3D printer for sale canada

Best Prices on 3D Printers, Accessories and Kits

-

Beginners

-

Designers

-

Educators

-

Makers & Engineers

-

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer Bundle

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer Bundle

- Vendor

- 3D Printernational

- Sale price

- $5,499.00

- Regular price

-

$6,799.99

- Unit price

- /per

-

FlashForge Adventurer 3 Pro Maker Bundle

FlashForge Adventurer 3 Pro Maker Bundle

- Vendor

- 3D Printernational

- Sale price

- $949.00

- Regular price

-

$1,199.00 - Unit price

- /per

-

Creatbot F160-PEEK 3D Printer Maker Bundle

Creatbot F160-PEEK 3D Printer Maker Bundle

- Vendor

- 3D Printernational

- Sale price

- $2,499.

00

00 - Regular price

-

$2,999.99 - Unit price

- /per

-

QIDI TECH iFast Dual Extruder Maker Bundle

QIDI TECH iFast Dual Extruder Maker Bundle

- Vendor

- 3D Printernational

- Sale price

- $3,249.00

- Regular price

-

$3,699.00 - Unit price

- /per

-

FlashForge Adventurer 4 Maker Bundle

FlashForge Adventurer 4 Maker Bundle

- Vendor

- 3D PrinterNational

- Sale price

- $1,349.

00

00 - Regular price

-

$1,799.00 - Unit price

- /per

-

Anycubic Photon Mono X 3D Printer Maker Bundle

Anycubic Photon Mono X 3D Printer Maker Bundle

- Vendor

- 3D Printernational

- Sale price

- $1,049.00

- Regular price

-

$1,249.99 - Unit price

- /per

-

ANYCUBIC Photon M3 Max Resin 3D Printer

ANYCUBIC Photon M3 Max Resin 3D Printer

- Vendor

- ANYCUBIC

- Sale price

- $1,549.

99

99 - Regular price

-

$1,699.00 - Unit price

- /per

-

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer

- Vendor

- CREATBOT

- Sale price

- $5,499.99

- Regular price

-

$6,299.99 - Unit price

- /per

-

Creatbot D600 Pro Industrial Professional Dual Extruder 3d Printer

Creatbot D600 Pro Industrial Professional Dual Extruder 3d Printer

- Vendor

- CREATBOT

- Sale price

- $15,499.

00

00 - Regular price

-

$17,999.00 - Unit price

- /per

-

ZONESTAR 4 Extruder Multi Color FDM Ultra Silent Auto Leveling Z9V5 PRO

ZONESTAR 4 Extruder Multi Color FDM Ultra Silent Auto Leveling Z9V5 PRO

- Vendor

- ZONESTAR

- Sale price

- $799.99

- Regular price

-

$999.00 - Unit price

- /per

-

Creatbot Peek-300 Gen 2 Ultra High-Temperature Industrial Size 3d Printer

Creatbot Peek-300 Gen 2 Ultra High-Temperature Industrial Size 3d Printer

- Vendor

- CREATBOT

- Sale price

- $16,999.

00

00 - Regular price

-

$19,999.00 - Unit price

- /per

-

MakerBot Method X - Carbon Fiber Edition 3D Printer

MakerBot Method X - Carbon Fiber Edition 3D Printer

- Vendor

- MakerBot

- Sale price

- $8,999.00

- Regular price

-

$10,499.99 - Unit price

- /per

-

FlashForge Hunter DLP UV Resin 3D Printer

FlashForge Hunter DLP UV Resin 3D Printer

- Vendor

- FlashForge

- Sale price

- $6,049.

00

00 - Regular price

-

$6,499.00 - Unit price

- /per

-

ANYCUBIC Photon Mono X 4K 8.9 Inch LCD UV Resin High Speed 3D Printer

ANYCUBIC Photon Mono X 4K 8.9 Inch LCD UV Resin High Speed 3D Printer

- Vendor

- ANYCUBIC

- Sale price

- $589.99

- Regular price

-

$649.99 - Unit price

- /per

-

QIDI TECH iFast Dual Extruder 3D Printer

QIDI TECH iFast Dual Extruder 3D Printer

- Sale price

- $3,195.

99

99 - Regular price

-

$3,499.00 - Unit price

- /per

-

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer

- Sale price

- $5,499.99

- Regular price

-

$6,299.99 - Unit price

- /per

-

Creatbot D600 Pro Industrial Professional Dual Extruder 3d Printer

Creatbot D600 Pro Industrial Professional Dual Extruder 3d Printer

- Sale price

- $15,499.

00

00 - Regular price

-

$17,999.00 - Unit price

- /per

-

CreatBot F160/F160-PEEK 3D Printer Single Extruder Large Build Size High Temp Hotend

CreatBot F160/F160-PEEK 3D Printer Single Extruder Large Build Size High Temp Hotend

- Sale price

- $2,499.00

- Regular price

-

$3,299.99 - Unit price

- /per

-

ZONESTAR 4 Extruder Multi Color FDM Ultra Silent Auto Leveling Z9V5 PRO

ZONESTAR 4 Extruder Multi Color FDM Ultra Silent Auto Leveling Z9V5 PRO

- Sale price

- $799.

99

99 - Regular price

-

$999.00 - Unit price

- /per

-

MakerBot Method X - Carbon Fiber Edition 3D Printer

MakerBot Method X - Carbon Fiber Edition 3D Printer

- Sale price

- $8,999.00

- Regular price

-

$10,499.99 - Unit price

- /per

-

MakerBot Method X 3D Printer

MakerBot Method X 3D Printer

- Sale price

- $8,699.

00

00 - Regular price

-

$9,499.99 - Unit price

- /per

-

Flashforge Creator Pro 2 Independent Dual Extruder 3D Printer

Flashforge Creator Pro 2 Independent Dual Extruder 3D Printer

- Sale price

- $1,199.00

- Regular price

-

$1,499.00 - Unit price

- /per

-

3D Printers

-

Filament

-

Accessories

-

ANYCUBIC Photon Mono X 4K 8.

9 Inch LCD UV Resin High Speed 3D Printer

9 Inch LCD UV Resin High Speed 3D Printer ANYCUBIC Photon Mono X 4K 8.9 Inch LCD UV Resin High Speed 3D Printer

- Sale price

- $589.99

- Regular price

-

$649.99 - Unit price

- /per

-

MakerBot Sketch 3D Printer Classroom Bundle For Educational Facilities

MakerBot Sketch 3D Printer Classroom Bundle For Educational Facilities

- Sale price

- $2,999.00

- Regular price

-

$3,299.00 - Unit price

- /per

-

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer

CreatBot F430 Dual Extruder Large Enclosed Chamber 3D Printer

- Sale price

- $5,499.

99

99 - Regular price

-

$6,299.99 - Unit price

- /per

-

MakerBot Method X - Carbon Fiber Edition 3D Printer

MakerBot Method X - Carbon Fiber Edition 3D Printer

- Sale price

- $8,999.00

- Regular price

-

$10,499.99 - Unit price

- /per

-

MakerBot Method - Carbon Fiber Edition 3D Printer

MakerBot Method - Carbon Fiber Edition 3D Printer

- Sale price

- $8,499.

00

00 - Regular price

-

$9,999.00 - Unit price

- /per

-

MakerBot Method X 3D Printer

MakerBot Method X 3D Printer

- Sale price

- $8,699.00

- Regular price

-

$9,499.99 - Unit price

- /per

-

MakerBot Method 3D Printer

MakerBot Method 3D Printer

- Sale price

- $7,499.

00

00 - Regular price

-

$8,999.00 - Unit price

- /per

-

Flashforge Creator 3 Independent Dual Extruder 3D Printer

Flashforge Creator 3 Independent Dual Extruder 3D Printer

- Sale price

- $3,979.99

- Regular price

-

$4,199.00 - Unit price

- /per

-

3D Printing for Beginners by ChatGPT App.

Overview, tips and 3D printing lifehacks for beginners, intermidiates and experts.

Overview, tips and 3D printing lifehacks for beginners, intermidiates and experts. For this article I decided to consult with the new ChatGPT app that everyone has been talking about lately. ChatGPT (Generative Pre-training Transf...

- GUIDE

- NEWS

- Read more

-

This Is How 3D Printing Is Affecting Your Business

3D printing changes spools of plastic filament or trays of resin into physical things. 3D printing is rather actually out of this world. NASA keep...

- Read more

-

First TinkerCAD 3D Printing Project Is Here!

This is the start of a series on practical prints for your 3D printer.

Lots of individuals have actually seen 3D printers in action, however much o...

Lots of individuals have actually seen 3D printers in action, however much o...- Read more

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

Official Canadian Sales Partner for Ultimaker & Formlabs

Your browser does not support the video tag.

- Top Notch Support

- Training & Resources

- Competitive Pricing

- Fast Shipping

Explore Solutions

Watch now

Watch now

Trusted by libraries, colleges, universities and school boards all over Canada. Shop3D.ca is a dedicated approved partner to hundreds of educational institutions Canada-wide. Our sales teams help put together great packages for any budget and our service teams provide 1:1 training and aftersales services to all our main brands. It's time Canadians can get instant access to direct technical and warranty support with no runarounds.

Find out more about our EDU offerings

Certified and tested product lines that passes our high standards.

Precise and Accurate 3D Scanning with Shining3D's Lineup of Handheld and Desktop 3D Scanners, Learn More

Discover the Ultimaker 3D printers that will streamline your workflow and deliver the quality results you need. Learn More

Dual extrusion 3D printers with independent heads allow for mirror and duplication modes. Built in Europe. Learn More

Next level customer service3D Print on Demand

Go from digital file to a finished part with our experienced print team. We’ll help you determine the best material and process selection to optimize for strength, surface finish or price, and have the part finished and shipped to your door.

- Per project printing service

- FDM or SLA process

- Dozens of material choices

- Send .STL + requirements

- Pickup or Ship your completed print

Upload a File

3D Scanning

Have your physical parts 3D scanned for reverse engineering, part fitting or analysis. Send in or drop off your part to be scanned and let our experts scan, cleanup the data, and produce an STL for you to use.

- Send or drop off part at any Shop3d.

- Initial consultation / evaluation

- Part scan

- Point cloud cleanup

- Triangulation and watertight mixing

- Optional Data processing (Process to solid)

Contact Us For Details

Laser Cutting & Engraving

Take advantage of our Laser Cutting and Engraving services a la carte to get precision cuts with different types of woods, acrylics and natural materials.

- Custom or stock material

- Design clean-up services

- Cut and Engrave patterns as large as 20” x 12”

- Bring in your custom materials to be cut*

Contact Us For Details

Installation & Training

Fully equip your team for success by having vendor certified shop3D staff install your systems and on-board your operators. Ensure that you are fully equipped to fully leverage the equipment from day 1.

- On-site installation & printer setup

- Onboarding training

- Basic operation

- Intro to printing software and workflow

- Best practices

- Samples

Contact Us For Details

Design Services

Have an idea but don’t have the capacity to engineer or design in-house? We can help you make it a reality from start to finish from discovery, consultation and design prototyping.

- 3D Design based on custom requirements

- 2D Design for Laser cutting

- Hourly rate

Contact Us For Details

Site Scan & Application Consultations

How can 3D printing help your Design & manufacturing process? Let our experts help you boil down the massive sea of choices to a few well considered solutions with clear expectations and outcomes.

- On-site visit & consultation

- Implementation & optimization Plan

- ROI calculation

- Maintenance plan

Contact Us For Details

All Services

Stay up-to-date with 3D printing innovation

View All

-

We're so excited for the holiday season and have a special treat in our showroom - the Shop3D.ca Christmas Park print designed by the talented @FULV.

Keep Reading

-

Holiday Closures - Vancouver Showroom

Tue, Dec 20, 2022

Shop3D.ca Vancouver will be closed the week of December 26-30 and on January 2nd. Shipping and walk-in appointments will resume in the New Year. Mississauga will be closed on the following dates: December 23 - Closed at 1:30PM, December 26 - Closed, December 27 - Closed, January 2 - Closed

Keep Reading

-

Shop3D.

ca has been announced by Mayku as one of their new Preferred Partners, meaning that we are considered as one of their trusted and reliable reseller for Mayku products.

ca has been announced by Mayku as one of their new Preferred Partners, meaning that we are considered as one of their trusted and reliable reseller for Mayku products. Keep Reading

View All News

Trusted by industry leaders in Healthcare, Manufacturing, Government and Education13 BEST CONSTRUCTION 3D PRINTERS OF 2019

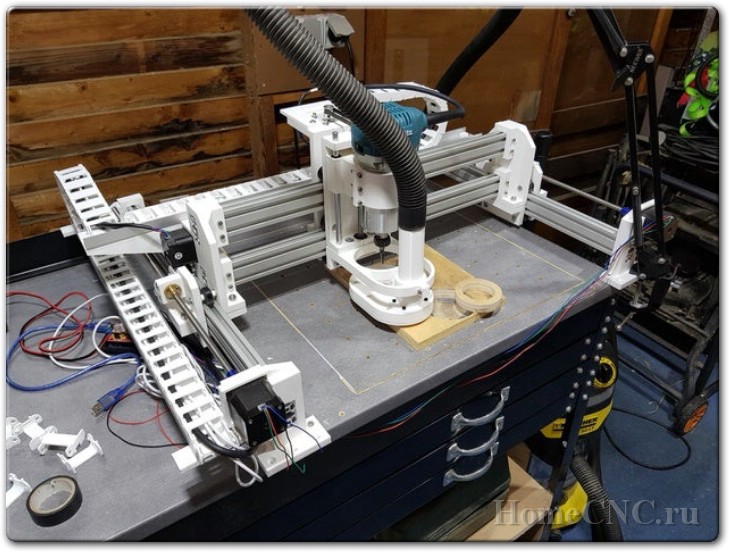

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations. nine0003 To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations. nine0003 To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

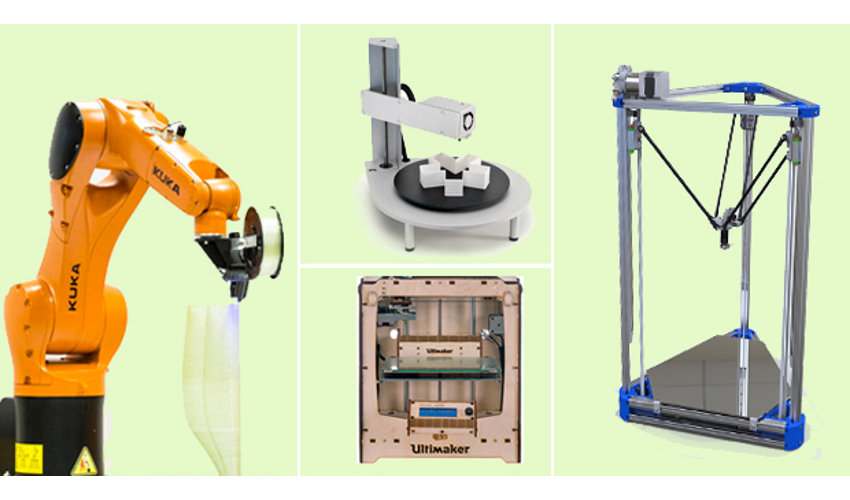

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm. nine0003 In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer builds foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm). nine0003 Benefits of building 3D printing

However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm). nine0003 Benefits of building 3D printing

• Eco-friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalability: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27. nine0003 • Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars. nine0003 • Partially Built Houses : Only house frames are built. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.). nine0003

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material: Concrete / Clay / Gypsum

• Country: Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing): and from small-format (for printing small architectural forms ) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

BetAbram is a small Slovenian team that has been working on building 3D printing equipment since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This construction 3D printer is fast, with a speed of up to 18 meters per minute. BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3. 8 m

8 m

• Material : Concrete

• Country : France Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another. nine0007

CyBe Construction CyBe RC 3Dp

• Assembly size: 2.75 x 2.75 x 2.75 m

• Material: Concrete

• Country: Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build Size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States of Mudts003 Concrete 3D Printers USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length. nine0003 According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length. nine0003 According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only). nine0007

WASP Crane WASP “Infinity 3D Printer”

• Build Size : Ø 6.3 x 3 m

• Material : Concrete / Earth materials

• Country : Italy

WASP Crane is an evolution of the previous WASP construction printer 12MT. This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers work projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D based construction company Francisco and claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer looks like a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed the Yhnova 3D print shop in Nantes, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as Square3D "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas. ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale. nine0007

ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale. nine0007

Construction printing services

Contour Crafting 3D Printing System

• Material • Material: Concrete

• Country: United States

This automatic construction system is capable of 3D -printing large buildings and high -high infrastings. Contour Crafting (also known as CC Corp) aims to improve the effectiveness of disaster relief through concrete admixture technology. nine0007

XtreeE 3D Printer

• Build Size : -

• Material : Concrete

• Country : France

XtreeE develops custom 3D printing solutions for construction, engineering and architectural design. This startup is located in France and has already completed a number of 3D construction projects.

Which 3D printer to choose for your business

3D printed business models

3D printing is making its way into more and more areas of life these days. At the same time, the demand for 3D printing remains at a high level and the demand for products produced by additive methods is constantly higher than the supply. In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request. nine0007

At the same time, the demand for 3D printing remains at a high level and the demand for products produced by additive methods is constantly higher than the supply. In a situation of such a shortage, a far-sighted businessman decides to enter this market in order to earn money by satisfying this request. nine0007

For new players in the 3D printing market, the choice of niche is closely related to the choice of technology, technique, and, sometimes, even specific models of 3D printers.

It is important that we are talking about business - a sphere of life in which everything can be found at a price expressed in the amount of money, which means that there are general requirements that apply to equipment. Maximum reliability allows you not to spend on repairs, which means it is worth the investment. The presence of all certificates for the equipment is required by the state from the business. The maximum level of after-sales service allows the entrepreneur not to learn 3D printing, but simply to do the business for which he created his business. The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous. nine0007

The cost of the 3D printer itself is not decisive in choosing a particular machine; in various areas, the payback period for investing in such equipment can be both short and almost instantaneous. nine0007

In general, there are several models for using a 3D printer for profit.

-

The company is introducing 3D printing to help existing processes.

-

The company switches to the production of a product using additive technologies

-

And there are companies that deal exclusively with printing, and the very idea of their business and their product is tied to additive technologies. nine0007

Let's see what 3D printing technologies are used in different models of companies on the market, as well as how to choose the right 3D printer for the business in your chosen niche!

Business 3D Printer

Modernization of existing business and technical processes is the key to the success of any enterprise. Not surprisingly, with the advent of new technologies, production strategies can be revised and even radically changed. nine0007

Not surprisingly, with the advent of new technologies, production strategies can be revised and even radically changed. nine0007

With the cost of additive technologies becoming cheaper, more and more enterprises are looking for ways to optimize their production using 3D printing. Sometimes, the optimization process leads to quite interesting results.

3D printing in production

Machine production is a method that allows you to get the most profit, and therefore the most interesting from a business point of view. Production line machines require constant maintenance and regular replacement of worn out parts. Usually, the process of replacing a part when it breaks down is as follows - a service employee localizes the malfunction, diagnoses the cause of the failure of a particular part, and orders a new part from the manufacturer according to the catalog. It’s good if the supplier has such spare parts in stock, but it happens that you have to wait until the spare part you need is produced. nine0007

nine0007

From the moment of ordering to receipt, it can take from a week to months. All this time the machine is idle, and in our time of widespread use of conveyor chains, this can mean idleness of the whole chain of machines. Moreover, for some machine tools, spare parts cannot be obtained in principle - they can be discontinued, and sometimes it turns out that the company - the manufacturer of the machine has already gone bankrupt and there will be no new parts for the existing machine in principle.

Possible production losses in this case can reach amounts comparable to the value of the enterprise.

But what if the part you need can be obtained without ordering it from the machine manufacturer? The increase in the availability of 3D printing has led more manufacturers to create 3D printing departments based on their service departments. Such a department consists of several 3D modelers, several 3D printers and several 3D printers.

Such 3D printers must meet several requirements - machine parts must be strong enough, the cost of maintaining a 3D printer fleet must be reasonable, and the 3D printer must be able to produce both the spare part itself and models to obtain parts using more expensive methods. nine0007

nine0007

Such requests are met by 3D printers using FDM and LCD technology.

Picaso 3D Designer X Pro

One of the bestsellers in this category is the Picaso 3D Designer X Pro printer. The defining advantages here are the omnivorousness of this model - you can print both ABS, PLA, PETG, Flex, Nylon, as well as more specific and composite plastics - and the ability to print simultaneously with two materials. nine0007

Phrozen Transform Standard

Phrozen Transform Standard is also a good choice. Huge build area - 292x165x400 mm, print speed up to 10mm/hour and high-intensity ParaLED system allow this printer to quickly and accurately print parts, including those from specific polymers.

Architectural 3D printing

In architecture, the ability to present a material model of the proposed project to the customer is of great importance. There is little to promote acceptance; a positive decision, such as the opportunity to inspect and feel live at least a model of a building or apartment. For the production of such models in architectural bureaus and studios, there are large departments. A few years ago, next to the powerful computers of architects, there were workshops for the manual production of models from papier-mâché and other materials that are little associated with modern technology; nine0007

For the production of such models in architectural bureaus and studios, there are large departments. A few years ago, next to the powerful computers of architects, there were workshops for the manual production of models from papier-mâché and other materials that are little associated with modern technology; nine0007

Affordable 3D printing has taken the manufacturability of the production of architectural models to a whole new level! Moreover, it turned out to be extremely simple to integrate 3D printing technologies into the work of an architectural bureau - engineers in this direction have already specialized in working with one or another software product related to the creation of 3D models, it only remained to bring this work to its logical conclusion - a layout.

The requirements for 3D printers for architectural offices are primarily related to the ability to produce large layouts. Strength here is not as important as the ability to convey the characteristic features of the project as accurately as possible - after all, the layout is a reduced copy, which means all the details will be tiny. These requirements are met by FDM 3D printers. nine0007

These requirements are met by FDM 3D printers. nine0007

Raise3D Pro2 Plus

A good choice for an architecture studio is the Raise3D Pro2 Plus 3D printer. A large construction area, coupled with precision, through the use of high-quality components and optimal kinematics, allow you to carry out large-scale projects. The ability to print with two materials at the same time makes the implementation of projects easier and allows you to simplify the post-processing of finished models.

BigRep Studio

For particularly demanding architects, BigRep Studio will be a pleasure to work with. Resume printing from the same place after a power outage, remote control and print management make it possible to install this truly large machine in a dedicated room. Well, if necessary, put it in the office, it will pass through the door, since the manufacturer provides the opportunity to disassemble it into 2 halves.

Advertising and exhibitions

The advertising business is probably one of the most demanding of novelty. The new attracts attention, and that's what advertisers do. The media that conveys the advertising message is of high importance. Today, any new way to attract a potential client is in demand.

The new attracts attention, and that's what advertisers do. The media that conveys the advertising message is of high importance. Today, any new way to attract a potential client is in demand.

A special area of this business is the organization of stands for exhibitions and similar events. It often happens that there is very little time to implement an idea, and success is achieved due to the possibility of implementing the maximum range of such ideas. nine0007

So in advertising, 3D printing is in demand in a huge number of its manifestations. Here the creation of handouts, and layouts of future projects, and noticeable signs of pylons and posters. Different 3D printing methods are suitable for different areas of the advertising business, FDM and LCD are very much in demand. One of the fastest growing areas of advertising using 3D printing is signage. A 3D printer creates an almost finished product - all that remains is to connect the backlight and electronics. This allows, firstly, to implement ideas that are too costly to implement by other methods, and secondly, to significantly simplify the tailor made approach to the customer - each customer wants his own, unique sign. The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from a distance. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics. nine0007

The requirements for such equipment are special. The size is of course very important, the sign must be highly visible, which means the print area must be suitable - wide and long, but not too high. Printing speed is more important than quality, you can't see small inaccuracies from a distance. Signs are most often placed on the street, which means that it is important that the products are resistant to use in different weather conditions, which means that it is necessary to be able to print with suitable plastics. nine0007

Flashforge AD1 Channel Letter

The Flashforge AD1 Channel Letter 3D printer is perfect for solving such problems. Its huge printable area allows you to print signs that will be visible from a great distance. The high-speed extrusion system will make this process relatively fast, and the ability to print in multiple colors makes the need for post-processing much lower. The use of such a machine allows not only to meet the requirements of the most fastidious customers, but also to significantly reduce the cost of production. nine0007

nine0007

Jewelry 3D Printer

Since ancient times, jewelry has been considered one of the most profitable. The history of jewelry creation dates back many centuries and goes back to the time of the birth of the Homo Sapiens species. Many techniques in this area of production have been preserved for decades, and are in many ways an art. But even in this area, we see that additive technologies help to realize more and more projects and ideas.

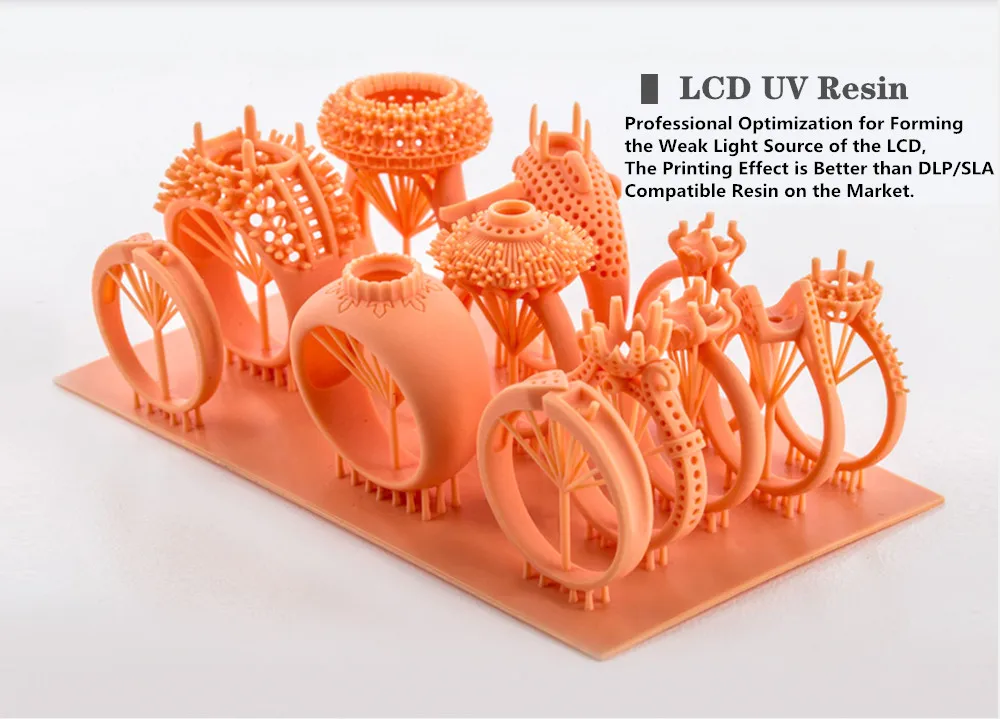

The meaning of the word “jewelry” itself is associated with miniature, precision and painstaking work. A lot of time and effort is spent on creating each piece of jewelry, which as a result can easily turn out to be a masterpiece of art. 3D printing helps to facilitate the production of highly detailed blanks, making the work of the craftsman easier. Most often, models are printed, according to which such semi-finished products are subsequently smelted. The achievements of modern technologies bring their quality to the level of an almost finished product. For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting. nine0007

For this, of course, the SLA 3D printing method is used - with its help you can create the most detailed models. The requirements for such 3D printers are related to the maximum resolution of finished models, as well as the ability to use materials created for subsequent transformation into metal, for example, by direct casting. nine0007

Phrozen Sonic XL 4K

A good example of a suitable 3D printer for jewelry is the Phrozen Sonic XL 4K LCD technology. The maximum resolution of 4K allows you to create the most detailed models, and the ParaLED system significantly reduces the time of their production.

Phrozen Sonic Mighty 4K

For workshops dealing with more miniature production, the Phrozen Sonic Mighty 4K may be sufficient. Although the build area is smaller and the ergonomics of the machine are not as well thought out, this printer performs well enough to be a rational choice when looking for a 3D printer for a small workshop. nine0007

nine0007

Sculpture

A striking example of a paradigm shift in production in our time is sculpture. Many people remember the saying of the great Michelangelo Buonarroti “I take a stone and cut off all that is superfluous.” How exactly the master defines the fundamental principle of subtractive technologies! Modern developments help to make the process of creating masterpieces more connected with working with the head than with the hands.

In our time, the sculptor has the opportunity not only to work with material objects, but to almost completely rid himself of such work. A chisel and hammer can replace a computer and a 3D printer. The requirements for the machine in this bundle are mainly related to the area of \u200b\u200bconstruction - sculptures can often be large. There is also a need for printing with different materials to implement projects that are complex in terms of 3D printing. It is important that the finished model can be processed by classical methods. Suitable 3D printing methods are FDM and SLA. nine0007

Suitable 3D printing methods are FDM and SLA. nine0007

CreatBot D600 Pro

The CreateBot D600 Pro 3D printer becomes a frequent inhabitant of the studios of successful architects. A huge build area, the ability to print with two materials at the same time make this machine ready for the implementation of projects of increased complexity. The presence of a special table cover, as well as a special compartment for drying plastics, makes the process as comfortable as possible and does not require extra space.

Peopoly Phenom XXL

For more detailed sculpting tasks, it will be useful to look at the Peopoly Phenom XXL 3D printer. The gigantic build area, coupled with the use of MSLA technology, makes this machine stand out from other printers in this price range.

Business converted to use a 3D printer

There are several periods of the so-called “breakthrough development of production” in history. One of the last can be called the Great Industrial Revolution in England. This revolution was made possible and resulted from the invention of a new method of production - production with an improved steam engine. Living during even such a revolution, it is difficult to realize the significance of a single invention or new technology for future generations. But even these difficulties do not prevent us from reasonably calling modern additive manufacturing methods revolutionary, of great importance, and changing entire business sectors. nine0007

This revolution was made possible and resulted from the invention of a new method of production - production with an improved steam engine. Living during even such a revolution, it is difficult to realize the significance of a single invention or new technology for future generations. But even these difficulties do not prevent us from reasonably calling modern additive manufacturing methods revolutionary, of great importance, and changing entire business sectors. nine0007

Today we see a huge number of companies that, while remaining fundamentally in the same area, are changing the entire production line of their product, based on the new opportunities that 3D printing provides.

Dental 3D printers

For me personally, going to the dentist is always stressful. Despite the fact that in our time, sitting in the dentist's chair and not feel real negative sensations, memories of visits to doctors in childhood encourage us to think less about the existence of problems with teeth. Perhaps you do the same. It is also possible that for this reason, you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical. nine0007

Perhaps you do the same. It is also possible that for this reason, you, like me, do not notice strong changes in this area of \u200b\u200bmedicine. And they are really huge and, in my opinion, even a little magical. nine0007

Modern technologies have made it possible to change the correction of such a frequent feature of dental clinic clients as malocclusion. In the days before 3D printing, overbite was corrected with braces or braces. This process was very pleasant, required a lot of attention from the client, and also forced to replace the usual tools, such as a toothbrush, with specific and inconvenient ones. For many, wearing braces was also unpleasant from an aesthetic point of view.

Why did people make such sacrifices? A metal brace attached to the teeth puts pressure on them in a certain direction, forcing them to shift towards the medically correct position. After a few months of wearing, the braces literally push the teeth where the dentist has determined. nine0007

This is what the aligners look like

3D printing has changed the approach to the process itself so much that a patient undergoing a course of bite changes practically does not change his habits and lifestyle! This technology is called aligners (from the English allign, align). Now the dentist takes a 3D map of your teeth, a special program calculates the necessary changes and creates 3D images of special onlays for teeth, which are subsequently cast from special materials according to 3D printed models. The patient puts on such linings before going to bed and takes them off in the morning. The accuracy of manufacturing is so high that it allows the maximum dosage of pressure on certain teeth, forcing them to move into place in the most natural and imperceptible way. The absence of the need to specially maintain such pads, the invisibility of the process to others, and the comfort make this technique very popular. The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models.

Now the dentist takes a 3D map of your teeth, a special program calculates the necessary changes and creates 3D images of special onlays for teeth, which are subsequently cast from special materials according to 3D printed models. The patient puts on such linings before going to bed and takes them off in the morning. The accuracy of manufacturing is so high that it allows the maximum dosage of pressure on certain teeth, forcing them to move into place in the most natural and imperceptible way. The absence of the need to specially maintain such pads, the invisibility of the process to others, and the comfort make this technique very popular. The purchase of what kind of 3D printers will allow you to enter the dental services market? The main requirement is medical neutrality, the machine itself, plastics, production quality must be such that use in medical institutions is justified. An important issue is the availability of the necessary specific certificates. Mandatory ability to produce high-precision models. nine0007

nine0007

One of the leading printer manufacturers for this market segment is Formlabs.

Formlabs Form 3

The Formlabs Form 3 3D printer allows you to create high-quality models using a wide range of plastics. Particular attention to issues related to the possibility of using printers from this company in medical institutions allows you to be sure of their safety. Ergonomics and ease of use make it possible to concentrate even more on the really important things - helping the patient. nine0003

Formlabs Form 3L

For dental clinics that have already increased their production volumes and the need for even more advanced equipment is clearly overdue, the Formlabs Form 3L 3D printer will be a rational choice. The advantages of this machine will not only be an increased build area, but also closed-loop calibration and simplified component replacement.

3D printing in modern orthotics

Will it be news to you that the left and right legs of each of us are of different lengths? And will it be news to you that this can affect your life much more than just complications with the choice of trousers? It turns out that the individual characteristics of a person associated with the length of the legs can be the cause of many diseases, including mental ones, such as depression. Orthopedists help to get rid of problems associated with the peculiarities of the bones, muscles and joints of the patient. Quite often, the healing technique of interaction is based on the principle that we discussed in the previous part of the article - gentle movement and maintenance of body parts in a medically correct place in the body. For example, if the disease is due to the fact that leaning on legs of different lengths, you have a curvature of the spine, the orthopedist prescribes insoles of different thicknesses for you, thereby leveling the difference in the length of your body supports. And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome. nine0007

Orthopedists help to get rid of problems associated with the peculiarities of the bones, muscles and joints of the patient. Quite often, the healing technique of interaction is based on the principle that we discussed in the previous part of the article - gentle movement and maintenance of body parts in a medically correct place in the body. For example, if the disease is due to the fact that leaning on legs of different lengths, you have a curvature of the spine, the orthopedist prescribes insoles of different thicknesses for you, thereby leveling the difference in the length of your body supports. And here 3D printing helps a lot with its accuracy, and most importantly, the ability to manufacture to individual sizes. Basically, in this area of medicine, solutions based on FDM technology are used. Machines capable of printing with various plastics, including elastic and hypoallergenic, are required. The ability to print products immediately in pairs is welcome. nine0007

Raise3D E2

These requirements are met by the Raise3D E2 3D printer. Automatic printing of products in pairs, the ability to use elastic materials for printing, convenient operation, and a filter make this model a good choice for an orthopedic clinic.

Automatic printing of products in pairs, the ability to use elastic materials for printing, convenient operation, and a filter make this model a good choice for an orthopedic clinic.

Cosplay

Many of us love masquerades. Probably one of the most exaggerated ways to dress up is cosplay (from the English costume play - costume play). Changing clothes, applying make-up, using additional accessories, cosplayers sometimes become almost like a copy of the heroes of movies, cartoons or comics. And if a pipe and a bowler hat can be enough to become Commissioner Maigret, then in order to turn into Iron Man or Wonder Woman, you need to create many elements of the costume from scratch. 3D printing helps with this. Cosplayers create such impressive costumes on a 3D printer that it is very difficult to guess about the use of 3D printing in their production. At the same time, if earlier costumes were created mainly with the help of papier mache and similar technologies, today most of the cosplay costumes are made using additive technologies. FDM is more commonly used, but LCD methods are also in demand. nine0007

FDM is more commonly used, but LCD methods are also in demand. nine0007

A cosplay 3D printer should be able to print large models as quickly as possible. Plastics used are different, but mostly inexpensive, accessible, and easy to process.

Anycubic Chiron

Cosplayers starting to print costume details often look at the Anycubic Chiron 3D printer. This is an inexpensive machine that allows you to print with affordable plastics and create models that fit into a large print area of 400x400x450mm. An additional advantage of the model is its high maintainability and unpretentiousness in maintenance. nine0007

Anycubic Photon Mono

To create accessories and details requiring more detail, purchase the Anycubic Photon Mono. The main advantage of this machine, of course, is its price. At the same time, the print resolution, although it does not reach the height of professional models, is at a level more than sufficient for use in cosplay.

Pure 3D printing business

Speaking about the various niches in the market that have been created by new technological opportunities, one cannot fail to mention those companies whose business appeared as a result of the advent of 3D printing and cannot exist without it. It happens that such companies were initially engaged in something else, but then they saw the economic feasibility of switching to a new business model. There are many companies that were originally created and designed for entrepreneurship based on 3D printing. Due to the fact that additive technologies literally burst into all areas of our lives like an avalanche, it may seem that they are indistinguishable from the companies described in the previous parts of this article. Looking closely, you can see that they make a profit exclusively by doing 3D printing. nine0007

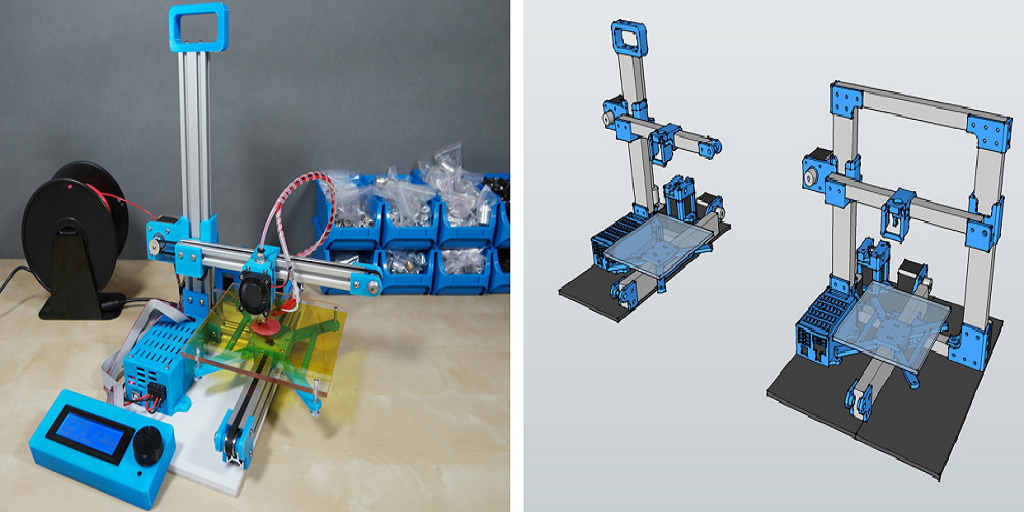

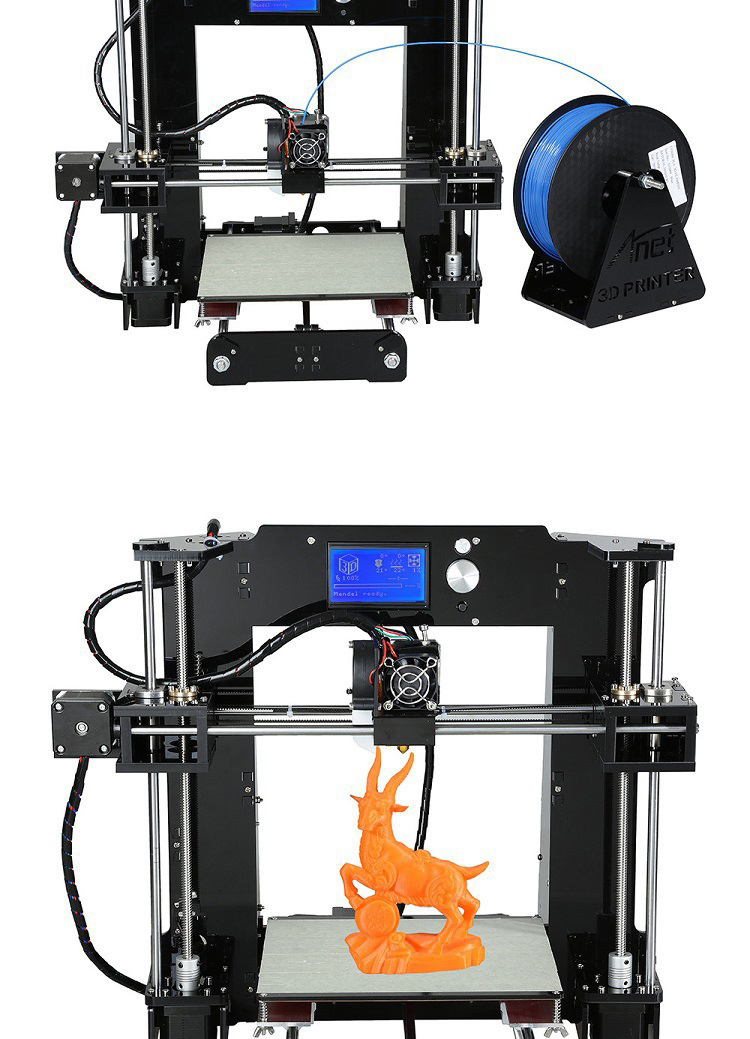

Prototyping

Personally, 3D printing has always seemed to me to be a way to create some kind of device or device parts. Moreover, it was important that if I made a mistake in calculations or taking measurements, I could always quickly correct the computer model and get a new version of the required component in the shortest possible time. Abroad for a long time, and now in our country, there are companies on the market that are engaged exclusively in the production of prototypes. Quite often it turns out that this is a subsidiary of some kind of laboratory or research center. Depending on the area in which these prototypes are used, 3D printing techniques and requirements for 3D printers can be different. Most often this is FDM printing, which must be accurate. A prototyping 3D printer should be easy to operate and maintain. nine0007

Moreover, it was important that if I made a mistake in calculations or taking measurements, I could always quickly correct the computer model and get a new version of the required component in the shortest possible time. Abroad for a long time, and now in our country, there are companies on the market that are engaged exclusively in the production of prototypes. Quite often it turns out that this is a subsidiary of some kind of laboratory or research center. Depending on the area in which these prototypes are used, 3D printing techniques and requirements for 3D printers can be different. Most often this is FDM printing, which must be accurate. A prototyping 3D printer should be easy to operate and maintain. nine0007

PICASO 3D Designer X

In our country, the PICASO 3D Designer X 3D printer is in great demand. The high printing accuracy of this printer is combined with a compact body with the ability to dry plastic in the process. Working with various plastics is facilitated by the system of profiling print parameters for each plastic - if you don’t like how the model was printed, you can print it with another plastic without using a computer, it’s enough to have a profile for it. Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer. nine0007

Ergonomics, ease of monitoring the printing process, a high degree of automation add significant advantages to the scales of this printer. nine0007

Flash Forge Finder

The FlashForge Finder 3D printer is used to create low-level prototypes and to teach the 3D printing process. Also, the low cost and bright appearance make this printer an attractive purchase for studios and circles, where children get acquainted with additive technologies.

Custom 3D printing

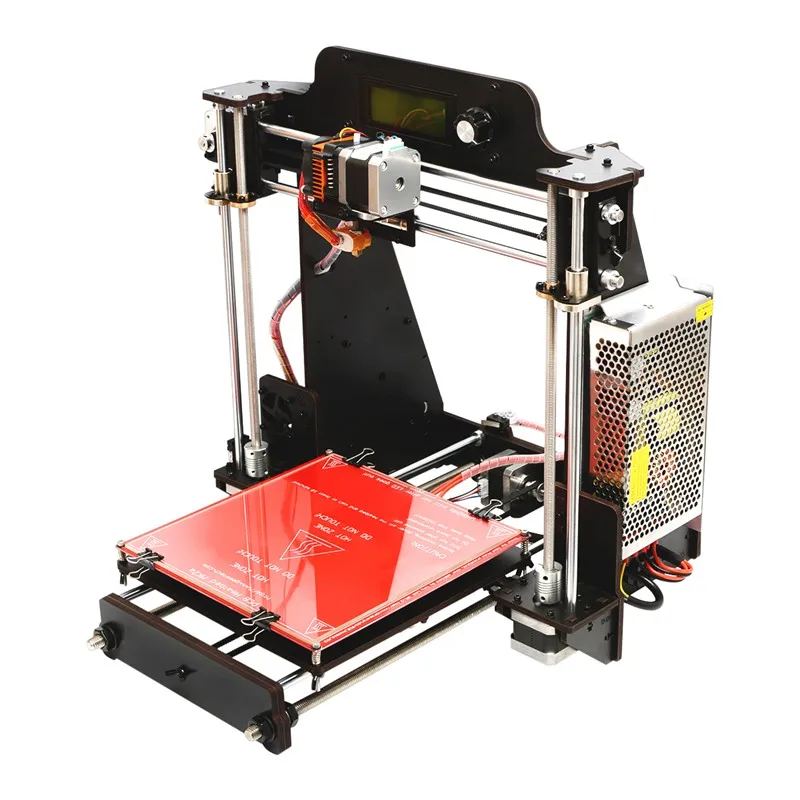

You can print on a 3D printer a huge, almost infinite number of types of things. And some of them need to be printed in one copy and that's it. Someone needs 3D printing not constantly, but not often or even very rarely. Custom 3D printing companies are helping to meet the needs of these potential customers. Usually a full service is provided - model development, 3D printing and processing. Often these companies have many 3D printers, and they are located in the same room. Such assemblies are called 3D printed trusses. The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work. nine0007

The technologies that are presented on such farms are FDM and LCD. The fact is that the requirements for printers here are formed mainly in terms of the price of the printer, the cost of maintenance and reliability. For the fastest return on investment in a 3D-printed farm, inexpensive printers are purchased for it in batches - the more unification, the easier it is to work. nine0007

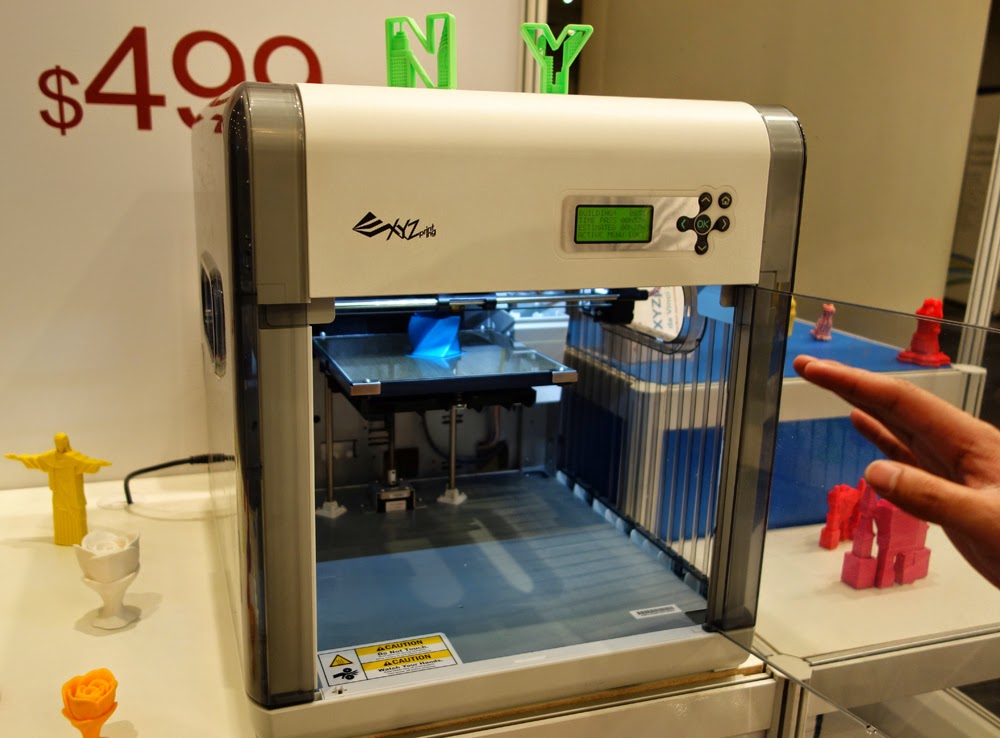

Creality3D Ender 3

The Creality3D Ender 3 3D printer holds the undisputed leader in terms of affordability/quality ratio in this market segment. Its cost, decent print quality, acceptable reliability and high maintainability make it possible to recoup investments in creating a farm based on such machines in the shortest possible time. Without a doubt, this is one of the best 3D printers for 3D printed farm!

Anycubic Photon Mono X

nine0007

It is not uncommon for 3D printed trusses to purchase multiple Anycubic Photon Mono X 3D printers to enable collaboration with customers who require a radically different level of detail. The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

The reliable linear guides, high level of consumables unitization, and low maintenance seem to be a strong point. arguments in his favor.

Multiple cases

It's always interesting to hear success stories. Let me give you a few real cases as an example. nine0007

3D printer - creator of scarce spare parts

There is an AUCHAN plant in the Tambov region. On the production lines of this enterprise, most of the machines are foreign. The machines use a huge amount of plastic parts, some of which are considered consumables and are ordered from the manufacturer with a margin.

In particular, there is a line for the production and processing of plastic containers. For the washing machine on this line, the plant regularly ordered washer nozzles in Europe. nine0007

One terrible day for the manufacturer, on another machine of this line, a plastic part failed, without which the line stood up. After contacting the supplier, it turned out that this particular part was out of stock. We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

We would have to wait for a new delivery for at least 2 months, and during this time the line would be idle. In such a case, the production would suffer big losses.

The management decided to turn to a 3D printing studio to urgently create a scarce part based on a failed one. The part was created in the shortest possible time, production resumed its work, although there was a loss, it turned out to be completely incomparable with what it could have been. nine0007

Seems like a success story. But it was not all success!

In the process of negotiations with the contractor, it turned out that it is possible to quickly produce a large range of parts for this line, in particular, washer nozzles. At the same time, with the same quality of parts, the cost of these consumables turned out to be much lower. Such production made it possible to abandon logistics costs, free up storage space, and the cost of the part itself turned out to be corny lower. As a result, prototypes were presented, and then finished parts. The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner! nine0007

The company was incorporated into UK Bekar and now this small 3D printed farm is doing contracts on a full-time basis for a large manufacturer. Everyone was a winner! nine0007

Legs of different lengths and what does 3D printing have to do with it

I had a terrible boss at one of my previous jobs. He always found fault with no reason, voiced conflicting demands, in general, it was uncomfortable to work, and I thought about quitting.

But I didn't quit, and here's why.

It turned out that the boss was such a radish simply because he was haunted by constant headaches. He went to different doctors, to no avail. He made a visit to the next doctor when I was just starting work in the company. It was a turning point, he went to the orthopedist. In Germany. There, in a few days, they determined that he had headaches from the fact that the pelvis was displaced. And the pelvis is displaced because one leg is longer. Special insoles were prescribed and produced right in the clinic. nine0007

nine0007

I remember that Thursday when he returned from his trip. I was shocked that he gave the bonus to our entire department, including me. Yes, and in person, it seemed that he had been replaced. Completely different, better person!

This story led him to invest in the creation of a laboratory for the production of such insoles in Russia based on the existing center of orthopedics. So to speak, I bought myself personal manufacturers of insoles. On this technological base, it was possible to produce, among other things, shoes designed taking into account the individual characteristics of the customer's foot. Subsequently, he sold this business, some of the specialists work in the Perseus Ortho center. nine0007

How the desire to help his wife turned into a business

And finally, a description of the case in which I took a personal part.

Alexander is my neighbor. Worked in a company that was engaged in deliveries abroad. We crossed paths with him on the topic of 3D printing, he bought himself an Ender 3 and printed all sorts of toys, trinkets and useful details. His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram. nine0007

His wife Marina, as a hobby, baked various cookies, and sold them a little through Instagram. After 2018, the company went bankrupt and Alexander found himself out of a job. He was looking for a new job via the Internet, and Marina asked him to find on the Internet and buy a form for cutting cookies - the goddaughter asked her to bake cookies in the form of a unicorn for her birthday. After a long search, Sasha decided that it was easier for him to model this form himself and print it on a 3D printer than to find the right one. Within one day, the work was done, the cookies were baked, the goddaughter was happy, the photos of the cookies were posted on Instagram. nine0007

I heard this story some time later, when Alexander asked me to help him complete an order for 3D printing. It turned out that Marina was literally inundated with questions about cookies, and subsequently, with orders for cutting molds. In just a couple of weeks, the number of orders for modeling and printing exceeded the capabilities of Sasha's printer, and he turned to me.

The ending of this story is good, Sasha has been creating and printing forms to order for some time. For this, a powerful computer and 6 printers were purchased. A year later, the business was sold and Alexander left for Canada for permanent residence. nine0007

Finalizing

3D printing helps companies of a completely different profile occupy a variety of niches in the market. At the same time, there are many free niches, and often the prospect of using 3D printing in a certain area is not so obvious.

The success stories associated with the use of additive technologies are numerous, from the aerospace industries to the creation of toys.

The presented cases help you look at the existing order of things a little differently. It makes economic sense to check how 3D printing can help the business you run. It may be profitable to enter a new sector of the market with the help of 3D printing. In any case, the ability to understand the choice of 3D printers for business can be an additional benefit.