Everything about 3d printing

Everything you need to know about 3D printing and its impact on your business

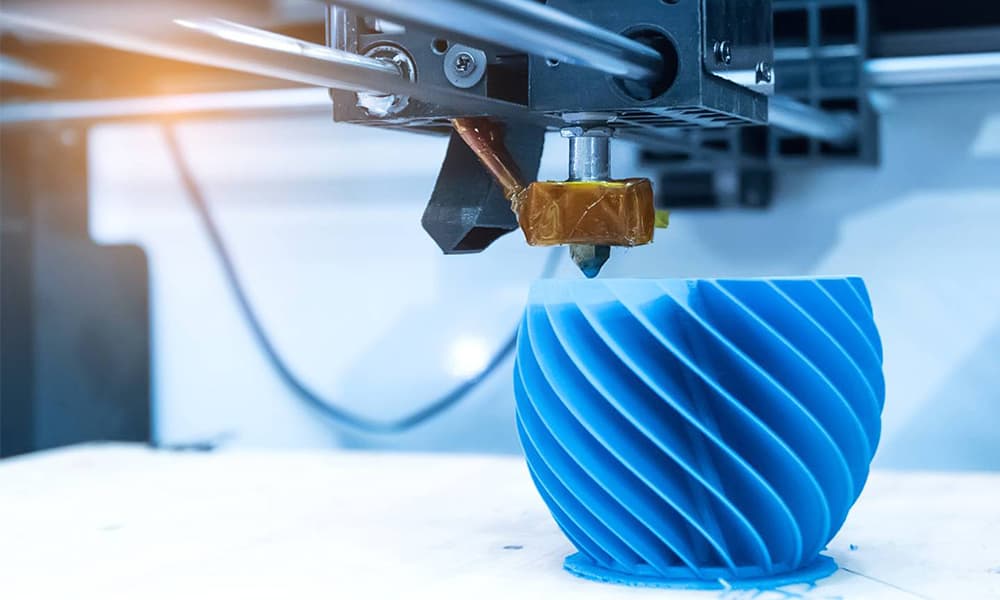

3D printing transforms spools of plastic filament or trays of resin into physical objects. 3D printing is quite literally out of this world. NASA maintains a 3D printer on the International Space Station and astronauts can build custom tools (like this maintenance wrench) without having to fly them into space.

3D printing has been adopted by students, entrepreneurs, hobbyists, and massive factories. Because 3D printing allows for the transformation of a digital design into a tangible object, a wide array of uses have been found.

Also: How Heineken is using 3D printing for on-demand brewery parts

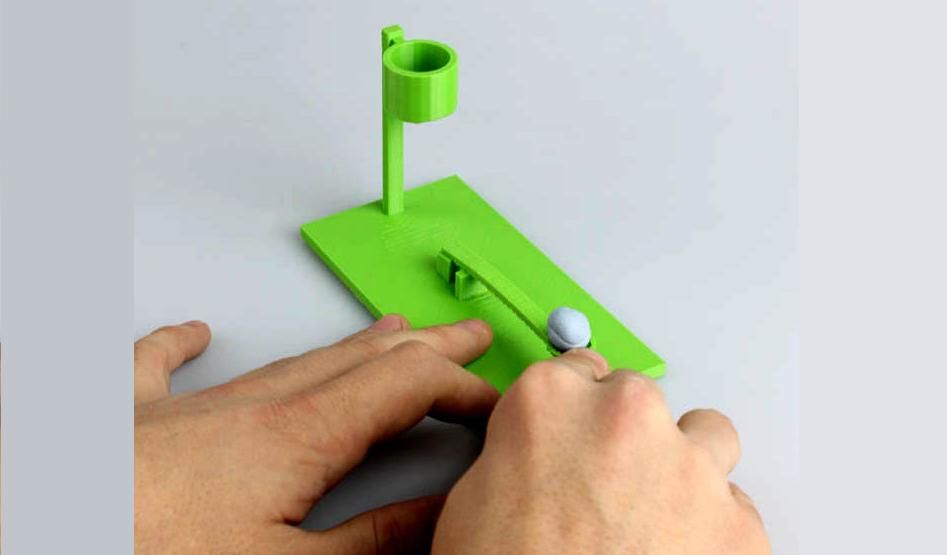

Physicians can print physical models of portions of patient anatomy to better visualize procedures and demonstrate practice. Engineers in factories can create custom jigs and fixtures that both save time and reduce injury during the manufacturing process. Communities foster makerspaces that teach STEM skills and aid in the start-up of new businesses, thereby creating new jobs and local opportunities.

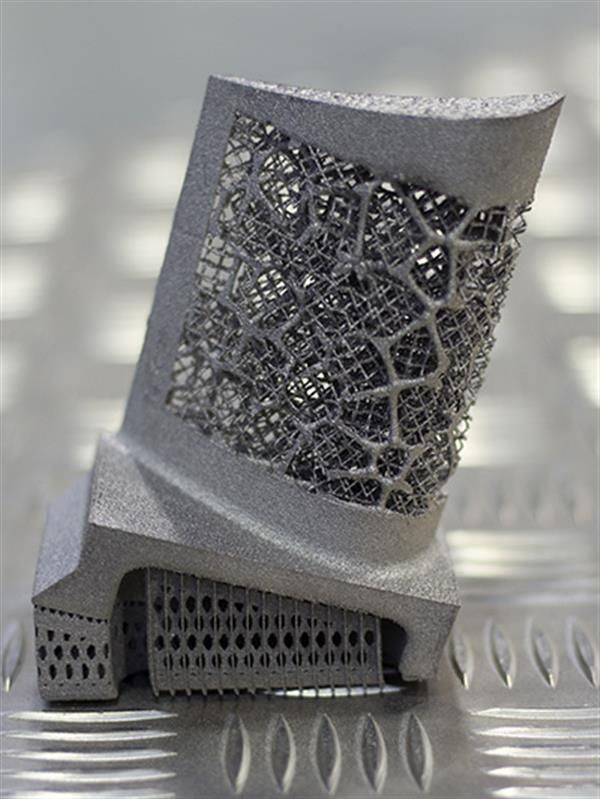

Although mostly used for the creation of plastic objects, 3D printing can also generate metal objects, although this is a much more costly and far less common process than plastic 3D printing.

What is 3D printing? 3D printing is the process of creating a physical object from a digital model. 3D printing is an additive process. Layers of plastic are built up one after the other to create an object.

How does 3D printing impact the economy? 3D printing is a component of the maker movement, which has benefits to communities, education, entrepreneurship, and traditional enterprises. It helps foster the creation of new products and new companies, and teaches skills transferable into a wide variety of technical and professional jobs.

How expensive is 3D printing compared to traditional manufacturing processes? That depends. It's far less expensive and takes far less time to create prototypes, jigs, tools, and fixtures using 3D printing. But once the setup and tooling costs are paid for, traditional manufacturing techniques like injection molding can produce objects in volume more quickly and at lower cost.

How does 3D printing affect the supply chain? 3D printing is ideal for short-run manufacturing and small production jobs. It also allows spare parts to be "stored in the cloud," so physical inventory isn't required until there is a demand for an object. By delivering 3D objects across the globe in digital form and printing locally, the cost and time of shipping can be completely eliminated.

Can 3D printing transform the manufacturing industry? The manufacturing industry is undergoing a vast transformation of which 3D printing is one element. Other factors include a huge increase in data volume and processing, improved analytics, improved human factors, and the automation of various production processes.

3D printing is the process of creating objects (usually plastic, but sometimes metal or composite material) from a digital model. Most 3D printers add material to the object one very thin layer at a time, which is why 3D printers are classified as "additive manufacturing."

How does additive manufacturing work?

The analogy to printing is not perfect. Computer printers generally operate a row at a time. 3D printers work much more like plotters, moving a print head along both the X and Y axis to draw a pattern. In the case of a 3D printer, the pattern is usually drawn with plastic, not ink. What makes the 3D printer three-dimensional is that once a pattern is drawn, the print head moves up (or the print surface moves down), and another pattern is drawn on top of the first.

How does a 3D printer work?

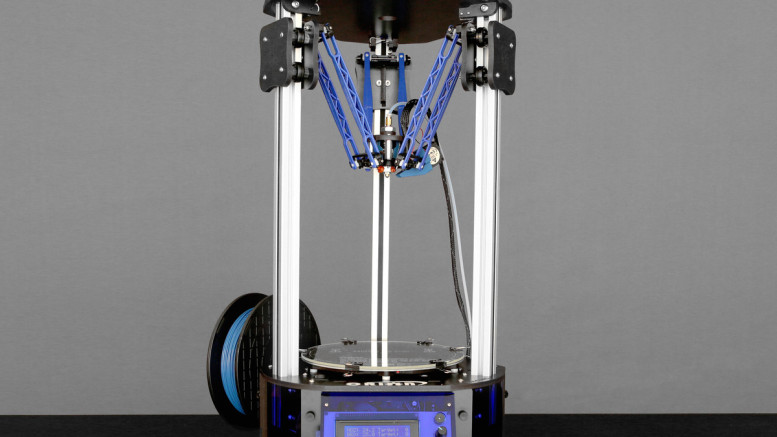

There are several types of 3D printers out there, but we'll be focusing on two: fused-deposition modeling (or FDM) and stereolithography (or SLA).

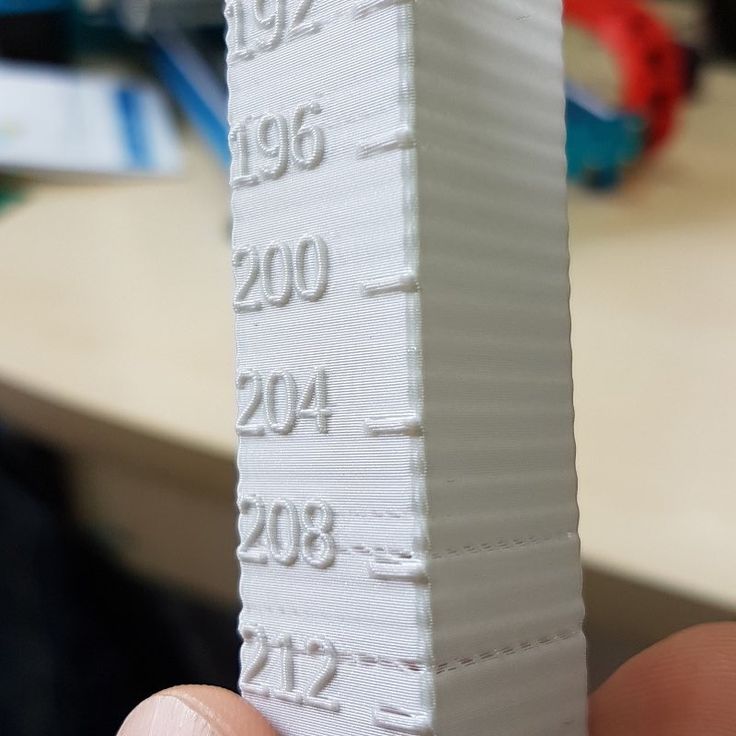

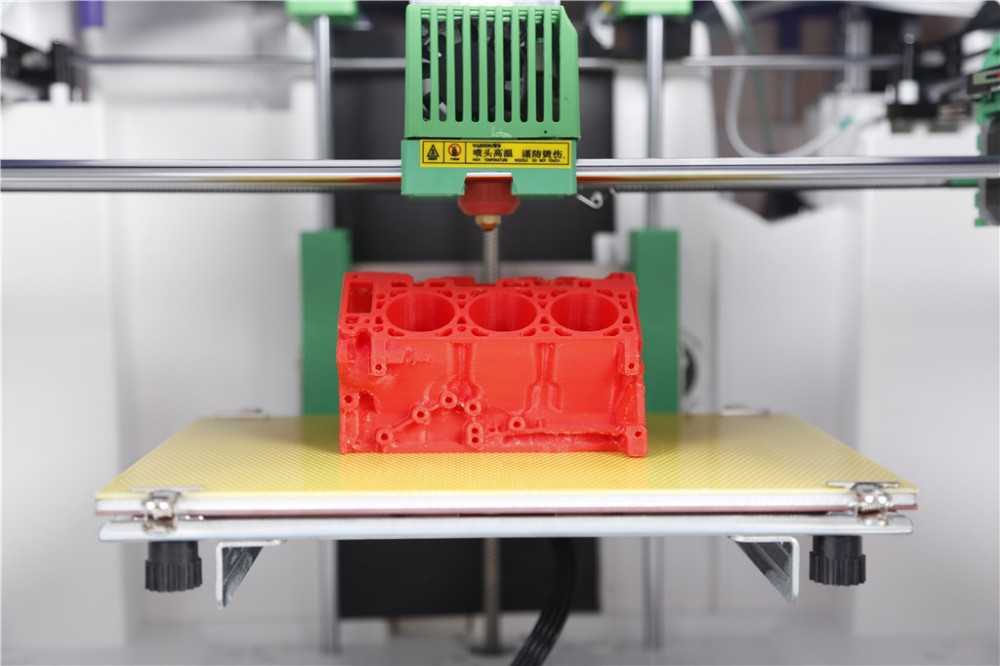

FDM starts with rolls of filament as its source material. These typically come in strands either 1.75 or 2.85 millimeters thick, rolled onto a spindle. An FDM printer heats the filament, squeezes it out through an extruder nozzle, and lays down layers on a build surface. The layers are incredibly thin, and as each molten layer is laid down on top of the previous layer, it partially fuses as it cools.

Also: 3D printing and robots power largest furniture maker in the world

Over time -- sometimes a lot of time -- an object is built up from hundreds or thousands of these layers.

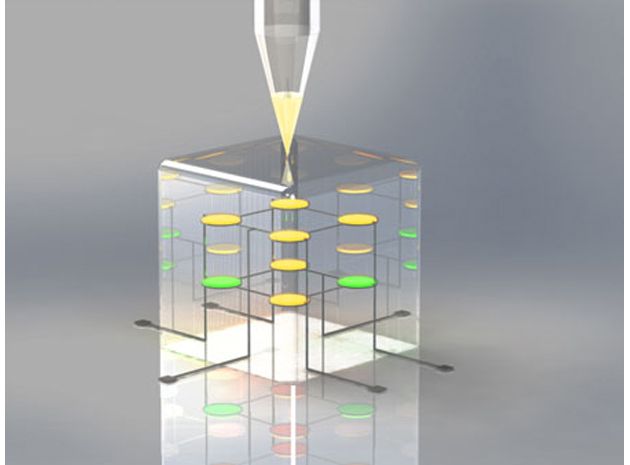

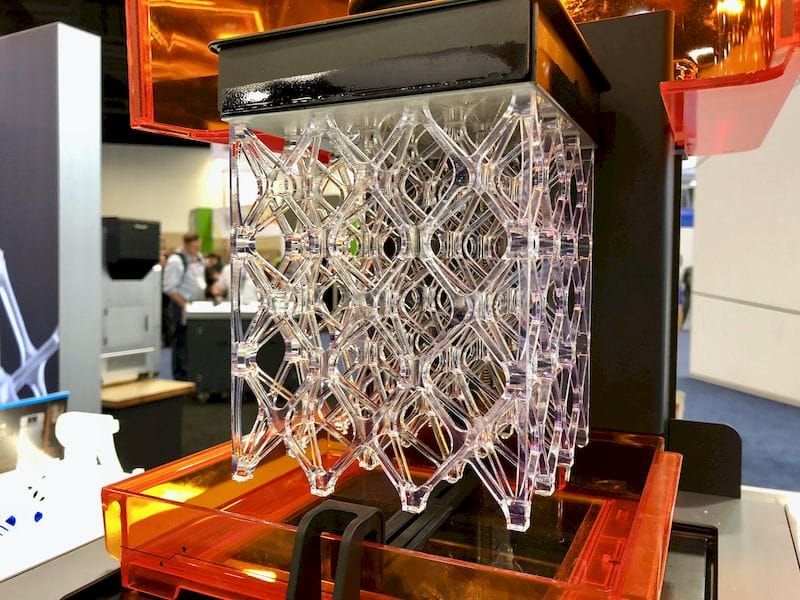

SLA starts with a liquid resin as its source material. A build tray is lowered into the resin (usually upside down) and light (sometimes from an LCD, sometimes from an ultraviolet laser) creates a chemical reaction in the resin that causes it to harden. As each layer is exposed to the light, the printer raises the build platform slightly out of the resin pool, exposing the next layer to light.

Innovation

- Tesla is changing the sensors in its cars. Here is why you should care

- What is the world's brightest flashlight? The top contenders ranked by lumens

- Selling an emotion and a feeling: How these companies see VR as the future of business

- The best affordable EVs and how the federal tax credit can save you $7,500

FDM is the most common form of material extrusion 3D printing. SLA is the most common form of light polymerization 3D printing. These two printing methods have reached a cost level low enough that consumers, hobbyists, educators, entrepreneurs, and small businesses can afford them, but they are generally limited to the production of plastics, plastic composites, and nylon-like materials.

Other forms of 3D printers are available, but at a substantial buy-in cost. These include powder bed 3D printing (which drops powder that is then fused in form), laminated object manufacturing (which glues sheets of material together and then cuts them to form), directed energy deposition (which is kind of like what would happen if a welding machine and an FDM printer gave birth), and electron beam freeform manufacturing (which shoots an electron beam in a vacuum to create molten metal based on a 3D model).

These last forms of 3D printing are generally used to fabricate metal parts, while FDM and SLA are most often used to fabricate plastic objects.

What all of these have in common is that they're creating new objects by incrementally adding and fusing a raw material.

Also: 3D printing: A cheat sheet TechRepublic

What 3D printing is not

3D printers are not Star Trek replicators. As anyone who owns a 3D printer will tell you, as soon as guests see the printer in action, their imagination stirs. Nearly immediately, they'll start calling out the types of objects they'd like to have made. Often these are not even existing items, but entirely new inventions they think can be produced overnight through the magic of 3D printing.

You can't ask one to produce a slice of pecan pie or a perfect, doll-sized replica of Captain Kirk's command chair. While there are 3D printers that actually will create chocolate creations and three-dimensional models of the Captain's chair, 3D printing does have production constraints and design limitations.

Over the next few sections of this guide, we'll dive into the strengths and weaknesses of common 3D printers and what it takes to make 3D prints.

How does 3D printing impact the economy?

In the same way that 3D printing is one element of the larger trend of digital manufacturing transformation, 3D printing is one element of a larger trend economically, the rise of the maker movement.

One exciting aspect of making is that it's all-inclusive and gender neutral. It encompasses everything from doll crafting to robot design, from scrapbooking to making furniture, from leatherworking to 3D printing. It's a word that embraces anyone who makes stuff, pure and simple.

Making is different from manufacturing, although making often leads to manufacturing. When someone designs a product, and builds a prototype, that can be considered making. Once that prototype is in active production, that's manufacturing. Now, combining desktop fabrication with crowdfunding, a very sophisticated prototype can be designed, and then the manufacturing funded by prospective customers.

The National League of Cities' Center for City Solutions and Applied Research has studied the maker movement, and believes that making empowers individuals and improves cities:

The maker movement is centered in cities. And this new, hyperlocal manufacturing environment holds potential not only for individual hobbyists but also for community-wide advances in local entrepreneurship and job creation. Cities have a great opportunity to catalyze this movement as a way to improve our local economies, diversify workforce opportunities, and support the creative economy.

They also believe that 3D printing can lower the barrier of entry for entrepreneurship, stating:

The emergence of makerspaces is effectively lowering the cost of entry for entrepreneurs. Whereas until recently an entrepreneur may have had to spend upwards of $100,000 to produce a prototype for a new product, the operating terrain has changed, and that cost can now range from as little as $2,000 to $4,000.

In short, the cost of developing prototypes has quickly become much more affordable for would-be entrepreneurs.

This cost reduction for prototypes (and by extension jigs, fixtures, and tools) applies to large organizations as well. When you can take an expense and reduce it to just 2-4% of its previous cost, innovation increases because the cost of risk decreases.

According to Paul Heiden, SVP of Product Management for 3D printer maker Ultimaker:

The future of additive manufacturing will not be in the hands of a select few engineers, but rather with any worker who may not have 3D printing experience. Software solutions enable those untrained workers to create parts and tools, closing their own personal skills gap and preparing them for a career in the factory of the future.

One interesting metric is the number of projects and the amount of money pledged through Kickstarter projects. Kickstarter is a crowdfunding platform that enables creators to fund products and projects. In fact, many 3D printer vendors have funded their efforts through Kickstarter.

In fact, many 3D printer vendors have funded their efforts through Kickstarter.

3D Printing

- The best 3D printers: From FDM to resin

- These are the most googled 3D printing questions of 2022, answered

- A 3D printed orthotic device made from castor oil

- This device recycles plastic water bottles into 3D printing filament

As of the moment of this writing, Kickstarter's always-updated stats page shows a cumulative $4.2 billion pledged for 162,912 successfully funded projects. This is directly relevant to 3D printing, because the company no longer allows photo-realistic images for funding pitches and requires an actual prototype be built -- which is often accomplished in part through 3D printing.

Another way to gauge the scope of the maker economy is to look at Etsy, which is fundamentally a marketplace for unique and creative goods. In its 2018 annual report, the company stated that it supports 2. 1 million active sellers, 87 percent of whom are women, and 97 percent who run their creative businesses from their home. According to an economic impact study conducted by ECONorthwest on behalf of Etsy, Etsy sellers...

1 million active sellers, 87 percent of whom are women, and 97 percent who run their creative businesses from their home. According to an economic impact study conducted by ECONorthwest on behalf of Etsy, Etsy sellers...

- Generated more than $1.76 billion in income.

- Contributed $5.37 billion to the U.S. economy, more than double their direct business sales.

- Created 1.52 million jobs in the independent worker economy.

- Produced $3 billion in additional economic value.

Of course, only a small percentage of Etsy sellers use 3D printing, but since many Etsy sellers are candidates for some form of desktop fabrication technology, they are a good proxy for market growth data.

Fundamentally, making in general and 3D printing in specific are transformative drivers for economic growth, helping to train students in tangible skills that produce value, helping entrepreneurs build and test prototypes and engage in initial manufacturing, all of which lead to a potent job-creation force all across the world.

Also:

- Mass production 3D printing? It's coming, and it's a big deal

- 3D Systems integrated into Nokia's Factory in a Box additive manufacturing effort

- Stratasys sheds more light on its metals additive manufacturing plans

Because FDM and SLA printers have become available for both hobbyists and professionals, they are the most common types of 3D printers. Consumer versions are available for a few hundred dollars and professional machines, used for prototyping and jig-making, are priced in the $3,000-6,000 range.

These are the 3D printing technologies in which you're most likely to invest.

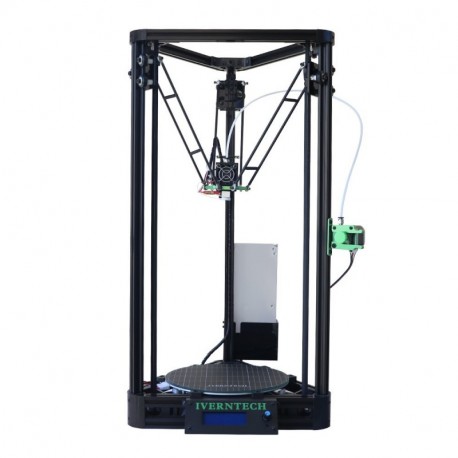

FDM printers

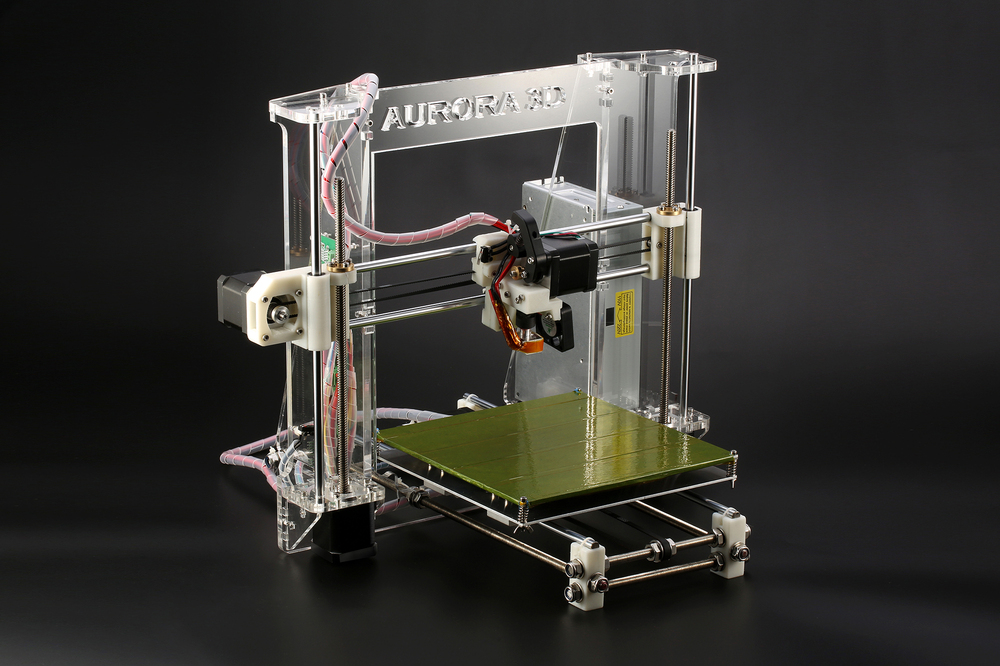

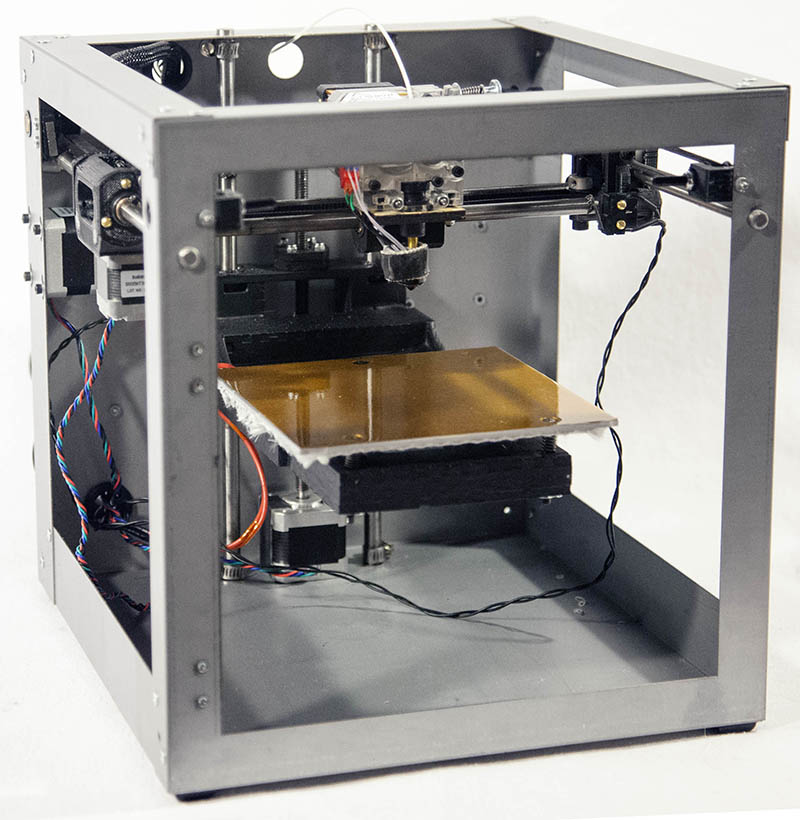

FDM was the first mainstream hobbyist 3D printing technology and still leads the market in terms of brands and product offerings, as well as number of units sold.

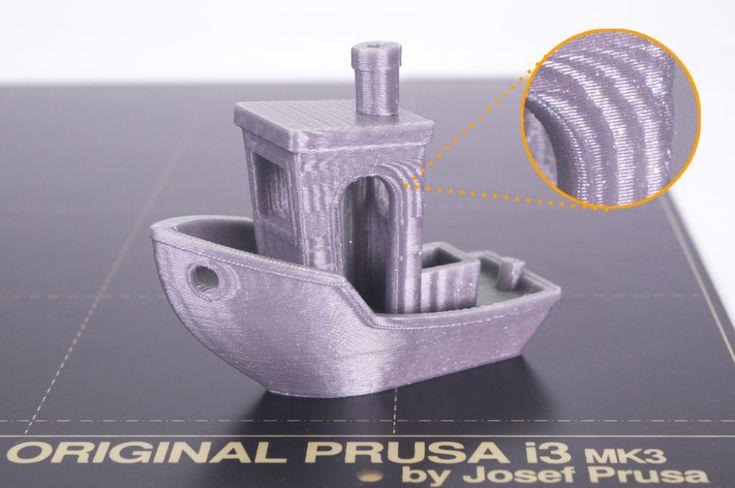

One of the key challenges with 3D printing is getting an object to successfully print. Prints fail because the deposited plastic heats or cools too quickly, because layers don't bond successfully, because the print detaches from the build plate print surface, because filament jams in the extruder, and a wide range of other production gotchas.

Prints fail because the deposited plastic heats or cools too quickly, because layers don't bond successfully, because the print detaches from the build plate print surface, because filament jams in the extruder, and a wide range of other production gotchas.

FDM printers will print in a wide range of plastics. Each plastic has differing characteristics, which can make printing easier or more difficult, and which yield differing characteristics in finished parts.

The most common filament type is PLA (polyactic acid), which is very easy to print, but can be brittle and will deform in sunlight.

Nylon is strong and flexible, but often requires a lot of fiddling to get its print settings to work.

ABS is stronger (it's what LEGOs are made from), but it cools at a rate that often causes the bottom layers to curl up, deforming the entire print. It also has a nasty odor and moderately toxic fumes.

Some vendors infuse the basic plastic (mostly PLA) with other materials, including wood, metals, and carbon fiber.

Each of these change the characteristics of the finished, printed object.

Each of these change the characteristics of the finished, printed object.

Most FDM printers have a single extruder and can print from a single filament roll at a time. More advanced (and expensive) FDM printers can print two, three, four or more filaments at a time, allowing the printer to mix colors, functional characteristics (like solid plastic with flexible hinges), and dissolvable support materials.

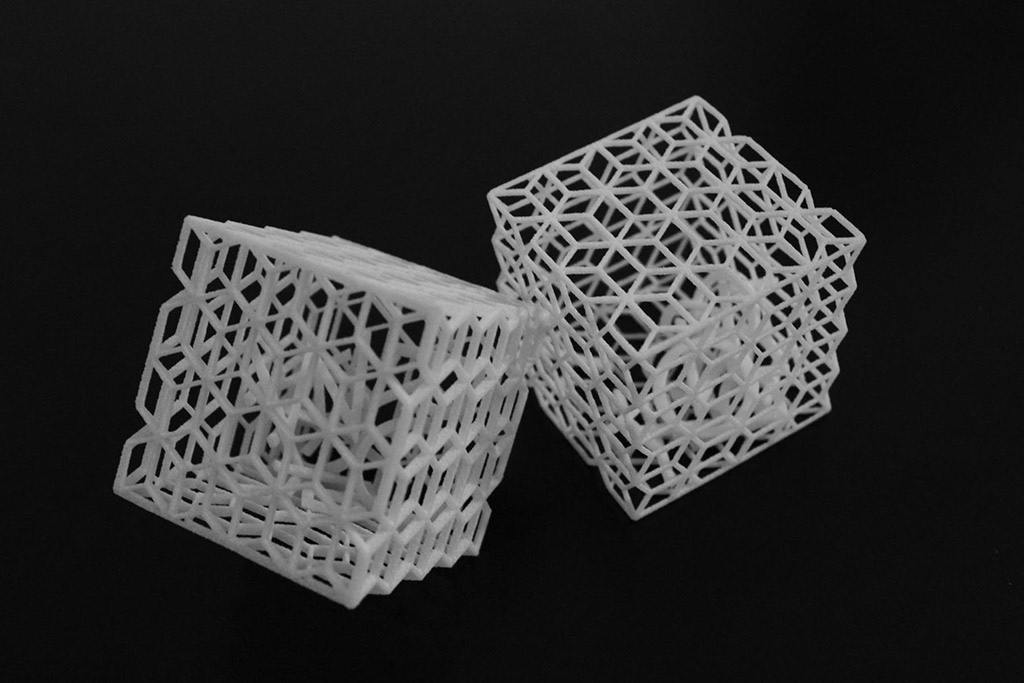

Prints are built up from strings of molten plastic, so overhangs can become an issue. While FDM printers can generally print circles or angles up to 45-60 degrees, they can't print over large air gaps because the molten plastic will simply settle into the gap.

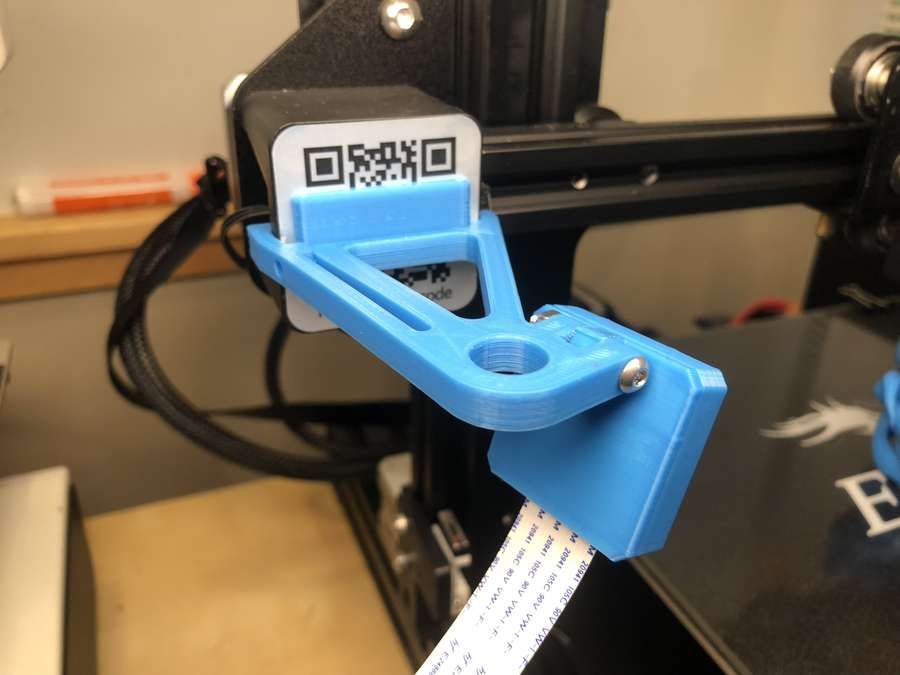

To compensate for the problem of large gaps, most printers will generate supports, or temporary towers of plastic that can hold up the bridged areas. Single filament printers use the same material as the object itself, with a variety of settings that can enable the supports to be removed with moderate ease.

Dual filament printers often print with a dissolvable support material like PVA (polyvinyl alcohol) which is pretty much the same material that Elmer's Glue is made from. Once the dual filament print is completed, it's submerged in water for hours (or sometimes days) and the PVA dissolves, leaving an intact print with the open voids the designer intended for the final object.

Because FDM printers print in layers, the orientation of the object being printed can be important. Bonds between layers are often weaker than linear runs of plastic. As such, placement on the bed should take that into account for any objects that are likely to be under stress.

FDM printers come in a variety of sizes. The larger the size, the more challenging the print, because it's often difficult to balance the heat characteristics within the full build area.

FDM printers also offer a variety of nozzle sizes. The larger the nozzle, the more material extruded per minute, but the less refined the final result. The smaller the nozzle, the more detailed the print. Printing with large nozzles or small nozzles will introduce other challenges, often related to supports, bridging, and heat management.

The smaller the nozzle, the more detailed the print. Printing with large nozzles or small nozzles will introduce other challenges, often related to supports, bridging, and heat management.

Also: 3D Printer Reviews CNET

SLA printers

SLA printers have a number of characteristics that have kept them out of the mainstream:

- They use a liquid resin that is quite toxic in its uncured form. If you get it on you, it could cause painful burns or rashes.

- Finished prints need to be processed in a bath and then cured. During this processing time, they are subject to deformation. They also remain toxic.

- Because of the liquid resin and the processing bath, SLA printers are much messier to work with than FDM printers.

SLA printers often have very small build areas, resulting in generally tiny prints. The resin is often specifically formulated for a given printer, so users can be locked into a vendor's offerings, which may limit material and color choices.

Even so, SLA printers have started to grow in popularity, mostly because they are capable of producing prints with very fine detail and few layer lines. This makes them particularly suited for prototyping jewelry designs and molds, small medical and dental designs, and hobbies, like model railroading and gaming miniatures.

Design and preparation of printsThe process of going from an idea to a 3D-printed object must always pass through two software tool technologies first: 3D-modeling (or CAD) software and slicers.

3D-modeling software

Think of 3D-modeling software, also called CAD (for Computer-Aided Design), as the creation engine for 3D models. In the same way you might use Photoshop to create a graphic, Illustrator to create an illustration, or Word to create an article like this one, CAD software is used to create the design for a 3D model.

There are many CAD programs out there, each best-suited to different tasks. I alternate between TinkerCAD and Fusion 360, depending on whether I need to build a quick part or a more complex design.

TinkerCAD is a very easy-to-use program that's often taught to school kids. It allows for super-quick prototyping of simple designs. Fusion 360 is a full engineering design program with features not only for design, but motion simulation and stress testing as well. There are many other tools, like ZBrush and Meshmixer, that are often used for sculpting in virtual space.

If you can draw a rectangle in PowerPoint, you can use a CAD program to make simple designs. Resources for learning common 3D printing programs are available in many online classes, taught in colleges, and found in abundance on YouTube.

That said, since tools like Fusion 360 can be used to design and virtually test projects like car engines, they can be challenging to master. Often specific-discipline engineering skill is required to understand not only how the tool works, but the physics involved in the operation of the final object.

Slicers

CAD programs produce virtual models of 3D objects. But most 3D printing occurs layer-by-layer, in slices. The process of converting a 3D design into a series of machine movements on a two-dimensional plane (and then moving the plane) is the job of a slicer program.

But most 3D printing occurs layer-by-layer, in slices. The process of converting a 3D design into a series of machine movements on a two-dimensional plane (and then moving the plane) is the job of a slicer program.

Featured

- Less is more: Why the four-day week is rocking the world of work

- Mastodon isn't Twitter but it's glorious

- How to add your driver's license to the Apple Wallet app (and why you should)

- Black Friday smartwatch deals: Get an Apple Watch for $179 right now

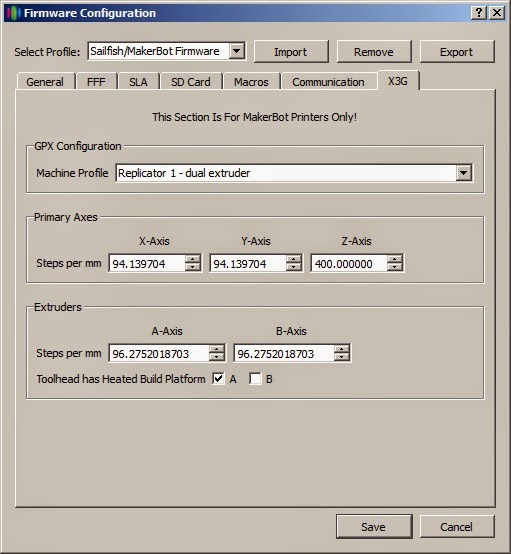

Most slicers produce G-code, a standard form of numerical control language understood by most computer-aided fabrication devices (not just 3D printers). While G-code is a standard (specifically, "EIA Standard RS-274-D Interchangeable Variable Block Data Format for Positioning, Contouring, and Contouring/Positioning Numerically Controlled Machines"), vendors often add extensions and modifications. This means that G-code usually needs to be generated by the slicer for specific brands and models of numerically controlled devices.

While some slicers can be operated programmatically by just passing a 3D model file into it and getting G-code output, most slicers today allow for a fully interactive interface. This allows the operator to adjust print orientation and examine the print process layer-by-layer in order to locate potential print problems before a print is sent to the printer.

It's also at this time that different printing settings are configured, ranging from nozzle and build plate temperature, adhesion techniques, infill methods, print speeds, and even custom G-code blocks to account for special procedures, like stopping a print to embed magnets, and then allowing the print to continue.

As with 3D printers and CAD programs, there are many slicers available to choose from. Some of the most popular, like Cura and Slic3r, are open source. There are also robust commercial offerings like Simplify3D.

Additionally, some vendors (like Zortrax and MakerBot) have created their own proprietary slicers tied to their individual hardware. As you might imagine, there are some benefits in this approach for tight machine integration, but the lock-in often means that operators who own multiple brands of 3D printers can't standardize on one slicing tool if they use these machines. Some machines with custom slicers ship with incomplete software, which tends to reflect poorly on the product's design and usability.

As you might imagine, there are some benefits in this approach for tight machine integration, but the lock-in often means that operators who own multiple brands of 3D printers can't standardize on one slicing tool if they use these machines. Some machines with custom slicers ship with incomplete software, which tends to reflect poorly on the product's design and usability.

For those organizations used to traditional production processes, 3D printers can save a tremendous amount of time. One example is Volkswagen Autoeuropa. In a discussion with 3D printer maker Ultimaker's president back in 2017, I was told:

The company [Volkswagen] turned to desktop 3D printing to create custom tools and jigs that are used daily on the assembly line, replacing an old process that required outsourcing and long lead times.

Not only did 3D printing introduce a more cost-effective way to produce the tools, it gave time back to the company.

The seemingly minor change saved $160,000 in just one plant in 2016, and it's projected to save $200,000 this year.

3D prints can take hours or days to print. I built a set of custom adapters that go between my shop dust collection system and the dust port for each of my tools. Printing each adapter at low resolution took about three hours. A detailed model of the Star Trek starship USS Discovery took a few days to produce as did a scale model of a Ford engine block.

I was able to create a custom adapter system perfectly tailored to my specific needs. 3D printing allowed me to make one-off objects at a material cost in pennies each. Because I was able to do my own design, I incurred no design cost.

Also: HP's new 3D printer has 3D-printed parts

How expensive is 3D printing compared to traditional manufacturing processes?

Adapters like these, built using traditional methods, would have required custom machining, and take weeks from design to delivery. Costs would have been thousands of dollars more than I paid. Because the turnaround from idea to object was so short, and because the out-of-pocket cost was so low, I was able to avail myself of a productivity-improving custom solution I might not otherwise have had.

Costs would have been thousands of dollars more than I paid. Because the turnaround from idea to object was so short, and because the out-of-pocket cost was so low, I was able to avail myself of a productivity-improving custom solution I might not otherwise have had.

This is another benefit of 3D printing: because the cost is so low, there's very little cost barrier to innovation, and as such, more innovation happens.

The thing is, comparing 3D printed objects to traditionally manufactured objects can't necessarily be quantified by cost. Traditionally manufactured objects often have a huge upfront expense necessary to build molds, fixtures, and even factories. But once those expenses have been incurred, the individual unit cost and time to delivery can be nearly instantaneous.

A tangible comparison

LEGO bricks (which are produced from ABS plastic) are made in astonishing quantities. The company reports:

- 19 billion LEGO elements are produced every year

- 2.

16 million LEGO elements are molded every hour

16 million LEGO elements are molded every hour - 36,000 are created every minute

Also: Stratasys launches F120 3D printer for $11,999; V650 Flex

I downloaded a classic 4x2 (four studs by two studs) rectangular LEGO brick model from 3D object sharing site Thingiverse. This is an exact fit-compatible version, which gives us an ideal comparison of production processes. We're comparing the exact models using the same plastic.

On my Ultimaker S5 (which is the same machine used in the Ford and Volkswagen factories), it would take 29 minutes to 3D print one brick, or about two an hour. Filling the large build plate, it's possible to print 65 bricks at once, but the process will take one day, seven hours, and 39 minutes to complete.

In the same 31 hours it takes to produce one plate of 65 bricks, LEGO produces 66.96 million. In other words, you'd need roughly one million 3D printers running full time to produce what LEGO produces in its factories.

Each brick produced by a 3D printer takes about 3g of filament (about half a meter). 3D printing costs about $0.06 per gram of filament for PLA or ABS. Not counting the cost of power, labor, maintenance, and real estate, each brick costs roughly $0.18. By contrast, LEGO sells its bricks to consumers for an average of 10.4 cents.

While it might be possible to produce LEGO bricks in volume via 3D printing, it's neither practical nor cost-effective. On the other hand, when LEGO wants to prototype and test new brick models, at about $0.18 per prototype, the hands-on design and testing process is certainly wildly cost-effective.

How does 3D printing affect the supply chain?

3D printing is also ideal for low volume or short run manufacturing. While some companies need to churn out products in the thousands or millions, other companies need to produce a relatively small number of units or produce units on-demand.

Low-volume production is needed in a variety of applications:

Production for in-house use: A small number of internal departments or users can benefit from the build.

:quality(90)/images.vogel.de/vogelonline/bdb/1157300/1157362/original.jpg) Jigs and frameworks fit this need perfectly.

Jigs and frameworks fit this need perfectly. Test market production: A limited number of units are produced at a manageable cost to test for either suitability for sale, or functionality and performance of features. If buyers respond well, more units can be produced using traditional production means.

On-demand production: Units needed rarely, or in a back catalog can be "stored in the cloud" and produced only when needed. This allows a large warehouse of parts to be stored virtually, and yet made available to customers as needed.

Entrepreneurial ventures: Small numbers of units can be produced as proof-of-concept for crowdfunding or to provide to influencers and reviewers to create initial press and awareness of a product before full funding has been closed.

It's this low-volume, on-demand capability that 3D printing provides that can be transformative to industry overall, not just manufacturing. By being able to quickly and inexpensively create and test new objects, it's possible to innovate at a pace impossible with traditional means.

By being able to quickly and inexpensively create and test new objects, it's possible to innovate at a pace impossible with traditional means.

Additionally, 3D printing promotes the idea of "think global, make local" in the sense that designs for objects can be shared internationally, but new units can be printed out wherever they are needed.

Take, for example, a fixture used in Ford's pilot plant in Cologne, Germany. The company has a small-scale manufacturing line which tests production of new vehicles. As part of this process, engineers use 3D printers to create jigs, tools, and fixtures.

Once tested and confirmed to be effective, delivering fixtures and jigs to other plants around the world would take shipping time, cost for international express shipping, as well as possible customs or other international transit paperwork. But if engineers at the AutoAlliance plant (a joint venture between Ford and Mazda) in the Rayong province of Thailand wanted to use a jig developed in Cologne, all they would need to do is download the digital file and print it.

The result would be the transferring of a custom-made tool across the world in hours, not days, for pennies, not hundreds or thousands of dollars, and with none of the paperwork hassle normally involved in international shipping.

How can 3D printing transform the manufacturing industry?

According to Ultimaker's Heiden: "3D printing continues to evolve within the manufacturing sector, and factory workers have led the adoption of the technology. As their skills continue to develop, the impact of 3D printing will continue to grow in every aspect of the manufacturing process."

That said, 3D printing is not necessarily suited to volume manufacturing. Because prints can take hours or days, once a prototype is developed, you may want to move to a faster production process for your final sale products.

On the other hand, 3D printing is ideal for creating molds, so you can design your object in a CAD program like Autodesk's Fusion 360, print out a prototype, and refine it until it meets your needs. Filament producer Polymaker, for example, has created a special ash-free filament called PolyCast. This filament can produce investment-casting objects that can be placed inside mold shells and then burnt out, creating a mold with no ash, ready for metal casting.

Filament producer Polymaker, for example, has created a special ash-free filament called PolyCast. This filament can produce investment-casting objects that can be placed inside mold shells and then burnt out, creating a mold with no ash, ready for metal casting.

But if you look at manufacturing solely through the lens of 3D printing, you'll be missing a much larger trend, that of "Industry 4.0." McKinsey estimates that the global manufacturing sector is worth roughly $10 trillion per year. The consulting firm contends there are four vast disruptions that will drive change in industrial processes and goods manufacturing:

Data volume and compute capacity: It's not just big data, it's the tremendous flow of data, the increase in computational power, and ubiquitous connectivity. McKinsey specifically calls attention to the impact of low-power, wide-area networks common among Internet of Things.

Analytics: Between AI and big data, the opportunity to subject every process to detailed examination and optimization based on advanced business analytics will drive supply chains that can be both dynamically reactive to worldwide events and micro-changes, as well as predictive based on accumulations of analytical resources from global sources.

New user interfaces: McKinsey believes that touch-interfaces, augmented-reality systems, and other forms of human-machine interaction will drive change in the manufacturing sector. You can consider 3D printing a new user interface as well, because the opportunity to hold a design concept in your hand can transform how you understand an object at a visceral level.

Digital numerical control: McKinsey describes this as "improvements in transferring digital instructions to the physical world," which is, in effect, G-code. But it's actually more than that. It's not only the transfer of instructions, which we've had for years. It's the technologies (ranging from 3D printing to robotics) capable of acting on those instructions that are proving to be transformative.

In looking at how manufacturing is transforming, it's necessary to look beyond just basics of production to transformations in asset management, labor (human, robot, and hybrid solutions), inventory management, quality (via advanced process control, machine vision, and business intelligence), supply chain management, time-to-market, and even after sales service.

Also: Despite growth, 3D printing represents only 0.1% of global manufacturing TechRepublic

Hands-on with 3D printingIf you're curious about 3D printing, perhaps the best way to understand how it might impact your business is to buy a 3D printer. Consumer-level 3D printers can be had for under $500, and excellent professional printers like those from Ultimaker, LulzBot, and MakerBot are available from about $3,000 to $6,000.

Here at ZDNet, we have run an extensive 3D Printing Discovery Series, with a whole range of articles, reviews, and hands-on video guides. Feel free to read and watch this series. In doing so, you'll be able to quickly and easily develop an in-depth understanding of 3D printing processes and potentials.

Now, go out there and make something great!

Related stories:

- HP sees 3D printing potential in transforming APAC manufacturing

- Dell Technologies using 3D printing to transform prosthetics

- 3D printing guns at home: Does new technology change America's gun control debate?

- Photos: 26 weird and useful things to 3D print for your desk TechRepublic

- Scientists build a 3D printer that turns goo into solid objects CNET

- Best 3D Printer of 2020 CNET

Everything You Need to Know About 3D Printing: The Ultimate Guide - Materials and Engineering Resources

Table of contents:

- What is 3D printing?

- What are the benefits of 3D printing?

- What are the disadvantages of 3D printing?

- How does 3D printing work?

- What 3D printer shall you use?

- Applications of 3D printing.

- The history of 3D printing.

- Bonus tips on 3D printing.

Heard about 3D printing and want to know what it is and how it really works? You’ve come to the right place.

From buildings to prosthetics to the aerospace and even food, 3D printing is a constantly evolving manufacturing technique that is getting more and more popular by the day.

Despite being in its early stages of development, 3D printing has taken the manufacturing world by storm with its unmatched advantages and amazing potential.

Whether you’re an utter beginner or an accomplished professional, you’re going to love the following explanation and tips on 3D printing.

So, without further ado, here is the complete guide into the world of 3D printing as it reveals all that you need to know in the simplest and most useful way.

Let’s dive right in.

What is 3D printing?

3D printing is the process of creating three-dimensional objects based on a predesigned digital model.

It works as a layering technology; i.e. manufacturing products by printing layers upon layers until the whole object is formed.

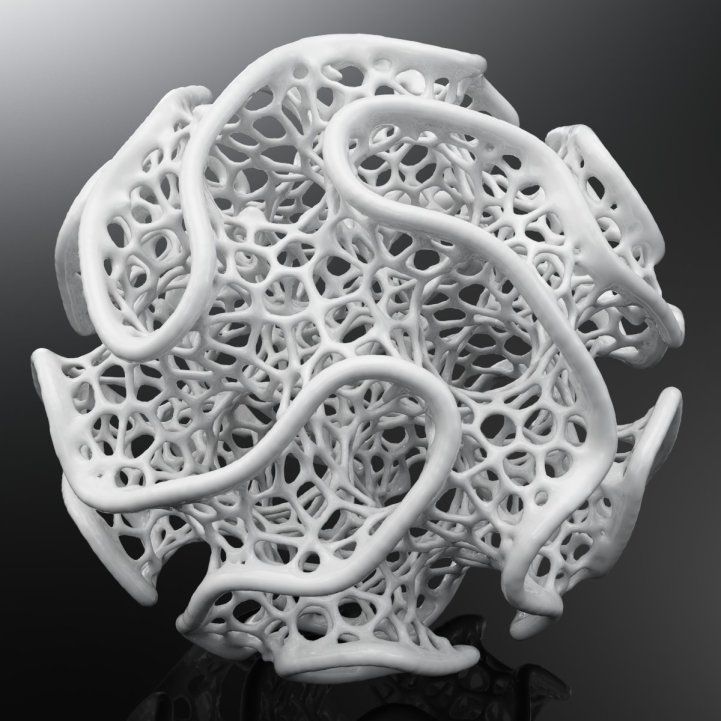

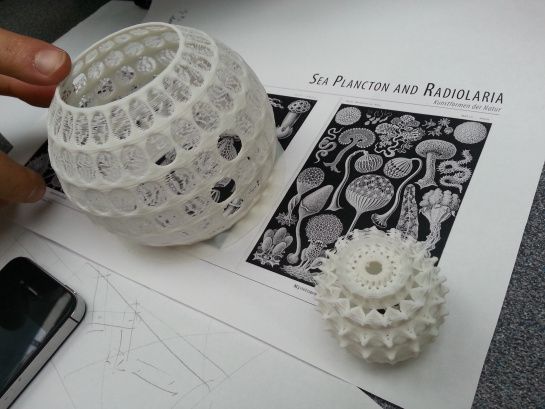

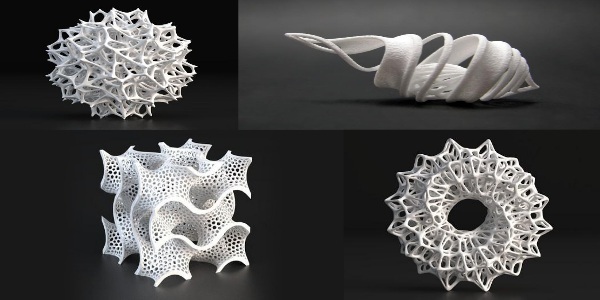

Whether it’s a piece of art, an architectural shape, a prototype of a product that you want to test, a home accessory, a car part, a biomedical device, an aerospace component, or even a biological organ, by building layer upon layer, you can actually create, with high degrees of complexity, products you wouldn’t normally be able to create with traditional fabrication methods.

Now, of course, this depends on the limitations of the 3D printer you’re using.

But it shows the expansive range of applications that 3D printing is already being used for (and can be used for in the future).

3D printing is also known as additive manufacturing (AM). Now, if you are one of those who are curious to know different names given to one thing, well I got you covered.

Here are some historical terms given to additive manufacturing:• Additive fabrication

• Additive processes

• Additive techniques

• Additive layer manufacturing

• Layer manufacturing

• Solid freeform fabrication

• Rapid prototyping

You’re welcome!

But what’s the point of all this?

Why should you go for 3D printing instead of other fabrication methods?

You see, in addition to its ability to manufacture complex parts, 3D printing does that essentially at a fraction of the time and at a significantly lower cost compared to traditional techniques such as forging, moulding and sculpting.

Now that’s impressive! Not only that.

Interestingly enough, more and more user-friendly printers are being released, which is the next step in revolutionizing the manufacturing world.

Say hello to building your kitchenware right on your kitchen counter…

Or your tools right in your own garage…

Or your next prototype in the easiest and quickest way possible.

What are the benefits of 3D printing?

Now, we’re on a roll. Here’s how 3D printing can leave you better off in your pursuit for better manufacturing.

1. Rapid Manufacturing

One of the most important factors in manufacturing is time.

It is crucial that the manufacturing time be made as short as possible while maintaining quality.

3D printing can save a lot of time.

That is why it is given the alternative name ‘rapid prototyping’.

Rapid prototyping is essentially a one-step fabrication process that helps minimize process time while preserving complexity, precision, and fidelity to the final product.

In short, a prototype that previously required days (even weeks) to finish or test can be simply 3D printed in the morning, tested, modified, and reprinted in the evening.

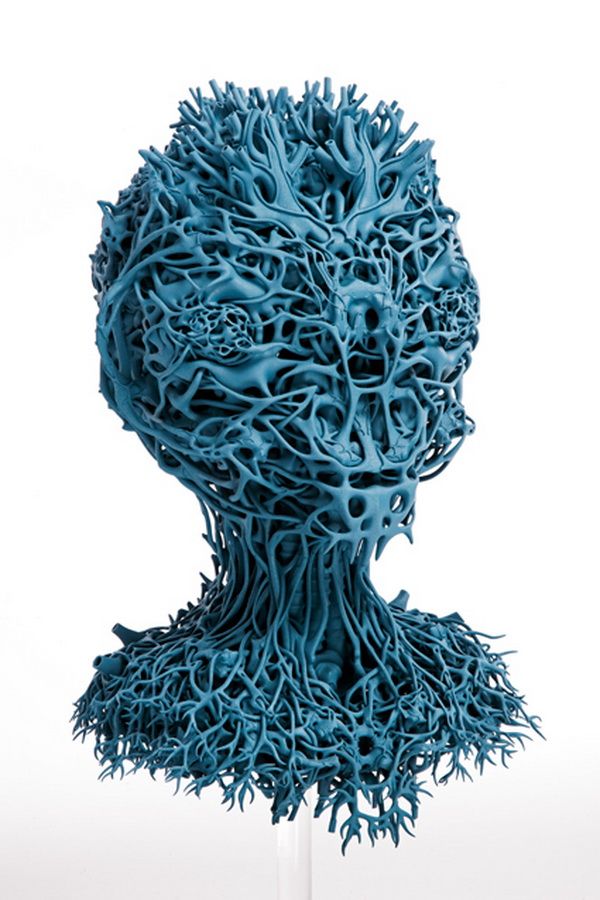

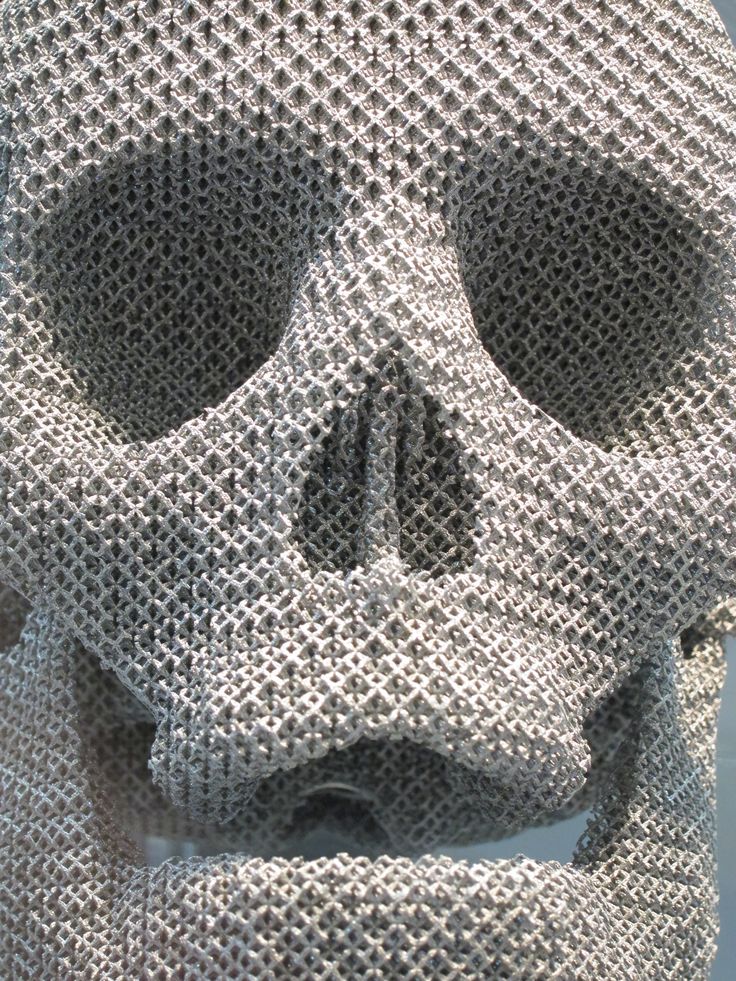

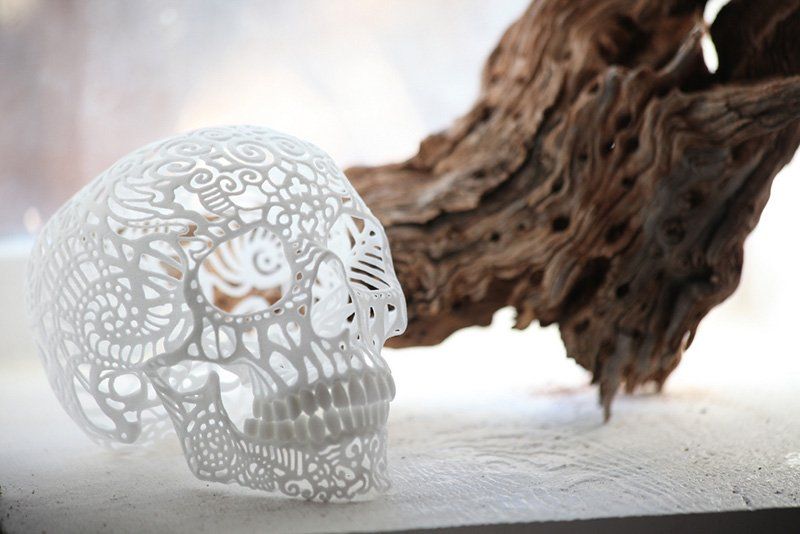

2. Precise complexity and flexibility in design

Conventional manufacturing techniques impose limitations when it comes to freedom of design and complexity.

Requirements such as undercuts, draft angles, and tool access restrict the design leeway.

3D printing gets you around this issue because of its intrinsic layering methodology.

No need for all those consuming requirements.

With 3D printing, you can print objects with high levels of complexity and precision.

3. Versatility and accessibility

An amazing feature of 3D printers is that they fit almost everywhere.

In your home.

In your office.

In your school.

In your lab or studio.

As long as you have a design software and a slicing software on your computer, your 3D printer will do the rest.

3D printing is being accessed by an increasing number of people…

And not necessarily professionals.

Its versatility and ease-of-use allows even amateur individuals to be able to use it effectively.

4. Personal customisation

Industrial manufacturers generally produce products via mass production;

That is the usage of the same moulds and design requirements to shape and produce their products.

Modifying the shape and design of the product to meet certain customer needs, even slightly, requires substantial effort and investment.

On the other hand, 3D printing provides endless freedom and ease of customisation.

Tweak your designs as you wish.

Give each family member their own personalised gift.

Set yourself apart in creating your jewellery design.

Fabricate customised dental or medical products for your customers.

The possibilities are infinite.

5. Risk alleviation

A very critical step in building projects is testing the prototype to avoid the risk of creating a faulty product or investing in big-budget tooling.

Once again, 3D printing comes to the rescue.

By printing and testing a prototype that has high conformity to the final product, you can establish a high confidence level before laying out the big money.

Not just that!

Traditional techniques consist of many manufacturing steps in order to deliver the desired product.

This generates a significant risk of error during the process.

3D printing, conversely, is fundamentally a one-step manufacturing technique that does not require the interference of the operator.

Thus, it helps you eliminate uncertainty and reduce error in a rapid and low-cost manner.

6. Sustainability and waste reduction

Conventional manufacturing methods are, by definition, top-down approaches.

They are subtractive. To form the product, they carve through a block of material. They extract significant volumes of unwanted material. This unwanted material goes to waste.

Some get recycled, but still require time, effort, and money. 3D printing, contrarily, is a bottom-up approach.

It is additive. It uses adequately the necessary amount of material for constructing the part. Those materials, moreover, are mostly recyclable and reusable. Consequently, little to no waste is generated.

Those materials, moreover, are mostly recyclable and reusable. Consequently, little to no waste is generated.

3D printing is also relatively energy-efficient.

This reduction in energy consumption and waste generation helps decrease the impact on the environment, and hence, increase the level of sustainability.

7. Cost-effectiveness

This is arguably the most outstanding feature of 3D printing.

The costs incurred by companies and individuals when employing traditional fabrication techniques are significantly high.

Think about it.

- All the tooling.

- The machinery…and its maintenance.

- The material cost.

- The energy cost.

- The labour cost…and the expenses due to errors and inflexibility.

Traditional techniques are especially expensive for low-volume manufacturing and prototyping.

This is where 3D printing can play an effective role.

Additive manufacturing has a significant competitive edge over other manufacturing methods in terms of machine costs, material costs, and labour costs.

Machine costs usually contribute the least to the total manufacturing cost.

However, the time efficiency and one-step manufacturing feature gives 3D printing an advantage, which in turn, results in a higher turnover.

Material costs vary depending on the type of technology used.

Labour costs are the bee’s knees of 3D printing!

You don’t need to employ several highly skilled operators to do the job.

All you need is one.

At a press of a button, most 3D printers are able to perform the whole process without further interference.

Other advantages include smaller storage spaces, staying ahead of competitors, market testing, better communication of products, and confidentiality.

3D printing is one of the most exciting manufacturing industries in the world right now – and blue chip companies such as Google, General Electric and Nike are investing into it.

In fact, Google’s even recreating Ancient Artifacts using 3D Printing!

Next, we flip the coin to see the other side of 3D printing.

What are the disadvantages of 3D printing?

OK, so all this sounds great so far.

But as any other technology, 3D printing is not perfect.

There are definitely some limitations, too. These include:

1. Product weakness

The layer by layer methodology of 3D printing may result in a product that can be 10-50% weaker and more brittle in certain directions vs bulk materials.

That’s not usually a major problem – however, you wouldn’t use this in critical applications.

Some 3D printers, such as DMLS and SLM, can produce stronger parts.

In industries where you need reliable, durable products – such as aerospace – these printers have become increasingly popular.

2.

Economies of scale

Economies of scale3D printing is quite advantageous at low-volume manufacturing.

But once the volume is scaled up, 3D printing loses its competitive advantage, as the production price per unit decreases minimally.

Comparatively, the price per product in traditional manufacturing processes drops dramatically with increasing volume.

More cost efficient processes for large-volume production include CNC machining and Injection Moulding.

Basically, 3D printing is great for small batch runs – but not cost efficient enough yet for bulk printing.

3. Accuracy

There’s a small margin of error when it comes to 3D printing.

This tends to range between ± 0.01 mm to ± 0.5 mm.

What does this mean?

Well, let’s say you’re printing a product with an 8.5 mm hole.

Its actual measurement could range between 8 mm to 9 mm.

So if you’re a commercial company manufacturing for a client, there’s a slight risk that your product isn’t going to accurately fit your client’s requirements.

Obviously as the technology develops, its accuracy should increase too.

4. Post-print processing

Once you’ve actually printed a part, it usually still requires a bit of post-processing to ensure it’s ready to be used.

This could include sanding and painting the part.

So although the 3D printing process saves time, you need to factor the time taken for post processing.

You might also need to create support parts too – especially if you have an overhang/underhang on the object.

Other drawbacks include by-product waste, possible toxic emissions, limited printing materials, size limitations, and potential counterfeit of products.

With all that in mind, next are your working steps.

How does 3D printing work?

Step 1: Create your design in a CAD modelling software

First of all, you need to create a 3D blueprint of the object you’re going to be printing.

How is this done?

Basically, by using CAD modelling software, you can create your own designs.

Whether you are a beginner or a professional, there are multiple software options at your disposal.

If you’re not planning to begin learning a complex set of tools, you can go for SketchUp and Autodesk Fusion 360.

They are beginner-friendly and they include all the tools you need to create, edit, and produce your 3D design.

You can find a lot of tutorials online if you’re just starting out.

You can also find templates online for 3D printing – especially if it’s a common object.

Useful websites for finding templates include Thingiverse and MyMiniFactory.

If your aim is professional design software and you are willing to take the time and learn how to use them, Autodesk provides other software options with advanced features.

Software such as 3DS Max, Maya, and NetFabb from Autodesk allow you to control every detail of your design.

SolidWorks, CATIA, and Rhino are also distinguished software for 3D design.

Your use of such software would depend on your area of work, whether you are an engineer, architect, or designer.

Another option to create your 3D model is to scan an already existing object.

So let’s say you’re trying to emulate an object.

With a 3D printing scanner, you can essentially create a digital version of the product.

Some scanners vary in terms of reliability and precision.

Yet, this can help speed up the design process, especially if you don’t have the time or the expertise to do it yourself.

Step 2: Export your design as a STL file

Once your model has been designed, export it as a . STL file, which is the usual file format used for 3D printing.

STL file, which is the usual file format used for 3D printing.

STL generally stands for ‘stereolithography’ – a type of 3D printing.

Sometimes, it is considered as an abbreviation for “Standard Triangle Language” or “Standard Tessellation Language”.

Basically, it’s the format your CAD software will export your design in to the slicing software.

Step 3: Import the STL file into a slicing software

After finalising the design, it has to be sliced before printing.

To do that, import your STL file into a slicing software.

This is where you layer the object of your design, in terms of materials.

You can do this via a slicing software or via your 3D printer.

Taking into account the dimensions allowed by your 3D printer, your design can easily end up being sliced into hundreds or even thousands of layers.

Slicing software helps you to customise:

- Each layer of the object

- The tool path

- Temperature

- Colours

- How fast you’d like to print

Basically, you’re customising the printing process your 3D printer will use.

Some of the most commonly used slicing software include MakerWare, Cura and Simplify 3D.

Step 4: Export your sliced design to your 3D printer

Once you’ve layered your design in your slicing software, export your sliced model as a G-code file.

G-code is a language for you to communicate commands to a machine.

In this case, the G-code file would contain instructions on how to move the 3D printer components.

Upon exporting, your design would be ready to be finally sent to your 3D printer.

Depending on your printer, you’ll either use a USB, an SD card or you can send the design via WiFi.

Once the printer receives your blueprint, it begins the printing process!

Now comes the main question.

What 3D printer shall you use?

Well, there are many types of 3D printers.

Your selection depends on several factors such as:

- Desired dimensions, material selection

- Cost structure

- Tolerance

- Mechanical properties

- Complexity

- Process time

- Energy consumption.

Now, here’s the cool part.

I compiled for you the most commonly used methods of 3D printing in the table below.

See which one suits your plan best in order to get the appropriate 3D printer.

Other 3D printing methods include inkjet printing, contour crafting, direct energy deposition (DED), and laminated object manufacturing (LOM).

If you’re interested in looking at 3D printing from a material point of view, Optimatter has provided data on different materials used in FDM.

This ranking on a scale of 1 (low) to 5 (high) may give you a head start as to which material to go for.

So, which 3D printer are you going to select?

Applications of 3D printing

Theoretically, you can print out almost any useful (or useless) solid object you can think of!

From sunglasses, shoes, tableware, and milk jugs, all the way to screws, boat propellers, aircraft engine compartments, and product prototypes…

The number of things that you can 3D print is unlimited.

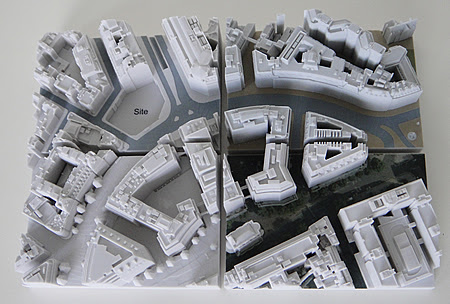

Some of the most popular application areas for 3D printing include consumer goods, the aerospace industry, the automotive industry, electronics, architecture and buildings, and the biomedical and healthcare sector.

Here’s a pie chart to have a better idea of the Additive Manufacturing market share.

3D printing is an industry that’s expected to grow from $7.34BN to $35.6BN by 2024.

Aerospace alone accounts today for over 18% of the AM industry’s revenue!

Boeing, for example, are already using 3D-printed titanium alloy parts on their 787 Dreamliner aircraft.

They’re even planning to use AM to produce as many as 1000 parts in the near future.

That’ll save them over $2 million per plane!

NASA, ESA, and SpaceX are studying the use of AM in building combustion chambers and igniters for their rocket engines.

Architecture, on the other hand, accounts for as little as 3% of the AM industry.

The most commonly used AM method in buildings today is the additive manufacturing of concrete (AMoC), which follows the approach of contour crafting (CC).

2014 was the year when the first 3D printed building was constructed by architects in Amsterdam.

In the same year, a company in Suzhou, China, 3D printed 10 houses in less than 24 hrs, for half the cost that it would entail when using traditional building methods.

The ESA is also planning to build a “moon village” by 2030 by using lunar soil as 3D printing material.

How awesome is that?!

And there’s even more!

3D printing has entered the world of microelectronics as it has been showing a promising future in manufacturing MEMS (micro-electromechanical system) devices, in particular LOCs (Lab-on-chip) and electronic packaging.

More astounding applications include 3D printing of food – even in space – and organ printing.

Yes, artificial hearts, kidneys, and livers could be customised and printed for transplants.

3D printing is exponentially growing.

It is penetrating almost all industries as it develops and becomes more accessible.

But how did it all start?

The history of 3D printing

3D printing is close to completing its fourth decade since it was first introduced.

Almost 40 years old…and still looking hot off the press!

3D printing was first presented in 1981, under the name “rapid prototyping”, by Hideo Kodama.

It was not until Charles Hull invented stereolithography in ‘83 and patented his SLA in ‘84 did 3D printing begin to gain traction and popularity.

Fast forward to 1992 when the world’s first SLA and first SLS machines were produced.

Despite many challenges, especially the issue of material warping, those two methods showed an unquestionable potential.

Since then, the technology took off.

In 1999, scientists were able to successfully implant the first 3D-printed organ in a human patient.

The idea of manufacturing being accessible to everyone began to materialise by the mid-2000s.

In 2008, RepRap’s ‘Darwin’ 3D printer was introduced.

It was allegedly a ‘self-replicating printer’ that gave people the instant ability to create whatever they want by themselves.

Today, 3D printing has almost certainly surpassed Hull’s dreams!

Innovation in jewellery design, car manufacturing, aircraft manufacturing, architecture, biomedical devices, robots, and even food…

All with 3D printing at the centre.

What do you think will the future hold for 3D printing?

Bonus tips on 3D printing

Since you’ve reached this much in your reading of this long guide, it’s only fair of me to give you some good tips to get you familiar and started with 3D printing.

So here you go!

- Buying a 3D printer is like buying a car but without the test drive.

In other words, user experience is very important. Don’t focus just on the specs and metrics. Ask about user experience and what people think and feel about the printer you want to buy.

In other words, user experience is very important. Don’t focus just on the specs and metrics. Ask about user experience and what people think and feel about the printer you want to buy. - Speak to the manufacturer about the power efficiency of the printer before you make a purchase. This will help you create a rough energy cost estimation and eventually, save money.

- If you’re planning to pursue 3D printing as a career, the most convenient way is to check university courses, online courses, and internship opportunities at additive manufacturing companies that can get you started.

- To improve your print quality, make sure the 3D printer’s bed is precisely horizontal and set the nozzle at an appropriate distance and a proper temperature.

- Keep the printing speed low enough to avoid ringing, an issue that would cause the part to have kind of a blurry looking surface.

- You need your printed part to stick to the bed so it doesn’t fall down during printing.

Find your go-to bed adhesive and stick with it.

Find your go-to bed adhesive and stick with it. - Drink your beer one sip at a time; that means instead of building the whole design all together at once, print a small piece as a test first to make sure issues and irregularities are minimised.

- If you’re working with a material that has weak toughness and ductility, like PLA, make sure to print multiple perimeter outlines to strengthen the part and reduce the chances of breaking.

- Hollowing is a technique that will help reduce your cost per unit. In essence, you create a hollow in your part, thus reducing the materials used. But be careful in how you design it because hollowing may be tricky when designing complex parts. Make sure to add escape holes in order to remove materials from inside.

- Get to know your printer. Get acquainted with it. Know its tools. Know its capabilities. Test all possible settings to make sure you know what you can get out of it.

- Keep asking people questions and gather as much information as you can, even if you don’t need it on the spot. It’ll help later on. You can do that on our Linkedin group.

Now it’s your turn

By now, I believe you can see how exciting and promising 3D printing is.

Its future is likely to bring amazing innovations and advancements.

If you didn’t know much about 3D printing before, keep your head up.

With this guide, you have formed a pretty good idea about what it is and how it works.

Now, are you ready to get started?

Let me know your thoughts and enquiries in the comment section below.

Supplier of 3D equipment since 2010

+7 495 646-15-338 800 333-12-82

3D-scanners 3D-printer-software service

On the Project-Zalgoskapkupservisation-Statement 30003 Contacts

Today, there are about 10 major 3D printing technologies. They differ in speed, accuracy, material used and other parameters. The choice of 3D printing technology depends on the tasks that you set for the 3D printer, on the requirements for the resulting products.

They differ in speed, accuracy, material used and other parameters. The choice of 3D printing technology depends on the tasks that you set for the 3D printer, on the requirements for the resulting products.

- FDM / FFF

- SLA

- SLM

- SLS

- CJP

- PolyJet

- FDM / FFF

- SLA

- SLM

- SLS

- CJP

- PolyJet

FDM (Fused Deposition Modeling) / FFF (Fused Filament Fabrication)

Operating principle: layer-by-layer construction of a product from molten plastic material.

Features:

- Various types of plastics (durable, flexible, heat resistant, etc.)

- Strength and durability of finished products

- Large Camera 3D Printers

- Low cost and high productivity

More about FDM technology >>

FDM (Fused Deposition Modeling) / FFF (Fused Filament Fabrication)

Operating principle: layer-by-layer construction of a product from molten plastic material.

Features:

- Various types of plastics (durable, flexible, heat resistant, etc.)

- Strength and durability of finished products

- Large Camera 3D Printers

- Low cost and high productivity

More about FDM technology >>

SLA (stereolithography)

Operating principle: layer-by-layer curing of a liquid polymer material under the action of a laser beam.

Features:

- Materials: polymer resins with different properties

- Laser curing

- High print speed

- High precision and detail

- Smooth surfaces

More about SLA technology >>

SLA (Stereolithography)

Operating principle: layer-by-layer curing of a liquid polymer material under the action of a laser beam.

Features:

- Materials: polymer resins with different properties

- Laser curing

- High print speed

- High precision and detail

- Smooth surfaces

More about SLA technology >>

SLM (Selective Laser Melting)

Other names: DMP, DMLS, EBM, etc. various metals and alloys

various metals and alloys

Learn more about SLM technology and its alternatives >>

SLM (Selective Laser Melting)

Other names: DMP, DMLS, EBM, etc.

Operating principle: layer-by-layer fusion of metal powders under the influence of a laser

Features:

- Working with various metals and alloys

- Unique Product Features

- Any geometry

More about SLM technology and its analogues >>

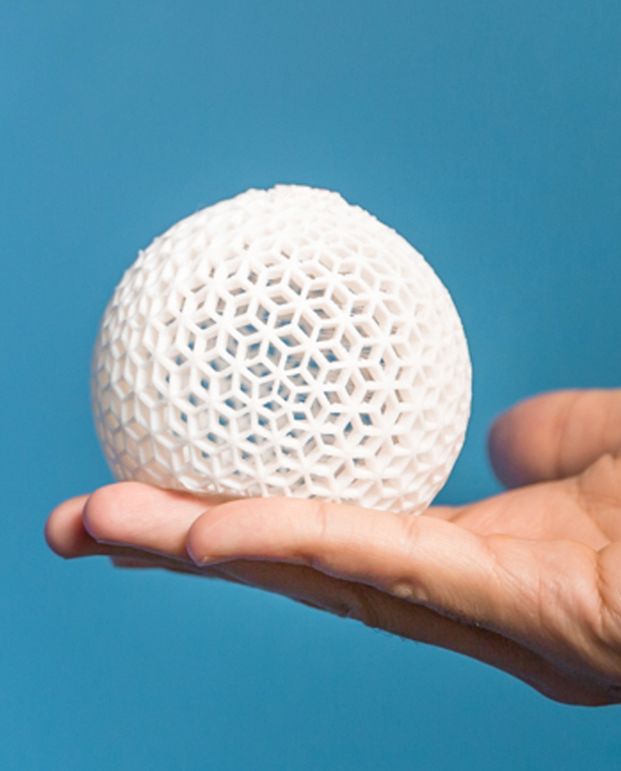

SLS (Selective Laser Sintering)

Operating principle: layer-by-layer sintering of polyamide powders under the influence of a laser

Features:

- Material: polyamide powders

- Any geometry

- Strength and precision

- High performance

Find out more about the SLS technology >>

SLS (Selective Laser Sintering)

Operating principle: laser-assisted layer-by-layer sintering of polyamide powders

Features:

- Material: polyamide powders

- Any geometry

- Durability and precision

- High performance

Learn more about SLS technology >>

CJP (Color-Jet Printing)

Function: layer-by-layer bonding and coloring of composite powder

Features:

- Gypsum based composite powder

- 3D full color CMYK

- Realistic prototypes for visual evaluation

- Complex geometries

- Low cost

More about CJP technology >>

CJP (Color-Jet Printing)

Function: layer-by-layer bonding and coloring of composite powder

Features:

- Composite powder based on gypsum

- 3D full color CMYK

- Realistic prototypes for visual evaluation

- Complex geometries

- Low cost

Learn more about CJP technology >>

PolyJet

Operating principle: curing liquid photopolymer material under UV radiation

Features:

- Photopolymer materials with different properties (transparent, rubbery, biocompatible, etc.

)

) - High detail, smooth surfaces

- Color 3D printing available

- Products do not require post-processing

Learn more about PolyJet technology >>

PolyJet

How it works: curing liquid photopolymer material under UV light

Features:

- Photopolymer materials with different properties (transparent, rubber-like, biocompatible, etc.)

- High detail, smooth surfaces

- Color 3D printing available

- Products do not require post-processing

Learn more about PolyJet technology >>

We will help you choose a professional 3D printer0003

Come to our demo hall

Learn moreI confirm the accuracy of the information I entered and agree to the processing of my personal data in accordance with the privacy policy and user agreement.

- +7 495 646-15-338 800 333-12-82

3d@globatek. ru

ru

2010–2022, Globatek JSC. All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer - that is, builds or grows.

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers, consisting of sheet material, liquid or powder, are combined with each other, turning into the final form.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

In order to print something , you first need a 3D model of the object, which you can create in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you have to do is import it into the Slicer, a program that adapts the model into codes and instructions for a 3D printer, most of the programs are open source and distributed free of charge. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

The whole process can take several hours and sometimes even days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts into the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts into the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Of course, when you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed?

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical use cases:

Custom Models

Create custom products that perfectly fit your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.