3D printer price drop

10 million 3D Printers to Sold by 2030

Global 3D printing market was valued at USD 13.84 billion in 2021, and it is expected to reach a value of USD 51.95 billion by 2028, at a CAGR of 20.80% over the forecast period (2022-2028).

| Source: SkyQuest Technology Consulting Pvt. Ltd. SkyQuest Technology Consulting Pvt. Ltd.

Westford, USA, Aug. 08, 2022 (GLOBE NEWSWIRE) -- 3D printing is quickly becoming one of the most popular technologies in the world. It has been used to create everything from prosthetic body parts and surgical implants to customized eyeglasses and airplane parts. The applications of 3D printing are only going to continue to increase in the future. This is because 3D printing is able to create complex objects very quickly and with high accuracy.

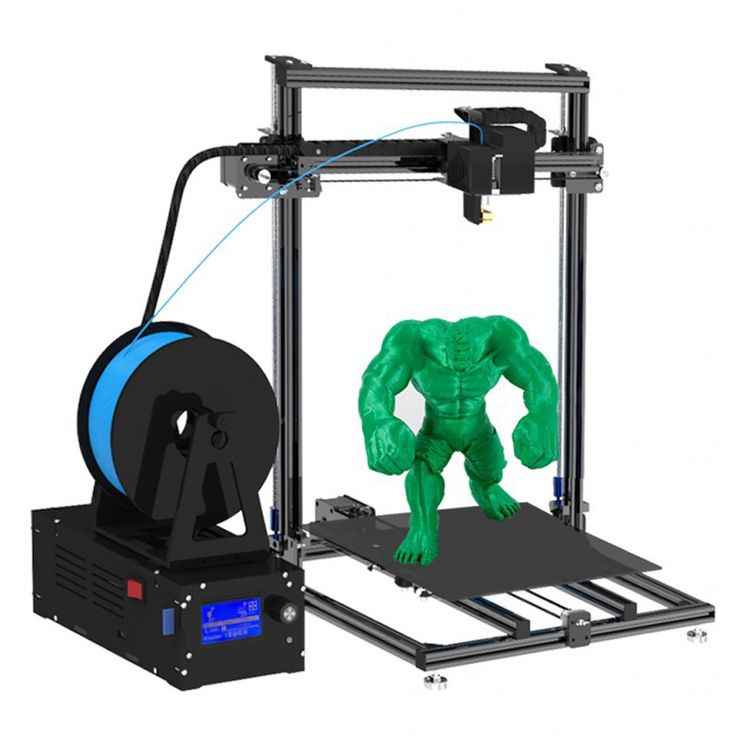

One of the biggest benefits of 3D printing market is that it can be used to create custom objects quickly and relatively cheaply. This means that it can be used in a variety of different industries, including manufacturing, construction, and medical research.

10 million 3D Printers to be Sold by 2030

Although the exact number of 3D printers to be sold by 2030 is impossible to predict with complete accuracy, SkyQuest analysis expect that the sales of 3D printers will continue to grow at a healthy CAGR of 20.38%. In 2015, global sales of 3D printers reached an estimated 0.8 million, and by 2019 this figure increased 1.5 million, and is projected to surpass a 10 million mark by 2030.

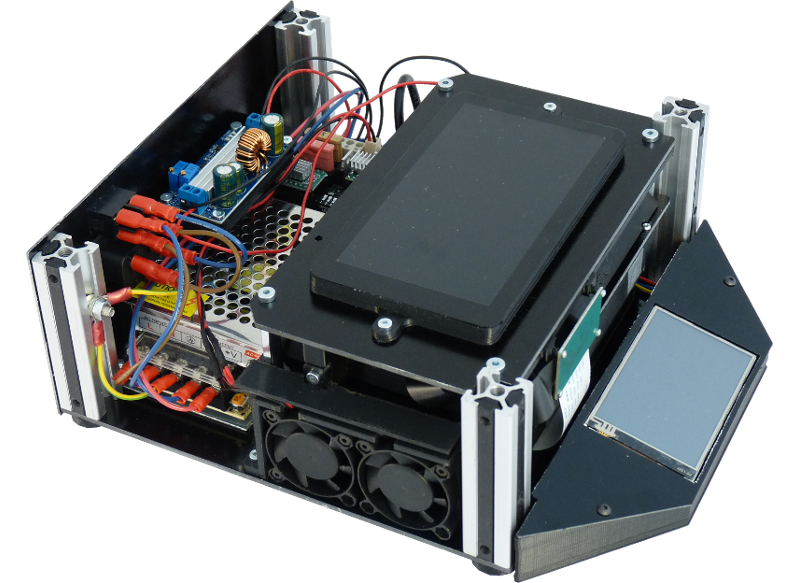

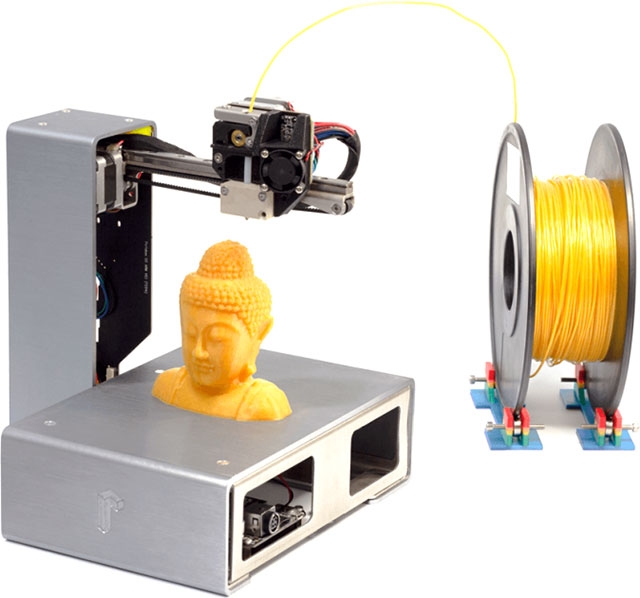

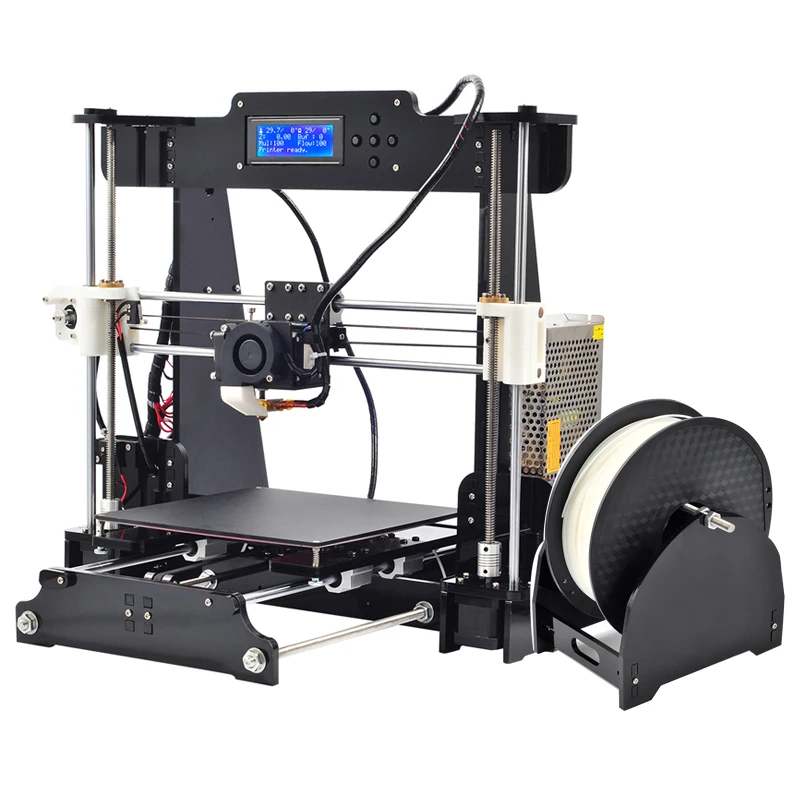

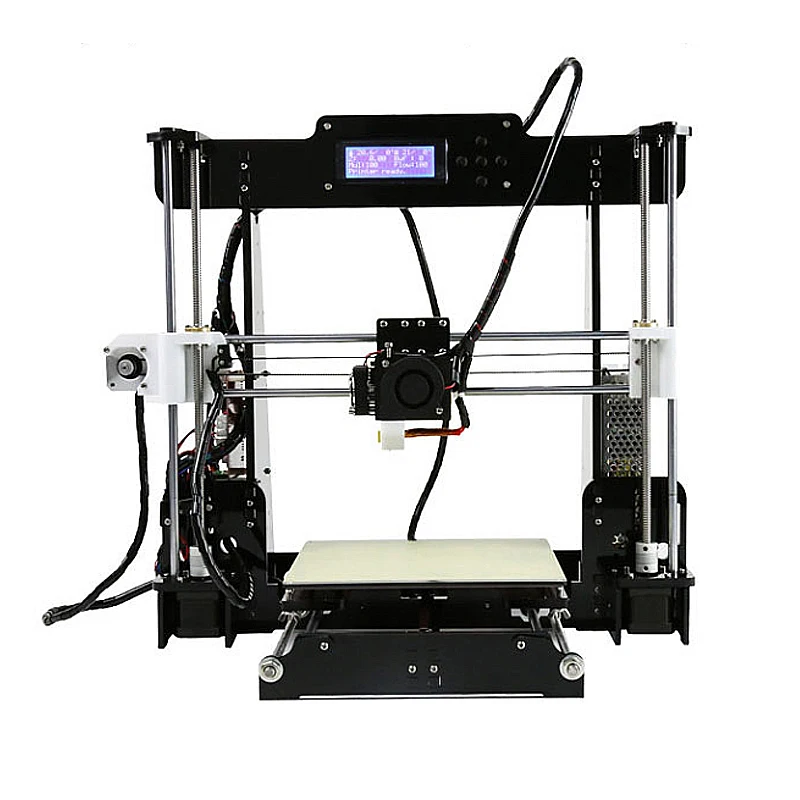

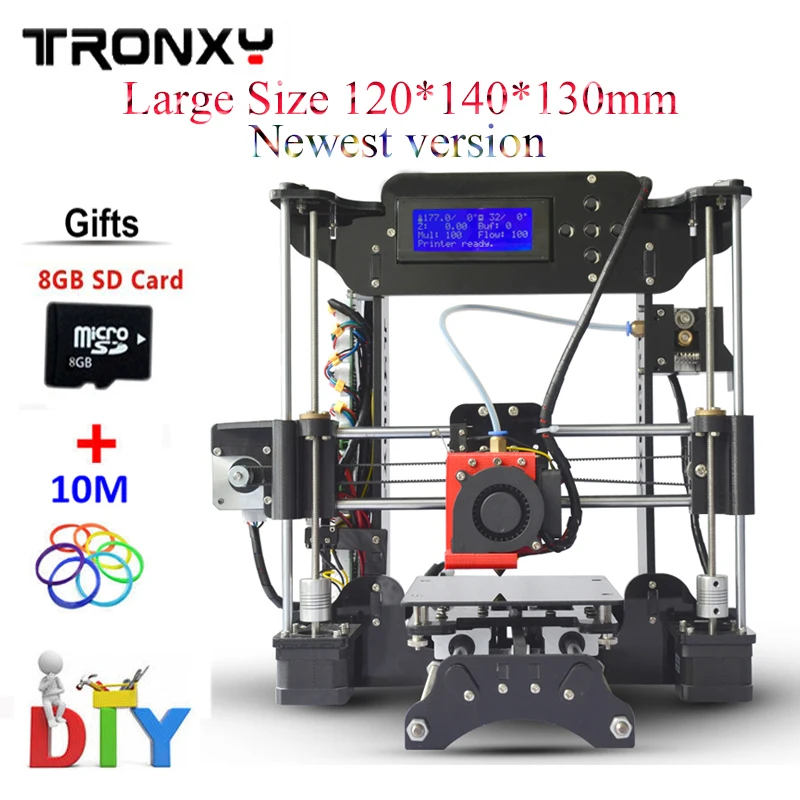

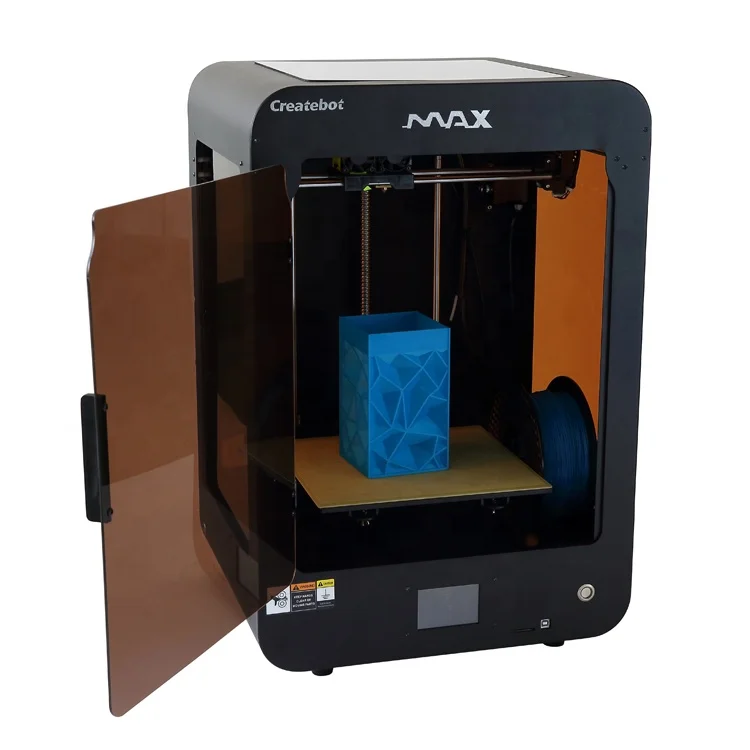

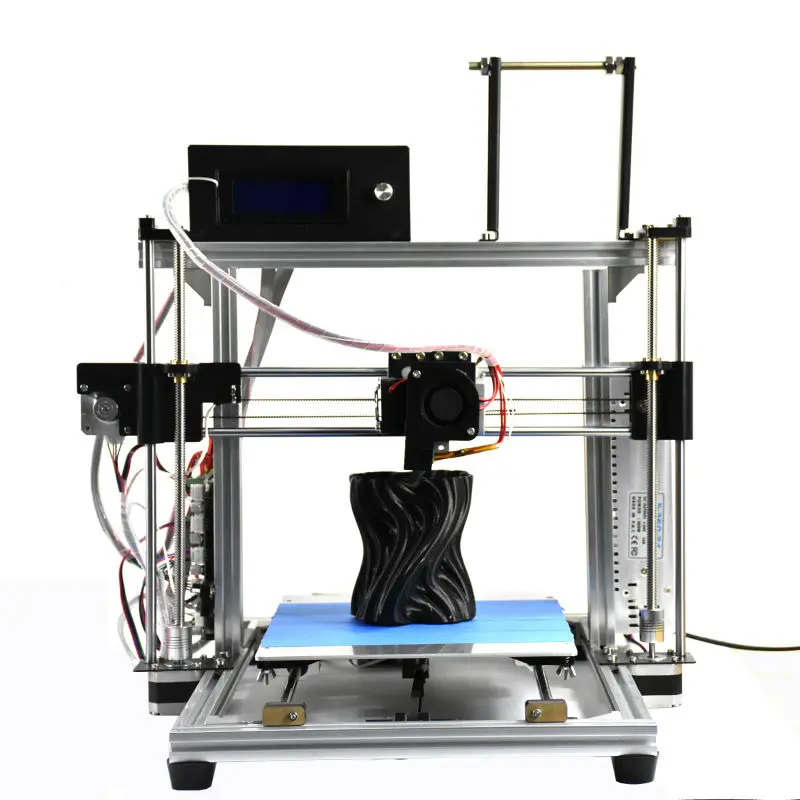

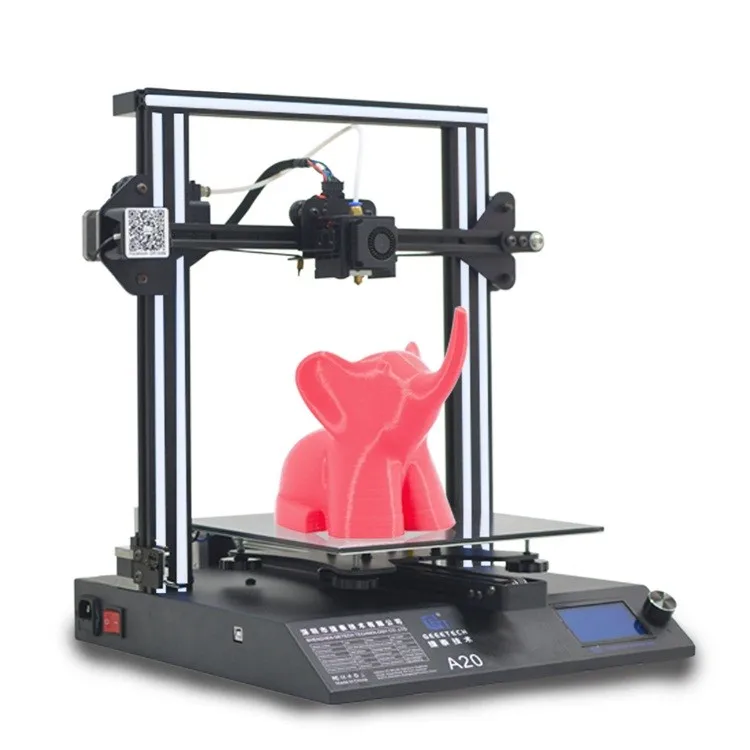

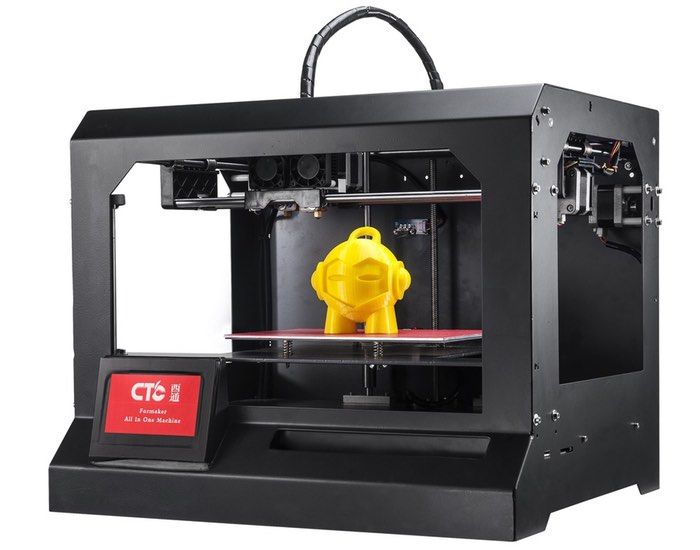

One key factor driving the growth of 3D printing market sales is the decreasing cost of these devices. In 2014, the average price of a consumer-grade 3D printer was approximately $1,000. Just two years later, in 2016, the average price of low-cost 3D printers has dropped to less $400. This decrease in prices is making 3D printers more affordable for a wider range of consumers and businesses, which is helping to drive growth in sales. On the other hand, industrial and professional 3D printer cost has come down to around $10,000 and $5,000 respectively, which used to more than $20,000 in 2015.

In 2014, the average price of a consumer-grade 3D printer was approximately $1,000. Just two years later, in 2016, the average price of low-cost 3D printers has dropped to less $400. This decrease in prices is making 3D printers more affordable for a wider range of consumers and businesses, which is helping to drive growth in sales. On the other hand, industrial and professional 3D printer cost has come down to around $10,000 and $5,000 respectively, which used to more than $20,000 in 2015.

The demand for 3D printing is expected to grow in the coming years, as the costs and technological developments for the technology decline. This is especially true for medical applications, which are expected to account for a large share of future growth.

3D printing has already revolutionized manufacturing processes, and it is expected to do even more in the future. The technology can be used to produce customized products, which is why it is often used to create medical devices.

Advantages of 3D printing over other manufacturing processes include the ability to produce multiple copies of a product with minimal mistakes. Additionally, 3D printing is faster than other methods and it does not require specialized equipment. This makes it suitable for small businesses and Manufacturing Enterprises who need quick turnaround times on products.

SkyQuest has published a report 3D printing market that primarily focuses on demand and sales of 3D printers by application and end-use industry. The report also provides a detailed insights into number of units sold in each sector and their major buyers by region. This would help the market participant to identify market opportunities and target their potential consumers in the global 3D printing market. To get a detailed market analysis, pricing analysis, value chain and supply chain optimization, and forecast,

Get sample copy of this report:

https://skyquestt. com/sample-request/3d-printing-market

com/sample-request/3d-printing-market

Automotive Industry Generates 27% of Sales in Global 3D Printing Market

The automotive industry generates a significant chunk of the global 3D printing market. As per SkyQuest Technology, the automotive industry generated 27% of sales in the global 3D printing market in 2021 and is projected to continue expanding their market share at a CAGR of around 22.3% in the years to come as the application area expands. As of 2021, the automotive industry generated market revenue of $2.3 billion and is projected attain a market value of $11.87 billion by 2028.

A number of factors are contributing to the growth in the automotive industry and 3D printing is one of them. Automotive companies are increasingly turning to 3D printing technology for various reasons. Some of the reasons include replacing parts with customized parts, manufacturing prototypes faster and more cost-effectively, and creating models for Toyota's Arcturus concept cars.

3D printing has also revolutionized the design process for carmakers. Instead of creating a model using 2D drawings, carmakers now use 3D prints to create accurate models that can be used for engineering and manufacturing purposes.

This report by SkyQuest on global 3D printing market provides a snapshot of the market trends and projections for 3D printing in the automotive industry. It provides insights on how this technology is changing the way carmakers work and helps to identify future opportunities.

Healthcare Holds 20% of Global 3D Printing Market

As per SkyQuest analysis, healthcare to generate a revenue of $5.8 billion by 2030. With rapidly changing market dynamics in the global healthcare market and advancing applications of 3D printing in healthcare domain, the market is projected to grow at a CAGR of around 20.9% until 2030.

While the healthcare industry only holds a 20% share of the global 3D printing market, it is clear that this technology is having a profound impact on how medical care is delivered. In particular, 3D printing is being used to create custom prosthetics and implants, as well as to produce models of organs and body parts for surgical planning. Additionally, 3D-printed pharmaceuticals are beginning to enter the market, offering patients personalized medication dosing based on their specific needs.

In particular, 3D printing is being used to create custom prosthetics and implants, as well as to produce models of organs and body parts for surgical planning. Additionally, 3D-printed pharmaceuticals are beginning to enter the market, offering patients personalized medication dosing based on their specific needs.

Medical implants and tissue engineering are booming industries that are seeing growing demand from patients all around the world. One reason for this increased demand is the advancement in 3D printing technology.

3D printing has revolutionized the manufacturing process for medical devices, and it is now more common than ever to find devices being printed using 3D printers. This is in part due to the fact that 3D printing is both cost-effective and accurate. Globally more than 30 million medical implants are done. Wherein, the US is the largest country and is holding higher market share. For instance, every year, the country witnesses over 1 million implants are being done for hip and knee replacement. On other hand more than 3 million dental implants taken place annually. This represents a huge opportunity and potential for 3D printing market for production of medical implants. As per SkyQuest analysis, the global market is flooded with at least 2 million types of medical devices, which is significantly huge.

On other hand more than 3 million dental implants taken place annually. This represents a huge opportunity and potential for 3D printing market for production of medical implants. As per SkyQuest analysis, the global market is flooded with at least 2 million types of medical devices, which is significantly huge.

In addition to medical devices, 3D printing is also being used to create tissues and organs for medical use. These tissues and organs can help to improve the quality of life for patients who have lost their own tissue or organ due to injury or disease. From the last few years, the global 3D printing market has been witnessing a significant surge in the demand for cosmetic and plastic surgeries. For instance, in 2021, more than 1.4 million surgical and non-surgical procedures were performed and this number is expected to grow at a CAGR of over 15.8% in the years come. As the number of procedures increases, it offers lucrative opportunity for the market participants since the demand for customized tissue is getting huge attention.

SkyQuest Technology has identified underlying market opportunities in the global 3D printing market by application and prepared report that answers how the market is advancing, where the demand is coming from, what are the market trends, which country and region has the most potential consumers, what are the government policies, and how end-users are responding in the market. The report also focuses on number of players active in the market, their market share, competitive landscape, and growth strategies. This comprehensive report would help you in identifying the most potential growth opportunities that the competitors have missed and provide deeper insights on how the market is performing across the globe. To get a detailed market analysis,

Browse summary of the report and Complete Table of Contents (ToC):

https://skyquestt.com/report/3d-printing-market

Recent Developments in 3D Printing Market

- Researchers at Rutgers University and the University of Louisville have developed a Fused Filament Fabrication (FFF) system that’s capable of using multiple nozzles to rapidly 3D print different areas of the same part on a single gantry.

The 3D printer is double the speed of standard FFF

The 3D printer is double the speed of standard FFF - In July 2022, a state of art 3D printing facilities is opened at Bengaluru, India

- In March 2022, The Department of Science and Innovation (DSI) of South Africa started a pilot project to use 3D printing technology to construct about 25 homes in an effort to address the housing shortage there.

- In March 2022, The INDUSTRY F421 industrial FFF machine was introduced by 3DGence, a European company, and is suitable for high performance materials. The company has also released AS9100, a brand-new high-temperature filament that is approved for use in the aerospace and defense industries and produced using polyether ether ketone (PEEK).

- In February 2022, Imaginarium partnered with Ultimaker to introduce desktop & industrial 3D printer range in the India market. In India, where additive manufacturing is anticipated to make significant strides in the following years, this alliance will aid Ultimaker in growing its operations there.

- In May 2021, GE Additive partnered with Protolabs and fashion designer Zac Posen to construct four gowns and a headdress for showing at the Met Gala. Electron-beam melting (EBM), Multi Jet Fusion (MJF), and stereolithography (SLA) technology were used across the items to fulfil the design requirements of wearable clothes.

Top Players in Global 3D Printing Market

- 3D Systems Corporation (US)

- The ExOne Company (Germany)

- voxeljet AG (Germany)

- Materialise NV (Belgium)

- Made in Space, Inc. (US)

- Envisiontec, Inc. (Germany)

- Stratasys Ltd. (US)

- HP, Inc. (US)

- General Electric Company (GE Additive) (US)

- Autodesk Inc. (US)

Speak to Analyst for your custom requirements:

https://skyquestt.com/speak-with-analyst/3d-printing-market

Related Reports in SkyQuest’s Library:

Global Smart Water Metering Market

Global IOT Connected Machines Market

Global Volumetric Video Market

Global Network Attached Storage Market

Global Crypto Wallet Market

About Us:

SkyQuest Technology is leading growth consulting firm providing market intelligence, commercialization and technology services. It has 450+ happy clients globally.

It has 450+ happy clients globally.

Address:

1 Apache Way, Westford, Massachusetts 01886

Phone:

USA (+1) 617-230-0741

Email: [email protected]

LinkedIn Facebook Twitter

Tags

Global 3D printing Market Global 3D printing Industry 3D printing Market size 3D printing Market growth 3D printingAre 3D Printers Getting Cheaper? The Facts Explained – Printing It 3D

Technology, in general, has become more advanced, more accessible, and more affordable. And that’s never been more apparent than with 3D printers, which can be found in homes all over the world. But are they really getting cheaper?

And that’s never been more apparent than with 3D printers, which can be found in homes all over the world. But are they really getting cheaper?

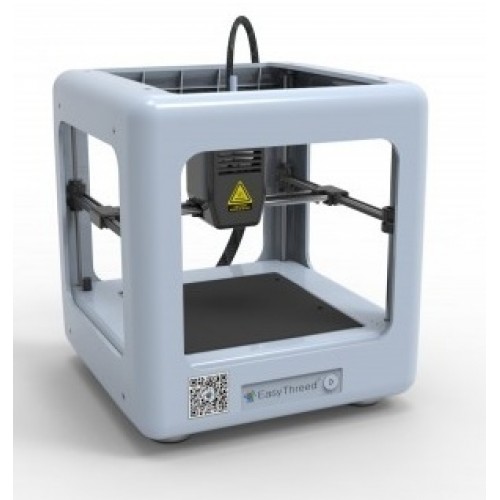

3D printers are getting cheaper, as are their components, and they will continue to decrease in price in the next few years. It used to cost around $2,000 to purchase a 3D printer, but now they can be as cheap as $100. Even mid-range 3D printers cost as low as a few hundred dollars.

This article will delve into the how and why of the price decrease of 3D printers, and hopefully, by the end, it will explain the trends in other areas of the technological field.

Factors That Make 3D Printers Expensive

There are several reasons why 3D printing is considered one of the more expensive hobbies and a costly and complex industry process.

For example, printing materials can be costly, not to mention it’s still a somewhat niche hobby.

So, let’s take a closer look at the costs involved in 3D printing.

Printing Materials

The main reason 3D printing is expensive is its material to print.

Filaments – such as metal, glass, plastic, and resin – are expensive at a lower grade “hobby” level but even more pricey at a higher grade of commercial production. This is mainly because these materials require extra processing before being used for production.

Additives Used To Strengthen Printing Materials

Additives contribute considerably to the quality and stability of printing materials.

These additives include but aren’t limited to:

- Dyes

- Flame retardants

- Antioxidizing agents

- Stabilizers

- Plasticizers

Processing and Packaging of Materials

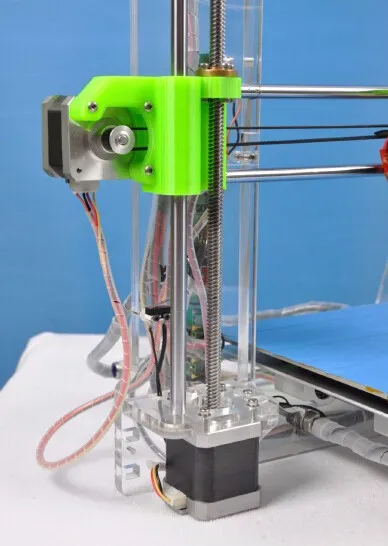

Processing 3D printing materials isn’t expensive, but the processing takes specialized pieces of equipment that cost quite a fair sum of money.

These pieces of tech are used for the process of extrusion, which is completed not in bulk but in individual threads (spooling).

This increases packaging and shipping costs considerably.

The Size of the Market

3D printing is growing in popularity, but it’s still a relatively niche market.

Increased demand means increased supply, which means lower cost – so the more popular the industry becomes, the cheaper it will become to participate in.

However, there’s still a long way to go until 3D printing is a commonplace artform accessible to everyone.

Why 3D Printing Is Getting Cheaper

Funnily enough, all of the reasons why 3D printing is expensive in the first place are also why it’s getting cheaper.

New Filaments

New filaments are being produced for less, and interfaces are becoming more accessible and intuitive, allowing even beginner artists to print full models.

Not only are materials and filaments getting cheaper, but they are also becoming more environmentally friendly. This is down to a move towards turning recycled plastics into filament rather than making new high-density filaments.

3D Printing Is Becoming More Commonplace

3D printers are increasingly being used for commonplace purposes like phone cases and figurines.

The initial cost of buying a printer can be considerable, but printing your own chess set can cost as little as a single spool of PLA, which is as low as $20.

Further to this, 3D printers are being used for more technical purposes like bone replacements and cosmetic dentistry.

It also becomes cheaper to 3D print your own printer parts than to buy them!

Why the Price of Tech as a Whole Is Dropping

You can’t remove 3D printing from the world of tech since almost every aspect involves software and hardware.

For example, you can’t print without slicer software, and you can’t build a model without the proper nozzles.

So, as software becomes more advanced, as will printing. Similarly, as more and more companies offer the hardware needed for 3D prints, it’s becoming cheaper to buy spare parts.

Less Innovation, More Choices

When tech, especially handheld tech, was still in its infancy, breakthroughs were made every other year.

In 2022, we already have a steady stream of smartphones, medical equipment, desktop computers, and every other piece of technology we can think of – but it isn’t changing much. In fact, the only significant advancements being made are in particular industries, such as Artificial Intelligence.

Consumer items are cheaper than ever before, and there is no sign of this changing as industry giants continue to lower prices for the average person to afford.

Additionally, whereas a select few companies specialized in marketing tech to the masses in the past, ordinary people are now spoiled for choice. Therefore, the industries must make their prices as attractive as possible to compete.

In a globalizing world, trade between nations is also becoming more common and even expected; thus, import and export costs are lowering, and international competition contributes to reducing prices.

Moore’s Law

Moore’s Law states that the number of resistors on a microchip or dense integrated circuit doubles every two years. Since the idea was conceived, the multiplication period has gone from two years to 18 months.

Since the idea was conceived, the multiplication period has gone from two years to 18 months.

However, this decline in the multiplication period isn’t exponential anymore as our technology and its designs grow in complexity.

The fact is that chips are getting smaller, tech is shrinking in size, and smaller tech is cheaper tech. Although this won’t be the case forever, for now, we can rest assured Moore’s Law is working in favor of the consumer.

Cheaper, More Sustainable Manufacturing

As stated before, the more something is produced, the cheaper, more efficient, and more sustainable it is to create moving forward.

As we produce technology on a larger scale, we rely more heavily on programming machines to labor in our place – these are more precise, so there is no need to factor in the cost of errors and material waste.

As a result, we also cut costs on paying workers and save valuable production time.

Conclusion

3D printing is still a niche art form and means of production, at least for the average consumer.

It is getting cheaper, that much is for sure, but 3D printers are not a wholly household item yet. There’s still a long way to go before this piece of tech is readily available to the public for a reasonable and affordable price.

Regardless of the industry’s current state, there is a comfort to be had in knowing that, albeit slowly, we are well on the way to making 3D printing an accessible means of production.

3D printing market. Is it time to buy shares? / Habr

In this article I would like to talk about companies, each of which is a "unicorn". Shares of two of the three can already be bought on the New York Stock Exchange. There is a pattern: they were all born in the large Boston metropolitan area. And if Silicon Valley is a Mecca for software startups, then Boston, and especially the Massachusetts Institute of Technology (MIT), is the Medina for manufacturing innovation.

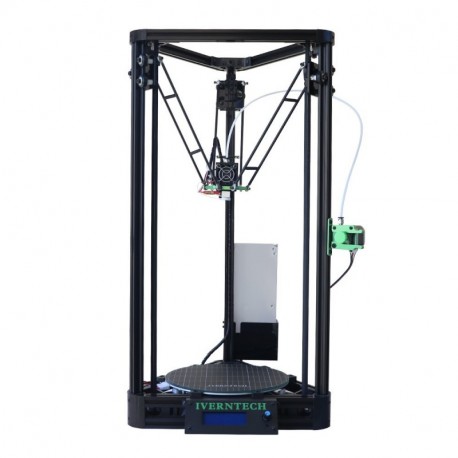

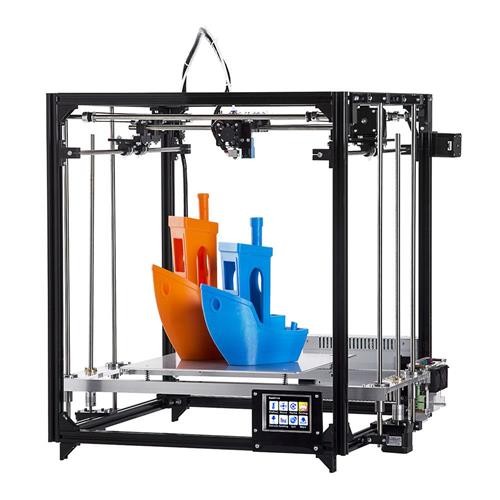

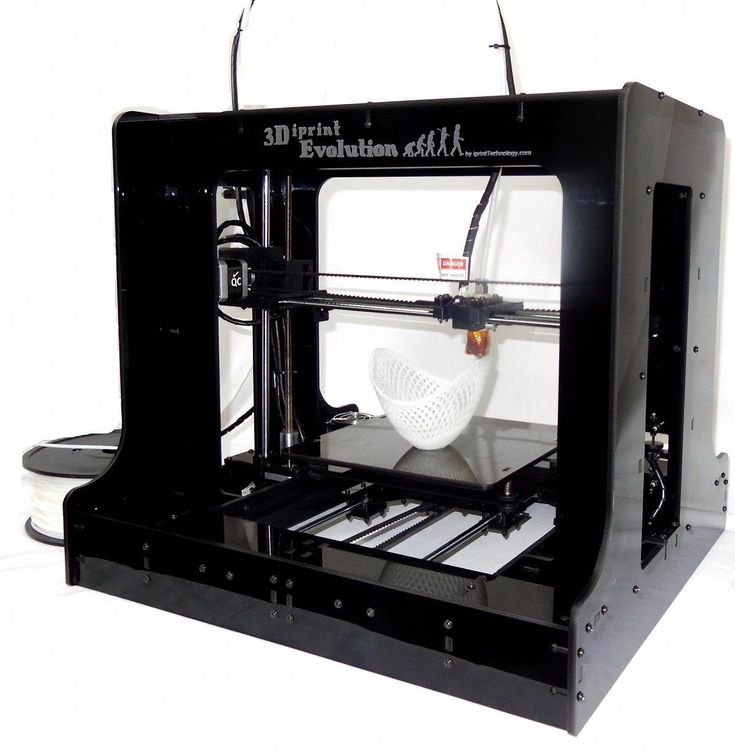

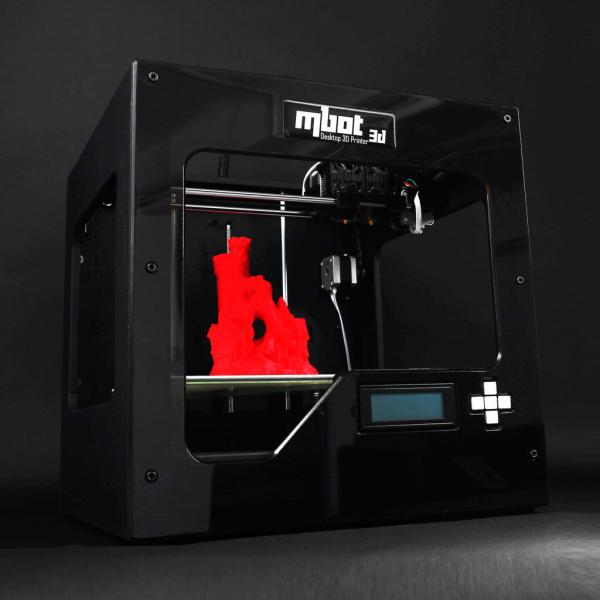

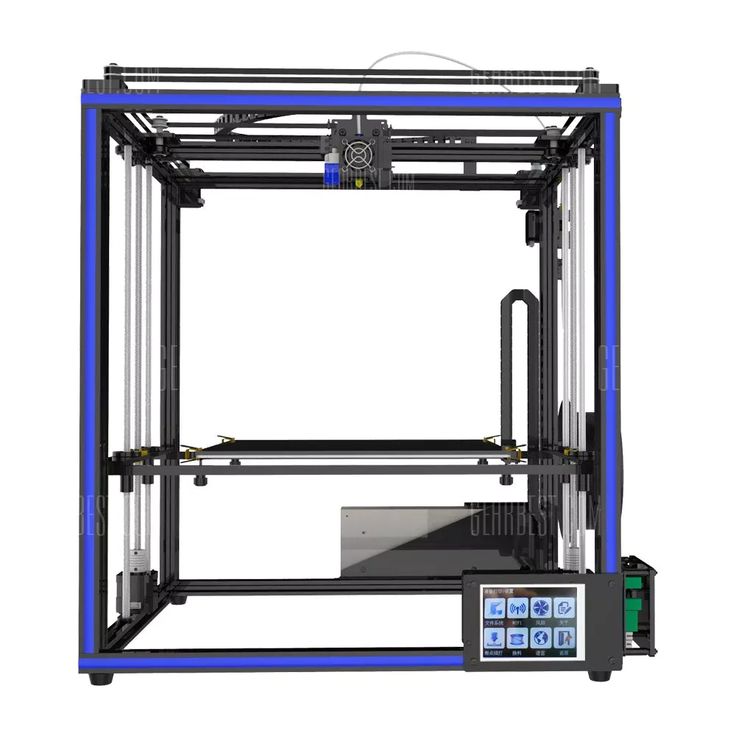

I'll make it clear right away: I won't analyze the entire 3D printing market, but will focus on some of the most notable representatives of the desktop 3D printing segment. But even here everything is very conditional, since in the process of improving technology, products smoothly flow from one category to another, and roughly three main categories can be distinguished: desktop, professional and industrial. So…

But even here everything is very conditional, since in the process of improving technology, products smoothly flow from one category to another, and roughly three main categories can be distinguished: desktop, professional and industrial. So…

In 2011, three American students founded Formlabs in their garage. It was headed by Max Lobowski. Born into a family of engineers - emigrants from Ukraine, from his youth he was interested in robotics and new technologies, attended various specialized additional classes in high school. After earning a bachelor's degree from Cornell University, he went on to graduate school at MIT, where he began designing his desktop 3D printer, which is both powerful and affordable.

Max Lobowski The friends were able to quickly get an angel investment, with which they launched their first product, the Formlabs Form 1 printer, in 2013. On the Kickstarter crowdfunding platform, they managed to raise almost $ 3 million from more than 2,000 bakers from around the world, who were excited about the new product, which promised to make 3D printing accessible to almost everyone. At that time, there were models of printers on the market using the technology of illumination with a laser beam of photopolymer resin (SLA) with a price of 100 thousand dollars, Formlabs offered a printer for 1500 dollars. The company, of course, faced a lot of difficulties in the production of the first batch, but it managed to ship the printers to all buyers. And even though they were far from perfect, this made it possible to attract round A investments in the amount of 19million dollars and return the "angel" money.

At that time, there were models of printers on the market using the technology of illumination with a laser beam of photopolymer resin (SLA) with a price of 100 thousand dollars, Formlabs offered a printer for 1500 dollars. The company, of course, faced a lot of difficulties in the production of the first batch, but it managed to ship the printers to all buyers. And even though they were far from perfect, this made it possible to attract round A investments in the amount of 19million dollars and return the "angel" money.

The company then continued to improve its product and create an ecosystem like Apple, which includes 3D printers themselves, consumables (resins for various tasks), software for preparing models for printing, and post-processing equipment. In 2019, the company's turnover reached $100 million, in May 2021 it received $150 million in a round of E from the SoftBank Investment Advisers fund, valuing the company at $2 billion. After that, there was talk of an IPO, which would be an absolutely logical step, since investment funds are planning this in the future for 7-10 years, and this period has already come for investors of the first round.

However, despite high market expectations, Max Lobowski said in an interview with BizJournals that he is in no rush to go public: “We would rather take our time and better prepare to be a great public company… We make more money than all 3D -companies taken together that have gone public with the help of SPAC (a procedure that allows startups to go public by merging with another private company). However, when I look at really large, successful, long-term public projects, which is what we are aiming for, I see that they are on a completely different level in terms of predictability and profitability than we are.” These are serious words, and apparently the head of the company has reason to pronounce them. Most likely, the forecast of the company's capitalization in the region of 4-6 billion dollars with a successful initial offering, which will make it the largest company in the market, because even the result of the veteran and long-term market leader - 3DSystems as of August 2021 is no more than 3. 5 billion. dollars.

5 billion. dollars.

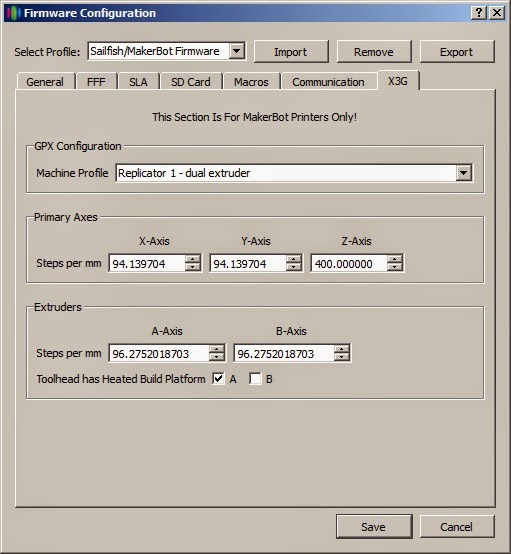

Unlike the students at Formlabs, Markforged was founded by older guys. However, even here it was not without MIT. MIT alumnus Mark Greg encountered 3D printing while his company was doing a job for the US Navy. Experiments in the field of improving the quality of products led him to the idea of creating a printer that could reinforce the printed model with carbon fiber to make it strong and suitable for use under load.

Employees of the company together with the Metal X printer, Mark Greg is seated to the right of the printer. The company was founded in 2013, and already in 2014 at the Solidworks World exhibition, the startup presented its first product - the Mark One printer, which had two extruders and could reinforce the printed model with nylon, fiberglass and even Kevlar. Later, The Digital Forge, a cloud-based print management platform, was introduced, and already in 2017, MarkForged announced the release of a Metal X desktop metal 3D printer worth $100,000, while competitors' counterparts cost a million. In 2020, the company's turnover amounted to $ 70 million, and the management decided to bring the company to an IPO using SPAC. The company introduced the concept of additive manufacturing 2.0 to potential investors, allowing the production of finished products rather than prototypes, paving the way for 3D printing to the production of goods. The volume of this market is estimated by experts at 13 trillion dollars.

In 2020, the company's turnover amounted to $ 70 million, and the management decided to bring the company to an IPO using SPAC. The company introduced the concept of additive manufacturing 2.0 to potential investors, allowing the production of finished products rather than prototypes, paving the way for 3D printing to the production of goods. The volume of this market is estimated by experts at 13 trillion dollars.

Based on the Wholers Report, in 2020 the company predicted the growth of the additive technologies market at an average rate of 27%, which means that in the next 8 years from the current 18 billion dollars, the market will grow to 118 billion in 2029 from 10 multiple growth of own revenue up to 700 million dollars already in 2025.

On July 15, 2021, MarkForged was listed on the New York Stock Exchange under the ticker MKFG. The placement was estimated at 2 billion dollars, but a month later the shares lost a little in price, and the current capitalization is about 1. 5 billion dollars. The question remains: is it worth buying shares of a company that plans to be unprofitable for at least another 2 years (the company predicts a turnover of about $100 million this year).

5 billion dollars. The question remains: is it worth buying shares of a company that plans to be unprofitable for at least another 2 years (the company predicts a turnover of about $100 million this year).

On the one hand, there are enough companies on the market trading at even higher multiples, and on the other hand, 3D printing is not yet such a mature technology that one can be sure of the 100% success of exactly the concept that MarkForged offers. In fact, the company itself considers the emergence of new technologies as one of the risks that could undermine its current technological superiority. In general, investors are now positive about the future of 3D printing. They were impressed by how the technology performed in the first, most difficult months of the pandemic, when production chains were disrupted and many transport arteries stopped working. With the help of 3D printing, it was quickly possible to establish the production of urgently needed valves for ventilation, protective masks, adapters and much more. The concept of distributed production immediately turned from a beautiful idea into a real necessity. So, as always, the coin has two sides, but if you are interested in stocks with great potential, you should at least take a closer look at this company and the market of additive technologies in general.

The concept of distributed production immediately turned from a beautiful idea into a real necessity. So, as always, the coin has two sides, but if you are interested in stocks with great potential, you should at least take a closer look at this company and the market of additive technologies in general.

The last one in my story is DeskTop Metal. Formlabs was created by MIT students, Markforged - MIT graduates, DeskTop Metal was created by experienced entrepreneurs Rick Fulop and Johan Mayerberg, as well as 4 (!) MIT professors. Going to the goal, Rick Fulop founded 6 different companies, also headed an investment fund. Johan Maierberg has been a lead engineer for various companies and became the CTO of DeskTop Metal.

Rick Fulop in front of DeskTop Metal Studio System 9 printers0002 The company's goal was to create an affordable desktop 3D printer that prints metal models. The company immediately became a favorite among investors and attracted investment rounds with enviable constancy. Among her donors were BMW, Ford Motor, Stratasys (a pioneer in the creation of 3D printing technology), SaudiAramco investment fund, General Electric and others. The total valuation in the latest round reached $2.4 billion, with a paltry $26 million turnover in 2019. The funds received were used for R&D and attracting the best engineers and developers to the company. In 2017, a three-component metal printing system based on FDM layer-by-layer printing technology was introduced, followed by burning and baking the final model. The system was very "raw": a small amount of materials was available for printing, and the printing itself had a lot of restrictions, the final products looked rough with large dimensional errors. Nevertheless, the developments continued, and the company announced its potential star - the Production System, a high-speed metal printing system, which can hardly be called a desktop one. The company claims that its Single Pass Jetting technology is 100 times faster than any other existing metal 3D printing technology, but deliveries of printers should begin only at the end of this year, so in this case you have to take our word for it.

Among her donors were BMW, Ford Motor, Stratasys (a pioneer in the creation of 3D printing technology), SaudiAramco investment fund, General Electric and others. The total valuation in the latest round reached $2.4 billion, with a paltry $26 million turnover in 2019. The funds received were used for R&D and attracting the best engineers and developers to the company. In 2017, a three-component metal printing system based on FDM layer-by-layer printing technology was introduced, followed by burning and baking the final model. The system was very "raw": a small amount of materials was available for printing, and the printing itself had a lot of restrictions, the final products looked rough with large dimensional errors. Nevertheless, the developments continued, and the company announced its potential star - the Production System, a high-speed metal printing system, which can hardly be called a desktop one. The company claims that its Single Pass Jetting technology is 100 times faster than any other existing metal 3D printing technology, but deliveries of printers should begin only at the end of this year, so in this case you have to take our word for it.

The company entered the IPO on December 10, 2020 under the same SPAC scheme and in its presentation for potential investors outlined the following parameters: planned turnover in 2025 - 942 million dollars, reaching operating profit in 2023, and also indicated that , which plans to spend a significant portion of the proceeds on acquisitions of other 3D printing companies.

Capitalization on the New York Stock Exchange at the time of its IPO on December 10 was a fantastic $6 billion. During the placement, $580 million was raised and the company was assigned the laconic ticker DM. Already in February 2021, the shares rose even more, and the company's capitalization exceeded $8 billion. DM has said it will be the first company in 3D printing history to have a capitalization of over $10 billion. Having received huge funds at its disposal, already in January 2021, DM announced the first takeover deal: the German manufacturer of professional photopolymer 3D printers EnvisionTEC (founded in 2002 and is one of the oldest on the market) was bought for $ 300 million. For me, this choice was not obvious, it is difficult to find something in common between DM and EnvisionTEC and it will be difficult to achieve a significant synergistic effect from this transaction. EnvisionTEC has continued to operate under its own brand as a 100% subsidiary of DM and plans to release a number of new models for its key customers - dental clinics and jewelry companies. Also during this year, several small companies specializing in the production of materials and software were bought. DM expands its patent base due to this and gathers under its wing the best ideas and people. The most high-profile acquisition was the $575 million purchase announced in August of another public company, the American ExOne. Established in 2005 in Pittsburgh, it specializes in the production of industrial 3D printers for creating injection molds from sand and other materials. It is also noteworthy that she managed to commercialize a patent for this technology, issued by MIT back in 1993 year.

For me, this choice was not obvious, it is difficult to find something in common between DM and EnvisionTEC and it will be difficult to achieve a significant synergistic effect from this transaction. EnvisionTEC has continued to operate under its own brand as a 100% subsidiary of DM and plans to release a number of new models for its key customers - dental clinics and jewelry companies. Also during this year, several small companies specializing in the production of materials and software were bought. DM expands its patent base due to this and gathers under its wing the best ideas and people. The most high-profile acquisition was the $575 million purchase announced in August of another public company, the American ExOne. Established in 2005 in Pittsburgh, it specializes in the production of industrial 3D printers for creating injection molds from sand and other materials. It is also noteworthy that she managed to commercialize a patent for this technology, issued by MIT back in 1993 year. In this case, we can say that the product lines of DM and ExOne are closer to each other and they have already presented a joint portfolio based on the products of both companies, in which one product complements the other.

In this case, we can say that the product lines of DM and ExOne are closer to each other and they have already presented a joint portfolio based on the products of both companies, in which one product complements the other.

It would be logical to assume that DM stock skyrocketed after such high-profile acquisitions, but in reality the opposite happened. Since its peak in February, the shares have fallen 4 times and are now trading at $8 a share, and the capitalization is slightly over $2 billion. Apparently, the first euphoria of investors gave way to a more sober approach to the current results of the company. Perhaps this was influenced by the dissatisfaction of some ExOne shareholders, who considered the sale price of the company unfair and were preparing a class action lawsuit against management in order to block the deal.

Should I buy DM stock now that it has fallen so much, or wait for further decline? I would say that their current level is very comfortable for entry, but, of course, such investments also have a certain risk. This is despite the fact that the company has reported strong first half results, which DM expects to generate over $100 million in revenue this year.

This is despite the fact that the company has reported strong first half results, which DM expects to generate over $100 million in revenue this year.

Summing up, I would like to say that a number of stock analysts consider what is happening in the market of additive technologies to be a "renaissance". The market came into motion after the pandemic, which gave everyone hope that the technology was ripe for serious tasks, and that the situation in the industry of 2013-2014 would not repeat itself. Then the technique was still very "raw", but attracted a lot of attention from the press and potential investors. This drove the stocks of market leaders 3DSystems and Stratasys to unknown heights, and then, when there was disappointment in the results of their work, the fall reached 20 times from peak values. Startups bought in batches, not really understanding what to do with them later. Most of these deals only made it harder for companies to focus on their core business. I would like to hope that history will be a good lesson for the new giants of the industry. There have already been a number of IPO exits by companies from the 3D printing industry through SPAC this year, with several more large listings planned for the end of the year. And, if you are interested in this sector, stay tuned.

There have already been a number of IPO exits by companies from the 3D printing industry through SPAC this year, with several more large listings planned for the end of the year. And, if you are interested in this sector, stay tuned.

Alexander Kornveits

Expert in the field of additive technologies and 3D equipment, founder and head of Tsvetnoy Mir

Why mass 3D printing has not yet become a trend

Photo: asharkyu / Shutterstock McGrath / Getty Images

The production of products with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When there was an acute shortage of personal protective equipment (PPE) for doctors, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization challenges

Since 2012, Nike and Adidas have been experimenting with 3D printing in the production of sneakers. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020 these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay many times more for customized sneakers when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production.”

Denis Alekseev, Head of Development and Production at ROBBO JSC (educational robotics, Skolkovo resident), is confident that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

The cost of individual products may be higher, but this increase must be of value to the customer.

Major disadvantages of 3D printing:

-

low production rate;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs who will find the answer to the question: who will buy them will be able to develop the production of personalized goods? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand.