How are 3d printers useful in studying evolution

The Use Of 3D Printers In The Study Of Evolution

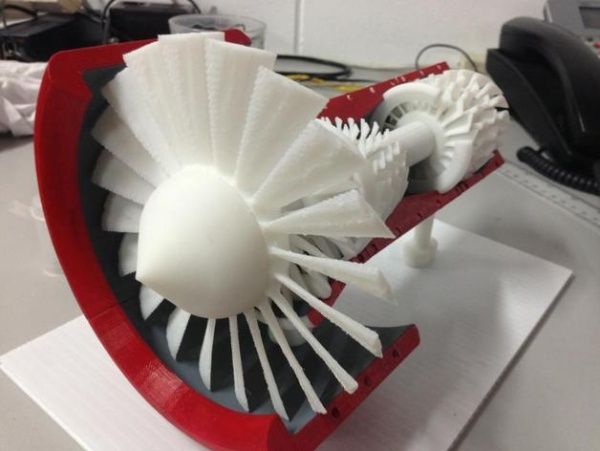

The study of evolution is an important part of understanding the natural world. 3D printers are increasingly becoming useful tools in this field of research. By being able to create physical models of organisms, researchers can more easily study how they have changed over time. This can help to shed light on the mechanisms of evolution and how different species have adapted to their environments. 3D printers are also useful for studying the anatomy of organisms. By being able to print out models of bones and other tissues, researchers can get a better understanding of how different species are put together. This can be helpful for understanding how different animals are related and how they have evolved over time. Overall, 3D printers are proving to be valuable tools for studying evolution. They can help researchers to better understand the process of evolution and how different species have adapted to their environments.

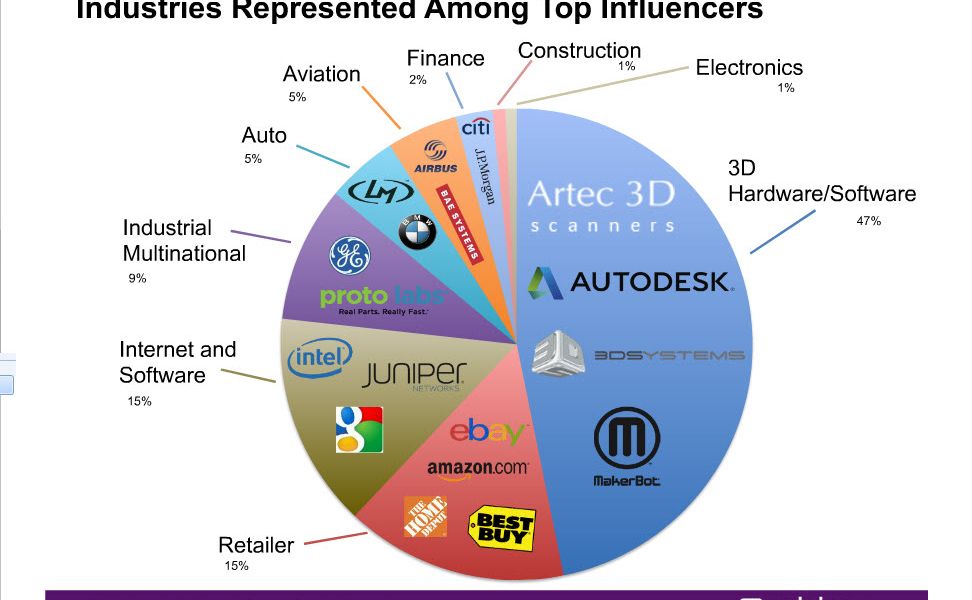

3D printing, or additive manufacturing, has the potential to democratize the production of goods from food to medical supplies, and it has the potential to save coral reefs. 3D printing machines are expected to be available in homes, businesses, disaster sites, and even outer space in the future. 3D printing is used to create personalized replicas of bones, organs, and blood vessels, as well as surgical cutting and drill guides and prosthetics. Can 3D printers make food? The process of 3D food printing can be accomplished by combining several additive manufacturing techniques. You should invest in a 3D printer if you know the process thoroughly and are willing to take the time to fully comprehend it. Printing particles can be toxic to the air in an enclosed space and cause health problems. Some estimates put the lifespan of 3D printed houses at 50 to 60 years, but most people agree on that figure.

How Are 3d Printers Used In Science?

Three-dimensional printing technology has been used in science and engineering since the early 1980s. In the late 1990s, 3D printing was commercialized and became widely available to consumers and small businesses. Today, 3D printers are used in a variety of industries, including aerospace, automotive, healthcare, and education. 3D printers are used to create prototypes and models for scientific research and experimentation. They can also be used to create parts for machines and vehicles, or to create customized medical implants. In education, 3D printers are used to create models and simulations for teaching and learning.

In the late 1990s, 3D printing was commercialized and became widely available to consumers and small businesses. Today, 3D printers are used in a variety of industries, including aerospace, automotive, healthcare, and education. 3D printers are used to create prototypes and models for scientific research and experimentation. They can also be used to create parts for machines and vehicles, or to create customized medical implants. In education, 3D printers are used to create models and simulations for teaching and learning.

3D printing and scanning have become increasingly popular as ways to preserve and display the past in archaeology. This list of the best 3D skeleton models will help you complete your project on time and to your specifications. Many people use 3D models in a variety of other contexts, including medicine, education, and animation. 3D printing has the potential to be used to create medical and scientific devices. Make your own Lucy Hominin Fossil out of a picture. BioLife4D successfully bioprinted a human cardiac patch using 3D printing. In Costa Rica, a variety of RoboToads are used to study the mating habits of color-changing toads.

BioLife4D successfully bioprinted a human cardiac patch using 3D printing. In Costa Rica, a variety of RoboToads are used to study the mating habits of color-changing toads.

With the current coral reef crisis, it appears that 3D printing can be an effective solution. Swiss researchers have developed a 3D printer capable of printing microscopic structures, including human hair, using only optical fibers. Machine learning and deep neural networks are used in the design of 3D printed objects by Neato AI.

The vast majority of benefits derived from 3D printing for research are undeniable. An example would be the rapid manufacture of complex, multi-component chemical equipment, which can be done without much delay that typically comes with traditional manufacturing methods. This is especially important in fundamental chemical research because it allows us to study complex molecules and systems in a more interactive and realistic manner. As part of its research and engineering activities, a significant amount of 3D printing has also been done. Organs, chemistry molecules, graphic design models, historical artifacts, and architecture models can all be 3D printed. Students can also print medical devices, study 3D printed molecules, and create 3D versions of their art. 3D printing has the potential to drastically transform many academic areas, and it has the potential to quickly speed up the experimentation process. The benefits of 3D printing in research are enormous, and the technology is here to stay.

Organs, chemistry molecules, graphic design models, historical artifacts, and architecture models can all be 3D printed. Students can also print medical devices, study 3D printed molecules, and create 3D versions of their art. 3D printing has the potential to drastically transform many academic areas, and it has the potential to quickly speed up the experimentation process. The benefits of 3D printing in research are enormous, and the technology is here to stay.

What Are 3d Printers Useful For?

Credit: Pinterest3D printers are useful for creating three-dimensional objects from a digital file. They are often used for prototyping or for creating small batches of custom parts.

3D printing is a rapidly expanding branch of the economy. The technology allows for rapid prototyping of not only the structure of the body, but also individual components. More and more universities are establishing departments dedicated to 3D printing. Furthermore, 3D printers can drastically reduce operating costs in manufacturing plants. Because of the necessity of 3D printing in R&D and design departments, it is becoming an increasingly important component of these departments. Technology accelerates work and reduces costs, regardless of whether it is already in use. Entrepreneurs who want to start their own businesses can take advantage of 3D printing. There’s no reason you couldn’t use it as a starting point for your business.

Because of the necessity of 3D printing in R&D and design departments, it is becoming an increasingly important component of these departments. Technology accelerates work and reduces costs, regardless of whether it is already in use. Entrepreneurs who want to start their own businesses can take advantage of 3D printing. There’s no reason you couldn’t use it as a starting point for your business.

Additive manufacturing has the potential to be a game-changer, and it is still in its early stages. Major corporations in a variety of industries, including automotive, are already using it. The technology has even more potential. Prosthetic manufacturers could benefit greatly from 3D printing because it is possible to create custom parts at a fraction of the cost of traditional manufacturing methods. Many amputees must spend thousands of dollars to replace their legs due to their disability. Surgery is also using 3D printing. Organs and hearts have been replicated to aid surgeons in their preparation for surgery. This advancement enables surgeons to perform operations with greater precision. Aside from 3D printing, bioprinting is becoming increasingly popular. Human cells and tissues are used in this technology to create “inks.” This technology is used to create artificial limbs and organs. This technology, in fact, has enormous potential because it can create fully functional organs. With 3D printing, we are creating the future of manufacturing. It is possible, however, to transform society in much larger ways through the adoption of new business models, changes in working environments, and the provision of additional value and sustainability. To be successful in this business, it is critical that you have access to companies like EOS. They were the first to pioneer and help to drive the adoption of this technology.

This advancement enables surgeons to perform operations with greater precision. Aside from 3D printing, bioprinting is becoming increasingly popular. Human cells and tissues are used in this technology to create “inks.” This technology is used to create artificial limbs and organs. This technology, in fact, has enormous potential because it can create fully functional organs. With 3D printing, we are creating the future of manufacturing. It is possible, however, to transform society in much larger ways through the adoption of new business models, changes in working environments, and the provision of additional value and sustainability. To be successful in this business, it is critical that you have access to companies like EOS. They were the first to pioneer and help to drive the adoption of this technology.

Defossilization: A Review of 3D Printing in Experimental Paleontology

Introduction

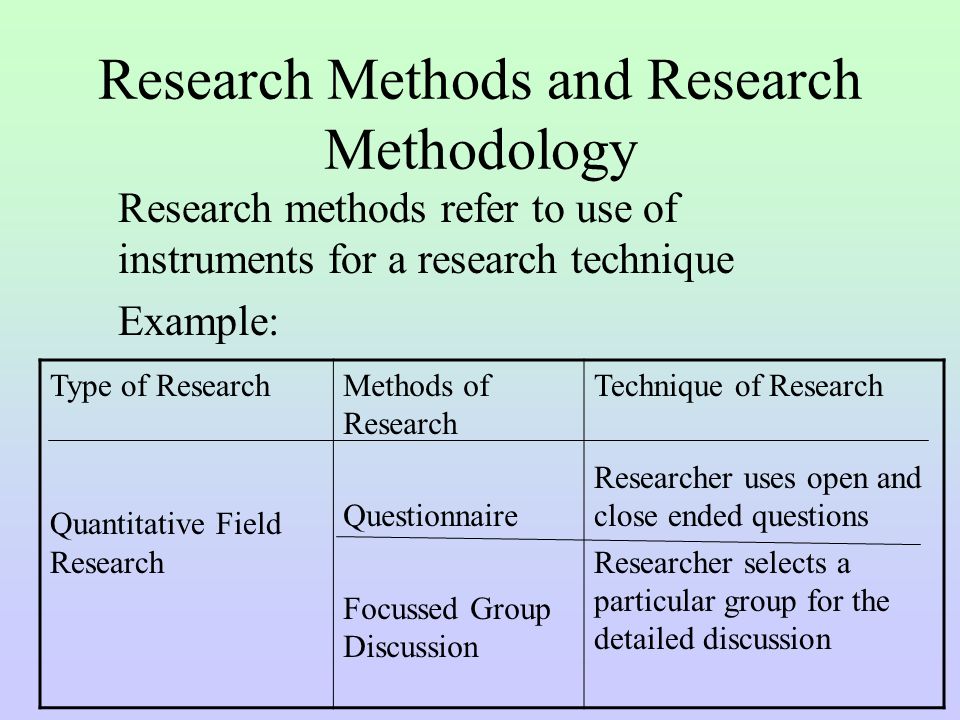

The fossilization process renders once dynamic, living taxa into static, geologic forms. Paleontologists are challenged to work within these limitations to reconstruct complex organisms and investigate related questions of functional morphology, paleoecology, and macroevolutionary processes. 3D printing, which has been widely used in related fields for years (e.g., Weber, 2001; Igic et al., 2015; Fiorenza et al., 2018) recently began to make a concerted appearance in experimental paleontology. This time lag, and lack of paleontological literature using this approach, likely reflects the unique limitations of historical sciences and the fossilization process. As a result, much of the literature on 3D printing in paleontology is still limited to conference abstracts (see topical session: Applications of 3D Printing and Other 3D Methods to Experimental Paleontology, Geological Society of America 2018). Although we, the authors of this paper, study fundamentally different taxa we found common challenges adopting 3D printing techniques to study functional morphology. In its limited scope, this mini-review provides a broad introduction to many potential uses of 3D printing in experimental paleontology.

Paleontologists are challenged to work within these limitations to reconstruct complex organisms and investigate related questions of functional morphology, paleoecology, and macroevolutionary processes. 3D printing, which has been widely used in related fields for years (e.g., Weber, 2001; Igic et al., 2015; Fiorenza et al., 2018) recently began to make a concerted appearance in experimental paleontology. This time lag, and lack of paleontological literature using this approach, likely reflects the unique limitations of historical sciences and the fossilization process. As a result, much of the literature on 3D printing in paleontology is still limited to conference abstracts (see topical session: Applications of 3D Printing and Other 3D Methods to Experimental Paleontology, Geological Society of America 2018). Although we, the authors of this paper, study fundamentally different taxa we found common challenges adopting 3D printing techniques to study functional morphology. In its limited scope, this mini-review provides a broad introduction to many potential uses of 3D printing in experimental paleontology. We outline a generalized approach to guide those new to using 3D printing.

We outline a generalized approach to guide those new to using 3D printing.

3D Replicas in Paleontology

Three-dimensional representations of fossil organisms have classically been integral to paleontological research. Early researchers used molds and casts to share fossil replicas with other investigators and the public (Vernon, 1957; Waters and Savage, 1971). Later, digital replicas generated by surface and Computed-tomography (CT) scanning were used for visualizing fossils in three dimensions (see Cunningham et al., 2014 for review). These virtual techniques allowed investigators to examine minute details of biological structures and provided insights to fossil interiors, previously unseen barring destructive sampling (see Rivera and Sumner, 2014; Schemm-Gregory, 2014). Today, researchers can render virtual files tangible once again, by converting scans to formats that allow modification and 3D printing for education and further study (Teshima et al., 2010; Rahman et al. , 2012; Cunningham et al., 2014; Hasiuk, 2014). Furthermore, the falling costs of printers has made 3D printing a viable option for explicit experimental paleontological study.

, 2012; Cunningham et al., 2014; Hasiuk, 2014). Furthermore, the falling costs of printers has made 3D printing a viable option for explicit experimental paleontological study.

3D printing is advantageous for paleontologists who wish to replicate and modify fossils. Specifically, printing enables investigators to remove and reform fossils from their matrix and permits the manipulation of taphonomically distorted specimens. Additionally, the ability to alter existing taxa or create new, hypothetical forms allows the study of non-existent morphologies, optimization, and evolutionary constraint (see Porter et al., 2015). Paleontologists have 3D printed numerous vertebrate morphologies including dinosaurs, fishes, marine reptiles, and mammals (Balanoff and Rowe, 2002; Bristowe et al., 2004; Schilling et al., 2013; Mitsopoulou et al., 2015; Das et al., 2017; Muscutt et al., 2017; White et al., 2017; Clark, 2018; Grant et al., 2018; Voegele et al., 2018) as well as invertebrates like mollusks, trilobites, brachiopods, and echinoderms (Huynh et al. , 2013; Pearson, 2017; Anderson et al., 2018; DiMarco et al., 2018; Garcia et al., 2018; Johnson et al., 2018; Morse et al., 2018; Peterman and Ciampaglio, 2018; Dievert et al., 2019). Designing meaningful physical models for experimentation requires thoughtful printing choices to isolate variables. Here we describe a generalized workflow for 3D printing in experimental paleontology, including creating a printable model of the taxa of interest, choosing materials, pre-processing prints, and finally printing and post-processing physical models.

, 2013; Pearson, 2017; Anderson et al., 2018; DiMarco et al., 2018; Garcia et al., 2018; Johnson et al., 2018; Morse et al., 2018; Peterman and Ciampaglio, 2018; Dievert et al., 2019). Designing meaningful physical models for experimentation requires thoughtful printing choices to isolate variables. Here we describe a generalized workflow for 3D printing in experimental paleontology, including creating a printable model of the taxa of interest, choosing materials, pre-processing prints, and finally printing and post-processing physical models.

A Generalized Workflow for 3D Printing in Experimental Paleontology

Model Creation

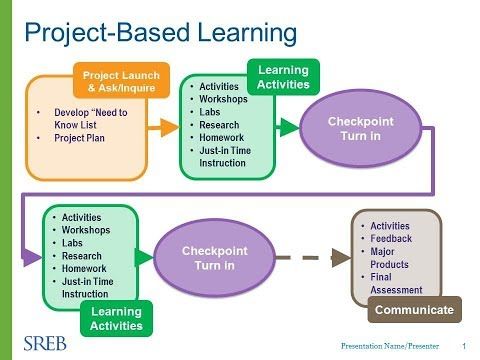

There are many different approaches to using 3D printing to test paleontological hypotheses. However, typically, the first step is to create a virtual model that accurately captures the morphology of interest (Figure 1). Subsequent decisions regarding printing material and methods rely heavily on the parameters of this virtual model. Such models are mainly derived from surface scans, internal scans, computer-generated models, or some combination of these methods (Figures 2A–D). Each model type has benefits that may be useful for various experiments.

Each model type has benefits that may be useful for various experiments.

Figure 1. A general workflow for 3D printing for experimental paleontology. Critical decisions are outlined next to each step.

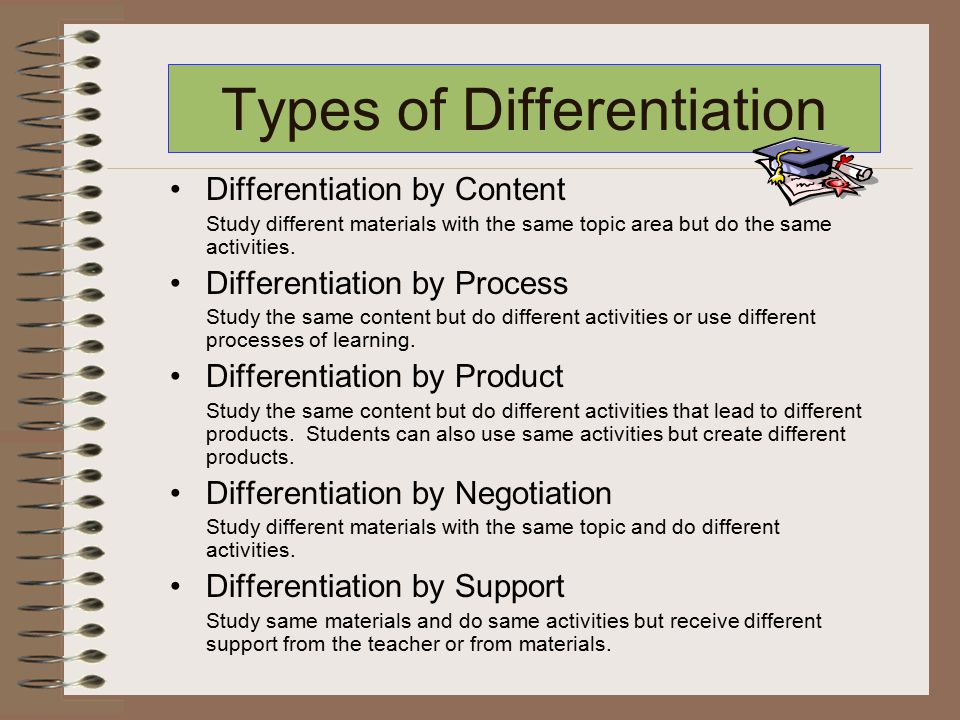

Figure 2. (A–D) Examples of models derived fully or in part using 3D software and (E–H) examples of different 3D printing materials. (A) Mathematically rendered bivalves, (B) scanned brachiopod with spines added in 3D program, (C) plesiosaur flipper reconstructed from bone measurements, (D) Theropod foot created with scan and Rhinoceros 5.0 [A from Germann et al. (2014) (used with permission via CC BY license, Palaeontological Association), B from Garcia et al. (2018) (used with permission from Elsevier), C from (Muscutt et al., 2017) (used with permission from the Royal Society), D from (White et al., 2017) (used with permission from permission via CC BY license, PeerJ) ]. (E) Composite powder snail shell (F) ABS brachiopod (G) Tranluscent ABS polymer blastoid (H) plaster radiolarian [E from (Crofts and Summers, 2014) (used with permission from How to best smash a snail: the effect of tooth shape on crushing load.), F from (Dievert et al., 2019) (used with permission from Elsevier), G (Huynh et al., 2013) (used with permission via CC BY license, Paleontological Society), H (Ishida and Kishimoto, 2015) (used with permission via CC BY license, Volumnia Jurassica). (Images not to scale).

(E) Composite powder snail shell (F) ABS brachiopod (G) Tranluscent ABS polymer blastoid (H) plaster radiolarian [E from (Crofts and Summers, 2014) (used with permission from How to best smash a snail: the effect of tooth shape on crushing load.), F from (Dievert et al., 2019) (used with permission from Elsevier), G (Huynh et al., 2013) (used with permission via CC BY license, Paleontological Society), H (Ishida and Kishimoto, 2015) (used with permission via CC BY license, Volumnia Jurassica). (Images not to scale).

Surface scans render exterior geometry by two main means: laser projection or a series of photographs taken at different angles (Sutton et al., 2014). Therefore, surface scans are incredibly useful tools to record and replicate fossils that cannot be moved from their current location. For example, Grant et al. (2018) used surface scanning to create prints of dinosaur tracks that could be widely distributed for educational purposes (see also Grant et al. , 2016). Moreover, scans of external morphology are tremendously useful for kinematic studies of geometry, where the investigator is concerned only with the boundaries defined by shape (Clark, 2018; Garcia et al., 2018; Grant et al., 2018). Clark (2018) laser-scanned and 3D printed Allosaurus teeth to study relationships between tooth shape and ability to puncture prey by relating tooth morphology to puncture depth. In this case, a surface scan was sufficient; however, studies seeking to isolate internal morphology cannot be captured with a laser scanner.

, 2016). Moreover, scans of external morphology are tremendously useful for kinematic studies of geometry, where the investigator is concerned only with the boundaries defined by shape (Clark, 2018; Garcia et al., 2018; Grant et al., 2018). Clark (2018) laser-scanned and 3D printed Allosaurus teeth to study relationships between tooth shape and ability to puncture prey by relating tooth morphology to puncture depth. In this case, a surface scan was sufficient; however, studies seeking to isolate internal morphology cannot be captured with a laser scanner.

Internal scans (e.g., Computed-tomography, Magnetic Resonance Imaging, Synchrotron) in general use magnetic energy (MRI) or X-rays (CT and Synchrotron) to generate images of sub-surface structures. CT scans and related methods are useful primarily for developing models of internal structures which may not be readily visible and cases in which the fossil is embedded in a matrix that must be differentiated from the specimen (Crofts and Summers, 2014; Kolmann et al. , 2015; Pearson, 2017; Anderson et al., 2018; DiMarco et al., 2018; Morse et al., 2018). Internal scans produce images slices that are later used to outline and excise morphologies of interest from unneeded morphologies or sediment (i.e., segmentation). This is done using visualization software, some of which are open source.

, 2015; Pearson, 2017; Anderson et al., 2018; DiMarco et al., 2018; Morse et al., 2018). Internal scans produce images slices that are later used to outline and excise morphologies of interest from unneeded morphologies or sediment (i.e., segmentation). This is done using visualization software, some of which are open source.

Internal scans have permitted studies of the form and function of previously inaccessible morphologies. DiMarco et al. (2018) CT scanned and printed baculite septa to study the capability of complex septa to resist crushing by a predator. CT scans allowed the investigators to isolate the chamber walls of shelled cephalopods and artificially create simple alternative walls for comparison. Ishida and Kishimoto (2015) instead used x-rays to print and study models of radiolarians to examine miniscule morphologies (Figure 2H). Morse et al. (2018) combined data from microCT scans and serial grinding of concavo-convex brachiopods to study the relationship between hinge morphology and life position.

Internal scans are useful for creating 3D printed replicas of specimens that cannot be studied otherwise due to their hidden nature. For example, Schilling et al. (2013) demonstrated the utility of CT scanning by segmenting a dinosaur vertebra out of surrounding matrix and 3D printing it. Likewise, Lak et al. (2008) used phase-contrast X-ray synchrotron imaging to identify fossils preserved in opaque amber, which could later be 3D printed for examination. Rather than scanning some investigators elect to create their models entirely in 3D modeling programs.

3D printing provides is the ability to physically test questions motivated by idealized and hypothetical morphologies; which may be later compared to realized forms in the fossil record or modern taxa. This can be achieved using mathematical models (Germann et al., 2014; Johnson et al., 2018) and designs based on morphological measurements (Muscutt et al., 2017) (Figure 2C). Such models can be constructed in many 3D programs, some of which are open access (e. g., Meshmixer1, Blender2, and Fusion 3603. Johnson et al. (2018) and Germann et al. (2014) (Figure 2A) used different mathematical models to design mollusk shells for studies of functional morphology. Johnson et al. (2018) employed equations that described gastropod shells as a surface rotating around an axis in a logarithmic spiral following the mathematical model of Raup (1966) (see also Raup and Michelson, 1965). The strength of these shell geometries was then physically tested in a compression apparatus to evaluate their adaptive value against shell-crushing predators. To study the functional morphology of burrowing bivalves, Germann et al. (2014) created shells with varying shapes and ornamentations. These shells were 3D printed to test the burrowing capabilities of different shell morphologies. Models for 3D printing have also been created based on metrics from vertebrate fossil specimens. For example, Muscutt et al. (2017) used profile and planform geometries of plesiosaur flippers to generate and print rigid plastic flippers.

g., Meshmixer1, Blender2, and Fusion 3603. Johnson et al. (2018) and Germann et al. (2014) (Figure 2A) used different mathematical models to design mollusk shells for studies of functional morphology. Johnson et al. (2018) employed equations that described gastropod shells as a surface rotating around an axis in a logarithmic spiral following the mathematical model of Raup (1966) (see also Raup and Michelson, 1965). The strength of these shell geometries was then physically tested in a compression apparatus to evaluate their adaptive value against shell-crushing predators. To study the functional morphology of burrowing bivalves, Germann et al. (2014) created shells with varying shapes and ornamentations. These shells were 3D printed to test the burrowing capabilities of different shell morphologies. Models for 3D printing have also been created based on metrics from vertebrate fossil specimens. For example, Muscutt et al. (2017) used profile and planform geometries of plesiosaur flippers to generate and print rigid plastic flippers. They then used these flippers for hydrodynamic tests to study the efficiency and effectiveness of propulsion using these shapes (Figure 2C). Additionally, it can be useful to combine multiple model creation methods. For example, White et al. (2017) used CT data to create a model Theropod foot in Rhinoceros 5.0 (Figure 2D). They 3D printed this foot to create a mold that was later filled with silicon to test its footprint in a simulated paleo-sediment. 3D modeling programs can also be used to modify shapes or add taphonomically-lost features.

They then used these flippers for hydrodynamic tests to study the efficiency and effectiveness of propulsion using these shapes (Figure 2C). Additionally, it can be useful to combine multiple model creation methods. For example, White et al. (2017) used CT data to create a model Theropod foot in Rhinoceros 5.0 (Figure 2D). They 3D printed this foot to create a mold that was later filled with silicon to test its footprint in a simulated paleo-sediment. 3D modeling programs can also be used to modify shapes or add taphonomically-lost features.

Garcia et al. (2018) combined surface scanning and 3D program editing to replace missing brachiopod spines, which are fragile and often not preserved, and study stability and scour (Figure 2B). The final printed brachiopod was created by mirroring the valve that was well enough preserved for use. While neontological studies are have different constraints, we highly recommend exploring this literature for applications relevant to the fossil record (e. g., Mehrabani et al., 2014; Wen et al., 2014; Porter et al., 2015; Walker and Humphries, 2019).

g., Mehrabani et al., 2014; Wen et al., 2014; Porter et al., 2015; Walker and Humphries, 2019).

Material Selection

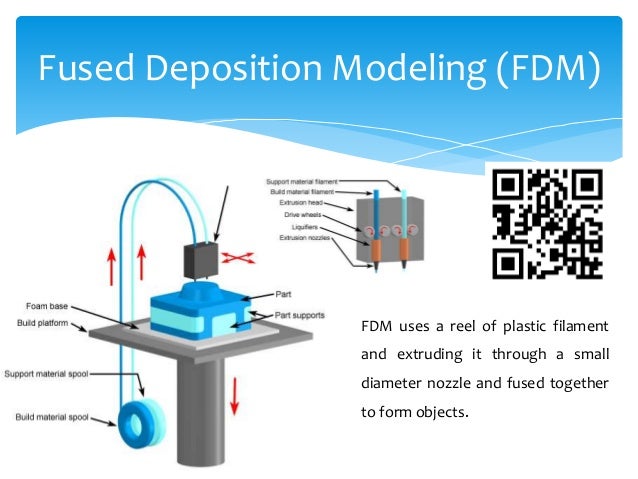

Once a model is in a 3D printable format, a printing material must be chosen. There is an ever-growing variety of materials available for 3D printing including plastics, steel, aluminum, sandstone, thermoplastic polyurethane, photopolymer resin, and composite powders (see Shapeways4 and Bluedge5). The methods used to create prints using these different materials are variable (e.g., Fused Deposition Modeling (FDM), Polyjet Technology, and Binder Jetting, Selective Laser Sintering (SLS), and Selective Laser Melting) (Bluedge5 and Shapeways4, see Walker and Humphries, 2019) as are their resolutions and capabilities. Many different materials have been used in previous paleontological and biological studies, primarily plastics (Huynh et al., 2013; Germann et al., 2014; Mehrabani et al., 2014; Porter et al., 2015; Muscutt et al. , 2017; Pearson, 2017; Anderson et al., 2018; Garcia et al., 2018; Voegele et al., 2018; Dievert et al., 2019), powders (Schilling et al., 2013; Crofts and Summers, 2014; Ishida and Kishimoto, 2015; Kolmann et al., 2015; Johnson et al., 2018), and resins (Jonsson et al., 2017; DiMarco et al., 2018). The cost of printers and materials varies widely. Printers themselves can vary significantly in cost [e.g., as of June 2019 printers from two prominent companies ranged from $1,299.00 to 6,499.00 (MakerBot) and $3,500 to 9,999.00 (Formlabs)]. Some printers also require additional post-processing equipment (e.g., Formlabs). Materials that can be used for inhouse printers also vary widely in cost (as of June 2019 a small spool of material for MakerBot was $16 while an XXL spool was $225 and FormLabs materials ranged from $149.00 to $399.00 per liter) (see Walker and Humphries, 2019 for additional review of materials and costs). The cost of printing with an external company often varies with the material and size of the print.

, 2017; Pearson, 2017; Anderson et al., 2018; Garcia et al., 2018; Voegele et al., 2018; Dievert et al., 2019), powders (Schilling et al., 2013; Crofts and Summers, 2014; Ishida and Kishimoto, 2015; Kolmann et al., 2015; Johnson et al., 2018), and resins (Jonsson et al., 2017; DiMarco et al., 2018). The cost of printers and materials varies widely. Printers themselves can vary significantly in cost [e.g., as of June 2019 printers from two prominent companies ranged from $1,299.00 to 6,499.00 (MakerBot) and $3,500 to 9,999.00 (Formlabs)]. Some printers also require additional post-processing equipment (e.g., Formlabs). Materials that can be used for inhouse printers also vary widely in cost (as of June 2019 a small spool of material for MakerBot was $16 while an XXL spool was $225 and FormLabs materials ranged from $149.00 to $399.00 per liter) (see Walker and Humphries, 2019 for additional review of materials and costs). The cost of printing with an external company often varies with the material and size of the print. It can be useful to get an estimate early in the process to approximate final costs.

It can be useful to get an estimate early in the process to approximate final costs.

Just as model creation is critical to accurately representing morphology, the properties of the chosen printing material will impact the fidelity and applicability of the study. The material selected will determine important limitations for the model and the necessary pre-processing before printing. For instance, if one seeks to create a hollow model from power or resin, often a built-in hole is required to release excess material which otherwise will become trapped inside. Added holes in biological models may have little to no effect on kinematic studies but an appreciable influence on kinetic studies (e.g., holes behave as stress concentrators in compression). Print thickness and precision is also tightly linked to the printing material. For example, we have found differences in the ability to print thin shell walls with rigid resins (successful print) and other resins (e.g., holes, wall collapse, failure to complete print). Here we discuss some common applications of materials for paleontological studies of functional morphology.

Here we discuss some common applications of materials for paleontological studies of functional morphology.

Powder has been demonstrated to be a useful material for tests of shape and strength for brittle biological morphologies. Crofts and Summers (2014), Kolmann et al. (2015), and Johnson et al. (2018) used composite powder to print gastropod shells and retain their brittle nature. In each study, the prints were used to isolate different morphologies involved in the interactions of shell-crushing predators and their prey. Crofts and Summers (2014) used 3D printed replicas of CT scanned gastropods to test the efficacy of different predator dentitions and found that idealized crushing morphologies contain biological tradeoffs that make them unlikely to occur in nature (Figure 2E). Kolmann et al. (2015) instead used the same shell prints to test relationships between crushing ability and stingray jaw morphology and found that jaw morphology was not predictive of performance. Rather than using scans, Johnson et al. (2018) created mathematically idealized 3D printed gastropods to test relationships between shell shape and strength to resist crushing by a predator. Powder composite prints were critical to all these experiments to realistically isolate the influence of geometry on systems involving brittle prey while negating the effects of microstructure. However, powder prints are not the optimal choice for all experiments.

(2018) created mathematically idealized 3D printed gastropods to test relationships between shell shape and strength to resist crushing by a predator. Powder composite prints were critical to all these experiments to realistically isolate the influence of geometry on systems involving brittle prey while negating the effects of microstructure. However, powder prints are not the optimal choice for all experiments.

Plastics have been a popular choice to study functional morphology in hydrodynamic studies (Huynh et al., 2013; Muscutt et al., 2017; Pearson, 2017; Anderson et al., 2018; Garcia et al., 2018; Peterman and Ciampaglio, 2018; Dievert et al., 2019). This is likely because of their comparatively low cost and easy accessibility compared to other waterproof materials. Anderson et al. (2018) used plastic prints of turritelline gastropods to study the influence of shell ornamentation on fluid flow on partially buried snails. Dievert et al. (2019) tested the influence of shape and orientation on brachiopod feeding; using a translucent plastic to visualize fluid flow within the valves (Figure 2F). Dievert et al. (2019) also printed dissolvable supports for the delicate brachidia inside their shells. Plastics were the most viable option for these tests, which required a rigid shell but not a brittle material.

Dievert et al. (2019) also printed dissolvable supports for the delicate brachidia inside their shells. Plastics were the most viable option for these tests, which required a rigid shell but not a brittle material.

Pre-processing

Once materials have been chosen, the digital model must be prepared to be printed according to the requirements of the printer. While pre-processing requires some knowledge of the best practice for specific printers and material, there are commonly shared challenges including solidifying, repairing holes/instabilities, choosing a possible printing orientation, and creating sufficient supports.

In this phase, meshes may be refined and smoothed to preserve shape and reduce complexity. Solidifying and repairing holes can reduce printing errors in specimens which may be taphonomically incomplete. Printing files can also be made water-tight in select printing programs; while this method may increase the amount of material needed and overall printing time, we have found it may decrease printer error by reducing the need for complex supports.

The optimal printing orientations can typically be determined using printer-specific software; however, some manual manipulation may be necessary for complex prints requiring specific supports. For example, some printing programs, like Preform and Netfabb, allow the user to change the density, location, and size of supports for ease of removal during post-processing. Depending on the material chosen and the desired morphology, hollow prints can contain both internal and external supports. When appropriate, making a model hollow can also reduce printing costs and time.

Once mesh repairs and supports are complete, the model must be globally scaled to an appropriate size for the printing bed. In some cases, if the desired size is larger than the bed, the investigator may be tasked with printing a model in multiple parts which can later be combined (e.g., White et al., 2017). Beyond the size limitations of the printing bed, experiments may require models to be a specific size to be meaningful for the test being conducted. For example, Huynh et al. (2013) scaled their models of spiraculate blastoid hydrospires to 72 times the original size to conduct fluid tests on prints made of a translucent ABS polymer (Figure 2G). While Huynh et al. (2013) had to scale their morphology to create an observable experiment, Garcia et al. (2018) had to scale brachiopods by a factor of 1.5 to reach maximum printer resolution. There are also biological reasons for scaling in the pre-processing phase. Johnson et al. (2018) scaled various shell shapes to be the same height in one dimension to make informed comparisons about defenses against crushing predation. Since shell crushing predators are limited by gape-size, this scaling was critical to their experimental design (Wainwright, 1987).

For example, Huynh et al. (2013) scaled their models of spiraculate blastoid hydrospires to 72 times the original size to conduct fluid tests on prints made of a translucent ABS polymer (Figure 2G). While Huynh et al. (2013) had to scale their morphology to create an observable experiment, Garcia et al. (2018) had to scale brachiopods by a factor of 1.5 to reach maximum printer resolution. There are also biological reasons for scaling in the pre-processing phase. Johnson et al. (2018) scaled various shell shapes to be the same height in one dimension to make informed comparisons about defenses against crushing predation. Since shell crushing predators are limited by gape-size, this scaling was critical to their experimental design (Wainwright, 1987).

Post-processing

Post-processing can be used to clean the model and change the material properties of the final print. Common post-processing techniques for cleaning the model include sanding down elements and support removal to increase model fidelity. To obtain relevant material properties, different techniques can be necessary. The duration and combination of alcohol washes, photo-curing, and baking change fundamental properties (e.g., tensile, flexural, and impact strength, and heat deflection temperature) of the final print. Generally, information about changes in material properties with post-processing treatments is found on the manufacture's website. Investigators may also seek additional post-processing beyond factory recommendations for experimental models. For example, print weight has been an important consideration in previous studies. Garcia et al. (2018) added iron shavings to make their printed brachiopods the density of calcium carbonate before subjecting them to tests underwater. Similarly, to compare results of virtual hydrodynamics models of orthoconic cephalopods to physical models Peterman and Ciampaglio (2018) distributed mass appropriately during post-processing to make the prints neutrally buoyant. Post-processing is a critical final step to maintain the desired qualities of the final model, and therefore, cannot be overlooked.

To obtain relevant material properties, different techniques can be necessary. The duration and combination of alcohol washes, photo-curing, and baking change fundamental properties (e.g., tensile, flexural, and impact strength, and heat deflection temperature) of the final print. Generally, information about changes in material properties with post-processing treatments is found on the manufacture's website. Investigators may also seek additional post-processing beyond factory recommendations for experimental models. For example, print weight has been an important consideration in previous studies. Garcia et al. (2018) added iron shavings to make their printed brachiopods the density of calcium carbonate before subjecting them to tests underwater. Similarly, to compare results of virtual hydrodynamics models of orthoconic cephalopods to physical models Peterman and Ciampaglio (2018) distributed mass appropriately during post-processing to make the prints neutrally buoyant. Post-processing is a critical final step to maintain the desired qualities of the final model, and therefore, cannot be overlooked.

Discussion and Conclusions

Geologic constraints obscure the wealth of information that lies in the fossil record. However, 3D printing has vastly expanded the possibilities for experimental tests on the functional morphology of fossilized taxa. New innovations in the properties of printed materials, methods of printing, and advances in bioinspired materials (Gbureck et al., 2007; Dorozhkin, 2010; Dimas et al., 2013; Murphy and Atala, 2014; Chia and Wu, 2015) hold promise for increasing the accuracy and precision of paleontological studies (see Walker and Humphries, 2019 for review). With increasing, accessibility to 3D-printing paleontologists can now investigate extinct taxa as if they were extant, conduct tests on hypothetical morphologies, and validate virtual experiments. Moving forward novel 3D printing techniques will allow us to re-examine existing hypotheses and develop new hypotheses to understand form-function relationships that were previously inaccessible.

Author Contributions

EJ collected primary sources. EJ and AC created workflow and wrote the paper.

EJ and AC created workflow and wrote the paper.

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

We would like to thank Peter Dodson, our reviewers: TV and RH, and our editor: MS, for helpful comments on this manuscript. We also thank Hermann Pfefferkorn for his support in our research program and Brendan Anderson for helpful conversations. Our thanks to Annelise Leonhart and David Vann for technical support on our 3D projects. This project was supported by internal funding through the Greg and Susan J. Walker Foundation and the Summer Research Stipend in Paleontology (Department of Earth and Environmental Science at the University of Pennsylvania). We also thank the Delaware Valley Paleontological Society for support through the Paul Bond Scholarship fund. This research was in part supported by funding to EJ through the NSF GRFP. https://www.bluedge.com

https://www.bluedge.com

References

Anderson, B. M., Miller, J., and Allmon, W. D. (2018). “When theoretical morphology gets real: 3-D printing of idealized turritellid gastropod shells to better understand the function of sculpture and whorl shape, in Conference Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-319161

CrossRef Full Text | Google Scholar

Balanoff, A., and Rowe, T. B. (2002). Osteological description of an elephant bird embryo using computed tomography and rapid prototyping, with a discussion of growth rates in Aepyornis. J. Vertebr. Paleonto. 27, 1–53. doi: 10.1671/0272-4634(2007)27[1:ODOAES]2.0.CO;2

CrossRef Full Text | Google Scholar

Bristowe, A., Parrott, A., Hack, J., Pencharz, M., and Raath, M. A. (2004). A nondestructive investigation of the skull of the small theropod dinosaur, Coelophysis rhodesiensis, using CT scans and rapid prototyping. Palaeontol. Afr. 40, 159–163.

Google Scholar

Chia, H. N., and Wu, B. M. (2015). Recent advances in 3D printing of biomaterials. J. Biol. Eng. 9:4. doi: 10.1186/s13036-015-0001-4

PubMed Abstract | CrossRef Full Text | Google Scholar

Clark, T. (2018). “The varying dentition of Allosaurus: a functional morphology experiment,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-318484

CrossRef Full Text | Google Scholar

Crofts, S. B., and Summers, A. P. (2014). How to best smash a snail: the effect of tooth shape on crushing load. J. R. Soc. Interface 11:20131053. doi: 10.1098/rsif.2013.1053

PubMed Abstract | CrossRef Full Text | Google Scholar

Cunningham, J. A., Rahman, I. A., Lautenschlager, S., Rayfield, E. J., and Donoghue, P. C. (2014). A virtual world of paleontology. Trends Ecol. Evol. 29, 347–357. doi: 10.1016/j.tree.2014.04.004

PubMed Abstract | CrossRef Full Text | Google Scholar

Das, A. J., Murmann, D. C., Cohrn, K., and Raskar, R. (2017). A method for rapid 3D scanning and replication of large paleontological specimens. PLoS ONE 12:e0179264. doi: 10.1371/journal.pone.0179264

J., Murmann, D. C., Cohrn, K., and Raskar, R. (2017). A method for rapid 3D scanning and replication of large paleontological specimens. PLoS ONE 12:e0179264. doi: 10.1371/journal.pone.0179264

PubMed Abstract | CrossRef Full Text | Google Scholar

Dievert, R. V., Barclay, K. M., Molinaro, D. J., and Leighton, L. R. (2019). Evaluating the effects of morphology and orientation on feeding in atrypide brachiopods using 3-D printed models. Palaeogeogr. Palaeoclimatol. Palaeoecol. 527, 77–86. doi: 10.1016/j.palaeo.2019.04.020

CrossRef Full Text | Google Scholar

DiMarco, B., Johnson, E. H., Carter, A. M., Sime, J. A., and Sallan, L. (2018). “Exploring the function of suture complexity with experimental compression of 3D printed ammonoids,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-321099

CrossRef Full Text | Google Scholar

Dimas, L. S., Bratzel, G. H., Eylon, I., and Buehler, M. J. (2013). Tough composites inspired by mineralized natural materials: computation, 3D printing, and testing. Adv. Funct. Mater. 23, 4629–4638. doi: 10.1002/adfm.201300215

(2013). Tough composites inspired by mineralized natural materials: computation, 3D printing, and testing. Adv. Funct. Mater. 23, 4629–4638. doi: 10.1002/adfm.201300215

CrossRef Full Text | Google Scholar

Dorozhkin, S. V. (2010). Bioceramics of calcium orthophosphates. Biomaterials 31, 1465–1485. doi: 10.1016/j.biomaterials.2009.11.050

PubMed Abstract | CrossRef Full Text | Google Scholar

Fiorenza, L., Yong, R., Ranjitkar, S., Hughes, T., Quayle, M., McMenamin, P. G., et al. (2018). The use of 3D printing in dental anthropology collections. Am. J. Phys. Anthropol. 167, 400–406. doi: 10.1002/ajpa.23640

PubMed Abstract | CrossRef Full Text | Google Scholar

Garcia, E. A., Molinaro, D. J., and Leighton, L. R. (2018). Testing the function of productide brachiopod spines on arenaceous substrates using 3D printed models. Palaeogeogr. Palaeoclimatol. Palaeoecol. 511, 541–549. doi: 10.1016/j.palaeo.2018.09.020

CrossRef Full Text | Google Scholar

Gbureck, U. , Hölzel, T., Klammert, U., Würzler, K., Müller, F. A., and Barralet, J. E. (2007). Resorbable dicalcium phosphate bone substitutes prepared by 3D powder printing. Adv. Funct. Mater. 17, 3940–3945. doi: 10.1002/adfm.200700019

, Hölzel, T., Klammert, U., Würzler, K., Müller, F. A., and Barralet, J. E. (2007). Resorbable dicalcium phosphate bone substitutes prepared by 3D powder printing. Adv. Funct. Mater. 17, 3940–3945. doi: 10.1002/adfm.200700019

CrossRef Full Text | Google Scholar

Germann, D. P., Schatz, W., and Hotz, P. E. (2014). Artificially evolved functional shell morphology of burrowing bivalves. Palaeontol Electron. 17, 1–25. doi: 10.26879/394

CrossRef Full Text | Google Scholar

Grant, C., Hastings, A., and Ziegler, M. J. (2018). “iDigFossils: engaging K−12 students in integrated STEM using 3D models of triassic dinosaur foot prints from culpepper,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-317698

CrossRef Full Text | Google Scholar

Grant, C. A., MacFadden, B. J., Antonenko, P., and Perez, V. J. (2016). 3-D fossils for K−12 education: a case example using the giant extinct shark Carcharocles megalodon. Paleontol. Soc. Papers 22, 197–209. doi: 10.1017/scs.2017.15

Paleontol. Soc. Papers 22, 197–209. doi: 10.1017/scs.2017.15

CrossRef Full Text | Google Scholar

Hasiuk, F. J. (2014). Making things geological: 3-D printing in the geosciences. GSA Today 24:28. doi: 10.1130/GSATG211GW.1

CrossRef Full Text | Google Scholar

Huynh, T. L., Evangelista, D., and Marshall, C. R. (2013). Visualizing the fluid flow through the complex skeletonized respiratory structures of a blastoid echinoderm. Palaeontol. Electron. 18, 1–17. doi: 10.26879/492

CrossRef Full Text | Google Scholar

Igic, B., Nunez, V., Voss, H. U., Croston, R., Aidala, Z., López, A. V., et al. (2015). Using 3D printed eggs to examine the egg-rejection behaviour of wild birds. PeerJ. 3:e965. doi: 10.7717/peerj.965

PubMed Abstract | CrossRef Full Text | Google Scholar

Ishida, N., and Kishimoto, N. (2015). Three-dimensional imaging of the Jurassic radiolarian Protunuma ochiensis Matsuoka: an experimental study using high-resolution X-ray micro-computed tomography. Volumina Jurassica 13, 77–82. doi: 10.5604/17313708

Volumina Jurassica 13, 77–82. doi: 10.5604/17313708

CrossRef Full Text | Google Scholar

Johnson, E. H., Allmon, W. D., Jerolmack, D. J., Sipzner, D., and Sallan, L. (2018). “3D printing reveals strengths and weaknesses of prey shape during the mesozoic marine revolution,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-323716

CrossRef Full Text | Google Scholar

Jonsson, T., Chivers, B. D., Brown, K. R., Sarria-S, F. A., Walker, M., and Montealegre-Z, F. (2017). Chamber music: an unusual Helmholtz resonator for song amplification in a Neotropical bush-cricket (Orthoptera, Tettigoniidae). J. Exp. Biol. 220, 2900–2907. doi: 10.1242/jeb.160234

PubMed Abstract | CrossRef Full Text | Google Scholar

Kolmann, M. A., Crofts, S. B., Dean, M. N., Summers, A. P., and Lovejoy, N. R. (2015). Morphology does not predict performance: jaw curvature and prey crushing in durophagous stingrays. J. Exp. Biol. 218, 3941–3949. doi: 10.1242/jeb.127340

Exp. Biol. 218, 3941–3949. doi: 10.1242/jeb.127340

CrossRef Full Text | Google Scholar

Lak, M., Néraudeau, D., Nel, A., Cloetens, P., Perrichot, V., and Tafforeau, P. (2008). Phase contrast X-ray synchrotron imaging: opening access to fossil inclusions in opaque amber. Microsc. Microanal. 14, 251–259. doi: 10.1017/S1431927608080264

PubMed Abstract | CrossRef Full Text | Google Scholar

Mehrabani, H., Ray, N., Tse, K., and Evangelista, D. (2014). Bio-inspired design of ice-retardant devices based on benthic marine invertebrates: the effect of surface texture. PeerJ. 2:e588. doi: 10.7717/peerj.588

PubMed Abstract | CrossRef Full Text | Google Scholar

Mitsopoulou, V., Michailidis, D., Theodorou, E., Isidorou, S., Roussiakis, S., Vasilopoulos, T., et al. (2015). Digitizing, modelling and 3D printing of skeletal digital models of Palaeoloxodon tiliensis (Tilos, Dodecanese, Greece). Quat. Int. 379, 4–13. doi: 10.1016/j.quaint. 2015.06.068

2015.06.068

CrossRef Full Text | Google Scholar

Morse, A., Dattilo, B., Dewing, K., and Hagadorn, J. W. (2018). “Mind the gape: the solution to the life habits of Rafinesquina alternata may turn on a 3D-printed hinge,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-323792

CrossRef Full Text | Google Scholar

Murphy, S. V., and Atala, A. (2014). 3D bioprinting of tissues and organs. Nat. Biotechnol. 32:773. doi: 10.1038/nbt.2958

PubMed Abstract | CrossRef Full Text | Google Scholar

Muscutt, L. E., Dyke, G., Weymouth, G. D., Naish, D., Palmer, C., and Ganapathisubramani, B. (2017). The four-flipper swimming method of plesiosaurs enabled efficient and effective locomotion. Proc. R. Soc. B Biol. Sci. 284:20170951. doi: 10.1098/rspb.2017.0951

PubMed Abstract | CrossRef Full Text | Google Scholar

Pearson, K. (2017). Experimental biomechanics of trinucleid fringe pits (Trilobita) (Doctoral dissertation), Oberlin College.

Google Scholar

Peterman, D., and Ciampaglio, C. N. (2018). “How stable were orthoconic cephalopods? Hydrodynamic analyses of restoring moments from neutrally buoyant, 3D printed models of ectocochleate cephalopods,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-317321

CrossRef Full Text | Google Scholar

Porter, M. M., Adriaens, D., Hatton, R. L., Meyers, M. A., and McKittrick, J. (2015). Why the seahorse tail is square. Science 349:aaa6683. doi: 10.1126/science.aaa6683

PubMed Abstract | CrossRef Full Text | Google Scholar

Rahman, I. A., Adcock, K., and Garwood, R. J. (2012). Virtual fossils: a new resource for science communication in paleontology. Evol. Educ. Outreach 5, 635–641. doi: 10.1007/s12052-012-0458-2

CrossRef Full Text | Google Scholar

Raup, D. M. (1966). Geometric analysis of shell coiling: general problems. J. Paleontol. 40, 1178–1190.

Google Scholar

Raup, D. M., and Michelson, A. (1965). Theoretical morphology of the coiled shell. Science 147, 1294–1295. doi: 10.1126/science.147.3663.1294

M., and Michelson, A. (1965). Theoretical morphology of the coiled shell. Science 147, 1294–1295. doi: 10.1126/science.147.3663.1294

PubMed Abstract | CrossRef Full Text | Google Scholar

Rivera, M. J., and Sumner, D. Y. (2014). Unraveling the three-dimensional morphology of Archean microbialites. J. Paleontol. 88, 719–726. doi: 10.1666/13-084

CrossRef Full Text | Google Scholar

Schemm-Gregory, M. (2014). A new Givetian athyridid species from northwest Africa discovered by three-dimensional reconstruction of shell morphology of internal molds. J. Paleontol. 88, 708–718. doi: 10.1666/13-086

CrossRef Full Text | Google Scholar

Schilling, R., Jastram, B., Wings, O., Schwarz-Wings, D., and Issever, A. S. (2013). Reviving the dinosaur: virtual reconstruction and three-dimensional printing of a dinosaur vertebra. Radiology 270, 864–871. doi: 10.1148/radiol.13130666

PubMed Abstract | CrossRef Full Text | Google Scholar

Sutton, M. , Rahman, I., and Garwood, R. (2014). Techniques for Virtual Palaeontology. West Sussex: John Wiley & Sons. doi: 10.1002/9781118591192

, Rahman, I., and Garwood, R. (2014). Techniques for Virtual Palaeontology. West Sussex: John Wiley & Sons. doi: 10.1002/9781118591192

CrossRef Full Text | Google Scholar

Teshima, Y., Matsuoka, A., Fujiyoshi, M., Ikegami, Y., Kaneko, T., Oouchi, S., et al. (2010). “Enlarged skeleton models of plankton for tactile teaching.” in International Conference on Computers for Handicapped Persons (Berlin; Heidelberg: Springer), 523–526. doi: 10.1007/978-3-642-14100-3_78

CrossRef Full Text | Google Scholar

Vernon, R. O. (1957). New technique for casting fossils and forming molds. J. Paleontol. 31, 461–463.

Google Scholar

Voegele, K. K., McDevitt, D. G., Tangorra, J., and Lacovara, K. J. (2018). “Comparison of digital and 3D printed robotic models of the elbow of the sauropod dinosaur Dreadnoughtus schrani,” in GSA Annual Meeting (Indianapolis, IN: Geological Society of America). doi: 10.1130/abs/2018AM-321567

CrossRef Full Text | Google Scholar

Wainwright, P. C. (1987). Biomechanical limits to ecological performance: mollusc-crushing by the Caribbean hogfish, Lachnolaimus maximus (Labridae). J. Zool. 213, 283–297. doi: 10.1111/j.1469-7998.1987.tb03704.x

C. (1987). Biomechanical limits to ecological performance: mollusc-crushing by the Caribbean hogfish, Lachnolaimus maximus (Labridae). J. Zool. 213, 283–297. doi: 10.1111/j.1469-7998.1987.tb03704.x

CrossRef Full Text | Google Scholar

Walker, M., and Humphries, S. (2019). 3D Printing: applications in evolution and ecology. Ecol. Evol. 9, 4289–4301. doi: 10.1002/ece3.5050

PubMed Abstract | CrossRef Full Text | Google Scholar

Waters, B. T., and Savage, D. E. (1971). Making duplicates of small vertebrate fossils for teaching and for re-search collections. Curator. 14, 123–132. doi: 10.1111/j.2151-6952.1971.tb00428.x

CrossRef Full Text | Google Scholar

Weber, G. W. (2001). Virtual anthropology (VA): a call for glasnost in paleoanthropology. Anat Rec. 265, 193–201. doi: 10.1002/ar.1153

PubMed Abstract | CrossRef Full Text | Google Scholar

Wen, L., Weaver, J. C., and Lauder, G. V. (2014). Biomimetic shark skin: design, fabrication and hydrodynamic function. J. Exp. Biol. 217, 1656–1666. doi: 10.1242/jeb.097097

J. Exp. Biol. 217, 1656–1666. doi: 10.1242/jeb.097097

PubMed Abstract | CrossRef Full Text | Google Scholar

White, M. A., Cook, A. G., and Rumbold, S. J. (2017). A methodology of theropod print replication utilising the pedal reconstruction of Australovenator and a simulated paleo-sediment. PeerJ. 5:e3427. doi: 10.7717/peerj.3427

PubMed Abstract | CrossRef Full Text | Google Scholar

Project "3D printer - technology of the future"

Author of the work:

Mingazutdinova Gulgena

Project manager:

Gabtelkhakova Razina Rafgatovna

Institution:

MBOU "Smailskaya secondary school" Baltasinsky district

In the presented research project in informatics "3D printer - the technology of the future" , theoretical information about printing on a printer and the emergence of an innovative 3D printing method that will make a breakthrough in all areas of human life is considered.

In the process of computer science research work "3D printer - technology of the future" , a 9th grade student set the goal of learning what a 3D printer is and how it is used by people.

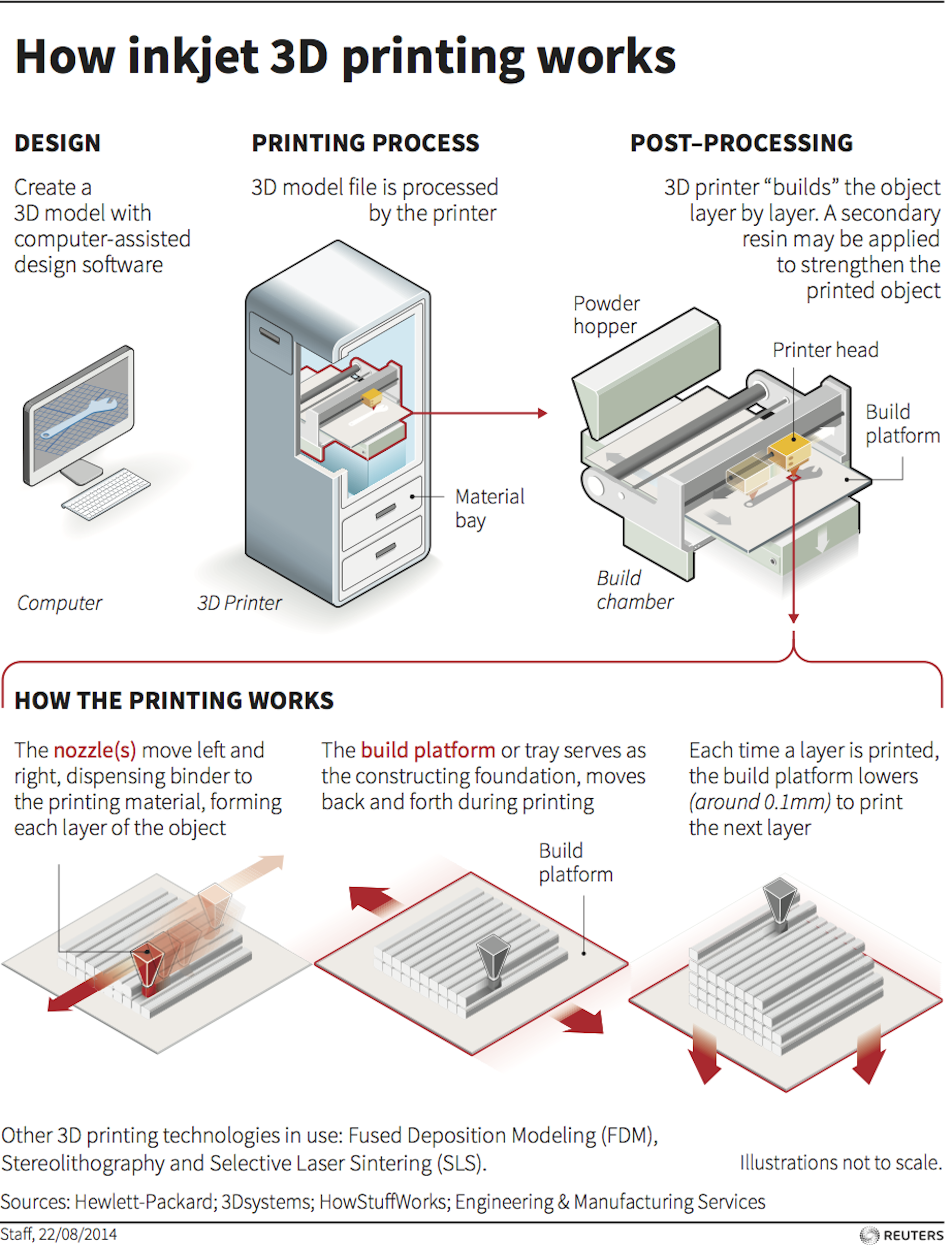

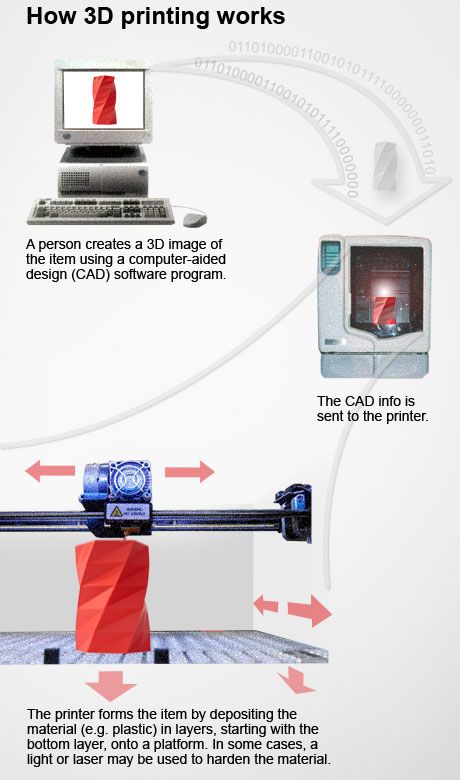

In the research work on computer science "3D printer - technology of the future" the author describes the history of the creation of a 3D printer, studies the principle of operation of this device, finds out what can be made with it.

In the computer science project proposed "3D printer - technology of the future" , the author hypothesizes that the capabilities of a 3D printer are very high at the moment, so in the future it will probably be in great demand in all areas of human life.

The results of this study can be useful as educational material, as well as for informatics lessons.

Contents

Introduction

1. The history of

2. How 3D printing works

3. The main technologies of 3D printing

The main technologies of 3D printing

4. Problems and prospects for using this technology in various areas of life

5. Applications

Conclusion

Literature

Introduction

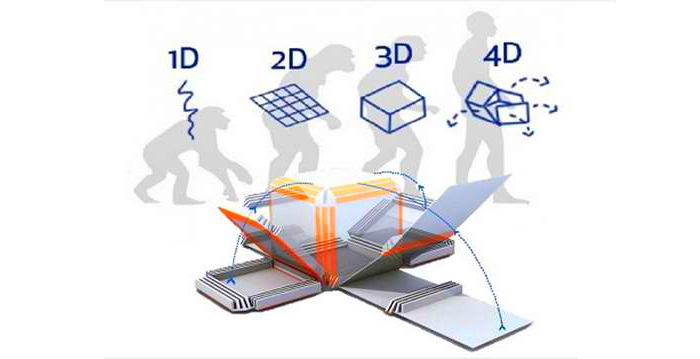

In this paper, we will focus on a new technology for creating objects and objects - a 3D printer. The history of occurrence is described, the basic principles and technologies of the device operation are indicated.

3D printing is becoming more and more accessible and opens up many opportunities, both positive and negative. You will learn the different uses of 3D printing.

3D entered our everyday life at the beginning of the new millennium. We naturally associate this definition with cinema or animation. But this technology covers much more spectrums of our life. So, what is a 3D printer, and what is printing on such a device?

Research objective: Find out what a 3D printer is and how it is used by people.

Tasks:

1. Find information about the history of the 3D printer.

2. Learn how this device works.

3. Find out what can be made with it.

4. Summarize and analyze the information received.

Hypothesis: Let's assume that the capabilities of a 3D printer are very high at the moment, so it will probably be in great demand in the future.

Research methods : Study of information obtained from the Internet, observation, comparison.

Research object : 3D printer.

Research subject: 3D printer capabilities.

Relevance research is that new information technologies are always developing very quickly and modern society is unthinkable without them.

The practical significance of this study is that it can be useful as an educational material, as well as for computer science lessons.

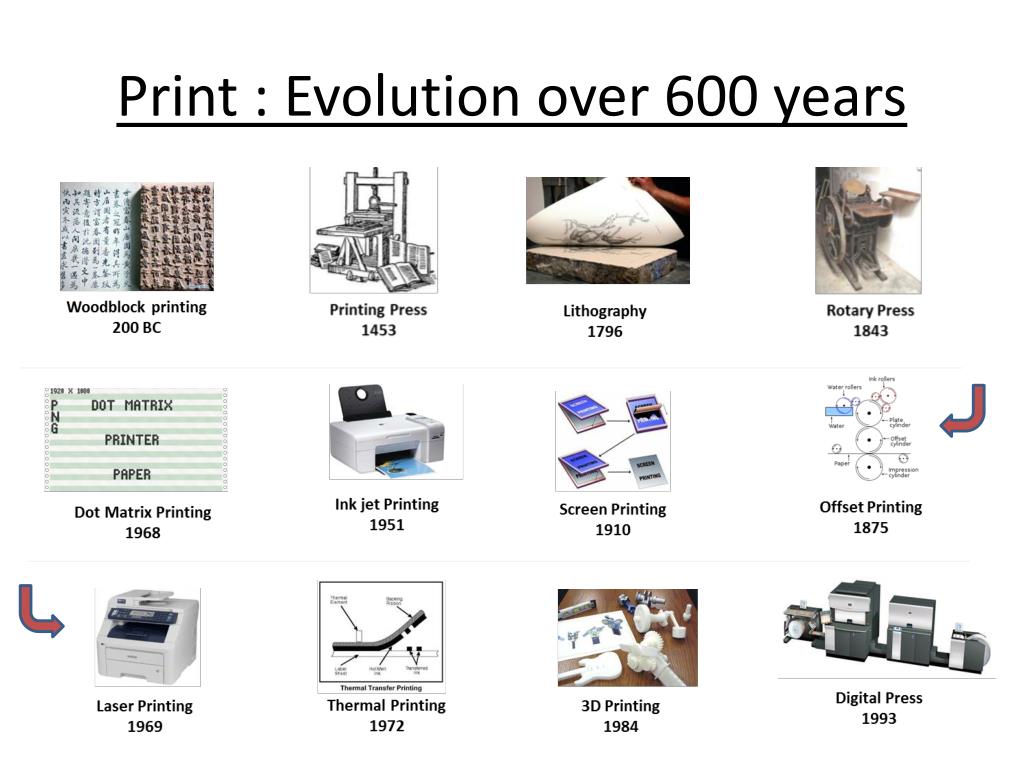

History of the 3D printer

By the mid-90s of the last century, an interesting situation had developed in the world economy: competing firms began not only to fight for consumers of products, but literally fulfill any of their wishes. Most importantly, as a result, monotonous products - for example, watches and cars - were no longer purchased in millions of quantities.

The volume of sales from manufacturing plants was reduced to several thousand pieces in one lot. This marked the beginning of the era of small-scale production. Ultimately, companies found that developing molds, patterns, and prototypes for more and more new models was very expensive.

Approximately at the same time, devices that can quickly and cost-effectively make models become popular - CNC machines, numerical control. Many of them remained in the manufacturing sector, but the intensive development of a separate branch of the " evolution of " led to the emergence of office 3D printers - this is how the history of the development of 3D printing began.

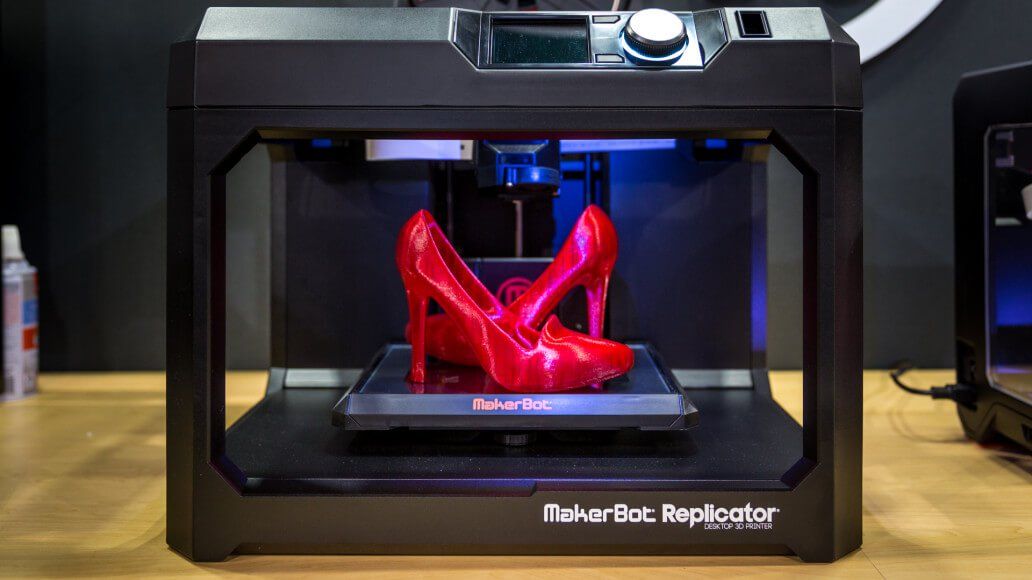

The very first 3D prototyping machine was an American SLA machine designed and patented by Charles Hull in 1986 and using stereolithography. Of course, this was not yet the first 3D printer in the modern sense, but it was she who determined how a 3D printer works: objects are built up in layers.

Hull immediately set up 3D Systems, which produced the first 3D printer called the Stereolithography Apparatus. The first model of this machine, which was widely used, was the SLA-250 developed in 1988. It is clear that such a 3 d printer was not color, but worked only with raw materials of the same color, but for that time it was akin to a miracle.

In 1990, a new method was used to obtain three-dimensional " printed impressions " - the fusing method. It was developed by Scott Crump, founder of Stratasys, and his wife, who continued the development of 3D printing.

The modern historical stage in the development of 3D printing started in 1993 with the creation of Solidscape. It produced inkjet printers that preceded 3D printers. In 1995, an inkjet printer was modified by two MIT students. He created images not on paper, but in a special container, and they were voluminous. At the same time, the concept of " 3D printing " and the first 3D printer. This method was patented and is now used by the Z Corporation, founded by the same students, and also by ExOne. Z Corp. still manufactures 3D printers using this technology.

It produced inkjet printers that preceded 3D printers. In 1995, an inkjet printer was modified by two MIT students. He created images not on paper, but in a special container, and they were voluminous. At the same time, the concept of " 3D printing " and the first 3D printer. This method was patented and is now used by the Z Corporation, founded by the same students, and also by ExOne. Z Corp. still manufactures 3D printers using this technology.

The history of the 3D printer continued with the emergence of a technology called PolyJet, based on the use of photopolymer liquid plastic. With this method of printing, the head draws a layer of photopolymer, which is instantly illuminated by a lamp. The method turned out to be advantageous in many respects: its price is much lower, and high accuracy makes it possible to manufacture not just models, but ready-to-use parts.

Over time, the development of the 3D printing industry accelerated, new 3D printer companies appeared to contribute to its development, new materials and principles were used, the sizes and prices of devices became smaller - the first 3D printers were huge, now they fit on a table (with the exception of an industrial 3D printer).

The modern 3D printer is becoming more and more like a traditional paper printer in appearance and application technology « coloring "substance. The models printed by him are also distinguished by high strength, therefore they can be used as finished products.

Now a 3D printer can take up very little space - of course, this depends on its purpose. At the beginning of development, the price of such a printer was affordable only for very large companies, but now anyone can purchase a 3D printer, the price of which is an average of $1000. The history of the 3D printer is not over yet, and the most interesting is ahead.

Go to section: 2. Principle of 3D printing

3D-printing in education-in which lessons is the 3D printer

Content

-

- Mathematics

- Biology

- Geography

This review article will focus on the use of 3D printing in education, in particular in school education. When starting to talk about 3D printing in schools, it is important to understand that 3D printing cannot be a separate discipline, teaching 3D printing as such cannot replace some existing school subjects, such as computer science, drafting or geometry.

When starting to talk about 3D printing in schools, it is important to understand that 3D printing cannot be a separate discipline, teaching 3D printing as such cannot replace some existing school subjects, such as computer science, drafting or geometry.

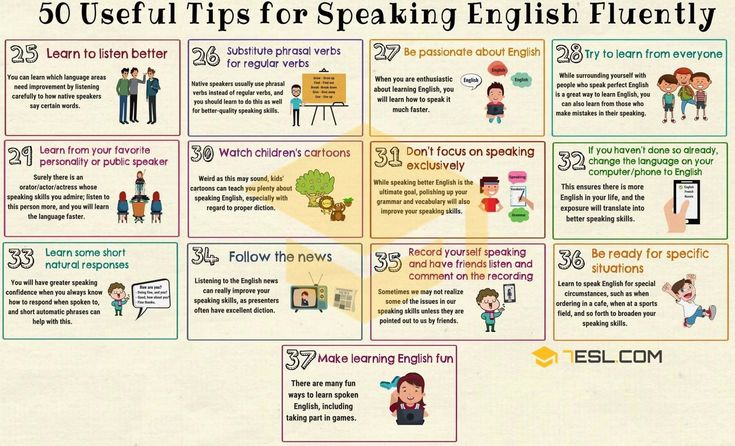

First of all, I would divide the teaching of 3D printing in schools into two large components, which, in principle, can exist one without the other.

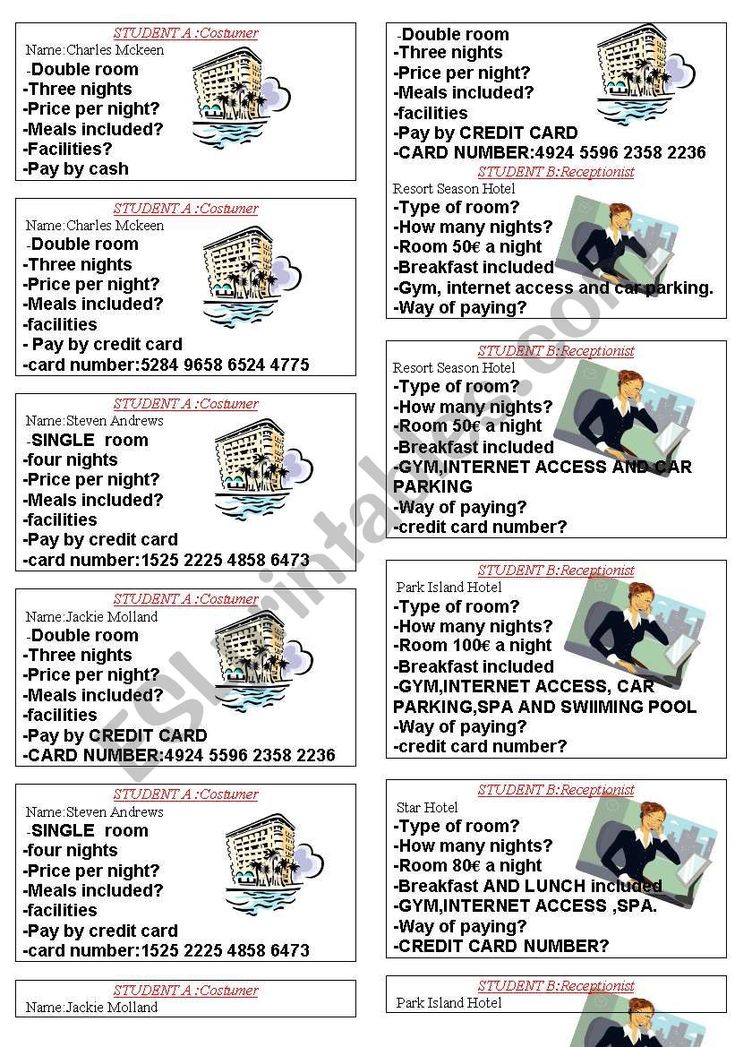

The first is learning 3D modeling , because in order to print any product, you must have an object for printing. In the case of conventional printing, this any document, table, picture, photograph, presentation, etc. In the case of 3D printing, this is a 3D model that needs to be created in one of the many editors, such as a simple editor like Autodesk Tinkercad.

Learning the process of creating 3D models can be compared to a more advanced computer science lesson. Learning takes place in stages from simple to complex, you can start by creating a model like a cube, then draw a cone, a gear, a small vase, add an inscription on the cube, for example, your name or the name of the school.

Further, the lessons become more complicated, you can try to create a small car, a Lego man, etc. Depending on the direction of study - engineering, art or architecture, you can continue learning 3D modeling in programs such as 3D Studio Max, ZBrush, ArchiCAD and others. The whole process of learning 3D modeling as such is not related to 3D printing, only an insignificant part of all 3D models created today are subsequently printed. Of the models created, the vast majority exists in digital format, as does the vast majority of other digital information, such as documents and graphic content. Is teaching 3D modeling necessary in school education today, the answer is of course not. Does it help in the education of children? Of course, this makes it possible to better master the computer, as well as in the process of creating models to visualize the knowledge gained in the lessons of geometry, drawing and drawing.

So, we found out that 3D modeling is a separate discipline that can be taught in schools as an additional course or as part of computer science lessons, but it is indirectly related to 3D printing. I would compare it with photography and newspaper publishing - all newspapers have photographs and it is difficult to imagine newspapers without photographs, but at the same time a huge number of photographs do not end up in newspapers, but are used for other purposes.

I would compare it with photography and newspaper publishing - all newspapers have photographs and it is difficult to imagine newspapers without photographs, but at the same time a huge number of photographs do not end up in newspapers, but are used for other purposes.

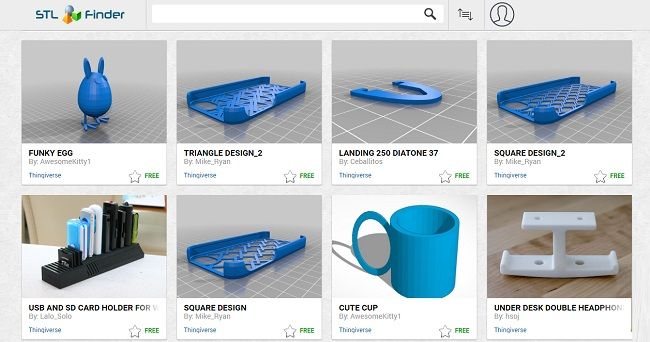

Moving directly to 3D printing, it is important to note that 3D printable models come from 3 sources:

- they can be simulated,

- find ready-made models on sites such as MyMiniFactory and many others

- obtained by 3D scanning.

The first step in getting started with typing is to get familiar with the slicing software. The slicer program is usually supplied with a 3D printer and is a “translator” from the language of the 3D model to the language of the printer. With the help of this program, the model is prepared for printing with the specified parameters.

The printer needs clear commands: what to do, how to move the carriage, how thick the layer will be printed, what material, at what temperature, how voids will be filled, and much more. Thus, a novice 3D printer needs to learn how to use this software product before starting direct printing.

Thus, a novice 3D printer needs to learn how to use this software product before starting direct printing.

The second part of the 3D printing training will be learning how to interact with a 3D printer, the 3D printing process requires certain knowledge and experience, in particular about the properties of various types of plastic or resin, interlayer adhesion, plastic sintering, its supply, etc. Using With an experienced mentor on the example of printing models of various shapes, with various settings, students can reach an initial level of knowledge of the printing process itself and improve them as they gain experience, taking into account the capabilities of the 3D printing equipment that they have at their disposal.

We understood how to get a 3D model, how to prepare it for printing and how to print it, but did not answer the main question, why do we need 3D printing at school?

It is important to understand here that it is pointless to teach 3D printing at school as a subject, since this is a highly specialized discipline that a small percentage of students need to apply in future professional tasks. Such knowledge is usually obtained during the acquisition of secondary specialized or higher education. But what 3D printing is great for is embedding it into the learning process in other subjects. At first glance, a bold statement is quite easy to prove on a number of simple examples.

Such knowledge is usually obtained during the acquisition of secondary specialized or higher education. But what 3D printing is great for is embedding it into the learning process in other subjects. At first glance, a bold statement is quite easy to prove on a number of simple examples.

Mathematics

A 3D printer will help you learn the multiplication table quickly and with pleasure.

Biology

It is not necessary to dissect a live frog, you can make a 3D printed model and carry out this procedure in a humane way.

Anatomy

You can print the skull or other organs and visually study its structure.

Geography

Each student can print a square and assemble the landscape of the earth's surface together.

A separate educational area where 3D printers are indispensable tools is the area of additional education, namely the numerous and very popular today circles of robotics, modeling, prototyping and others.

3D printing is in great demand in such educational institutions as children's technoparks Quantoriums and TsMITs, which are analogous to the circles of young technicians from our childhood. These centers are equipped with everything you need, including 3D printers, 3D scanners, milling machines, mini CNC machines, and more.

This set of equipment allows not only and not so much to learn the skills of 3D printing, scanning, modeling, and so on, but also to create real design works that can be presented at olympiads, exhibitions, or even subsequently turned into technology startups. At the end of each module, a final lesson is provided, during which the team defense of scientific and technical projects, students and natural science research works takes place.

At the end of this short article, I would like to give some tips for choosing the equipment that is best suited for schools and institutions of further education.

If 3D modeling is included in the computer science course at your school or as a separate additional course and the task is to print simple models of an initial or intermediate level of complexity, then I would recommend paying attention to budget models of 3D printers created specifically for these purposes.

For example, the FlashForge Adventurer 3 3D printer model has a closed housing, a safe, easily removable nozzle, a webcam for remote monitoring of printing from an application, a color touch-screen display familiar to children from smartphones and tablets.

For a more advanced level of learning, a model like FlashForge Inventor is perfect, which allows you to create more complex semi-professional models.

If the task is to provide Quantorium or TsMIT with 3D printers, then you need to choose the most versatile models that can print a wide range of different materials, preferably with an enlarged camera for large projects. Such printers are able to cope with various, sometimes very complex and, most importantly, diverse tasks. These models certainly include the Raise3D Pro2 printer, which, due to its versatility, the presence of a fully functional slicer, cloud service and a host of additional functions, is rightfully considered a leader in its segment.

Such printers are able to cope with various, sometimes very complex and, most importantly, diverse tasks. These models certainly include the Raise3D Pro2 printer, which, due to its versatility, the presence of a fully functional slicer, cloud service and a host of additional functions, is rightfully considered a leader in its segment.

If some specific areas of printer use are known in advance, then you can choose a model for these specific tasks, for example, to create detailed miniatures, printers using photopolymer printing technology are suitable, for example, the Phrozen Shuffle 4K model, which is capable of creating models of jewelry accuracy and detail.

We hope this article was useful for you, and you got a rough idea about 3D printing in education, our company's specialists will always be happy to help you with the choice of the necessary equipment.