Concrete 3d printer for sale

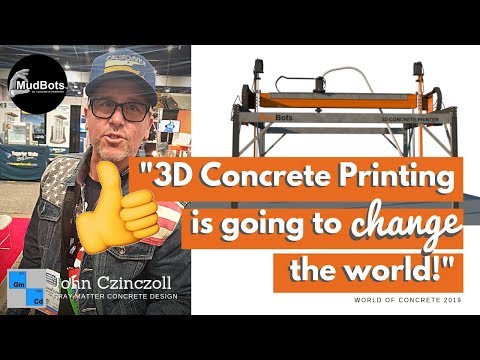

MudBots 3D Concrete Printers - Print a House

Our printers come in a variety of sizes, from smaller 15'x15' up to 100'x50'

Shop Printers

Want to see how much you will save when 3D Printing a home versus traditional building? Check out our cost calculator.

Cost Calculator

Marketable Designs

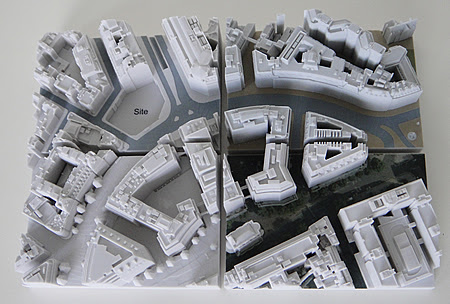

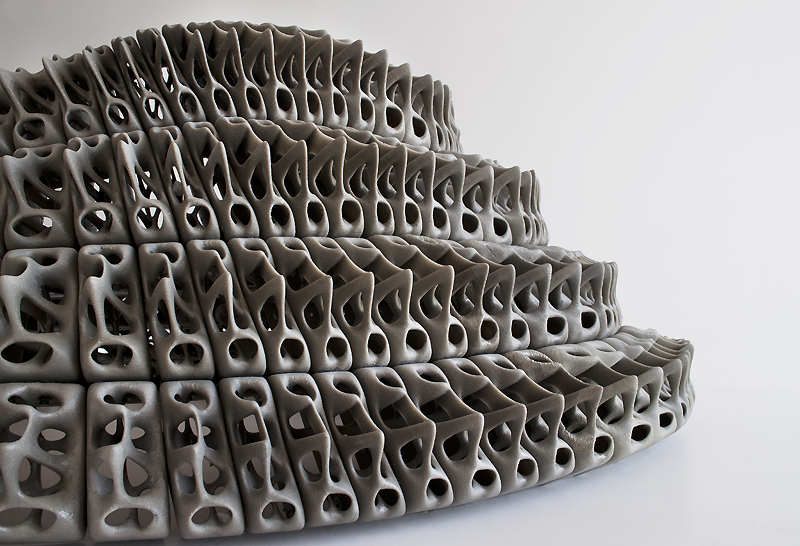

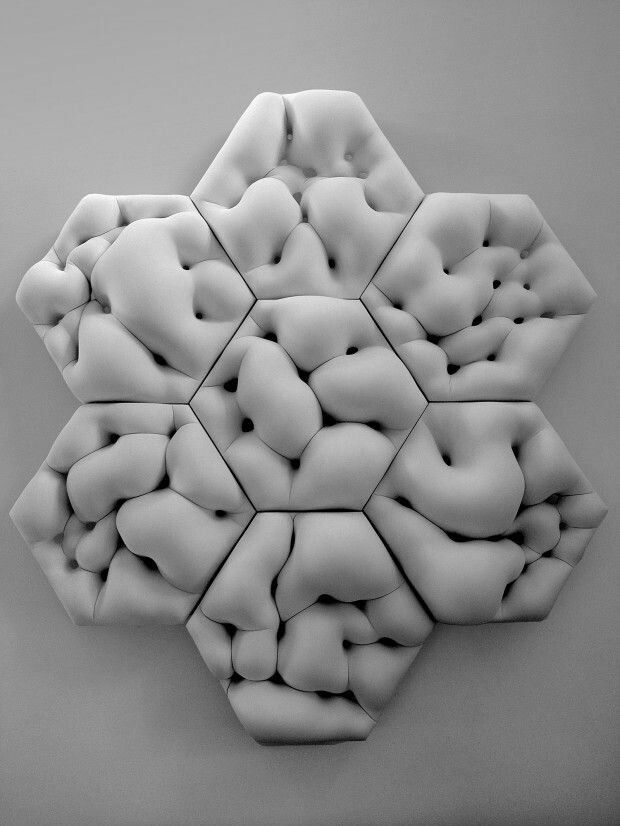

We’ve been told that if the printer wasn’t any faster and wasn’t any cheaper to build with, it would still be the most significant tool ever, because it allows architects everywhere to begin offering designs that were cost prohibitive in the past.

Consumers are tired of the costs associated with conceptual designs. Traditional construction is limiting without astronomical costs. Architects have the ideas, but most consumers aren’t willing to pay for them. With a printer the cost between boring and amazing is the same.

Industries

Want to build one? Call us.

3D Print Walls

Want to build one? Call us.

3D Print Fireplace

Want to build one? Call us.

3D Print Monument Letters

Want to build one? Call us.

3D Print Benches

Want to build one? Call us.

3D Print Fences and Walls

Want to build one? Call us.

3D Print Signs

Want to build one? Call us.

3D Print Monuments

Want to build one? Call us.

3D Print Fountains

Want to build one? Call us.

3D Print Retainer Blocks

Want to build one? Call us.

3d Print Monument and Waterfalls

Want to build one? Call us.

3D Print Planters

Want to build one? Call us.

3D Print Sheds

Want to build one? Call us.

3D Print Monument Boulders

Want to build one? Call us.

3D Print Drainage

Want to build one? Call us.

No More Forming

Want to build one? Call us.

3D Print Stairs

How It Works

1

Concrete printing is possible with the construction of a large 3D printer capable of printing large scale structures, from spas and barbeques to homes and larger commercial buildings, without the need of traditional framing, forming or blocks. MudBots offers printers from 15' x 15' up to 100' x 100'.

2

There are hundreds of different mix formulas that closely resemble a mortar type mix. Each mix requires months of testing for different characteristics, such as fluidity, bonding, water impenetrability, Seismic resistance, as well as curing and strength. Mixes are designed for 1200 PSI up to 10,000 PSI, depending on the structure and engineered objectives.

3

First step is to decide what you want to print.

4

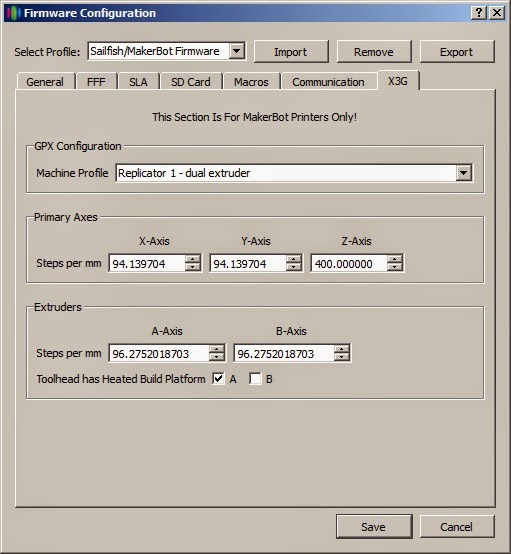

The next step is to conceptualize a 2D design using a CAD program, and then converting the design to a 3D model using any 3D software that can export an STL file.

5

Once the 3D model is ready, the STL file is imported into a slicing software, where the height of each printed pass is specified.

After slicing the model into individual print passes, the system exports the code which is interpreted into actual nozzle movement.

6

Electrical boxes and plumbing are added during the print leaving perfect finish without gaps.

7

The mix is batched on site after which, the liquid ingredients are added to the dry mixes and mixed for delivery to a computer-controlled pump, which works in unison with the printer to control nozzle speed, and the volume rate of material at the nozzle.

8

After printing the walls, windows and doors are cut out while the print is still green, leaving perfect openings for window/door casings.

9

The key to printing without stopping every 12" as seen by the rest of the world, is utilizing a batch plant that meters all the dry and liquid ingredients as the temperature, wind and humidity change. the mix formula being used at 5am is not the mix being used an hour later. MudBots provides a variety of mix formulas with differing strengths and cure times without being forced to buy proprietary mixes and paying 5 times as much when everything needed is already available at local batch plants.

the mix formula being used at 5am is not the mix being used an hour later. MudBots provides a variety of mix formulas with differing strengths and cure times without being forced to buy proprietary mixes and paying 5 times as much when everything needed is already available at local batch plants.

Process

Step 1

Three men assembly in 3 hours without any lifting devices or need for heavy footings

Step 2

Print layout for footings with spray nozzle attachment

Step 3

Move printer for escavators in just 10 minutes

Step 4

Print forms for footings and flatwork

Step 5

Print walls up to 10' without stopping

Step 6

Add electrical boxes, rebar, and trowel walls while printing

Understanding What We Do & Don't Do

Here's how you can save.

Layout for Footings Dig

The first cost savings will be the elimination of 3 men, string lines, and marking paint. Simply add the airless attachment to the nozzle of the printer, and your entire layout for footing is done in minutes. Push the printer out of the way and start digging.

Simply add the airless attachment to the nozzle of the printer, and your entire layout for footing is done in minutes. Push the printer out of the way and start digging.

(The printer is able to print forms for footings)

Footing Forming

The layout and forming for footings and stem walls are very time-consuming. It takes a lot of lumber, diesel, stakes, and labor that is no longer necessary. Simply level the area, compact them, level the four corners of your printer, and PRINT.

(Forms do not need to be stripped when printed)

Footing Stripping

Perfect level and square forms are printed right from the computer. Grading is also easier, as the only real important level is the 4 corners of the printer. Printer can be set up for uneven grades.

(The printer can print the forms for slab)

Slab Forming

The slab layout and forming is critical to all other subs on the job. If a mistake is made at this point of the project, nothing else is square, and all other subs suffer. With the Concrete Printers, the house is square every time.

If a mistake is made at this point of the project, nothing else is square, and all other subs suffer. With the Concrete Printers, the house is square every time.

Slab Finishing

Not there yet, but our concrete printer will be finishing slabs within the next 6 to 12 months, and can be ordered as an option. If you’re waiting for all the options to be available before buying, you’ll never buy a printer, because we will never stop innovating. All upgrades will be available and are designed to be added to all of our printers.

(We can print basements)

Basements

Our printers easily print basement walls without the need of forming, backfilling, stripping forms, forming interior walls, drywall, insulation or taping. All of this is done by the printer.

(There is no need for the labor or time to do layout on slab)

Framing Layout

The printer knows where your wall is going to be. No chalk lines needed. Once the slab is poured, all you have to do is hit print.

No chalk lines needed. Once the slab is poured, all you have to do is hit print.

(No need for framing)

Framing

No warped studs, better fire rating, no mildew. No matter how you look at it, printing a home is far better than framing a home. Concrete printing is faster, more accurate, just better all around.

(No need to drill studs for electrical)

Rough Electrical

This is not necessary as walls can be printed that are hollow. Depending on the mix that is used, there is also no need for rebar or solid pour exterior and bearing walls. We know the idea of exterior walls and bearing walls without rebar seems ridiculous, but it's time to learn something new. Look up 20,000 PSI concrete and geopolymer. It's real.

(No need to drill studs for plumbing)

Rough Plumbing

This isn’t necessary as walls can be printed hollow. Same as above. Your electrical and plumbing will be less expensive.

Same as above. Your electrical and plumbing will be less expensive.

(Printed walls are finished without additive material during the print)

Drywall

You will still need to hang the lid, but not the walls. This goes for the basement. Just trowel the printed wall and when done, it's as smooth as a 3-coat drywall. Most countries do not wood frame at all. They build with bricks and then send a crew of mason finishers, and when it’s done, it’s smooth as anything.

(No need for taping as the walls are troweled smooth during printing)

Taping

Some print finishes may not need to be finished if acceptable to the customer. Taping takes days for each coat to dry. This is not the case with mason finishing. Within 3 hours of the walls being printed, the walls are already finished.

Finishes

If builders want to finish the smooth walls with a knock down broquet, orange peel or other finish, just come back the next day and spray with a hopper, top coat and trowel.

(Exterior walls are finished during the print)

Stucco / Siding

No paper, mesh or additive material is needed. This isn't a process that is done days after framing and sheeting. The finish is done real time as the wall is printing.

(Printers can be purchased with an insulation attatchment)

Insulation

You can have any R Factor you want depending on the density and material. A solid concrete wall has an R9 Value. If you print a hollow wall and back fill with fiberglass, polystyrene or cellulose, you can achieve any R value you desire.

(Mudbots is working on a composite truss system that can be printed on site)

Trusses

Additionally, house plans can be modified to allow for dome roofing, which can also eliminate trussing and sheeting costs. The truss system utilizes the same printer, but with the use of a different mixer/pumping system. As new advances become available, they will be bolt-on solutions with your existing printer.

As new advances become available, they will be bolt-on solutions with your existing printer.

Underground

More and more customers are starting to experiment with additional uses. Underground is definitely something worth considering. The cost is high for underground but can be significantly reduced by printing on site.

Landscape and Hardscape

The 3D Concrete Printer is a landscaper’s dream. Never before could you have offered products at a fraction the cost of your competition while still earning profits. It is basically unheard of. Developers will rethink their offerings when they realize how affordable the little extras are. The extras will set them apart from all the others.

Pool and Spa

By now, you may be realizing how significantly concrete printing is about to change so many industries. Pool and spa is just another market that will benefit. The cost for traditional pool construction is about to change. Homes can be sold with included water features at a fractional cost.

Homes can be sold with included water features at a fractional cost.

Signage

Very seldom do we see breathtaking signage. Everyone is looking for ways to stand out, but it keeps getting back to budgets. Imagine the development entries that are possible now. These printers like to print and with everything they can do, it would be foolish to have any down time.

Registration is required to access our Cost Calculators. We provide online tools for calculating the cost for mix formulas and “side by side” project costs comparisons using 3D technology.

Apples Comparison Test New

Complete the worksheet to have a better idea of where you will save in terms of Materials and Labor.

Bag Cost

Use this worksheet to determine the Cubic Inch Cost of the ingredients that will be used in the specialty mix for printing.

Mix Formula

This is a necessary first step to determine the material cost of any mix formula.

3D Printing Costs

Use this calculator to estimate costs to build using concrete printing over traditional construction methods.

Will It Pass Code?

First time callers don’t have any problem recognizing that concrete printing would be far faster and cheaper. They also don’t question the feasibility of learning the tech. The single most asked question relates to passing code. No fear of the tech, just fear of their building department.

Truth is concrete printers are already building homes and commercial buildings all around the world, so when considering the application in your backyard, here are a few things to consider.

ICF Construction

The best way to wrap your head around concrete printing is to start with the basics, and there is no better way than to liken 3D Concrete Printing, or 3DCP, to Insulated Concrete Block construction. ICF code is accepted everywhere yet a foam block has virtually no structural strength at all. So when you are considering how you would pass code, keep ICF in mind. For the most part, a concrete printer is doing nothing more than printing a hollow wall shell that can be filled with rebar and concrete. The only difference is foam has no strength at all, compared to what we print in most cases, which is twice the strength of cinderblock.

ICF code is accepted everywhere yet a foam block has virtually no structural strength at all. So when you are considering how you would pass code, keep ICF in mind. For the most part, a concrete printer is doing nothing more than printing a hollow wall shell that can be filled with rebar and concrete. The only difference is foam has no strength at all, compared to what we print in most cases, which is twice the strength of cinderblock.

CMU Construction

Now with that in mind, let's look at the similarities with CMU (Cinderblock). No one questions the ability to build with cinderblock. While we don’t encourage it, take into consideration the fact that you can print walls that are the exact dimension and design as cinderblock yet twice as much the strength, and without grouted joints that are susceptible to seismic cracking.

The advantage of concrete printing is the ability to print hollow walls which reduced costs for electrical, plumbing and insulation. Additionally, hollow walls can be insulated to almost an R factor with ease with the absence obstructive studs.

Additionally, hollow walls can be insulated to almost an R factor with ease with the absence obstructive studs.

The challenge isn’t whether or not it's possible, as it's already being done everywhere. The challenge is whether or not you can find a structural engineer that makes it possible. It's all about math. The code already exists, all you have to do is exceed the code, and to do that, you need to start with the mix.

Testing and Math

We have developed and tested a myriad of different mixes with different characteristics, such as PSI, tensile strength, water impenetrability, fire resistance, as well as cold weather mixes, hot weather mixes, accelerated mixes, and retarded mixes. We provide the formulas and the lab results that your engineer will need to determine what the wall designs will be. Once they have the testing results, they can design a wall that exceeds any code anywhere.

Some choose to stay close to traditional methods by printing walls that resemble ICF and CMU, but others, who have more confidence, take it all the way by utilizing stronger mixes, so that they can capitalize on ALL the cost-saving benefits.

Plans and Details

As for the other considerations, we have plenty of videos that address common questions about headers, attaching hurricane straps, installing electrical boxes, securing plumbing, mounting top plates for trussing and methods for tying the wall to the foundation. Although, most engineers want to see the methods being used by others first before reinventing the wheel, as they learn more and more until there isn’t a question that they can’t offer up to 4 or 5 solutions when asked. Most of this is common sense, nevertheless, we have the plan details and math to share.

As we’re saying this, bear in mind that every state, and sometimes even cities, have different building codes. What we will share is determined by specific code and conditions that are not specific to your state. Far too many factors come into play, such as mix characteristics, code, water table, frost level, annual snow loads, wind, seismic, soil compaction for starters. We do not provide structural engineering, but we can point you in the right direction.

We do not provide structural engineering, but we can point you in the right direction.

Deal Breakers?

Everyone who is considering the use of concrete printing has a lot of work to do before they can commit to a purchase. There is no shortcut. The investment of time is inevitable. As you start down the path to making a decision, it’s easy to get confused as to what’s most important, and where you should spend your time, but as you consider the options presented to you, there will be some paths that obviously are a waste of time. Everyone needs to know what their deal breakers are. They will be different for each person, but from speaking with others, we have a pretty good idea of what most consider their deal breakers.

Design

From the onset, our engineers understood the importance of creating a design that had all the same features but was also easily understood. A printer that is lightweight and easily assembled in the field. MudBots printers weigh 75% less than any printers in the industry, with an assembly time that is 80% faster. This is a printer that does it all, does it faster, and is half the price of anyone.

MudBots printers weigh 75% less than any printers in the industry, with an assembly time that is 80% faster. This is a printer that does it all, does it faster, and is half the price of anyone.

Basements and Second Story

In some parts of the world, the ability to print basements and a second story isn’t a big deal, but in North America, it’s essential. Look around and you will find that most printers in this marketplace don’t have the ability to do either without tremendous unnecessary excavation or back filling. If you’re going to invest in a printer, most agree that the ability to quickly set up for footings, basements and second story is a must.

Assembly

Look at any other printer and you will recognize right off that assembly is going to be an expensive challenge. Imagine the worst IKEA assembly ever. That’s about what you get. Think about parts that are heavy to manage without forklifts and cranes, imagine hundreds of nuts and bolts. In some cases, needles cosmetic plastics that serve no function, waste hours of assembly, and will undoubtedly be broken and expensive to replace. Most printer designs make sense to the engineers that built them, but not so much to the contractors that will need to assemble it in the field. A 20' x 20' MudBots printer can be assembled with 2 workers in two hours without any mechanical lifting. MudBots can also be moved from one lot to another without disassembly by simply adding wheels. Additionally, the printer can print entire structures without being moved multiple times.

In some cases, needles cosmetic plastics that serve no function, waste hours of assembly, and will undoubtedly be broken and expensive to replace. Most printer designs make sense to the engineers that built them, but not so much to the contractors that will need to assemble it in the field. A 20' x 20' MudBots printer can be assembled with 2 workers in two hours without any mechanical lifting. MudBots can also be moved from one lot to another without disassembly by simply adding wheels. Additionally, the printer can print entire structures without being moved multiple times.

Proprietary Mixes

If you think your printer cartridges are expensive, wait until you have to buy and ship proprietary concrete mixes from halfway around the world or even the USA. MudBots is the only ones that provide the mix formulas for your printer and allow you to use any mix without voiding your warranty. This should be a deal breaker for everyone as they begin to realize what they will be paying for are mixes that are (mostly) available at their local hardware store, not to mention the cost of and any delay in shipping.

Customer Service

Does it feel like the others are sleeping on the job? There is far more to consider when thinking who to buy from than a few online videos and website. This is a significant purchase for most, but as you're out knocking on doors, the one thing you should consider the most is customer service. Start calling around and you’ll discover that there’s no one to talk to. Phone numbers are hidden, and emails go unanswered for weeks. You have to ask yourself, if no one will talk to you now when you have the money on hand, what’s it going to be like when you need support.

Price

If you’ve been lucky enough to get this far with anyone, the first thing you will find is that MudBots isn’t just a little better in price. MudBots is 1/2 to 1/3 the price of other printers, with more features and options than anyone. Price is always a factor, as well as ROI. Do the numbers and you’ll find that within 60 days, you’ll have already paid for your printer in savings, and likely will be looking for your second purchase because of the advantages.

Franchise

Most of our customers contact us because they are excited about the income possibilities that our printers will offer them, but for this very reason, the greater opportunity is in securing the exclusive distribution rights for their state. By merely owning and using our printers, our customers will undoubtedly generate tremendous excitement as they begin printing unbelievable designs at a third the cost and a third the time. It would be impossible to keep such a tool a secret. As news of this innovation begins making its way to the public, demand will become unimaginable. Since our customers are creating the exposure and excitement, it’s only right that they share in the success and residual income opportunity.

Jurisdiction

Most contracts start off with optimism and the best intentions, but if you’ve been doing this a while, you have learned that in the event of any legal actions, jurisdiction is an issue. If you’ve ever had to litigate outside your state, you recognize the challenges, but litigating outside the country is altogether different. We take a lot for granted in America, but that is not the case intentionally. Imagine trying to hire legal counsel abroad and trying to interpret international laws. This does not certainly offer home court advantage, and asking anyone who has tried, you’ll see that this is problematic at best. But even if you prevail, collecting on a judgement with corporate assets abroad is nearly impossible.

We take a lot for granted in America, but that is not the case intentionally. Imagine trying to hire legal counsel abroad and trying to interpret international laws. This does not certainly offer home court advantage, and asking anyone who has tried, you’ll see that this is problematic at best. But even if you prevail, collecting on a judgement with corporate assets abroad is nearly impossible.

Master Dealer

We thought so!

Want more time with your family?

Want to earn over 100K a month?

Want to have your own company?

MudBots is looking for the best. If you have a background in construction, love new technology, and especially love business in general, you're in the right place. MudBots has developed the first line of 3D Concrete Printers available to the world. Media everywhere is saying that the new technology will change the construction industry forever. Seldom do opportunities come along with the huge market interest and untapped market. This is what business opportunist dream of.

Media everywhere is saying that the new technology will change the construction industry forever. Seldom do opportunities come along with the huge market interest and untapped market. This is what business opportunist dream of.

Quality of Life

Success is measured in many ways, but true success is measured by the peace a person feels when they know they are doing something they love, their efforts are rewarded with increased gain, and they have the time to enjoy both with the ones they love. There are countless ways to make a living, but if you don’t enjoy what you’re doing or you don’t have the time to enjoy anything else, it’s hard to be satisfied. MudBots Master Dealers enjoy all three. They earn a remarkable living, they have the freedom to work when they want and because of their success, they get to focus on the more important things in life – their Family.

Job Description

The only way to manage a company that is growing as fast as MudBots is to have qualified individuals in every region of the country who can demonstrate products and serve their dealers. The Master Dealer program gives the company and its dealers the representation needed while offering a significant opportunity to those who embrace the call.

The Master Dealer program gives the company and its dealers the representation needed while offering a significant opportunity to those who embrace the call.

Exclusive Region

As an RMD, you will be given an exclusive license to represent and profit off of ALL the MudBots sales in your state/region. It is generally a full state, but in larger markets, a state may be divided to provide for better reachability and service.

Residual Income

There are many ways to profit as an RMD but the “residual commission” is by far the most enticing. Sell it once and continue earning for years to come. As an RMD you will earn up to 10% on every printer sold. With printers ranging from 284k to 1.3 million, it’s not hard to see how lucrative the venture can be. If RMDs sign up one new dealer every month who sells one printer a month within 12 months, depending on the profit sharing each RMD sets up with their dealers, earning after 12 months of work with 12 compliant dealers should be well over 100k a month. Why so much? Quite simply, we want to attract the best in the industry. An organization is only as good as its people. We want professionals, self-motivated individuals who are passionate about building their own business along ours.

Why so much? Quite simply, we want to attract the best in the industry. An organization is only as good as its people. We want professionals, self-motivated individuals who are passionate about building their own business along ours.

Economy

One of the best thing about concrete printers is the recession-proof nature of products. If the economy slows, the need for faster and more affordable construction methods increases. Those trying to compete with traditional construction methods will quickly discover they can’t even come close, resulting in even more demand for MudBots products. Prospects can get on board now or wait until they are losing contracts without one.

Previous Next

Minimum Requirements

Training

Attend a 4-week training in Utah

Printers

Purchase two (2) demo printers equaling 500k or more

Truck

Must have a late model truck

Trailer

Must have an enclosed branded trailer

Demo Product

Demo product to 2 dealers each week

1 Dealer / Month

Sign one dealer each month

Work or Fun

The best thing about a career with MudBots is that it’s just plain fun. As more and more ways are discovered for utilizing 3D Concrete Printers, every day is an exciting adventure. It’s fun to make money doing what you love and this is definitely an exciting product that sells itself. Industry professional everywhere are in awe when they see products being printed without the need of straight lines and forms. This is a product that people will watch for hours in amazement. The longer they watch, the more they realize how valuable 3D Printing will be to their business.

As more and more ways are discovered for utilizing 3D Concrete Printers, every day is an exciting adventure. It’s fun to make money doing what you love and this is definitely an exciting product that sells itself. Industry professional everywhere are in awe when they see products being printed without the need of straight lines and forms. This is a product that people will watch for hours in amazement. The longer they watch, the more they realize how valuable 3D Printing will be to their business.

Getting Started

To get started, call and request an NDA and RMD application. Once accepted, you may attend the next RMD training where you will spend three full days of training and Q&A. You will learn about the industry, the opportunity, printer operation, specific mixes, lab testing, structure engineering, potential markets & marketing strategies. By the time you return home, you will be confident in your ability to promote and service the dealers in your area.

Welcome to MudBots.

Connect The Dots

As companies begin down this road the process and solutions for building with 3DCP’s can seem daunting at first but it doesn’t take much looking around to realize that answers and solutions are not far away. Here are some videos that will help with connecting those dots.

Fiber Cement Siding to Block

Hardy Plank over Block

Hardy Plank Siding on Block

Architectural Foam Accents

Applying Architectural Foam Accents

Spraying Finish on Artictectural Foam & Finishes (1/2)

Cement Screws and Fasteners

Cement Board Screws

Faux Concrete Wall Panels

Wall Cladding Systems

Concrete Counter Tops 1

How To Layout like a PRO - NOT NEEDED ANYMORE

Engineering Footings

Soil and Footings

Tiny Home Village - Making a Difference

Affordable Housing in Detroit

Spec Mix Delivery

Site Tools and Methods

Why Choose MudBots - Best 3D Concrete Printer

Why Choose MudBots - Best 3D Concrete PrinterMudBots didn't start first, but we did finish first.

As you attempt to get information from others, you will discover that finding a phone number or getting any kind of response is problematic at best. Being first to market MudBots has moved away from conceptual ideas to real-time input from customers all over the world. What looks good on paper doesn't always make sense in the real world.

The Right

Design

A perfect example of this is the printer still under design by the Germans. There is no question that Germans are exceptional engineers, but though their printer will likely do what it was designed for when they finally get it to market, it is — in all practicality — the wrong machine for the job, and overlooks the primary advantage concrete printing is becoming famous for ( which is "time savings" ). Take a look at the information HERE and you will quickly know what we mean. MudBots 3D Concrete Printers can be set up and printing in hours, rather than days, without the need of cranes, permits and inspections. Being able to complete jobs in just a third of time as conventional construction methods usually take is one of the strongest attributes of this new technology.

Take a look at the information HERE and you will quickly know what we mean. MudBots 3D Concrete Printers can be set up and printing in hours, rather than days, without the need of cranes, permits and inspections. Being able to complete jobs in just a third of time as conventional construction methods usually take is one of the strongest attributes of this new technology.

Epson Printer

Ideology

Another significant advantage with MudBots printers is our transparency when it comes to printer mixes. Most others are not satisfied with merely selling you a machine, they want to lock down the printer ink as well. This is the Epson Printer Ideology. Sell customers a printer for $35.00 and then force them to buy proprietary ink at $50.00 a set every few weeks. When we started down this road, it was agreed early on that, although we understand why others are trying to do this, our customers would not like the idea of voided warranties for running their own mixes, especially since the primary ingredients in all Portland mixes is sand, cement and lime, which are readily available from hardware stores everywhere. Why would anyone be happy about shipping truckloads of specialty mix at accelerated prices when most of the materials are just down the street?

Why would anyone be happy about shipping truckloads of specialty mix at accelerated prices when most of the materials are just down the street?

MudBots is working with specialty mix companies and additive companies from all over the world. It's just a matter of time before customers discover on their own the best mix formulas for their needs, and when they do, they will not want to pay for expensive pre-mix scenarios when the idea is to reduce costs and efficiency.

Affordable

Special

Mix

Solutions

MudBots has tested, and continues to test, a myriad of different mixes from standard Portland scenarios to hempcrete, clay, polyethylene, polyurethane, geopolymer and geopolycrete. While most have never heard of some of these mix solutions, they are on their way to becoming industry standards in the not so distant future. MudBots has spent most of their time printing with nothing more than standard Type S Mortar mix. The strength of Type S is about 2500 to 3000 psi which is more than enough for print jobs, but when you begin adding other attributes like hardeners, synthetic fibers, polystyrene fillers, powder adhesives, plasticizers and dies, you can significantly change the mix's characteristics.

MudBots provides lab results for several most common mix formulas, which are included with the purchase of every machine, but the company has also partnered with a Vegas group that owns a series of mines from Mexico to Utah that will allow for the production of off-the-shelf (affordable) mixes that can be added to everyday mortar mixes. It doesn't make sense to ship truckloads of 90-lbs bags of especialty mix with the high cost of shipping when what all customers really need is the right combination of additives. Just add 5 lbs to every yard of sand, cement and lime at a fraction the time and cost.

As time goes on, more and more companies will want to get into the 3D Concrete Printer Business. When this technology can reduce production costs by 70% and in a 3rd the time, builders everywhere will not have a choice but to accept the changing times and get on board. The demand will encourage others to get involved. But there is far more to consider when thinking who to buy from than a few online videos and a website.

This is a significant purchase for most, but as you're out knocking on doors, the one thing you should consider most is customer service. Start calling around and most report that there is no one to talk to. Phone numbers are hidden and emails go unanswered for weeks. You have to ask yourself, if no one will talk to you now when you have the money in hand, and want to buy, what it is going to be like when you need support with men on the clock.

MudBots is a subsidiary of USABotics. We automate factories all over the world and do business with companies like 3M, Tesla, LG and Honeywell. These are serious companies that demand a level of professionalism and transparency that most are not prepared for. MudBots' ideology comes from decades of experience from its parent company, and is one of the attributes of who we are that is valued THE MOST by all our customers. Price is one thing, but when you can't provide adequate support, your product's customers suffer. MudBots' customers are from all over the world and as such provides 24/7 support. MudBots also continues to build its franchise network that very shortly will provide local support with qualified dealers in every state in the country.

MudBots' customers are from all over the world and as such provides 24/7 support. MudBots also continues to build its franchise network that very shortly will provide local support with qualified dealers in every state in the country.

Remote

Visioneering

Support

(See what I see)

Not only does MudBots provide 24/7 support, but our engineers insisted that the company provide FREE remote visioneering with every printer purchase. Remote visioneering allows for real-time, hands-free (see what I see) diagnostics. RVS allows for quicker solutions by allowing our engineers to see everything you see as though they were actually there. Implementing RVS eliminates costly delays and expensive travel that made remote service so cost-prohibitive in the past. Now, our engineers can lend support instantly in a way that was unheard of or possible years ago.

Price

One of the most common statements we get from prospective customers is the affordability of our printers. Our startup printer is 20-30% less than the next reported price by any competition. We do sell machines that sell for more than a million, but rather than forcing customers to buy more than they need, we sell the right printer for the right job. In almost all cases, we are told that our printers are more than half the cost of any others. There are many reasons for this, but the two best reasons are, first, that there is just way too much "blue sky" in what others are offering, but besides that, we have simplified the process and done away with all the fluff.

Our startup printer is 20-30% less than the next reported price by any competition. We do sell machines that sell for more than a million, but rather than forcing customers to buy more than they need, we sell the right printer for the right job. In almost all cases, we are told that our printers are more than half the cost of any others. There are many reasons for this, but the two best reasons are, first, that there is just way too much "blue sky" in what others are offering, but besides that, we have simplified the process and done away with all the fluff.

The best example of this is seen in most of the videos online today. You will see print nozzles with fancy aluminum rings, digital lights and buttons that are nothing but nonsense. At the end of the day, take away all the misleading gadgets and you will find cement coming out of a 1 1/4 pipe. It's nothing but smoke and mirrors designed to make the process mysterious and to justify prices that are unnecessary.

USABotics has established a reputation for providing affordable automation solutions by identifying simple yet efficient solutions for challenging objectives. What you will find with MudBots is a straightforward concrete printer machine that was designed with the end-user and common trade practices in mind.

What you will find with MudBots is a straightforward concrete printer machine that was designed with the end-user and common trade practices in mind.

Add finishing to your concrete structure in real time — right after

or even while printing.

Real Time

Finishing

That being said, don't doubt where we're going from here and what's about to be unveiled, least of which is real-time finishing. While some like the layer by layer appeal of what's commonly seen, the next evolutionary step is a system for real-time finishing for a smooth finish without the need of trowels. We are speaking from experience when we say that anything you’ve seen online so far is never going to work. Automated trowel systems or roller systems may work for straight vertical prints and walls, but never for cantilever prints. The beauty of 3D Printing is the new flexibility of designs. No one is going to want straight boring walls, which means that what's being shown isn't anywhere close to what customers will want. MudBots knows this because we've been there and have done that a long time ago. After going down that road, we quickly realized that we were going in the wrong direction.

MudBots knows this because we've been there and have done that a long time ago. After going down that road, we quickly realized that we were going in the wrong direction.

Today, we are finishing an RTF system that will change everything. We're unable to say more until patents are in place but rest assured, when it comes to Concrete Printing, we are pushing the envelope because our customers are driving the need. Their input and ideas have been invaluable as we consider where we need to be.

Residual Income

Opportunity

Last of all... We at MudBots know that to be successful in this marketplace, it's going to require lots of good people and support. We can’t be everywhere at the same time, and with hundreds of trade shows across the country each week, we recognize the need for professional representation. It's not only very valuable to the brand, but essential to the growth of the company.

Most of our customers contact us because they are excited about the income possibilities that our printers will offer them, but for this very reason, the greater opportunity is in securing the exclusive distribution rights for their state. By merely owning and using our printers, our customers will undoubtedly generate tremendous excitement as they begin printing unbelievable designs at a third the cost and a third the time. It would be impossible to keep such a tool a secret. As news of this innovation begins making its way to the public, demand will become unimaginable. Since our customers are creating the exposure and excitement, it's only right that they share in the success.

By merely owning and using our printers, our customers will undoubtedly generate tremendous excitement as they begin printing unbelievable designs at a third the cost and a third the time. It would be impossible to keep such a tool a secret. As news of this innovation begins making its way to the public, demand will become unimaginable. Since our customers are creating the exposure and excitement, it's only right that they share in the success.

MudBots offers exclusive distribution to professional businesses that can prove their ability to support our products and generate the exposure by enlisting dealers throughout their state. Imagine having the exclusive rights to sell and profit off such a significant tool that everyone is soon to have. With earnings up to 30% of each sale, it's not hard to imagine the advantage. States are going out fast so tell us if you would like to know more.

the

Bottom

Line

As you knock on doors, know what to ask for. In this case, what you don't know can hurt you. We want our customers to make informed decisions so they can utilize a technology that will give them an unfair advantage over competition with a company that will be there all along the way.

In this case, what you don't know can hurt you. We want our customers to make informed decisions so they can utilize a technology that will give them an unfair advantage over competition with a company that will be there all along the way.

Buy from the Manufacturer of

#1 Concrete Printer in the World.

13 BEST CONSTRUCTION 3D PRINTERS OF 2019

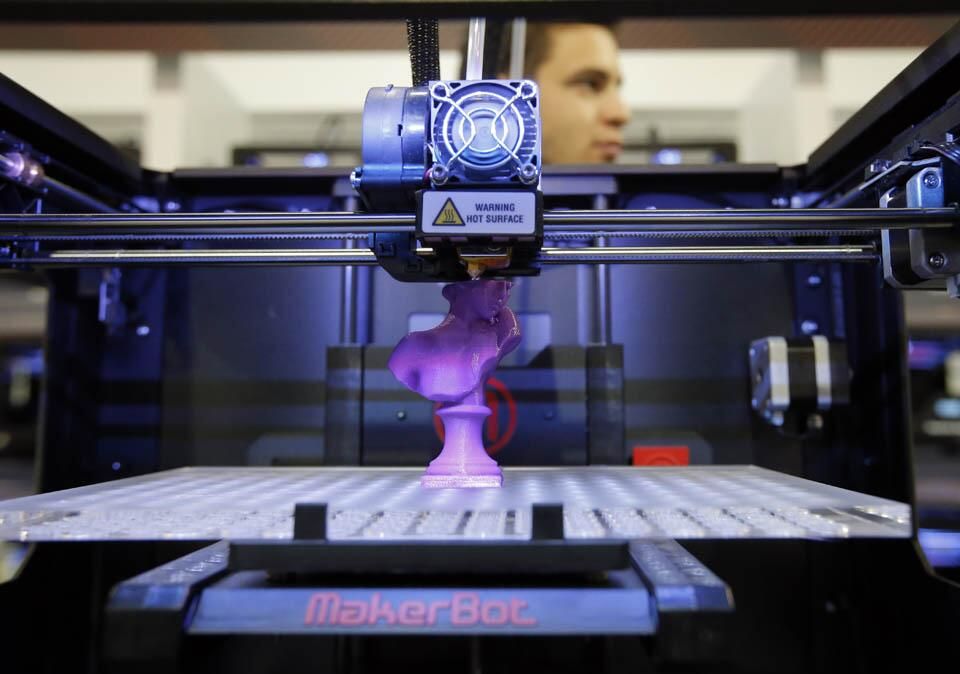

A 3D construction printer is a machine that can build houses by applying material (concrete) layer by layer. The paste type material used, in this case concrete or earth, is forced through the nozzle in layers to print buildings.

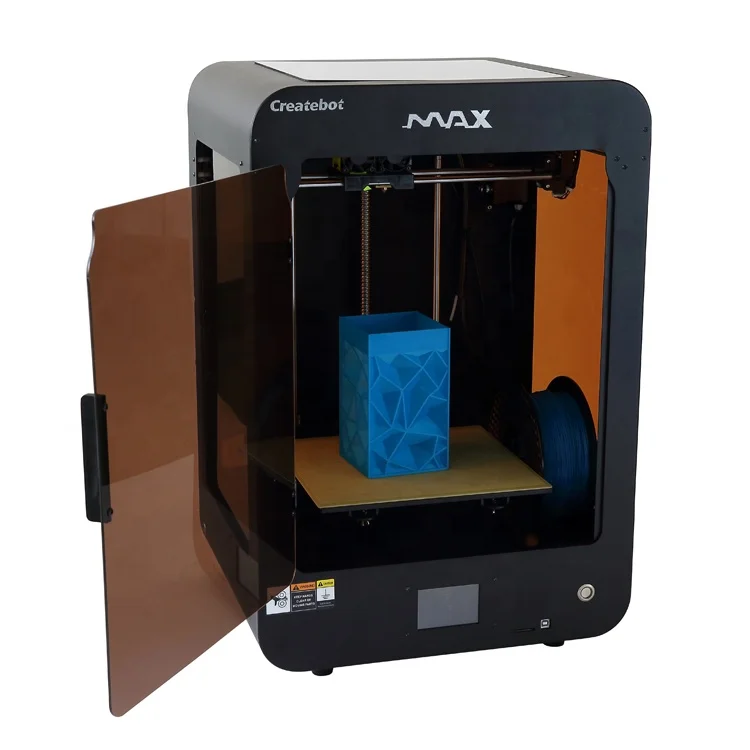

Concrete 3D printing in the construction industry saves time, effort and material when compared to traditional methods. However, it is important to note that 3D printers are not yet capable of creating a fully functional home, only the frame and walls can be created, other elements such as windows, electricity or plumbing must be installed separately. Concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed the top 12 construction 3D printing solutions. Some of them are 3D printers already available for sale, while others are still in the prototype stage or provide 3D printing services for external structures.

HOW TO BUILD A 3D PRINTED HOUSE?

Construction 3D printers use extrusion technology. Some construction 3D printers are similar to FFF/FDM desktop 3D printers, only larger (gantry style), while others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as the filament. The material is ejected from a special nozzle to form layers. In simpler (very) extrusion of pasta is like using a bag to dispense frosting on a cake.

The printer builds foundations and walls layer by layer. The base is literally the printer's build plate. However, some concrete 3D printers are used to 3D print brick molds. Once molded, the bricks are stacked on top of each other manually (or with a robotic arm).

Benefits of building 3D printing

• Eco-friendly : 3D printed houses can be built with sustainable materials. What's more, some construction 3D printers use solar energy and emit little CO2.

• Affordable: 3D construction printers can build affordable housing, providing great relief to people in poor areas or after natural disasters.

• Scalability: 3D construction printing reduces certain construction costs. For example, the cost of 1 square meter of wall using traditional construction methods is approximately $75, while for an Apis Cor house 3D printer it is only $27.

• Efficient: Because materials are 3D printed on demand, machines produce less waste. In addition, 3D construction printers can complete the foundation of a house in less than a few days, while traditional construction methods take weeks or even months.

• Design flexibility: Curved walls and unique facades can be easily created with a 3D printer

Disadvantages of 3D construction

• Expensive initial investment: These 3D printers can sometimes cost up to a million dollars.

• Partially Built Houses : Only house frames are built. The 3D printing process is usually paused to manually install plumbing, wiring, and fittings.

• Rough Appearance : The exterior of most 3D printed houses is not as smooth as traditional houses.

• Lack of Certification: Construction sites are regulated by law and there are important safety standards that must be met, which can be difficult with 3D printing methods (different repeatability, dimensional stability, etc.).

CONSTRUCTION 3D PRINTERS: OVERVIEW

We divide construction 3D printers into three categories: house building 3D printers that you can buy, prototype concrete printers, and concrete 3D printing services.

Home 3D printers available

AMT printers

Pictured: AMT S-6044 Long and AMT S-300

), 11 x 31 x 80 (maximum)

• Material: Concrete / Clay / Gypsum

• Country: Russia

Equipment manufactured by AMT-SPETSAVIA - workshop and field portal construction 3D printers (COP-printers, Construction Objects Printing): and from small-format (for printing small architectural forms ) to large (for printing buildings up to 30 floors high). Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

Productivity from 0.5 to 2.5 cubic meters per hour, management by 2 people. AMT printers are capable of printing with any kind of concrete, clay and gypsum.

BetAbram P1

• Assembly size : 1.6 x 8.2 x 2.5 m

• Material : Concrete

• Country : Slovenia

BetAbram is a small Slovenian team that has been working on building 3D printing equipment since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second iteration and is available with additional printheads: basic, "Orto" for smoother layers, and rotatable for more design options.

COBOD BOD2

• Build size : 11.98 x 45.07 x 1.53 m

• Material : Concrete

• Country : Denmark

This construction 3D printer is fast, with a speed of up to 18 meters per minute. BOD2 is modular and can be adapted to various sizes. COBOD is a 3D Printhuset company.

Constructions-3D 3D Constructor

• Assembly size : 13 x 13 x 3. 8 m

8 m

• Material : Concrete

• Country : France Their 3D Constructor machine is mobile thanks to its rubber tracks and fits in a 20ft shipping container for easy transportation from one construction site to another.

CyBe Construction CyBe RC 3Dp

• Assembly size: 2.75 x 2.75 x 2.75 m

• Material: Concrete

• Country: Netherlands This easy-to-use 3D printer is capable of reaching heights of up to 2.75 meters and only requires two people to operate.

ICON Vulcan II

• Build Size : 2.6 x 8.5 x ∞ m

• Material : Concrete

• Country : United States

ICON wants to revolutionize the construction industry with its Vulcan II printer. The whole process is designed to be user friendly with a tablet-based interface, and the ICON Lavacrete concrete mix is optimized for easy printing.

MudBots Concrete 3D Printer

• Build Size : 1.83 x 1.83 x 1.22 m (minimum)

• Material : Concrete

• Country : United States of Mudts003 Concrete 3D Printers USA. Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

Their smallest model (approximately 1830 x 1830 x 1220 mm) is available for $35,000. Large build sizes are also available, reaching up to 30 meters in length.

According to MudBots, their 3D printers can print a small house in just 12 hours and cut costs by 70% compared to traditional building methods.

Stroybot2

Build Size : 10m x 15m x 6m

Material : Concrete

Country : United States

StroyBot, also known as the Rudenko 3D Printer, is a versatile mobile design printing system supplied as a build kit user. On average, he can print a 100 square meter house in 48 hours (walls only).

WASP Crane WASP “Infinity 3D Printer”

• Build Size : Ø 6.3 x 3 m

• Material : Concrete / Earth materials

• Country : Italy

WASP Crane is an evolution of the previous WASP construction printer 12MT. This open source builder is modular and multiple Crane printers can work together on the same project, giving theoretically endless 3D printing possibilities.

Concrete printers work projects

Apis Cor 3D printer

• Assembly size : 8.5 x 1.6 x 1.5 m

• Material : Concrete

• Country : United States

Apis Cor, a 3D based construction company Francisco and claims to be able to 3D print a house in less than 24 hours. Their Apis Cor printer is similar to a robotic arm and won first place in NASA's 3-stage 3D printing competition.

Batiprint3D 3D Printer

• Build Size : -

• Material : Concrete / Other

• Country : France

Batiprint 3D made headlines internationally when it completed the Yhnova 3D print shop in Nantes, France. Their 3D printer not only prints cement but also insulating foam, making it one of the most complete 3D building solutions.

S-Squared ARCS VVS NEPTUNE

• Build Size : 9.1 x 4.4 x ∞

• Material : Concrete

• Country : United States

S-Squared, also known as Square3D "4D printing", which aims to provide fast, reliable, environmentally friendly and affordable housing for poor areas. ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale.

ARCS VVS NEPTUNE is one of the company's working models, but it will not be available for commercial sale.

Construction printing services

Contour Crafting 3D Printing System

• Material • Material: Concrete

• Country: United States

This automatic construction system is capable of 3D -printing large buildings and high -high infrastings. Contour Crafting (also known as CC Corp) aims to improve the effectiveness of disaster relief through concrete admixture technology.

XtreeE 3D Printer

• Build Size : -

• Material : Concrete

• Country : France

XtreeE develops custom 3D printing solutions for construction, engineering and architectural design. This startup is located in France and has already completed a number of 3D construction projects.

3D printing with concrete [expert opinion] - Studia3D

02/16/2020 in Expert's Blog, Observations, Equipment, Technologies segment. And I made certain conclusions for myself, which I will try to briefly outline.

And I made certain conclusions for myself, which I will try to briefly outline.

Actually, when it comes to 3D printing with concrete, my opinion is mixed. I will try to explain why:

Concrete 3D printing technology.

Concrete 3D printing is a semi-finished product. Not because 3D printing with concrete needs additional post-processing (Any production technology in most cases does not give the final result, be it a milling machine, casting, etc. It always requires bringing the product to customer requirements), but because the process of 3D printing with concrete has so many crutches and sores that it becomes very difficult to call this process 3D printing.

Administrative building. Construction. Dubai. It was built by a Russian guy. Read more here.

Of all the solutions on the market that I could find, the concrete printing process is a layer-by-layer application of concrete, which is essentially a repetition of the well-known FDM technology.

Concrete 3D printing technology. How does this happen.

But it wasn't there. Contrary to traditional filament printing, concrete does not use supporting structures during model growth. Instead, workers have to fence supports made of wood, plastic, foam and just improvised means. Although this approach is characterized rather not by technology, but by materials.

Administrative building. Construction. Dubai.

Concrete support structures are not easy to break if present. However, this is not an excuse. Should I buy an industrial building 3D printer and still have the workers to run around and build something? Only now not formwork for pouring concrete, but supporting structures for a 3D printer. So it is necessary to teach the workers what support structures are. But even if I print in segments, then to assemble the whole structure, I will already need several cranes and more qualified staff of "so-pro-matchers" so that it all does not collapse to hell.

3D printed bridge. China.

Money.

However, despite all the difficulties and shortcomings of the technology, the main advantage of using such technologies in 2020 is the presence of your own, already established, construction company. The use of 3D printing technologies will essentially be the hallmark of the company.

3D printed Dubai Future Foundation headquarters. Dubai.

And if not a solution to production issues, but an excellent publicity stunt. In fact, there is not even an input investment. Investments in advertising, if you can justify this expense.

Conclusion:

If you want to open a business with 3D printing in 2020, it is only in the concrete segment. The remaining segments are already simply occupied and have already been studied quite deeply. Building houses on a 3D printer is a tempting and profitable business. But! This area seemed to me irrelevant for this year in terms of starting a business and for such established centers of additive technologies as Studia3D in terms of expansion.