3D printer refills

3D Printer Filament | MatterHackers

- Home

- Store

- 3D Printer Filament

At MatterHackers, we take pride in offering the largest selection of 3D printing filament available. From our affordable MH Build Series filament, to our professional-grade PRO Series filament, you can find any material, like PLA, ABS, NylonX, PETG, TPU, TPE, Flexibles, Polycarbonate, and more! Along with our industry-proven brand of filament, we also carry other top-notch materials from ColorFabb, Taulman3D, NinjaTek, Ultimaker, 3DFuel, and more.

3D Printer Filament Collections

All 3D Printer Filament

Getting Started

3D Printer Filament Comparison Guide

3D Printer Filament

PLA Filament

The most common filament, PLA is a great go-to material for its ease of use.

Metal 3D Printing Filament

Print with real metal on your desktop 3D printer.

ABS Filament

ABS is a durable, versatile material perfect for projects that need strength.

PETG Filament

PETG is a strong, reliable material that is great for end-use parts.

Nylon Filament

Nylon and Nylon Composites for strong, functional 3D printed parts.

Quantum Dual-Color PLA

Mind-bending, dichromatic PLA that works on every printer

Support Filament

Dissolvable and breakaway support materials for dual extrusion 3D printing.

MH Build Series Filament

MH Build Series filament is designed and priced for every maker

MH Build Series PLA

An affordable, low-cost PLA filament intended for producing quality, 3D printed parts.

MH Build Series ABS

An affordable 3D printing filament meant for every maker with projects that require durable and temperature resistant parts.

MH Build Series PETG

An affordable, low-cost PETG filament intended for producing tough and sturdy 3D printed parts.

MH PVA Support Filament

MH PVA Support Filament is a dissolvable support material for dual extrusion parts.

PRO Series Filament

When reliability and consistency counts, be a PRO.

PRO Series PLA

PRO Series PLA is intended for producing professional, high quality, 3D printed parts.

PRO Series ABS

A formulation intended to help your prints stand out with a beautiful, glossy, opaque finish.

PRO Series PETG

A strong material combining the ease of PLA printing with the durability of ABS.

PRO Series Tough PLA

Strong like ABS and much easier to use - it's the best material for reliably printing functional prototypes.

PRO Series Flex

All the benefits of flexible filament together with improved strength over other flexible filaments

PRO Series Nylon

The strength and durability of Nylon now in vibrant colors.

PRO Series Ryno

Excellent at bridging and retraction to keep your parts clean with minimal post-processing.

NylonX

The durability of Nylon combined with the stiffness of carbon fiber

NylonG

Glass infused nylon for strong, functional prints

Carbon Fiber Reinforced PLA

Carbon Fiber reinforced PLA adds more strength and rigidity compared to regular PLA.

ColorFabb

With several varieties available, ColorFabb filament is consistent and reliable.

ColorFabb Fill Series

PLA filaments infused with wood, metal and glow-in-the-dark particles for eye-popping prints.

ColorFabb PLA/PHA Series

A unique 3D printing filament tougher and less brittle than just PLA.

MadeSolid

Affordable materials from MadeSolid - limited time only.

NinjaTek

High quality and industry-leading flexible materials.

PVA (Polyvinyl Alcohol)

Polyvinyl Alcohol, a water-soluble support material that dissolves away in a water bath to leave only your perfectly printed part.

Polymaker Filament

Browse all filament collections from Polymaker!

Polypropylene Filament

Polypropylene (PP) is a semi-crystalline thermoplastic filament used to produce durable and lightweight prototypes through Fused Filament Fabrication (FFF).

Proto-Pasta PLA Blends

PLA filaments blended with metal, wood and glow-in-the-dark materials for cool print effects.

Soft PLA

Soft PLA is a flexible material great for parts that need to bend to fit their environment.

PRO Series TPU

Strong yet bendable filament that has excellent layer to layer bonding.

Taulman 3D

High-strength nylons and engineering-grade materials for functional 3D printing.

Ultimaker ABS Filament

Get beautiful, glossy prints with Ultimaker ABS filament

Ultimaker CPE Filament

Get high impact strength and chemical resistance with Ultimaker CPE

Ultimaker Materials

High-grade filament for any 3D printer from Ultimaker

Ultimaker Nylon Filament

Get impact and abrasion resistance with Ultimaker Nylon filament

Ultimaker PLA Filament

Highly versatile, easy to print and available in a variety of colors.

Ultimaker Polycarbonate Filament

3D Print molds, tools, and functional Prototypes with Ultimaker PC

Ultimaker TPU Filament

Get qualities of rubber and plastic and resistance with Ultimaker TPU

Fillamentum

From ASA to exotic colors, Fillamentum provides a quality 3D printing experience.

3DXTech Filament

Explore advanced manufacturing filament from PEEK to ESD-safe materials.

Proto-Pasta

Metallic filament and unique composites make Proto-Pasta 3D filament stand out.

SpoolWorks

3D printing materials from the creators of the industry-leading All-metal v6 HotEnd.

PRO Series Breakaway Support Material

Provides fast, easy, and clean mechanical breakaway for 3D printed parts.

AprintaPro Filament

3D printing filament with great layer adhesion that produces excellent parts.

Kodak 3D Printing Filament

A wide range of 3D printing materials with a focus on color and quality.

eSUN

Consistent and reliable 3D printing filament for entry-level 3D printing.

BASF Ultrafuse 316L Metal 3D Printing Filament

Reliable metal manufacturing for industrial applications - right from your desktop 3D printer.

FiberForce Pantone (R) Certified PLA

Browse a selection of Pantone® certified colors.

Ultimaker Tough PLA Filament

The ease of PLA printing with the impact resistance and stiffness of ABS.

Kai Parthy Lay Series

Browse unique and experimental 3D printing materials.

DSM 3D Printing Filament

Engineering-grade, advanced 3D printing materials for industrial production.

Engineering Grade Filament

High-temperature and advanced materials used in several industrial applications.

MakerBot 3D Printing Filament

Rigorously tested for quality, and optimized for Method Printers.

Fillamentum ExtraFill Series

An excellent baseline PLA that prints amazingly well.

Fillamentum Extrafill ABS Filament

Fillamentum Extrafill ABS Filament

Fillamentum Crystal Clear Series

An incredible line of semi-transparent, colored materials.

Fillamentum FlexFill Series

Flexfill is rubbery and elastic, making it impact, oil and abrasion-resistant.

Fillamentum Vertigo Series

Vertigo PLA series reflect light and create awesome, eye-catching prints with flecks of gold, silver and blue.

Fillamentum PVC Vinyl Filament

Fillamentum PVC Vinyl Filament

Fillamentum ASA Series

A rugged weather-resistant material that is much more resistant to UV light.

Fillamentum TimberFill Series

Made from a PLA base with wood particulate, Timberfill gives you 3D prints that look like they were carved from wood.

Fillamentum CPE

Fillamentum CPE

Dow OBC 3D Printer Filament

Strength and Flexibility in One Easy-to-Print Material

Raise3D Filaments

Browse Raise 3D selection of 3D printing filaments

Kodak Nylon 3D Printing Filament

Kodak Nylon 3D Printing Filament

Kodak PLA+ 3D Printer Filament

Kodak PLA+ 3D Printer Filament

Kodak Flex 98 3D Printing Filament

Kodak Flex 98 3D Printing Filament

Kodak PLA Tough 3D Printer Filament

Kodak PLA Tough 3D Printer Filament

Kodak PETG 3D Printer Filament

Kodak PETG 3D Printer Filament

Kodak ABS 3D Printing Filament

Kodak ABS 3D Printing Filament

BASF Ultrafuse 3D Printer Filament

Industrial grade filament for technical and engineering level 3D printing.

BASF Advanced Specialty Materials

Sophisticated, advanced materials created by the world's leading chemical company.

Clearance Items - Materials

Filament and resins at reduced prices for great savings.

Metallic 3D Printing Filament

Browse real stainless steel metal filament and metal composites

Guides & Articles

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

How to Succeed when 3D Printing with PETG Filament

This in-depth guide provides everything you need to succeed when printing with PETG filament. Embrace the fantastic properties of durable and easy to print, PETG filament!

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When Printing With Flexible Filament

Let’s take a look at what makes flexible filaments easier to print and how you can add flexible filament to your 3D printing material toolbox.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

How to Succeed When 3D Printing with MH Build Resin

Make SLA resin 3D printing easier with this helpful detailed article on how to successfully fine-tune photopolymer resin to your 3D printer.

How To Succeed: 3D Printing with Nylon and Nylon Composites

Nylon and nylon composites perform exceptionally well in a variety of uses, it just takes a gentler touch to print it successfully.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

What is 3D printing filament?

3D printing filament is a thermoplastic, or polymer, that melts when heated and is extruded through a nozzle layer by layer to create a three-dimensional object. After the filament is extruded, it cools and becomes the surface the next layer is deposited on top of.

After the filament is extruded, it cools and becomes the surface the next layer is deposited on top of.

3D printing filament is sold in spools ranging in weight from 0.5 kg to 10 kg. It comes in two diameters; 1.75mm and 2.85mm.

The most commonly used filaments are PLA and ABS. Both have advantages for different applications.

What types of filament are there?

Below is a chart showing the more common types of filament, along with their transition temperatures, bed temperatures, and ideal printing surfaces.

| Filament | Common Transition Temps | Common Bed Temps | Printing Surface |

| PLA | 205±15 °C | 40±15 °C | Glass |

| ABS | 230±10 °C | 90±10 °C | Glass with ABS slurry or kapton tape |

| PETG | 245±10 °C | 60±10 °C | Blue painters tape or bed adhesive |

| Nylon | 255±15 °C | 70±10 °C | Garolite |

| ASA | 250±10 °C | 90±10 °C | Hairspray, bed adhesive |

| Polypropylene | 250±15 °C | 110±10 °C | Packing tape or polypropylene |

| TPU/TPE | 230±10 °C | 50±15 °C | Glass, painters tape |

| PCTPE | 235±10 °C | 70±10 °C | Glass with kapton tape or hairspray |

| Polycarbonate | 290±20 °C | 130±15 °C | Gluestick/hairspray |

| PVA Support | 180±20 °C | 45±10 °C | LayerLock PEI |

| Breakaway Support | 210±10 °C | 50±5 °C | LayerLock PEI |

| HIPS Support | 230±10 °C | 50±10 °C | Glass with kapton tape or hairspray |

Best 3D Printing Filament in 2022

You've got the best 3D printer you can buy, so it's time to start printing! If you chose an FDM printer -- the most common type of 3D printer for hobbyists -- then you'll need some material to print with. The material we use for FDM 3D printing is called filament and it is an easy material to pick up. There are, however, different types of filament, each good for certain projects and terrible for others. You'll want to make sure you're using the best filament for the job at hand, or it may fail.

The material we use for FDM 3D printing is called filament and it is an easy material to pick up. There are, however, different types of filament, each good for certain projects and terrible for others. You'll want to make sure you're using the best filament for the job at hand, or it may fail.

I've put together this primer of the different types of filament as well as choices of the best filaments from my favorite brands. This will be updated regularly and contains some great choices for you to start.

James Bricknell/CNETIt's important to choose both the right type of material and the right brand of that type, be it PLA, ABS or something more exotic. Here are the best of each of the five main filament types.

Read more: Best 3D Printers

Those categories are

- PLA

- ABS

- PETG

- TPU

- Exotics

PLA is the easiest material to use to make awesome things.

Polylactic acid

Polylactic acid, or PLA, is the most common 3D printing filament and the easiest to use. Unlike most plastic, it's made from corn starches so it is non-toxic and, in theory, compostable, though it takes an industrial composter to do it. PLA uses a fairly low heat -- between 190 and 215 degrees Celsius (or between 374 and 419 degrees Fahrenheit) -- to melt the plastic for extrusion so it is the safest of the filaments. Almost every FDM 3D printer in the world can print PLA.

PLA pros

- Nontoxic

- No awful smell

- Easy to use for a beginner

- Almost universally usable on any FDM printer

- Very cheap

PLA cons

- Can require a lot of sanding

- Can easily warp in the sun or high-temp environments

- Can be brittle

Matterhackers

Matterhackers Build PLA

Best overall

Build PLA from Matterhackers is great for projects that require finishing (sanding, painting and so on). I have about 12 rolls of it in my workshop, and use it for large projects, including my Mandalorian armor or cosplay swords. The dimensional accuracy -- how consistent the diameter is along the length of the roll -- is good, though nothing mind-blowing. It's well within the sweet zone.

I have about 12 rolls of it in my workshop, and use it for large projects, including my Mandalorian armor or cosplay swords. The dimensional accuracy -- how consistent the diameter is along the length of the roll -- is good, though nothing mind-blowing. It's well within the sweet zone.

Post-processing is where Build Series PLA shines. It is simple to sand and holds paint well, as long as you use a good primer and filler first. Like all PLA, it holds together well using superglue and even takes putty and Bondo without complaint.

$21 at Matterhackers

Cookiecad

CookieCad Mint chip

My new favorite color

I have been meaning to buy some of this beautiful filament for some time now, and I'm really happy I did. The color is almost exactly the same as Mint choc chip ice cream and the tiny flecks of marble color enhance the look even more. It prints great, with a nice glossy finish, and I found printing it at a higher temperature brings out that gloss really well.

More importantly than the print quality though, I love it for the way it makes me feel. The color just makes me happy and reminds me of days at the beach with my kids. It's gorgeous.

$35 at Amazon

Sunlu

Sunlu PLA Filament

Best on a budget

Sunlu is one of those filaments that is really easy to get hold of and prints well every time you use it. It says its dimensional accuracy is +/- 0.02mm but I've been lucky to never have the variance above 0.01mm in hands-on use.

Sunlu also comes in some beautiful matte colors, which is a nice break from more common shiny filaments. Sanding and printing with it is easy. If you're new to 3D printing and need to increase your collection of PLA, this is a cheap way to do it.

$19 at Amazon

Polymaker

Polymaker PolyTerra

Environmental thinking

For projects you can show off without having to paint them first, PolyTerra might be for you. The colors are vivid, and because they are matte, you don't lose details in the reflections like with shiny filament.

The colors are vivid, and because they are matte, you don't lose details in the reflections like with shiny filament.

PolyTerra also comes in recycled cardboard reels, and the creator, Polymaker, will plant a tree in the area where the roll was bought to help offset the cardboard used. This filament is still plastic of course, but it helps my conscience to use it.

$20 at Amazon

Ataraxia Art

Ataraxia Art

Bouncy bouncy

In this article about this flexible PLA I explained how, although this isn't technically PLA, it does print much easier than TPU, a more common flexible filament. I used it to print an amazing Mandalorian Blacksmith helmet for my 4-year-old. She can't break it because it's so bouncy.

This isn't for newbies, though. It took a lot of trial and error to get the setting for my 3D printer right, and because it is so soft the accuracy can be pretty wonky. But for something that's different from normal PLA, it is worth checking out.

But for something that's different from normal PLA, it is worth checking out.

$40 at Amazon

Matterhackers

Matterhacker Quantum PLA

Something new and exciting

For something completely different in the PLA world, check out Quantum by Matterhackers. Transitional filament, mixing multiple colors, has been around for a while, but it normally changes color across the length of the material. This causes it to change color as it goes further up the model.

Quantum is actually two colors fused across the entire width, so you get an amazing transition from left to right. It's absolutely mesmerizing, and I love using it for all sorts of different projects. From vases to giant articulated octopuses, it makes any model look breathtaking.

$37 at Matterhackers

Acrylonitrile Butadiene Styrene

ABS was one of the more 3D printing filaments a few years back, and it still has some excellent uses. The biggest downside is the toxicity. You don't want to breathe in ABS as it melts, so you'll need a well-ventilated area. That aside, it's sturdier and more heat-resistant than PLA. Most printers can print ABS, but you'll need a heated bed that can reach 100 degrees Celsius for best results and protecting your printing job in an enclosed printer is a good idea.

The biggest downside is the toxicity. You don't want to breathe in ABS as it melts, so you'll need a well-ventilated area. That aside, it's sturdier and more heat-resistant than PLA. Most printers can print ABS, but you'll need a heated bed that can reach 100 degrees Celsius for best results and protecting your printing job in an enclosed printer is a good idea.

ABS pros

- Can withstand a lot of heat

- Easy to sand

- Can be smoothed with acetone for a perfect shine

ABS cons

- Its fumes are toxic so it requires ventilation

- It needs far more heat to print than PLA

- You will need an enclosure to get good results

Inland

Inland 1.75mm Black ABS

Cheap and cheerful

Inland makes good filament across the board and its ABS is no different. I've never had issues with the dimensions, and the final product has consistent layer lines. Sanding Inland ABS is a joy as the material can be wet-sanded to a smooth finish.

Sanding Inland ABS is a joy as the material can be wet-sanded to a smooth finish.

$22 at Amazon

Matterhackers

Fillamentum ExtraFill ABS

Bright and beautiful

Fillamentum is one of my favorite ABS makers. The colors are always so vibrant, and while it costs a little more than the competition, it keeps that vibrancy even after the model is finished printing. If you're looking for ABS that you don't need to paint, Fillamentum is a great place to start.

$45 at Matterhackers

Polyethylene Terephthalate Glycol

PETG is chemically similar to the plastic that water and soft drink bottles are made of, and is a great alternative to ABS. It has the heat-resistant properties of ABS without the toxic fumes and can be sanded much like PLA. Most FDM printers that can print PLA can print PETG, though it takes a little more effort to get right.

PETG pros

- Easier to print than ABS

- Holds a finish well

- Easier to store than other filaments

PETG cons

- Requires high temps, which can damage printer parts over time.

Matterhackers

Matterhackers Pro series PETG

Glorious colors

Pro series filament from Matterhackers is a much nicer product than a lot of standard PETG. Yes, it costs a little more, but it's designed to help reduce some of the issues that filament suffers from. It reduces shrinkage, so the part you make is as close to the part you designed as possible. This is a great material for those who make 3D printed models for a living, rather than a hobby.

$57 at Matterhackers

Overture

Overture PETG Filament 2-pack

Stock up on your PETG

Overture PETG is a favorite because it comes in an economical two-pack, making it ideal for multiple or larger jobs. I've used a lot of Overture products, including PETG and PLA, and they always print well. I once printed an 11-foot-long Masamune sword using Overture and it came out looking awesome.

I've used a lot of Overture products, including PETG and PLA, and they always print well. I once printed an 11-foot-long Masamune sword using Overture and it came out looking awesome.

$39 at Amazon

Thermoplastic Polyurethane

TPU is a flexible material that can make cool rubbery models. Most people use it to 3D print phone cases, but more serious modelers often use it to create connectors or flexible hinges to other materials. It can be a difficult material to work with and is best used on a direct-drive 3D printer such as the Prusa Mk3s, rather than a Bowden printer like the Anycubic Vyper. A direct drive printer places the gears to move the filament directly on the print head, while a Bowden setup has them on the frame of the printer.

TPU pros

- Flexible

- Won't warp in the heat

- Available in fun colors

TPU cons

- Terrible for making solid prints

- Hard to work with on budget printers

NinjaTek

Ninjaflex TPU 500 grams

The original and best

While Ninjaflex is at the high end of what you should pay for filament, it is definitely the easiest TPU I have worked with. Save this pricey material for more serious projects that need to succeed the first time.

Save this pricey material for more serious projects that need to succeed the first time.

$30 at Amazon

Matterhackers

Matterhackers Build Series TPU

For everyday use

Matterhackers Build Series Materials sit in the perfect balance between usability and cost. Yes, I've had failures with the Build Series, but once you get it dialed into your printer, you can make dozens of fun, springy models.

I like to use it to make fun toys for my kid's preschool as they can be thrown around with no fear of breaking into small, sharp pieces.

$29 at Matterhackers

Exotic filaments

Exotic filaments are ones that are outside the normal five choices, or interesting variations on those choices. They're often PLA mixed with carbon fiber or glow-in-the-dark chemicals and something that prints outside the normal parameters of a 3D printer. You'll often need to upgrade your printer nozzle to use these. It's advanced stuff, but I wanted to show you my favorite glow-in-the-dark filament, which is fun to print with.

It's advanced stuff, but I wanted to show you my favorite glow-in-the-dark filament, which is fun to print with.

Amolen PLA

Amolen PLA Filament Glow in The Dark Multicolor PLA

Get a good glow on!

Glow-in-the-dark filament normally comes in a standard "radioactive" green, but this beautiful roll transitions through multiple colors. It's simply gorgeous.

It's also worthwhile to buy some replacement brass nozzles for your printer as glow-in-the-dark filament can chew them up pretty quickly because the glowing material is more abrasive than standard colors.

$37 at Amazon

Filament FAQ

What filament should I start with?

If you're buying a printer for the first time, the best choice of filament is PLA. It is the easiest to print with, the safest in terms of fumes and the most readily available. Think about laying in a store of PLA when you first start. A 1-kilogram roll feels like a lot, but once you get the itch, materials get eaten up quickly.

A 1-kilogram roll feels like a lot, but once you get the itch, materials get eaten up quickly.

Are there different sizes of filament?

Yes. There are two main thicknesses of filament and if you get them mixed up, your machine won't print.

1.75mm filament is the most common. It's been adopted by most of the 3D manufacturers in the world and if you have an entry-level printer, it's likely to run on 1.75mm filament.

Some 3D printers still use the thicker 3mm style, though, so make sure you know which one yours uses before you spend a lot of money on the wrong material.

Are all filaments toxic?

When 3D printing with any filament, it is important to remember that you are essentially burning plastic. Inhaling that kind of thing is never going to be good, but not all filaments are equally bad.

Of the four main filament types, ABS is easily the most toxic. You shouldn't think about printing it unless you have a well-ventilated space away from your day-to-day living spaces. I have a workshop with a full ventilation system and the fumes can still be pretty bad.

I have a workshop with a full ventilation system and the fumes can still be pretty bad.

Both PLA and PETG are considered nontoxic, though you still want to keep your area ventilated as you use them. Both filaments are safe to print inside your home and while the fumes can smell pretty bad, they're not classed as carcinogenic. While other forms of TPU can be toxic, the filament you use for 3D printing is considered nontoxic and nonreactive so you should be fine printing that as well.

Does the filament keep the same color after printing?

Normally yes. If your printer isn't calibrated well, it could burn the filament, which would discolor it. But normally the color accuracy is pretty close.

A special note on clear plastics: You will not be able to get a completely translucent print with filament. The nature of the printing process makes any clear plastic misty and infill makes it blurry as well. If you are looking to print glass-like models, you will need a resin printer.

Having the right diameter makes for a better print

Dan Ackerman/CNETHow we test filament

The testing of filament is mainly focused on a few details: Dimensional accuracy, winding precision, and printing quality. Winding precision is a visual test where I check to make sure the filament works well on the spool, without any crossovers that can cause snags while printing.

Print quality is done using a CNET calibration test that I use to test all of the 3D printers I review. When checking for filament quality, I'm looking for noticeable roughness and missing filament where moisture or other contaminants have interrupted the process of melting and cooling.

James Bricknell/CNETDimensional accuracy is perhaps the most important test as it measures the consistency of filament. As you move along, the filament changes in diameter will cause the 3D printer to over- or under-extrude filament. This creates noticeable scarring in your model, or worse, complete failure. You want the material to have the same diameter the whole way through.

As you move along, the filament changes in diameter will cause the 3D printer to over- or under-extrude filament. This creates noticeable scarring in your model, or worse, complete failure. You want the material to have the same diameter the whole way through.

To measure the accuracy, I take a 5-meter piece of filament from the beginning, middle and end of the roll and measure the diameter at four equally spaced points. I then add all of those measurements up and divide the total by 12 -- the total number of measurements taken -- to give me an average across the roll. Most modern printers use 1.75mm filament so you want the filament to be as close to that as possible.

Great filament has a variance of +/- 0.02mm, good filament is +/- 0.03mm and rough filament is anything +/- 0.05mm. All of the filaments we have recommended here are at least 0.03mm on average.

Read More: The Best 3D Printer Resin

3D printer is filled with

What to fill?

For those who are planning to purchase a three-dimensional printer or are just thinking about such an acquisition, the issue of servicing this device is quite acute. After all, it is on its complexity and cost that the adoption of such a decision mainly depends. In this article, we will try to understand in more detail what materials and knowledge the user needs to ensure the operation of a 3D printer.

After all, it is on its complexity and cost that the adoption of such a decision mainly depends. In this article, we will try to understand in more detail what materials and knowledge the user needs to ensure the operation of a 3D printer.

Materials used for 3D printing

- ABC plastic - this name is a simplified version, as chemists call this substance acrylonitrile butadiene styrene. Such material is characterized by high strength and a sufficient level of elasticity. In the field of three-dimensional printing, a powder mixture of ABC plastic is widely used when bulk products are made by pouring an extruded melt. Plastic for a 3D printer is one of the most durable manufacturing materials, but it quickly breaks down when exposed to sunlight. Such material is completely unsuitable for recreating transparent objects. You can buy plastic for a 3D printer in specialized stores or order it online.

- Polycaprlactone is considered one of the most promising and sought-after materials for 3D printing.

It can be used in several technologies: selective laser sintering, pouring with an extrudable melt, etc. A distinctive feature of this substance can be considered a low melting temperature, which is successfully combined with a fairly high solidification rate. Moreover, its chemical composition does absolutely no harm to the human body and is characterized by unprecedented impact resistance.

It can be used in several technologies: selective laser sintering, pouring with an extrudable melt, etc. A distinctive feature of this substance can be considered a low melting temperature, which is successfully combined with a fairly high solidification rate. Moreover, its chemical composition does absolutely no harm to the human body and is characterized by unprecedented impact resistance. - Low-density polyethylene - such a substance has long been rightfully considered one of the most popular types of plastics in the world, which is why it is not surprising that the developers of three-dimensional printers have found application in this area. We all know what a plastic bag, plastic bottle and other food grade plastic items look like. All this is low-pressure polyethylene, which today is one of the recognized leaders in the field of 3D printing. Another factor that contributes to such a wide use of this substance is that it is suitable for any 3D printing technology.

Few materials have the same versatile properties, but the advantage of polyethylene is its low cost.

Few materials have the same versatile properties, but the advantage of polyethylene is its low cost.

Fig. 1. Coils of multi-colored plastic ABC

Fig. 2. Material polycaprlactone

Fig. 3. Low density polyethylene

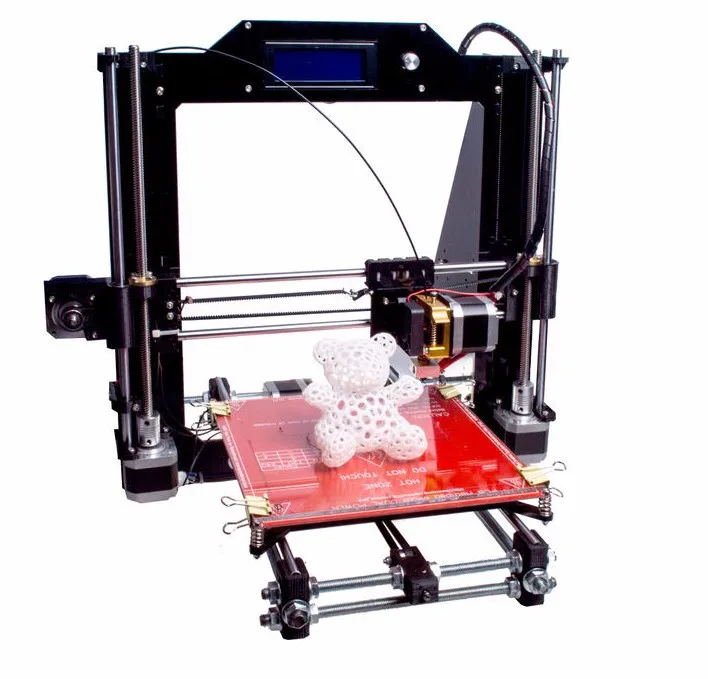

How to refill a 3D printer

The process of refilling a 3D printer is not much different from a conventional 2D inkjet printer. It is worth noting that the "ink" of 3D printers is enough for a long time, so you often do not have to carry out such a procedure. When answering the question of how to fill a 3D printer, you should first of all think about the purpose of using this device. The most popular material has always been and remains plastic for a 3D printer, which can be bought either in specialized stores or on the Internet on manufacturers' websites.

They fill the 3D printing device and other substances, it all depends on the object being created. Today, culinary 3D printers that are filled with food products are already known. Some 3D devices based on human or animal stem cells recreate real living organs, ready for transplantation. It is clear that plastic for a 3D printer that produces machine parts and metal structures will not work. Industrial 3D printing devices can generally “eat” any materials, while simpler units work with a limited amount of substances.

It is clear that plastic for a 3D printer that produces machine parts and metal structures will not work. Industrial 3D printing devices can generally “eat” any materials, while simpler units work with a limited amount of substances.

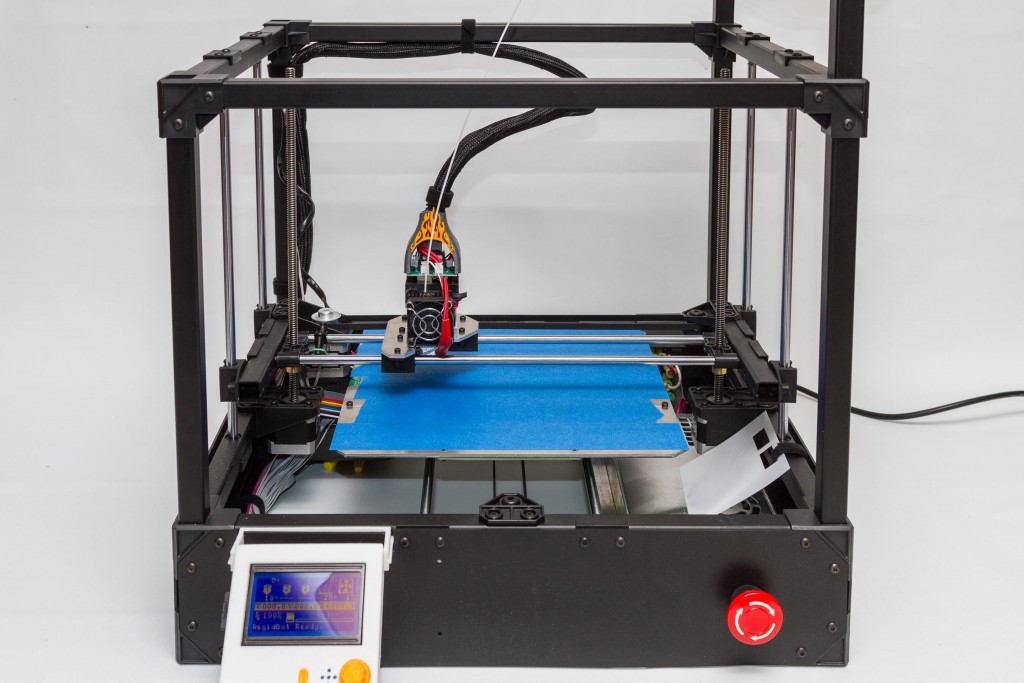

As a rule, an inkjet 3D printer is sold complete with a spool of specialized plastic and a set of necessary tools. Depending on how much the 3D printer costs, these kits can be quite impressive or contain only the bare essentials. Three working platforms and special gloves for the safe operation of the devices are also often included in this kit. In addition, each individual model of a three-dimensional printing machine is provided with detailed instructions, which, using a detailed description of the device and visual pictures, explain the process of refueling the unit and many other useful points.

Software for three-dimensional printers

By itself, a 3D printing device will not be able to work, since all processes occurring in the working chamber of such a printer are based on one or another software tool. The specificity of his work lies in the fact that he must project a three-dimensional image or figure instead of a flat picture. Moreover, models for a 3D printer should be an ideal virtual version of the future object, because they will guide the 3D printer in the future. Every detail and delicate contour must be made with maximum precision, as the quality of production depends on it.

The specificity of his work lies in the fact that he must project a three-dimensional image or figure instead of a flat picture. Moreover, models for a 3D printer should be an ideal virtual version of the future object, because they will guide the 3D printer in the future. Every detail and delicate contour must be made with maximum precision, as the quality of production depends on it.

No matter how much a 3D printer costs, in any case, it needs software, which in turn is divided into several types:

- Programs for managing the printer;

- 3D editors that are responsible for performing specific tasks on the device.

It is important that these programs are carried out in accordance with existing norms and standards. How the 3D printer actually works, products, or rather their quality and accuracy, and much more will depend on this. Among the most important features of such software, it is worth noting the data formats that they must read and edit:

- STL is a specialized programming language that uses triangles to describe the planes of a given object;

- X3D - this language is based on the so-called XML standard, according to which the countdown is based on predefined profile data;

- VRML - based on triangles that do not have common vertices.

Creation of three-dimensional figures using volumetric printing begins with the formation of STL models for a 3D printer. They provide the system operator with all the necessary information about the object being created. The development of an STL model for a 3D printer is usually carried out using CAD programs. I must say that such software is quite expensive. If it can be quite difficult to buy a good 3D printer at a low cost, then with such software there is a slightly different picture. Of course, when it comes to large-scale production, it makes no sense to save on specialized programs. However, most of the necessary functions can be performed by the free Google SketchUp application.

Google SketchUp 3D editor

As practice shows, using this program is perfect for portable and even some professional 3D printers. Its peculiarity lies in the fact that all models are created in the native format for the program, but at the end of all work they are converted to STL. The software from Google SketchUp has a user-friendly interface and a number of effective working tools, thanks to which the work of a 3D printer is greatly simplified:

The software from Google SketchUp has a user-friendly interface and a number of effective working tools, thanks to which the work of a 3D printer is greatly simplified:

- There is a special software tool that can turn a flat surface into a three-dimensional image with just a few clicks.

- The high accuracy of compliance with the entered data and parameters allows you to create a 3D printer product with the maximum level of compliance of the virtual model with the resulting product.

- This software tool supports collaboration with many other programs, such as AutoCAD, from where you can transfer various geometric characteristics of the created object.

- If necessary, to convert a two-dimensional plane into a three-dimensional figure, you can use the "extrude" function, which is ideal for a 3D printer that works on the principle of extrusion.

- The user can see how this or that part of the created figure looks in section.

- Another interesting and popular feature of this editor is the extended operator's ability to view and display models.

Any selected view can be saved in a separate folder, as well as rotate the resulting model in a variety of planes.

Any selected view can be saved in a separate folder, as well as rotate the resulting model in a variety of planes. - It is possible to make an internal inspection of a reproduced object at absolutely any stage of work.

- With this program you can create large-scale layouts with a wide variety of elements. Each such site can be assigned individual parameters and physical qualities. You can see similar models for a 3D printer in the figure below.

- The program supports many other model formats, so a person can easily import any additional element from another object. The same applies to various images in the most popular formats (JPG, PDF, PNG, etc.).

- Raster images can be exported in a variety of formats as long as they are less than ten thousand pixels in size.

Fig. 4. Model of a lock made using a 3D printer

The most popular 3D editors of today

In addition to Google SketchUp, there are many other useful programs for 3D printing that meet all the required standards. We have already figured out that buying a 3D printer means doing only half the job. To date, a lot of software tools have been developed that help simplify and control 3D printing:

We have already figured out that buying a 3D printer means doing only half the job. To date, a lot of software tools have been developed that help simplify and control 3D printing:

- ZPrint is a fairly good 3D printing software with a standard set of features. Supports Z-Corporation 3D printers.

- ZEdit - with this software, the user's capabilities become much wider thanks to additional services:

- Materialize Magics is a service that monitors the appearance of defects in products and helps to eliminate them. Correction of errors occurs at the stage of recreating the virtual model. If STL models for a 3D printer are loaded into the program in a ready-made form, it is also able to analyze them for errors and malfunctions.

- Tinkercad - such a program allows a person to recreate the desired object directly in his browser, without the need to install one or another application. It works with various 3D printers themselves, and also supports mobile devices or tablets.

As for the cost of using such software, it is completely free for any user.

As for the cost of using such software, it is completely free for any user. - SolidWorks Standart is an interesting working tool that allows the user to model an object or a set of objects of various levels of complexity. Allows the planning of figures and objects, taking into account the characteristics of the future materials used, for example, metal structures or plastic parts. It is considered one of the most convenient software tools in its field and is easy to manage.

- OpenSCAD is a specialized working tool that deals exclusively with the production of solid volumetric objects and figures. This technology is most often used for the design and manufacture of automotive and aircraft parts. Supports 3D printers that work on the principle of extrusion.

- Compass 3D is a universal software that has been used mainly in the field of communication modeling. The program allows you to simultaneously monitor the change and operation of each individual element of the system, recreate large-scale operating layouts of entire buildings or complex machines, and then carry out their direct construction.

Modern power supply systems in most cases use this software tool. Almost any 3D printer can work with it, the photo below will introduce you to the capabilities of such a program in more detail.

Modern power supply systems in most cases use this software tool. Almost any 3D printer can work with it, the photo below will introduce you to the capabilities of such a program in more detail. - T-FLEX CAD 3D - designed to automate the technological and design part of production. All working tools of the program are highly accurate and reliable, and the power of such software is quite enough to ensure uninterrupted round-the-clock operation of an industrial 3D printer, the photo of which you can see below.

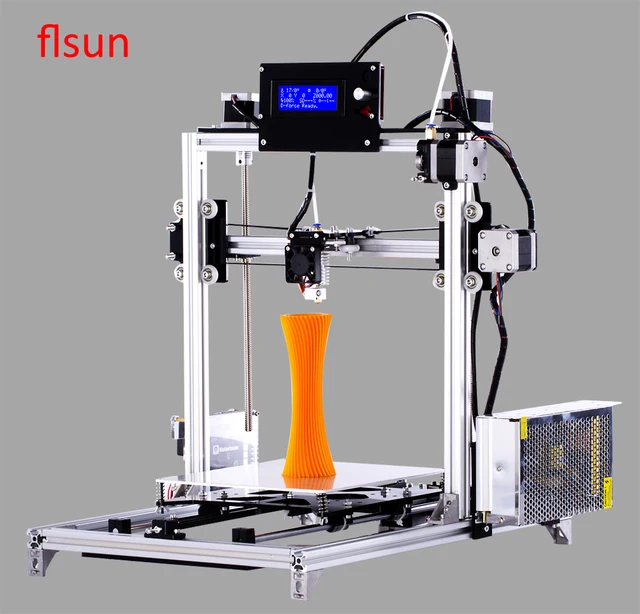

Fig. 5. Building a three-dimensional model in the Compass 3D

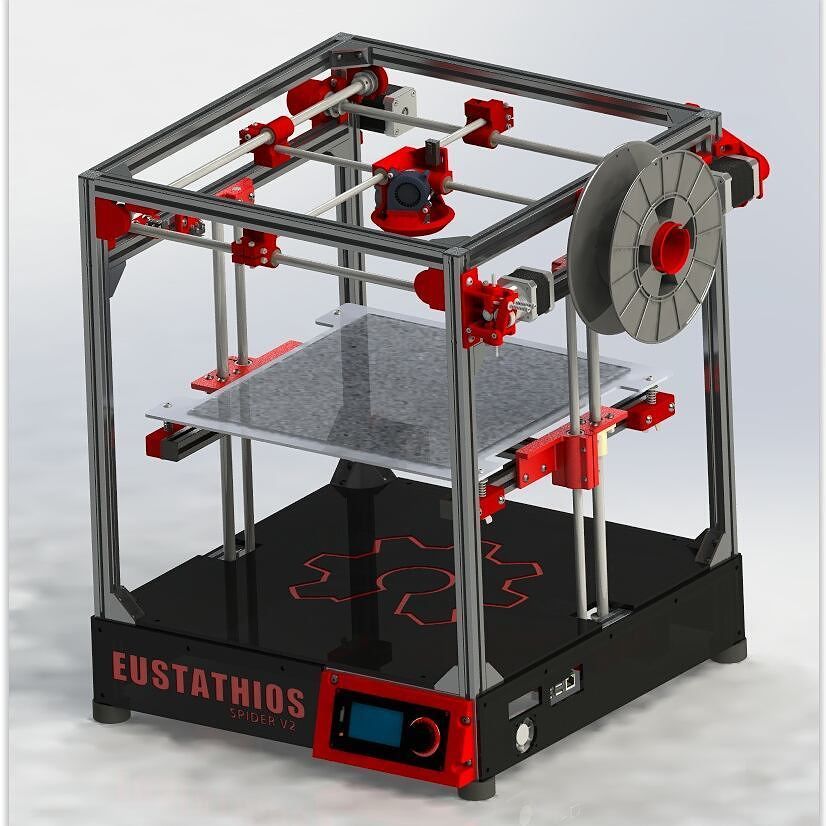

programFig. 6. Industrial 3D printer

A person who is trying to choose a suitable 3D printer for his business should also pay attention to the capabilities of the software tool that could best suit his needs, because the quality and speed of future tasks will depend on it. The performance of a 3D printer mainly depends on the software chosen by the user.

How to 3D Print - Beginner's Guide to 3D Printing

- Home

- 3D -ip

- Guide for beginners

- Sale 3D printer

- Best handle 3D

- Files for 3D printing

- BEST PLA

- trenches follow

- Long Range Drones

- Long Range Drones

- Kids Drones

- Cheap Action Cameras

- How to link a printer to a computer

- How to connect a printer to a computer remotely

- Printer does not see paper what to do

- What to do if paper is jammed in the printer

- What to do if the printer does not want to print from the computer

- How to clear a printer jam

- How to set the printer password

- How to get sheet 9 out of the printer0013

- How to connect a printer to a computer and set up

- What's inside the printer

- How to change the printer's print settings

- Extruder - the print head through which the thread passes. The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface.

- Work surface - a printing platform on which a 3D model is formed.

- Motors - mechanisms responsible for the accuracy of movement and speed of printing.

- Sensors are electronic devices that limit moving parts to specified coordinates.

- The frame is the structure that connects all parts of the printer.

- Architecture - creation of models of buildings.

- Medicine - dental prosthetics, making models of organs for study.

- Construction - production of houses using 3D printing technology.

- Education - a visual aid for learning 3D printing.

- Automotive - creation of tuning parts, prototype layouts and other products.

- RepRap - self-reproducing printers that can create their own copies.

- DIY-kit - the device comes disassembled with instructions, the assembly of which will take a sufficient amount of time.

- Ready-Made - models are delivered assembled and ready to use.

- Commercial and industrial - devices capable of printing metal, concrete, polymers and other materials.

- Mechanical - is carried out by sanding the surface with sandpaper or a special sponge for grinding.

- Chemical - surface treatment with aggressive solvents such as acetone and dichloroethane.

- Mixed - in this case, the above two processing methods are used.

- Calibrate and test the 3D printer before starting work.

- Be sure to use the correct file extension for quality printing.

- Do not remove the finished product from the printer immediately after it has been processed: this may damage the part and cause defects.

- If you encounter errors during the 3D printing process, try restarting the device - this usually helps.

- If restarting the printer still does not help, try changing the settings or re-entering the model.

- When assembling the 3D printing devices, follow the enclosed instructions carefully.

- Use only the correct materials for your 3D printer.

- Subscribe to helpful channels on 3D printing and read articles.

In this article, we will focus on the inside of the part, filling . Laminating programs (Cura3D, Simplify3D, etc.) allow the to select the shape and infill percentage of the that we want. In the following, we present the most important possible configurations.

Laminating programs (Cura3D, Simplify3D, etc.) allow the to select the shape and infill percentage of the that we want. In the following, we present the most important possible configurations.

3D printing infill percentage

fills the amount of material that occupies the interior of part . Typically, rolling programs allow you to change the percentage of material from 0% (hollow part) to 100% (fully solid part) .Always talking about the same ply height and body width configuration, the ideal fill percentage depends on the end use of the part in question. The most commonly used percentage, which many lamination programs use as the default data, is 20% . With this percentage, you can get pieces with medium/high strength, low weight and very efficient print times of that turn into parts with a good resistance/cost ratio.

For non-functional prototypes, models and other simple display objects, 10% infill is recommended. This low percentage reduces long print times for complex shapes or objects that do not need to be resistant to any kind of stress. On the contrary, it is clear to every user that in order to achieve maximum tensile strength, they must produce parts with 100% fill, but this implies higher costs in terms of both time and material, as well as that the parts are heavier. In addition to the values already mentioned, we recommend to study each case in detail depending on the resistance / printing time, considering that from 25% to 50% fill resistance increases by 25% and from 50% to 70. % fill resistance increases by only 10%.

This low percentage reduces long print times for complex shapes or objects that do not need to be resistant to any kind of stress. On the contrary, it is clear to every user that in order to achieve maximum tensile strength, they must produce parts with 100% fill, but this implies higher costs in terms of both time and material, as well as that the parts are heavier. In addition to the values already mentioned, we recommend to study each case in detail depending on the resistance / printing time, considering that from 25% to 50% fill resistance increases by 25% and from 50% to 70. % fill resistance increases by only 10%.

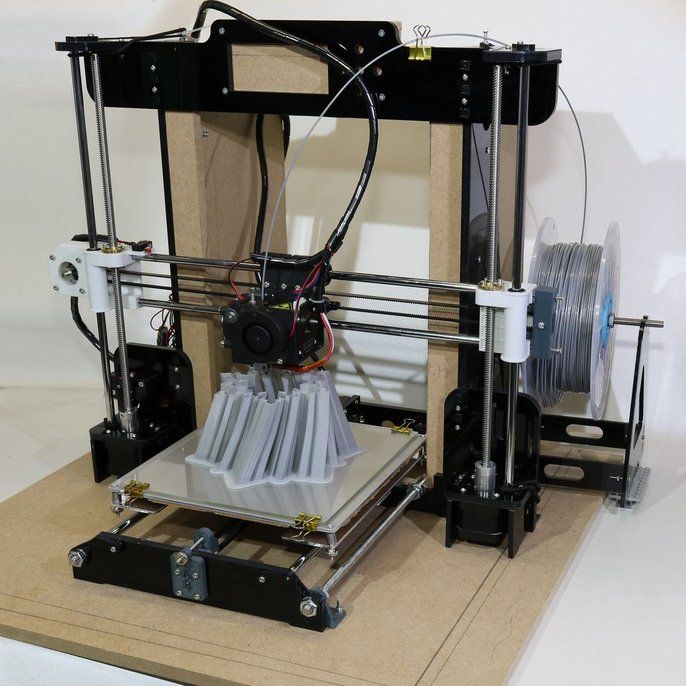

Image 1: Varying degrees of filling

Our recommendation is to use infill 10% for figures and objects that cannot withstand loads, 20% for parts of normal use with medium / low loads, 60% in case you need to make the final parts with an average resistance of and suitable for punching or screwing, and finally 100% for maximum material strength. We want to emphasize that the manufacturing orientation of the parts affects the final resistance, i.e. the orientation has the same meaning as the fill percentage.

We want to emphasize that the manufacturing orientation of the parts affects the final resistance, i.e. the orientation has the same meaning as the fill percentage.

Infill type

Depending on the laminating software used, there are different types of infill, but in the four most commonly used (rectangular, triangular or diagonal, jiggle and honeycomb) appear in all (Simplify3D, Cura3D, Slic3r, etc.) . D.).

Rectangular infill

By default, these programs use a rectangular infill, which is logical since it has a strong structure in all directions and is relatively fast at creating perpendicular layers on top of each other.

Triangular infill

Triangular infill is used, as in the constructions of everyday life, to achieve maximum resistance in the direction of the walls, this is due to the decomposition by half of the force applied to the lines forming each layer at an angle of 45 °.

WiFi the top of the product.

Honeycomb core (tri-hexagonal)

Finally, in wisdom, hexagonal honeycomb core (bee panel) is widely used as a core to give strength to parts made of carbon fiber and other types of fibers. In 3D printing, FDM/FFF offers products great resistance in all directions, greater than rectangular infill but with longer print times.

In our opinion, the rectangular fill is strong enough for 90% of 3D printing applications, the other 10% are cases where a very specific fill should be used.

Our recommendations for filling selection

Proper seal configuration is a very important step to obtain the desired resistance of FDM/FFF 3D printed parts. We recommend using a rectangular infill of 10% density for non-functional parts, models or prototypes, 20% infill for parts in normal use subjected to low/medium loads, and 60% for items that must withstand high loads. Infill type and percentages must also be adjusted for each , and 3D printer type if the material used is rigid (PLA, ABS, PETG, nylon, etc.) or flexible (Filaflex TPE or TPU) for best results.

Infill type and percentages must also be adjusted for each , and 3D printer type if the material used is rigid (PLA, ABS, PETG, nylon, etc.) or flexible (Filaflex TPE or TPU) for best results.

Do you want to receive similar articles in your email?

Subscribe to our monthly newsletter and receive the latest 3D printing news and tips by email every month.

* By registering, you accept our privacy policy.

.

What is a 3D printer? Introduction to

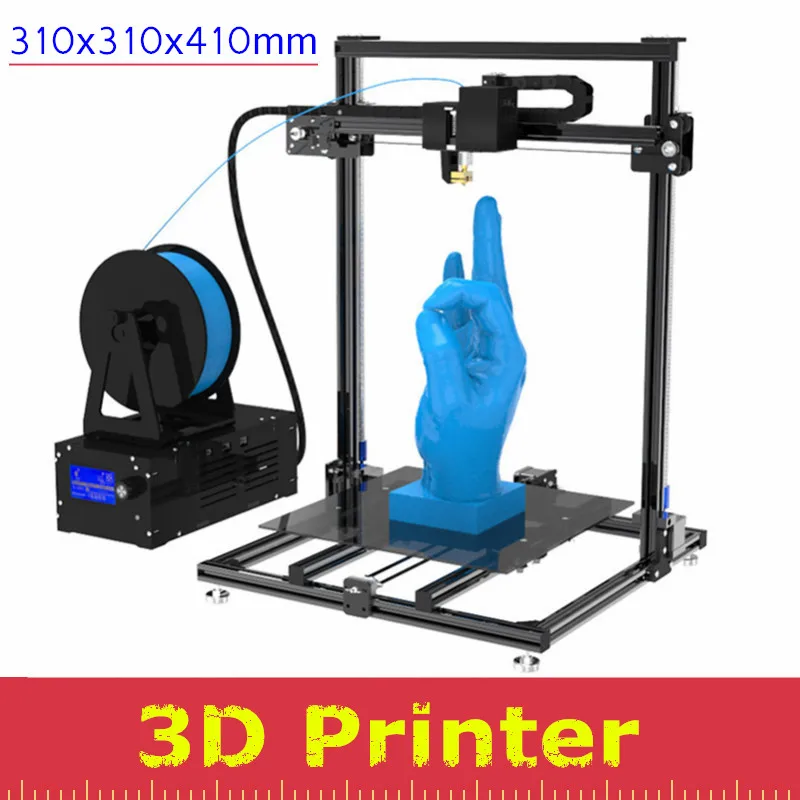

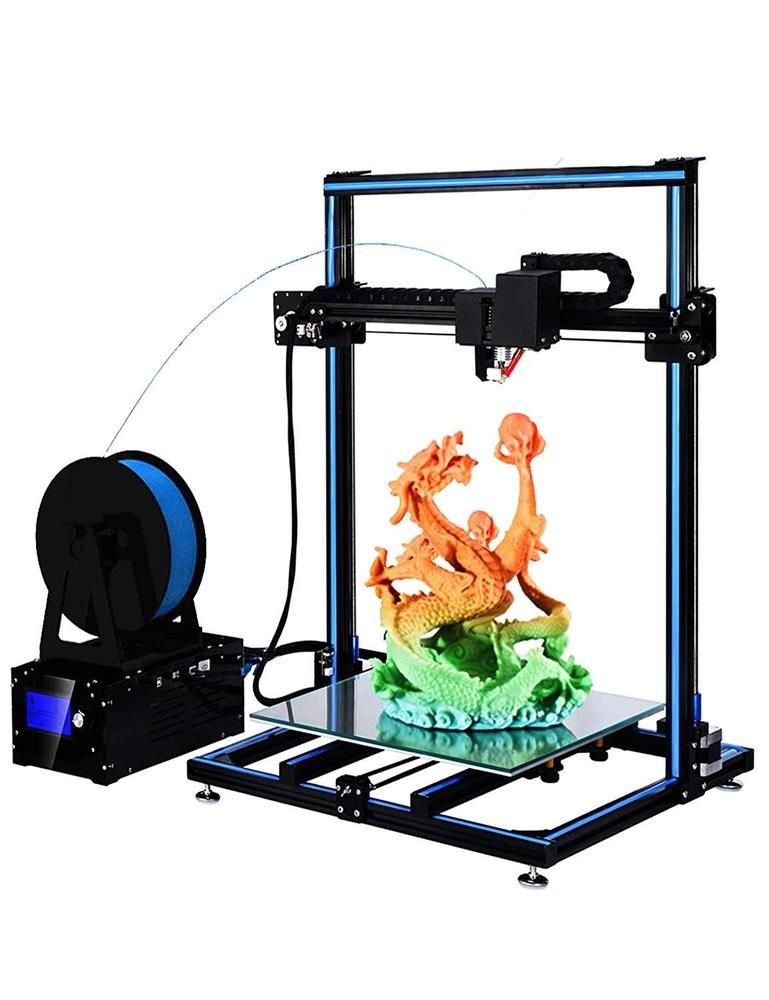

3D Printers 3D printing is a revolutionary technology that has created a buzz recently due to their ingenious concept that was used in their invention and the huge potential to impact the current manufacturing process. An incomparable device that is used to create a three-dimensional object from a digital file; 3D printers have created wonders in the digital world of printers. The practice of creating a three-dimensional object uses a chemical approach and additive processes in which an object is made by arranging a series of its coatings on top of each other until an intact object is formed. Each of these coatings is a very finely cut horizontal piece of the finished object, which must be made by the printer.

Each of these coatings is a very finely cut horizontal piece of the finished object, which must be made by the printer.

What is a 3D printer?

3D printers are used to create 3D objects and objects by printing. This process is also called additive manufacturing. In these printers, successive films and layers of specific media are stacked under computer control. The objects that are created on these printers can be of any shape, size and geometry. The printers sequentially place the material on a powder pad to which the inkjet printer heads are attached. Although they are commonly referred to as 3D printers or 3D printing machines, these devices are referred to in technical standards as , AM process .

How do 3D printers work?

These printers first formulate the fundamental design of the object you want to create. This plan is created using a CAD file that applies a 3D modeling program that is used to create a new project, or it can also use a 3D scanner that duplicates the exact model of the object and also creates a 3D digital file of the object. These scanners combine different methods of creating 3D -models. To create a digital printable file, 3D modeling software breaks down the final model into millions of layers. When these fragments are loaded into the printer, the final object can be created by layering each other. The 3D printer examines each 2D piece of the image and creates the final object by creating a 3D model of the image. Is

These scanners combine different methods of creating 3D -models. To create a digital printable file, 3D modeling software breaks down the final model into millions of layers. When these fragments are loaded into the printer, the final object can be created by layering each other. The 3D printer examines each 2D piece of the image and creates the final object by creating a 3D model of the image. Is

This video explains the entire 3D printing process.

Technologies used in 3D printers

Different types of 3D printers use different technologies. There are many ways to print that differ only in the way the layers are built to complete the absolute object. While some technologies use a melting process to create layers, for which they use either a selective layering or weld deposition process. One of the most widely used technologies is Stereolithography . It also utilizes other technologies such as Bath Curing , Material Blasting , Heet Lamination , Powder Fusion and many more.

It also utilizes other technologies such as Bath Curing , Material Blasting , Heet Lamination , Powder Fusion and many more.

3D modeling

3D printed models can be shaped using a CAD package or a 3D scanner that uses a conventional digital camera and photogrammetric software. The 3D scanning procedure evaluates and stores digital data and causes it to materialize in the form of a real object. Based on this technique, 3D models can be made. Regardless of the 3D modeling software used, this 3D model is converted to .STL or .OBJ format so that the software that prints the object can make it readable.

Before printing a 3D model from an STL file, check the file for multiple errors. This step is called patching. There can be many errors in STL files that occur during the 3D scanning process, and these errors must first be corrected before cutting the layers of the file. After that, the . STL file must be developed by software that converts the model into several thin layers and converts to a file with specific instructions. The 3D printer tracks this file and the directions attached to it and applies multiple layers of liquid, powder, or paper material to create a model from a series of cross sections. There are several materials that can be applied through a printing nozzle, such as plastic, sand, metal, and sometimes even chocolate. These layers, which correspond to different cross-sections of the CAD model, are then automatically connected or merged to give them their final shape.

STL file must be developed by software that converts the model into several thin layers and converts to a file with specific instructions. The 3D printer tracks this file and the directions attached to it and applies multiple layers of liquid, powder, or paper material to create a model from a series of cross sections. There are several materials that can be applied through a printing nozzle, such as plastic, sand, metal, and sometimes even chocolate. These layers, which correspond to different cross-sections of the CAD model, are then automatically connected or merged to give them their final shape.

3D Printer Applications

3D printing has many applications in industries ranging from automotive to aerospace and aviation, to bioprinting and medical instruments. 3D printing can also be very useful for everyday items and personal projects.

The most striking advantage of these printers is that they can create almost any shape and geometry of any object. Well, the time it takes to print a 3D model of any object largely depends only on the size and structure of the object that needs to be printed. Printing any object can take from several hours to several days. It also depends on the method used by the printer and the complexity of the model. The additive system technology allows you to save your time and help you print an object in a few hours.

Well, the time it takes to print a 3D model of any object largely depends only on the size and structure of the object that needs to be printed. Printing any object can take from several hours to several days. It also depends on the method used by the printer and the complexity of the model. The additive system technology allows you to save your time and help you print an object in a few hours.

3D printing services

3D printers

are expensive and not everyone can afford them for their individual purposes, so there are various companies and firms that offer 3D printing services. There are also online 3D printing services. printers that provide 3D printing services at an economical price range and can print and deliver any object from a digital file that you upload to their website.

.

3D printing process

At a high level, the 3D printing process involves cutting a CAD file into separate layers and then building that part layer by layer. The FFF process does this by accurately extruding 3D printable materials along discrete toolpaths that track the outside of the layer and its cell filling.

The FFF process does this by accurately extruding 3D printable materials along discrete toolpaths that track the outside of the layer and its cell filling.

The characteristics of the printer format - its design, what it is made of and the quality of its components - affect the quality and scale of the parts it can produce.

3D Printer Parts

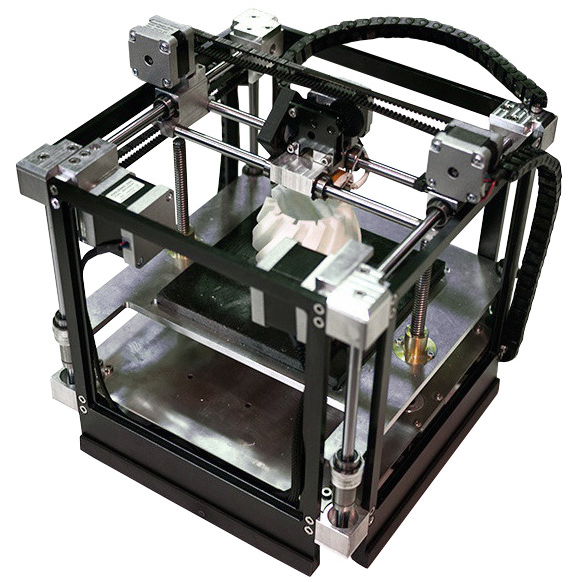

Although FDM printers vary in size, materials and features, almost all of them have three different electromechanical systems. The quality of the print depends on the function of these systems.

3D printer core systems, annotated.

Print Head and Extrusion System: A system responsible for heating and extruding the thermoplastic print material through a nozzle to form a part. Factors such as nozzle size and extrusion speed affect the level of detail a printer can achieve as well as its print speed.

Print Bed and Z-Drive System: The print head and extrusion system applies material to the print bed. As the part is printed, the Z motion system moves the bed in discrete, equal steps to form the layers of the part. The precision motors driving the Z motion system controls the resolution and quality of the part as it is created in the Z direction.

As the part is printed, the Z motion system moves the bed in discrete, equal steps to form the layers of the part. The precision motors driving the Z motion system controls the resolution and quality of the part as it is created in the Z direction.

XY Gantry : The Print Portal directly controls the X and Y movement of the printhead. It is responsible for "drawing" the toolpaths that create each layer. The rigidity of this gantry and the quality of the motors and sensors that control it affect the precision and accuracy of the part in plane with the platen.

How a part is created

The FFF 3D printer builds its parts in discrete layers called layers. As discussed in our 3D printing software review, a 3D printing slicer takes an STL file, divides it into layers, then calculates and creates a toolpath for each layer. At the beginning of each layer, the print bed is set to a predetermined height and the gantry movement system moves the print head along the tool path as the extrusion system deposits material.

A 3D printer creates a part by applying material layer by layer.

Since the printer cannot extrude plastic into the air without destroying it, all parts of each layer must be connected to the underlying layer. While this is implicitly true for some parts, others have protrusions that require support. Supports are automatically generated sacrificial frameworks that come in several different forms: tear-off supports made from the same material as the part, dissolvable supports that dissolve in the bath after printing, or release layer supports that create a framework from the part material with an intermediate layer of detachable material, in-between the part and the supporting structure. Printers with recycled support material use a second nozzle on the printhead specifically for the media material.

The layered nature of the 3D printing process causes 3D printed parts to exhibit transversely isotropic material properties. While isotropic materials have uniform material properties in all directions, transversely isotropic materials have one set of properties along an axis and a different set of properties in planes perpendicular to that axis. This applies to 3D printed parts that exhibit higher part strength in the XY planes along the Z axis. This is why it is important to consider print orientation during development.

While isotropic materials have uniform material properties in all directions, transversely isotropic materials have one set of properties along an axis and a different set of properties in planes perpendicular to that axis. This applies to 3D printed parts that exhibit higher part strength in the XY planes along the Z axis. This is why it is important to consider print orientation during development.

3D printed parts are stronger in the XY plane parallel to the build platform than along the Z axis perpendicular to the build platform.

Infill Basics

While the shell of a part determines its shape and precision, the infill is incredibly important in determining its performance. The infill is optimized for durability and print quality and always consists of a tiled shape distributed over the area of the layer. Triangles are commonly used because of their ideal load distribution, but other shapes can be used. Changing the shape and infill density changes the mass and (to a lesser extent) strength of the part. The infill orientation is determined by the print orientation, so if you want the infill to go in a specific direction, you will need to plan for it when you first orient the part.

Changing the shape and infill density changes the mass and (to a lesser extent) strength of the part. The infill orientation is determined by the print orientation, so if you want the infill to go in a specific direction, you will need to plan for it when you first orient the part.

3D printed parts are usually printed with a sparse infill pattern to save material, cost and print time.

Solid fiber reinforcement replaces conventional filler in some geometries, significantly improving mechanical properties. On certain layers, you can replace the regular part fill with automatically laid continuous fibers. The increase in strength of these fibers depends on the orientation of the print, the amount of continuous fiber you add to the part where the continuous fiber is added, and which fiber you choose.

Continuous strands of composite fibers can be stacked instead of filled, making the part much stronger, stiffer and more durable.

Print time and media

Print time is largely determined by how many material paths the printer has to run on each layer. First, infill prints very quickly, but shells print very slowly. Secondly, they support printing very slowly, since they have a large surface area. All of these factors add up to the total time it takes to print a given part. As a result, surface area, supports, and volume are equally important in determining print times. Because part volume is difficult to control based on part size, try to minimize surface area and support to reduce print time.

Printer material estimates are accurate and easy to calculate with 3D printing because the printer knows how much material it uses when extruding a toolpath. Similar to calculating print time, a similar rule applies to material consumption: the more surface area and supports you have the more material will be used. Support material can make up a significant portion of material usage, so minimizing supports can reduce material usage for an equal sized part.

3D Printing Accuracy and Build Size

3D printing accuracy depends on a number of factors, including material, print settings, and part orientation. However, there are a few things you can do for maximum accuracy:

Printing with default settings: Most industrial printers optimize their accuracy for printing using basic settings.

Printing functions that require high precision in the XY plane: Because the XY gantry is a unified motion system, printers produce much more accurate geometries in the XY (horizontal) plane than in the XZ or YZ (vertical) planes. Try to design or orient your part so that the holes and other important details lie on the build platform.

Determine the critical dimensions of your part and orient it so that these parts lie on the print bed.

Reduction of supports and protrusions: Supports guarantee the success of geometrically complex prints; however, they also degrade the supported surface and are significantly less accurate than unsupported sections.

Reducing the angled tab supports saves printing time and improves part quality.

Build Quantity: The size of the printer is determined by the build volume - the maximum reach of the gantry and z-travel system. However, this does not mean that you should try to fill the entire volume with one part. 3D printing is the opposite of subtractive manufacturing where you start with a block of raw material and try to remove as little material as possible. As a result, large and blocky parts are often cheaper and faster to produce by other methods.

.

how to work from scratch for beginners and dummies, what it looks like

Three-dimensional printing has become increasingly introduced into our daily lives. Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible.

Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible.

What is a 3D printer and how does it work?

The 3D device consists of the printer itself and a computer that controls all processes. The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

How a 3D printer works: features

Work with the aim of building a three-dimensional model begins with a sketch, which is created in a special program. After that, the software independently generates a plan for the movement of the print head and a print sequence. The 3D model is reproduced by strongly heating the plastic and distributing it evenly.

3D printers are used in many areas. Let's list some of them:

This is a small list of industries where 3D printing is actively used. Today, almost every entrepreneur and just an enthusiastic person can afford a printer.

The following printers are distinguished by design features:

How to use a 3D printer: tips for beginners, where to start

Mastering the technique of 3D printing is not difficult if you follow the recommendations and tips. Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Printer Installation

To begin, you will need to carefully unpack the box and remove any stops. The next step is to install the printer on the surface using the building level. This will allow you to place the device as evenly as possible, which will provide better printing.

Note. Some 3D printers come with a level for installation.

Next, you will need to connect the printer to your computer and install the necessary drivers. The software disc comes with the 3D device.

Preparation for work

To get started, you need to calibrate the working surface - without this, printing quality products is impossible. This process is carried out automatically or manually. The attached instructions have detailed information on how to perform manual calibration.

Extruder patency test

The next important step is setting up the extruder. First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism.

First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism.

Working with models

Models can be created using a variety of 3D modeling programs. The process of manufacturing three-dimensional parts is creative, requiring careful preparation. The better and more detailed the model is drawn, the better the 3D layout will be at the output.

Start printing

After creating the model in the program and preparing the printer for work, you need to send the file for printing and wait for the result. The print speed varies depending on the printer model and specifications, as well as the media used.

Processing the finished product

3D products obtained from a printer usually do not please the user with an ideal appearance: the parts have an uneven surface. But this is typical for models of 3D printers on FDM, SLA and DLP devices, which are distinguished by higher print quality. Owners of FDM printers should not despair - a simple processing of products will give products an attractive appearance and make the surface smooth.

Several powerful ways to post-process 3D printed parts:

What are the possible errors and how to avoid them?

Even a novice can master the technology of 3D printing, but, despite this, the production of the first products causes excitement for the user. Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

Following the above tips will allow you to set up your 3D printer, get it ready for operation and, most importantly, print your first 3D products.