3D print speed loader

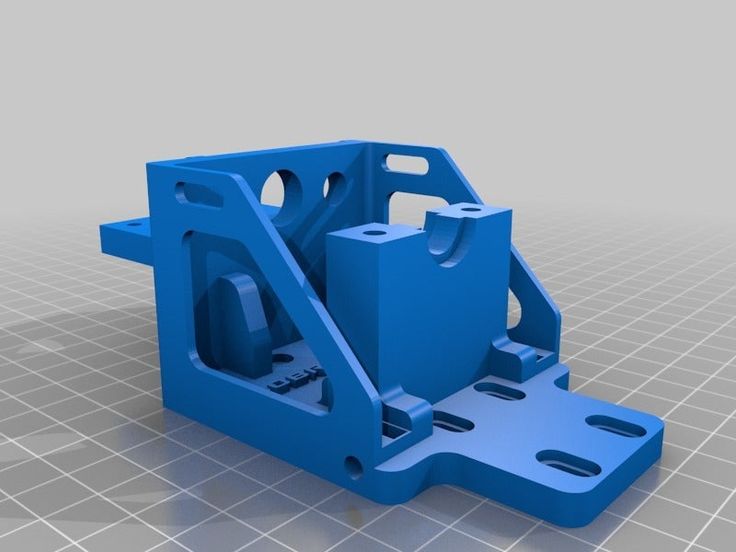

Speedloader best STL files for 3D printer・Cults

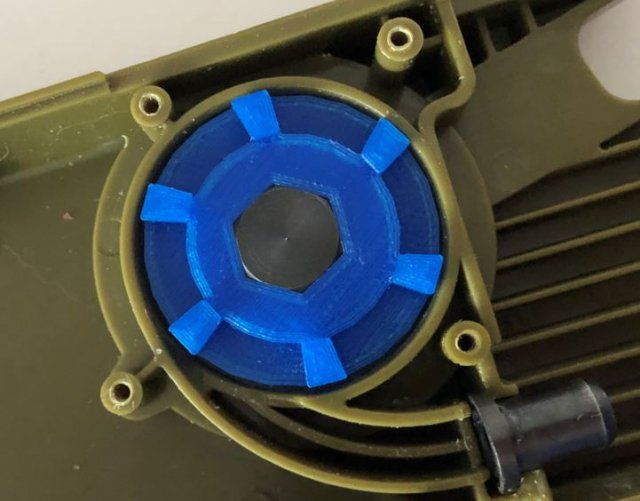

ODIN Sidewinder Adapter for Tokyo Marui NGRS STANAG Magazine

Free

airsoft speed loader adapter for pistol mags v5 (WORKING PROTOTYPE)

Free

ODIN MAG EMPTY

€1

EK Archery Vlad Speed Loader

€5 -75% €1.25

DCD Airsoft - KWA MP9 Magazine Loader Adapter

€3.48

Fast charger for Stinger 2

€2.97 -33% €1.99

Mk2 speedloader for Dan Wesson (push-button)

Free

NERF Roughcut Speedloader

Free

Ruger (and possibly others) Thumb Saver

Free

UNW P90 MAG LOADER SET: mag winder and mag speed loader

€5

Glock mag thumb saver

€0. 93

Hatsan AT44 and BT65 magazine carrier - Speedloader

€4.50

Speedloader for SIG Sauer P365/XL & P226 9mm Magazine

€1.88

ASG EVO 3 speed loader

Free

Odin shotgun adaptor

Free

Airsoft speed unloader

Free

Dan Wesson speedloader (push-button)

Free

BFG 209 primers speedloader

€6.77

M4 to SR25 AEG Speedloader Adapter V1

Free

KWC airsoft Desert Eagle speed loader adapter

€0.70

STANAG Speed Loader (5.56mm/.223 Rem)

€3.13

Maglula Uplula 1911 Aligner Insert

Free

KWA TK45 Magazine Adapter for Odin M12 Sidewinder

€3. 90

90

9mm speed loader/ thumb saver

Free

Airsoft sniper speed loader

€1

Speedloader adaptor for P90

€3.50

Airsoft magazine speed loader adapter

€1.90

ODIN Adapter M4 to HK417

€3.50

MP7 HPA TM Bb loader adapter for Odin

€5.34

Glock SpeedLoader v2 LION

€1.03

Glock SpeedLoader v1 dragon

€1.03

SPEEDLOADER FOR ALL MAGS!

€2.02

SSG Speedloader Adapter

€1.09

AEG pistol mag loader (E1)

€1. 09

09

LOGI C1 / Hi/Mid-Cap Speedloader Adapter

€1.61

MIDCAP UNLOADER FOR BB BOTTLE

€0.93

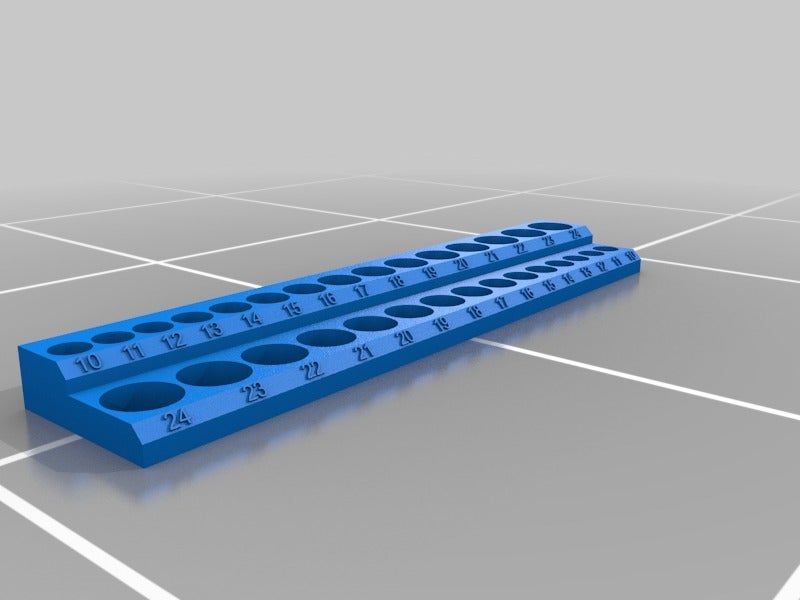

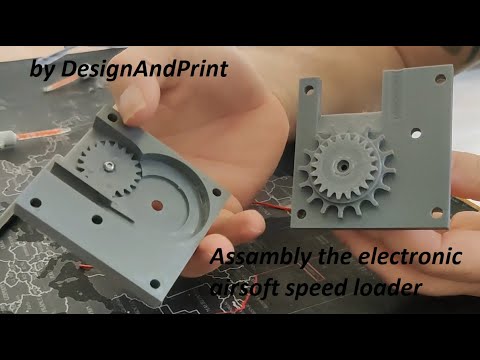

Airsoft Speed Loader (Gear and Handle)

€5

FX Impact Speedloader for High Cap Magazine

€7.95

SSP18/ Glock/ AAP-01 Speedloader Adapter (UH)

€2.50

Airsoft Madbull 10 barrel 120rd 40mm Airsoft Speedloader

€14.10

Speedloader for Colt Python Cal.357

€20

SSP1/ Hi-Capa Speedloader Adapter (OHR)

€2.50

Glock 17/19 Speed Loader

Free

UNW BB feeder funnel, for Tokyo Marui M4 styled BB loader

Free

Speedloader adaptor for AEP

Free

Speedloader adaptor small for AEP

Free

airsoft speed loader drill operated

€1. 34

34

Futura Muffler

€3

Any 3d printers out there? Looking for Impact M3 speed loader stl files | Airgun Forum | Airgun Nation | Best Airgun Site

rodjava

Member

- Add bookmark

- #1

I'm looking for FX Impact m3 .25 cal speed loading .stl files.

I tried a few from thingaverse which did not impress me.

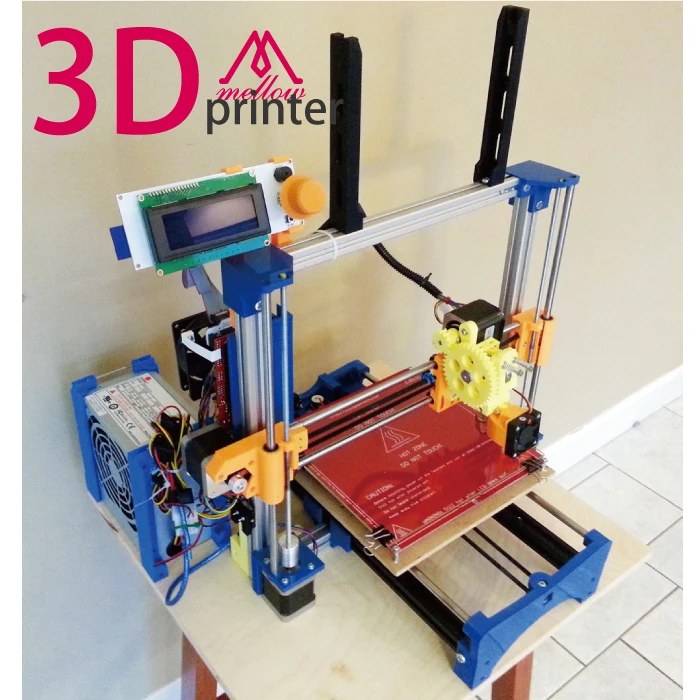

I'm willing to pay a small fee for a great working design. I have both FDM and Resin 3d printers.

I have both FDM and Resin 3d printers.

Rod in San Francisco

Saltlake58

Member

- Add bookmark

- #2

Which designs did you see on Thingiverse and what didn't you like about it?

Upvote 0

heavy-impact

Member

- Add bookmark

- #3

Here's Impact thingyverse files for others to checkout https://www. thingiverse.com/search?q=fx+impact&type=things&sort=relevant

thingiverse.com/search?q=fx+impact&type=things&sort=relevant

Upvote 0

rodjava

Member

- Add bookmark

- #4

Yes, I have seen those thingiverse speed loaders like https://www.thingiverse.com/thing:4337364

The new speed loaders have a feature where you pour the slugs in a form and the pellets automatically register in the right position.

https://hardairmagazine.com/news/stud-magazine-loader-for-fx-impact-now-available/

Even though I could afford to buy these great speed loaders, I find it challenging to 3d print my own if possible Anybody with a 3d printer will know what I mean. I only 3d print parts for my own use and not for resale.

I only 3d print parts for my own use and not for resale.

Upvote 0

Saltlake58

Member

- Add bookmark

- #5

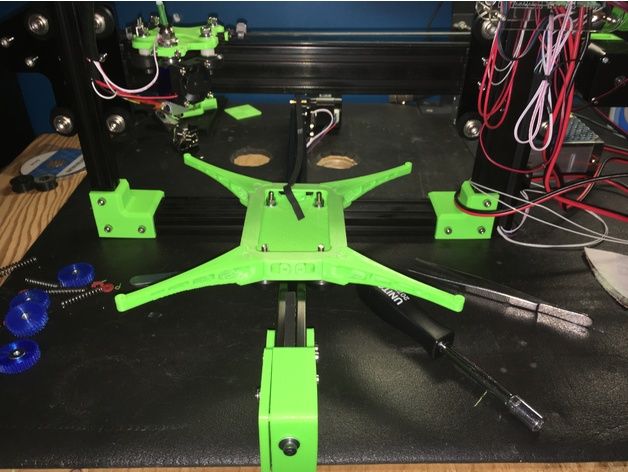

I printed this one: FX IMPACT SPEED LOADER .25 by dye29 - Thingiverse

I printed 10 so I can preload at home, go to the range and just load from the speed loaders. Makes loading on a cold day so much easier. As for all the nifty features of the new loaders, I don't have the skill or time to reverse engineer those products, so just live with the easily available loaders. After all, I can print these for about $.50 each, so 10 loaders is a whole $5. Someday, I'll get into design, but not today. Just don't have time and energy.

After all, I can print these for about $.50 each, so 10 loaders is a whole $5. Someday, I'll get into design, but not today. Just don't have time and energy.

Upvote 0

heavy-impact

Member

- Add bookmark

- #6

Could someone show me a close up picture of this self orienting tray along with any required dimensions?

Upvote 0

rodjava

Member

- Add bookmark

- #7

https://hardairmagazine. com/news/stud-magazine-loader-for-fx-impact-now-available/

com/news/stud-magazine-loader-for-fx-impact-now-available/

Upvote 0

qball

Member

- Add bookmark

- #8

That’s neat, kinda like a speed loader for the speed loaders? Might have to try to figure it out, seems like it’s just a bunch of tapered holes, fantastic idea and design. I really want one for Dreamline/crown mag in 177!!!!

https://youtu.be/bidiQMO2KQg

Upvote 0

ChRiSiS

Member

- Add bookmark

- #9

There is a big difference between the stuff on Thingiverse and the commercial stuff.

The STUDMag Loader guys have invested a great deal of time and effort in their design, and in the manufacturing of it. I don’t think its reasonable to expect them to then give away the design. If it was easy then anyone could do it. I have 3D printers, and have used them to print Leshiy 2 speedloaders. Even then, I ended up purchasing a few. From others, since their design and print efforts were much better than mine.

I have also purchased the STUDMag loaders (both the original designs and these new ones). I can honestly say that they are (1) ingenious, (2) work very well, and (3) given the effort are well worth the price. I also don’t think that they would be a simple 3D print.

Qball, the .177 loaders are the best of the bunch, especially since I have such a hard time managing those tiny pellets.

Chris

Upvote 0

qball

Member

- Add bookmark

- #10

Qball, the .

177 loaders are the best of the bunch, especially since I have such a hard time managing those tiny pellets.

Chris

Click to expand...

definitely agree! 177 pellets are a pain to load, the design is excellent. I’m ordering the sorter for sure, already got quite a few loaders. No issues supporting folks bring a lot of value to our little addition. Sadly their sorter won’t work on slugs or I would order more calibers.

Upvote 0

timmah

Member

- Add bookmark

- #11

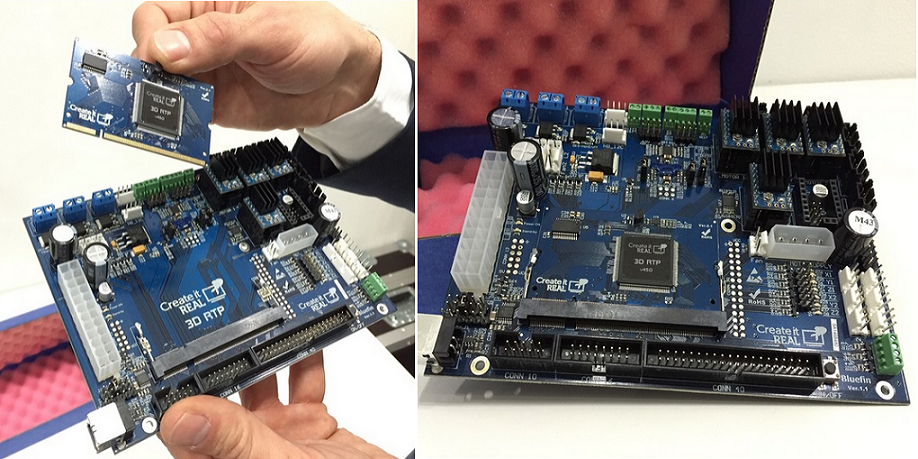

Saw this design for purchase: https://cults3d. com/en/3d-model/various/fx-impact-speedloader-for-high-cap-magazine

com/en/3d-model/various/fx-impact-speedloader-for-high-cap-magazine

Upvote 0

rodjava

Member

- Add bookmark

- #12

timmah,

Thanks for the link. Looks promising.

For a 3d printer like me, even $8.99 is too much for me.

Call me frugal.

I agree with the other members that the Stud Mag guys put a lot of time, money and effort in their product. I would never try to copy their idea and sell them. I would only do it for the challenge and pride as a 3d printer. This is the reason we paid $$$$ for our printers!

I would only do it for the challenge and pride as a 3d printer. This is the reason we paid $$$$ for our printers!

Upvote 0

ChRiSiS

Member

- Add bookmark

- #13

timmah,

Thanks for the link. Looks promising.

For a 3d printer like me, even $8.99 is too much for me.

Call me frugal.I agree with the other members that the Stud Mag guys put a lot of time, money and effort in their product.

I would never try to copy their idea and sell them. I would only do it for the challenge and pride as a 3d printer. This is the reason we paid $$$$ for our printers!

Click to expand...

I think trying it for your own use (as opposed to selling it) is fair game. That's why I got a 3D printer too. I just find that its harder than it looks sometimes.

Upvote 0

bigHUN

Member

- Add bookmark

- #14

I have now a second SLA printer (the first one mid range machine didn't meat my expectations) and for my own rapid protoyping I am printing engineering hard-tough resins only and that material is upscale $$$.

Even the new printer I upgraded with my own designed accessories, also I developed a pretty robust post processing system and I am also annealing my parts.

From my perspective I don't have a business case making parts for sale to anybody else, you cannot pay me for the amount of work these my SLA parts need

I am feeding my own hobbies only.

Forgive me for my comment, but I really not seeing the benefits of a speedloader. Maybe because when I go shooting BR that is at least 2-3 hundred shots per visit, loading it to a speedloader or directly to the mag is a same poop to me (OK I have to admit I have 3 large mags in .25). This just my opinion and may not float your boat.

Upvote 0

ChRiSiS

Member

- Add bookmark

- #15

I have now a second SLA printer (the first one mid range machine didn't meat my expectations) and for my own rapid protoyping I am printing engineering hard-tough resins only and that material is upscale $$$.

Even the new printer I upgraded with my own designed accessories, also I developed a pretty robust post processing system and I am also annealing my parts.

From my perspective I don't have a business case making parts for sale to anybody else, you cannot pay me for the amount of work these my SLA parts need

I am feeding my own hobbies only.

Forgive me for my comment, but I really not seeing the benefits of a speedloader. Maybe because when I go shooting BR that is at least 2-3 hundred shots per visit, loading it to a speedloader or directly to the mag is a same poop to me (OK I have to admit I have 3 large mags in .25). This just my opinion and may not float your boat.

Click to expand...

BigHUN, the real benefit in a speedloader only exists if it is easier and faster/more convenient than loading the magazine. The STUDMag loaders really deliver this, especially in smaller calibers. The difference with an Impact magazine, especially in . 177, has to be experienced to be believed. It is faster to throw a bunch of pellets on the Feeder, then use that to load the Speed Loader and then use the Speed Loader to fill the magazine than to try and fill the magazine directly. For FX high capacity magazines, say an Impact, or a Crown the difference is huge in all calibers up to .25 For .30 caliber Crown/Maverick/Wildcat/Dreamline mags it is more marginal, since the capacity is lower (13) and the pellets larger.

177, has to be experienced to be believed. It is faster to throw a bunch of pellets on the Feeder, then use that to load the Speed Loader and then use the Speed Loader to fill the magazine than to try and fill the magazine directly. For FX high capacity magazines, say an Impact, or a Crown the difference is huge in all calibers up to .25 For .30 caliber Crown/Maverick/Wildcat/Dreamline mags it is more marginal, since the capacity is lower (13) and the pellets larger.

Upvote 0

bigHUN

Member

- Add bookmark

- #16

Click to expand.

..

BigHUN, the real benefit in a speedloader only exists if it is easier and faster/more convenient than loading the magazine. .............especially in .177, has to be experienced to be believed............

Click to expand...

I didn't knew that I have only a .25, sorry for my comment, I didn't meant to hurt .....

I gave up with .177 and .22 long time ago, my reading glasses on and off and on and off just started making me emotional. .25 is a so so I can reload the mag in a mid noon, later afternoon or indoors getting problematic.

Upvote 0

You must log in or register to reply here.

Share:

Facebook Twitter Reddit Pinterest Tumblr WhatsApp Email Share Link

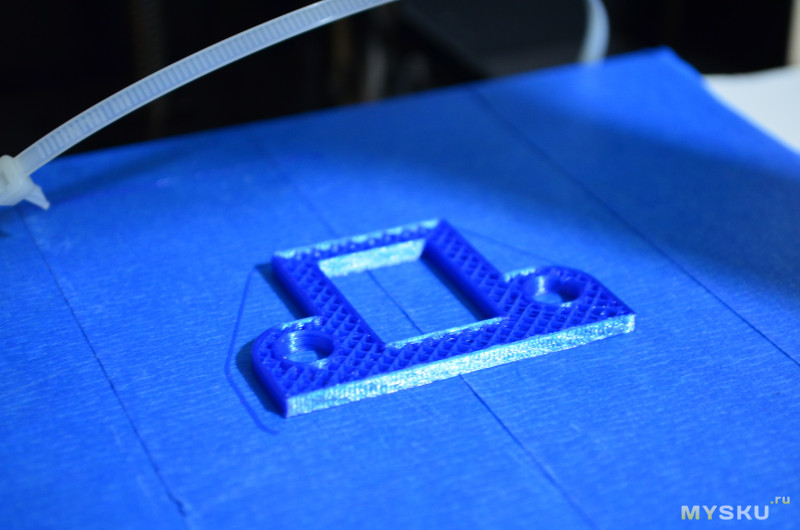

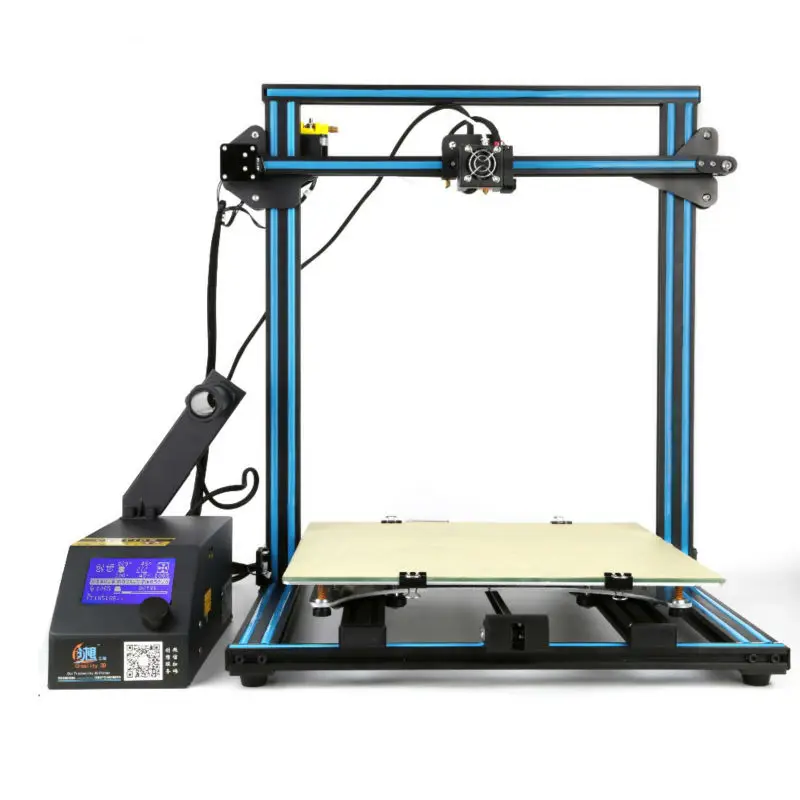

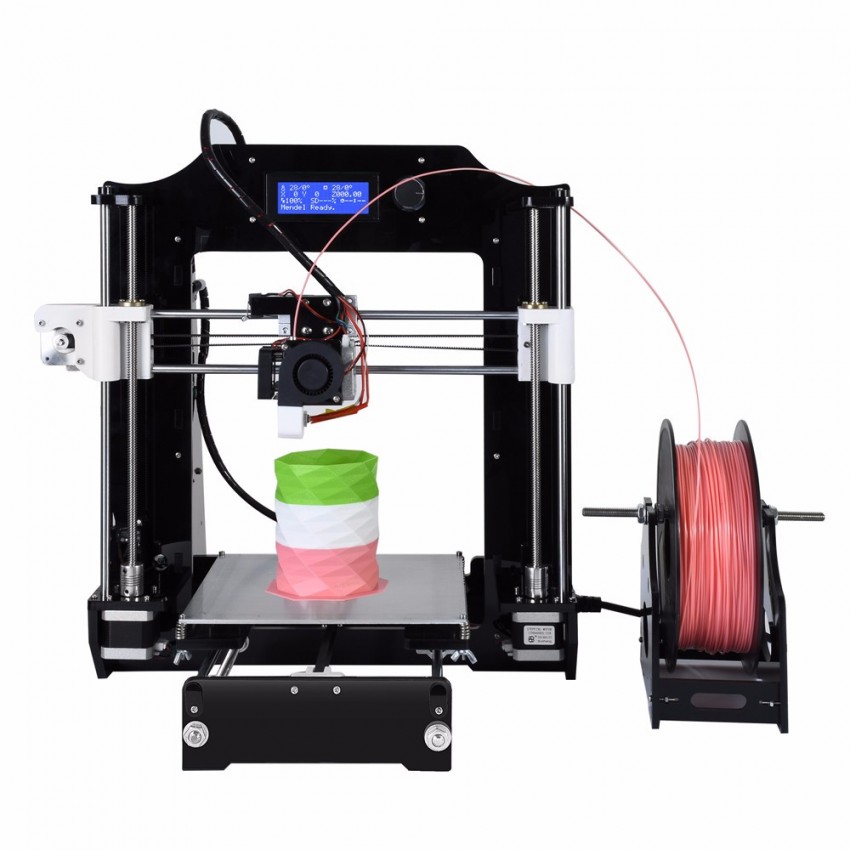

3D printer speed: how to set it up correctly?

3DPrintStory 3D printing process 3D printer speed: how to set it up correctly?

3D printing is often referred to as "rapid prototyping". The irony is that the creation of individual models can take up to several hours. Fortunately, 3D printing speed can be adjusted to reduce production time, but setting the speed incorrectly can also lead to defects and 3D printing failures. nine0005

The irony is that the creation of individual models can take up to several hours. Fortunately, 3D printing speed can be adjusted to reduce production time, but setting the speed incorrectly can also lead to defects and 3D printing failures. nine0005

In this article, we will introduce you to the general speed settings of a 3D printer. By the end of this guide, you'll know how to find the perfect balance between print speed and quality. Please be aware that different 3D printers, slicing software and materials may behave differently and retesting may be required.

Well, run the slicing software and let's get started!

3D Print Speed

3D Print Speed is the main setting that affects the printing of your 3D model. As the name suggests, print speed determines how fast your printer's motors move. This includes the motors that control the X and Y axes, as well as the motor(s) of the extruder. nine0005

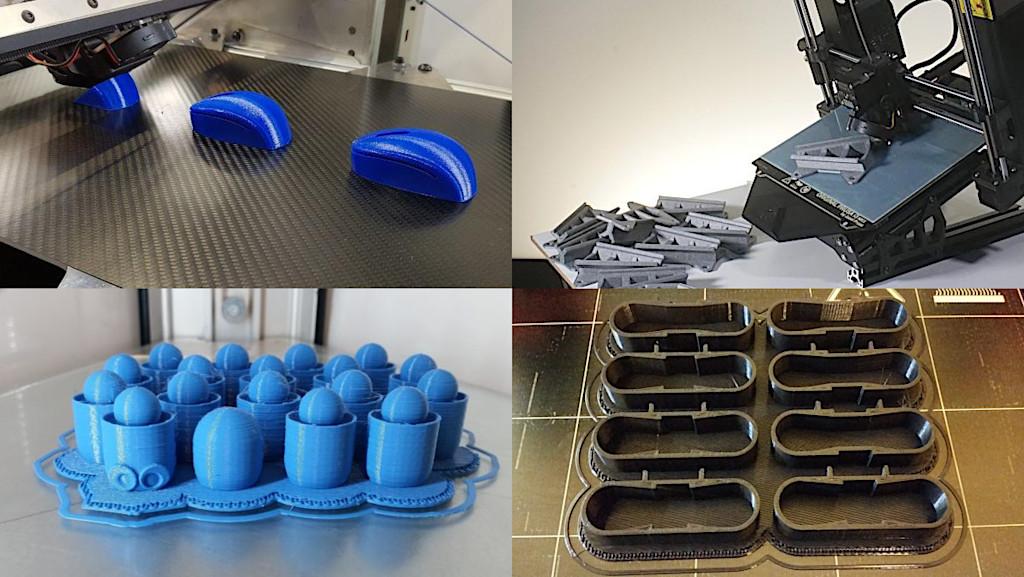

To test your 3D printing speed, download the test model to determine the optimal print speed above. The description of this 3D model also contains recommendations for speed settings. In essence, the experiment is that the same model will be printed, but at a gradually increasing speed, which will allow you to visually determine the optimal speed setting.

The description of this 3D model also contains recommendations for speed settings. In essence, the experiment is that the same model will be printed, but at a gradually increasing speed, which will allow you to visually determine the optimal speed setting.

Too low a 3D print speed can cause deformation due to the nozzle being on the plastic for too long. If too fast, other overheating artifacts may appear, caused by insufficient cooling, as well as extrusion and poor adhesion of the layers. The optimal speed should be as fast as possible for your 3D printer without compromising print quality too much. This 3D model will help you determine what speed will be optimal for your particular case. nine0005

To optimize print speed, this parameter is usually divided into several sub-parameters:

- Outer Wall/Shell 3D Print Speed : This parameter controls the print speed of the outer perimeter of the model. Usually it is slightly reduced to improve the surface quality.

- Inner Wall/Shell 3D Print Speed : This parameter controls the print speed of the inner perimeter(s) of the model. It is usually the same as the overall print speed to reduce print time while maintaining durability. nine0028

- Infill 3D Print Speed : This parameter controls the infill print speed of the model. This is usually the same as the overall print speed to reduce 3D printing time while maintaining strength.

- Top/Bottom 3D Print Speed : This setting adjusts the print speed of the top and bottom of the model. Usually it is slightly reduced to improve the surface quality.

Travel speed (idle)

Travel speed controls how fast the print head moves when it is not extruding plastic. Increasing the movement speed can save a lot of 3D printing time, but increasing it too much can lead to many defects, including misaligned layers (and therefore 3D printing failure). nine0005

To determine the optimal idle travel speed for your printer, print this test pattern at various travel speeds, starting at 100 mm/s and working up in increments of 5 mm/s. Continue to increase the speed if the surface quality is acceptable, and decrease if the 3D print quality is deteriorating. Pay attention to defects such as mismatched layers.

Continue to increase the speed if the surface quality is acceptable, and decrease if the 3D print quality is deteriorating. Pay attention to defects such as mismatched layers.

Retract Speed

Retract Speed controls how fast the 3D printer pulls material back before moving. This setting is critical for reducing material waste and improving 3D print quality. Too slow and you may be left with unsightly threads and blemishes on your models. Too fast and you can get excessive material wear on the extruder drive gear, resulting in voids. nine0005

To determine the optimal retract speed for your 3D printer, print this test model at various retract speeds, starting at 25mm/s and adjusting in 5mm/s increments. Pay attention to the remnants of plastic in the form of a web, stretched between the spikes of the model. The ideal retract speed should be the maximum value that minimizes these artifacts without deforming the material in the feed mechanism.

To better tune the retract speed, this parameter is usually divided into two additional parameters:

Retraction Retract Speed : This parameter controls how fast the retraction (actually pulling the thread back) occurs. This is usually the same as your overall retract speed and is set the same way.

This is usually the same as your overall retract speed and is set the same way.

Retraction Prime Speed: This setting controls how fast the filament is re-feeded after the initial retraction in preparation for further printing. Increasing this speed will result in shorter 3D printing times and fewer defects due to prolonged exposure to heat on the plastic. However, increasing it too much can also cause the newly fed media to not heat up enough before printing resumes. For most cases, this setting should be left the same as Retraction Retract Speed. nine0005

To learn more about reducing retract speed defects, see our separate retract speed tuning guide.

Walls, infill and layer height

The speed of your 3D printer is not only affected by "speed". It is also significantly affected by how much and how thick plastic is extruded onto each layer of the 3D model. These settings are incredibly detailed, so we'll only cover general information about how each of them affects 3D print speed. nine0005

nine0005

- Walls : The wall setting specifies how many perimeters of plastic are extruded to form the outline of your part. Increasing the number of layers increases the strength of the part, but also increases the 3D printing time.

- Infill : Infill is an internal structure designed to save material when 3D printing the interior of 3D models. The infill pattern will slightly affect the speed of 3D printing, while the density of the infill will significantly change the print time. Higher infill density increases part strength, but also increases print time. nine0028

- Layer Height : The layer height greatly affects the speed at which your parts print. The higher the layer height, the thicker each layer of your 3D models and therefore the faster they will be completed. Adjust this depending on what print resolution you need.

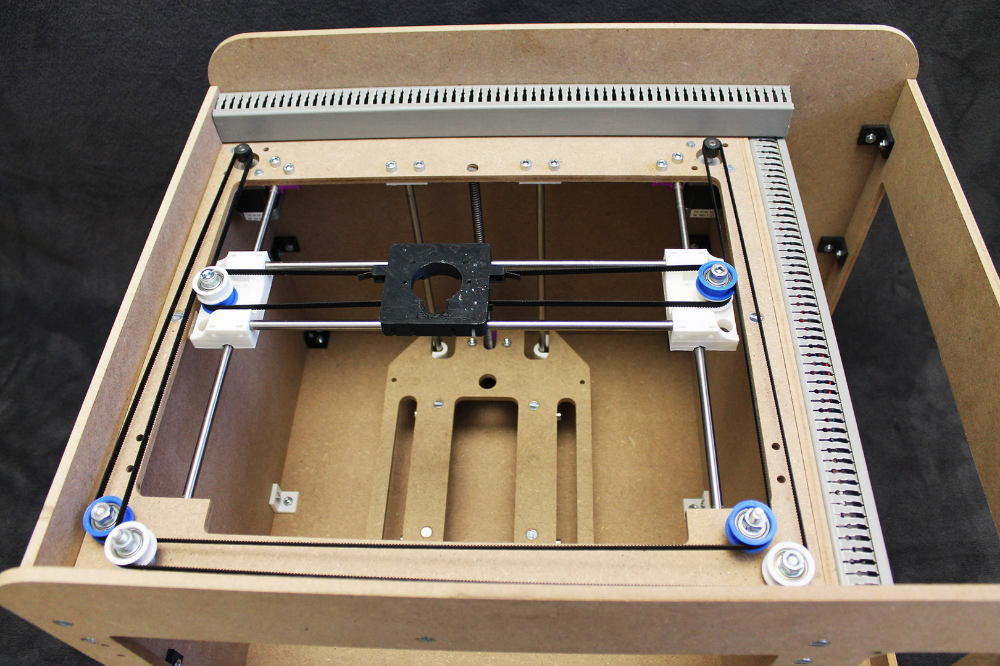

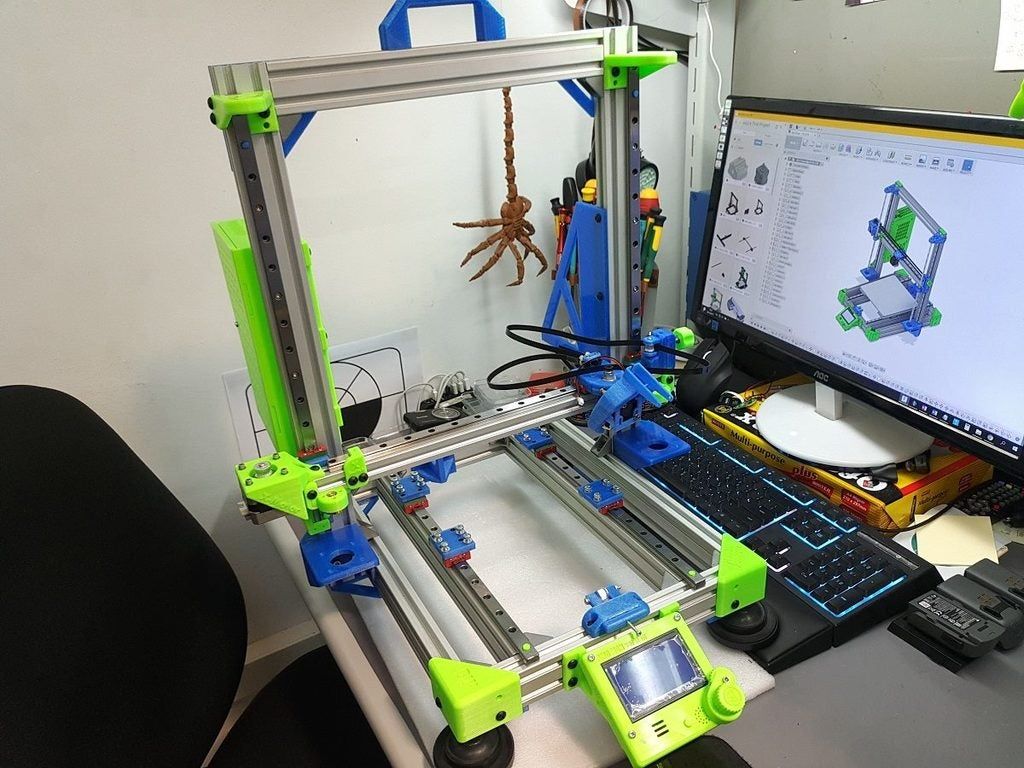

In search of the holy grail or how to find the maximum speed of 3D printing.

How to do a quick extruder performance test? How to find the maximum print speed on an FDM printer? What is the best print speed? How to find the optimal print speed? Why is the extruder throat clogged, did I put everything together correctly? How to quickly print on a 3D printer? Why is the filament wrinkled in Bowden? Why does the extruder chew on the filament? nine0005

About the main thing

Only three parameters are responsible for the maximum print speed on an FDM printer:

- The technical characteristics of the printer are how fast it can move the printing machine.

You can learn them from the user manual, so the study of mechanics is not considered here - your printer will not be able to move the print head faster than it is physically capable of.

You can learn them from the user manual, so the study of mechanics is not considered here - your printer will not be able to move the print head faster than it is physically capable of. - Extruder performance - whether the extruder is able to melt enough plastic to produce a line of a given height and width at a given print speed. This is an important parameter that depends on the design of the heating block, the standard E3D V6 melts less plastic than VOLCANO, but, as practice shows, there are no problems in the vast majority of cases, since on standard nozzles with a diameter of 0.2 to 0.6 mm you you will encounter another main reason for not being able to increase the print speed, namely:

- Maximum nozzle output!

Yes, the most critical point on the way to print speeds is precisely the performance of the nozzle - the amount of plastic that it can pass through itself without damaging the thread, without clogging the extruder, etc.

It is the nozzle output that is the total output of the entire extruder, which affects the maximum line speed.

So, the output of the extruder is equal to the output of the installed nozzle. nine0005

How does it work? (short retelling, no details)

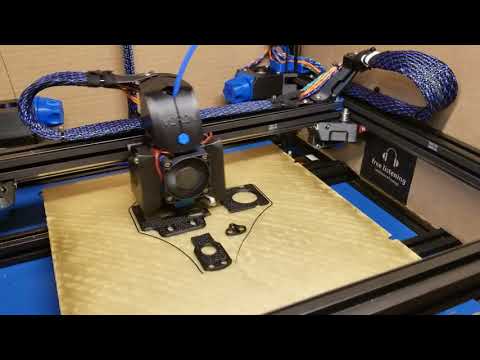

For those who are more interested in watching and listening - here is the video.

For those who are not interested in the details and who want more action immediately, without reading the abbreviations - a link to an Excel spreadsheet.

- Pre-set the flow (number of motor steps per mm), there are a lot of instructions on the Internet, I won’t write here - let’s assume that you have the flow set up.

- Uploading an excel spreadsheet. nine0028

- Enter the diameter of your nozzle, the diameter of the filament used, the height of the print layer in the fields marked in yellow (do not touch anything else!).

- In the table below you get the speed of feeding the filament into the extruder and the length of the extruded filament sufficient to print a line with a given width and height for 3 minutes at the specified print speed.

- Heat the extruder to the required temperature, and extrude the resulting length of the filament through the slicer at the selected feed rate (it is the feed rate, not the print speed, do not confuse!). nine0028

Extruder sticking? Filament does not gnaw? Is the diameter of the extruded thread equal to the diameter of the nozzle? Throat not clogged? Does the filament wrinkle in the Bowden tube? Does the heating unit successfully melt plastic? Does the diameter of the extruded filament match the diameter of the nozzle?

Excellent! Go to the next line of the table and extrude the plastic at the next feed rate. As soon as the problems start - you have reached the performance limit, print at the speed that was successfully tested last, for example, if the plastic bites at a print speed of 70 mm / sec, but everything was fine at a speed of 60 mm / sec - print at a speed of 60 mm \sec. You have found the maximum possible print speed with your nozzle, on your plastic, with your print temperature and your layer height. nine0005

You have found the maximum possible print speed with your nozzle, on your plastic, with your print temperature and your layer height. nine0005

That's all, if you did everything right, it means that I helped you. You can leave thanks in the comments and / or donate using the details on the profile page, I won’t be offended :).

But what does not need to do is send me curses without reading the article to the end if something did not work out.

If you have read, but do not understand - I'm waiting for your questions in the comments, I'll try to answer.

If you have read and understood, but have your own opinion - also write constructive criticism in the comments, it will be useful to everyone. nine0005

How does it work?

And here are the details of the study, for people interested in the details.

To print at a given speed, we need the volume of filament of a given diameter (1.75 mm or 3 mm) supplied to be equal to the required volume of the printed line . We know that a certain amount of plastic is required to build a line, equal to Volume of extruded plastic (OP) = line height (HL) * line width (SL) * line length (DL) , where Line Width (WL) is the diameter of the nozzle used, and Line Height (LH) is the height of the printed layer. The volume of extruded plastic (OP) is a tabular value and is constant regardless of the material used, it is determined only by the height, length and width of the printed line, for ease of use, these data are dynamically calculated in the Excel table attached at the link at the end of the article.

We know that a certain amount of plastic is required to build a line, equal to Volume of extruded plastic (OP) = line height (HL) * line width (SL) * line length (DL) , where Line Width (WL) is the diameter of the nozzle used, and Line Height (LH) is the height of the printed layer. The volume of extruded plastic (OP) is a tabular value and is constant regardless of the material used, it is determined only by the height, length and width of the printed line, for ease of use, these data are dynamically calculated in the Excel table attached at the link at the end of the article.

Knowing the volume of plastic (OP) per second of time 93 filaments per second of time, which is equal to a filament feed rate of 3.3 mm/sec.

If the nozzle copes with the extrusion of a given volume of filament, no excess pressure is created in it, no excess plastic is ejected from the melt zone into the throat (there is no plug in the barrier), there is no jamming or jamming of the filament, and the thread squeezed out by the nozzle does not deviates from the specified diameter, which means that the selected maximum print speed (as well as the filament feed into the extruder) can be used in printing. nine0005

nine0005

Actually, this is the answer to the question of what maximum print speed your extruder can support, on a given type of plastic, height and line width, at a given temperature.

The nozzle is the bottleneck of the whole system, even if the heating block is able to melt a lot of plastic - you will not be able to successfully extrude it if the nozzle does not allow it.

Many problems and questions may arise, but there is only one answer - the extrusion speed is greater than the throughput of the nozzle - it is necessary to experimentally (using the table) determine the allowable maximum printing speed and not exceed it. nine0005

The test can be carried out for each type of plastic you print with - their physical properties are approximately the same from type to type. I indicated at the very beginning how to use the table at the link at the end of the article - use it. I hope this helped you.

Important: if you experiment with different layer heights without changing the nozzle diameter, you will find the following: The change in layer height is inversely proportional to the printing speed.

And it's true, how many times you reduced the height of the layer - so many times you can increase the speed of printing! This is a consequence of the fact that the maximum allowable volume of extruded plastic does not change. Unfortunately, another conclusion follows from this - as the layer height increases, you will be forced to reduce the speed. nine0005

Important: If the filament is extruded with a larger diameter than the nozzle, reduce the print speed, do not try to reduce the flow rate in the slicer!

The slicer initially sets the amount of extruded filament required to print the line, and changing the setting will create underextrusion. Forget about slicer flow control (the topic of a separate article) - slicer flow control is necessary in exceptional cases, and believe me, your case is not exceptional, since the flow is perfectly controlled by the feed rate and setting the number of microsteps of the extruder motor (if the flow is configured incorrectly).