3D printer india bangalore

Best 3D Printing Company in Bangalore India

3D Printing ServicesFor For 3D Printing Services Made in India 3 Printing Filament

With With Made in India 3D Printing Filament For

3D Printing Machine 3D Printing Machine For

Reduction in time to

market

Cost Saving to our

customers

Number of 3D Parts

Designed

Faster time to launch

new product

Reasons to Choose

Aurum3D

Reduction in time to

market

cost saving to our customers

number of 3d parts designed

faster time to launch new product

reasons to choose aurum3d

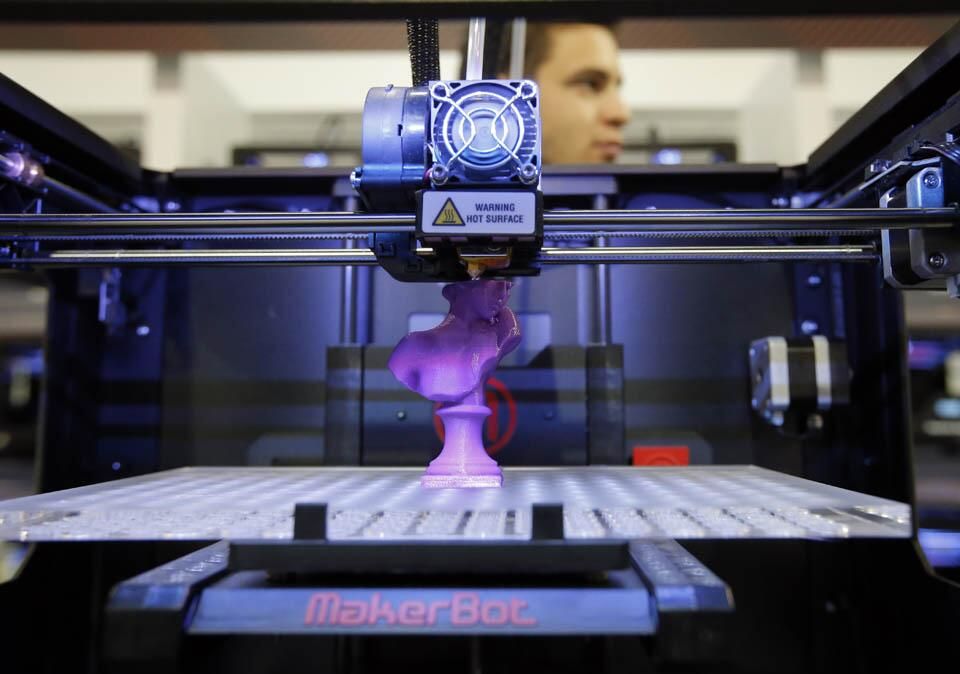

3D Printing Services

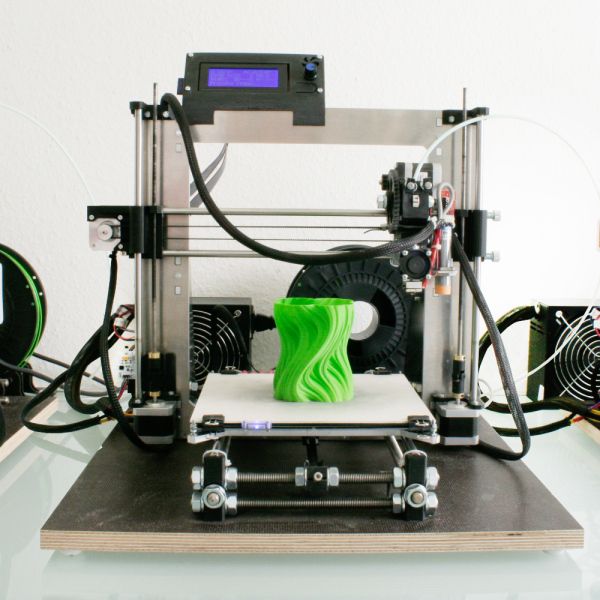

The 3D printers create the consumer or industrial product by depositing thin layers of materials successfully according to the CAD/CAM-based design diagram.

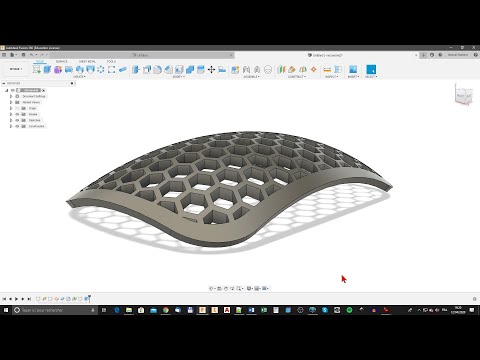

3D Design Services

We allows clients from various industries to choose from a wide range of 3D Modelling and design services according to their precise needs and requirements.

3D Scanning Services

In this changing technological transformation now we have so many handheld 3D scanning devices to scan and reproduce the geometry of any small to big complex geometry.

Aurum3D can be considered as a one-stop-shop for all 3D Printed Products and Services

Aurum3D can be considered as a one-stop-shop for all 3D Printed Products and Services

Click here

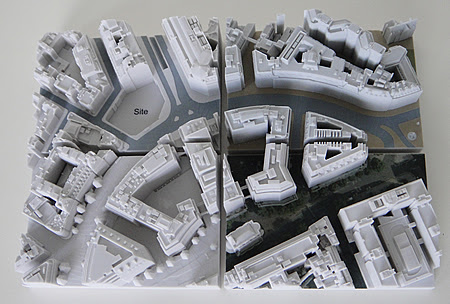

Aerospace & Defence Automitive Engineering Home Decor Education Manufacturing Medical

Aerospace & Defence

3D Printing Makes Patternless Production a Reality in the Aerospace Industry. The ability to 3D print intricate castings directly from 3D CAD files – which can be modified quickly to accommodate design changes – provides greater opportunities to design parts with aerospace applications. View more

View more

Automotive

3D printing can be used to make molds and thermoforming tools, rapid manufacturing of grips, jigs, and fixtures. This allows automakers to produce samples and tools at low costs and to eliminate future losses in production when investing in high-cost tooling. View more

Engineering

3D printers allow you to create prototypes, models and products out of materials such as plastics and metals. The printers do this by creating layer upon layer of your design in your chosen material until the final product is formed. View more

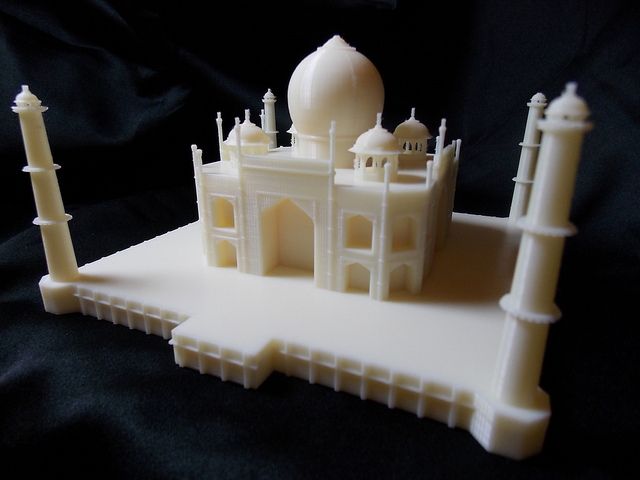

Home Decor

This stackable hex drawers design is one of those fantastic DIY room decor ideas that is so obvious and so simple, you wish you'd thought of it yourself. It's a modular design where you can 3D print as many hex drawers as you need, and then simply clip them together. View more

Education

3D printers can help create an engaging learning environment by making subjects more exciting and fun. It creates an immersive experience and makes learning more hands-on, which encourages students to be more active. This technology promotes problem-solving and critical-thinking skills. View more

It creates an immersive experience and makes learning more hands-on, which encourages students to be more active. This technology promotes problem-solving and critical-thinking skills. View more

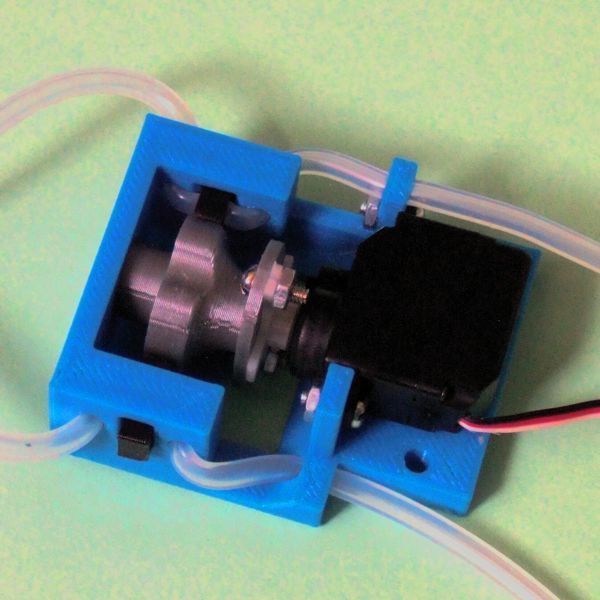

Manufacturing

On the other hand, 3D printing is a very precise manufacturing process. Whatever is designed is 3D-printed using the raw materials, no cutting down, no leftover material, no need to reprocess the materials. Therefore, it's only an additive process and not subtractive View more.

Medical

Additive manufacturing has been used to produce hearing aids, replacement limbs, surgical implants, and detailed models of organs, bones, and blood cells. Access to this technology has greatly advanced the potentials of the medical field. View more

Aerospace & Defence

3D Printing Makes Patternless Production a Reality in the Aerospace Industry. The ability to 3D print intricate castings directly from 3D CAD files – which can be modified quickly to accommodate design changes – provides greater opportunities to design parts with aerospace applications. View more

View more

Automotive

3D printing can be used to make molds and thermoforming tools, rapid manufacturing of grips,jigs, and fixtures. This allows automakers to produce samples and tools at low costs and to eliminate future losses in production when investing in high-cost tooling. View more

Engineering

3D printers allow you to create prototypes, models and products out of materials such

as plastics and metals. The printers do this by creating layer upon layer of your design in your chosen material until the final product is formed.View more

Home Decor

This stackable hex drawers design is one of those fantastic DIY room decor ideas that is so obvious and so simple, you wish you’d thought of it yourself. It’s a modular design where you can 3D print as many hex drawers as you need, and then simply clip them together.View more

Education

3D printers can help create an engaging learning environment by making subjects more exciting and fun. It creates an immersive experience and makes learning more hands-on, which encourages students to be more active. This technology promotes problem-solving and critical-thinking skills. View more

It creates an immersive experience and makes learning more hands-on, which encourages students to be more active. This technology promotes problem-solving and critical-thinking skills. View more

Manufacturing

On the other hand, 3D printing is a very precise manufacturing process. Whatever is designed is 3D-printed using the raw materials, no cutting down, no leftover material, no need to reprocess the materials. Therefore, it’s only an additive process and not subtractive.View more

Medical

Additive manufacturing has been used to produce hearing aids, replacement limbs, surgical implants, and detailed models of organs, bones, and blood cells. Access to this technology has greatly advanced the potentials of the medical field.View more

Client case studies

Next-Gen Transformation Solutions

Digital Transformational Solutions

Design Life-cycle Transformation

Previous

Next

REQUEST A PROPOSAL

Leave your details for our manager to contact you.

Let our consultants and design team assess your project requirements.

Receive a proposal and free consultation.

Company

Services

3D Printing Materials

Registered Address

D-208, Innovative Petal,

Near BMA College, Doddanekundi,

Bangalore, Karnataka, India 560037

Ph: +91-8310758536

Industries

Resources

Design Centre

#210, 12th Cross, 29th Main Road

BTM Layout 2nd Stage

Bangalore, Karnataka 560076

Ph: +91-6360294071

Follow Us

Link

© 2021 Aurum3D. All Rights Reserved.

Company

Services

3D Printing Materials

Industries

Resources

Registered Address

D-208, Innovative Petal,

Near BMA College, Doddanekundi,

Bangalore, Karnataka, India 560037

Design Centre

#210, 12th Cross, 29th Main

BTM Layout, 2nd Stage

Bangalore, Karnataka 560076

Follow Us

Youtube

WordPress

© 2020 Aurum3D.

All Rights Reserved.

All Rights Reserved. 3D Printing Service in Bangalore

Is 3D printing just for rapid prototyping?

3D printing is an essential tool for accelerating the prototyping process. However, its applications stretch well beyond prototyping to other facets of the product lifecycle.

• Manufacturing – Design freedom and economically viable low-to-mid-volume production enable new possibilities for product design and operational improvement. Applied in combination, these two capabilities have the potential to transform decades-old supply chains and business models.

• Tooling – 3D printed tooling advantages include on-demand production, customization, digitization of designs and unrestrained design flexibility. This cuts out costly suppliers, compresses lead times, enables digital warehousing and accelerates manufacturing floor productivity.

• Sales and Retail – 3D printing gives retailers the ability to innovate, delivering highly customized, on-demand products and new experiences such as “co-designed” items developed in conjunction with the customers.

• Aftermarket Supply – Businesses that embrace 3D printing for spare and replacement parts can replace warehouses of spare parts with 3D printers or a contract 3D printing service bureau to produce parts on a just-in-time basis.

How does 3D printing impact product development and speed to market?

3D printing accelerates the process by reducing the time and cost associated with prototyping and refining the design. Many more 3D printed prototypes can be produced in the time needed to mold or machine them and for much less cost. Highly realistic prototypes printed on full-color multimaterial printers look like the final product, cultivating faster and better decisions.

What can designers do with 3D printing?

3D printing gives designers the capability to drastically shorten the design process compared to traditional methods of hand-modeling or outsourcing to model shops.

Keep the design process entirely in-house. With 3D printing, designers gain full control over the design process. Creating models in-house saves the time associated with outsourcing. More timeline flexibility empowers designers to try new ideas and iterate often, resulting in better products that stand out.

With 3D printing, designers gain full control over the design process. Creating models in-house saves the time associated with outsourcing. More timeline flexibility empowers designers to try new ideas and iterate often, resulting in better products that stand out.

Prototype faster and smarter. Outsourcing is often too expensive and time-consuming to allow iteration of more detailed prototypes, especially models that incorporate CMF (color-material-finish). The speed and streamlined workflow of 3D printing gives designers the freedom to create dozens of detailed prototypes while reducing the time to arrive at the optimal design.

Create beautiful, highly detailed models. With full-color, multimaterial printing, designers can create prototypes that look, feel, and even function like the real thing in just a few hours. The ability to assess the color, texture, and ergonomics of a product means better feedback and faster approval from clients.

Is 3D printing a replacement for conventional manufacturing technology?

3D printing is not a wholesale replacement for existing manufacturing methods like molding and machining. Its benefit lies in supplementing these other technologies at points where they can’t compete. For example, 3D printing’s additive nature is able to make structures that aren’t possible with machining or molding. It also makes low- to mid-volume production economically viable because there’s no need for the tooling investment. Similarly, it’s much faster to get started, which is why GM turned to 3D printing to retool its production line to produce ventilators in the pandemic. In short, 3D printing is another tool in the toolbox, but one that offers key benefits over traditional manufacturing practices when used strategically.

Its benefit lies in supplementing these other technologies at points where they can’t compete. For example, 3D printing’s additive nature is able to make structures that aren’t possible with machining or molding. It also makes low- to mid-volume production economically viable because there’s no need for the tooling investment. Similarly, it’s much faster to get started, which is why GM turned to 3D printing to retool its production line to produce ventilators in the pandemic. In short, 3D printing is another tool in the toolbox, but one that offers key benefits over traditional manufacturing practices when used strategically.

What are the pros of using a service bureau?

Contracting with a service bureau to make your 3D printed parts is a good way to get introduced to the benefits of the technology. You gain the expertise and insight of a 3D printing specialist who can possibly guide you in optimizing the use of the technology for your specific purposes. Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

Your out-of-pocket expenses are usually lower initially since you avoid the up-front expense associated with a printer purchase.

Which industries use it and how?

Additive manufacturing shows promise for the defense, energy, aerospace, medical and commercial sectors. Its alternative approach to machining, forging, molding and casting makes it a good choice for rapidly making highly customized parts. The technology also shows promise for creating parts on site, such as at forward-stationed military bases. Because of its potential, many companies are using the technology to get themselves into a position to use it. The growing field of companies using the technology includes makers of machine parts and novelty items.

How can THINK3D help me?

We’ve been in the business of helping customers solve problems for over 8 years with our 3D printing solutions. We can help you determine what technology is right for your application, whether a printer or a service bureau is more appropriate, as well as answer any questions you might have.

Are companies using Additive Manufacturing?

Yes, lots of different companies across a range of industries use additive manufacturing, including the medical industry, aerospace and more. Additive manufacturing is particularly useful for making complex or bespoke parts – whether for a new application or to replace an old part that may no longer be available.

How long does the 3DP process take?

The printing time takes in a few factors, including the size of the part and the settings used for printing. The quality of the finished part is also important when determining printing time as higher quality items take longer to produce. AM can take anything from a few minutes to several hours or days – speed, resolution and the volume of the material are all important factors here.

How do I find out if AM is right for me?

You probably know the answer to this one by now! It takes a discovery to analyze your current parts and determine whether or not there is an ROI for you at this point. If a basic ROI exists, then you will also profit from other AM benefits such as:

If a basic ROI exists, then you will also profit from other AM benefits such as:

- Freedom to design parts and sub-assemblies for the design, not for the manufacturing processes (DFM*)

- Have inventory on demand for both production and spare parts

- Eliminate costs of inventory and the time lag of supply chains

And!

- Gain the ability to quickly prototype with the same process with which you will manufacture — true rapid prototypes!

Custom 3D Printing near you

64 3D Printing Services are ready to take your order now and ship parts to Bangalore, Karnataka, India. Through our platform, you can order 3D printing of prototypes, spare parts and any projects according to your own design without restrictions in size and quantity. If you know exactly which technology, material or application is right for your project, use the filters to narrow your search results. For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of various types.

For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of various types.

Download files to compare prices of local 3D printing services

Download filesor contact us for a discount on large orders.

If you are looking for a 3D printing service with delivery to Bangalore, Karnataka, India, then you have come to the right place. All companies that provide prototyping and printing services near you are listed above.

How much does it cost to 3D print my products?

To find out the cost of services, select a company and use the "Quick Order" button. Based on your 3D model in STL, PLY, OBJ or 3MF format, we will automatically determine the cost of 3D printing. If you are not sure which service to choose, use the order button at the top of the page to compare prices from all eligible print services.

How can I order a print without a 3D file?

3D printing starts with a model, so a 3D file is needed to make the part. Most printing and additive manufacturing companies can help you with a simple 3D design. For more complex modeling tasks, we recommend hiring a professional.

Most printing and additive manufacturing companies can help you with a simple 3D design. For more complex modeling tasks, we recommend hiring a professional.

How to choose a 3D printing service?

Treatstock strives to provide a transparent workflow between the 3D printing company and the client for the best result. In order for you to have complete information about the future performer, we show the company's printers and customer ratings. On the public page of each service, you will also find a complete list of their services.

How does it work?

- Download 3D file for instant order;

- Specify order details and delivery address;

- Confirm order;

- Track the progress of your order in the Purchases section;

- Get your finished product.

Our support team is always ready to help. To learn more about the different types of 3D printing, check out our Technology Guide, as well as our Materials Guide for information on them.

4th International Additive Manufacturing Technology Conference and Exhibition in India

01 Sep - 02 Sep 2014

Bangalore

convention center

4th International Conference and Exhibition "Additive Manufacturing Technologies: Summit 2014 Additive Manufacturing in the Military, Aerospace, Automotive and Biomedical Industries"

We are pleased to inform you about the 4th International Conference and Exhibition "Technologies of Additive Manufacturing: Summit 2014 Additive Manufacturing in the military, aerospace, automotive and biomedical industries" to be held at the Nimhans Convention Centre, Bangalore, 1-2 September 2014.

This event is organized by the respected professional organization The Additive Manufactured in India (AMSI)." The event is approved by the "International Union of Rapid Prototyping Associations" (GARPA) and is supported by various national and international professional organizations.

The 4th International Conference "Additive Manufacturing Technologies - AM 2014: Summit 2014 Additive Manufacturing in the Military, Aerospace, Automotive and Biomedical Industries" will be dedicated to the transfer of knowledge and exchange of experience between specialists in the field of additive manufacturing technologies. The conference will feature guest speakers from various industries, as well as academics from around the world.

To be discussed:

- additive layered manufacturing technologies and metal additive manufacturing technologies,

- latest developments in 3D printing and additive manufacturing,

- virtual rapid prototyping,

- CAD,

- product design and development,

- engineering analysis,

- laser scanning and 3D data processing,

- materials for additive manufacturing technologies,

- application of additive manufacturing technologies in the military, aerospace, automotive and biomedical industries.

Learn more