3D printer services australia

Professional 3D Printing Services available in Australia from Thinglab

Professional 3D Printing Services.

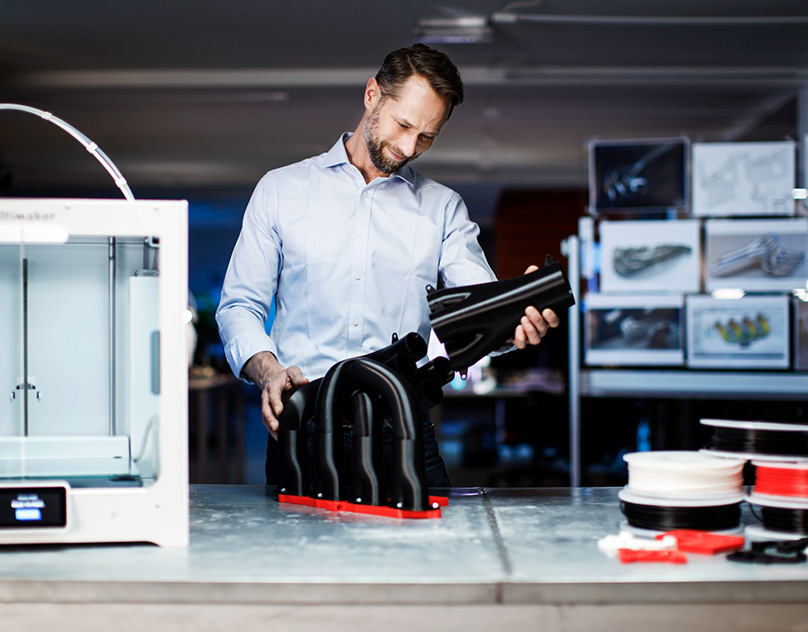

We provide professional 3D printing services out of our studio in Melbourne and can deliver Australia wide. With decades of combined experience in 3D printing services, and a large range of 3D printers in house, no one is better equipped to print your models.

We offer

- quick turnaround

- express service (available on request)

- affordable prices

- large build volumes

- a wide range of technologies and materials

- one off prints to large volume production runs

- expertise that will save you time and money

- NDA’s for sensitive projects

Instant Quote FAQs Contact Us

We Provide 3D Printing Services Across All Industries

Aerospace

Architecture

Arts

Engineering

Entertainment

Fashion

Forensics

Heritage

Medical

Product Design

Schools

Universities

We print to your needs

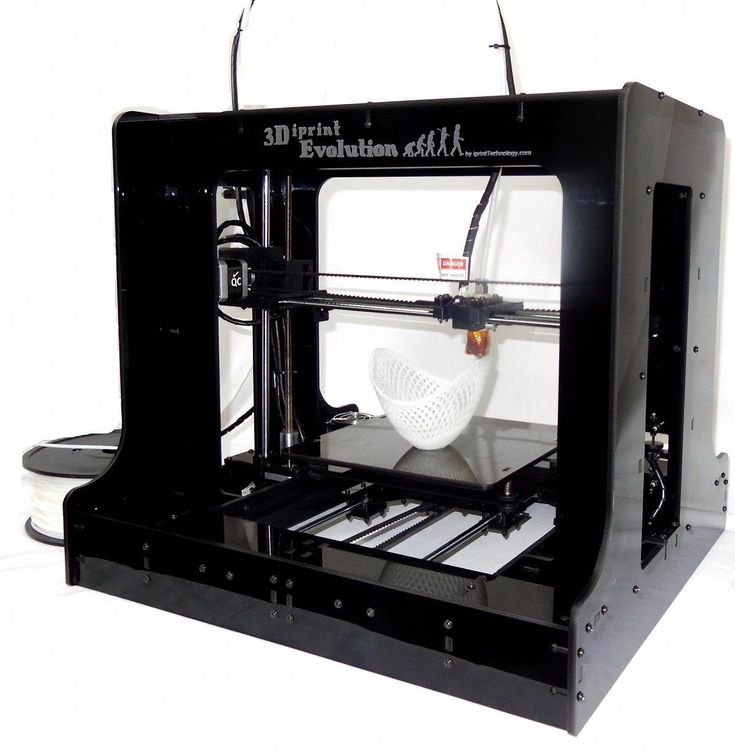

Low Cost Rapid Prototyping Through to Professional Quality Production Prints

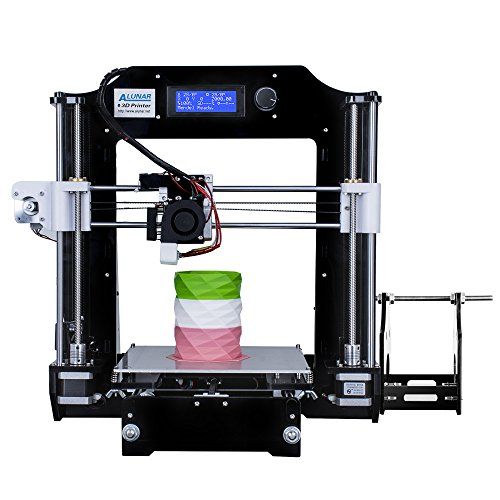

A Wide Variety of 3D Printers to Choose From

Large Build Volume

Build Your Parts Up to 1m³

Instant Quote

Having trouble with our instant quote?

Contact one of our team directly who will assist with your 3D printing needs.

Contact Us

Frequently Asked Questions

+How much does it cost to print a 3D model?

Our 3D printing services team are able to produce 3D prints in a range of different materials across a variety of 3D printing technologies to a maximum print volume of 1m³.

The minimum charge for a 3D print service is $150 and lead times range from overnight to several weeks dependent on size of print and machine availability.

We charge for 3D printed models based on a formula that takes into consideration build time, setup and labour time. For data that contains errors there may be an additional charge for the time required to repair the file for printing.

You can request an official quotation by sending us a STL (Stereolithography) file to [email protected] so that we can identify your requirements and check the suitability of the parts for 3D printing.

+What can I print?

You can print almost any 3D object using 3D printing technology, but some techniques are more suited to some shapes than others. Not all parts are suitable for printing. If you are unsure, send us an stl file and we will be happy to assess it for you. There are some important things to take into consideration when 3D printing:

Not all parts are suitable for printing. If you are unsure, send us an stl file and we will be happy to assess it for you. There are some important things to take into consideration when 3D printing:

- What is the end use of the prototype?

- Do you require specific material properties/characteristics?

- Does the part(s) need support structures for overhanging surfaces?

- What orientation is required for the part you’re building?

+What services do Thinglab provide?

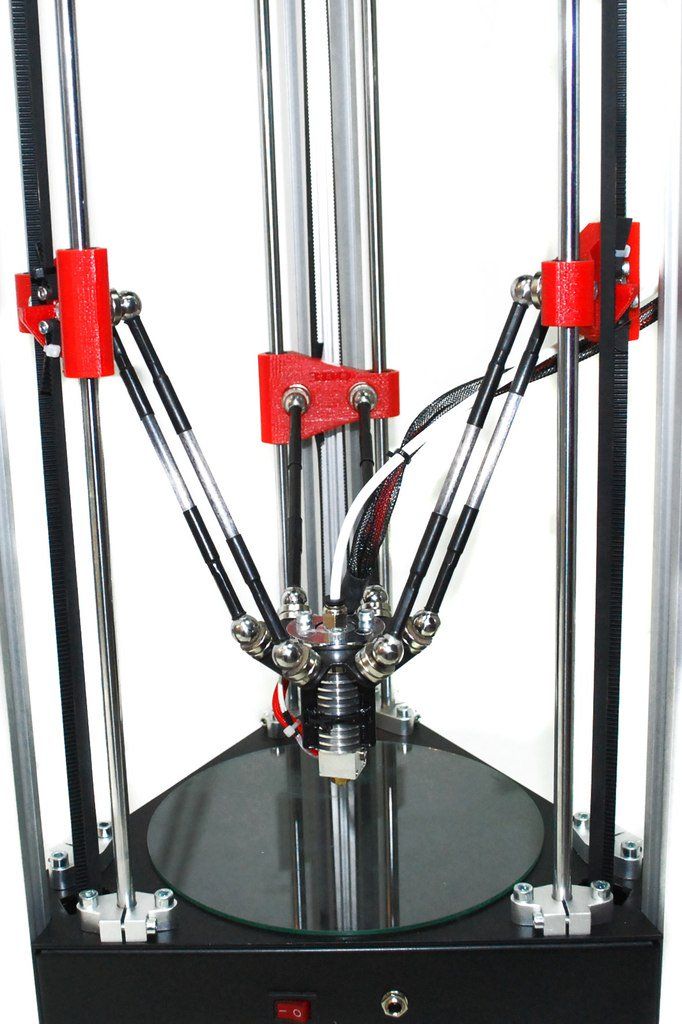

We can provide prototyping services in a range of materials and 3D printing technologies, as well as 3D printing consultancy to determine the best technology and materials for your application. If you need a prototype not suited to FFF or SLA let us know and we can help with other 3D print technologies.

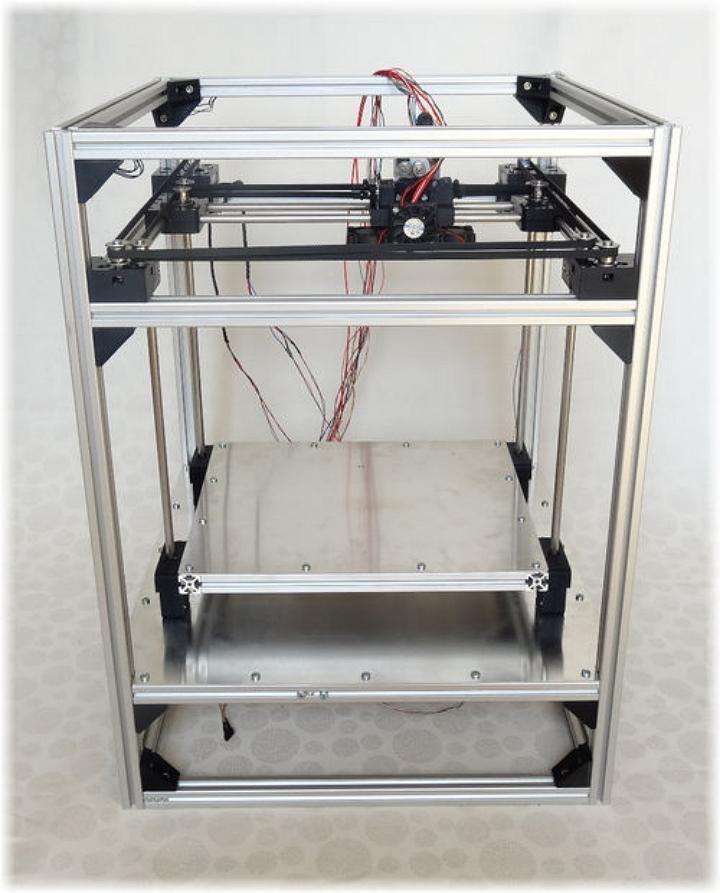

+How big can I print a part?

Depending on the material required we can provide printed prototypes up to a size of 1m³ (in FFF) or 140 x 140 x 170 mm (in SLA). *Multiple parts can be bonded together post production, but this is not a service we currently provide.

+How long does it take?

3D printing is one of the fastest ways to prototype physical objects, but it is not instant. Build times can take days to print for larger models, plus additional time for pre and post processing. Specifying your deadline is one of the best ways for our 3D printing services team to prioritise your work and ensure delivery for a time suited to you.

+What do I need to 3D print a part?

All you need is a CAD model of your part and this will need to be saved as a *.stl file, which is the standard file format for 3D printing.

Want To Know More?

Our team of 3D printing services professionals are just an email or a phone call away.

contact us

3D Printing Service | 3D modeling, scanning, printing.

Contact us using the form below for your FREE quote

Note: Model formats can be sent as .stl or .obj

Instant Quote

Professional Service You Can Trust

We are serious about 3D Printing. Originating from a background in Mechanical Engineering with a professional knowledge base in additive manufacturing, your part will be optimized completely - including slicing options and custom support material to ensure it comes out right first time, every time.

Originating from a background in Mechanical Engineering with a professional knowledge base in additive manufacturing, your part will be optimized completely - including slicing options and custom support material to ensure it comes out right first time, every time.

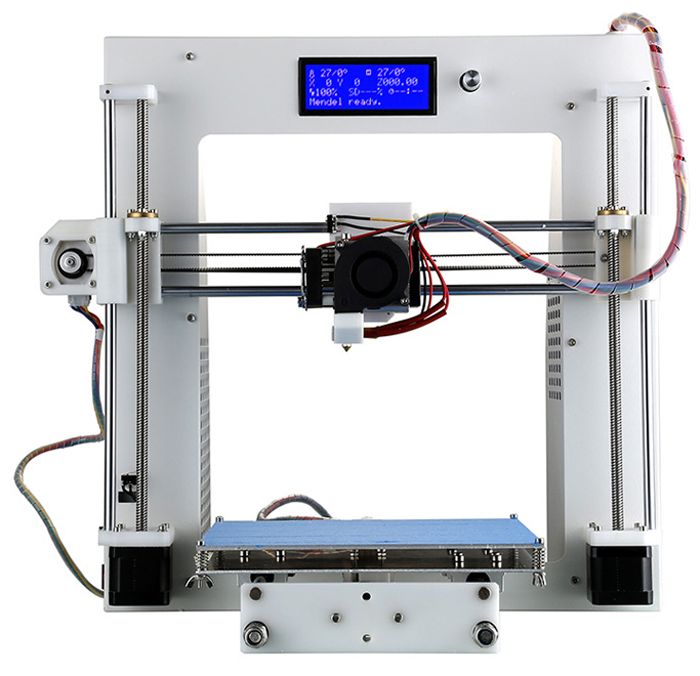

Various Printing Methods

Various objects require different types of printing methods. At Kad3D we recognise this and now offer a range of printing options to suit your part/model/invention

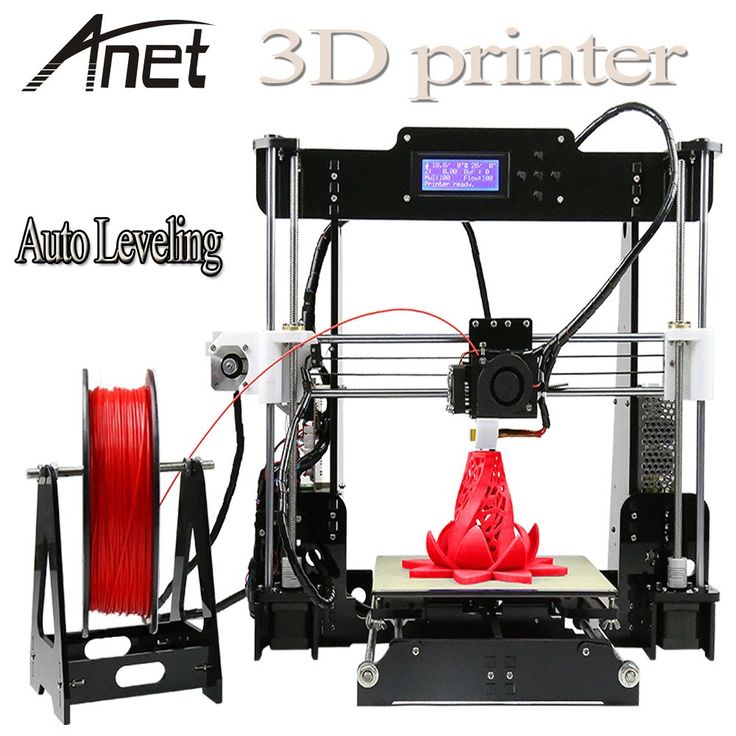

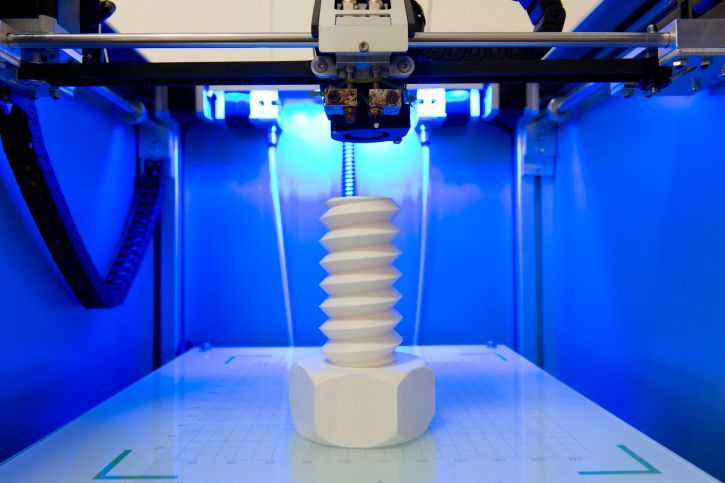

FDM (Fused Deposition Modelling): Plastic is melted and deposited layer by layer.

Advantages: Gives strength to parts, usable, affordable, fast turnaround

Example Uses: Replacements parts, end products, engineered components,

SLS (Selectve Laser Sintering): Powder bonded layer by layer via a laser

Advantages: Highly detailed static objects not under force

Example Uses: Architecture models, sculptures, figurines

SLA (Stereolithography): Liquid resin cured via a laser and UV light

Advantages: Small and highly detailed intricate objects

Example Uses: Rings, jewellery, small figurines, highly detailed objects

Priority Printing

Time is valuable. We will strive to complete your model within the shortest amont of time possible.

We will strive to complete your model within the shortest amont of time possible.

Quality is our promise. If you are unhappy with your part or it falls out of tolerance, we will replace it.

Affordable

We can print your model or design for a fraction of the price as compared to other forms of manufacture.

If you're a student, take 20% off the entire printing service.

We can also repair the mesh of your model or give expert advice on the design to ensure it is capable of being 3D printed.

Lowest Shipping Costs Australia Wide

No matter where you are in Melbourne, if you can't personally pick up your model we will deliver it for a flat fee of $1 for registered post of $2 for express post

Professional

$1 Shipping

Quality

Guaranteed

Wide Range

Materials

Affordable

Quality Settings

We offer 3 quality options depending on your desired finish; high quality, standard quality and draft quality.

Since we quote based on time, you are now able to choose which print quality best suits your budget whether its a quick draft to check dimensions, a finished product to showcase or something in between.

Please note the default is set at 0.2mm (standard quality)

High Quality

0.1mm layer resolution

Printing Time: 3h 26m

Standard Quality (default)

0.2mm layer resolution

Printing Time: 1h 45m

Draft Quality

0.3mm layer resolution

Printing Time: 1h 11m

Printing Method FDM (plastics), SLS (powder), SLA (resin)

Material Options PLA (default), ABS, Nylon, Wood, Copper, Bronze, Rubber

Layer Resolution High (0.1mm), Standard (0.2mm), Draft (0.3mm)

Print Speed 80mm/s

Support Material Standard

Minimum Thickness 1.0mm

Maximum Build Dimensions 500mm x 500mm x 500mm (X,Y,Z)

Colour Please Specify

Specifics

Students, we understand the rush of uni and the strict time curfews those lecturers provide.

At Kad3D we're here to make your life that little bit easier by providing a fast turnaround time and a 15% discount* to all students.

1. Upload your model below to view your instant quote

2. Use your student email

3. Use the discount code STUDENT to receive 15% off your order.

4. Pay for your order and let us do the rest

If you run into any problems, please contact us using the contact form below

Students

Instant Quote

Click on the link below for an instant quotation for 3D printing.

If you're having trouble with our online quote system, please use the contact form below.

Instant Quote

Please be patient, model analysis may take some time

IMPORTANT:

For interstate users we charge a flat rate of $1 for registered shipping and $2 for express

Professional

$1

Shipping

Quality

Guaranteed

Wide Range

Materials

Affordable

Free Model Repair

If you are unable to submit your model or you see an ERROR please repair your design by clicking the link below.

This service will save you time by taking care of the many common errors in 3D designs to create a model capable of 3D printing.

Contact Form

If you would like to order a large quantity, have any questions about your model or need further assitance, please use the contact form below

Unless specified, by submitting your file for printing you are allowing us to publish your work onto our social media accounts through the form of photographs uploaded to the KAD 3D Facebook and Instagram accounts. We will cite all work to the respective owners.

All uploads will be handled discretely with non-disclosure contracts available for innovative work.

3D printer as a service - does it make sense? / Habr

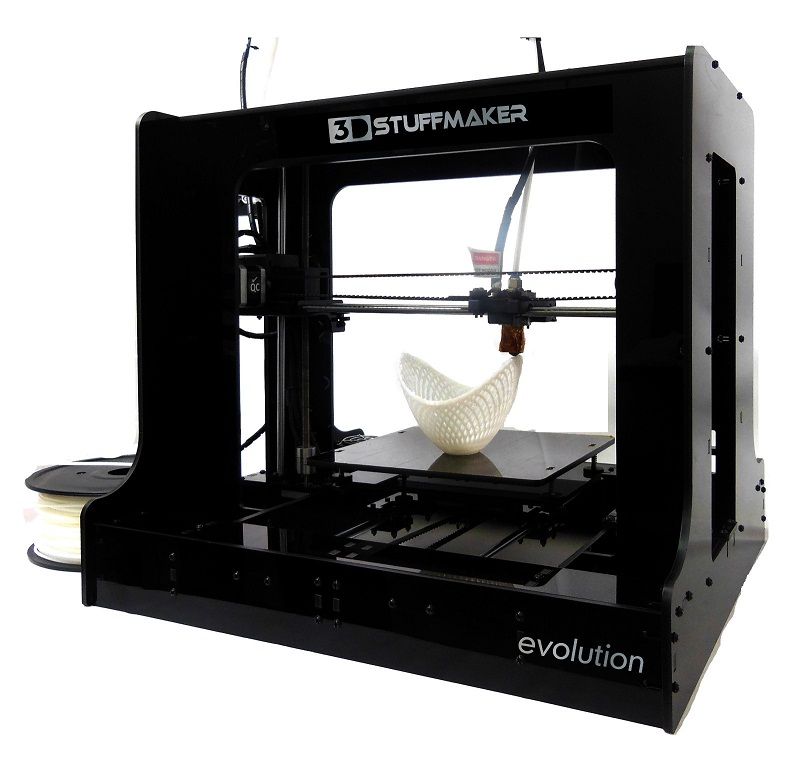

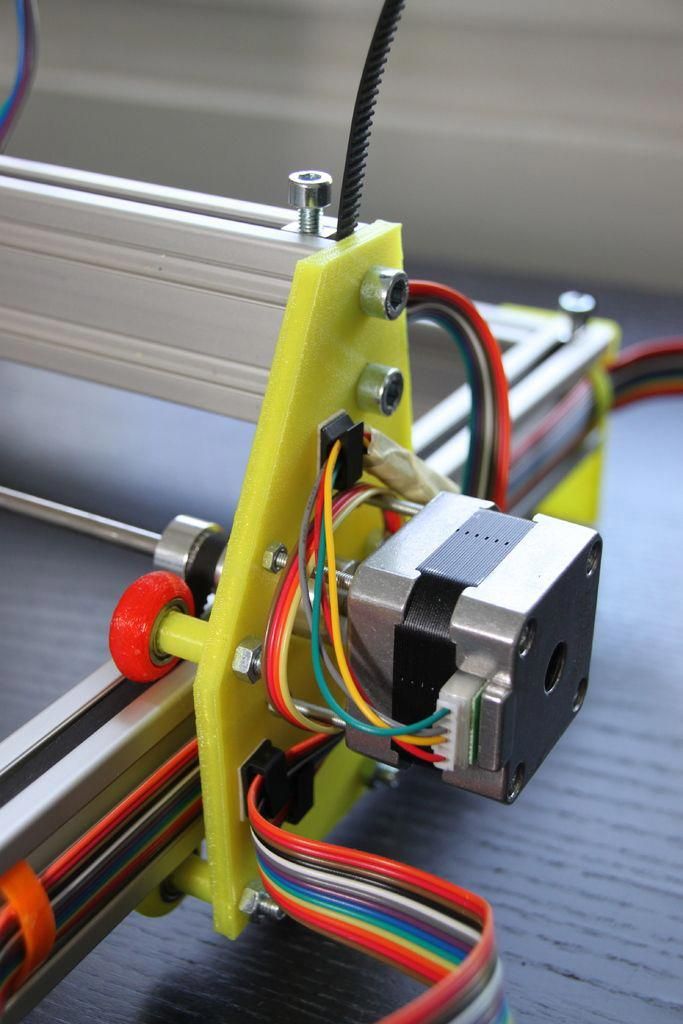

Our company has one main project that we have been working on for more than four years. During this time, we have acquired a lot of rather specific knowledge and skills in the field of development, manufacture and logistics of electronic products. One of the problems that electronics designers face is making cases. And if there are no special surprises with their mass production for a long time (only three things are needed - money, money and money), then with prototyping, until recently, everything was very difficult. And suddenly the era of 3D printers has come!

One of the problems that electronics designers face is making cases. And if there are no special surprises with their mass production for a long time (only three things are needed - money, money and money), then with prototyping, until recently, everything was very difficult. And suddenly the era of 3D printers has come!

We are ripe for buying ourselves a 3D printer. Naturally, we will use it in our projects, but we are unlikely to be able to provide (at least for the first time) 100% load. We know for sure that many companies provide printing services on their devices to everyone. So, it is proposed to discuss the "ideal" 3D printing service - what should it be?

The fact is that one of the by-products of our main project is the entry of one of our companies into the Special Economic Zone. The status of a SEZ resident gives (among other things) the opportunity to save on the purchase of equipment - there are no customs duties and import VAT. We will have to customs the consumables in the usual way, but for the printer itself we will not pay anything in excess of its price and the cost of delivery to our office. It's great, right?

It's great, right?

Another one of our “tricks” (which was born as part of the work on the main project) is the ability to buy anything cheap in China, control the quality of the purchase on the spot and deliver the purchase to Moscow inexpensively. It is clear that the printer can be bought outside of China, but there is a suspicion that in China you can find something very tasty for much less money than, for example, in the USA (although if it suddenly turns out that the best option is sold in the USA or Australia - we can also buy it without any problems).

And here the well-known problem of choice arises. There are so many delicious things on the market in terms of 3D printing right now - it’s just dizzying! Therefore, the first question to the community is: what to take in the budget, for example, up to 10K USD? What is it now - the 3D printer of our dreams? We need printing from ABS - does it make sense to consider universal units that can also use PLA? Or maybe it's better in this budget to buy two printers for different materials? What sizes of products are in demand - is it necessary to chase large platforms? Plastic of different colors - is it necessary? Maybe just white and/or black is enough?

If we bought a printer only for ourselves, we would answer all these questions ourselves. There are suitable candidates (and even in a budget of up to 1500 USD), and an understanding of what we need in terms of materials ... But, once again, why not do a good deed to our colleagues? Gentlemen, what do you need for ?

There are suitable candidates (and even in a budget of up to 1500 USD), and an understanding of what we need in terms of materials ... But, once again, why not do a good deed to our colleagues? Gentlemen, what do you need for ?

Now for the actual service.

3D printing "to order" is not our core business. We are not going to “make a fortune” on this, but the extra money for our tiny company will not hurt. Therefore, the pricing of the service will be extremely transparent - the cost (which consists of the cost of consumables, electricity and the salary of the personnel involved in this particular order) plus a reasonable margin (say, 20-25%). So the prices promise to be very humane.

With the terms a little less rosy: it may take several working days for production, legal export from the territory of the SEZ and delivery to Moscow.

In terms of additional attraction, we plan to provide customers with access to a webcam that will show the process of printing their order online. Well, or someone comes to us (this is not very simple, but in principle possible) and rents “printer time” right on the spot.

Well, or someone comes to us (this is not very simple, but in principle possible) and rents “printer time” right on the spot.

Another possible service: after successful prototyping, we will be able to organize industrial production. There is a Russian company that can do this, but there is a common Russian problem - we need circulation, or rather, even - CIRCULATIONS . There are our proven Chinese who will make an industrial batch cheaply and cheerfully, and we will bring the result here. In general, we can help with this too.

So, gentlemen, there are two main questions:

1. Does it make sense to bother with all this or just buy a 3D printer for our needs and use it “secretly”?

2. If we imagine that we do organize such a service, then (subject to reasonable prices) what else would you like to receive from such a service?

Well, advice/suggestions on specific printer models and types of consumables are welcome.

The Masters Movement, IP Litigation and Law Reform

October 2019

Author: Matthew Rimmer KTU, Brisbane, Australia

3D printing is an industry based on the principle of additive manufacturing (as opposed to the principle of subtractive manufacturing that underlies the traditional manufacturing industry). 3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

3D printing is currently in transition. The consumer "3D printing revolution", which aimed to have a 3D printer in every home, has failed. MakerBot, a pioneer in 3D printing, is having trouble with its changing approach to intellectual property (IP) issues, disrupting its ties to the open source software community, and the user audience turned away from it. As former MakerBot CEO Bre Pettis said in an interview, "The open source community has kicked us out of their paradise." As a result, MakerBot was acquired by Stratasys, a leader in the 3D printing industry, which restructured and repurposed it.

Some other key players also went bankrupt. In particular, TechShop, a membership-funded and open-to-all network of studio-workshops for home craftsmen, went bankrupt. Maker Media, which publishes Make magazine and hosts craft festivals in the United States, has gone under external control. Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

Industrial 3D printing continues to grow

While personal 3D printing has not developed as expected, there has been growth in a number of other forms and categories of 3D printing. Along with robotics and big data, 3D printing has become one of the promising technologies in the manufacturing industry. Companies specializing in information technology and design are working to improve the way 3D printing is used. Significant investments, especially from transport companies, have been attracted by the technology of 3D printing of metal products. In addition, there have been large-scale experiments related to the application of 3D printing in the healthcare sector, including 3D printing in dentistry, 3D printing in medicine, and bioprinting.

As technology improves and develops, there have been several cases of lawsuits being filed in the courts, as well as certain political developments regarding the regulation of the 3D printing industry. Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

3D printing and copyright law

A few years ago, there was a panic that the widespread use of 3D printing would lead to a wave of large-scale copyright infringements, similar to the situation that arose with the advent of the Napster file-sharing network . Although such fears have not yet materialized, there have been various conflicts related to copyright and 3D printing. For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

3D printing was also subject to the on-demand removal of content under the Digital Millennium Copyright Act (USA). Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

In addition, discussions took place on issues related to the use of technical protection measures in the context of copyright law and 3D printing. For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

3D printing and design law

Developments in 3D printing have also raised the issue of product repair rights.

Efforts have been made in the European Union to recognize the right to repair in order to support consumer rights and develop a circular economy. In this regard, one of the important factors in achieving changes in the behavior of companies and consumers has become the European Greening Directive (Directive 2009/125/EC).

In July 2019, the United States Federal Trade Commission held a Hearing on "Can't be Repaired: A Workshop on Product Repair Restrictions. " Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

" Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

Significant and first-of-its-kind litigation in Australia regarding right to repair under Design Law ( GM Global Technology Operations LLC v S . . . - S - Auto Parts Pty Ltd [2019] FCA 97). The Australian Treasury is considering policy options regarding the practice of sharing vehicle repair information.

Australian Capital Territory (ACT) Consumer Affairs Minister Shane Rettenbury called for recognition of the right to repair from the rostrum of the Consumer Affairs Forum, which includes ministers from both Australia and New Zealand. Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Calls for right-to-repair laws, both at the provincial and federal levels, are also being heard in Canada. As Laura Tribe, Executive Director of Open Media, noted in this regard, “We are committed to ensuring that people have the opportunity to be the real owners of the products they own.”

3D printing and trademark law

3D printing also brings uncertainty to trademark law and related legal regimes, including product substitution, identity rights, commercial use of characters, and brand identity. The legal conflict surrounding Katy Perry's trademark application for the "shark on the left" image provides some insight into some of the issues that arise in this regard.

Regarding bioprinting, Advanced Solutions Life Sciences sued Biobots Inc. Due to the alleged violation of its trademark rights ( Advanced Solutions Life Sciences , LLC V BIOBIOTS MAY 201. Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

3D printing and patent law

According to the 2015 WIPO Global Intellectual Property Report, Revolutionary Innovation and Economic Growth, 3D printing patent applications are on the rise. Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

With the growing commercial importance of 3D printing in the manufacturing industry, there have been a significant number of litigations related to 3D printing of metal products. In July 2018, as part of the “Desktop Metal Inc.” v. Markforged, Inc. and Matiu Parangi (2018 Case No. 1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

(See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs." For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

In 2018 (after the above verdict) Desktop Metal Inc. and Markforged Inc. entered into a confidential financial agreement that settled all other litigation between them. However, in 2019 Markforged Inc. filed another lawsuit against Desktop Metal Inc. due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

3D printing and trade secrets

In addition, the first litigation regarding 3D printing and trade secret legislation took place. In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc ." v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

3D printing and open licensing

In addition to proprietary IP protections, 3D printing has a widespread practice of open licensing. Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Other issues arising from the development of 3D printing

In addition to IP issues, the development of 3D printing also raises a number of other legal, ethical and regulatory issues. In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

Litigation regarding 3D printing of firearms is also ongoing in the United States. Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Footnotes

* Dr. Matthew Rimmer is Head of the KTU Research Program on Intellectual Property Law and Innovation and is involved in the KTU Electronic Media Research Center, the KTU Australian Health Law Research Center and the KTU International Law Research Program and global governance.

Learn more