, come to us and trust in our expertise.

Play Video about 3d video cover

OUR WORKS

GALLERY

CONTACT US

LET'S WORK

Click here

Testimonials

3D Use Cases

3D Printing, Scanning and Modelling can be useful in the following use cases.

Architecture

Create detailed three-dimensional models of buildings and other structures.

Automotive

3D can be used in the automotive industry to create prototypes of cars, car parts, and accessories.

Bobblehead

Add a unique and personal touch to your home or office. It is perfect for any room and makes a great gift for any occasion.

Engineering

Create models and designs of products or structures. Visualize and test out scenarios before moving forward with a project.

DIY Projects

If you love crafting and DIY projects, you need 3D in your life! Create unique and one-of-a-kind pieces. Let your imagination run wild.

Houseware

3d print your own houseware. Check out the latest 3d printing technology and get started!

Manufacturing

Create products with precision and accuracy never before possible. Get ahead of the competition with 3d!

Medical

From X-rays to MRIs, 3d technology is changing the way we see the world. Learn more about how it's helping medical professionals here.

Restoration

With 3D printing technology, you can restore statues, broken wares, and equipment.

Toys

With 3d printing, you can make toys that are just as fun and exciting as the ones you buy. Go and create something new!

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business? nine0003

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods. nine0003

for 3D printing and other production methods. nine0003

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited numbers. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models. nine0003

SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models. nine0003

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

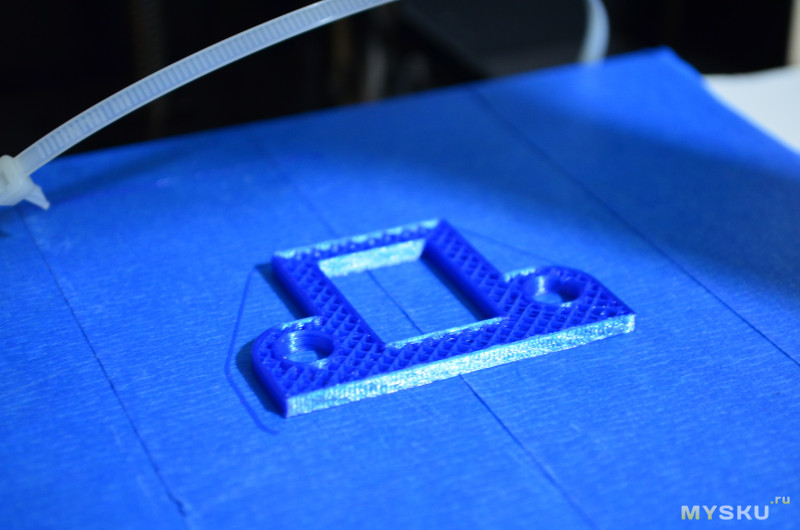

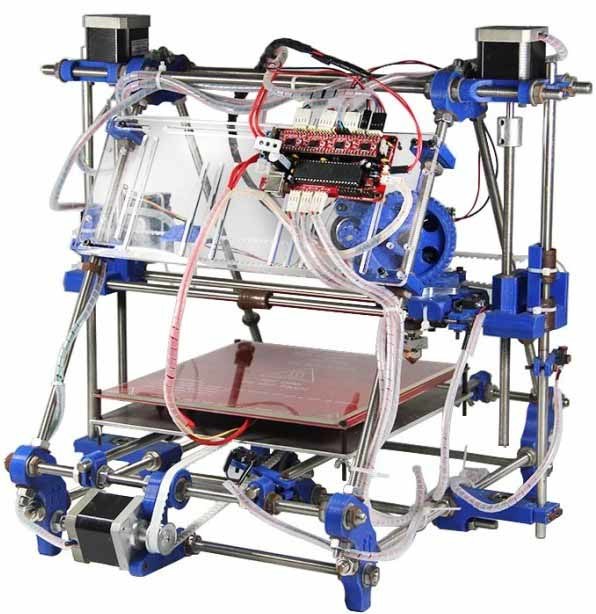

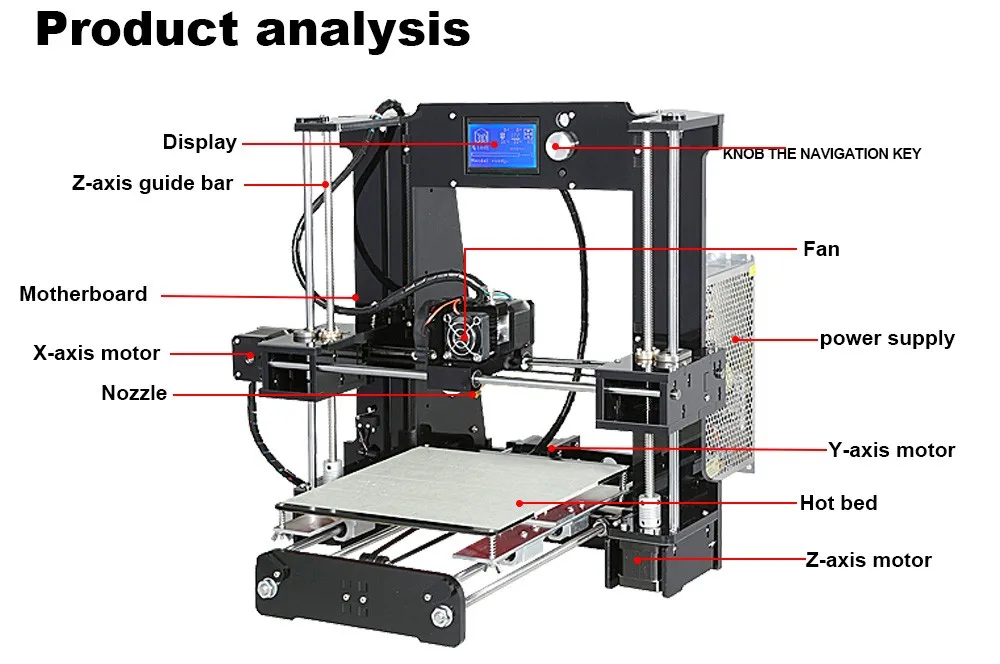

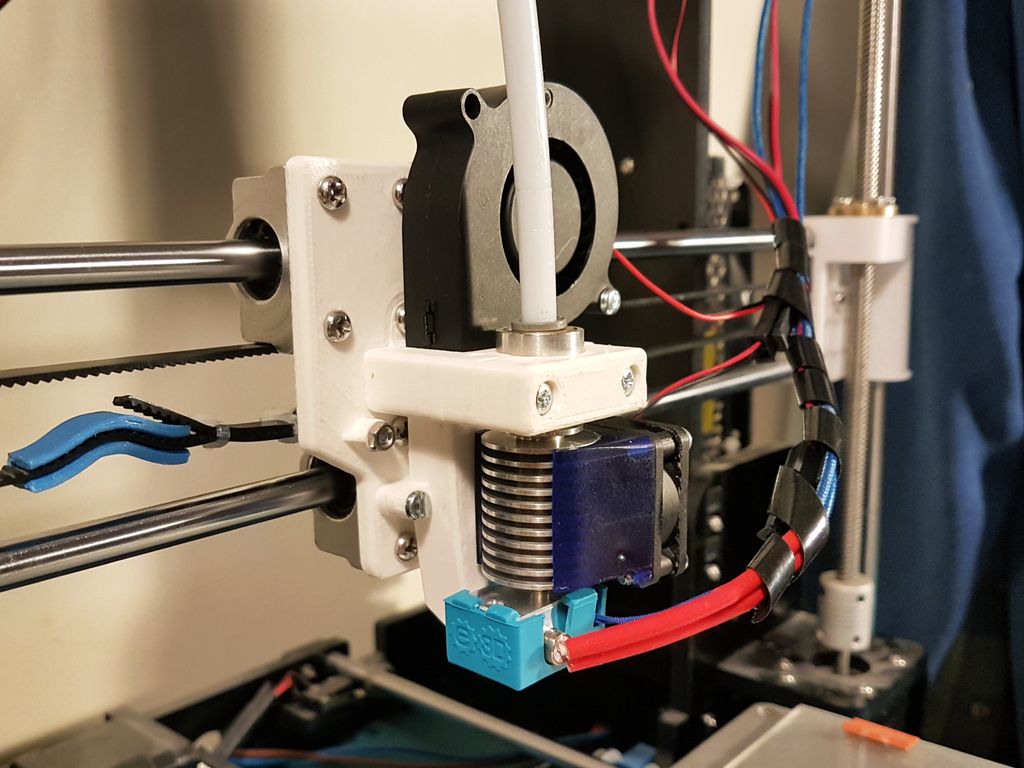

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made. nine0003

nine0003

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

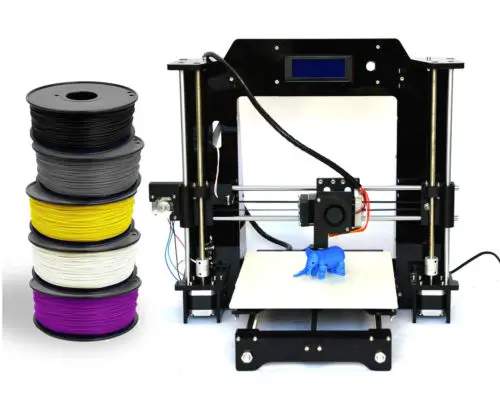

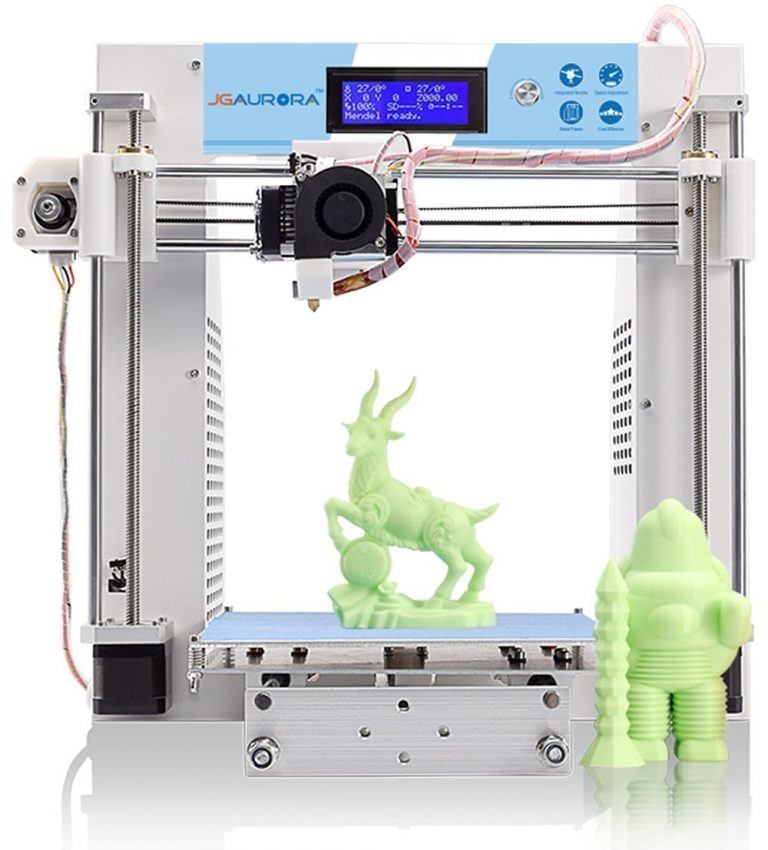

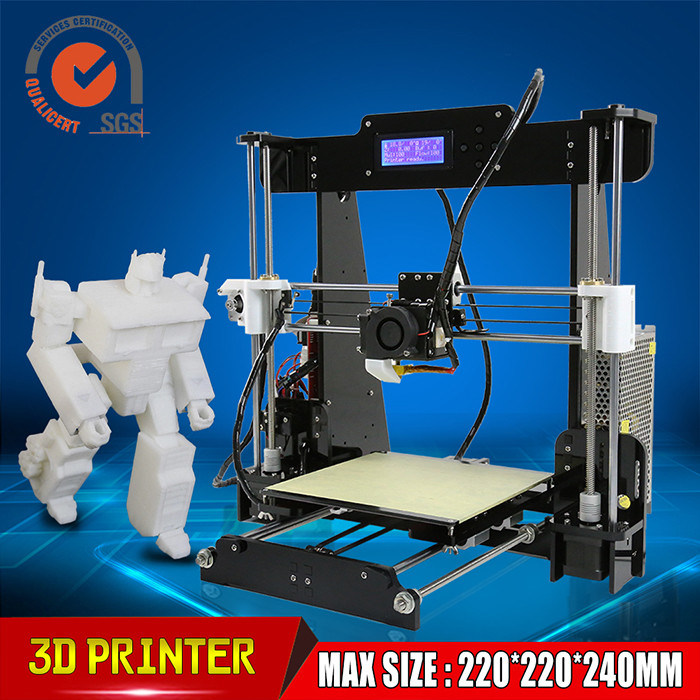

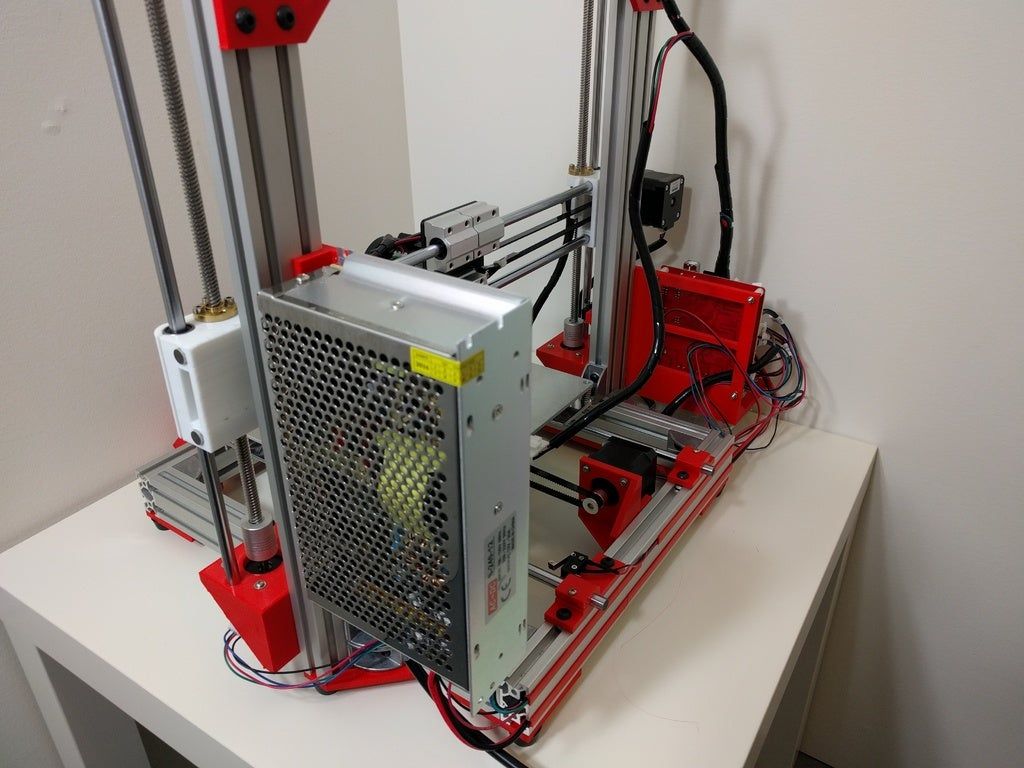

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that take a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience. nine0003

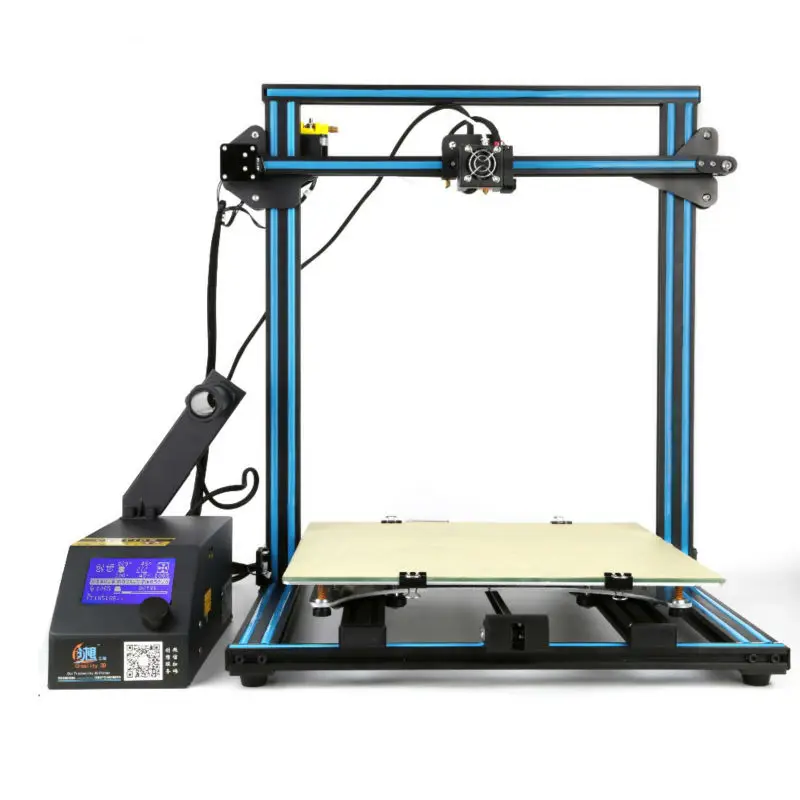

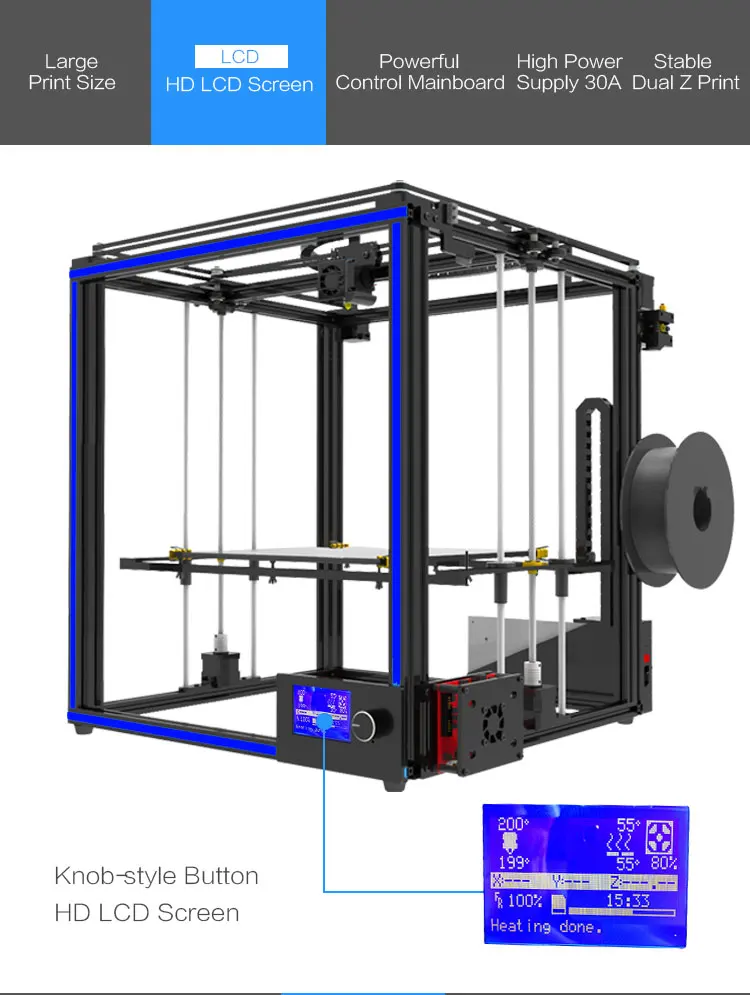

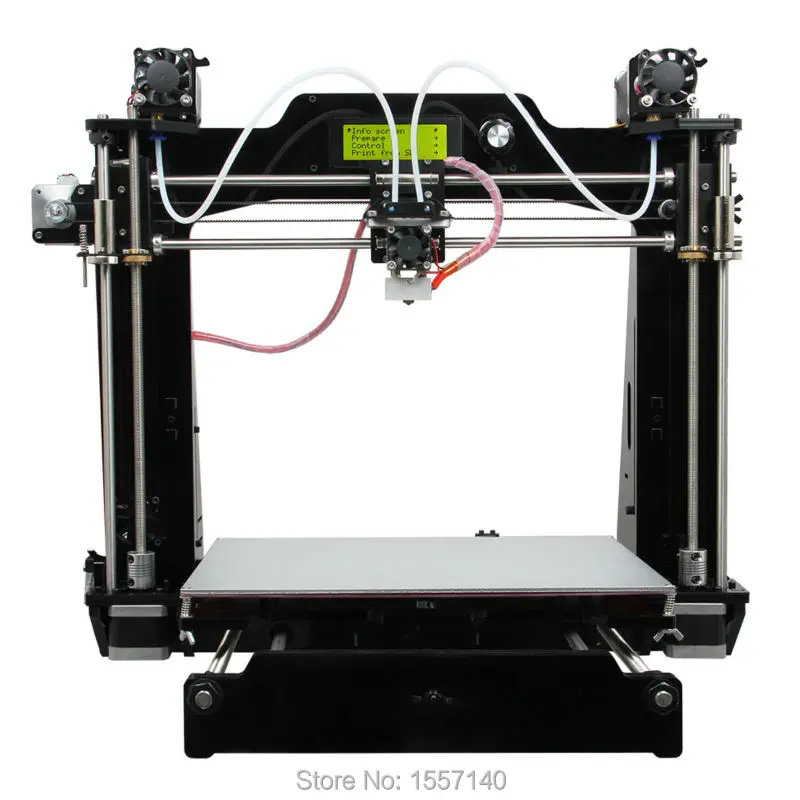

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting. nine0003

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary. nine0003

nine0003

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000. nine0003

With Form 3L, large format SLA printing starts at just $11,000. nine0003

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter. nine0003

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

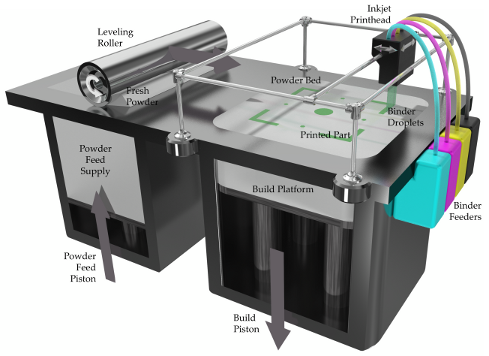

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. nine0003

This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. nine0003

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support. nine0003

The package includes in-depth training and fast technical support. nine0003

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals. nine0003

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. SLM and DMLS-based 3D printers create strong, precise, and complex metal products, making the process ideal for the aerospace, automotive, and medical industries. nine0003

nine0003

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM) and Direct Metal Sintering (19008) 9008 | |

|---|---|---|---|---|---|

| Permission | ★☆ | ★ opa ★ ution | ★ opa | ★cle | ★cle ★ MyQUTION | SUMPLE | 1112 HICE | ★ opa ☆ | 1111111 ☆☆☆ | 1 ☆ | ★ opa |

| Ease of use | x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm |

| Price range | DIY kits for 3D printers start at $200 and hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750 and high-volume large format desktop printers are available from $11,000. nine0112 | Workshop industrial printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. |

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | US$50-150/L for most standard and engineering polymers. | US$100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. nine0112 |

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. nine0112 | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. |

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). nine0112 nine0112 | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. |

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring close tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. nine0112 | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs. nine0003

It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs. nine0003

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model. nine0003

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself? nine0003

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce. nine0003

These costs largely depend on the number of models you produce. nine0003

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials. nine0003

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive. nine0003

nine0003

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases involve cleaning models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer. nine0003

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

nine0298 -

How long does it take to post-process one specific model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to 3rd party service bureaus or labs when you use 3D printing only occasionally or to produce large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes. nine0003

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months. nine0003

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue. nine0003

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could get products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition. nine0003

Top results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.

Interaction: Having high-quality prototypes and models allows you to communicate more effectively with customers, clients, suppliers and other stakeholders. Avoid misunderstandings and costly mistakes. nine0003

Intellectual Property Protection: Do you work with confidential information? Making your own models means you don't have to transfer intellectual property (IP) to third parties, reducing the risk of IP leakage or theft.

Usually, calculating cost per part, lead time, and comparing alternatives to see if a solution is right for your business is a tedious task of creating a complex spreadsheet in an attempt to collect all of the often hidden information from a manufacturer. nine0003

Use our simple online tool to calculate cost per model and order lead time when printing with a Formlabs stereolithographic 3D printer and compare time and cost savings with other manufacturing methods.

Calculate the cost and time

Read the article - Construction 3D printing. 8 reasons why she will be an achievement

3D printing has long outgrown its initial capabilities of rapid prototyping and has evolved into a full-fledged manufacturing process known in the industry as additive manufacturing. It is being used to manufacture an ever-wider range of products, from dental implants to jet engine parts. Indeed, it was only a matter of time before she made it to the construction industry. nine0003

nine0003

Simply put, houses built with a 3D construction printer are built by layering the material. The paste-like concrete mix is extruded through the nozzle, creating walls from scratch one layer at a time.

At first glance, this does not seem complicated, but in fact it is not. While the prospects for such a construction process are enormous, it is still in the very early stages of development, but has already shown promising results and has quickly attracted media attention. nine0003

The question is, is the hype around 3D construction printing really deserved? In this article, we will delve into this topic and show why we believe 3D printed homes could be the next big thing.

Construction speed

3D printing a house is significantly faster compared to traditional building methods. While the actual timeline is highly dependent on the size of the project, in most cases, construction takes only a few days. nine0003

Take, for example, the first fully 3D printed house in America, built by construction company ICON for the nonprofit New Story in 2018. The 33-square-foot house in Texas took about 47 hours of print time to create, spanning several days.

The 33-square-foot house in Texas took about 47 hours of print time to create, spanning several days.

Just two years later, another American company built a huge 177 square meter home in just 8 days, taking just 48 hours of total printing time. However, remember that 3D printers can only create exterior and interior walls. nine0003

However, according to SQ4D, the company responsible for the project, this is 40% less compared to conventional building technologies. While this may seem insignificant at first glance, 3D construction printing is still an evolving technology that still has a lot to improve. So, most likely, the construction time will be reduced even more.

Fewer builders

At construction sites, 3D printing requires fewer workers than traditional sites as the printing equipment does most of the work. nine0003

Traditional construction requires many stages, including a whole team of five to six people who unload, transport and mix materials before laying the structures. Once set up, the concrete 3D printer only needs a few people to monitor and control the process.

Once set up, the concrete 3D printer only needs a few people to monitor and control the process.

For example, for the aforementioned house of 177 sq. meters from SQ4D will require only 3 people on site, which, according to the company, will replace a team of more than 20 unskilled workers. This shows just how well this whole process is automated, and why 3D construction printers are such a promising alternative. nine0003

In addition, fewer workers on site also result in fewer work-related injuries and deaths. According to OSHA statistics, construction alone is the cause of death for one in five workers in the US. If done responsibly, 3D printers can help reduce these numbers significantly.

Lower construction cost

It is believed that 3D oven houses are cheaper to build, but this is somewhat debatable as mass building 3D printers are expensive equipment and still have many limitations. But let's stick to facts and figures. nine0003

We've already established that 3D printing a home is faster than traditional building, and as they say, time is money. Less time spent on site means both equipment and workers are more quickly available for other projects, theoretically doubling construction volume compared to today.

Less time spent on site means both equipment and workers are more quickly available for other projects, theoretically doubling construction volume compared to today.

Add this to the greatly reduced number of workers required. In addition, the raw materials used by some 3D printers can be partially assembled on site, reducing the costs associated with finding, storing, and transporting them to the site. nine0003

Now let's get down to the numbers: Apis Cor's 40 sq. m in Russia, according to rumors, cost about $ 10,000, including all windows, roofing, wiring and interior decoration. This is shockingly small. ICON is currently working on 60-square-meter homes that are planned to cost as little as $4,000.

Yes, 3D printing construction equipment is still very expensive, like any other cutting-edge technology, but there is a lot of room for improvement, and as the technology advances, the costs associated with equipment and operation will undoubtedly decrease. nine0003

Unique building possibilities

3D printing opens up unique building opportunities that would be either impossible or too expensive to implement with conventional building technologies.

Some say that in order to get the most out of any 3D printing process, the high degree of design freedom afforded by these technologies must be taken into account. This also applies to construction and architecture, where innovation and creativity are especially encouraged. nine0003

3D printing allows you to create complex shapes and forms without any extra effort. For example, a concrete 3D printer can create intricately curved walls just as easily as straight ones. Unconventional architecture can improve the appearance of buildings and even optimize interior space.

Take, for example, the "Office of the Future" in Dubai, 3D printed by the Chinese company Winsun, which houses the Dubai Futures Foundation. The curved appearance would require an excessive amount of work to recreate using traditional building techniques. nine0003

Engineers can also get creative as the print media can be finely tuned to achieve the best properties. From a finished batch, concrete is already a first-class building material, resistant to most environmental influences such as fire and moisture, as well as an excellent thermal insulator for cold and warm weather.

High performance materials

The 3D printing process is more efficient in terms of energy and material use compared to traditional construction. nine0003

3D printers produce less waste because they only use the right amount of material to create designs: there is no waste from cutting or cutting materials. In addition, since concrete-based raw materials are not shaped, any leftovers can and should be used in the next building.

In addition, raw materials can be made from recycled materials. Back in 2014, the Chinese company Winsun was able to build at least 10 houses in one day using only recycled concrete material, while the Italian 3D printing company WASP made a house from natural mud mixed with waste from local rice production, which included crushed straw and rice husks. nine0003

3D printers also consume less energy compared to the entire production chain of conventional construction. Consider all the energy needed to transport raw materials and move entire crews of workers daily to the construction site. By reducing labor intensity and sourcing materials in situ, 3D printing can be more sustainable in the long run.

By reducing labor intensity and sourcing materials in situ, 3D printing can be more sustainable in the long run.

Situational applicability

Overall, 3D printers can play a central role in various scenarios around the world. All the key points we've covered so far - reducing time, cost, manpower, expanding unique capabilities and efficiency - show how this technology can be very useful in certain situations. nine0003

Developing countries constantly face housing problems. The ability to provide enough quality homes at affordable prices is a key factor in sustainable economic development. The relatively fast process of building 3D printers could potentially solve the problems of the homeless in the short term.

This is exactly what New Story and ICON are trying to achieve in Mexico, in Tabasco. The idea is to create the very first community of 3D printed houses for local families who currently live in extreme poverty. A total of 50 fully 3D printed houses of 50 square meters will be built. nine0003

nine0003

3D printed houses can also be useful in situations of humanitarian crisis, especially after natural disasters when houses are tragically destroyed by earthquakes, fires or tsunamis. Communities affected by such events end up with labor and material shortages, not to mention logistical problems. Restoration with 3D printing could be an effective and cheap solution to at least start rebuilding these communities. nine0003

Lastly, 3D printing could also make space exploration like Mars possible. The idea is to send automated 3D printing equipment to the red planet, and since the raw materials could be collected locally, the printers could start building living quarters long before the first humans arrived. No wonder NASA is so interested in this technology.

Industry shift and investment

Construction 3D printing not only attracts the attention of industry leaders and investors, it also attracts their money! nine0003

The construction 3D printing market has been growing steadily in recent years. Concrete 3D printer maker COBOD reported earnings in just its second year of operation in 2019, which is a huge achievement for any company and more considering how raw this particular market is still.

Concrete 3D printer maker COBOD reported earnings in just its second year of operation in 2019, which is a huge achievement for any company and more considering how raw this particular market is still.

After 2020, the coronavirus crisis has affected most industries around the world, and construction 3D printing is no exception. However, it seems to be a suitable solution for such cases, given the reduction in the number of workers on site. For this and other reasons, the global construction 3D printing market is expected to grow from $350M in 2022 to $11B in 2027. nine0003

You don't have to take our word for it. Just remember that industry leaders are at the top because they understand the market, while big investors only invest their money in real and really promising technologies. 3D printed houses are the next big thing in technology.

Global distribution

3D printed houses are already a reality and they are rapidly spreading around the world. nine0003

nine0003

While 3D printed houses are often seen in architecture competitions or as concept designs, there are plenty of real-life residential structures that are already in use. Take, for example, the Lewis Grand Hotel in the Philippines with 140 sq. meters, completely made using 3D printing, including bedrooms and living rooms.

Governments are also involved in this. In 2019, Russian company Apis Cor built the largest 3D printed building to date. Two-story building with an area of 640 sq. m is currently home to Dubai Municipality, being the second government building to be 3D printed after the aforementioned Office of the Future. nine0003

In Europe, the 3D printed Yhnova House became one of the first residential buildings in the world in 2018 when the Ramdani family moved in. The structure was designed by the University of Nantes using its own proprietary equipment, and the 92 sqm structure was 3D printed. meters took no more than 54 hours.

The next time you hear about 3D printed homes, remember that although it is still an evolving technology, it has shown great results and is already being used around the world.