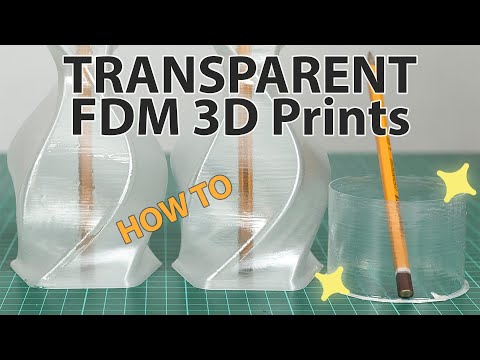

How to 3d print clear plastic

How to 3D print clear plastic parts

3D printing offers unparalleled freedom when it comes to the appearance of the objects you print. It’s possible to change the color, texture, size, and shape of your print, just by changing what material you use. There is one material property that is often overlooked, however, and that’s transparency.

Whether you need a part to be clear for functional reasons, or you just want something that looks nice, it’s good to have the option of printing clear parts. Read on to find out how you can do so.

Is it possible to 3D print clear parts?

The answer to that is yes, and… maybe. Depending on your definition of clear and whether you’re willing to do some post-processing.

While it is possible to print an object using the right material and settings and then pull a translucent print off the build plate. You’ll have to do some extra work if you’re hoping to print anything that is perfectly transparent.

In order to understand why that is, we should talk about what we mean when we use the words transparent and translucent.

What is the difference between a transparent print and a translucent one?

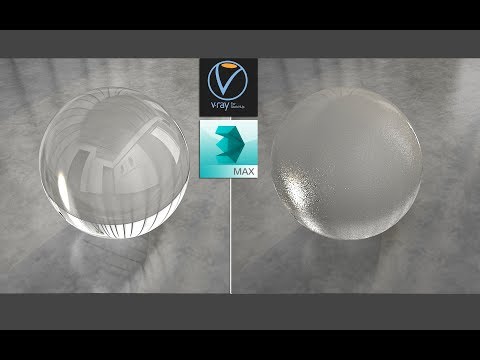

There is a whole bunch of science around what makes something transparent or translucent but for the purposes of this article, transparent is what you’re probably thinking of when you imagine a clear material like a glass window or a flawless crystal. It lets almost all visible light pass through it. A translucent material is instead one that lets only some light through and is therefore not perfectly clear, like a stained-glass window or the lenses of your sunglasses. Any material that lets no light through whatsoever is opaque.

When it comes to 3D printing, these terms are often conflated, and it is standard in the industry to label 3D printing filament and resin with translucent properties as ‘transparent’ despite it being very difficult to get perfectly transparent prints with them. In order to follow those naming conventions, when talking about materials with translucent properties we will refer to them as transparent.

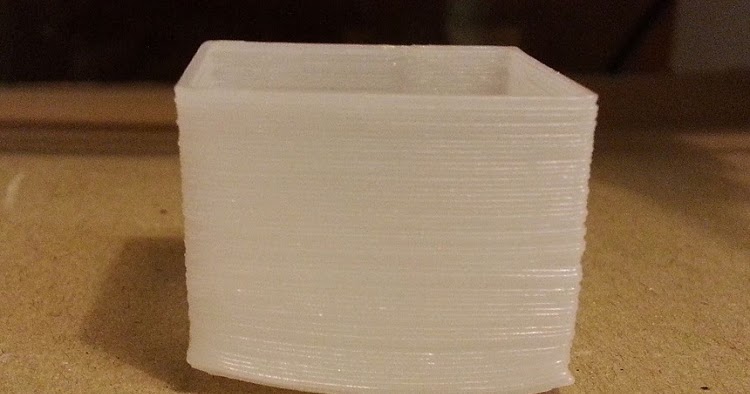

Most of the time, when you try to 3D print using a transparent filament, particularly with an FFF printer, your prints will end up looking cloudy. Depending on your settings, you will probably still be able to see some light pass through them, but they will be translucent at best.

This is because a 3D print is made up of lots of layers of material stacked on top of each other. The small gaps and irregularities between these layers refract and scatter light, preventing it from passing through. Luckily, there are ways of reducing and possibly even eliminating this issue.

How do you print clear parts?

To get the best clear parts, there are three areas that are important. The material used, your slicer settings, and post-processing.

Materials for printing clear parts

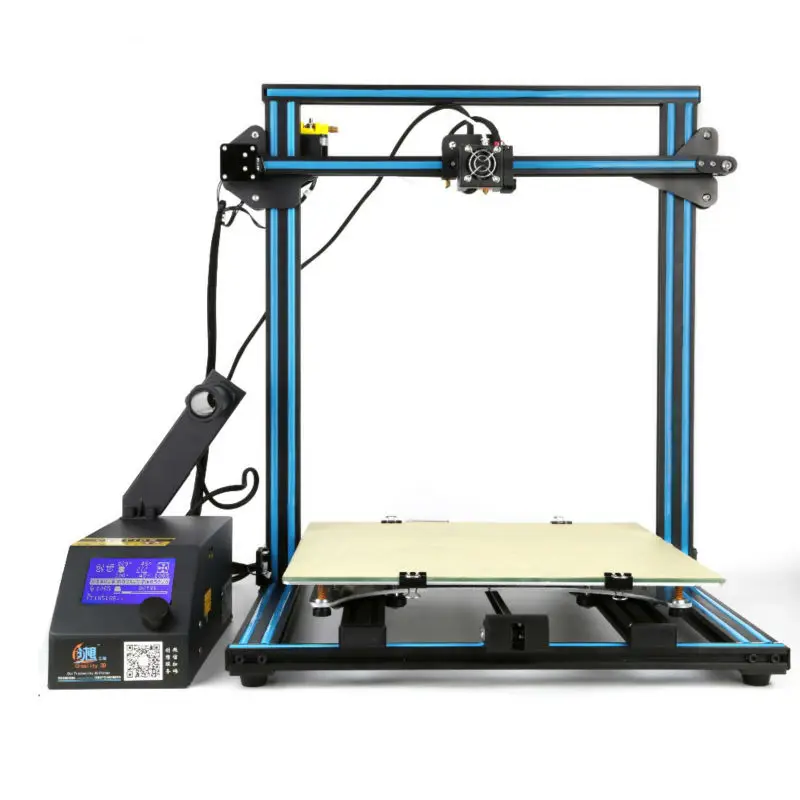

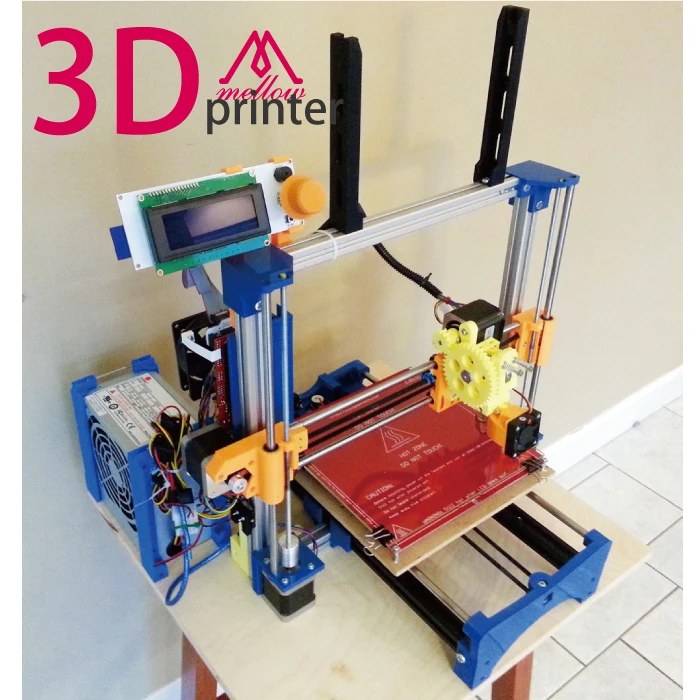

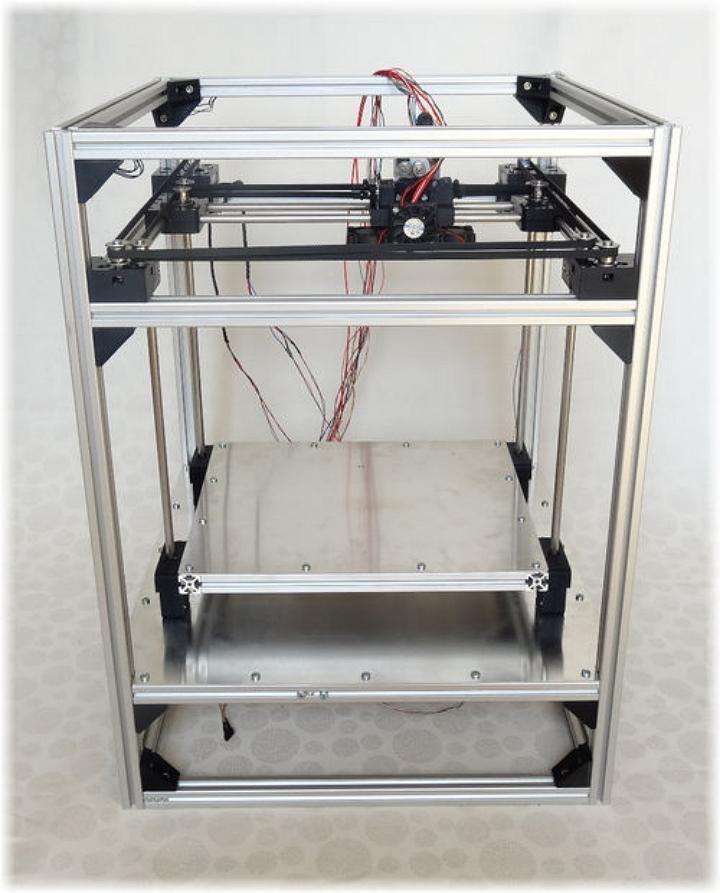

When it comes to printing both translucent and transparent parts, there are two very different material categories you can use. The first is thermoplastics using an FFF printer. And the second is resins using an SLA or PolyJet/MultiJet printer.

As a rule of thumb, resin and resin-based printing technologies give you the most transparent parts. However, getting good prints with resin can be a more difficult and much messier affair. Polyjet/MultiJet printers are also astronomically more expensive than FFF printers.

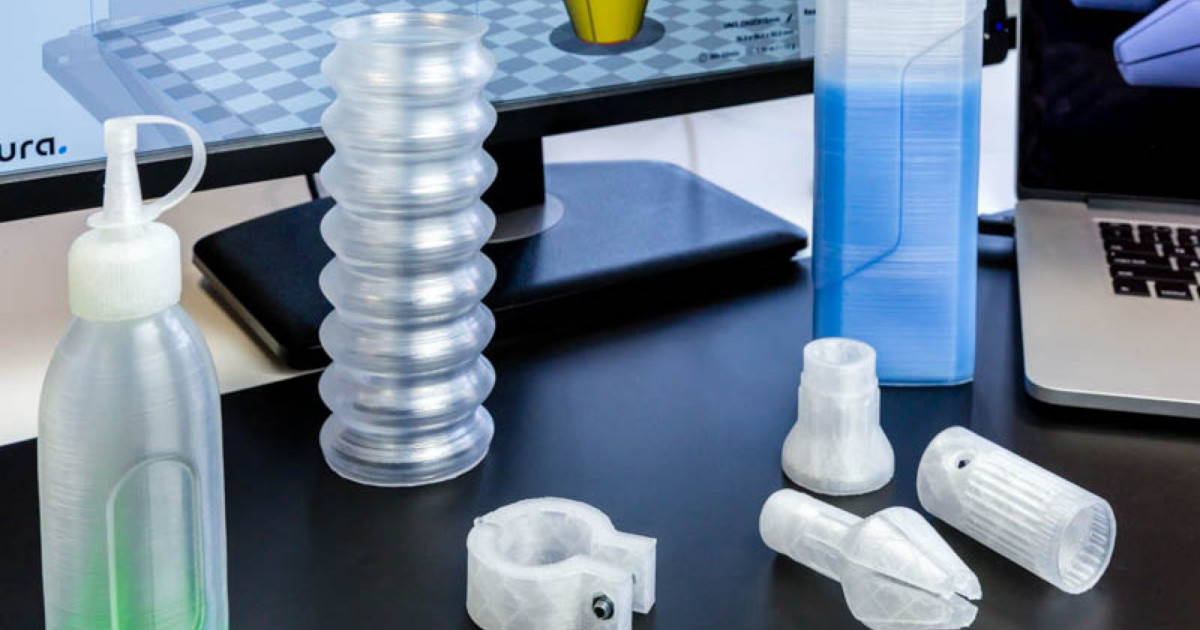

Thermoplastics have the advantage of being accessible, requiring less cleanup, and coming in a wide range of options. Some of the FFF materials that can be printed transparent are:

PLA

PLA is one of the cheapest and most used FFF materials. It is possible to find transparent PLA and in fact, when it first came onto the market, most PLA was transparent. However, it is difficult to get clear prints with PLA, and the other materials mentioned are normally a better option if you’re looking to get the clearest prints possible.

PETG

If you are looking for an easy and affordable way to get translucent prints without post-processing, PETG is your best bet. Transparent PETG is easy to find and it prints better than transparent versions of PLA and ABS will. Post-processing is still required if you want an actually transparent final print, however.

Transparent PETG is easy to find and it prints better than transparent versions of PLA and ABS will. Post-processing is still required if you want an actually transparent final print, however.

CPE/CPE+

Both CPE and CPE+ can be found in transparent varieties and CPE+, in particular, is suited to being printed transparent as it can be more easily post-processed with heat treatment due to its higher heat resistance. It also had good mechanical properties which makes it a good option for functional parts.

PP

Polyproylene is another material with transparent filament options. PP is a little more expensive than other options but it is possible to get decently translucent prints using it and it also has some specific mechanical properties that the other materials mentioned don’t have, making it appropriate for certain functional parts.

ABS

ABS is common, affordable, and comes in transparent varieties. The downside of ABS is that it’s harder to print than PLA and PETG as it requires an enclosed printer and, similar to PLA, the prints you get off the build plate are unlikely to be especially transparent. The one major upside that ABS has is that it can be vapor smoothed using acetone. We will talk more about vapor smoothing in the post-processing section.

The one major upside that ABS has is that it can be vapor smoothed using acetone. We will talk more about vapor smoothing in the post-processing section.

PVB

PolySmooth is a PVB-based material made by PolyMaker that is easy to print and has mechanical properties similar to PETG with the added advantage that it can be vapor smoothed with isopropyl alcohol in a manner similar to how ABS is smoothed with acetone. PolySmooth is more expensive than ABS but it’s easier to print and isopropyl alcohol is much less dangerous to work with than acetone making the smoothing process easier and safer.

Which settings to use for printing clear parts?

The settings you need to tune and tweak for printing clear parts are mostly the same you need for getting a good print in general.

Different materials and printers will also have different requirements but there are some of the settings that you should pay special attention to. Most are relevant for FFF printing. They are:

They are:

Infill percentage

There are two options for infill percentages. 100% or 0% (for any infill pattern except lightning). 100% percent will create clear solid objects and is the best option for functional parts. However, for large parts, the amount of filament used will be high. The alternative is to use no infill and a wall that is a single line thick That will create a hollow object with very little material to displace light passing through it. The downside is that many objects will not be able to be printed without infill. Any other infill percentage will create complex internal structures that will reflect light and make the print less transparent.

Spiralize outer contour (vase mode)

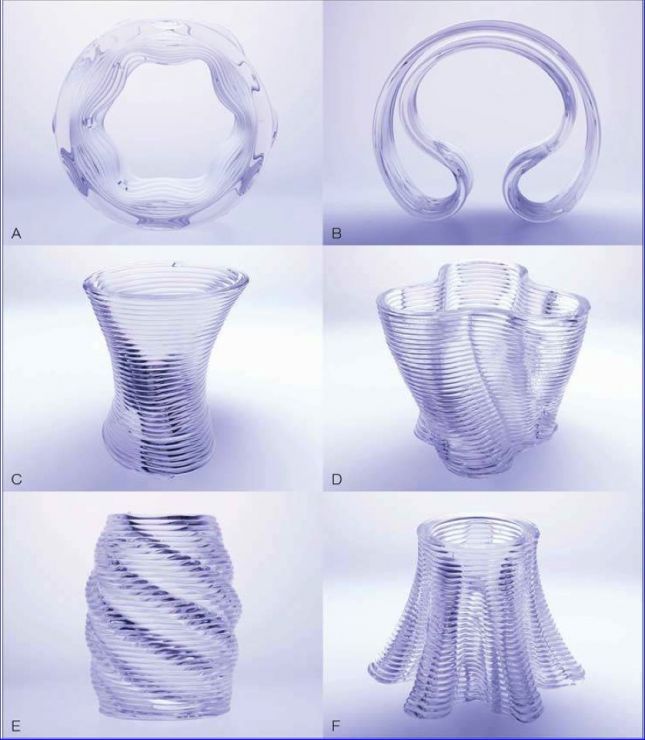

Vase outer contour is a setting that enables smooth printing of objects with a single wall thickness. It turns the print into one continuous print path which means there are no retractions between layers and therefore no Z seam. This can be perfect for making thin translucent parts like a lampshade.

Layer height

Changing your layer height will change how translucent your parts are. As a rule, low layer heights create smaller gaps between layers which creates clearer parts. This is also the only setting in this list that is also relevant to resin printing. As with FFF, a lower layer height is usually best. For FFF printing, there is one exception when larger layers are better. That is when using vase mode with a single line thick wall. In that case, larger layers and even a larger nozzle size will often result in a clearer part.

Temperature

Temperature can have an effect on clarity. A higher temp will help your layers fuse more completely resulting in more clarity but once the temp gets too high your material will bubble or even burn as it leaves the nozzle resulting in a less transparent part.

Extrusion rate

Increasing the extrusion rate slightly above 100% can prevent under extrusion and help fill in the gaps between layers better leading to clearer prints. If you increase the extrusion rate too much you will get over extrusion which will have the opposite effect.

If you increase the extrusion rate too much you will get over extrusion which will have the opposite effect.

How to post-process a 3D print to make it transparent

Post-processing is the magic step that, in the right circumstances, can turn a cloudy underwhelming print into one that’s crystal clear. In most cases, a bit of post-processing will at least help. Some of the techniques you can use include:

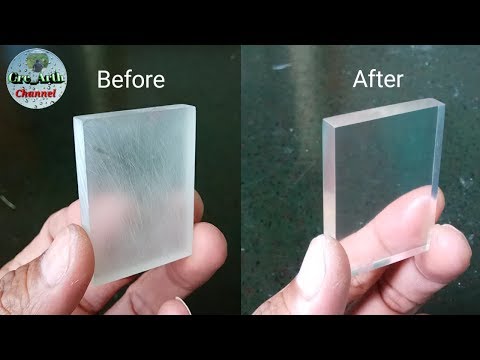

Sanding and polishing

Sanding a print is one of the most straightforward way to smooth out the layer lines that stop a print from being transparent. However, you will need to use an extremely fine grit of sandpaper and ideally even polish to get a perfectly smooth surface. This is also very difficult to do on parts with complex geometries. It’s also worth mentioning that you should wet sand PLA or any material with a low thermal resistance to stop the heat created when sanding from damaging the part.

Clear coating

When done properly, clear coating a 3D print can be transformational. A clear coat is a transparent layer of paint that, when applied, sinks into the layer lines, filling them up and giving the part a smooth finish. If all of your settings have been dialed in and the right material was used, a clear coat can be the difference between a translucent part, and a transparent one.

A clear coat is a transparent layer of paint that, when applied, sinks into the layer lines, filling them up and giving the part a smooth finish. If all of your settings have been dialed in and the right material was used, a clear coat can be the difference between a translucent part, and a transparent one.

Vapor smoothing

Vapor smoothing is the process of using either acetone (for ABS) or isopropyl alcohol (for PVB) to ‘melt’ the outer layer of a print thereby smoothing out the layer lines that prevent a print from being transparent. Vapor smoothing can be a difficult process to get right as overexposing a part can actually cause the part to melt completely.

With practice, this can be a great technique for improving the transparency of your parts. Be aware though that vapor smoothing can be dangerous (especially when using acetone) so you should only do this in a controlled environment and when using the appropriate safety precautions.

Temperature treatment

It is possible to fuse the layer lines of a print by exposing the outer surface of

the print to heat. The principle is similar to vapor smoothing except using

The principle is similar to vapor smoothing except using

heat instead of a chemical reaction to melt the surface of the model. This can

be done with a heat gun and works particularly well with temperature-resistant

materials such as PETG and CPE+. This is extremely difficult to do reliably with

materials that melt quickly like PLA as you can easily deform your print by

accident.

What are the applications for 3D printed clear parts?

The uses you can find for clear 3D printed parts are limited only by your imagination. Here are some possibilities to get you started:

Scientific Research

Custom transparent parts have various uses for scientific research. For example, researchers at Cardiff University have used 3D printed parts to study microfluidics in a way that is cheaper and more flexible than traditional alternatives would provide.

Visual prototypes

Visual prototypes are an important part of the rapid prototyping process and the more accurate they are, the more useful. If you are working on a product with transparent parts, being able to print those parts and have them look exactly how you want them to can be extremely valuable.

Household decorations

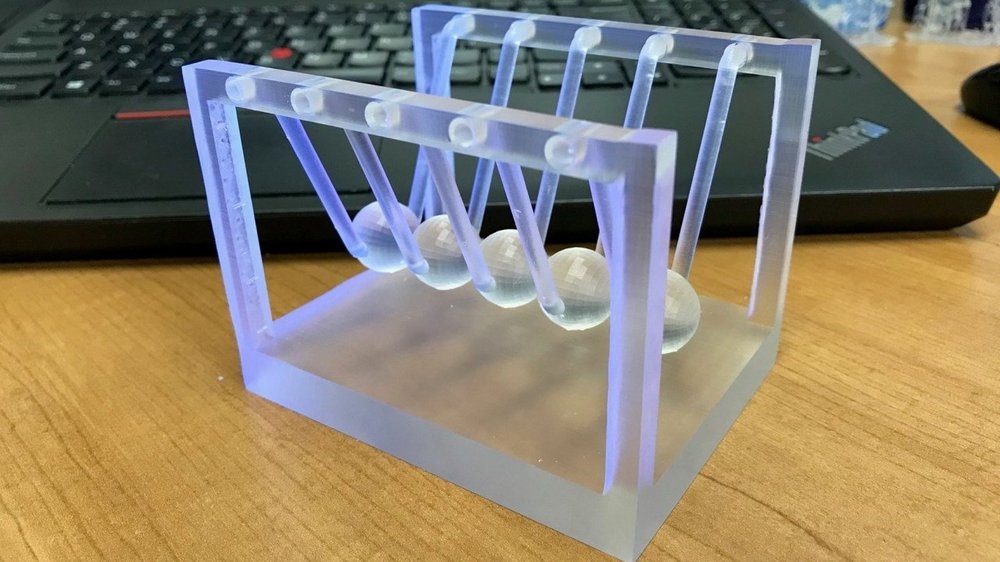

Why not spruce up your home with some fancy new lampshades or vases? With 3D printed transparent parts, you can decorate your home exactly how you want it with parts that not only look good, but are functional too.

Art projects

3D printed transparent and translucent parts open up a whole new world of artistic opportunities. One example is lithophanes. Lithophanes are made by varying the thickness of an object so that when a light shines on it, an image is revealed. It’s possible to create lithophanes with

Can You 3D Print Clear Plastic

Many consumer products, from cell phone cases to kitchen appliances, use transparency to help with both functionality and appearance. But unlike other materials traditionally used in prototyping – foam, clay, fabric – fully transparent materials can be difficult to manipulate.

But unlike other materials traditionally used in prototyping – foam, clay, fabric – fully transparent materials can be difficult to manipulate.

Now that 3D printing has been identified as a solution for design problems, you might be wondering if you can 3D print transparent materials the same way you can print opaque plastics and photopolymers.

The short answer? Yes!

Multi-material 3D printing technology makes creating custom translucent and transparent parts easier than ever. Read on to find out more about transparent materials, how 3D printing them works, and possible applications.

What's the difference between transparent, translucent, and opaque materials?

Opaque materials entirely block the passage of light, meaning nothing can be seen through them. The majority of materials, like colored plastics, wood, and metal, are opaque.

Translucent or semi-transparent materials allow some passage of light, but you usually can’t see clear shapes through them. Examples of common translucent materials include wax paper, sheer fabric, and frosted glass.

Examples of common translucent materials include wax paper, sheer fabric, and frosted glass.

Transparent materials allow enough light to pass through so that objects on the other side of the material can be seen clearly. Clear glass, water, and cellophane are all examples of common transparent materials.

Designers use all of these types of materials – and every opacity in between – for product development. Certain applications may require semi-transparent materials, while others might need fully transparent components.

How can you 3D print transparent materials?

As with most 3D printing methods, it truly depends on the application. For rough prototypes or tooling, one option is FDM technology and transparent filament. With extensive sanding and/or coating, a degree of translucence can be achieved.

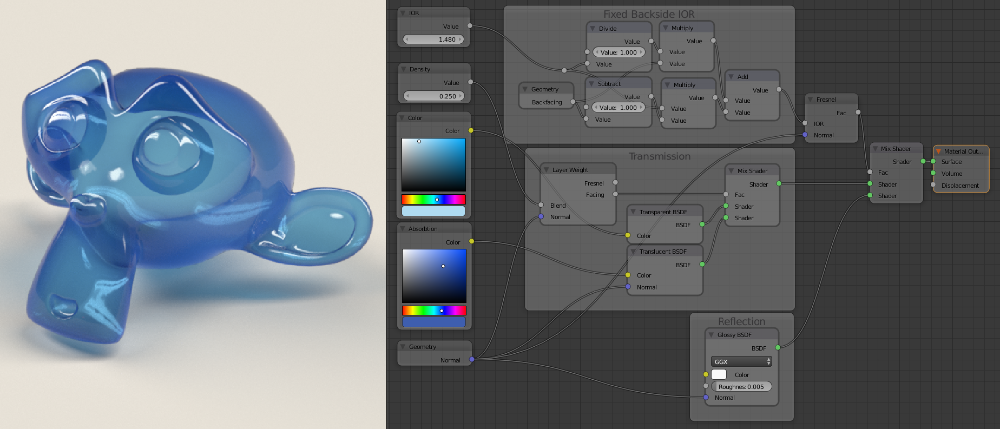

However, for high-fidelity models or final use parts, a smooth finish and true transparency may be required. Photopolymer materials like Stratasys VeroClear™ and VeroUltraClear™ are engineered for a smooth finish and high light transmission for excellent clarity.

Can you 3D print acrylic?

PMMA, also known as acrylic, is a transparent thermoplastic often used as a more durable alternative to glass. For 3D printing, VeroClear and VeroUltraClear simulate the physical properties of acrylic, and can be combined with thousands of opaque color options for a full range of colored transparencies.

VeroClear offers similar mechanical properties to acrylic, with good strength, stiffness, and impact resistance. VeroUltraClear provides excellent, improved clarity and a lower yellow index for truly transparent parts. 3D printed fish.

What are practical applications for transparent materials?

Consumer products.

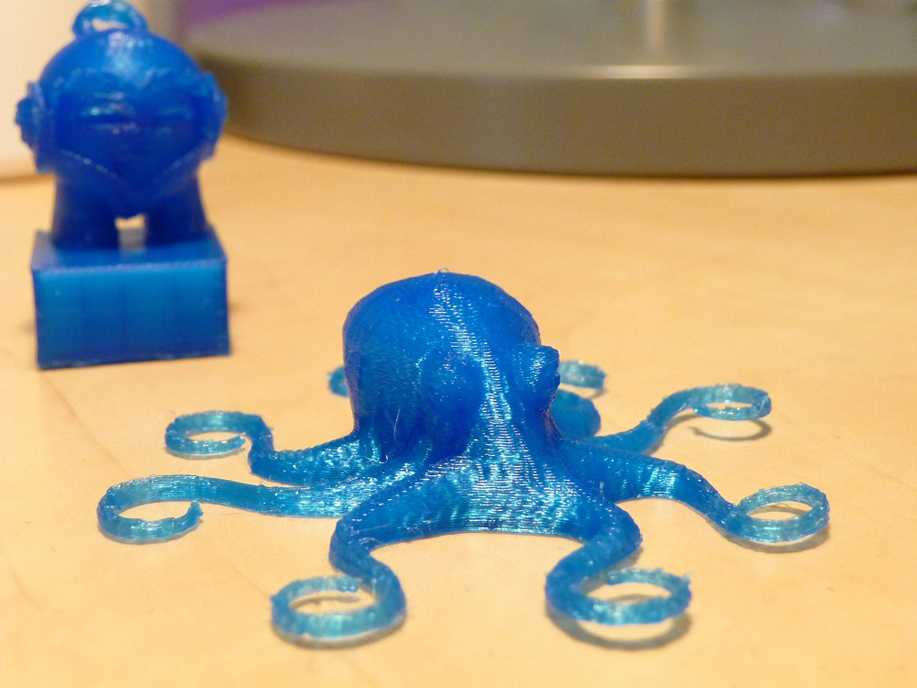

For consumer products, the applications for 3D printed transparent materials are endless.

Incorporate transparency into prototypes for cosmetics packaging, kitchen products, and food and beverage containers. Tinted transparent components help build up model realism, helping designers see their ideas become reality.

Medical devices.

For models that need to simulate glass or clear polymers for eyewear, VeroClear and VeroUltraClear are ideal choices. Nidek Technologies, an Italian company specializing in ophthalmology R&D, used VeroClear to prototype a special new optic device.

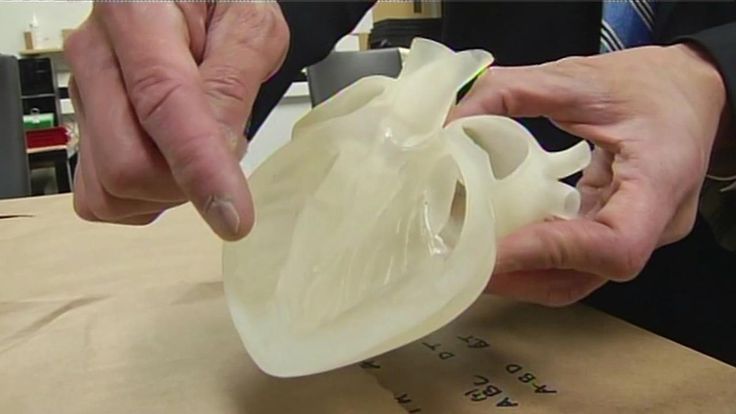

Medical models.

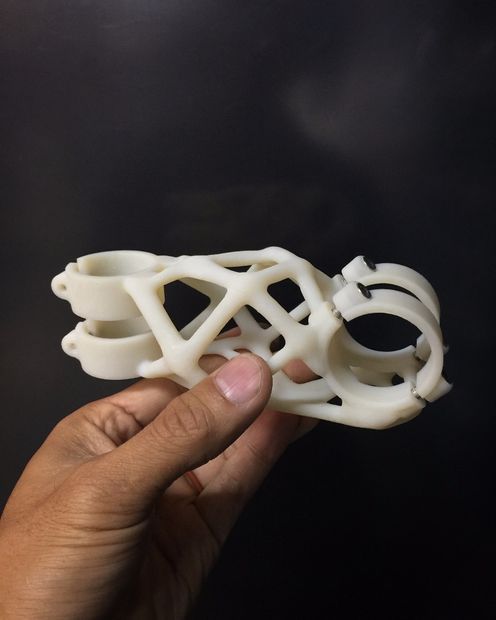

For surgical training or preparation, anatomical models with transparent components or walls are useful when studying complex anatomies like vascular systems. Clear 3D printed materials allow the creation of custom, transparent geometries, opening up a range of possibilities for medical research and patient care.

3D printing clear plastics can provide a whole new way of designing, whether for consumer products or medical research. With the ability to create fully custom transparent parts, you can create models that show internal mechanisms, accurately represent a final product, or allow for functional, real-world testing.

To learn more about what you could do with transparent 3D printing, visit the material pages for VeroClear and VeroUltraClear.

Do-it-yourself lightsaber or choosing transparent plastic for 3D printing Bringing what we see on the big screen to life in a believable way requires a lot of trickery, and with limited resources and budgets, creative skills are sharpened to the limit.

PapaTony's Shield&Hammer team offers their own solution to the task of making a lightsaber.

One of the rare materials is transparent tubes. They can be obtained in advertising workshops, where light structures are made. We conducted an on-duty call to all those involved in such a case within a radius of 500 kilometers around Krasnoyarsk. All that they could offer us was the certainty that some factory would put the required pipe into the production plan and it might be delivered in 3-4 months. Plus prepayment. Obviously not our choice.

Decided to do everything by hand. nine0003

In general, we did not make a Jedi sword, but the design is similar. So, to create a luminous blade, you need a strong transparent plastic.

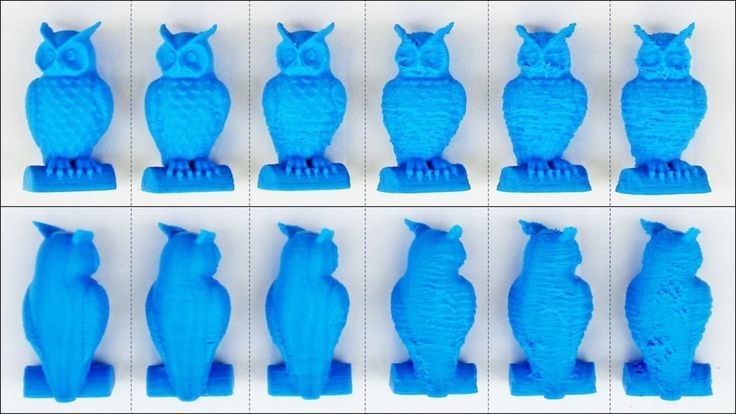

For tests, we took materials already known to us and decided to master new ones:

- Natural PLA is a material widely known to everyone working with 3d printing. Differs in ease of the press, high rigidity.

- Natural Watson (SBS) is a very popular thin-walled plastic. The ease of post-processing to give the product evenness and transparency has made this plastic the best choice for creating vases/bottles/dishes/lamps, etc. They are easy to print with moderate softness. nine0018

- Natural PETG is a material that has recently gained popularity. It has excellent interlaminar adhesion. Practical experience with him is not enough, we will catch up.

- Transparent ABS is a very mysterious material. Natural ABS is ivory white with a slight warm yellowish tint. Apparently, transparency is achieved by adding some substance. According to the manufacturer, printing and processing is no different from conventional ABS.

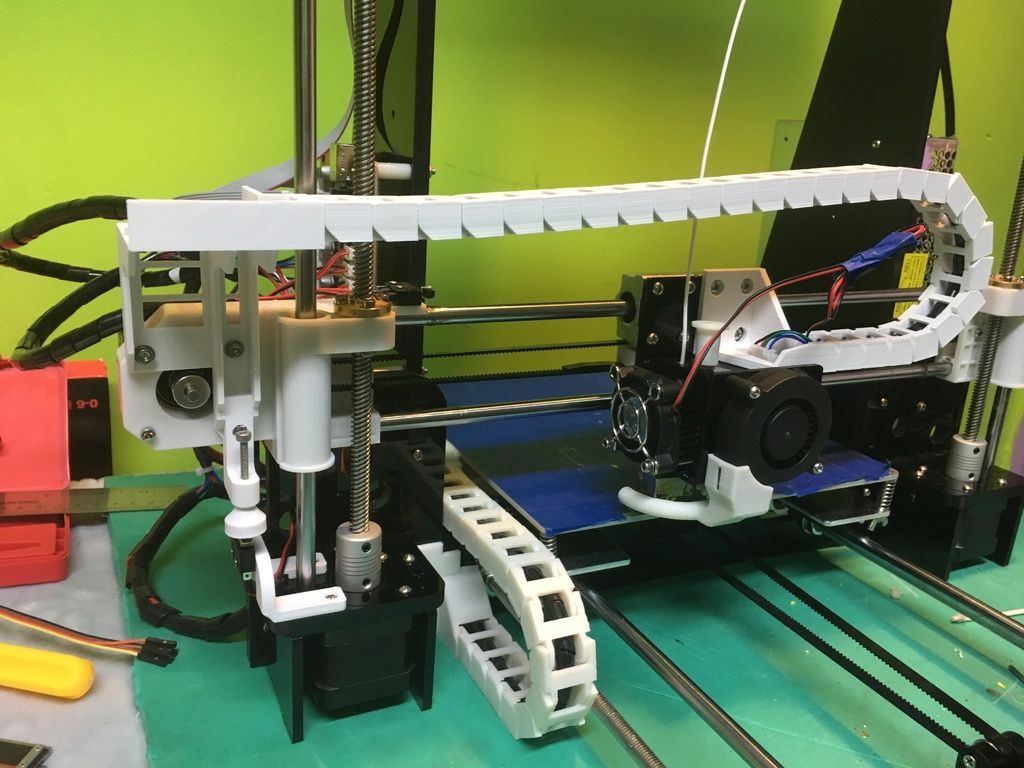

A printer with a print height of 1 meter was also not found, and there was not enough time to assemble my own. Therefore, a test for bonding strength was added to the test for the strength of the structure itself.

Therefore, a test for bonding strength was added to the test for the strength of the structure itself.

Printing was done with the following settings:

- The print and bed temperatures for each material were selected closer to the upper limit of the manufacturer's recommendations - this way there is a higher probability of obtaining a stronger adhesion of the layers

- Nozzle 1.2 mm, layer 0.6 mm, extrusion width 2.4 mm. Print mode - spiral vase. nine0018

- Airflow is switched on from 3 layers even for ABS - there is a risk that a thick layer of plastic will not have time to cool and the structure will float.

- Print speed 15 mm/sec — you should not rush when printing such objects, the lower the speed, the better the sufficiently thick plastic layer cools down.

- Model - a simple cylinder with a diameter of 30 mm and a height of 200 mm (print height of the vast majority of popular printers).

PETG looks the most transparent in appearance due to the excellent adhesion of the layers. Next comes Watson. ABS and PLA are tied for third place. nine0003

Next comes Watson. ABS and PLA are tied for third place. nine0003

Since the print height of the printer is not enough for a more or less decent sword, it remains only to glue:

- PLA - with dichloromethane.

- Watson - solvent or xylene (let's try both options).

- PETG - no solvents were found, so we will use cyanoacrylate (aka superglue).

- ABS - acetone.

When printing with a spiral vase, the tubes are smooth on one side, with a step on the other:

It is not necessary to cut the step - it is great for joining the two upper parts of the tube:

Cyanoacrylate hards due to moisture in the air, to accelerate the process, the moisturizer was included:

Ready for tube tests:

To begin with, all gluings were tested for static load. A package with dumbbells weighing 2 kg was suspended from the center of each rod.

PLA turned out to be the most rigid, 60 cm of the tube practically did not bend:

ABS confidently holds 2 position on the deflection

Petg slightly lags behind ABS

, Watson behaves softer than all

To evaluate the strength in the dynamics, we decided to break the trumpets of Sinai-a training sword sword for kendo.

All specimens withstood at least one well placed impact. The fragments were collected for study.

PLA parted along the seam in the first place of gluing, broke near the seam in the second:

Watson is split and broken:

PETG is half split at the joint, half cracked:

ABS is split at the bond. At the point of impact, a change in the transparency of the plastic is visible:

Subtotal: all plastics held up with dignity. To be honest, I expected that everyone would break with one blow.

Based on the test results, we chose transparent ABS in our project - in case of breakage, it is easily and quickly glued with acetone / dichloromethane and perfectly processed (were sanded so that the light from the LEDs was more uniform). nine0003

nine0003

The resulting sword is:

A little about lighting. The problem with LED strips, and LEDs in general, is pointiness. Without tricky tricks it is impossible to create the effect of a uniform glow in any type of plastic:

However, if you add a matte tube to the center, the lighting is evened out

. nine0003

Transparent ABS was a pleasant discovery for me - it retained the qualities of conventional ABS (easy to process, high strength, solvents available, high temperature resistance, great printing experience with this material) and at the same time expanded the boundaries of the material.

Thank you for your attention, and may the Force be with you.

Primer for plastic models: how to polish transparent plastic

FDM printing technology, in which the vast majority of lines are even, makes the post-processing of printed products an important step. Especially often this procedure is required in cases where the surface of the printed product must be even. nine0003

nine0003

Post-processing of 3D models

Post-processing is the process that takes place after the product has been printed. It is necessary for the layer-by-layer printed 3D model to have the highest quality appearance, without irregularities and shortcomings.

Post-processing does more than just make a product look more professional. But in some cases, it makes it more durable by changing the elasticity parameters of the material, its density, as well as some structural and textural features. nine0003

How to process the model after 3D printing: step-by-step instructions

Processing of finished products after printing is completed can be carried out by different methods. The choice of method depends on the final goal and the characteristics of the filament with which the product was printed.

Support Removal

If the part has been printed with support structures, the first step in post-processing is to remove them. The processing method in this case directly depends on what material was used to create them - soluble or insoluble. nine0003

nine0003

IMPORTANT! Unlike other finishing methods, support removal is a must. However, their removal does not guarantee an improvement in the surface quality of the object.

To remove supports printed with insoluble materials, you will need the following tools:

- Pliers.

- Set of brushes with bristles of different degrees of hardness.

The support material can be easily removed from the product surface. This process does not require much effort. In places with difficult access (recesses, holes, etc.), you can remove excess layers using pliers or a brush. nine0003

This post-processing method does not affect the geometric proportions of the manufactured item, but cleaning may leave marks on the surface that can be removed by further processing using other methods.

Printing supported items almost always leaves marks on the surface of the item. This not only worsens the appearance of the product, but also reduces the accuracy of printing in case of insufficient quality settings of the 3D printer.

Scraping

Once all supporting structures have been removed, the product can be sanded. This will not only level the surface, but also give it smoothness, as well as remove obvious defects and marks remaining at the points of contact of the product with supporting structures.

The choice of sanding paper depends on how thick the layer was when printing, as well as the quality of the finished product.

For example, if the layer thickness is 200 microns, a P150-marked sandpaper would be suitable for post-processing. If there are obvious flaws on the product, and the layer thickness during printing was from 300 microns, cleaning must begin with the use of P100 sandpaper. nine0003

The deburring process can be continued with a change in grit size up to P2000.

IMPORTANT! During cleaning, the surface must be cleaned with brushes, soapy water and a soft sponge. This will remove dirt, dust, and improve the quality of processing.

It should be remembered that sanding is recommended to be carried out in a circular motion, cleaning the entire surface of the product. Parallel or perpendicular movement of the skin must be avoided - this can lead to the formation of deep furrows and scratches. nine0003

Once the sanding step is complete, the surface will be as smooth as it needs to be, and subsequent post-processing steps will be much easier.

The disadvantages of the method include the impossibility of using it for parts that have one or two shells due to the high risk of damage to the printout, as well as the complexity of applying the method if the product has a large number of small parts.

Filling voids

After the supports are removed and the part is sanded, voids may form on the surface of the part. This defect may appear directly during printing in cases where the layers for any reason are incomplete. nine0003

nine0003

Small crevices and voids can be filled with epoxy, and large defects, which often occur when printing a large product consisting of several parts at once, with a special filler used in bodywork. However, this method has a significant drawback - the filler used in body repairs, like any other polyester epoxy adhesive, leaves discolored areas on the product when dried.

IMPORTANT! After filling the voids, the part must be resurfaced.

You can also fill voids in the printed product with putty. The part in which the voids are filled with its help can be easily processed with sandpaper and then painted. In addition, voids connected by a filler acquire additional strength, which has a positive effect on the performance of the product.

If the printout was made with ABS, the voids can be filled with specially thinned ABS. After filling, the solution reacts with the walls of the cavity and seeps into the voids. nine0003

Dichloromethane is also popular and is suitable for most types of filament, including ABS, PLA, HIPS, SBS, etc.

How to prime?

After the printed product has been cleaned, it can be treated with a primer. To do this, you will need:

- Lint-free material to be used to wipe the product.

- Toothbrush.

- 150/220/400/600 grit sandpaper.

- Primer for plastics (spray is preferred). nine0018

- Polishing sticks.

- Polishing paper.

- Personal protective equipment - mask and gloves.

IMPORTANT! The method is suitable for all types of filaments.

Having prepared the part, it is necessary to treat its surface with primer from a distance of 20–25 centimeters, evenly applying a primer coat. After the primer dries, the irregularities will need to be cleaned with sandpaper with a P600 grit, after which a second coat of primer will be applied. nine0003

Painting

When the primer layer on the product is completely dry, you can start applying the paint.

IMPORTANT! You can paint a 3D-printed product with any tool, but the use of a special spray gun will provide the greatest smoothness.

Do not use household spray paints when painting. As a rule, they are characterized by increased viscosity and their application is quite difficult to control. The best option would be to use paints designed for painting models. nine0003

The application of paint must also be carried out in layers, and each subsequent layer can be applied only after the previous one has completely dried.

After the product has been painted, it is necessary to wait for complete drying and carry out the polishing paper. After using it, the coating will shine.

IMPORTANT! Do not shake the can while applying the paint. Mixing propellant and pigment leads to the formation of bubbles, which reduces the quality of the coating. To mix the paint, it is recommended to rotate the can in a circle for several minutes, achieving the rolling of the mixing ball.

nine0003

Epoxy

To coat the product with epoxy you will need:

- Epoxy (two-component).

- Applicator for application of compound.

- Container in which ingredients will be mixed.

- Sandpaper marked P1000 or higher.

Processing must be carried out in several stages:

- Cleaning.

- Mixing resin and hardener. The use of a glass container is not recommended as resins are highly exothermic. nine0018

- Mixing resin and hardener. Stirring should be carried out smoothly to avoid air bubbles entering the composition.

- Applying the first coat of resin. At this stage, it is necessary to minimize the number of irregularities on the product.

- After the first coat of the compound has fully cured, the subsequent coats can be applied.

- When the result is achieved, the product should be cleaned with sandpaper.

Removing Soluble Supports

If soluble filaments were used to print the support structures, you will need to remove them:

- Sufficient container.

- Solvent.

Typically, the process is to place the printed part in a solvent container long enough to dissolve the supports. Any container made from a non-porous material may be used for this purpose.

IMPORTANT! You can speed up the process by using an ultrasonic cleaner, heating the solvent and replacing it in a timely manner.

Cold Weld

The cold weld method uses the following materials:

- Acetone (for ABS).

- Adhesive (for PLA filament).

This method is used when the item is too large to print in one go. In this case, the model is divided into several parts, which are subsequently connected to each other. nine0003

For PLA filament, assembly is done using Bond-O brand adhesive or other suitable compounds, while for ABS, the components are attached to each other with acetone.

The surfaces prepared for joining are lubricated with a joining compound and pressed against each other. They should be held together until the chemical reaction is complete.

They should be held together until the chemical reaction is complete.

How to grind and polish?

For sanding:

- Soft cloths. nine0018

- Sandpaper with various grits (P100 to P2000).

- Toothbrush.

- Soap solution.

The initial grain size of the pelt depends on the layer and print quality.

Sanding to 2000 grit. During processing, the model should be wetted regularly. This will help reduce friction and help keep the sandpaper clean.

For polishing use:

- Special compounds for polishing plastic materials. nine0018

- P2000 grit sandpaper.

- Wiping material.

- Polishing wheel.

- Microfibre cloth.

IMPORTANT! Do not polish the product if it is to be painted later. After polishing, the primer and paint will not stick to its surface.

Smoothing

The smoothing procedure can be performed on all FDM thermoplastics. This will require:

This will require:

- Solvent resistant container.

- Wiping cloth.

- Solvent.

- Aluminum foil.

- Personal protective equipment.

Line the bottom of the container with paper towels and apply a small amount of solvent to them. It is important to lightly moisten, and not soak them.

Acetone is suitable as a solvent for ABS, dichloromethane and other compounds for PLA. A foil stand should be placed in the center of the wet towels and the printed product should be placed on it. nine0003

The container must then be sealed. Polishing with solvent vapors can take different times, so it is recommended to check the workpiece from time to time so as not to miss the desired stage.

The process can be accelerated by gently heating the container.

Metallization

Metallization of products allows to give forgings the appearance of metal products. For this post-processing method you will need:

For this post-processing method you will need:

- Electroplating solution. nine0018

- Sacrificial anode.

- Conductive paint.

- Acetone with graphite.

- Power rectifier.

- Conductive metal screw.

- Non-conductive container.

- Contacts.

- Non-conductive protective gloves and goggles.

At home, the galvanization procedure can be performed using copper or nickel. It is extremely important that the surface of the product is as smooth as possible. Any unevenness after processing will be enhanced, which will spoil the appearance of the product. nine0003

The procedure takes place in several stages:

- Preparing the surface of the product.

- Conductive paint application.

- Connecting a screw or eyelet to the negative terminal of the rectifier.

- The anode must be connected to the positive terminal of the rectifier.

- After turning on the rectifier, the printout is immersed in the container.

- Next, set the voltage to 1-3 Volts and wait for the metallization of the product.

- When the process is completed, the product must be removed from the container and varnished to protect against corrosion. nine0018

How to polish transparent plastic and make it glossy?

Polishing of transparent plastics is carried out using sandpaper with a grit of more than P2000 and special polishing compounds. For small parts, it is recommended to use polishing wheels or other rotary tools.

Post-processing errors and how to avoid them

The most common mistakes made by users during product post-processing are:

- Excessive exposure. If the wall thickness is insufficient, when polishing and grinding, it is easy to wipe the walls to holes.

- When working with adhesives or solvents, precautions must be taken: work in well-ventilated areas, and use a mask, goggles and seals.

- Sanding PLA should not be rushed - the material can roll off under the influence of sanding paper.

Learn more